Enhancement of Nonlinear Dielectric Properties in BiFeO3–BaTiO3 Ceramics by Nb-Doping

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Microstructure Characterization and X-ray Diffraction

2.3. Electrical Property Measurements

3. Results and Analysis

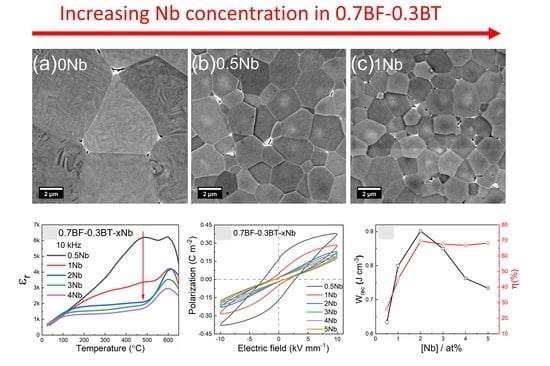

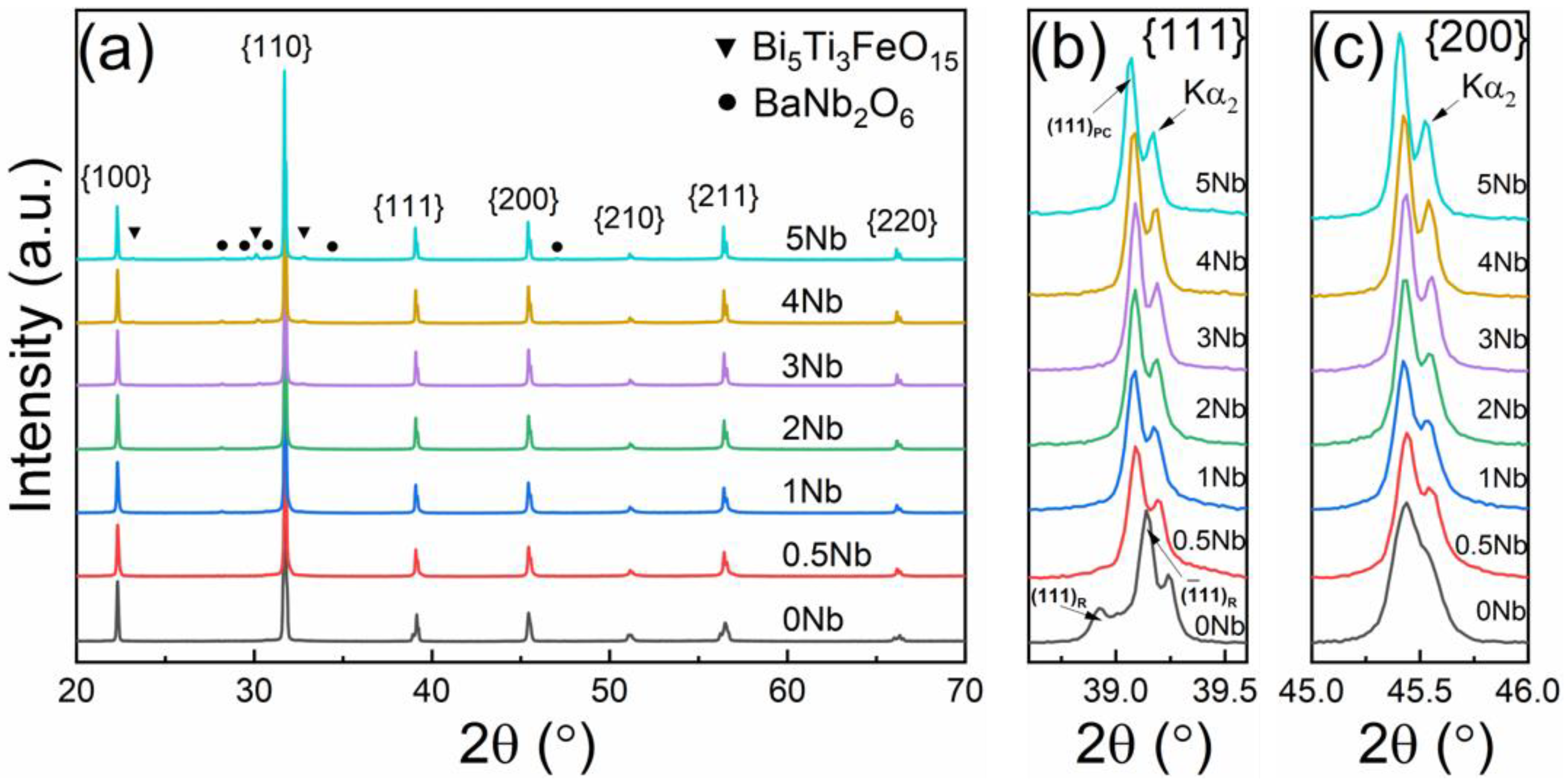

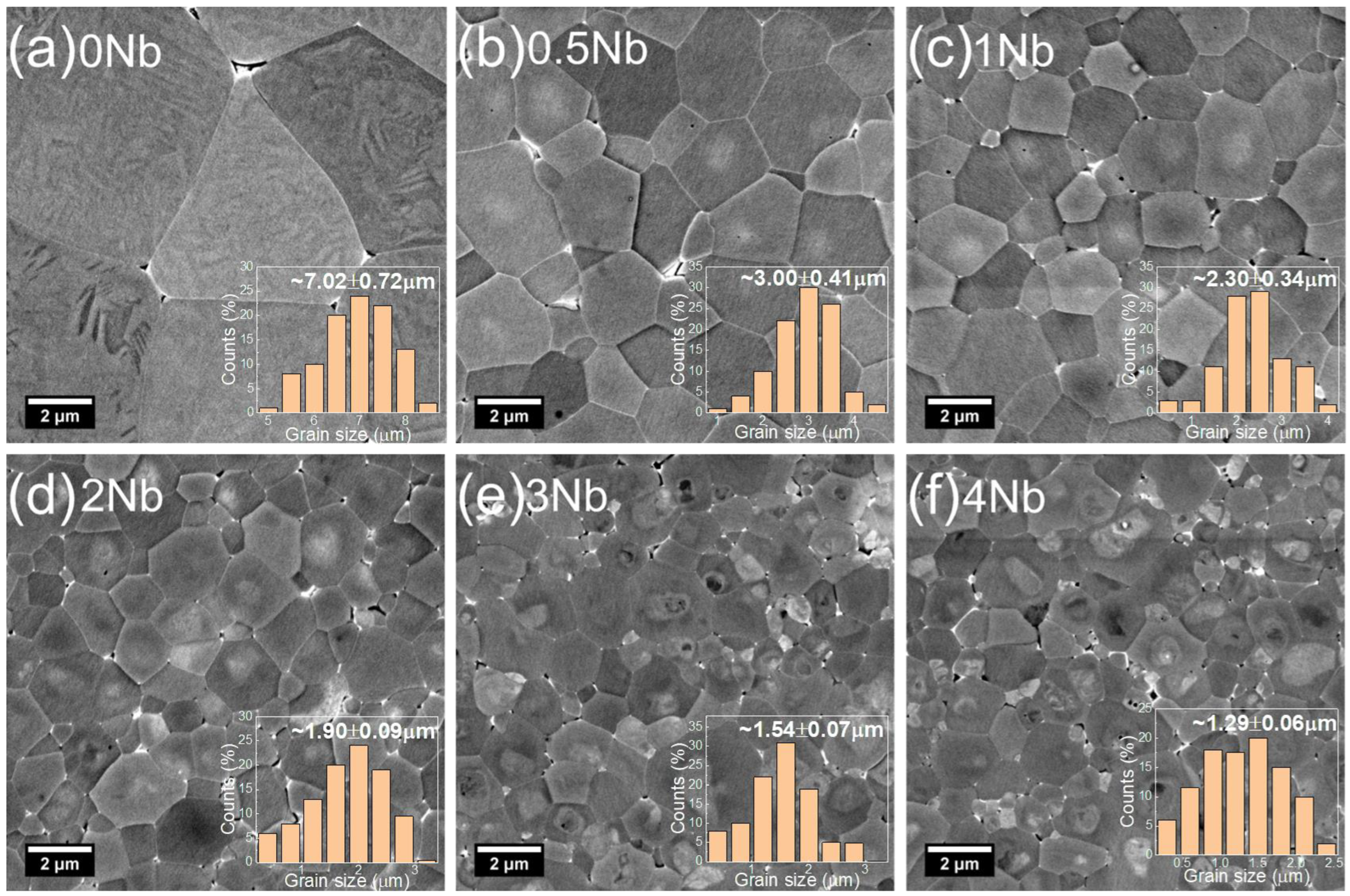

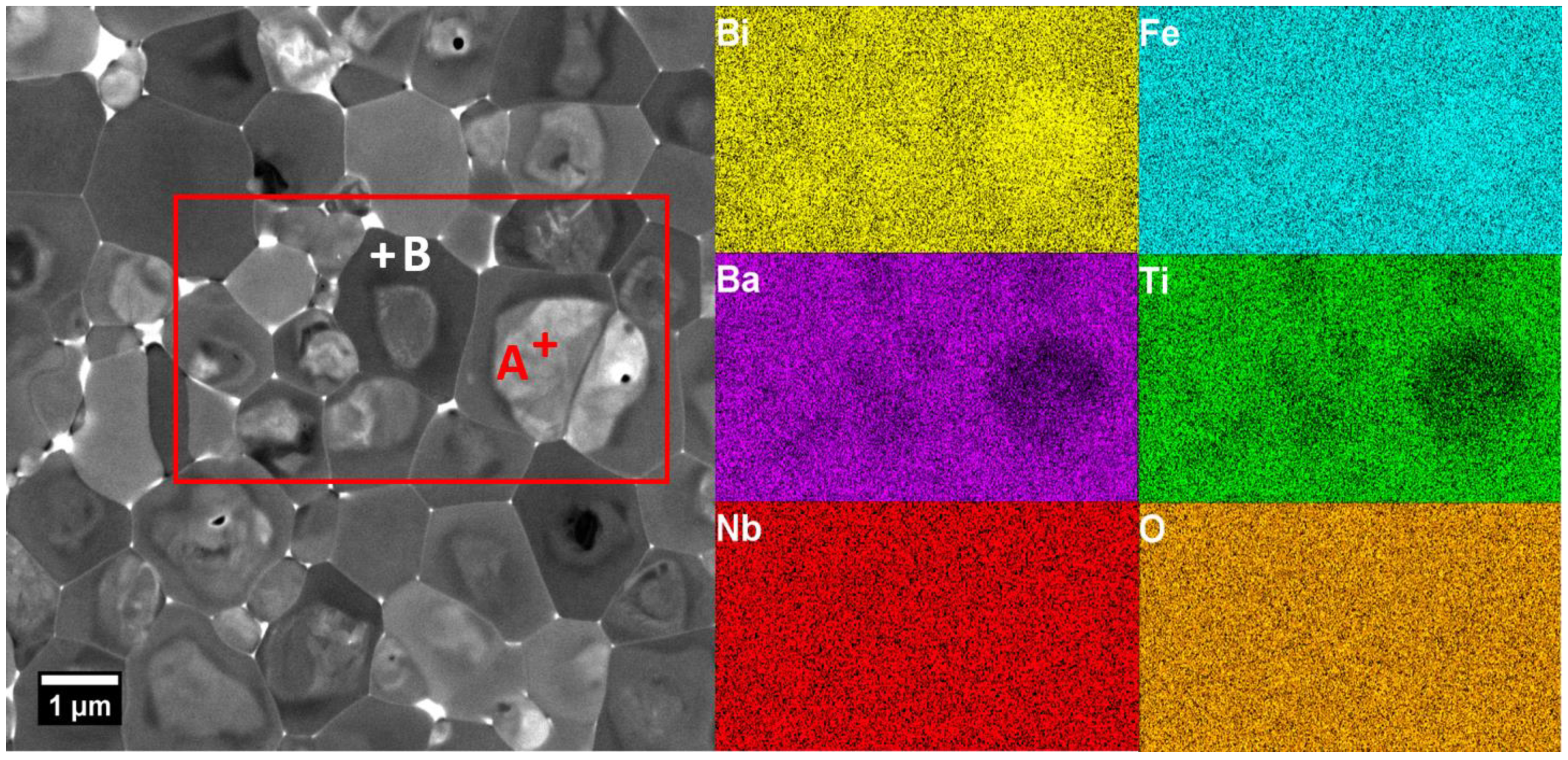

3.1. Structure and Microstructure

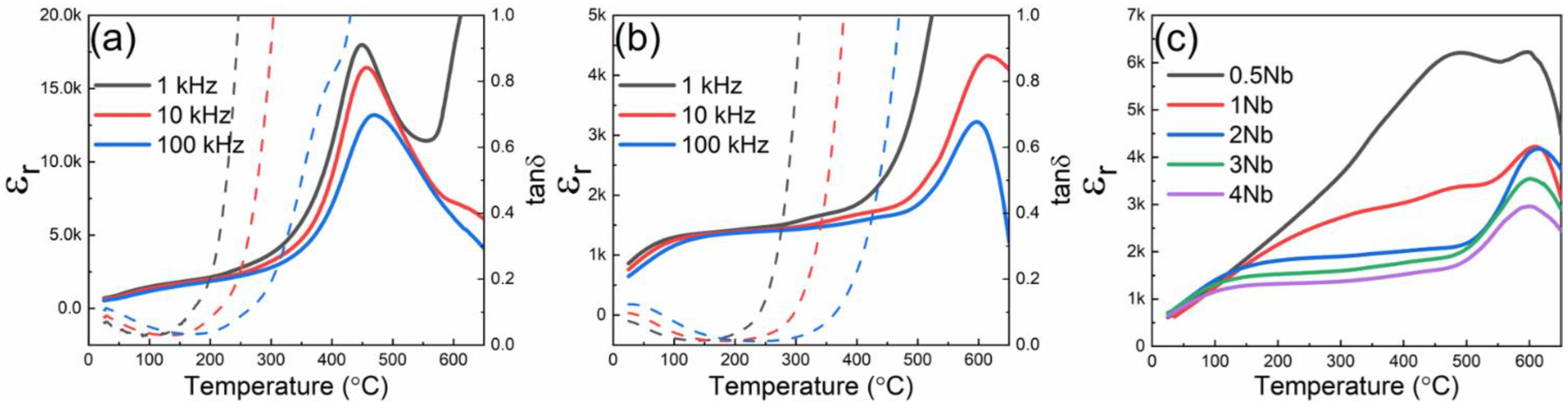

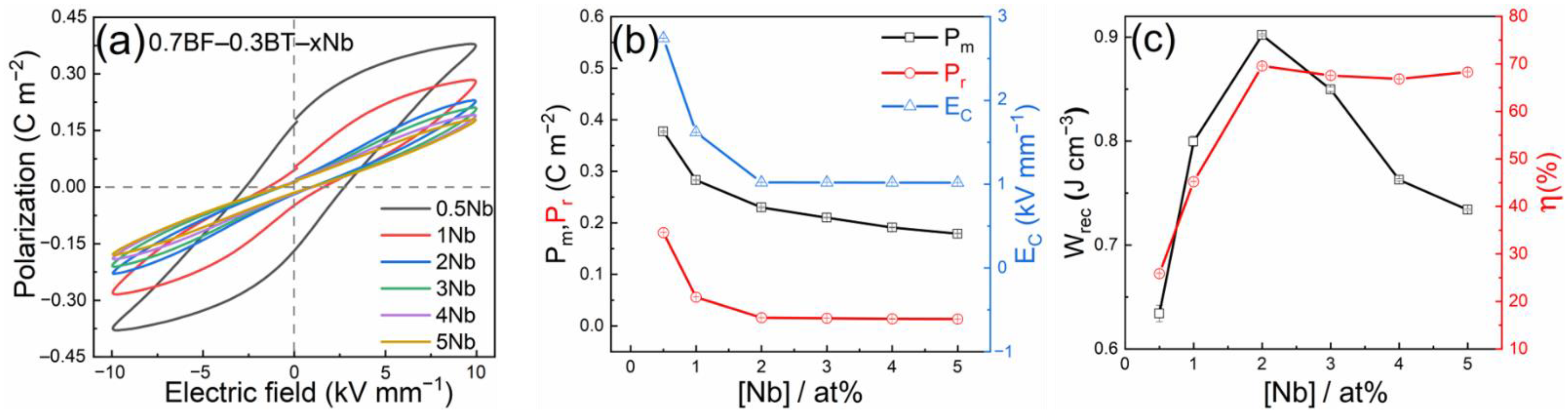

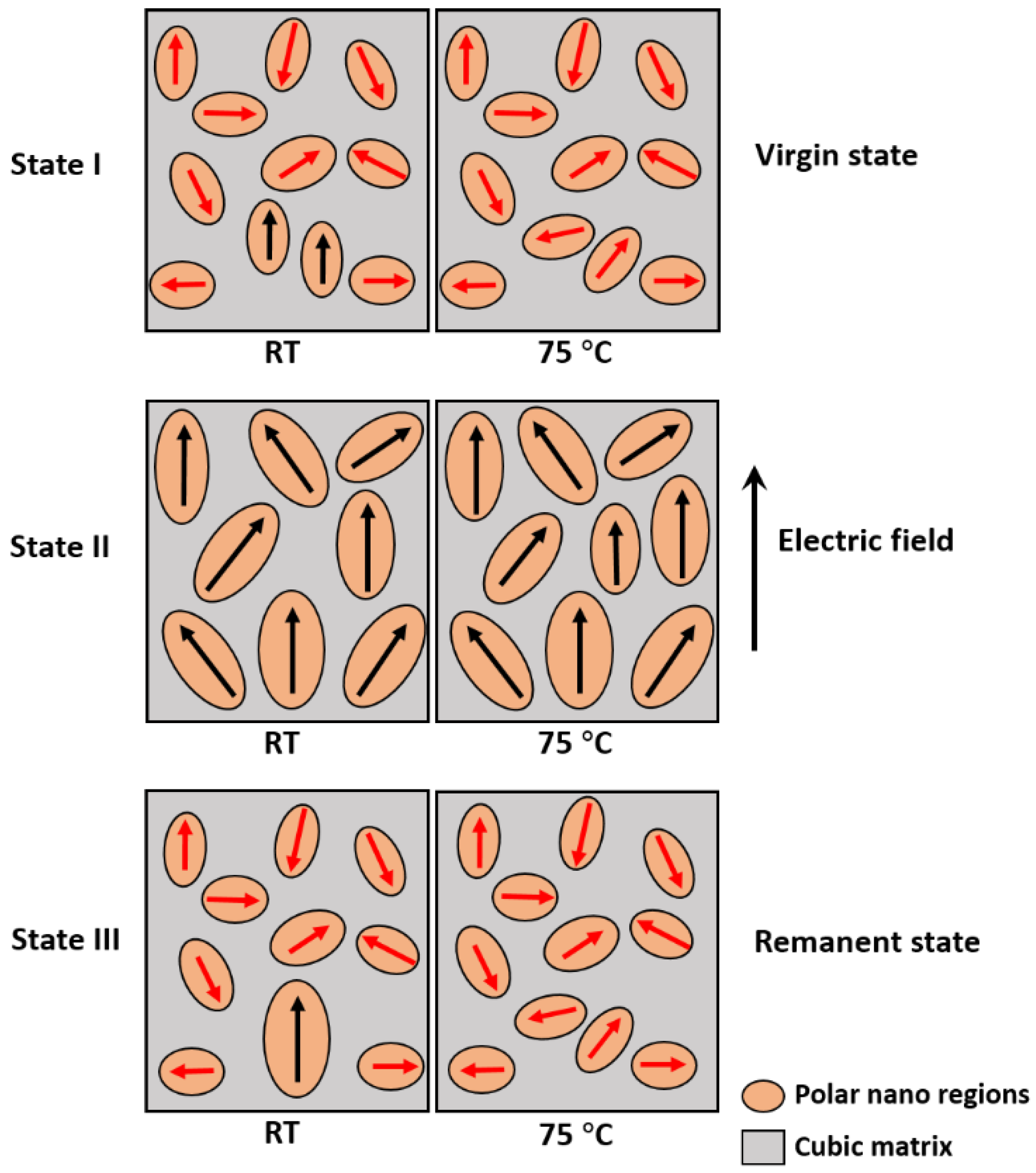

3.2. Dielectric and Ferroelectric Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hao, X. A review on the dielectric materials for high energy-storage application. J. Adv. Dielectr. 2013, 3, 1330001. [Google Scholar] [CrossRef]

- Peddigari, M.; Palneedi, H.; Hwang, G.T.; Ryu, J. Linear and nonlinear dielectric ceramics for high-power energy storage capacitor applications. J. Korean Ceram. Soc. 2019, 56, 1–23. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Lu, T.; Ye, J.; Wang, G.; Dong, X.; Withers, R.; Liu, Y. Antiferroelectrics for Energy Storage Applications: A Review. Adv. Mater. Technol. 2018, 3, 1800111. [Google Scholar] [CrossRef]

- Liu, X.; Yang, T.; Gong, W. Comprehensively enhanced energy-storage properties in (Pb1−3x/2Lax)(Zr0.995Ti0.005)O3 antiferroelectric ceramicsviacomposition optimization. J. Mater. Chem. C 2021, 9, 12399–12407. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, P.; Zhang, Y.; Kandula, K.R.; Xu, J.; Zhang, G.; Jiang, S. Low electric-field-induced strain and high energy storage efficiency in (Pb,Ba,La)(Zr,Sn,Ti)O3 antiferroelectric ceramics through regulating the content of La. Ceram. Int. 2020, 46, 18106–18113. [Google Scholar] [CrossRef]

- Peng, B.; Tang, S.; Lu, L.; Zhang, Q.; Huang, H.; Bai, G.; Miao, L.; Zou, B.; Liu, L.; Sun, W.; et al. Low-temperature-poling awakened high dielectric breakdown strength and outstanding improvement of discharge energy density of (Pb,La)(Zr,Sn,Ti)O3 relaxor thin film. Nano Energy 2020, 77, 105132. [Google Scholar] [CrossRef]

- Kumar, A.; Kim, S.H.; Thakre, A.; Lee, G.; Chae, Y.G.; Ryu, J. Increased Energy-Storage Density and Superior Electric Field and Thermally Stable Energy Efficiency of Aerosol-Deposited Relaxor (Pb0.89La0.11)(Zr0.70Ti0.30)O3 Films. J. Therm. Spray Technol. 2021, 30, 591–602. [Google Scholar] [CrossRef]

- Qi, H.; Zuo, R.; Xie, A.; Tian, A.; Fu, J.; Zhang, Y.; Zhang, S. Ultrahigh Energy-Storage Density in NaNbO3-Based Lead-Free Relaxor Antiferroelectric Ceramics with Nanoscale Domains. Adv. Funct. Mater. 2019, 29, 11–17. [Google Scholar] [CrossRef]

- Qi, H.; Xie, A.; Tian, A.; Zuo, R. Superior Energy-Storage Capacitors with Simultaneously Giant Energy Density and Efficiency Using Nanodomain Engineered BiFeO3-BaTiO3-NaNbO3 Lead-Free Bulk Ferroelectrics. Adv. Energy Mater. 2020, 10, 1903338. [Google Scholar] [CrossRef]

- Yang, Z.; Du, H.; Qu, S.; Hou, Y.; Ma, H.; Wang, J.; Wang, J.; Wei, X.; Xu, Z. Significantly enhanced recoverable energy storage density in potassium-sodium niobate-based lead free ceramics. J. Mater. Chem. A 2016, 4, 13778–13785. [Google Scholar] [CrossRef]

- Luo, N.; Han, K.; Zhuo, F.; Xu, C.; Zhang, G.; Liu, L.; Chen, X.; Hu, C.; Zhou, H.; Wei, Y. Aliovalent A-site engineered AgNbO3 lead-free antiferroelectric ceramics toward superior energy storage density. J. Mater. Chem. A 2019, 7, 14118–14128. [Google Scholar] [CrossRef]

- Neaton, J.B.; Ederer, C.; Waghmare, U.V.; Spaldin, N.A.; Rabe, K.M. First-principles study of spontaneous polarization in multiferroic BiFeO3. Phys. Rev. B-Condens. Matter Mater. Phys. 2005, 71, 014113. [Google Scholar] [CrossRef] [Green Version]

- Lebeugle, D.; Colson, D.; Forget, A.; Viret, M. Very large spontaneous electric polarization in BiFeO3 single crystals at room temperature and its evolution under cycling fields. Appl. Phys. Lett. 2007, 91, 2005–2008. [Google Scholar] [CrossRef] [Green Version]

- Cheng, S.; Zhang, B.P.; Zhao, L.; Wang, K.K. Enhanced insulating and piezoelectric properties of 0.7BiFeO3-0.3BaTiO3 lead-free ceramics by optimizing calcination temperature: Analysis of Bi3+ volatilization and phase structures. J. Mater. Chem. C 2018, 6, 3982–3989. [Google Scholar] [CrossRef]

- Qi, X.; Dho, J.; Tomov, R.; Blamire, M.G.; MacManus-Driscoll, J.L. Greatly reduced leakage current and conduction mechanism in aliovalent-ion-doped BiFeO3. Appl. Phys. Lett. 2005, 86, 062903. [Google Scholar] [CrossRef]

- Calisir, I.; Hall, D.A. Chemical heterogeneity and approaches to its control in BiFeO3-BaTiO3 lead-free ferroelectrics. J. Mater. Chem. C 2017, 6, 134–146. [Google Scholar] [CrossRef] [Green Version]

- Sun, H.; Wang, X.; Sun, Q.; Zhang, X.; Ma, Z.; Guo, M.; Sun, B.; Zhu, X.; Liu, Q.; Lou, X. Large energy storage density in BiFeO3-BaTiO3-AgNbO3 lead-free relaxor ceramics. J. Eur. Ceram. Soc. 2020, 40, 2929–2935. [Google Scholar] [CrossRef]

- Zheng, D.; Zuo, R.; Zhang, D.; Li, Y. Novel BiFeO3-BaTiO3-Ba(Mg1/3Nb2/3)O3 Lead-Free Relaxor Ferroelectric Ceramics for Energy-Storage Capacitors. J. Am. Ceram. Soc. 2015, 98, 2692–2695. [Google Scholar] [CrossRef]

- Zheng, D.; Zuo, R. Enhanced energy storage properties in La(Mg1/2Ti1/2)O3-modified BiFeO3-BaTiO3 lead-free relaxor ferroelectric ceramics within a wide temperature range. J. Eur. Ceram. Soc. 2017, 37, 413–418. [Google Scholar] [CrossRef]

- Zhu, L.F.; Lei, X.W.; Zhao, L.; Hussain, M.I.; Zhao, G.Z.; Zhang, B.P. Phase structure and energy storage performance for BiFeO3–BaTiO3 based lead-free ferroelectric ceramics. Ceram. Int. 2019, 45, 20266–20275. [Google Scholar] [CrossRef]

- Pan, H.; Li, F.; Liu, Y.; Zhang, Q.; Wang, M.; Lan, S.; Zheng, Y.; Ma, J.; Gu, L.; Shen, Y.; et al. Ultrahigh–energy density lead-free dielectric films via polymorphic nanodomain design. Science 2019, 365, 578–582. [Google Scholar] [CrossRef] [PubMed]

- Radojković, A.; Golić, D.L.; Ćirković, J.; Stanojević, Z.M.; Pajić, D.; Torić, F.; Dapčević, A.; Vulić, P.; Branković, Z.; Branković, G. Tuning of BiFeO3 multiferroic properties by light doping with Nb. Ceram. Int. 2018, 44, 16739–16744. [Google Scholar] [CrossRef]

- Wang, M.; Xie, A.; Fu, J.; Zuo, R. Energy storage properties under moderate electric fields in BiFeO3-based lead-free relaxor ferroelectric ceramics. Chem. Eng. J. 2022, 440, 135789. [Google Scholar] [CrossRef]

- Chaudhary, P.; Shukla, R.; Dabas, S.; Thakur, O.P. Enhancement of structural, magnetic, dielectric, and transport properties of Nb substituted 0.7BiFeO3-0.3BaTiO3 solid solution. J. Alloys Compd. 2021, 869, 159228. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, C.; Zhang, J.; Wang, W.; Zhang, M.; Ni, B.; Qi, X. Improved electric insulation ability and ferromagnetic property in Nb2O5 doped BiFeO3-based multiferroic ceramics. J. Electroceramics 2021, 3. [Google Scholar] [CrossRef]

- Xu, D.; Zhao, W.; Cao, W.; Li, W.; Fei, W. Electrical properties of Li and Nb modified BiFeO3 ceramics with reduced leakage current. Ceram. Int. 2021, 47, 4217–4225. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, H.; Yan, T.; Zhao, J.; Guo, S.; Sun, R.; Lu, Z.; Wang, D. Microstructure and electrical properties of Nb-doped SrTiO3-BiFeO3 based lead-free ceramics. J. Am. Ceram. Soc. 2022, 105, 2020–2028. [Google Scholar] [CrossRef]

- Wang, T.; Jin, L.; Tian, Y.; Shu, L.; Hu, Q.; Wei, X. Microstructure and ferroelectric properties of Nb2O5-modified BiFeO3-BaTiO3 lead-free ceramics for energy storage. Mater. Lett. 2014, 137, 79–81. [Google Scholar] [CrossRef]

- Stewart, M.; Cain, M.G.; Hall, D. Ferroelectric Hysteresis Measurement & Analysis; National Physical Laboratory: Teddington, UK, 1999; pp. 1–57. [Google Scholar]

- ICSD—Details on Search Result. Available online: https://icsd.psds.ac.uk/display/details.xhtml (accessed on 4 March 2022).

- Shannon, R.D. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallogr. Sect. A Cryst. Phys. Diffr. Theor. Gen. Crystallogr. 1976, 32, 751–767. [Google Scholar] [CrossRef]

- Wang, B.; Li, Y.; Hall, D.A. Surface structure and quenching effects in BiFeO3-BaTiO3 ceramics. J. Am. Ceram. Soc. 2022, 105, 1265–1275. [Google Scholar] [CrossRef]

- Brzozowski, E.; Castro, M.S. Grain growth control in Nb-doped BaTiO3. J. Mater. Process. Technol. 2005, 168, 464–470. [Google Scholar] [CrossRef]

- Murakami, S.; Ahmed, N.T.A.F.; Wang, D.; Feteira, A.; Sinclair, D.C.; Reaney, I.M. Optimising dopants and properties in BiMeO3 (Me = Al, Ga, Sc, Y, Mg2/3Nb1/3, Zn2/3Nb1/3, Zn1/2Ti1/2) lead-free BaTiO3-BiFeO3 based ceramics for actuator applications. J. Eur. Ceram. Soc. 2018, 38, 4220–4231. [Google Scholar] [CrossRef]

- Calisir, I.; Amirov, A.A.; Kleppe, A.K.; Hall, D.A. Optimisation of functional properties in lead-free BiFeO3-BaTiO3 ceramics through La3+ substitution strategy. J. Mater. Chem. A 2018, 6, 5378–5397. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Zhang, Z.; Chen, Y.; Hall, D.A. Electric field-induced strain in core-shell structured BiFeO3–K0.5Bi0.5TiO3–PbTiO3 ceramics. Acta Mater. 2018, 160, 199–210. [Google Scholar] [CrossRef] [Green Version]

- Härdtl, K.H. Electrical and mechanical losses in ferroelectric ceramics. Ceram. Int. 1982, 8, 121–127. [Google Scholar] [CrossRef]

- Bokov, A.A.; Ye, Z.G. Reentrant phenomena in relaxors. Nanoscale Ferroelectr. Multiferroics Key Process. Charact. Issues Nanoscale Eff. 2016, I–II, 729–764. [Google Scholar]

- Fang, M.; Ji, Y.; Zhang, Z.; Yang, Y.; Liu, C.; Wang, D.; Zhang, L.; Gao, J.; Ren, X. Re-entrant relaxor–ferroelectric composite showing exceptional electromechanical properties. NPG Asia Mater. 2018, 10, 1029–1036. [Google Scholar] [CrossRef]

- Fan, P.; Liu, K.; Ma, W.; Tan, H.; Zhang, Q.; Zhang, L.; Zhou, C.; Salamon, D.; Zhang, S.T.; Zhang, Y.; et al. Progress and perspective of high strain NBT-based lead-free piezoceramics and multilayer actuators. J. Mater. 2021, 7, 508–544. [Google Scholar] [CrossRef]

| 0 Nb | 0.5 Nb | 1 Nb | 2 Nb | 3 Nb | 4 Nb | 5 Nb | |

|---|---|---|---|---|---|---|---|

| Phase | R3c | Pmm | Pmm | Pmm | Pmm | Pmm | Pmm |

| a = b = c (Å) * | 4.0017(7) | 3.9941(7) | 3.9945(1) | 3.9944(6) | 3.9945(7) | 3.9950(4) | 3.9955(7) |

| Cell volume (Å3) | 63.713(8) | 63.720(4) | 63.736(9) | 63.734(5) | 63.739(8) | 63.762(2) | 63.787(5) |

| O | Bi | Fe | Ba | Ti | Nb | |

|---|---|---|---|---|---|---|

| Theoretical average | 60 | 14 | 13.44 | 6 | 6 | 0.56 |

| Point A (core) | 59.0 | 17.1 | 15.1 | 4.7 | 3.8 | 0.3 |

| Point B (shell) | 59.4 | 13.5 | 11.7 | 8.3 | 6.7 | 0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Wang, B.; Li, Y.; Hall, D.A. Enhancement of Nonlinear Dielectric Properties in BiFeO3–BaTiO3 Ceramics by Nb-Doping. Materials 2022, 15, 2872. https://doi.org/10.3390/ma15082872

Yang Z, Wang B, Li Y, Hall DA. Enhancement of Nonlinear Dielectric Properties in BiFeO3–BaTiO3 Ceramics by Nb-Doping. Materials. 2022; 15(8):2872. https://doi.org/10.3390/ma15082872

Chicago/Turabian StyleYang, Ziqi, Bing Wang, Yizhe Li, and David A. Hall. 2022. "Enhancement of Nonlinear Dielectric Properties in BiFeO3–BaTiO3 Ceramics by Nb-Doping" Materials 15, no. 8: 2872. https://doi.org/10.3390/ma15082872