Effect of Laser Remelting Strategy on the Forming Ability of Cemented Carbide Fabricated by Laser Powder Bed Fusion (L-PBF)

Abstract

:1. Introduction

2. Experimental Details

2.1. Powder Characteristics

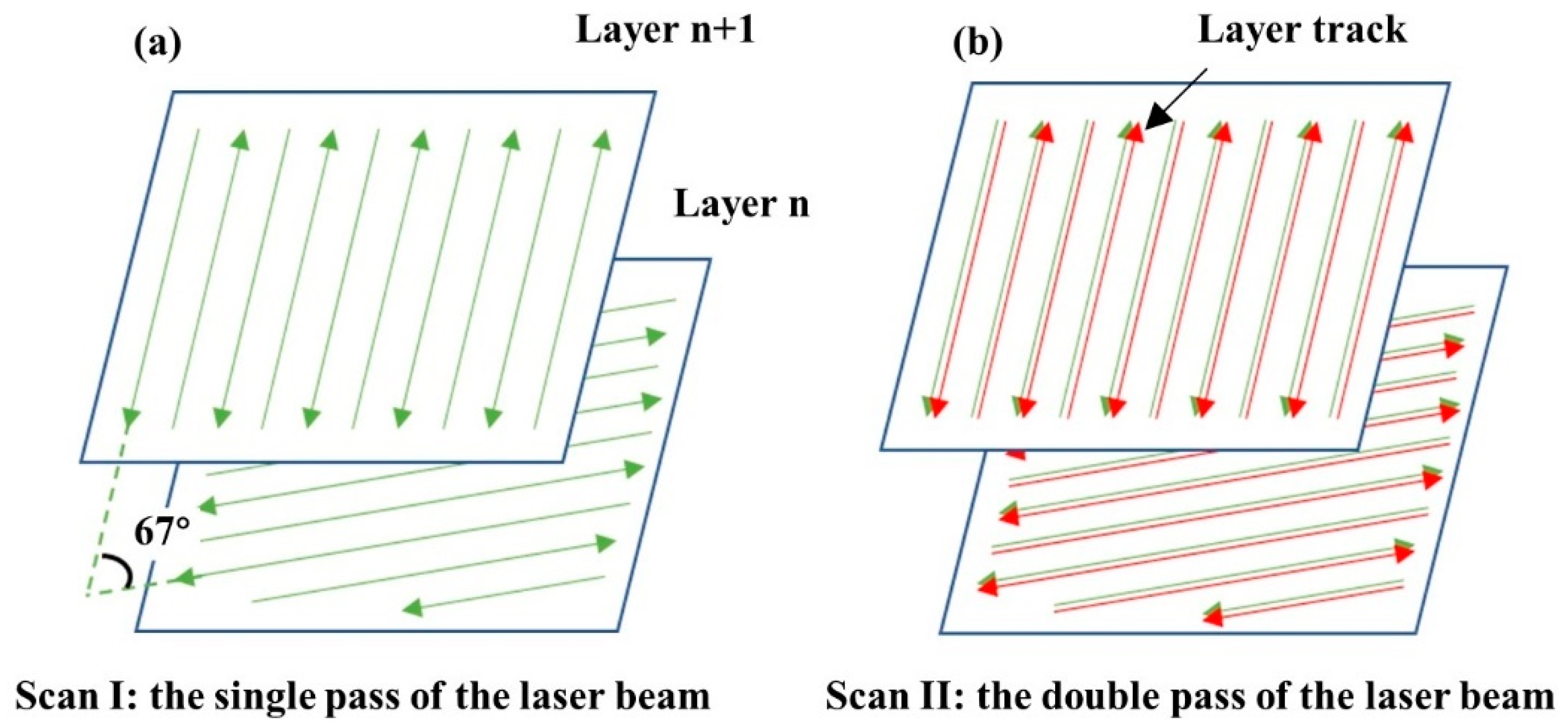

2.2. L-PBF Process

2.3. Characterization

3. Results

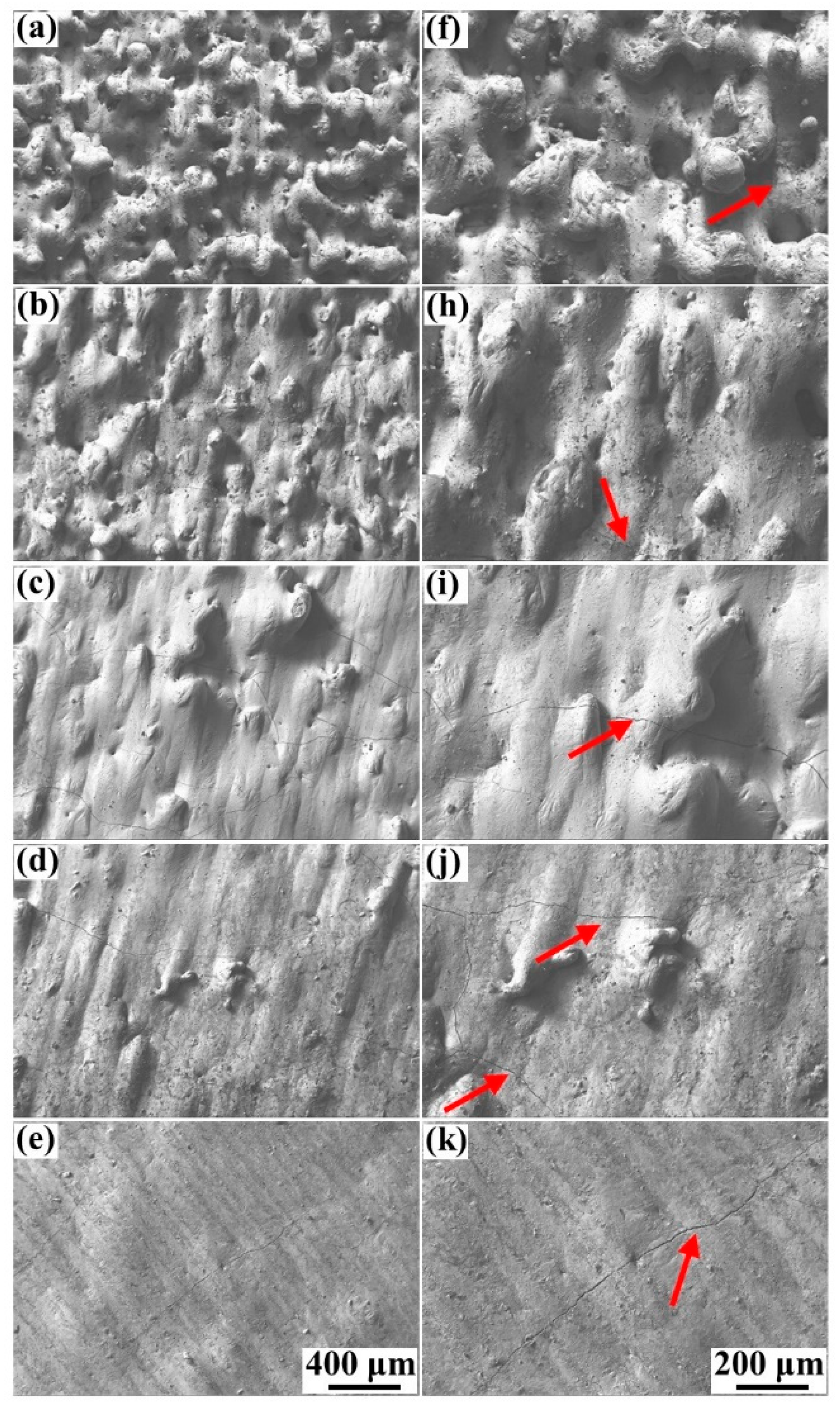

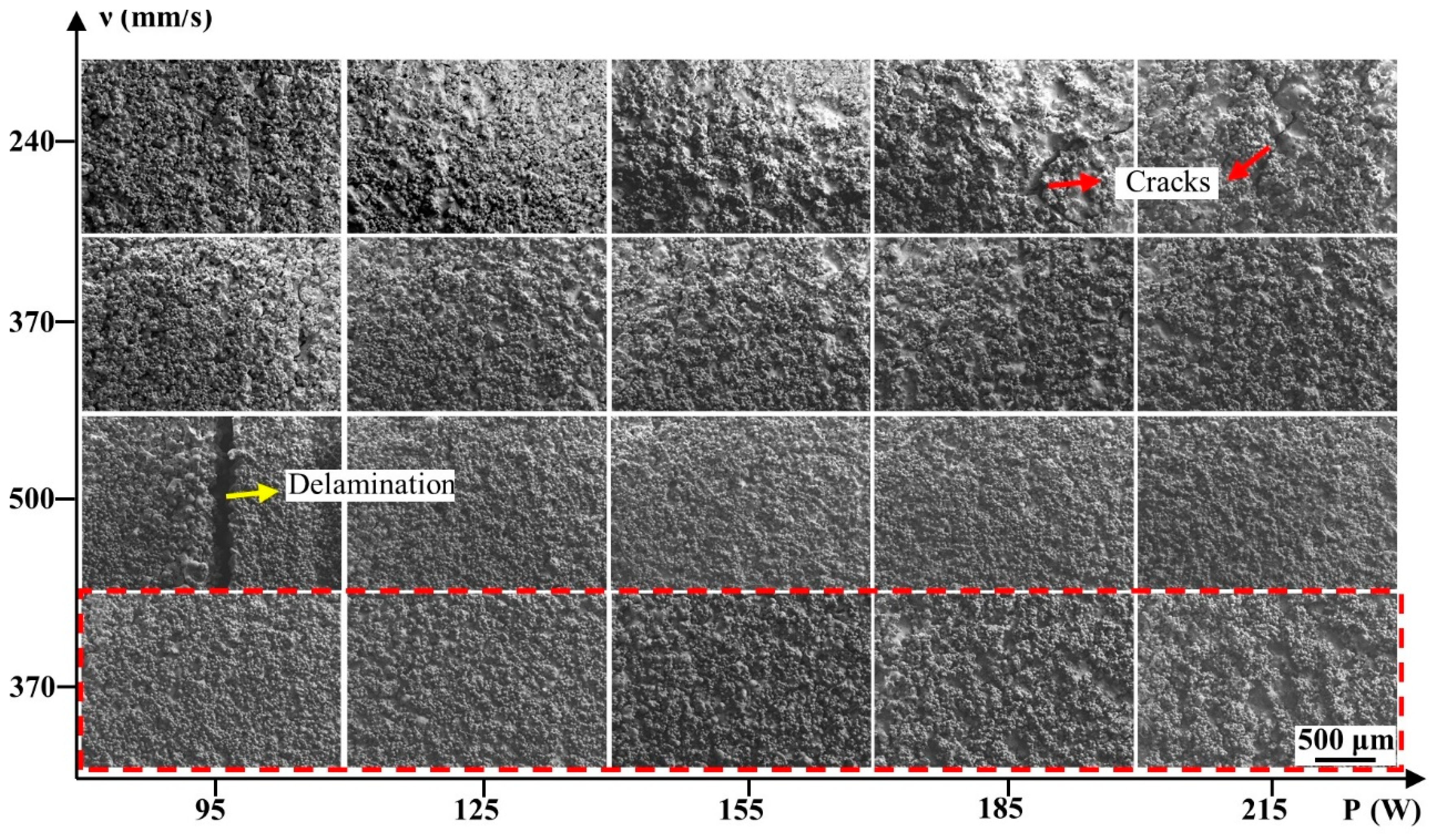

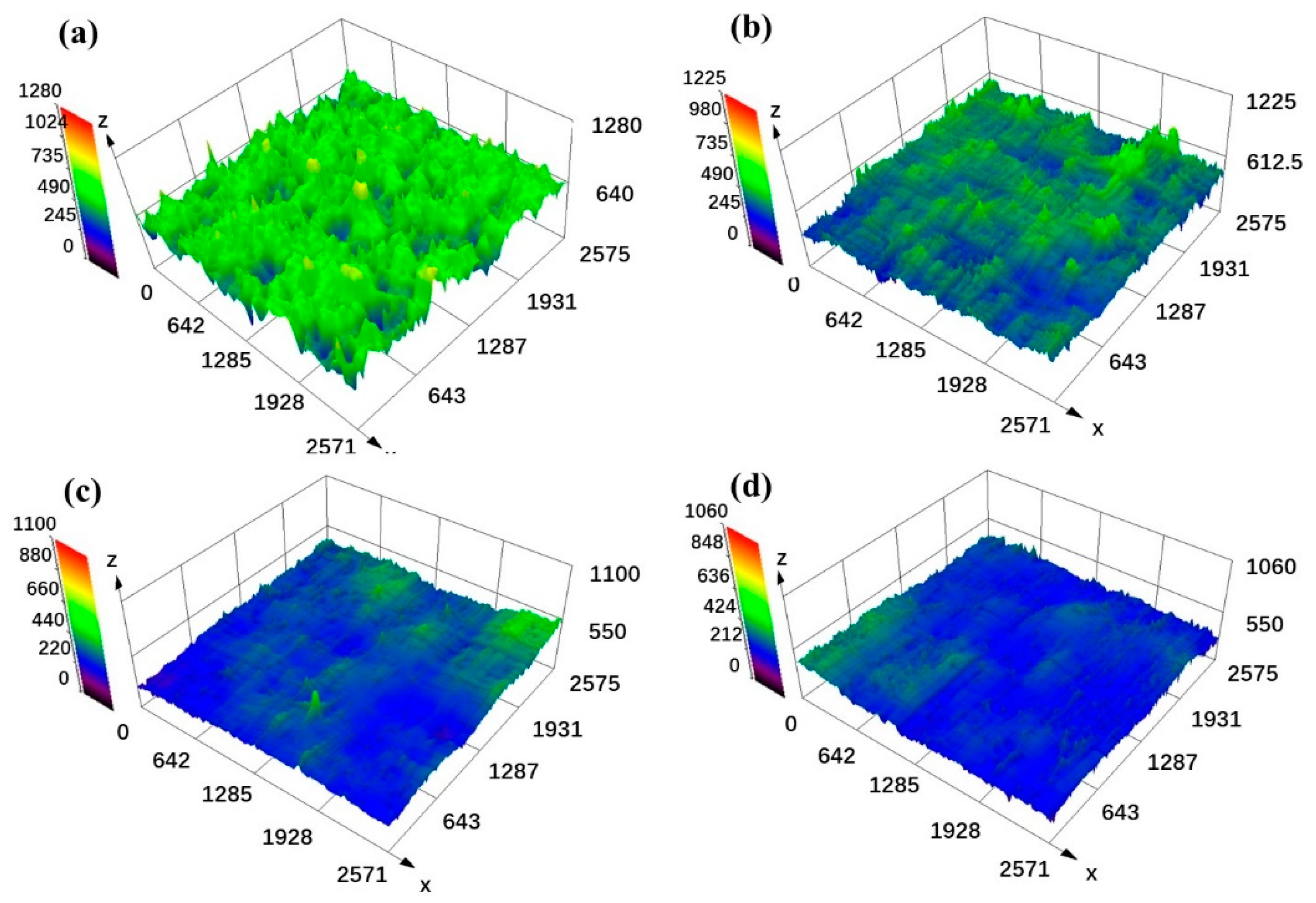

3.1. Surface Morphology

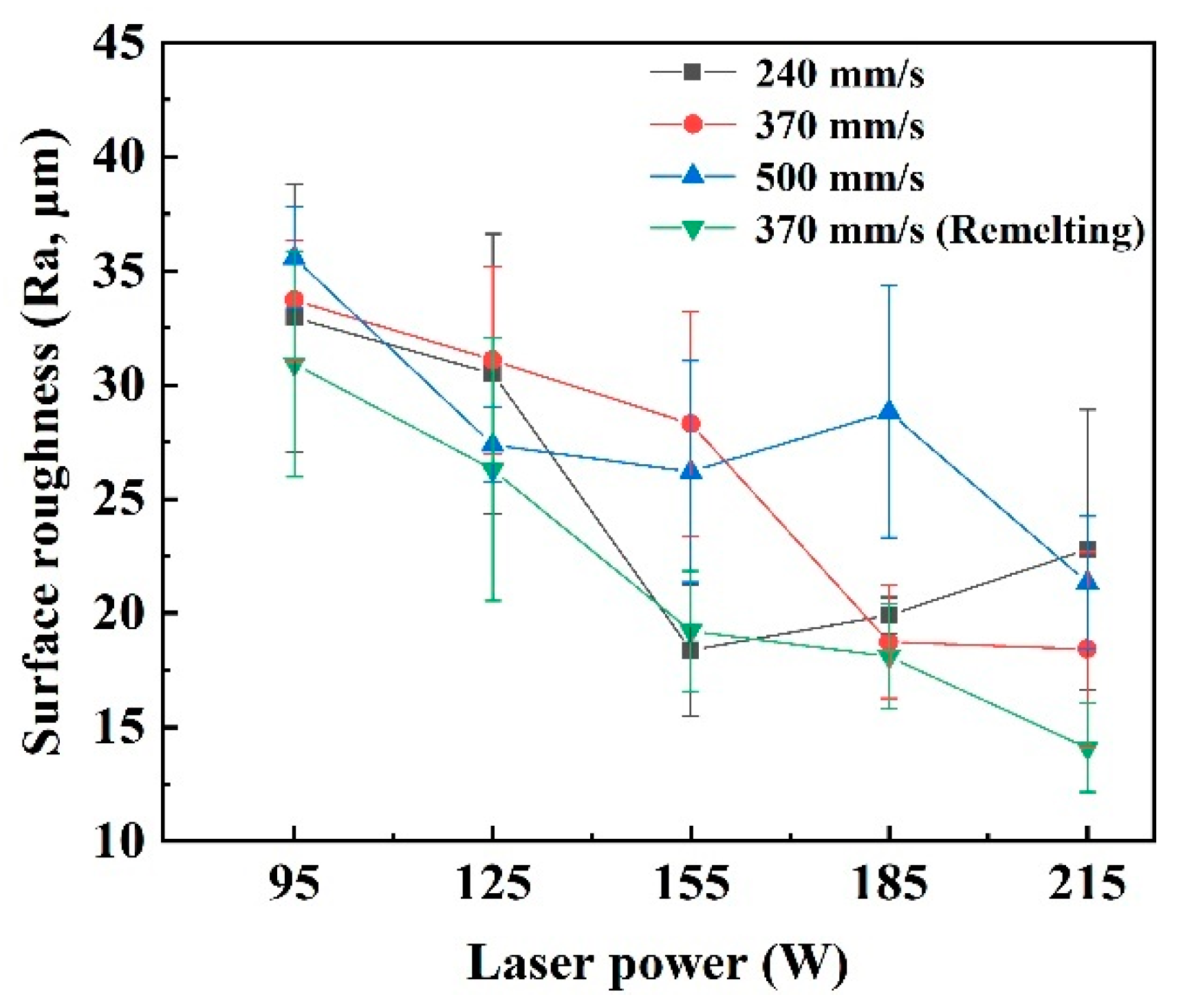

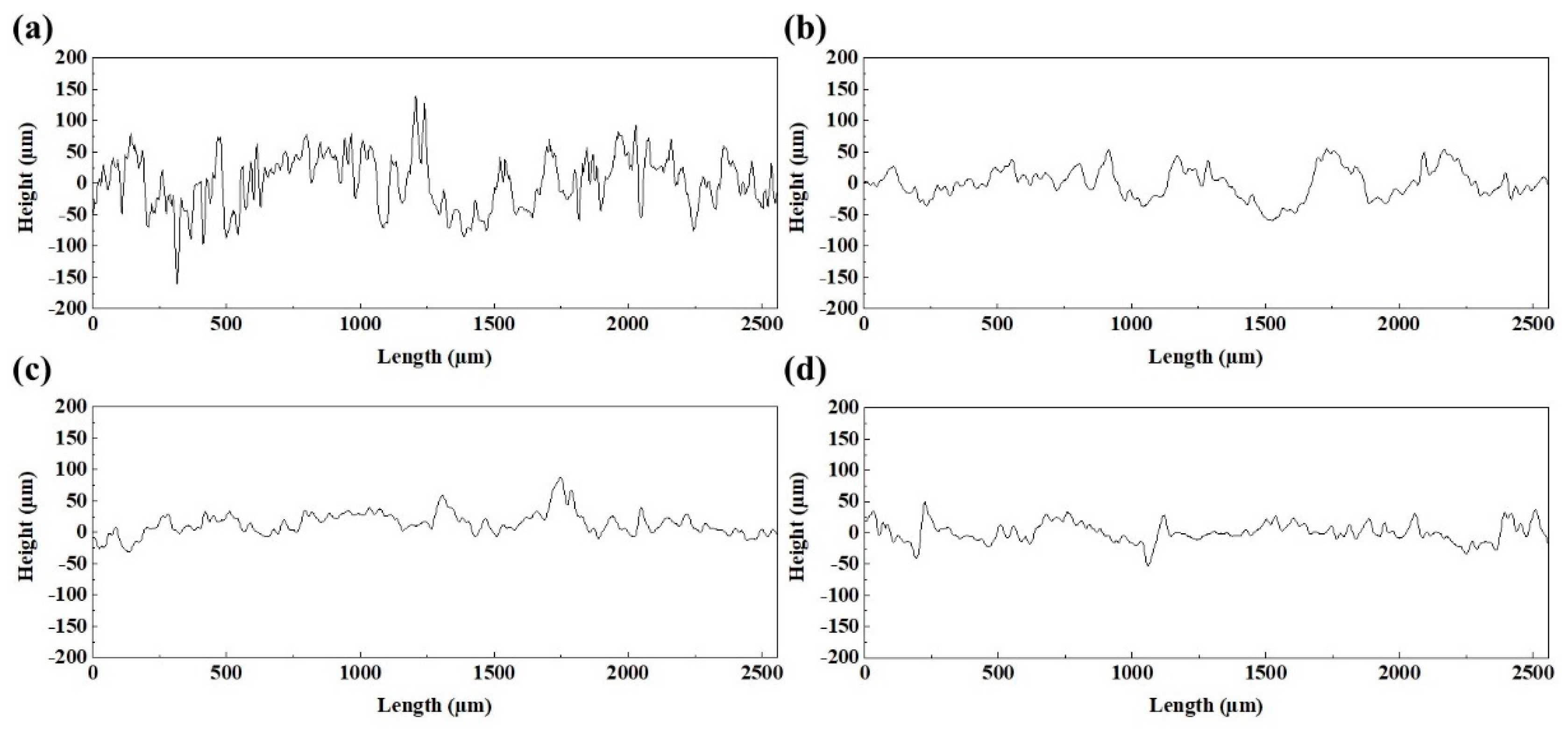

3.2. Surface Roughness

3.3. Densification Behaviors

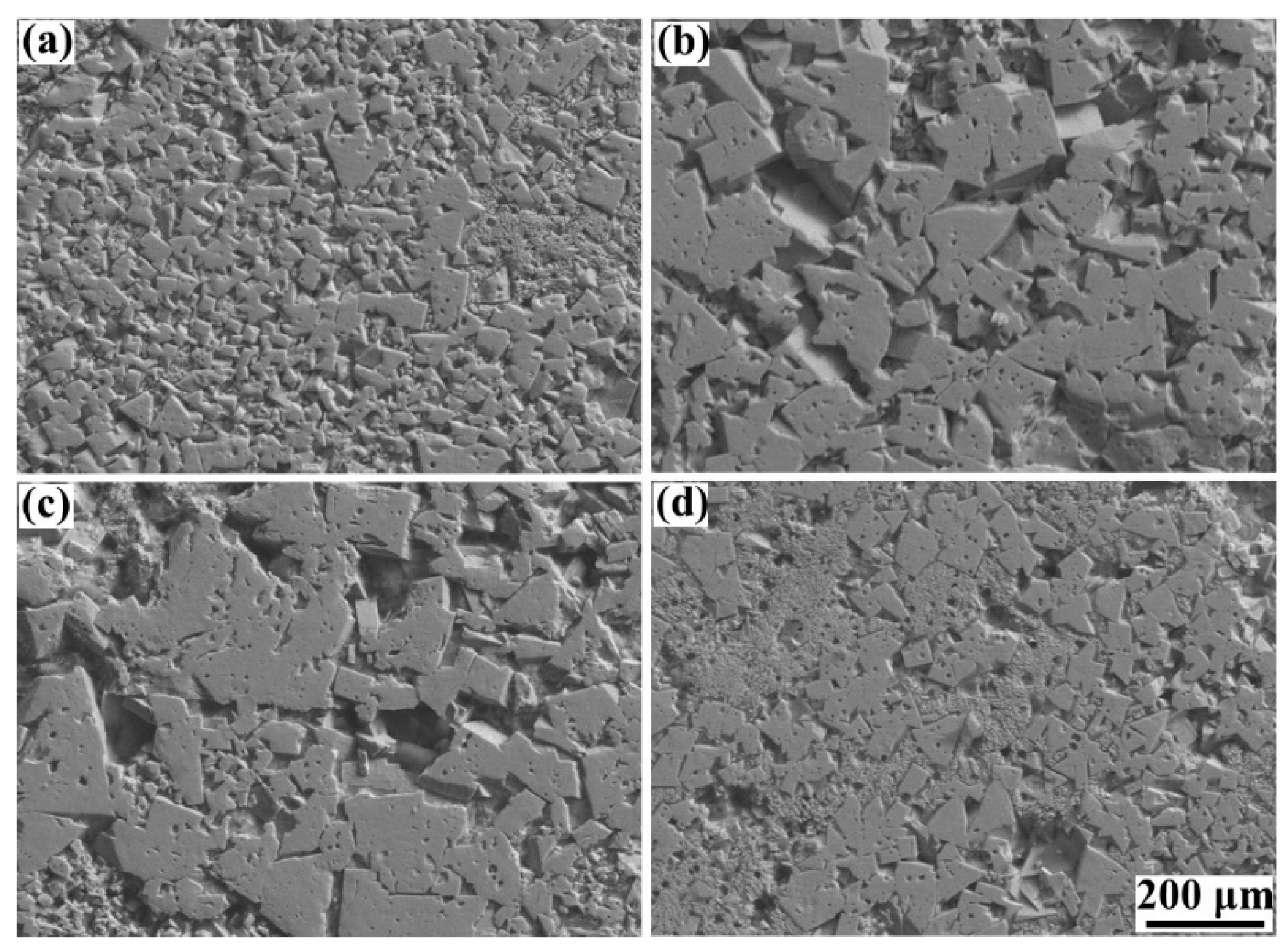

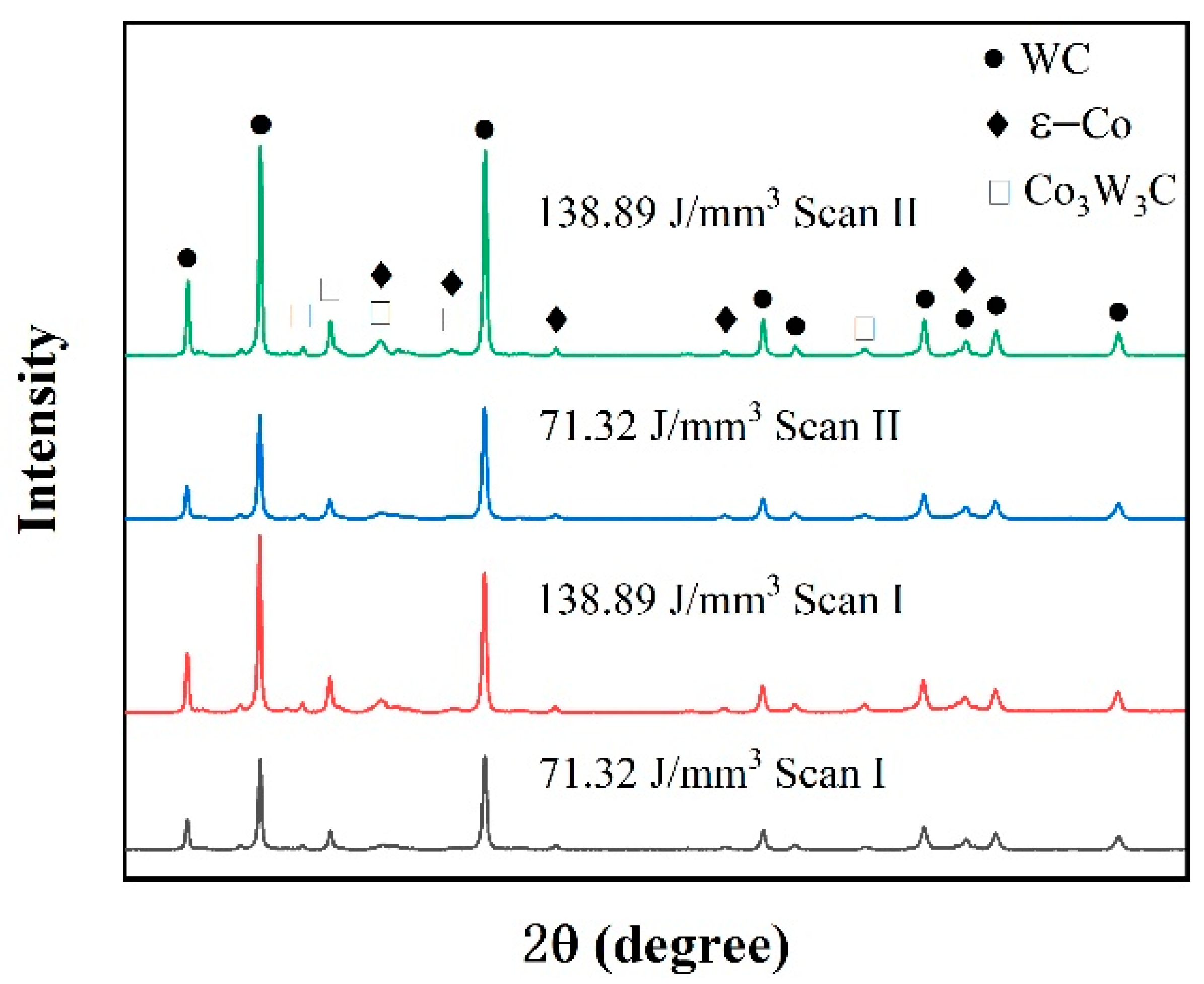

3.4. Microstructures

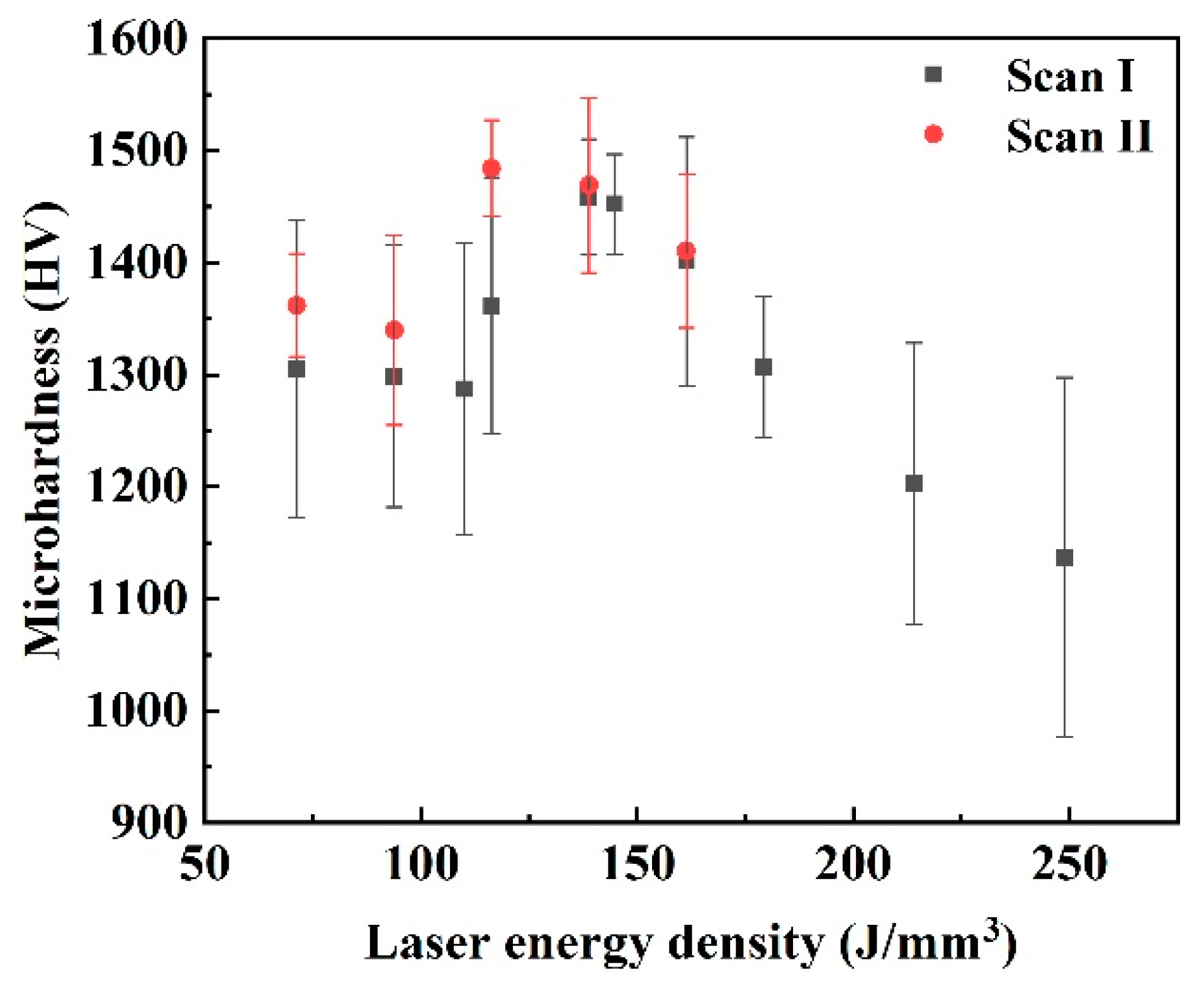

3.5. Microhardness

4. Conclusions

- Irregular scanning tracks formed under a low laser energy density constituted a coarse surface. Increasing the laser energy density and using the remelting strategy could decrease the defects of scanning tracks, thus improving the surface quality. However, the overly high laser energy input more easily aggravated the formation of cracks.

- The surface roughness of the cemented carbide specimens widely varied from 35.57 to 18.38 μm at the single melting strategy. In contrast, the remelting strategy improved the best surface roughness to 14.10 μm.

- Under the single melting strategy, the large number of pores induced by the low laser energy density and the serious cracks induced by the overly high laser energy density led to a poor relative density for the specimens. However, under the remelting strategy, the pores were decreased effectively on the specimens at a low energy density. The cracks on the blocks did not worsen, in contrast to the single melting strategy, thus obtaining the best relative density of 97.50%.

- The size and homogeneity of WC grains could be effectively improved by increasing the laser energy density or using the remelting strategy. However, an overly high laser energy density would lead to coarse grains.

- The best microhardness of the specimens formed at the single melting strategy was approximately 1401.2–1458.2 HV. In contrast, the best microhardness of approximately 1410.4–1484.4 HV was obtained with the remelting strategy.

- When the cemented carbide specimens formed under a laser energy density from 116.37 to 161.41 J/mm3 with the remelting strategy, good formation quality of the specimens could be obtained.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gokuldoss, P.K.; Kolla, S.; Eckert, J. Additive Manufacturing Processes: Selective Laser Melting, Electron Beam Melting and Binder Jetting—Selection Guidelines. Materials 2017, 10, 672. [Google Scholar] [CrossRef] [Green Version]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Murr, L.E.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Rodela, A.; Martinez, E.Y.; Hernandez, D.H.; Martinez, E.; Medina, F.; Wicker, R.B. Microstructure and mechanical behavior of Ti–6Al–4V produced by rapid-layer manufacturing, for biomedical applications. J. Mech. Behav. Biomed. 2009, 2, 20–32. [Google Scholar] [CrossRef]

- Sing, S.L.; An, J.; Yeong, W.Y.; Wiria, F.E. Laser and electron-beam powder-bed additive manufacturing of metallic implants: A review on processes, materials and designs. J. Orthop. Res. 2016, 34, 369–385. [Google Scholar] [CrossRef] [PubMed]

- Gunasekaran, J.; Sevvel, P.; Solomon, I.J. Metallic materials fabrication by selective laser melting: A review. Mater. Today Proc. 2020, 37, 252–256. [Google Scholar] [CrossRef]

- Hu, Z.; Qi, Y.; Nagarajan, B.; Nie, X.; Zhang, H.; Zhu, H.; Zeng, X. Top surface roughness evolution during selective laser melting of AlCu5MnCdVA aluminum alloy. J. Manuf. Process. 2021, 64, 1180–1195. [Google Scholar] [CrossRef]

- Wang, T.; Dai, S.; Liao, H.; Zhu, H. Pores and the formation mechanisms of SLMed AlSi10Mg. Rapid Prototyp. J. 2020, 26, 1657–1664. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Lorusso, M.; Pakkanen, J.; Aversa, A.; Ambrosio, E.P.; Lombardi, M.; Fino, P.; Manfredi, D. On the Selective Laser Melting (SLM) of the AlSi10Mg Alloy: Process, Microstructure, and Mechanical Properties. Materials 2017, 10, 76. [Google Scholar] [CrossRef] [Green Version]

- Liverani, E.; Toschi, S.; Ceschini, L.; Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Mater. Process. Technol. 2017, 249, 255–263. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M. Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef] [Green Version]

- Koutiri, I.; Pessard, E.; Peyre, P.; Amlou, O.; De Terris, T. Influence of SLM process parameters on the surface finish, porosity rate and fatigue behavior of as-built Inconel 625 parts. J. Mater. Process. Technol. 2018, 255, 536–546. [Google Scholar] [CrossRef]

- Moussaoui, K.; Rubio, W.; Mousseigne, M.; Sultan, T.; Rezai, F. Effects of Selective Laser Melting additive manufacturing parameters of Inconel 718 on porosity, microstructure and mechanical properties. Mater. Sci. Eng. A 2018, 735, 182–190. [Google Scholar] [CrossRef] [Green Version]

- Li, R.; Liu, J.; Shi, Y.; Wang, L.; Jiang, W. Balling behavior of stainless steel and nickel powder during selective laser melting process. Int. J. Adv. Manuf. Technol. 2011, 59, 1025–1035. [Google Scholar] [CrossRef]

- Wang, Z.; Xiao, Z.; Tse, Y.; Huang, C.; Zhang, W. Optimization of processing parameters and establishment of a relationship between microstructure and mechanical properties of SLM titanium alloy. Opt. Laser Technol. 2018, 112, 159–167. [Google Scholar] [CrossRef]

- Hu, Z.; Nagarajan, B.; Song, X.; Huang, R.; Zhai, W.; Wei, J. Formation of SS316L Single Tracks in Micro Selective Laser Melting: Surface, Geometry, and Defects. Adv. Mater. Sci. Eng. 2019, 2019, 9451406. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.; Li, B.Q.; Li, Z. Selective laser remelting of an additive layer manufacturing process on AlSi10Mg. Results Phys. 2019, 12, 982–988. [Google Scholar] [CrossRef]

- Xiong, Z.G.; Zhang, P.P.; Tan, C.L.; Dong, D.D.; Ma, W.Y.; Yu, K. Selective Laser Melting and Remelting of Pure Tungsten. J. Adv. Eng. Mater. 2020, 22, 1901352. [Google Scholar] [CrossRef]

- Yasa, E.; Deckers, J.; Kruth, J.P. The investigation of the influence of laser re-melting on density, surface quality and microstructure of selective laser melting parts. J. Rapid Prototyp. J. 2011, 17, 312–327. [Google Scholar] [CrossRef]

- Qiu, C.L.; Wang, Z.; Aladawi, A.S.; Kindi, M.A.; Hatmi, I.A.; Chen, H.; Chen, L. Influence of Laser Processing Strategy and Remelting on Surface Structure and Porosity Development during Selective Laser Melting of a Metallic Material. J. Metall. Mater. Trans. A 2019, 50, 4423–4434. [Google Scholar] [CrossRef]

- Wei, K.K.; Lv, M.; Zeng, X.Y.; Xiao, Z.X.; Huang, G.; Liu, M.; Deng, J.F. Effect of laser remelting on deposition quality, residual stress, microstructure, and mechanical property of selective laser melting processed Ti-5Al-2.5Sn alloy. J. Mater. Charact. 2019, 150, 67–77. [Google Scholar] [CrossRef]

- García, J.; Ciprés, V.C.; Blomqvist, A.; Kaplan, B. Cemented carbide microstructures: A review. Int. J. Refract. Met. HardMater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Upadhyaya, G.S. Materials science of cemented carbides—An overview. Mater. Des. 2001, 22, 483–489. [Google Scholar] [CrossRef]

- Uhlmann, E.; Bergmann, A.; Gridin, W. Investigation on Additive Manufacturing of Tungsten Carbide-cobalt by Selective Laser Melting. Procedia CIRP 2015, 35, 8–15. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Wang, D.; Nie, L.; Wellmann, D.; Tian, Y. Additive manufacturing of WC-Co hardmetals: A review. Int. J. Adv. Manuf. Technol. 2020, 108, 1653–1673. [Google Scholar] [CrossRef]

- Chen, J.; Huang, M.; Fang, Z.Z.; Koopman, M.; Liu, W.; Deng, X.; Zhao, Z.; Chen, S.; Wu, S.; Liu, J.; et al. Microstructure analysis of high density WC-Co composite prepared by one step selective laser melting. Int. J. Refract. Met. Hard. Mater. 2019, 84, 104980. [Google Scholar] [CrossRef]

- Uhlmann, E.; Bergmann, A.; Bolz, R. Manufacturing of carbide tools by Selective Laser Melting. Procedia Manuf. 2018, 21, 765–773. [Google Scholar] [CrossRef]

- Liu, D.; Yue, W.; Kang, J.; Wang, C. Effects of Different Substrates on the Formability and Densification Behaviors of Cemented Carbide Processed by Laser Powder Bed Fusion. Materials 2021, 14, 5027. [Google Scholar] [CrossRef]

- Li, C.W.; Chang, K.C.; Yeh, A.C. On the microstructure and properties of an advanced cemented carbide system processed by selective laser melting. J. Alloy. Compd. 2018, 782, 440–450. [Google Scholar] [CrossRef]

- Aramian, A.; Razavi, S.M.J.; Sadeghian, Z.; Berto, F. A review of additive manufacturing of cermets. Addit. Manuf. 2020, 33, 101130. [Google Scholar] [CrossRef]

- Khmyrov, R.S.; Safronov, V.A.; Gusarov, A.V. Obtaining crack-free WC-Co alloys by selective laser melting. Phys. Procedia 2016, 83, 874–881. [Google Scholar] [CrossRef] [Green Version]

- Gu, D.D.; Meiners, W. Microstructure characteristics and formation mechanisms of in situ WC cemented carbide based hardmetals prepared by Selective Laser Melting. J. Mater. Sci. Eng. A 2010, 527, 7585–7592. [Google Scholar] [CrossRef]

- Domashenkov, A.; Borbély, A.; Smurov, I. Structural modifications of WC/Co nanophased and conventional powders processed by selective laser melting. J. Adv. Manuf. Processes. 2017, 32, 93–100. [Google Scholar] [CrossRef]

- Elsayed, M.; Ghazy, M.; Youssef, Y.; Essa, K. Optimization of SLM process parameters for Ti6Al4V medical implants. Rapid Prototyp. J. 2019, 25, 433–447. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Zhu, H.H.; Liu, J.H.; Zeng, X.Y. Track evolution and surface characteristics of selective laser melting Ti6Al4V. J. Rapid Prototyp. J. 2018, 24, 1554–1662. [Google Scholar] [CrossRef]

- Wang, D.; Liu, Y.; Yang, Y.; Xiao, D. Theoretical and experimental study on surface roughness of 316L stainless steel metal parts obtained through selective laser melting. Rapid Prototyp. J. 2016, 22, 706–716. [Google Scholar] [CrossRef]

- Guo, M.; Gu, D.D.; Xi, L.X.; Du, L.; Zhang, H.M.; Zhang, J.Y. Formation of scanning tracks during Selective Laser Melting (SLM) of pure tungsten powder: Morphology, geometric features and forming mechanisms. J. Int. J. Refract. Met. Hard. Mater. 2019, 79, 37–46. [Google Scholar] [CrossRef]

- Liu, S.; Yang, W.; Shi, X.; Li, B.; Duan, S.; Guo, H.; Guo, J. Influence of laser process parameters on the densification, microstructure, and mechanical properties of a selective laser melted AZ61 magnesium alloy. J. Alloys Compd. 2019, 808, 151160. [Google Scholar] [CrossRef]

- Pasquet, I.; Baco-Carles, V.; Chamelot, P.; Gibilaro, M.; Massot, L.; Tailhades, P. A multimaterial based on metallic copper and spinel oxide made by powder bed laser fusion: A new nanostructured material for inert anode dedicated to aluminum electrolysis. J. Mater. Process. Technol. 2019, 278, 116452. [Google Scholar] [CrossRef]

| AOR | Flowability |

|---|---|

| 20° < α < 30° | Very free-flowing |

| 30° < α < 38° | Free-flowing |

| 38° < α < 45° | Fair to passable flow |

| 45° < α < 55° | Cohesive |

| 55° < α < 70° | Very cohesive |

| Sample | Laser Power (W) | Scanning Speed (mm/s) | Hatching Space (μm) | Layer Thickness (μm) | Scanning Strategy |

|---|---|---|---|---|---|

| I | 95, 125, 155, 185, 215 | 240, 370, 500 | 90 | 40 | Scan I |

| II | 95, 125, 155, 185, 215 | 370 | 90 | 40 | Scan II |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, D.; Yue, W.; Kang, J.; Wang, C. Effect of Laser Remelting Strategy on the Forming Ability of Cemented Carbide Fabricated by Laser Powder Bed Fusion (L-PBF). Materials 2022, 15, 2380. https://doi.org/10.3390/ma15072380

Liu D, Yue W, Kang J, Wang C. Effect of Laser Remelting Strategy on the Forming Ability of Cemented Carbide Fabricated by Laser Powder Bed Fusion (L-PBF). Materials. 2022; 15(7):2380. https://doi.org/10.3390/ma15072380

Chicago/Turabian StyleLiu, Decheng, Wen Yue, Jiajie Kang, and Chengbiao Wang. 2022. "Effect of Laser Remelting Strategy on the Forming Ability of Cemented Carbide Fabricated by Laser Powder Bed Fusion (L-PBF)" Materials 15, no. 7: 2380. https://doi.org/10.3390/ma15072380

APA StyleLiu, D., Yue, W., Kang, J., & Wang, C. (2022). Effect of Laser Remelting Strategy on the Forming Ability of Cemented Carbide Fabricated by Laser Powder Bed Fusion (L-PBF). Materials, 15(7), 2380. https://doi.org/10.3390/ma15072380