Investigation into Changes of Microstructure and Abrasive Wear Resistance Occurring in High Manganese Steel X120Mn12 during Isothermal Annealing and Re-Austenitisation Process

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

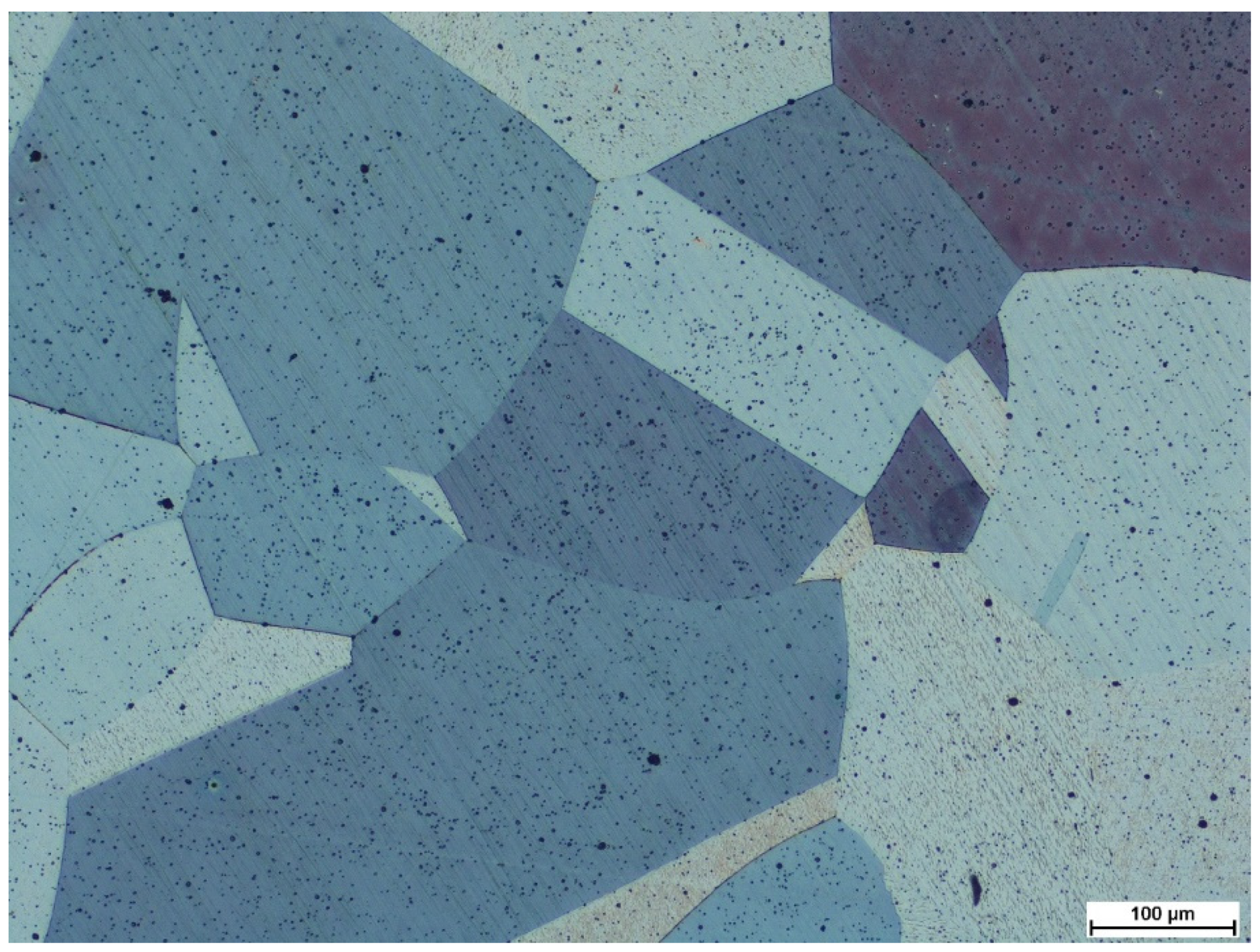

3.1. Analysis of the Material in the As-Delivered Condition

3.2. Analysis of the Material after Heat Treatment

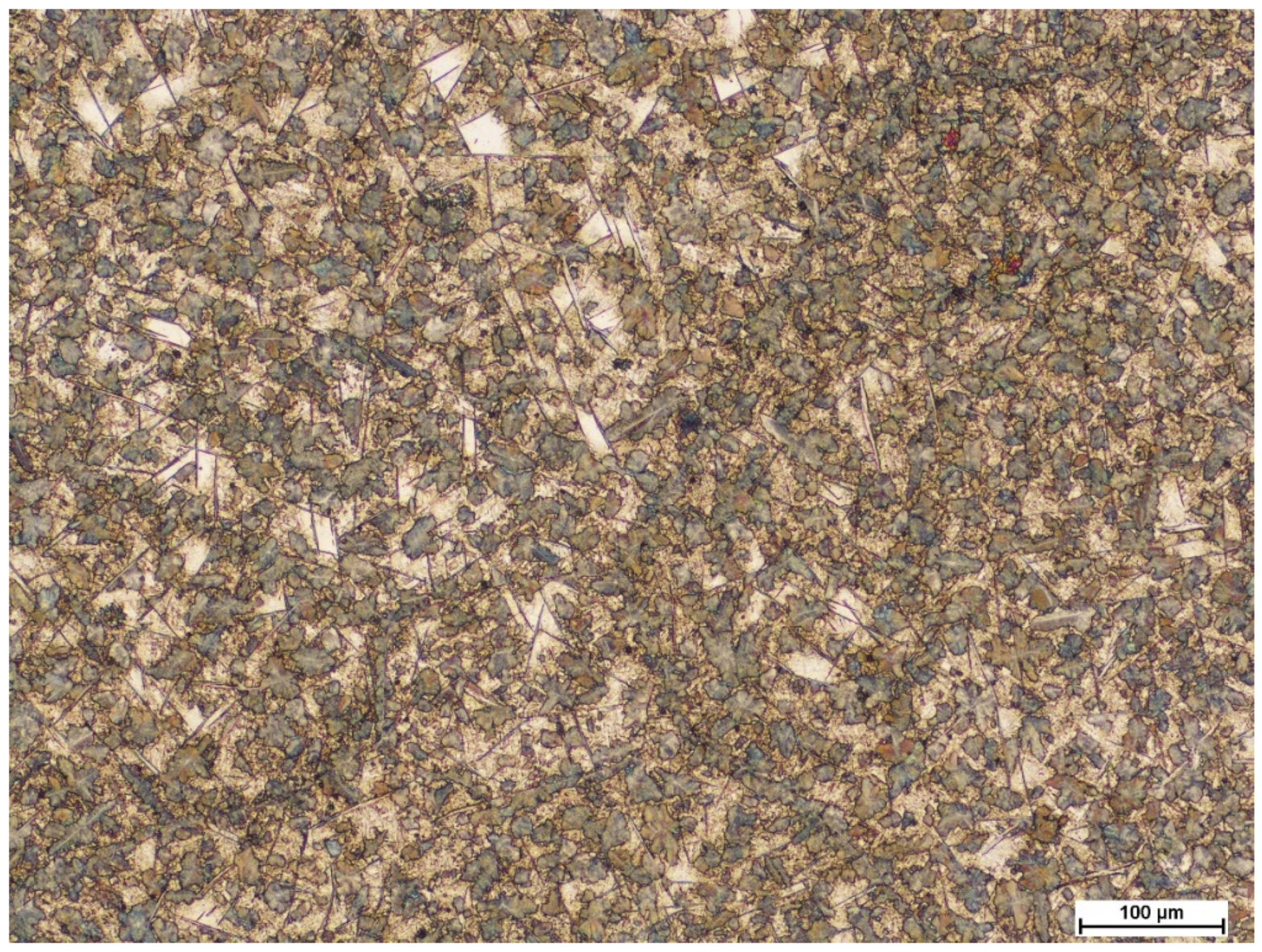

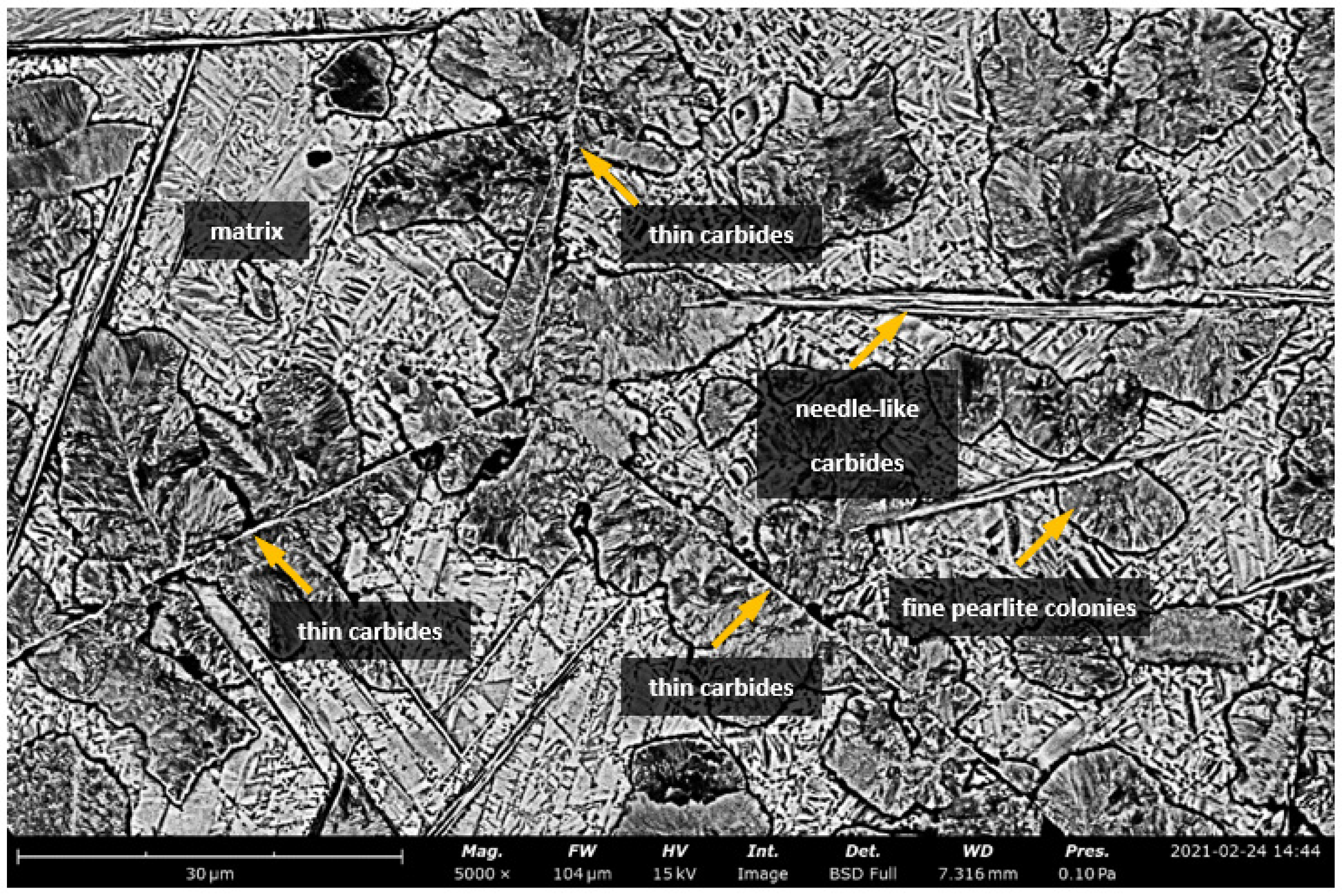

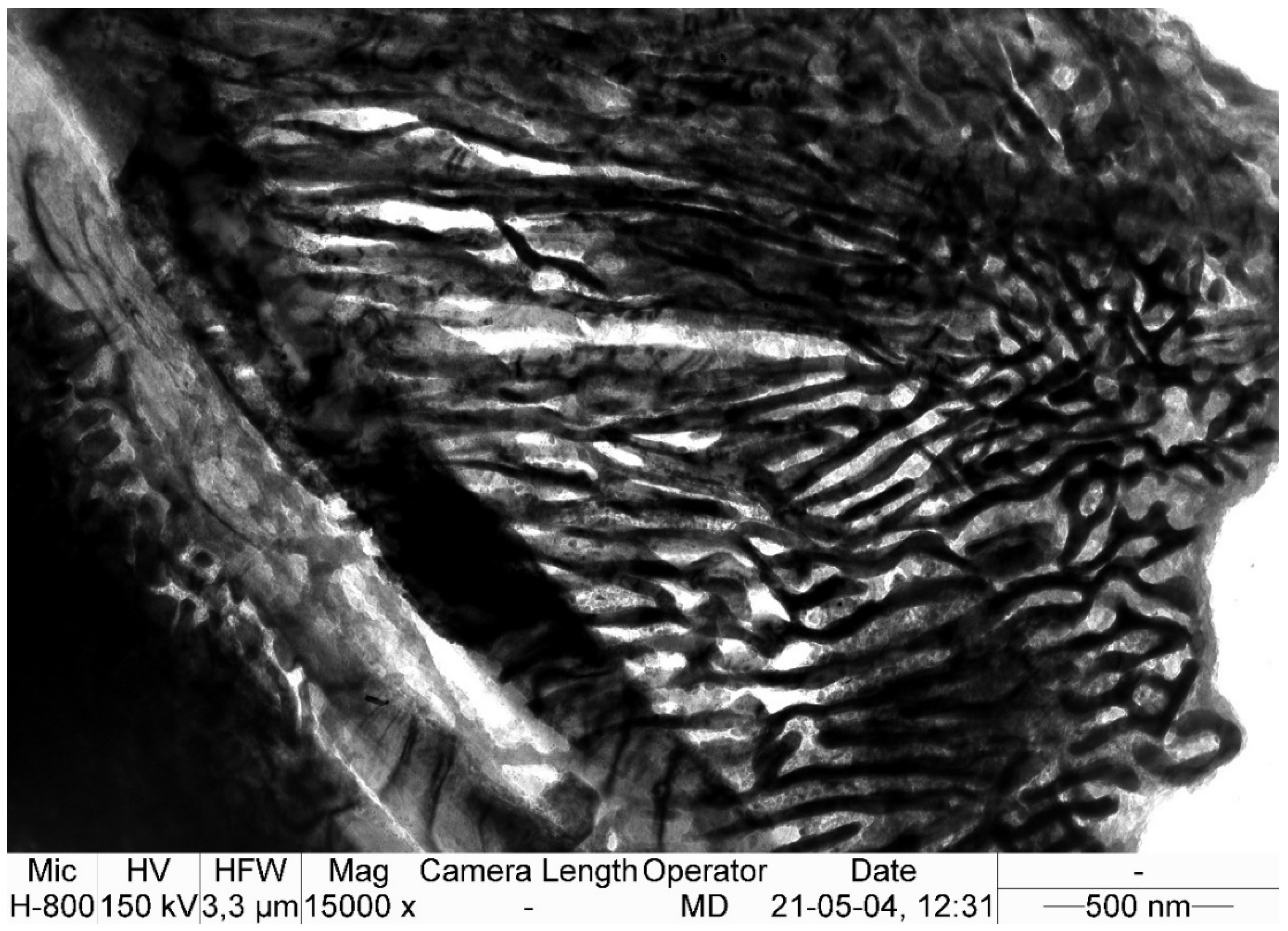

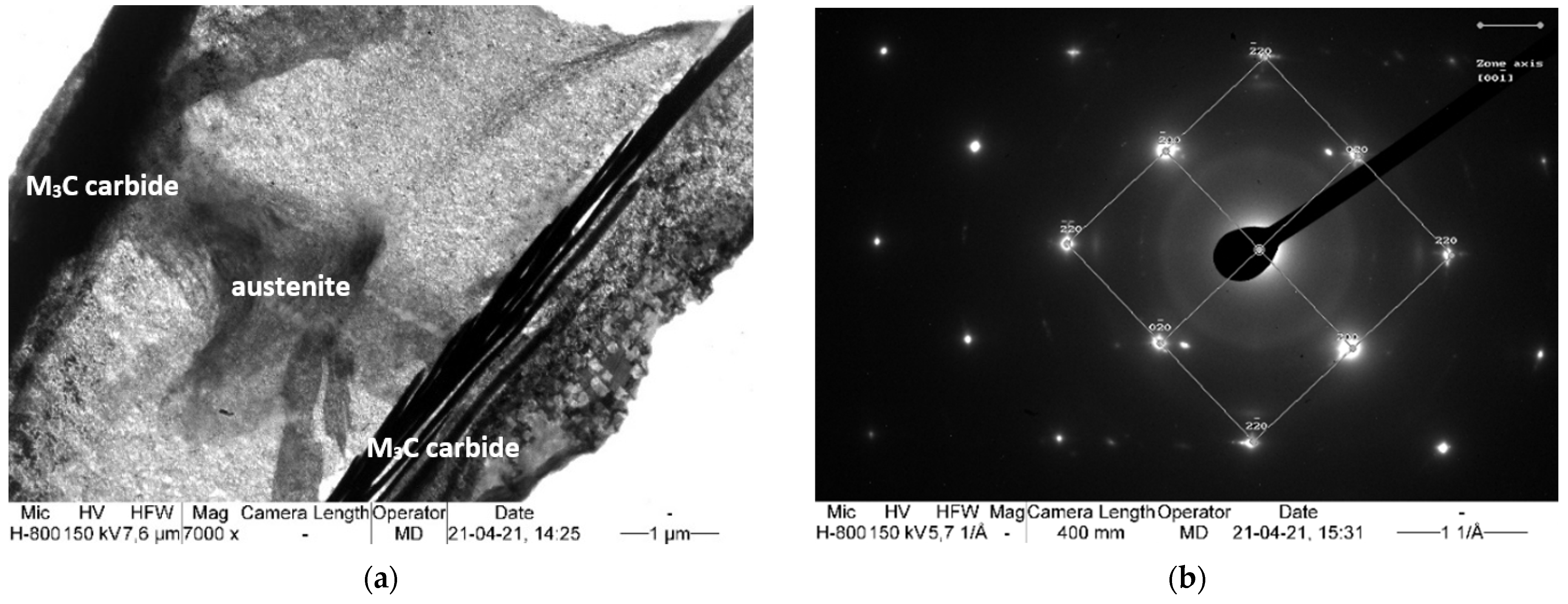

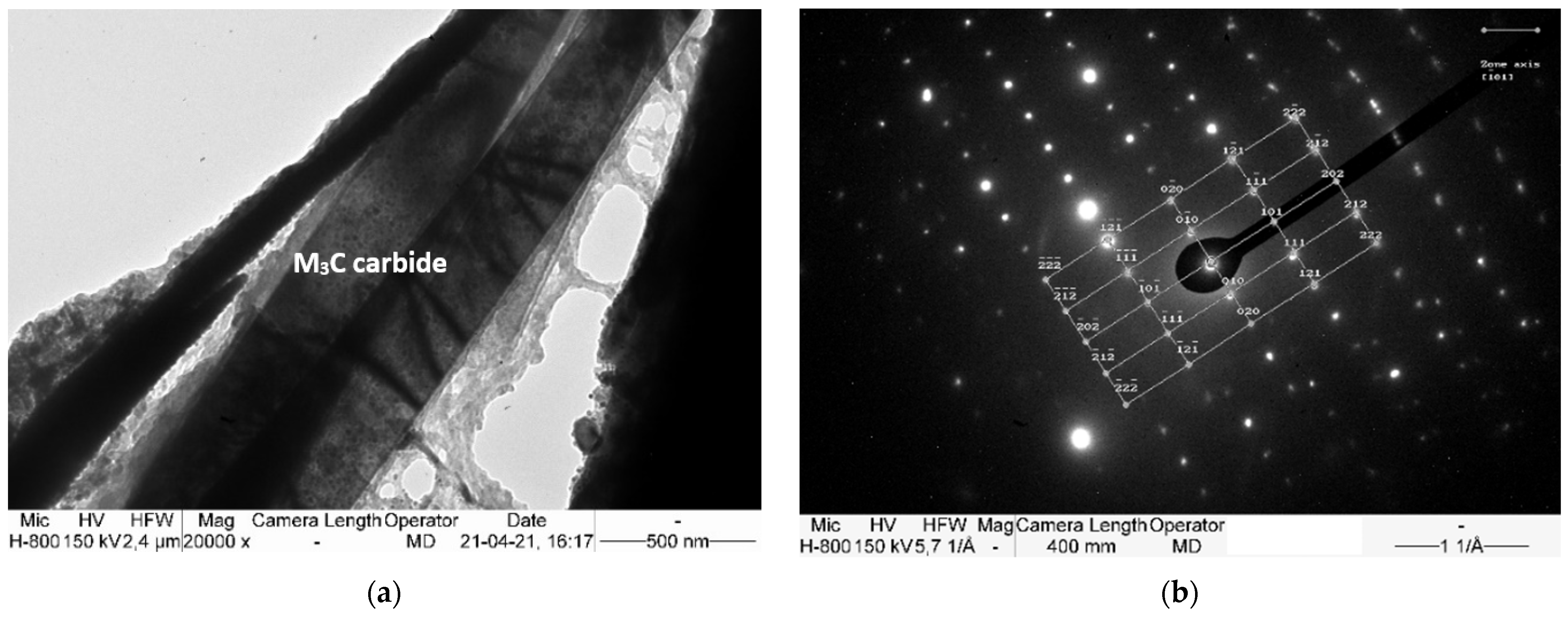

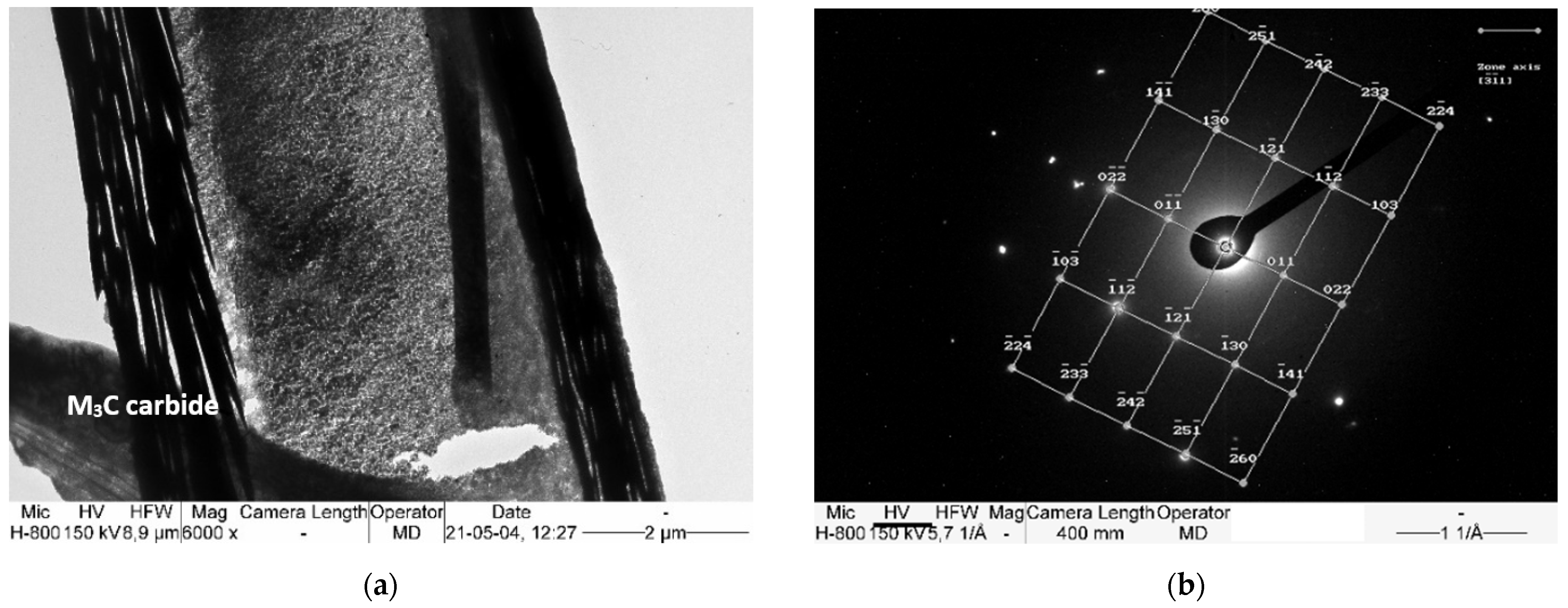

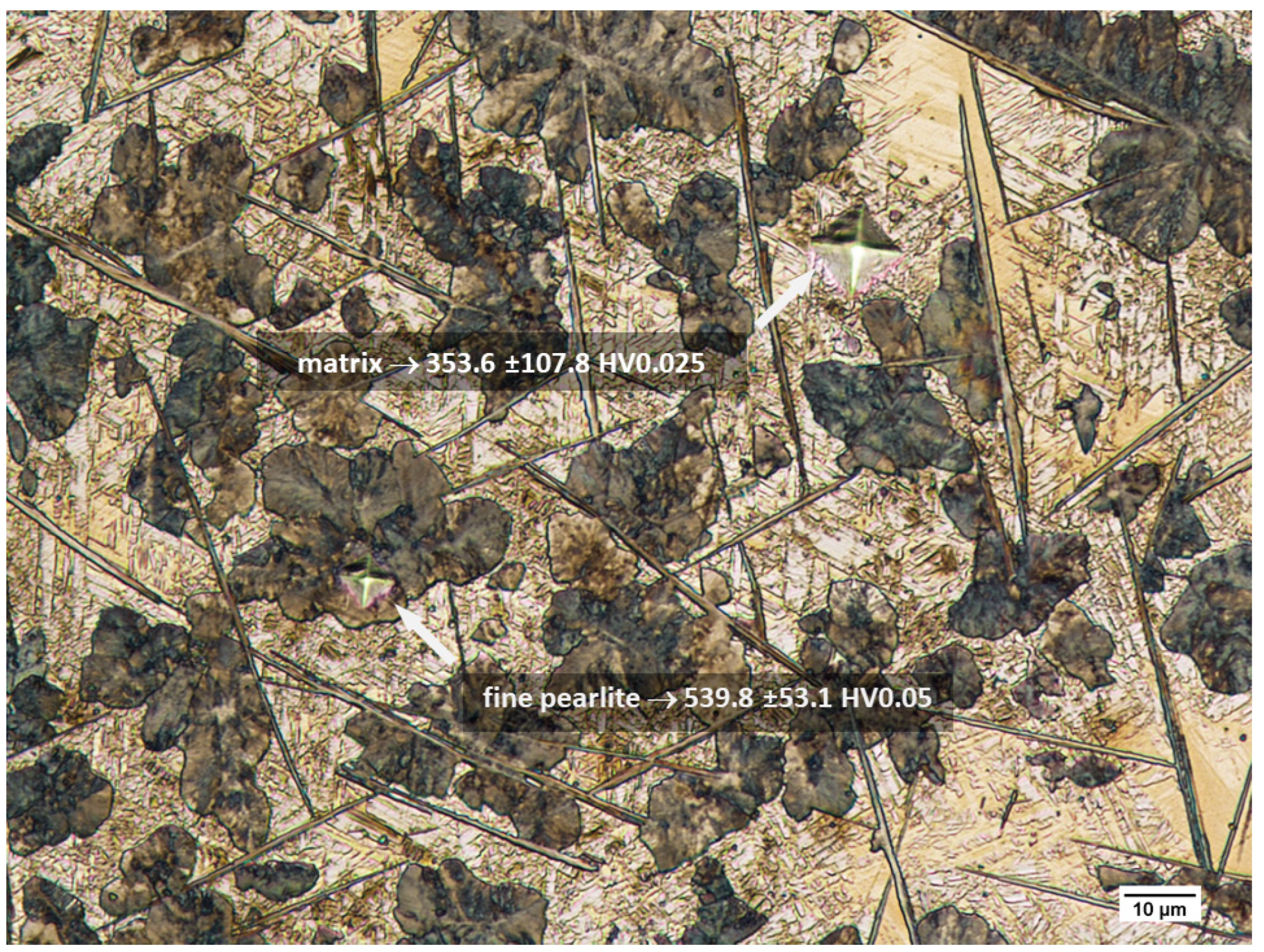

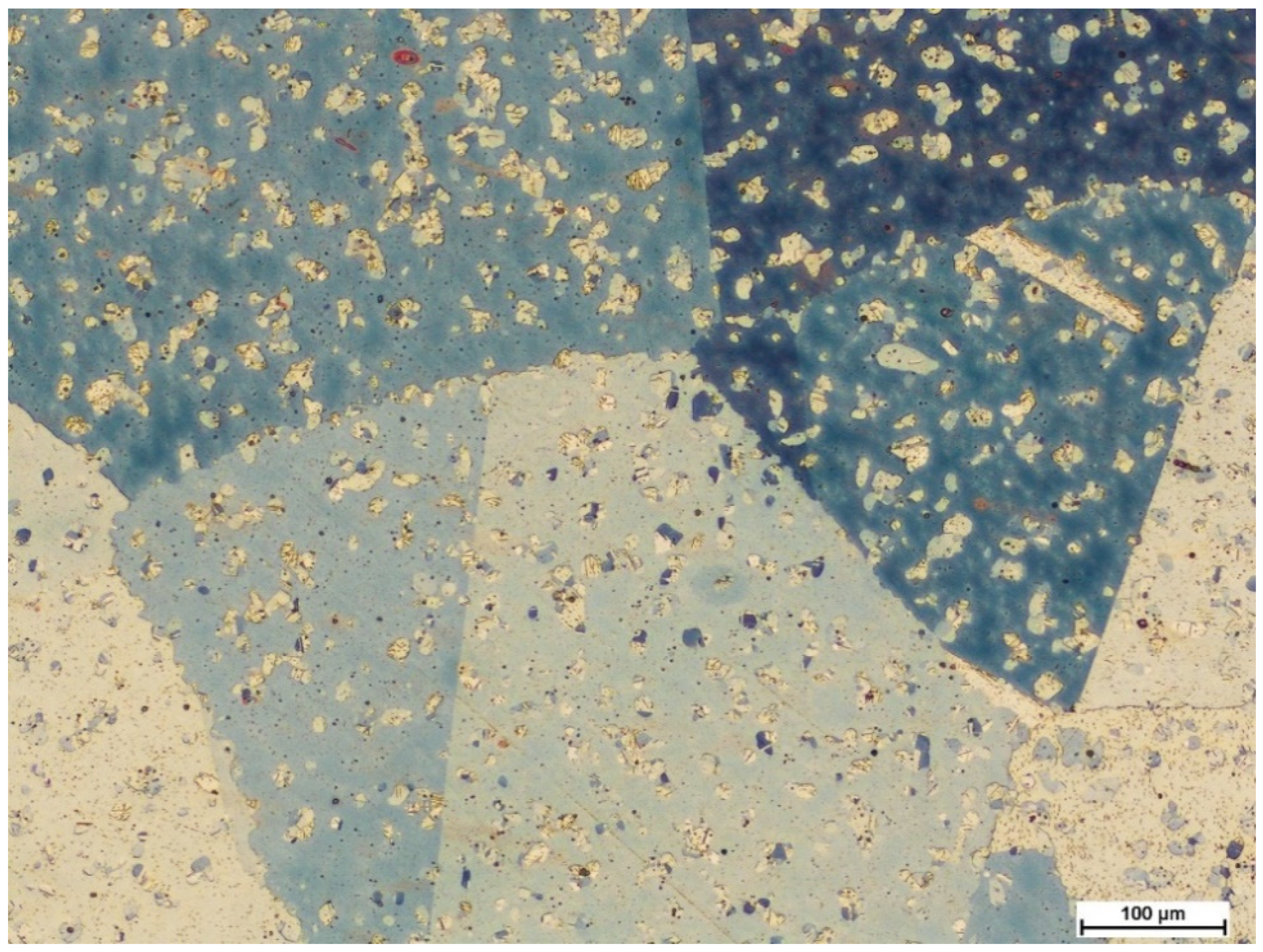

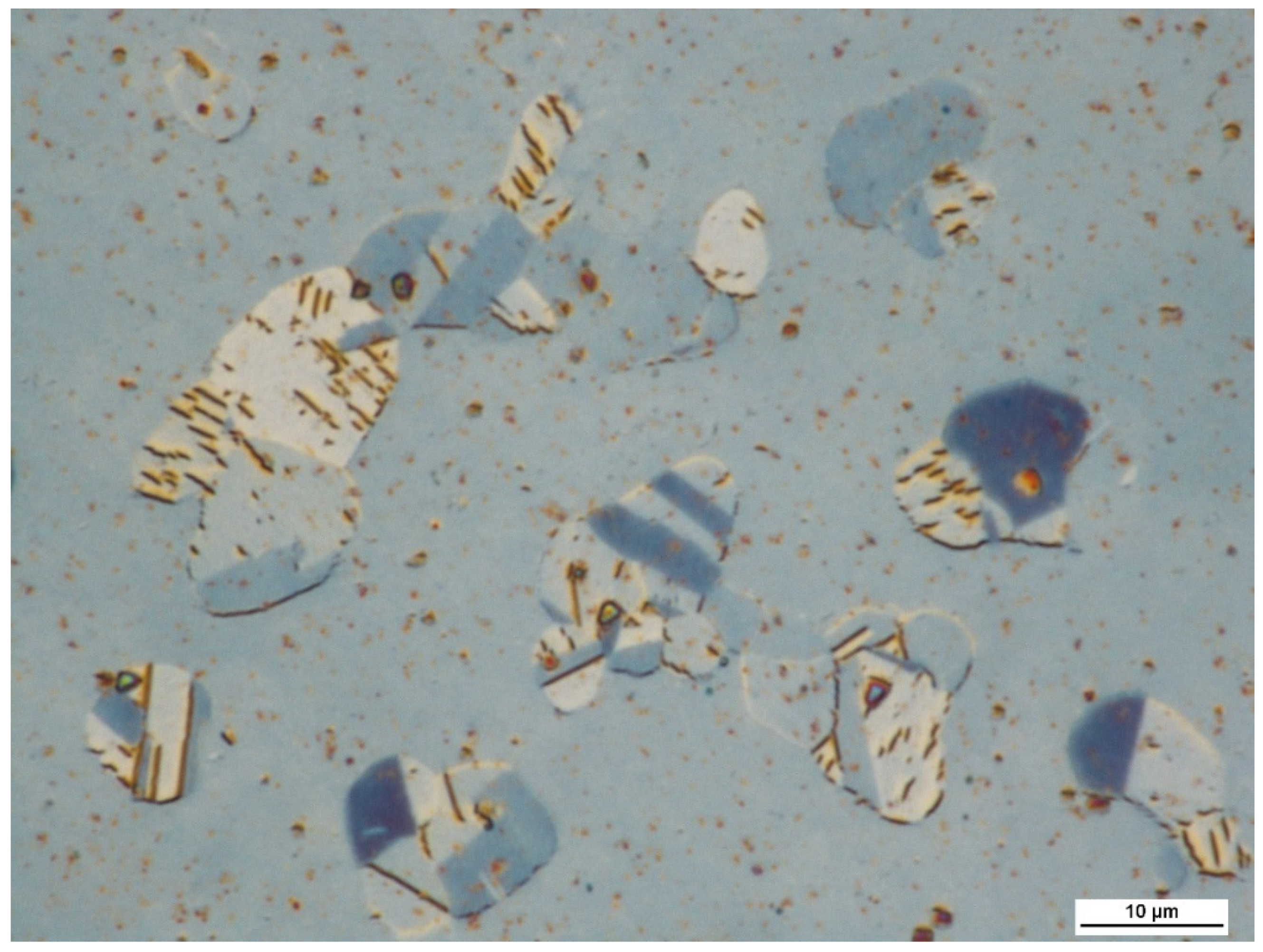

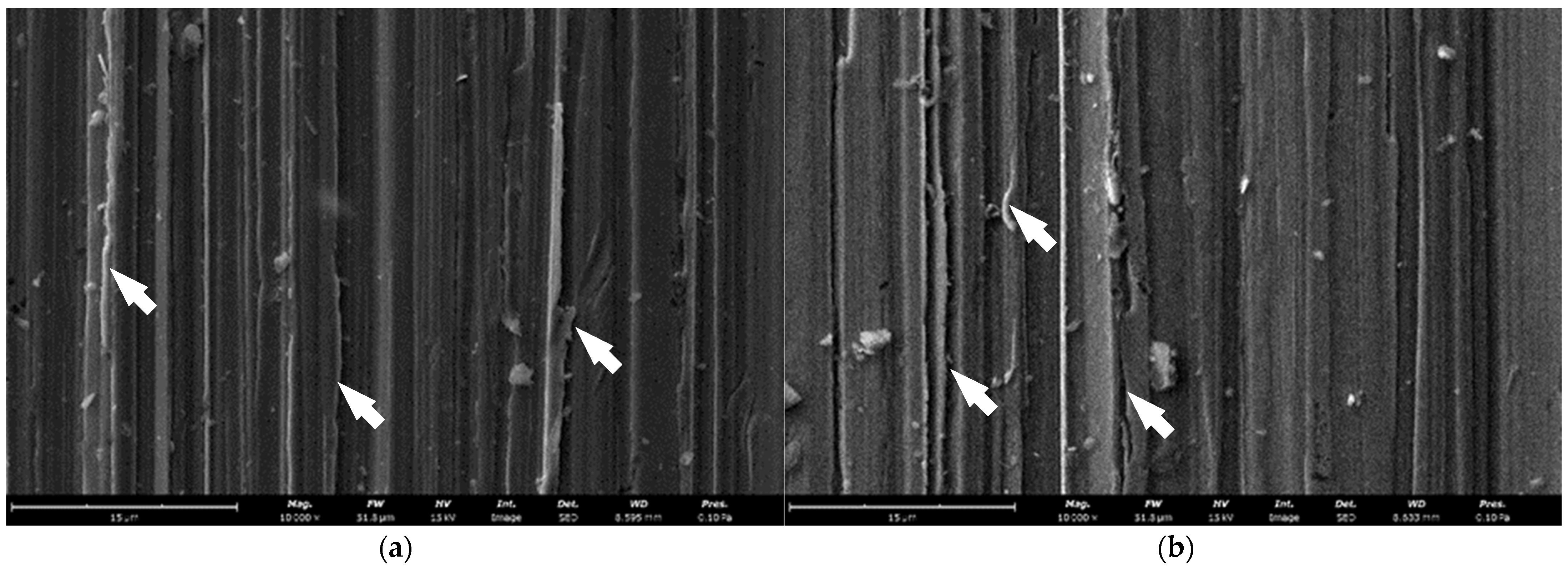

3.2.1. Identification of Microstructural Components

3.2.2. Distribution of Chemical Elements

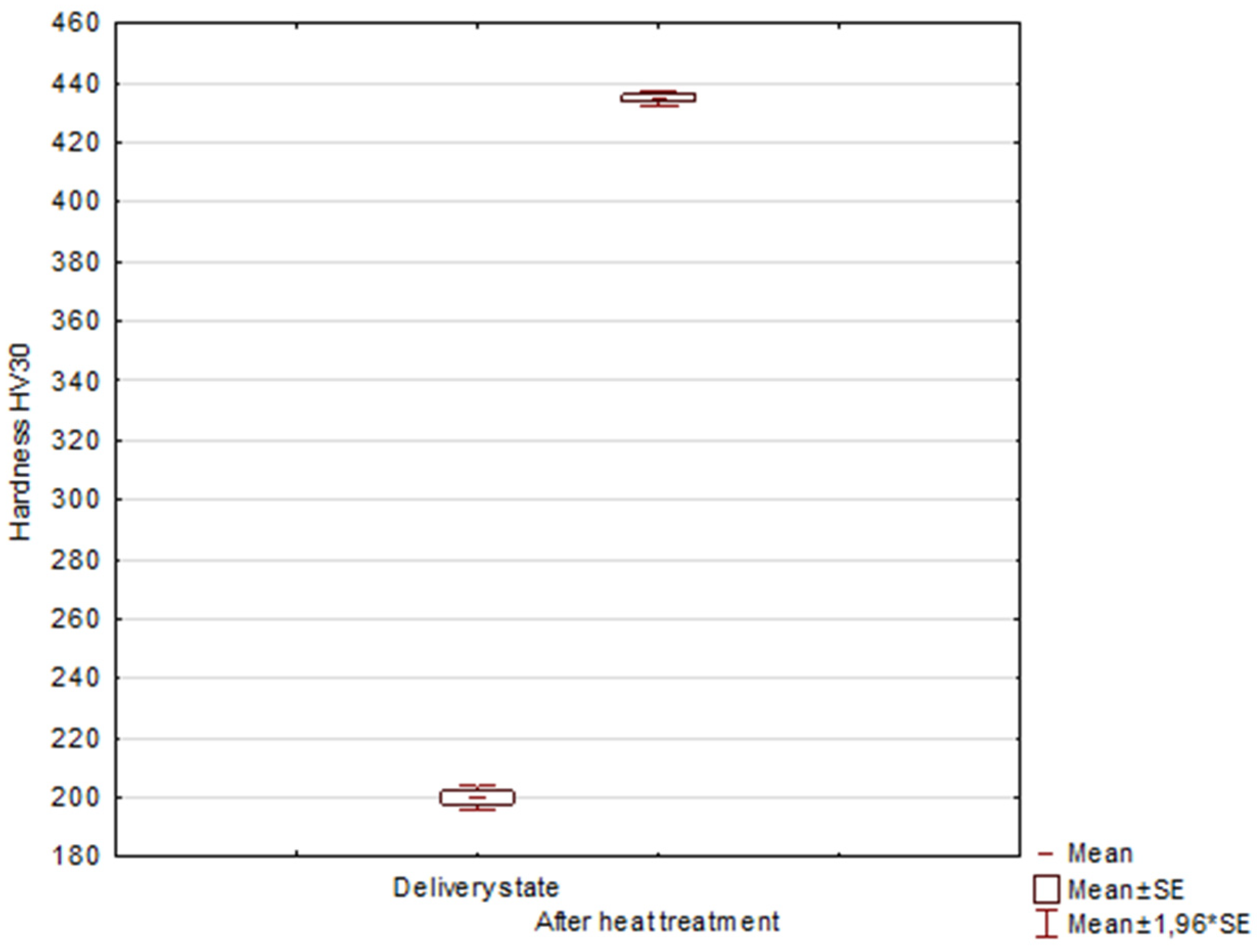

3.2.3. Hardness Measurements

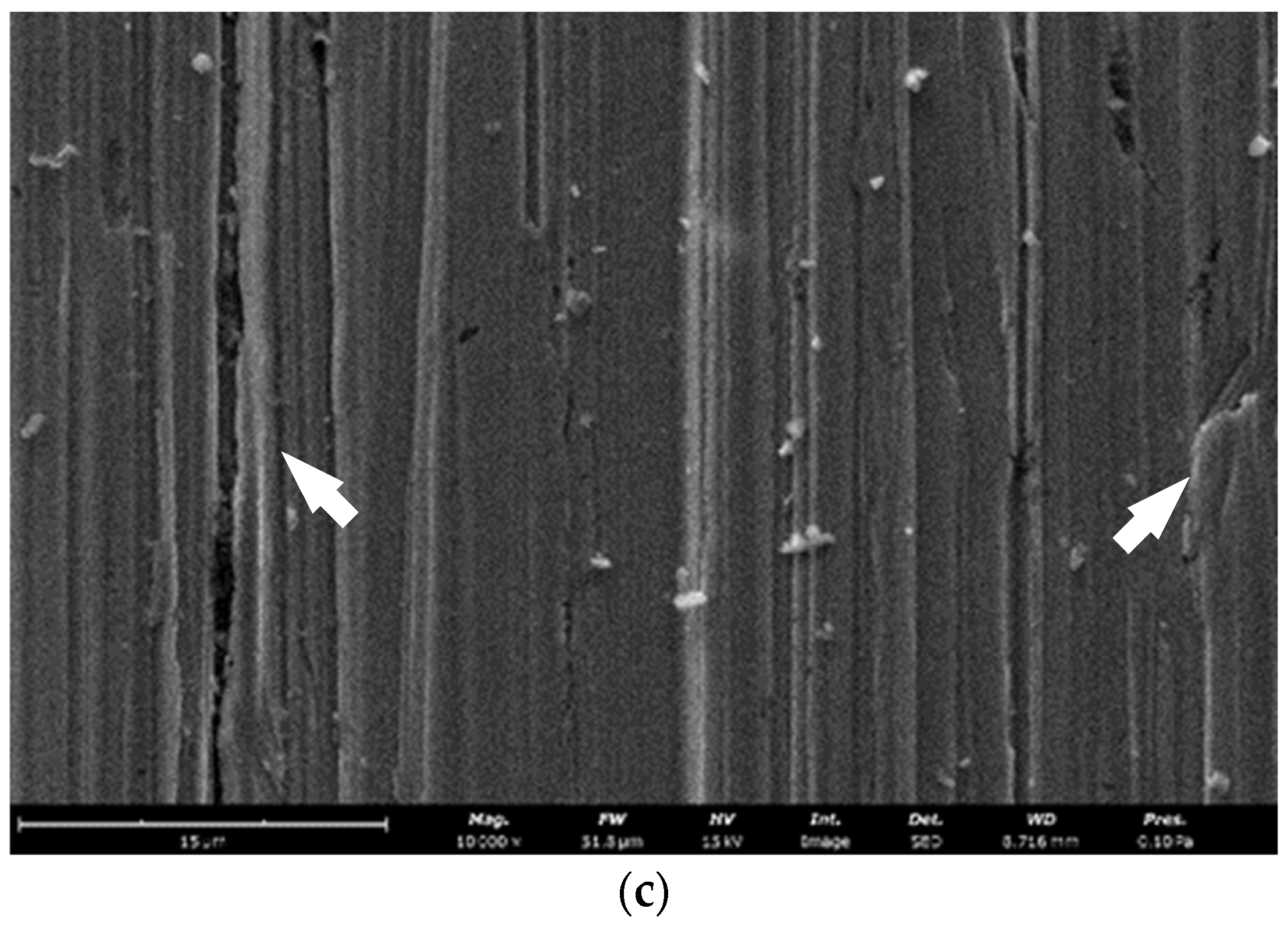

3.3. Re-Saturating Heat Treatment (Re-Austenitisation)

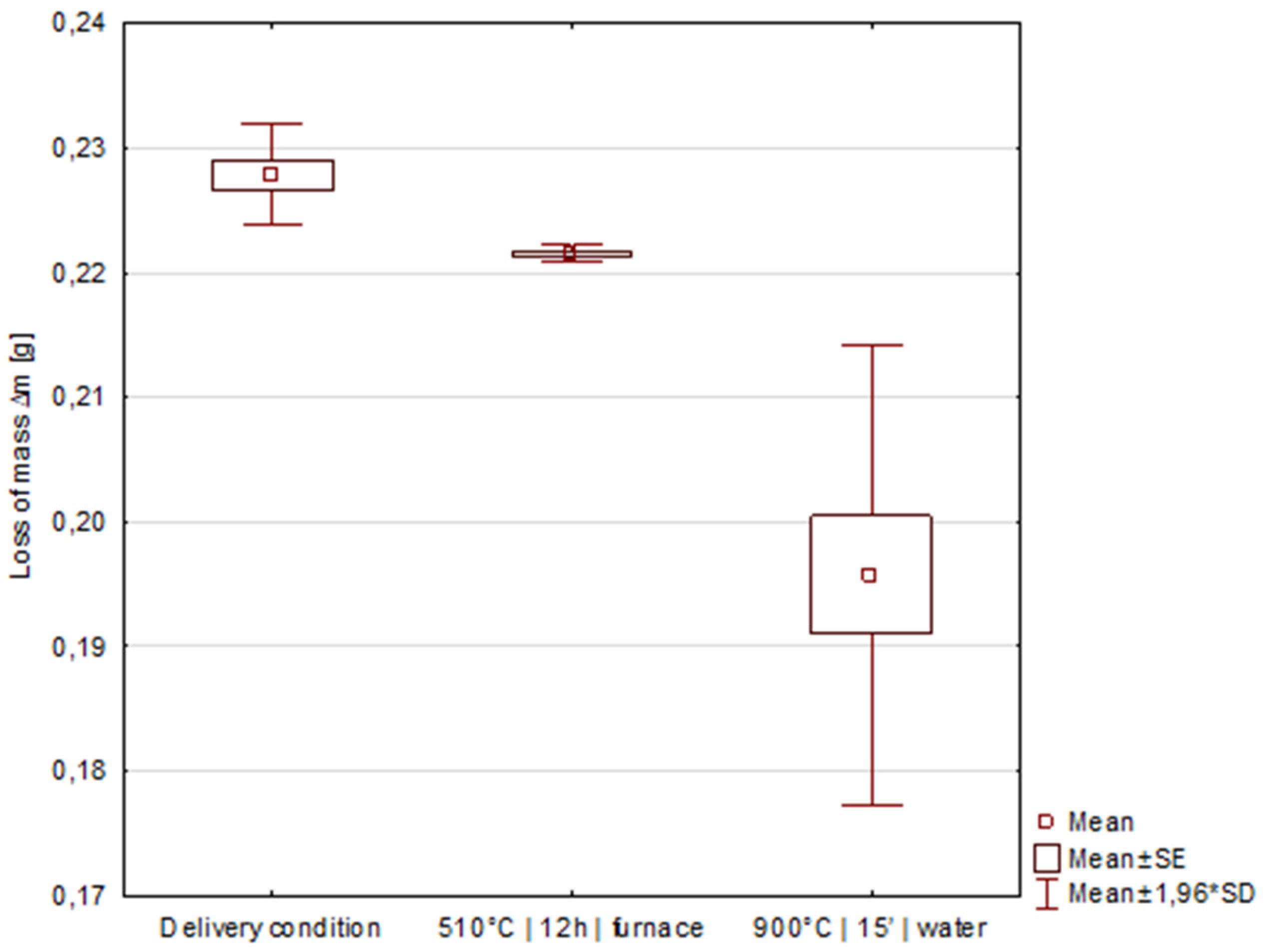

3.4. Comparative Abrasive Wear Resistance Tests

4. Conclusions

- The examined isothermally annealed steel is composed of four microstructural components: an austenitic matrix, (Fe,Mn)3C carbide in the form of a continuous network along the grain boundaries of the former austenite, (Fe,Mn)3C carbide in the form of needle-like precipitations, and fine pearlite colonies.

- The hardness of the steel in the as-delivered condition was 200.0 ± 6.7 HV30, which after the isothermal annealing treatment increases in a statistically significant manner, when compared to the as-delivered condition, to 435.0 ± 4.2 HV30. This growth is due to the precipitation of (Fe,Mn)3C carbides and the formation of numerous fine pearlite colonies.

- Final re-saturation at a lower than recommended temperature results in refining of the original coarse-grained microstructure of the steel. Furthermore, the morphology obtained is heterogeneous, and with a uniform and globular distribution of not fully dissolved carbide precipitations in the refined austenite matrix (Fe,Mn)3C, which resulted in a hardness of 228.5 ± 6.4 HV30, i.e., greater than in the as-delivered condition. The percentage of new grains in the re-austenised sample is 21.3% and their size is G = 11.5 acc. to ASTM E112-13 compared to the initial austenite grains with a size of G = 1.5. For this reason, the phenomenon of precipitation and the strengthening of the grain boundaries may be a mechanism to increase the abrasive wear resistance of X120Mn12 steel with an unmodified chemical composition without the addition of carbide-forming elements.

- Comparative wear resistance tests carried out indicate that a two-stage heat treatment (isothermal annealing followed by re-austenitisation) results in a 16.4% increase in abrasion resistance compared to the delivered condition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Subramanyam, D.K.; Swansiger, A.E.; Avery, H.S. Austenitic Manganese Steels. In Properties and Selection: Irons, Steels, and High-Performance Alloys; ASM International: Materials Park, OH, USA, 1990; pp. 822–840. [Google Scholar]

- Okechukwu, C.; Dahunsi, O.A.; Oke, P.K.; Oladele, I.O.; Dauda, M. Prominence of Hadfield Steel in Mining and Minerals Industries: A Review. Int. J. Eng. Technol. IJET 2017, 3, 83–90. [Google Scholar] [CrossRef] [Green Version]

- Hadfield, R.A. Method of Toughening Manganese-Steel Castings. U.S. Patent 572,891, 13 June 1896. [Google Scholar]

- Canadinc, D.; Sehitoglu, H.; Maier, H.J.; Niklasch, D.; Chumlyakov, Y.I. Orientation Evolution in Hadfield Steel Single Crystals under Combined Slip and Twinning. Int. J. Solids Struct. 2007, 44, 34–50. [Google Scholar] [CrossRef] [Green Version]

- He, Z.-M.; Jiang, Q.-C.; Fu, S.-B.; Xie, J.-P. Improved Work-Hardening Ability and Wear Resistance of Austenitic Manganese Steel under Non-Severe Impact-Loading Conditions. Wear 1987, 120, 305–319. [Google Scholar] [CrossRef]

- Tsakiris, V.; Edmonds, D.V. Martensite and Deformation Twinning in Austenitic Steels. Mater. Sci. Eng. A 1999, 273–275, 430–436. [Google Scholar] [CrossRef]

- Karaman, I.; Sehitoglu, H.; Beaudoin, A.J.; Chumlyakov, Y.I.; Maier, H.J.; Tomé, C.N. Modeling the Deformation Behavior of Hadfield Steel Single and Polycrystals Due to Twinning and Slip. Acta Mater. 2000, 48, 2031–2047. [Google Scholar] [CrossRef] [Green Version]

- Owen, W.S.; Grujicic, M. Strain Aging of Austenitic Hadfield Manganese Steel. Acta Mater. 1998, 47, 111–126. [Google Scholar] [CrossRef]

- Olawale, J.O.; Ibitoye, S.A.; Shittu, M.D. Workhardening Behaviour and Microstructural Analysis of Failed Austenitic Manganese Steel Crusher Jaws. Mater. Res. 2013, 16, 1274–1281. [Google Scholar] [CrossRef] [Green Version]

- Sant, S.B.; Smith, R.W. A Study in the Work-Hardening Behaviour of Austenitic Manganese Steels. J. Mater. Sci. 1987, 22, 1808–1814. [Google Scholar] [CrossRef]

- Stradomski, Z. Mikrostruktura w Zagadnieniach Zużycia Staliw Trudnościeralnych; Wydawnictwo Politechniki Częstochowskiej: Częstochowa, Poland, 2010. [Google Scholar]

- Fernandes, P.E.G.; Santos, L.A. Effect of Titanium and Nitrogen Inoculation on the Microstructure, Mechanical Properties and Abrasive Wear Resistance of Hadfield Steels. REM-Int. Eng. J. 2020, 73, 77–83. [Google Scholar] [CrossRef] [Green Version]

- Najafabadi, V.N.; Amini, K.; Alamdarlo, M.B. Investigating the Effect of Titanium Addition on the Wear Resistance of Hadfield Steel. Metall. Res. Technol. 2014, 111, 375–382. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Das, K. Microstructure and Abrasive Wear Study of (Ti,W)C-Reinforced High-Manganese Austenitic Steel Matrix Composite. Mater. Lett. 2008, 62, 3947–3950. [Google Scholar] [CrossRef]

- Tęcza, G.; Zapała, R. Changes in Impact Strength and Abrasive Wear Resistance of Cast High Manganese Steel Due to the Formation of Primary Titanium Carbides. Arch. Foundry Eng. 2018, 18, 119–122. [Google Scholar] [CrossRef]

- Tęcza, G.; Garbacz-Klempka, A. Microstructure of Cast High-Manganese Steel Containing Titanium. Arch. Foundry Eng. 2016, 16, 163–168. [Google Scholar] [CrossRef] [Green Version]

- Efstathiou, C.; Sehitoglu, H. Strengthening Hadfield Steel Welds by Nitrogen Alloying. Mater. Sci. Eng. A 2009, 506, 174–179. [Google Scholar] [CrossRef]

- Tęcza, G.; Głownia, J. Resistance to Abrasive Wear and Volume Fraction of Carbides in Cast High-Manganese Austenitic Steel with Composite Structure. Arch. Foundry Eng. 2015, 15, 129–133. [Google Scholar] [CrossRef]

- Hamada, A.S.; Karjalainen, L.P.; Somani, M.C. The Influence of Aluminum on Hot Deformation Behavior and Tensile Properties of High-Mn TWIP Steels. Mater. Sci. Eng. A 2007, 467, 114–124. [Google Scholar] [CrossRef]

- Ayadi, S.; Hadji, A. Effect of Chemical Composition and Heat Treatments on the Microstructure and Wear Behavior of Manganese Steel. Int. J. Met. 2021, 15, 510–519. [Google Scholar] [CrossRef]

- Gürol, U.; Can, K. Effect of Carbon and Manganese Content on the Microstructure and Mechanical Properties of High Manganese Austenitic Steel. J. Min. Metall. Sect. B Metall. 2020, 56, 171–182. [Google Scholar] [CrossRef]

- Bandanadjaja, B.; Hidayat, E. The Effect of Two-Step Solution Heat Treatment on the Impact Properties of Hadfield Austenitic Manganese Steel. J. Phys. Conf. Ser. 2020, 1450, 012125. [Google Scholar] [CrossRef]

- Mishra, S.; Dalai, R. A Comparative Study on the Different Heat-Treatment Techniques Applied to High Manganese Steel. Mater. Today Proc. 2021, 44, 2517–2520. [Google Scholar] [CrossRef]

- Ayadi, S.; Hadji, A. Effect of Heat Treatments on the Microstructure and Wear Resistance of a Modified Hadfield Steel. Metallofiz. I Noveishie Tekhnol. 2019, 41, 607–620. [Google Scholar] [CrossRef] [Green Version]

- Shih, C.H.; Averbach, B.L.; Cohen, M. Work Hardening and Martensite Formation in Austenitic Manganese Alloys; Wright Air Development Center, Massachusetts Institute of Technology: Cambridge, MA, USA, 1955.

- Azadi, M.; Pazuki, A.M.; Olya, M.J. The Effect of New Double Solution Heat Treatment on the High Manganese Hadfield Steel Properties. Metallogr. Microstruct. Anal. 2018, 7, 618–626. [Google Scholar] [CrossRef]

- Venturelli, B.N.; Albertin, E.; de Azevedo, C.R.F. The Effect of the Austenite Grain Refinement on the Tensile and Impact Properties of Cast Hadfield Steel. Mater. Res. 2018, 21, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Totten, G.E. (Ed.) Steel Heat Treatment; CRC Press: Boca Raton, FL, USA, 2006; ISBN 9780429133411. [Google Scholar]

- Srivastava, A.K.; Das, K. Corrosion Behaviour of TiC-Reinforced Hadfield Manganese Austenitic Steel Matrix In-Situ Composites. Open J. Met. 2015, 5, 11–17. [Google Scholar] [CrossRef] [Green Version]

- ASTM E112-13; Standard Test Methods for Determining Average Grain Size. ASTM International: West Conshohocken, PA, USA, 2013.

- Pearson, W.B. Tabulated Lattice Spacings and Data of Borides, Carbides, Hydrides, Nitrides, and Binary Oxides. In A Handbook of Lattice Spacings and Structures of Metals and Alloys; Elsevier: Amsterdam, The Netherlands, 1958; pp. 218–246. [Google Scholar]

- Pearson, W.B. Tabulated Lattice Spacings and Data of the Elements. In A Handbook of Lattice Spacings and Structures of Metals and Alloys; Elsevier: Amsterdam, The Netherlands, 1958; pp. 123–130. [Google Scholar]

- Pearson, W.B. Tabulated Lattice Spacings and Data of Intermediate Phases in Alloy Systems. In A Handbook of Lattice Spacings and Structures of Metals and Alloys; Elsevier: Amsterdam, The Netherlands, 1958; pp. 131–217. [Google Scholar]

- PN-H 83160:1988; Staliwo Odporne Na Ścieranie-Gatunki. Polski Komitet Normalizacyjny: Warszawa, Poland, 1988.

- Bhero, S.W.; Nyembe, B.; Lentsoana, K. Common Causes of Premature Failure of Hadfield Steel Crushers and Hammers Used in the Mining Industry. In Proceedings of the International Conference on Mining, Mineral Processing and Metallurgical Engineering, Johannesburg, South Africa, 15–16 April 2013; pp. 174–176. [Google Scholar]

- Kuyucak, S.; Zavadil, R.; Gertsman, V. Heat-Treatment Processing of Austenitic Manganese Steels. In Proceedings of the 66th World Foundry Congress, Istanbul, Turkey, 6–9 September 2004. [Google Scholar]

- Chojecki, A.; Telejko, I. Cracks in High-Manganese Cast Steel. Arch. Foundry Eng. 2009, 9, 17–22. [Google Scholar]

- Zhang, Y.; Li, Y.; Han, B.; Zhang, F.; Qian, L. Microstructural Characteristics of Hadfield Steel Solidified under High Pressure. High Press. Res. 2011, 31, 634–639. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Das, K. Microstructural Characterization of Hadfield Austenitic Manganese Steel. J. Mater. Sci. 2008, 43, 5654–5658. [Google Scholar] [CrossRef]

- Qichuan, J.; Zhenming, H.; Yanping Jilin, C. Influence of Carbides and Strain-Induced Martensite on Wear Resistance of Austenitic Medium Manganese Steels. J. Mater. Sci. Technol. 1989, 5, 268–272. [Google Scholar]

- Haakonsen, F. Optimizing of Stromhard Austenitic Manganese Steel. Doctoral Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2009. [Google Scholar]

- Sabzi, M.; Farzam, M. Hadfield Manganese Austenitic Steel: A Review of Manufacturing Processes and Properties. Mater. Res. Express 2019, 6, 1065c2. [Google Scholar] [CrossRef]

| for n = 10 Replicates | C | Mn | Si | P | S | Cr | Cu | Mo | Ni | Al | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|

| average | 1.04 | 12.5 | 0.404 | 0.023 | 0.000 | 0.230 | 0.151 | 0.019 | 0.077 | 0.025 | 0.006 |

| standard deviation | ±0.01 | ±0.1 | ±0.005 | ±0.000 | ±0.000 | ±0.004 | ±0.003 | ±0.000 | ±0.001 | ±0.001 | ±0.000 |

| Content | Mn | C | Si | Fe |

|---|---|---|---|---|

| at. [%] | 11.81 | 11.05 | 0.95 | bal. |

| wt. [%] | 12.82 | 2.62 | 0.53 | bal. |

| Samples | Heat Treatment Variants Subjected to Abrasive Wear Test | |||

|---|---|---|---|---|

| Delivery Condition | 510 °C|12 h|Furnace | 900 °C|15′|Water | ||

| Loss of mass ∆m * [g] | 1 | 0.2256 | 0.2214 | 0.2066 |

| 2 | 0.2297 | 0.2219 | 0.1917 | |

| 3 | 0.2282 | 0.2212 | 0.1850 | |

| 4 | - | - | 0.1998 | |

| Average | 0.2278 | 0.2215 | 0.1958 | |

| Relative resistance to abrasive wear in relation to delivery condition ** [–] | - | 1.0286 (≈2.9%) | 1.1638 (≈16.4%) | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dziubek, M.; Rutkowska-Gorczyca, M.; Dudziński, W.; Grygier, D. Investigation into Changes of Microstructure and Abrasive Wear Resistance Occurring in High Manganese Steel X120Mn12 during Isothermal Annealing and Re-Austenitisation Process. Materials 2022, 15, 2622. https://doi.org/10.3390/ma15072622

Dziubek M, Rutkowska-Gorczyca M, Dudziński W, Grygier D. Investigation into Changes of Microstructure and Abrasive Wear Resistance Occurring in High Manganese Steel X120Mn12 during Isothermal Annealing and Re-Austenitisation Process. Materials. 2022; 15(7):2622. https://doi.org/10.3390/ma15072622

Chicago/Turabian StyleDziubek, Mateusz, Małgorzata Rutkowska-Gorczyca, Włodzimierz Dudziński, and Dominika Grygier. 2022. "Investigation into Changes of Microstructure and Abrasive Wear Resistance Occurring in High Manganese Steel X120Mn12 during Isothermal Annealing and Re-Austenitisation Process" Materials 15, no. 7: 2622. https://doi.org/10.3390/ma15072622

APA StyleDziubek, M., Rutkowska-Gorczyca, M., Dudziński, W., & Grygier, D. (2022). Investigation into Changes of Microstructure and Abrasive Wear Resistance Occurring in High Manganese Steel X120Mn12 during Isothermal Annealing and Re-Austenitisation Process. Materials, 15(7), 2622. https://doi.org/10.3390/ma15072622