Flammability and Thermoregulation Properties of Knitted Fabrics as a Potential Candidate for Protective Undergarments

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Conclusions

| No. of Fabric | Inner Layer (in Contact with the Skin) | Outer Layer |

| 1A |  |  |

| 2A |  |  |

| 3A |  |  |

| 4A |  |  |

| 5A |  |  |

| 6A |  |  |

| 7A |  |  |

| 8A |  |  |

| 1B |  |  |

| 2B |  |  |

| 3B |  |  |

| 4B |  |  |

| 5B |  |  |

| 6B |  |  |

| 7B |  |  |

| 8B |  |  |

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Glombikova, V.; Komarkova, P. The efficiency of non-flammable functional underwear. AUTEX Res. J. 2014, 14, 174–178. [Google Scholar] [CrossRef] [Green Version]

- Varga, K.; Noisternig, M.F.; Griesser, U.J.; Alja, L.; Koch, T. Thermal and sorption study of flame-resistant fibers. Lenzing. Ber. 2011, 89, 50–59. [Google Scholar]

- Bajaj, P. Heat and flame protection. Handb. Tech. Text. 2000, 12, 223. [Google Scholar]

- Mbise, E.; Dias, T.; Hurley, W.; Morris, R. The study of applying heat to enhance moisture transfer in knitted spacer structures. J. Ind. Text. 2018, 47, 1584–1608. [Google Scholar] [CrossRef]

- Cardoso, I.; Gomes, J.R. The application of microcapsules of PCM in flame resistant non-woven materials. Int. J. Cloth. Sci. Technol. 2009, 21, 102–108. [Google Scholar] [CrossRef] [Green Version]

- House, J.R.; Squire, J.D. Effectiveness of Proban® flame retardant in used clothing. Int. J. Cloth. Sci. Technol. 2004, 16, 361–367. [Google Scholar] [CrossRef]

- Mamalis, P.; Andreopoulos, A.; Spyrellis, N. The effect of a durable flame-retardant finishing on the mechanical properties of cotton knitted fabrics. Int. J. Cloth. Sci. Technol. 2001, 13, 132–134. [Google Scholar] [CrossRef]

- Ozcan, G.; Dayioglu, H.; Candan, C. Impact of finishing processes on flame resistance of knitted fabric. Text. Res. J. 2004, 74, 490–496. [Google Scholar] [CrossRef]

- Weil, E.D.; Levchik, S.V. Flame retardants in commercial use or development for textiles. J. Fire Sci. 2008, 26, 243–281. [Google Scholar] [CrossRef]

- Zhang, H.; Song, G.; Ren, H.; Cao, J. The effects of moisture on the thermal protective performance of firefighter protective clothing under medium intensity radiant exposure. Text. Res. J. 2018, 88, 847–862. [Google Scholar] [CrossRef]

- Troynikov, O.; Wardiningsih, W. Moisture management properties of wool/polyester and wool/bamboo knitted fabrics for the sportswear base layer. Text. Res. J. 2011, 81, 621–631. [Google Scholar] [CrossRef]

- Öner, E.; Atasağun, H.G.; Okur, A.; Beden, A.R.; Durur, G. Evaluation of moisture management properties on knitted fabrics. J. Text. Inst. 2013, 104, 699–707. [Google Scholar] [CrossRef]

- Aihua, M.; Yi, L. Numerical heat transfer coupled with multidimensional liquid moisture diffusion in porous textiles with a measurable-parameterized model. Numer. Heat Transf. Part A Appl. 2009, 56, 246–268. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, Q. A model of coupled liquid moisture and heat transfer in porous textiles with consideration of gravity. Numer. Heat Transf. Part A Appl. 2003, 43, 501–523. [Google Scholar] [CrossRef]

- Wakatsuki, K.; Tsuji, H.; Kato, T.; Ogawa, Y. Evaluation of Functional Underwear for Firefighter clothing by Total Heat Loss. Adv. Mater. Res. 2013, 796, 617–622. [Google Scholar] [CrossRef]

- Eryuruk, S.H.; Koncar, V.; Kalaoglu, F.; Gidik, H.; Tao, X. Thermal Comfort Properties of Firefighters’ Clothing with Underwear. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Lesvos, Greece, 2018; p. 459. [Google Scholar]

- Eryuruk, S.H.; Gidik, H.; Koncar, V.; Kalaoglu, F.; Tao, X.; Saglam, Y. Heat and moisture transfer properties of a firefighter clothing with a new fire-resistant underwear. J. Ind. Text. 2021, 2021, 1528083721993775. [Google Scholar] [CrossRef]

- Halavska, L.; Ielina, T.; Mikučionienė, D.; Milašius, R.; Bobrova, S. Development of knitwear for protection against increased thermal effects. AIP Conf. Proc. 2022, 2430, 030001. [Google Scholar]

- LST EN 14971:2006; Textiles—Knitted Fabrics—Determination of Number of Stitches Per Unit Length and Unit Area. Textiles. Lithuanian Standards Board: Vilnius, Lithuania, 2006.

- LST EN 12127:1997; Textiles—Fabrics—Determination of Mass Per Unit Area Using Small Samples. Lithuanian Standards Board: Vilnius, Lithuania, 1999.

- Abramaviiūtė, J.; Mikučionienė, D.; Čiukas, R. Structure properties of knits from natural yarns and their combination with elastane and polyamide threads. Mater. Sci. 2011, 17, 43–46. [Google Scholar] [CrossRef] [Green Version]

- Au, K.F. (Ed.) Advances in Knitting Technology; Elsevier: Cambridge, UK, 2011. [Google Scholar]

- Ciukas, R.; Tvarijonaviciene, B.; Mikucioniene, D. Estimating the linear density of fancy ribbon-type yarns and the structure indices of fabrics knitted from them. Fibres Text. East. Eur. 2006, 14, 41. [Google Scholar]

- Matukonis, A.; Palaima, J.; Vitkauskas, A. Tekstilės Medžiagotyra; Mokslas: Vilnius, Lithuania, 1978; p. 424. (In Lithuanian) [Google Scholar]

- Scott, R.A. (Ed.) Textiles for Protection; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Horrocksand, A.R.; Anand, S.C. Handbook of Technical Textiles, The Textile Institute; Woodhead Publishing Limited, Elsevier: Cambridge, UK, 2000; pp. 25–43. [Google Scholar]

- LST EN ISO 5084:2000; Textiles—Determination of thickness of textiles and textile products (ISO 5084:1996). Lithuanian Standards Board: Vilnius, Lithuania, 2000.

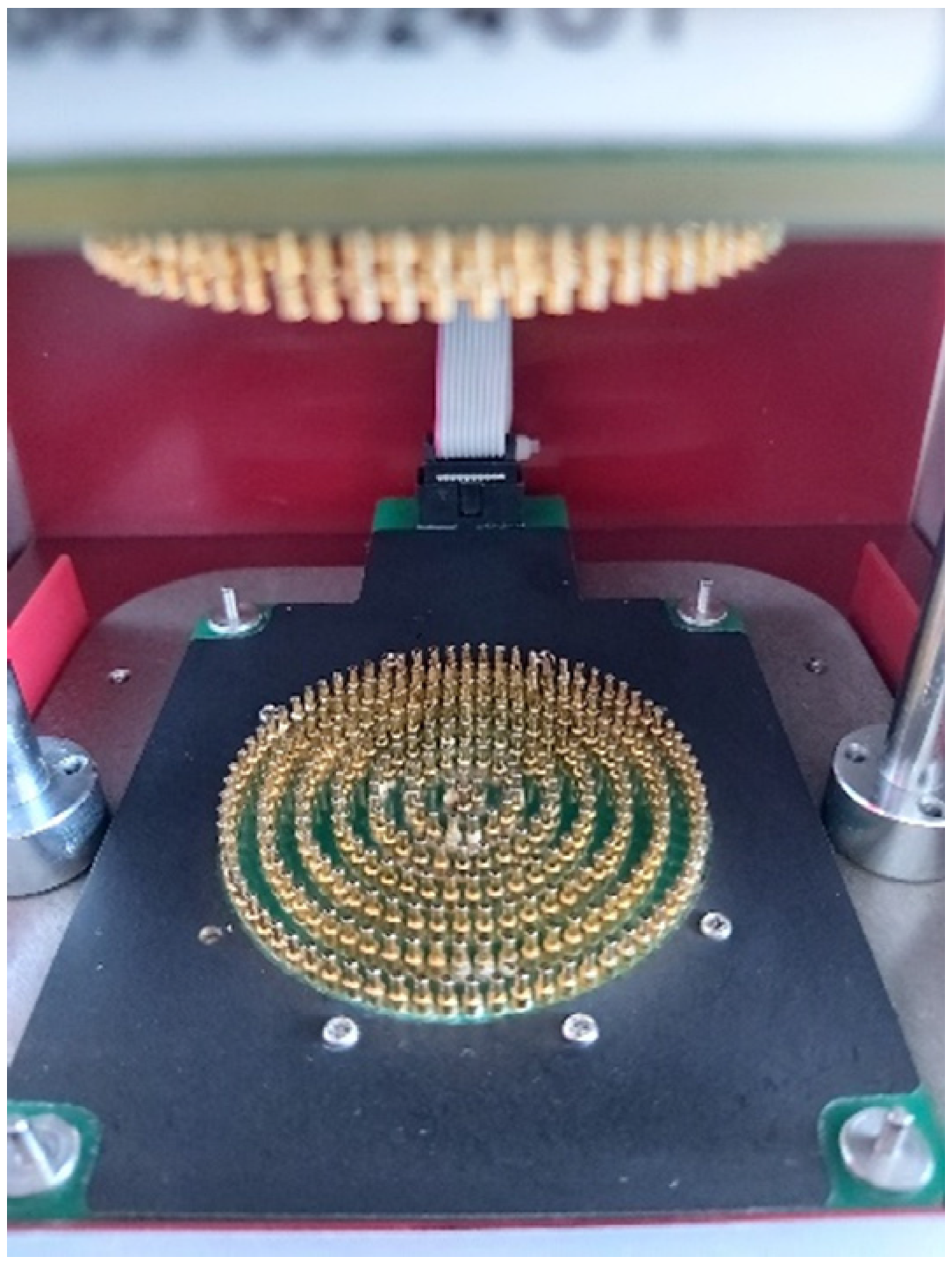

- AATCC 195:2017; Test Method for Liquid Moisture Management Properties of Textile Fabrics. American Association of Textile Chemists and Colorists (AATCC): Charlotte, NC, USA, 2020.

- CEN/TR 16422:2012; Classification of Thermoregulatory Properties. European Committee for Standartization: Brussels, Belgium, 2012.

- LST EN ISO 9237:1997; Textiles—Determination of permeability of fabrics to air (ISO 9237:1995). Lithuanian Standards Board: Vilnius, Lithuania, 1997.

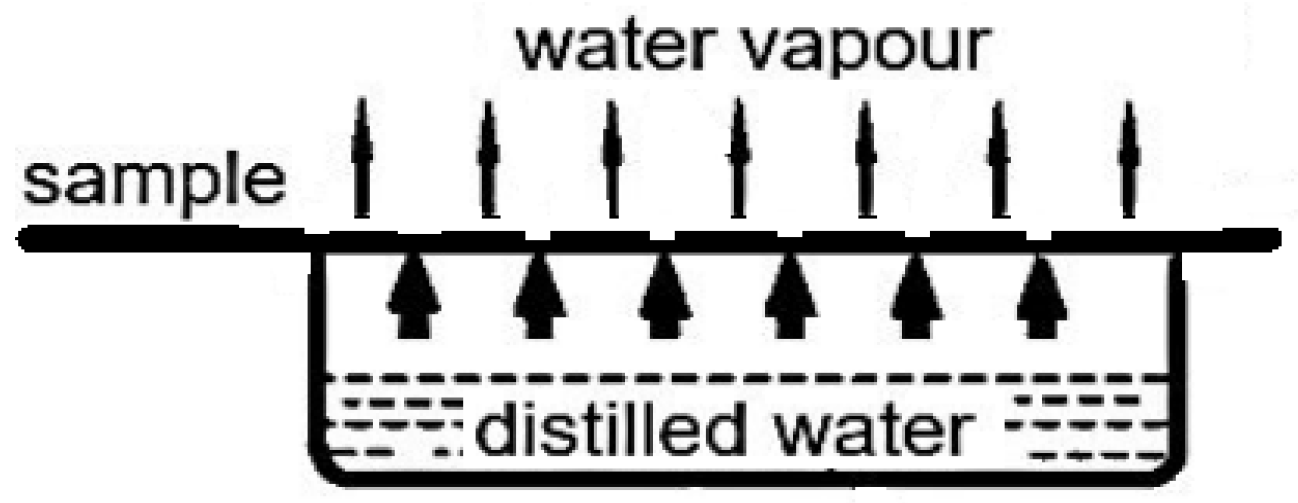

- LST EN ISO 11092:2015; Textiles—Physiological Effects—Measurement of Thermal and Water-Vapour Resistance under Steady-State Conditions (Sweating Guarded-Hotplate Test) (ISO 11092:2014). Lithuanian Standards Board: Vilnius, Lithuania, 2015.

- LST EN ISO 15025:2017; Protective Clothing—Protection against Flame—Method of Test for Limited Flame Spread (ISO 15025:2016). Lithuanian Standards Board: Vilnius, Lithuania, 2017.

- Baltušnikaite, J.; Abraitienė, A.; Stygienė, L.; Krauledas, S.; Rubežienė, V.; Varnaitė-Žuravliova, S. Investigation of moisture transport properties of knitted materials intended for warm underwear. Fibres Text. East. Eur. 2014, 4, 93–100. [Google Scholar]

- Bear, J. Dynamics of Fluids in Porous Media; Courier Corporation: Mineola, NY, USA, 2013. [Google Scholar]

- Suganthi, T.; Senthilkumar, P. Moisture-management properties of bi-layer knitted fabrics for sportswear. J. Ind. Text. 2018, 47, 1447–1463. [Google Scholar] [CrossRef]

- Sonee, N.; Arora, C.; Parmar, M.S. Burning behaviour of aramid and FR viscose blended fabrics. Indian J. Fiber Text. Res. 2019, 44, 238–243. [Google Scholar]

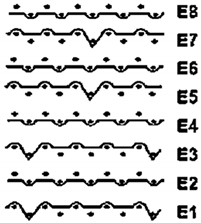

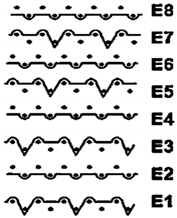

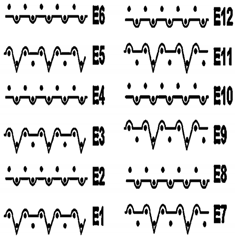

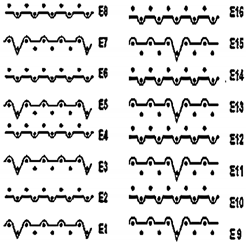

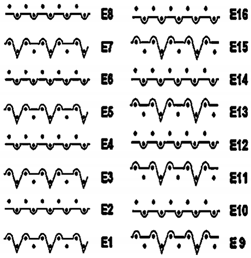

| Code of Pattern | Pattern of Knitted Fabric | Code of Pattern | Pattern of Knitted Fabric |

|---|---|---|---|

| I A | I B | ||

| II A |  | II B |  |

| III A |  | III B |  |

| IV A |  | IV B |  |

| No. of Fabric | Pattern Code (See Table 1) | Type of Separate Layer * | Type of Flame-Retardant Spun Yarn, Linear Density (Tex) | Pattern Courses (See Table 1) | Mass Per Unit Area (g/m2) | Mean Loop Length L, mm | Tightness Factor TF (tex1/2/mm) | Thick-Ness h (mm) | Volume Filling Rate Ev | Porosity E, % |

|---|---|---|---|---|---|---|---|---|---|---|

| 1A | IA | Inner | METAFINE.X.95®, 16.4 | E1, E3…–E15 (uneven) | 212 | 3.67 | 1.56 | 1.27 | 0.23 | 77.37 |

| 2A | IIA | 230 | 3.98 | 1.44 | 1.37 | 0.23 | 77.24 | |||

| 3A | IIIA | METALEN®, 16.4 | E2, E4…–E16 (even) | 231 | 4.00 | 1.43 | 1.40 | 0.22 | 77.63 | |

| 4A | IVA | Outer | 236 | 4.09 | 1.40 | 1.43 | 0.22 | 77.63 | ||

| 5A | IA | Inner | METAFINE.X.95®, 16.4 | E2, E4…–E16 (even) | 191 | 3.31 | 1.73 | 0.97 | 0.27 | 73.31 |

| 6A | IIA | 195 | 3.38 | 1.70 | 1.02 | 0.26 | 74.08 | |||

| 7A | IIIA | METALEN®, 16.4 | E1, E3…–E15 (uneven) | 192 | 3.33 | 1.72 | 1.05 | 0.25 | 75.21 | |

| 8A | IVA | Outer | 198 | 3.43 | 1.67 | 1.10 | 0.24 | 75.60 | ||

| 1B | IB | Inner | METAFINE.X.95®, 16.4 | E1, E3…–E15 (uneven) | 248 | 4.30 | 1.33 | 1.40 | 0.24 | 75.99 |

| 2B | IIB | 224 | 3.88 | 1.48 | 1.37 | 0.22 | 77.83 | |||

| 3B | IIIB | METALEN®, 16.4 | E2, E4…–E16 (even) | 234 | 4.05 | 1.41 | 1.33 | 0.24 | 76.15 | |

| 4B | IVB | Outer | 226 | 3.92 | 1.46 | 1.32 | 0.23 | 76.79 | ||

| 5B | IB | Inner | METAFINE.X.95®, 16.4 | E2, E4…–E16 (even) | 208 | 3.60 | 1.59 | 1.11 | 0.25 | 74.60 |

| 6B | IIB | 198 | 3.43 | 1.67 | 1.07 | 0.25 | 74.91 | |||

| 7B | IIIB | METALEN®, 16.4 | E1, E3…–E15 (uneven) | 197 | 3.41 | 1.68 | 1.05 | 0.25 | 74.57 | |

| 8B | IVB | Outer | 203 | 3.52 | 1.63 | 1.03 | 0.27 | 73.28 |

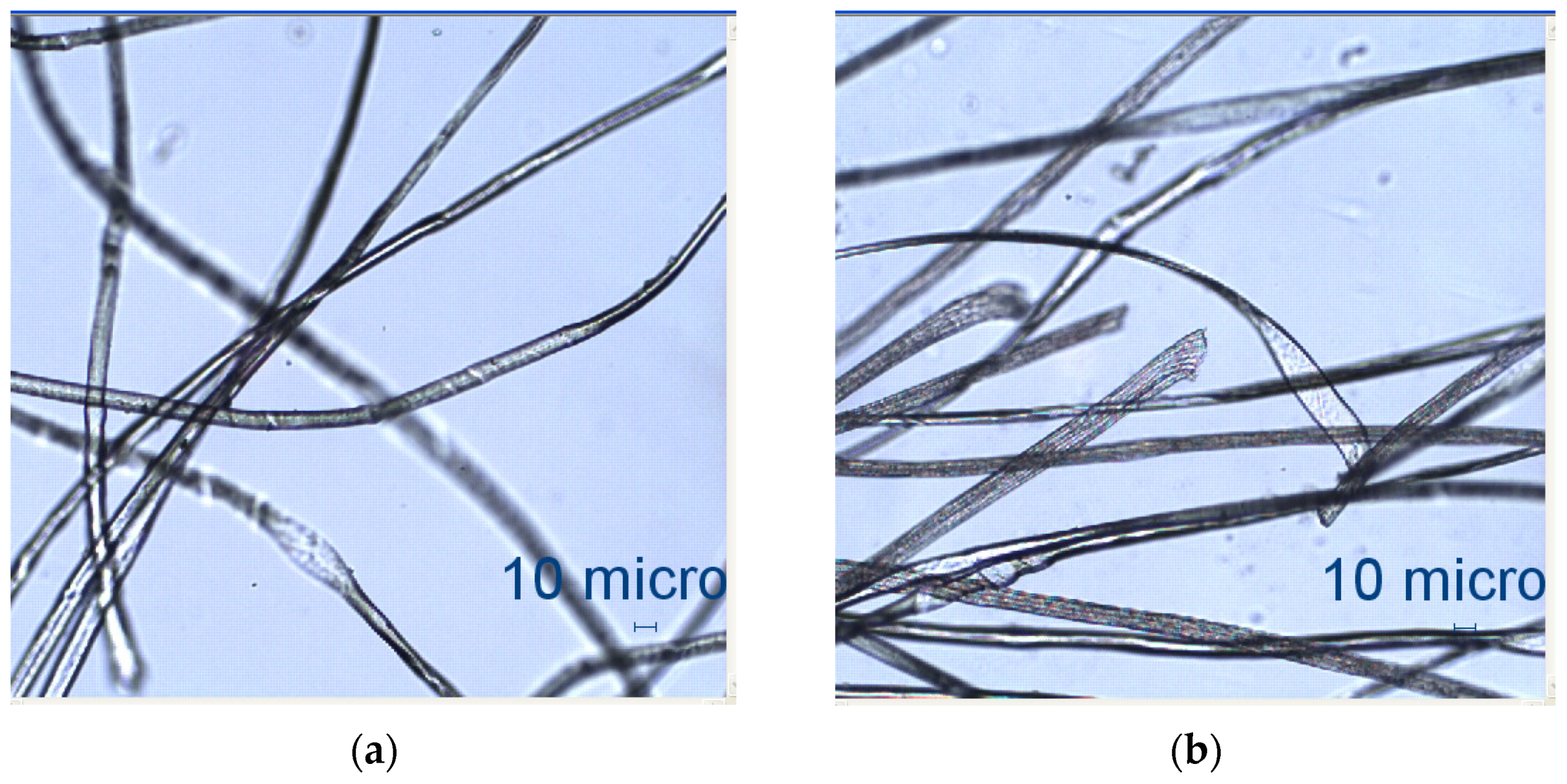

| Brand Name of Yarn | Fiber Content, % | Density, kg/m3 | Conventional Diameter d, µm | |

|---|---|---|---|---|

| Of Individual Fiber [19,20] | Of Yarn | |||

| METAFINE.X.95® | 95% meta-aramid | 1.46 × 103 | 1.459 × 103 | 119.70 |

| 5% para-aramid | 1.44 × 103 | |||

| METALEN® | 50% meta-aramid | 1.46 × 103 | 1.485 × 103 | 118.65 |

| 50% viscose FR | 1.51 × 103 | |||

| Grade Index | 1 | 2 | 3 | 4 | 5 | |

|---|---|---|---|---|---|---|

| Wetting time, WT, s | Top-WTT | ≥120 | 20–119 | 5–19 | 3–5 | <3 |

| No wetting | Slow | Medium | Fast | Very fast | ||

| Bottom-WTB | ≥120 | 20–119 | 5–19 | 3–5 | <3 | |

| No wetting | Slow | Medium | Fast | Very fast | ||

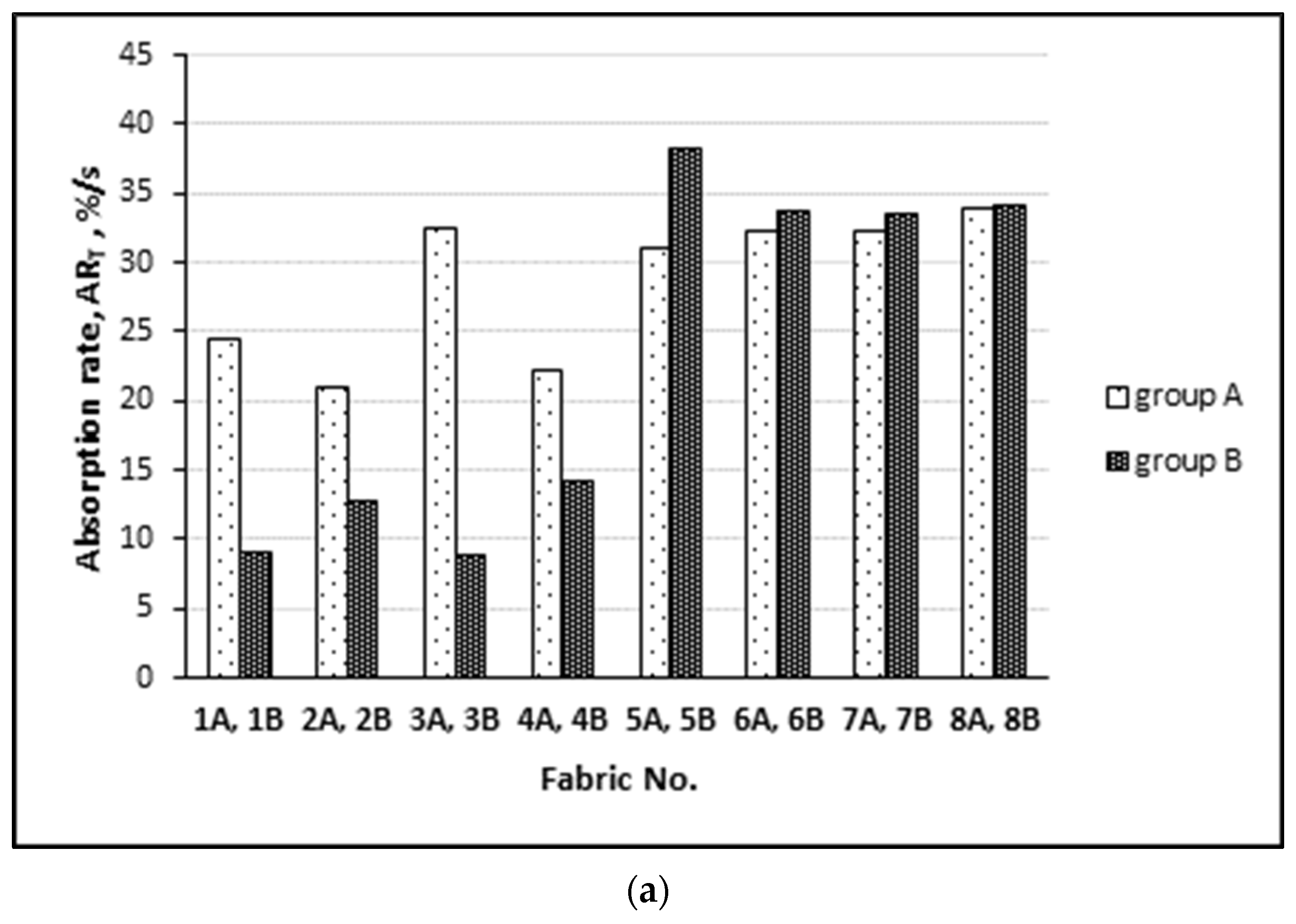

| Absorption rate, AR, %/s | Top-ART | 0–9 | 10–29 | 30–49 | 50–100 | >100 |

| Very slow | Slow | Medium | Fast | Very fast | ||

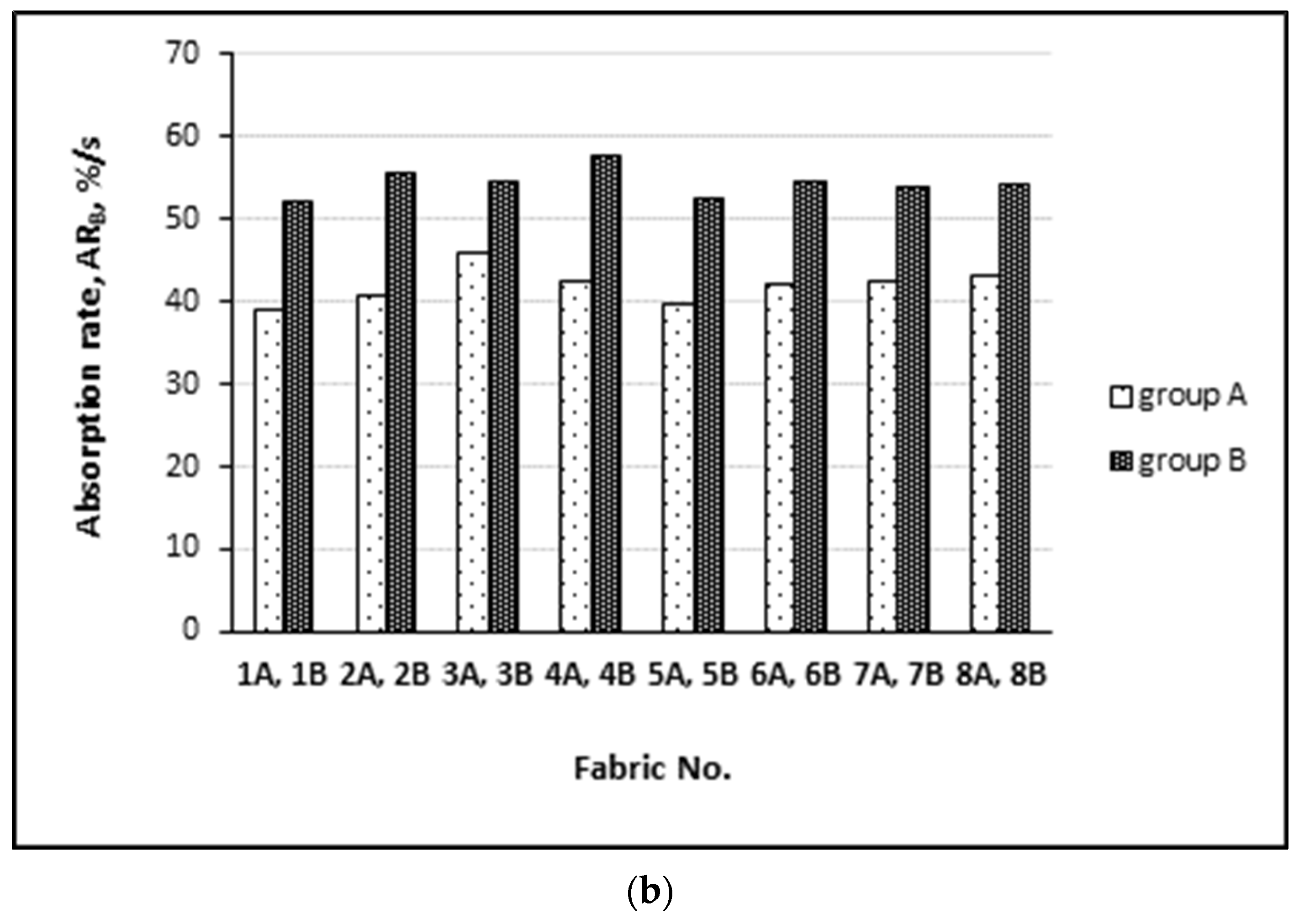

| Bottom-ARB | 0–9 | 10–29 | 30–49 | 50–100 | >100 | |

| Very slow | Slow | Medium | Fast | Very fast | ||

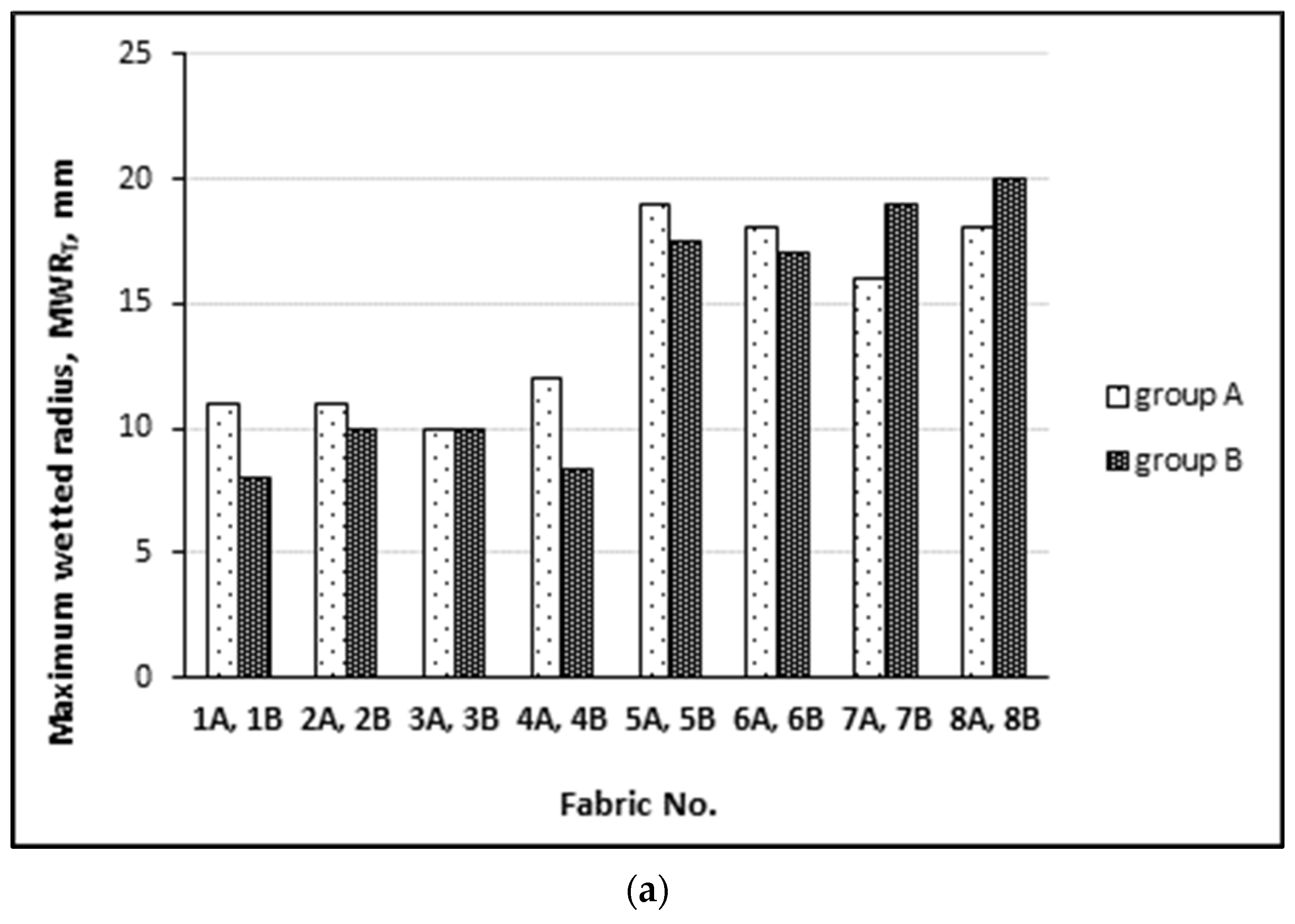

| Max wetted radius, MWR, mm | Top-MWRT | 0–7 | 8–12 | 13–17 | 18–22 | >22 |

| No wetting | Small | Medium | Large | Very large | ||

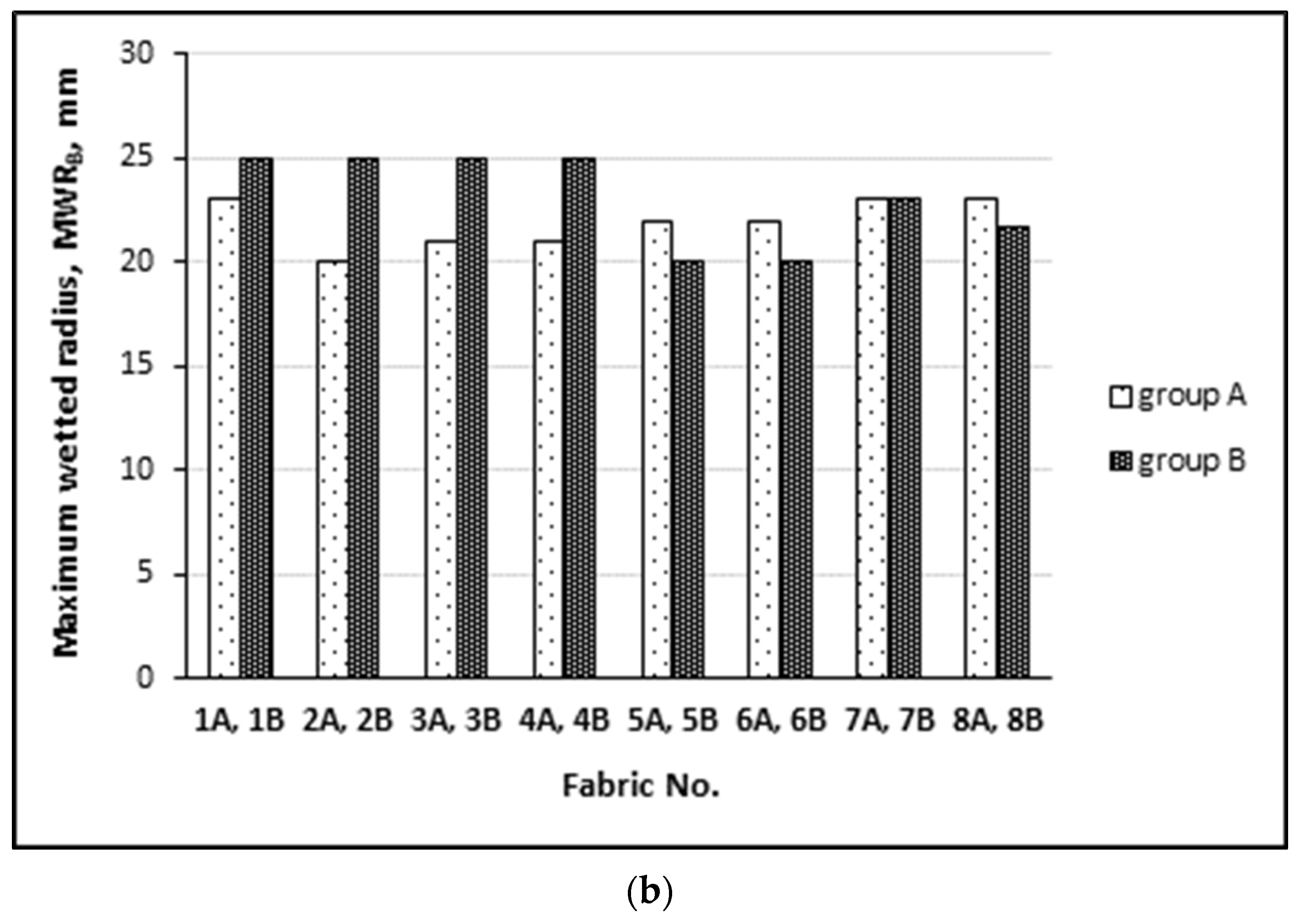

| Bottom-MWRB | 0–7 | 8–12 | 13–17 | 18–22 | >22 | |

| No wetting | Small | Medium | Large | Very large | ||

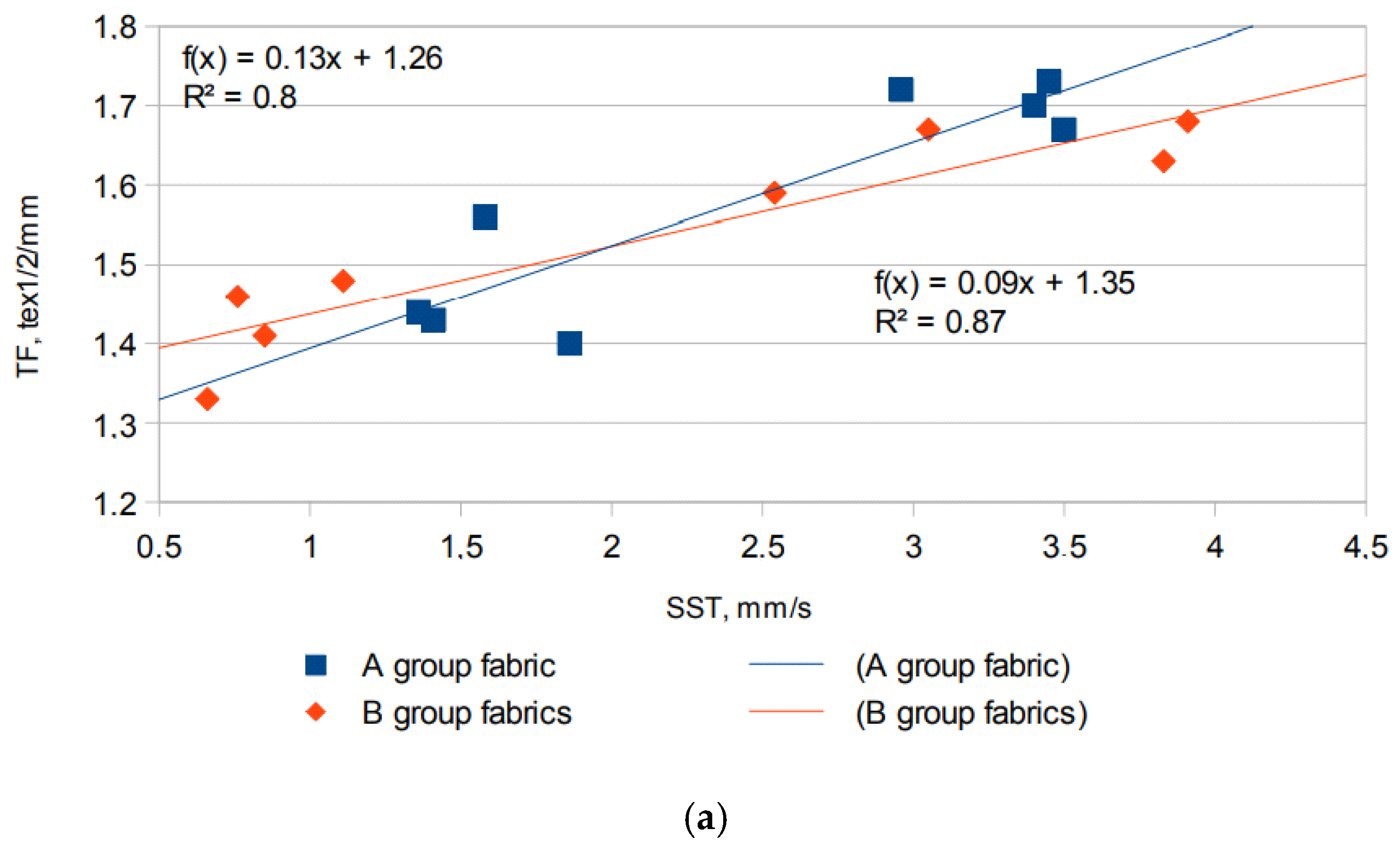

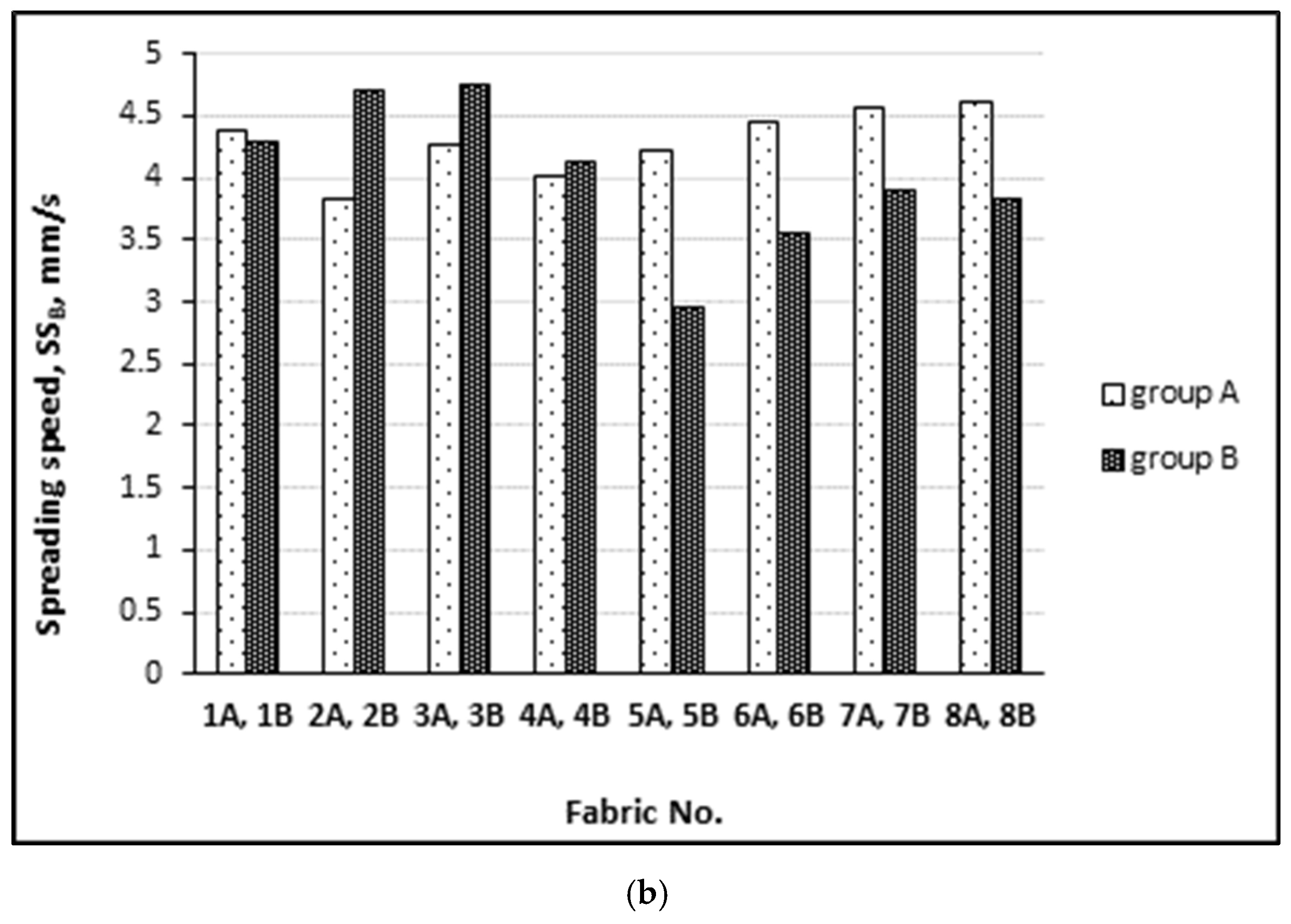

| Spreading speed, SS, mm/s | Top-SST | 0–0.9 | 1–1.9 | 2–2.9 | 3–4 | >4 |

| Very slow | Slow | Medium | Fast | Very fast | ||

| Bottom-SSB | 0–0.9 | 1–1.9 | 2–2.9 | 3–4 | >4 | |

| Very slow | Slow | Medium | Fast | Very fast | ||

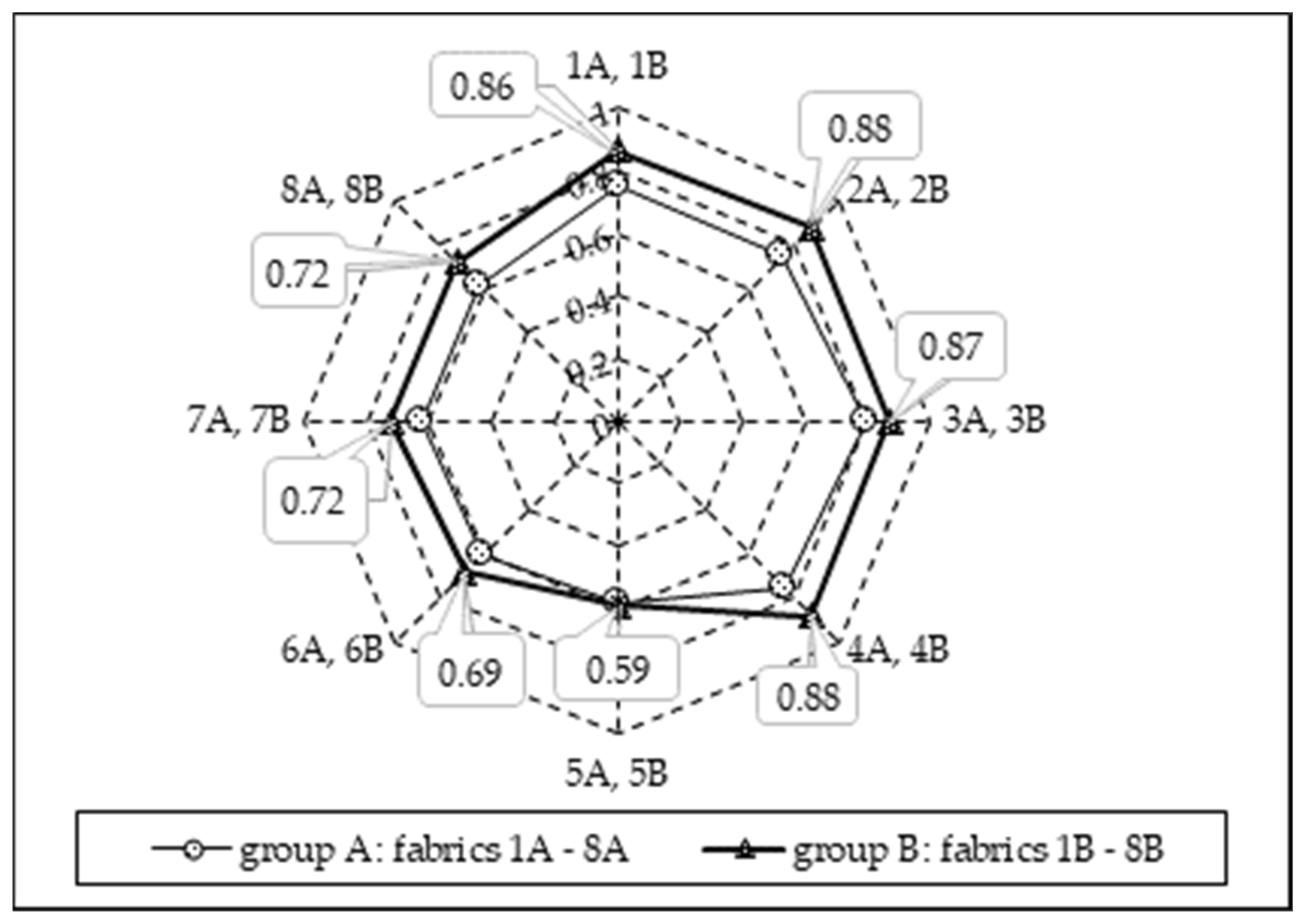

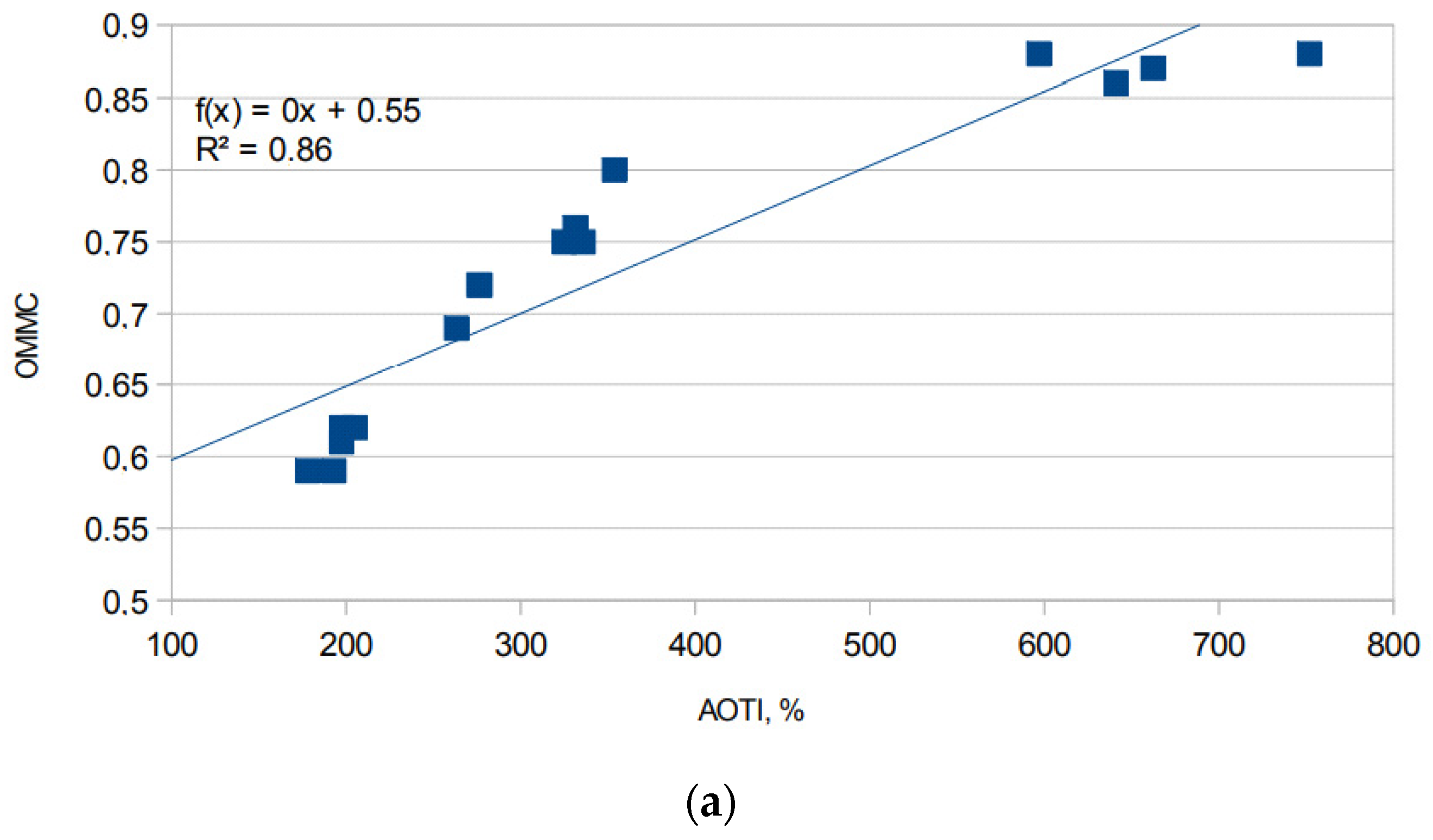

| Accumulative one-way transport capability, AOTI, % | <−50 | −50 to 99 | 100–199 | 200–400 | >400 | |

| Poor | Fair | Good | Very good | Excellent | ||

| Overall moisture management capacity, OMMC | 0–0.19 | 0.2–0.39 | 0.4–0.59 | 0.6–0.8 | >0.8 | |

| Poor | Fair | Good | Very good | Excellent | ||

| Property | Measuring Unit | Level | ||

|---|---|---|---|---|

| A | B | C | ||

| Warm climate | ||||

| Liquid moisture management: overall moisture management capacity (OMMC) [AATCC 195] | index | index ≥ 4 | 4 > index ≥ 3 | index ˂ 3 |

| 1–5 | (OMMC ≥ 0.6) | (0.6 > OMMC ≥ 0.4) | (OMMC ˂ 0.4) | |

| Thermal resistance, Rct [EN ISO 11092] | m2 K/W | Rct ≤ 0.015 | 0.015 ˂ Rct ≤ 0.03 | 0.03 ˂ Rct ≤ 0.04 |

| Cold climate | ||||

| Liquid moisture management: overall moisture management capacity (OMMC) [AATCC 195] | index | index ≥ 4 | 4 > index ≥ 3 | index ˂ 3 |

| 1–5 | (OMMC ≥ 0.6) | (0.6 > OMMC ≥ 0.4) | (OMMC ˂ 0.4) | |

| Thermal resistance, Rct [EN ISO 11092] | m2 K/W | Rct ≥ 0.08 | 0.08 > Rct ≥ 0.05 | Rct ˂ 0.05 |

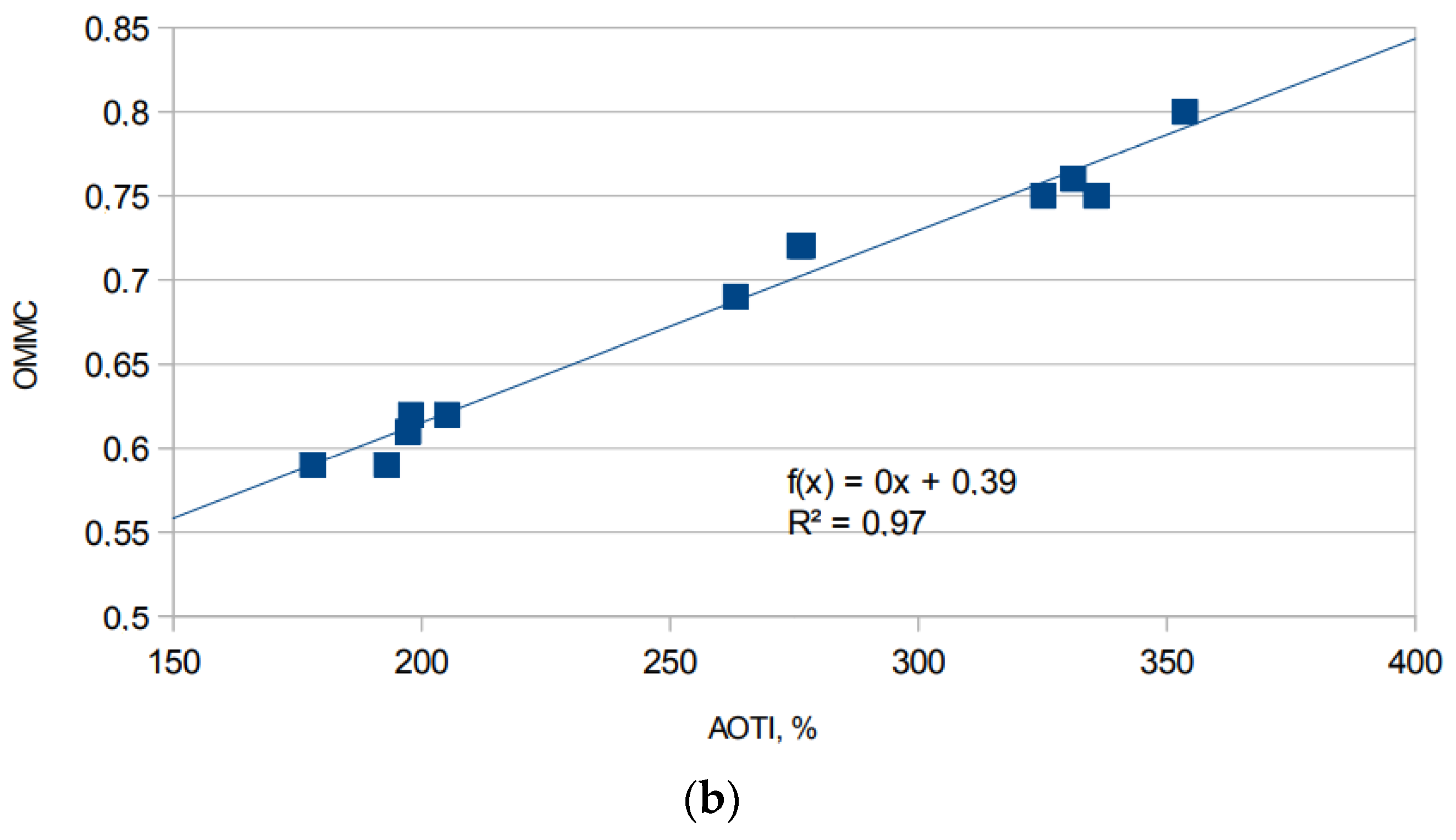

| Code of Fabric | WTT, s (Grade) | WTB, s (Grade) | ART, %/s (Grade) | ARB, %/s (Grade) | MWRT, mm (Grade) | MWRB, mm (Grade) | SST, mm/s (Grade) | SSB, mm/s (Grade) | AOTI, %; (Grade) | OMMC; (Grade) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1A | 6.37 ± 1.56 (3) | 2.75 ± 0.33 (5) | 24.56 ± 3.42 (2) | 38.84 ± 0.99 (3) | 11 ± 2.24 (2) | 23 ± 2.74 (5) | 1.58 ± 0.34 (5) | 4.37 ± 0.21 (5) | 325.11 ± 23.15 (4) | 0.75 ± 0.03 (4) |

| 2A | 7.38 ± 0.39 (3) | 3.09 ± 0.24 (4) | 20.95 ± 1.80 (2) | 40.58 ± 1.21 (3) | 11 ± 2.24 (2) | 20 ± 0 (4) | 1.36 ± 0.16 (5) | 3.84 ± 0.21 (4) | 335.77 ± 14.04 (4) | 0.75 ± 0.03 (4) |

| 3A | 6.93 ± 0.43 (3) | 3.88 ± 2.50 (4) | 32.54 ± 2.06 (3) | 45.87 ± 7.48 (3) | 10 ± 0 (2) | 21 ± 2.24 (4) | 1.41 ± 0.18 (5) | 4.26 ± 0.20 (5) | 353.68 ± 10.77 (4) | 0.80 ± 0.03 (4) |

| 4A | 5.19 ± 1.64 (3) | 2.92 ± 0.10 (5) | 22.29 ± 2.72 (2) | 42.54 ± 0.58 (3) | 12 ± 2.74 (2) | 21 ± 2.24 (4) | 1.86 ± 0.54 (5) | 4.01 ± 0.16 (5) | 331.19 ± 32.112 (4) | 0.76 ± 0.04 (4) |

| 5A | 3.29 ± 0.20 (4) | 2.77 ± 0.31 (5) | 30.96 ± 1.83 (3) | 39.72 ± 0.66 (3) | 19 ± 2.24 (4) | 22 ± 2.74 (4) | 3.45 ± 0.31 (4) | 4.22 ± 0.37 (5) | 178.02 ± 28.75 (3) | 0.59 ± 0.03 (3) |

| 6A | 3.56 ± 0.26 (4) | 2.73 ± 0.31 (5) | 32.40 ± 1.08 (3) | 42.17 ± 0.65 (3) | 18 ± 2.74 (4) | 22 ± 2.74 (4) | 3.40 ± 0.36 (4) | 4.46 ± 0.31 (5) | 197.31 ± 15.77 (3) | 0.61 ± 0.02 (4) |

| 7A | 3.74 ± 0.19 (4) | 2.94 ± 0.18 (5) | 32.23 ± 1.17 (3) | 42.41 ± 0.86 (3) | 16 ± 2.24 (3) | 23 ± 2.74 (5) | 2.96 ± 0.24 (4) | 4.56 ± 0.32 (5) | 205.15 ± 8.87 (4) | 0.62 ± 0.01 (4) |

| 8A | 3.67 ± 0.51 (4) | 2.9202 ± 0.58 (5) | 33.937 ± 0.92 (3) | 42.9662 ± 1.18 (3) | 18 ± 2.74 (4) | 23 ± 2.74 (5) | 3.4970.37 (4) | 4.61 ± 0.27 (5) | 197.84 ± 10.50 (3) | 0.62 ± 0.01 (4) |

| 1B | 13.67 ± 0.59 (3) | 3.16 ± 0.69 (4) | 9.05 ± 3.74 (1) | 52.19 ± 1.98 (4) | 8 ± 2.74 (2) | 25 ± 0 (5) | 0.6553 ± 0.46 (1) | 4.30 ± 0.34 (5) | 641.10 ± 31.14 (5) | 0.86 ± 0.01 (5) |

| 2B | 8.63 ± 2.76 (3) | 3.03 ± 0.71 (4) | 12.81 ± 5.00 (2) | 55.72 ± 2.1 (4) | 10 ± 0 (2) | 25 ± 0 (5) | 1.11 ± 0.22 (2) | 4.71 ± 0.56 (5) | 596.93 ± 38.78 (5) | 0.88 ± 0.01 (5) |

| 3B | 11.14 ± 1.43 (3) | 2.92 ± 0.44 (5) | 8.92 ± 2.04 (1) | 54.50 ± 1.76 (4) | 10 ± 0 (2) | 25 ± 0 (5) | 0.85 ± 0.11 (1) | 4.75 ± 0.28 (5) | 662.28 ± 42.37 (5) | 0.87 ± 0.01 (5) |

| 4B | 11.61 ± 0.46 (3) | 3.46 ± 0.16 (4) | 14.30 ± 1.43 (2) | 57.48 ± 0.72 (4) | 8.33 ± 2.88 (2) | 25 ± 0 (5) | 0.756 ± 0.16 (1) | 4.13 ± 0.15 (5) | 751.92 ± 22.72 (5) | 0.88 ± 0.002 (5) |

| 5B | 6.77 ± 2.13 (3) | 5.85 ± 1.94 (3) | 38.27 ± 2.98 (3) | 52.46 ± 8.48 (4) | 17.50 ± 2.74 (3) | 20 ± 0 (4) | 2.54 ± 0.52 (3) | 2.96 ± 0.49 (3) | 192.92 ± 27.00 (3) | 0.59 ± 0.05 (3) |

| 6B | 3.99 ± 0.48 (4) | 3.44 ± 0.18 (4) | 33.83 ± 2.65 (3) | 54.55 ± 1.27 (4) | 17 ± 2.74 (3) | 20 ± 0 (4) | 3.05 ± 0.17 (4) | 3.56 ± 0.13 (4) | 263.23 ± 39.37 (4) | 0.69 ± 0.04 (4) |

| 7B | 3.67 ± 0.21 (4) | 3.30 ± 0.28 (4) | 33.61 ± 2.26 (3) | 53.84 ± 1.14 (4) | 19 ± 2.24 (4) | 23 ± 2.74 (5) | 3.25 ± 0.17 (4) | 3.91 ± 0.24 (4) | 276.67 ± 36.44 (4) | 0.72 ± 0.05 (4) |

| 8B | 3.87 ± 0.11 (4) | 3.46 ± 0.32 (4) | 34.15 ± 1.12 (3) | 54.12 ± 1.21 (4) | 20 ± 0 (4) | 21.67 ± 2.88 (4) | 3.42 ± 0.14 (4) | 3.83 ± 0.16 (4) | 276.06 ± 13.26 (4) | 0.72 ± 0.02 (4) |

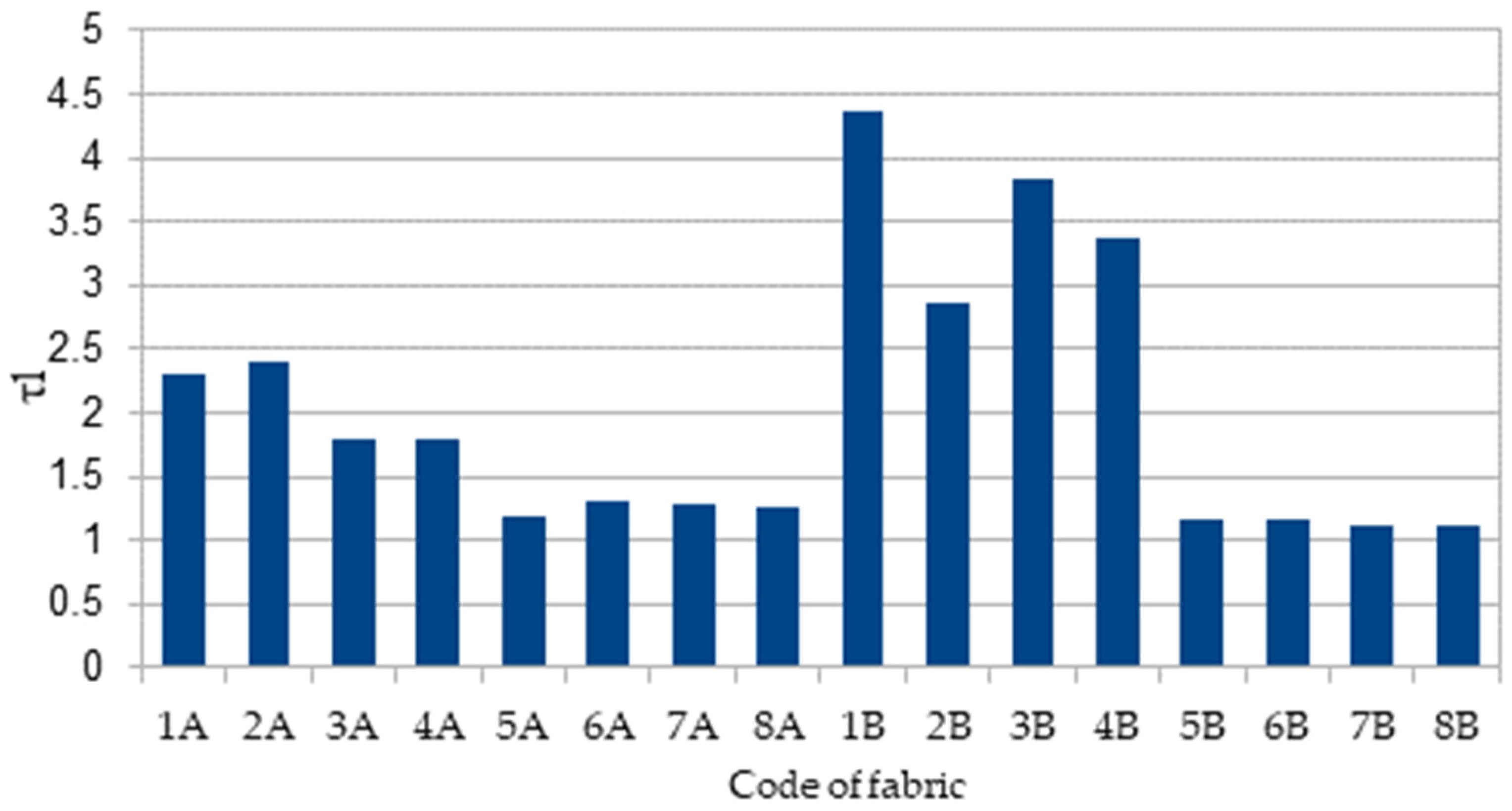

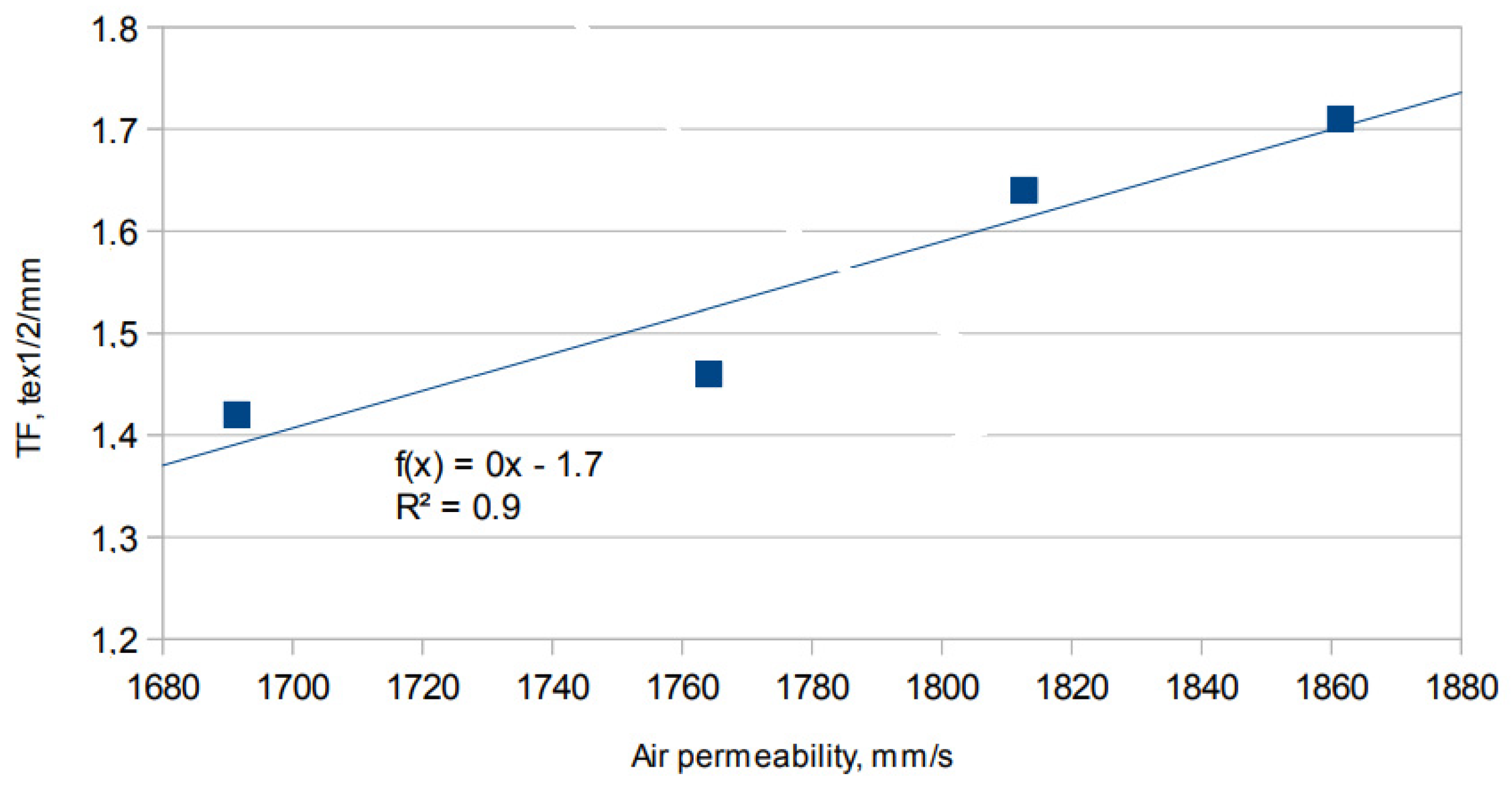

| Code of Fabrics Group | Water Vapor Permeability WVP, g/m2 24 h ± Standard Deviation | Thermal Resistance, Rct, m2 K/W ± Standard Deviation | Air Permeability, mm/s ± Standard Deviation | Tightness Factor TF, tex1/2/mm ± Standard Deviation |

|---|---|---|---|---|

| 1A–4A | 1404 ± 37 | 0.063 ± 0.010 | 1764.1 ± 26.6 | 1.46 ± 0.06 |

| 5A–8A | 1624 ± 27 | 0.068 ± 0.011 | 1861.4 ± 49.7 | 1.71 ± 0.02 |

| 1B–4B | 1612 ± 70 | 0.082 ± 0.013 | 1691.4 ± 71.1 | 1.42 ± 0.06 |

| 5B–8B | 1349 ± 39 | 0.052 ± 0.00 | 1812.7 ± 82.7 | 1.64 ± 0.04 |

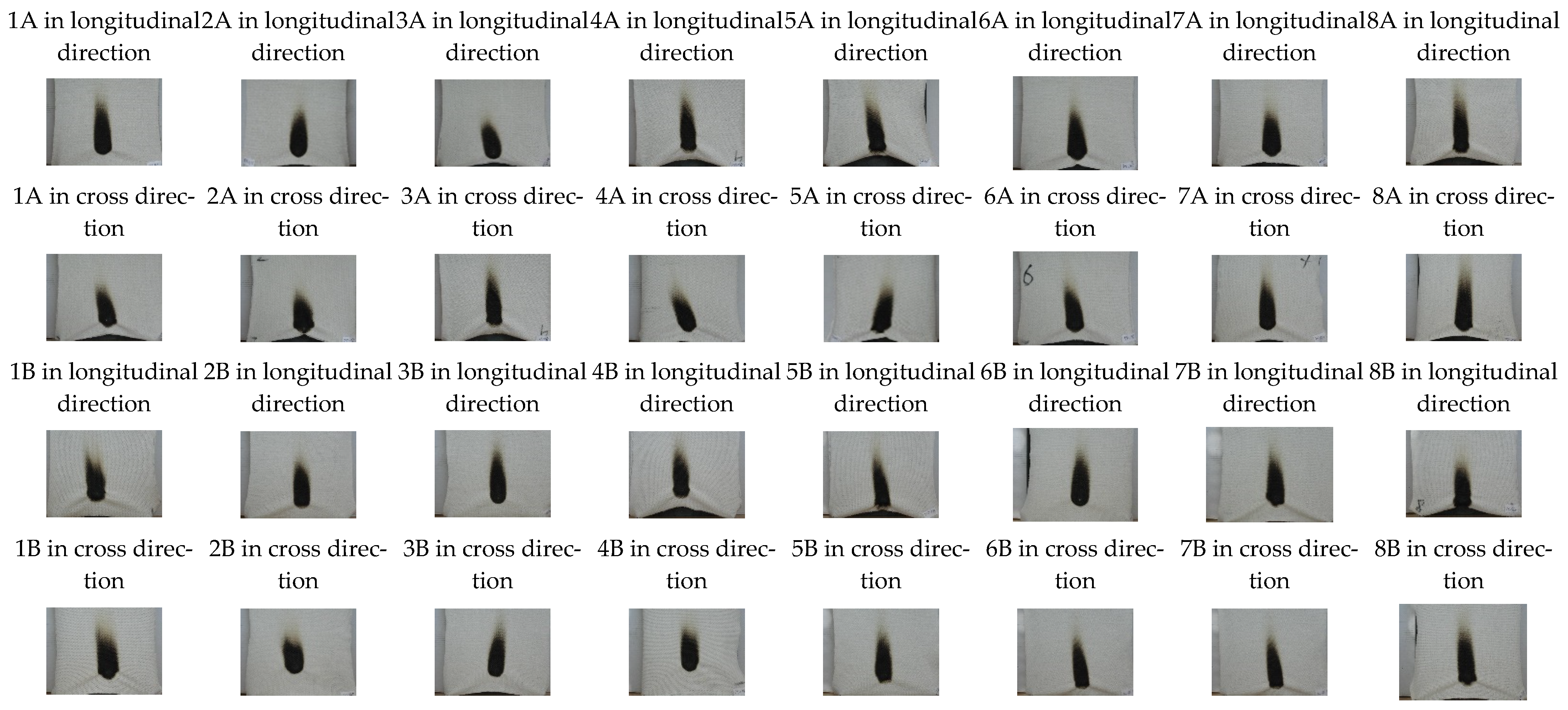

| Code of Fabric | Charred Area Parameters | |||||||

|---|---|---|---|---|---|---|---|---|

| Specimens in Longitudinal Direction | Specimens in Cross Direction | |||||||

| Area, mm2 | Perimeter, mm | Length, mm | Width, mm | Area, mm2 | Perimeter, mm | Length, mm | Width, mm | |

| 1A | 4791 | 1030 | 40.86 | 25.52 | 5054 | 1102 | 45.55 | 25.47 |

| 2A | 5273 | 1090 | 42.27 | 29.08 | 4108 | 976 | 37.45 | 24.94 |

| 3A | 7196 | 1154 | 51.74 | 31.40 | 5397 | 1148 | 47.07 | 27.21 |

| 4A | 6324 | 1182 | 46.91 | 30.22 | 3621 | 956 | 30.22 | 25.50 |

| 5A | 5674 | 1148 | 47.26 | 27.06 | 3736 | 1090 | 68.66 | 16.11 |

| 6A | 5479 | 1156 | 42.24 | 27.56 | 4835 | 1170 | 37.43 | 31.23 |

| 7A | 4162 | 1086 | 41.68 | 22.20 | 5939 | 1114 | 31.07 | 32.62 |

| 8A | 5588 | 1190 | 49.09 | 27.03 | 4629 | 1058 | 36.15 | 29.32 |

| 1B | 5254 | 1124 | 44.88 | 26.19 | 5869 | 1148 | 47.24 | 27.04 |

| 2B | 5473 | 1138 | 40.34 | 31.61 | 3660 | 1010 | 40.18 | 21.90 |

| 3B | 5274 | 1096 | 43.39 | 28.57 | 2794 | 1188 | 38.43 | 15.59 |

| 4B | 5317 | 1090 | 47.87 | 24.96 | 5088 | 1092 | 46.37 | 27.21 |

| 5B | 3930 | 970 | 39.84 | 21.40 | 5428 | 1034 | 43.77 | 27.51 |

| 6B | 3637 | 946 | 33.98 | 20.44 | 4758 | 1080 | 45.35 | 24.86 |

| 7B | 7586 | 1238 | 48.56 | 35.61 | 5479 | 1102 | 45.38 | 28.40 |

| 8B | 4476 | 1056 | 41.53 | 25.32 | 5723 | 1096 | 45.85 | 31.61 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stygienė, L.; Krauledas, S.; Abraitienė, A.; Varnaitė-Žuravliova, S.; Dubinskaitė, K. Flammability and Thermoregulation Properties of Knitted Fabrics as a Potential Candidate for Protective Undergarments. Materials 2022, 15, 2647. https://doi.org/10.3390/ma15072647

Stygienė L, Krauledas S, Abraitienė A, Varnaitė-Žuravliova S, Dubinskaitė K. Flammability and Thermoregulation Properties of Knitted Fabrics as a Potential Candidate for Protective Undergarments. Materials. 2022; 15(7):2647. https://doi.org/10.3390/ma15072647

Chicago/Turabian StyleStygienė, Laimutė, Sigitas Krauledas, Aušra Abraitienė, Sandra Varnaitė-Žuravliova, and Kristina Dubinskaitė. 2022. "Flammability and Thermoregulation Properties of Knitted Fabrics as a Potential Candidate for Protective Undergarments" Materials 15, no. 7: 2647. https://doi.org/10.3390/ma15072647

APA StyleStygienė, L., Krauledas, S., Abraitienė, A., Varnaitė-Žuravliova, S., & Dubinskaitė, K. (2022). Flammability and Thermoregulation Properties of Knitted Fabrics as a Potential Candidate for Protective Undergarments. Materials, 15(7), 2647. https://doi.org/10.3390/ma15072647