Finite-Element Analysis of High-Strength Steel Extended End-Plate Connections under Cyclic Loading

Abstract

:1. Introduction

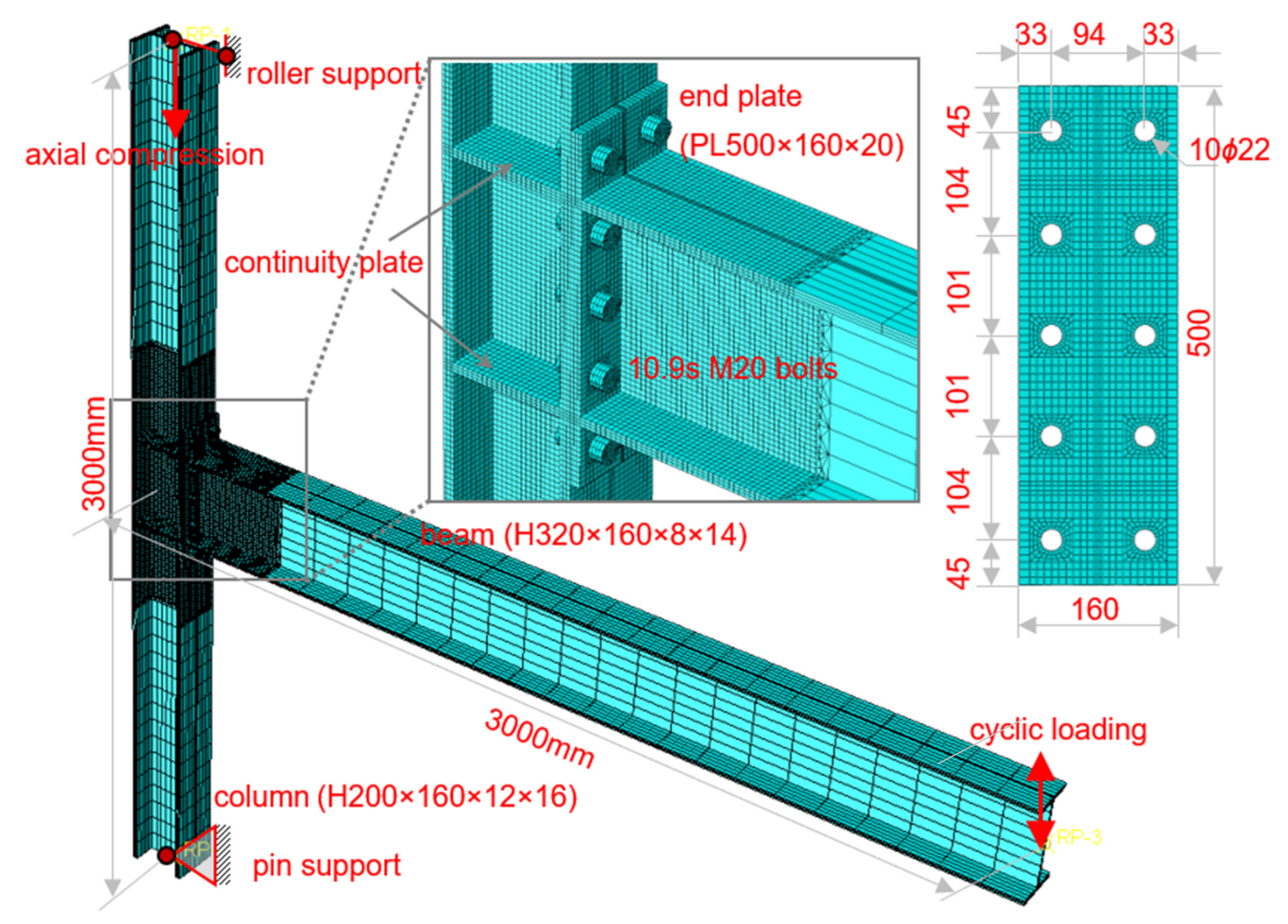

2. Finite-Element Model

2.1. Geometrical Dimensions

2.2. Boundary Conditions

2.3. Element Types and Meshes

2.4. Contact Modeling

2.5. Material Modeling

2.5.1. Material Modeling of Steel Plates

2.5.2. Material Modeling of High-Strength Bolts

3. Verification

3.1. Description of Test Program

3.2. Comparison of Tests and Finite-Element Analysis

3.2.1. Deformation Modes

3.2.2. Hysteresis Loops

4. Conclusions

- (1)

- The proposed finite-element model could give a quite accurate prediction for the pinched hysteresis loops and deformation modes of bolted end-plate connections. It proved the rationality of selected element types, contact interaction properties, and, in particular, the material constitutive model for high-strength structural steels. This finite-element model provided a powerful tool for further studying the connection performance under earthquakes.

- (2)

- The weak panel zone design demonstrated its stable and plump hysteresis behavior, and the panel zone had a much larger energy dissipation capacity than the bolted end-plate, in the case of them all made up of high-strength steels. It indicated the need to further investigate the potential to take advantage of the superior seismic performance of panel zones in connection design. The weak column flange design, however, did not show much impact on the overall hysteresis behavior of the end-plate connection.

- (3)

- Because the bolt fracture or cracking in the end-plate was not taken into account in modeling, the connection failures in experimental tests were not simulated. It is suggested to calibrate accurate material failure models for high-strength steels and bolts so that they can be implemented in Abaqus to capture the connection failure. This is required for reasonable identification of the ultimate resistance, ductility, and energy dissipation capacity of high-strength steel end-plate connections.

- (4)

- Generally, high-strength steel extended end-plate connections survived cycles up to a story drift angle amplitude of 5%; while when the panel zone dominated the plastic response, such an amplitude was as high as 7%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tremblay, R.; Filiatrault, A.; Timler, P.; Bruneau, M. Performance of steel structures during the 1994 Northridge earthquake. Can. J. Civ. Eng. 1995, 22, 338–360. [Google Scholar] [CrossRef]

- Tremblay, R.; Bruneau, M.; Nakashima, M.; Prion, H.G.L.; Filiatrault, A.; De Vall, R. Seismic design of steel buildings: Lessons from the 1995 Hyogo-ken Nanbu earthquake. Can. J. Civ. Eng. 1996, 23, 727–756. [Google Scholar] [CrossRef]

- Tsai, K.C.; Popov, E.P. Cyclic behavior of end-plate moment connections. ASCE J. Struct. Eng. 1990, 116, 2917–2930. [Google Scholar] [CrossRef]

- Ghobarah, A.; Korol, R.M.; Osman, A. Cyclic behavior of extended end-plate joints. ASCE J. Struct. Eng. 1992, 118, 1333–1353. [Google Scholar] [CrossRef]

- Sumner, E.A.; Murray, T.M. Behavior of extended end-plate moment connections subject to cyclic loading. ASCE J. Struct. Eng. 2002, 128, 501–508. [Google Scholar] [CrossRef]

- Guo, B.; Gu, Q.; Liu, F. Experimental behavior of stiffened and unstiffened end-plate connections under cyclic loading. ASCE J. Struct. Eng. 2006, 132, 1352–1357. [Google Scholar] [CrossRef]

- Shi, G.; Shi, Y.; Wang, Y. Behaviour of end-plate moment connections under earthquake loading. Eng. Struct. 2007, 29, 703–716. [Google Scholar] [CrossRef]

- Kukreti, A.R.; Biswas, P. Finite element analysis to predict the cyclic hysteretic behavior and failure of end-plate connections. Comput. Struct. 1997, 65, 127–147. [Google Scholar] [CrossRef]

- Ádány, S.; Dunai, L. Finite element simulation of the cyclic behaviour of end-plate joints. Comput. Struct. 2004, 82, 2131–2143. [Google Scholar] [CrossRef]

- Wang, M.; Shi, Y.; Wang, Y.; Shi, G. Numerical study on seismic behaviors of steel frame end-plate connections. J. Constr. Steel Res. 2013, 90, 140–152. [Google Scholar] [CrossRef]

- ElSabbagh, A.; Sharaf, T.; Nagy, S.; ElGhandour, M. Behavior of extended end-plate bolted connections subjected to monotonic and cyclic loads. Eng. Struct. 2019, 190, 142–159. [Google Scholar] [CrossRef]

- Belardi, V.G.; Fanelli, P.; Vivio, F. Theoretical definition of a new custom finite element for structural modeling of composite bolted joints. Compos. Struct. 2021, 258, 113199. [Google Scholar] [CrossRef]

- Ye, J.; Quan, G.; Yun, X.; Guo, X.; Chen, J. An improved and robust finite element model for simulation of thin-walled steel bolted connections. Eng. Struct. 2022, 250, 113368. [Google Scholar] [CrossRef]

- Shi, G.; Hu, F.; Shi, Y. Recent research advances of high strength steel structures and codification of design specification in China. Int. J. Steel Struct. 2014, 14, 873–887. [Google Scholar] [CrossRef]

- Ban, H.; Shi, G. A review of research on high-strength steel structures. Proc. Inst. Civ. Eng.-Struct. Build. 2018, 171, 625–641. [Google Scholar] [CrossRef]

- Hu, F.; Shi, G. Constitutive model for full-range cyclic behavior of high strength steels without yield plateau. Constr. Build. Mater. 2018, 162, 596–607. [Google Scholar] [CrossRef]

- Chen, X.; Shi, G. Experimental study on seismic behaviour of cover-plate joints in high strength steel frames. Eng. Struct. 2019, 191, 292–310. [Google Scholar] [CrossRef]

- Chen, X.; Shi, G. Cyclic tests on high strength steel flange-plate beam-to-column joints. Eng. Struct. 2019, 186, 564–581. [Google Scholar] [CrossRef]

- Hu, F.; Shi, G.; Shi, Y. Experimental study on seismic behavior of high strength steel frames: Global response. Eng. Struct. 2017, 131, 163–179. [Google Scholar] [CrossRef]

- Hu, F.; Shi, G. Experimental study on seismic behavior of high strength steel frames: Local response. Eng. Struct. 2021, 229, 111620. [Google Scholar] [CrossRef]

- American Institute of Steel Construction (AISC). Seismic Provisions for Structural Steel Buildings; ANSI/AISC 341-16; American Institute of Steel Construction: Chicago, IL, USA, 2016. [Google Scholar]

- Girão Coelho, A.M.; Bijlaard, F.S.K. Experimental behaviour of high strength steel end-plate connections. J. Constr. Steel Res. 2018, 63, 1228–1240. [Google Scholar] [CrossRef]

- Girão Coelho, A.M.; Bijlaardd, F.S.K. Ductility of high performance steel moment connections. Adv. Steel Constr. 2007, 3, 765–783. [Google Scholar]

- Girão Coelho, A.M.; Bijlaard, F. High strength steel in buildings and civil engineering structures: Design of connections. Adv. Struct. Eng. 2010, 13, 413–429. [Google Scholar] [CrossRef]

- Li, D.; Uy, B.; Wang, J. Behaviour and design of high-strength steel beam-to-column joints. Steel Compos. Struct. 2019, 31, 303–317. [Google Scholar]

- Jia, C.; Li, J.; Shao, Y.; Wang, Y. Parametric analysis of end-plate joint in hybrid strength steel frame subjected to static loads. Int. J. Steel Struct. 2007, 20, 1916–1928. [Google Scholar] [CrossRef]

- Kim, S.Y.; Shin, K.J.; Lee, S.H.; Lee, H.D. Experimental investigation of beam-to-column connection with SHN490 steel under cyclic loading. Int. J. Steel Struct. 2020, 16, 1299–1307. [Google Scholar] [CrossRef]

- Sun, F.F.; Xue, X.Y.; Jin, H.J.; Sun, M.; Tang, Z.M.; Xiao, Y.; Li, G.Q. Hysteretic behavior and simplified simulation method of high-strength steel end-plate connections under cyclic loading. J. Constr. Steel Res. 2016, 158, 429–442. [Google Scholar] [CrossRef]

- Dassault Systèmes Simulia Corp. Abaqus Documentation, 2020th ed.; Dassault Systèmes Simulia Corp: Providence, RI, USA, 2020. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China (MOHURD). Technical Specification for High Strength Bolt Connections of Steel Structures; JGJ 82-2011; China Building Industry Press: Beijing, China, 2011. (In Chinese) [Google Scholar]

- Chaboche, J.L. Time-independent constitutive theories for cyclic plasticity. Int. J. Plast. 1986, 2, 149–188. [Google Scholar] [CrossRef]

- Chaboche, J.L. Constitutive equations for cyclic plasticity and cyclic viscoplasticity. Int. J. Plast. 1989, 5, 247–302. [Google Scholar] [CrossRef]

- Hu, F.; Shi, G.; Shi, Y. Constitutive model for full-range elasto-plastic behavior of structural steels with yield plateau: Formulation and implementation. Eng. Struct. 2018, 171, 1059–1070. [Google Scholar] [CrossRef]

- Hu, F.; Shi, G.; Shi, Y. Constitutive model for full-range elasto-plastic behavior of structural steels with yield plateau: Calibration and validation. Eng. Struct. 2016, 118, 210–227. [Google Scholar] [CrossRef]

| Steel Gr. | E (MPa) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q355 (8 mm) | 205,500 | 406 | −203 | 0 | 108 | 0 | 203,000 | 40,600 | 3127 | 374 | 0 | 0.5 |

| 1.2% | 0.5% | 300 | 0 | 25 | 0 | 3000 | 300 | 52 | 0 | 0 | 0.3 | |

| Q355 (14 mm) | 203,500 | 368 | −184 | 0 | 129 | 0 | 184,000 | 36,800 | 3560 | 377 | 0 | 0.5 |

| 1.8% | 0.5% | 300 | 0 | 25 | 0 | 3000 | 300 | 52 | 0 | 0 | 0.3 | |

| Q690 (8 mm) | 208,300 | 610 | −122 | −122 | 98 | 49 | 366,000 | 36,600 | 3672 | 34,678 | 272 | 0 |

| 0 | 0 | 3000 | 300 | 35 | 650 | 3000 | 300 | 45 | 850 | 0 | 0.2 | |

| Q690 (12 mm) | 205,800 | 775 | −155 | −155 | 30 | 15 | 465,000 | 46,500 | 928 | 8764 | 260 | 0 |

| 0 | 0 | 3000 | 300 | 35 | 650 | 3000 | 300 | 45 | 850 | 0 | 0.2 | |

| Q690 (16 mm) | 219,800 | 811 | −162 | −162 | 25 | 13 | 486,600 | 48,660 | 733 | 6919 | 266 | 0 |

| 0 | 0 | 3000 | 300 | 35 | 650 | 3000 | 300 | 45 | 850 | 0 | 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, T.; Wang, Z.; Hu, F.; Wang, P. Finite-Element Analysis of High-Strength Steel Extended End-Plate Connections under Cyclic Loading. Materials 2022, 15, 2912. https://doi.org/10.3390/ma15082912

Lin T, Wang Z, Hu F, Wang P. Finite-Element Analysis of High-Strength Steel Extended End-Plate Connections under Cyclic Loading. Materials. 2022; 15(8):2912. https://doi.org/10.3390/ma15082912

Chicago/Turabian StyleLin, Tao, Zhan Wang, Fangxin Hu, and Peng Wang. 2022. "Finite-Element Analysis of High-Strength Steel Extended End-Plate Connections under Cyclic Loading" Materials 15, no. 8: 2912. https://doi.org/10.3390/ma15082912

APA StyleLin, T., Wang, Z., Hu, F., & Wang, P. (2022). Finite-Element Analysis of High-Strength Steel Extended End-Plate Connections under Cyclic Loading. Materials, 15(8), 2912. https://doi.org/10.3390/ma15082912