Experimental Study on Chloride Ion Diffusion in Concrete Affected by Exposure Conditions

Abstract

:1. Introduction

2. Experimental Program

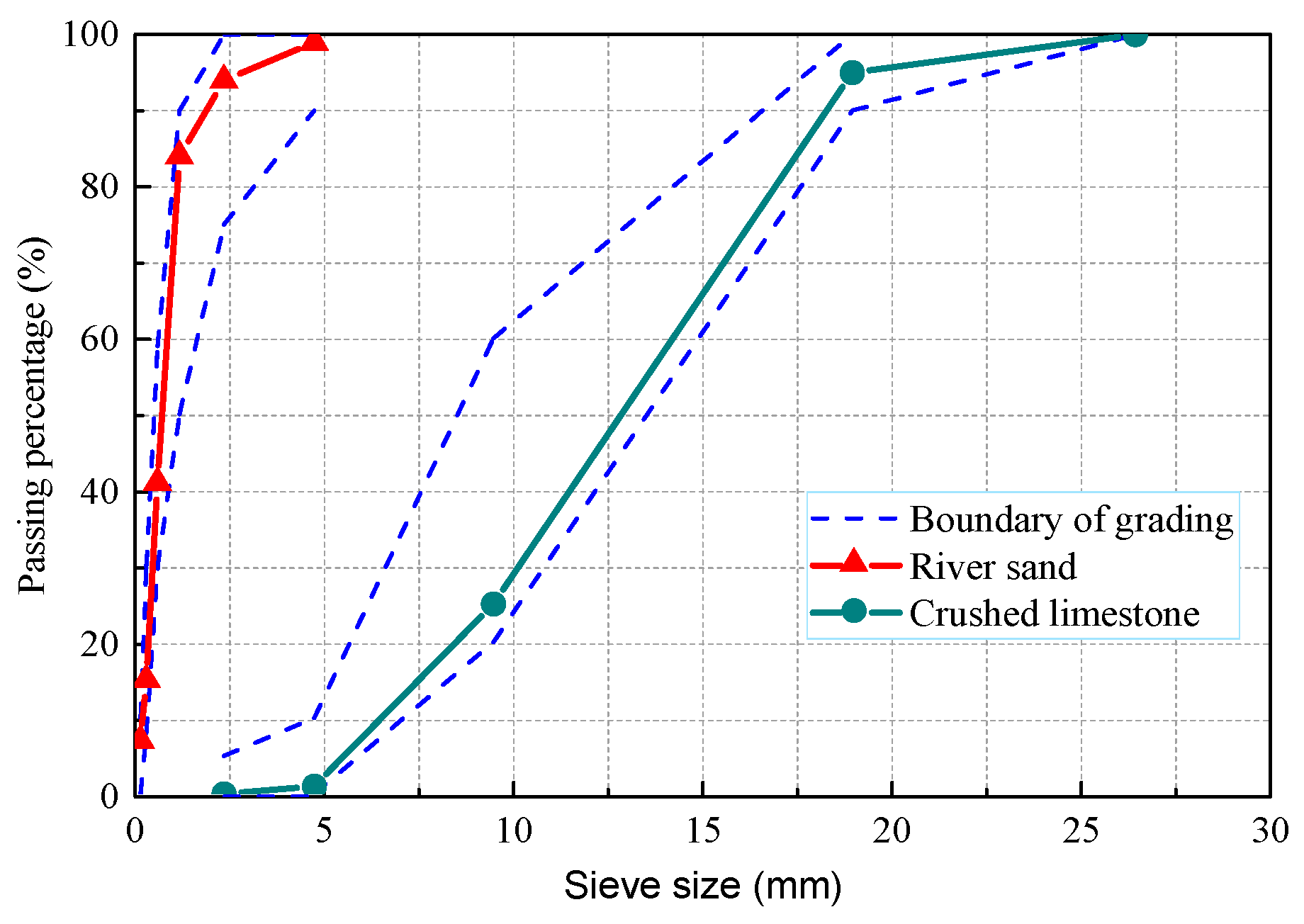

2.1. Specimen Preparation

2.2. Chloride Ion Erosion Test

2.3. Chloride Ion Content Test

3. Experimental Results and Analysis

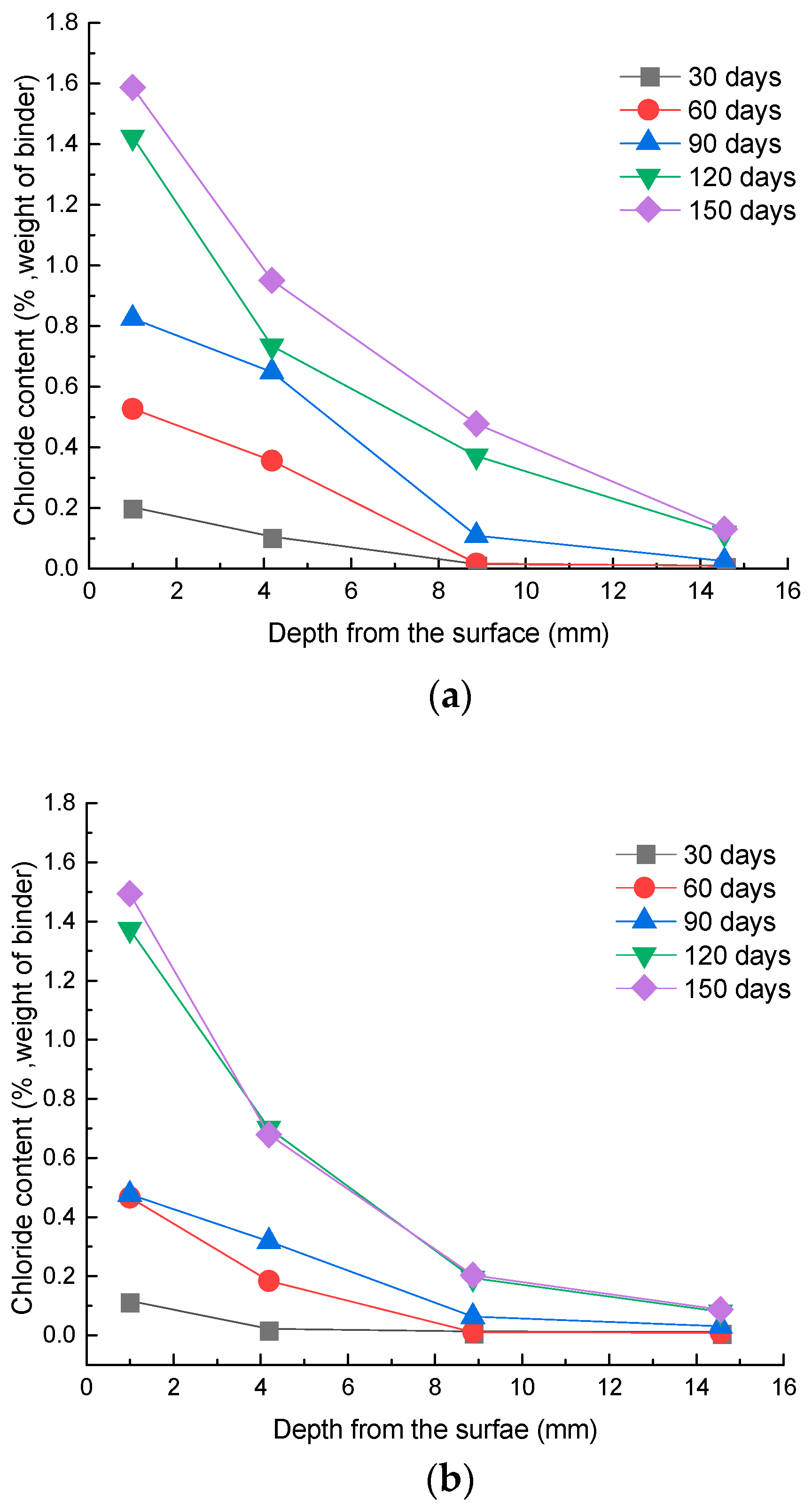

3.1. Distribution of Chloride Ions

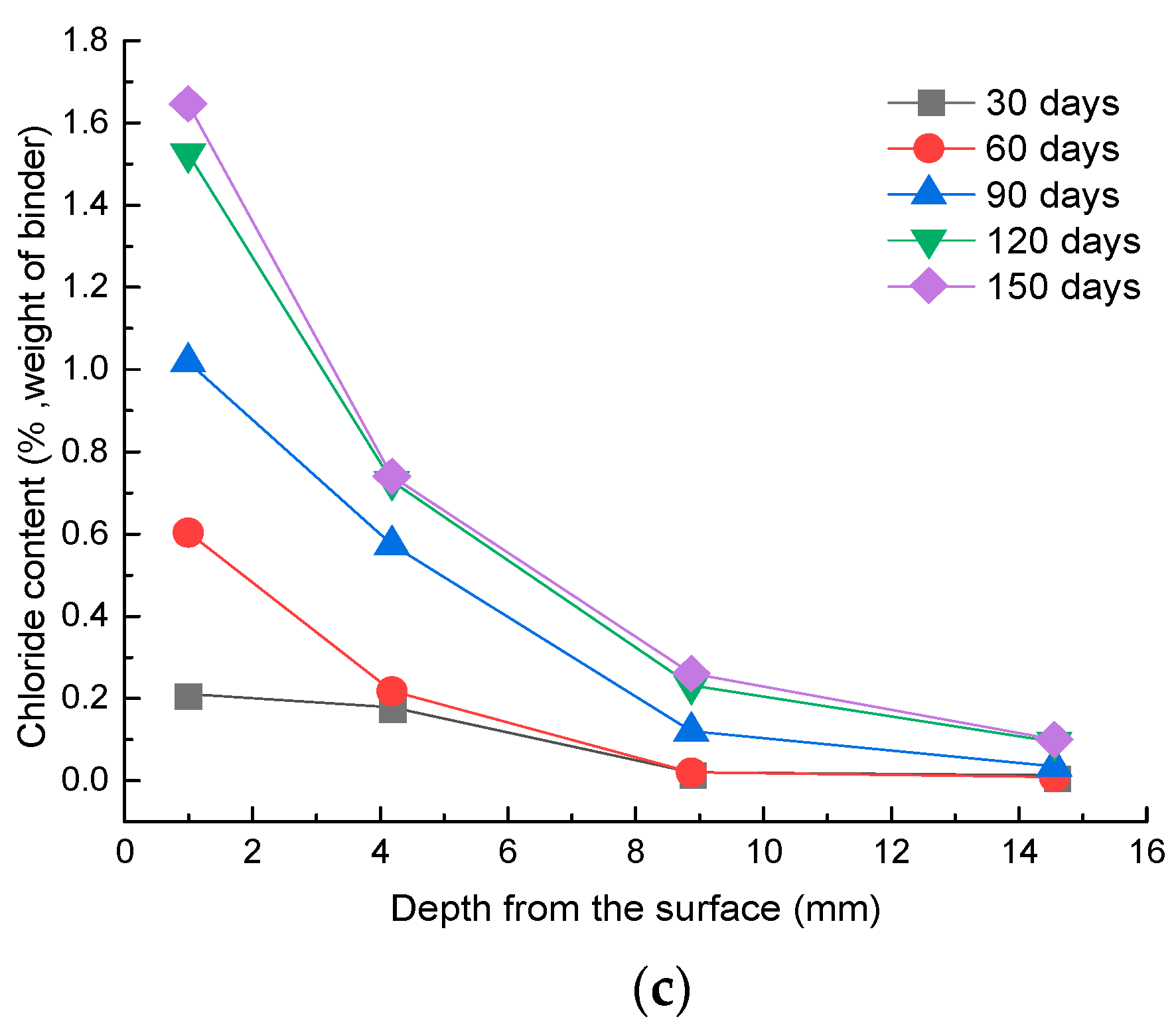

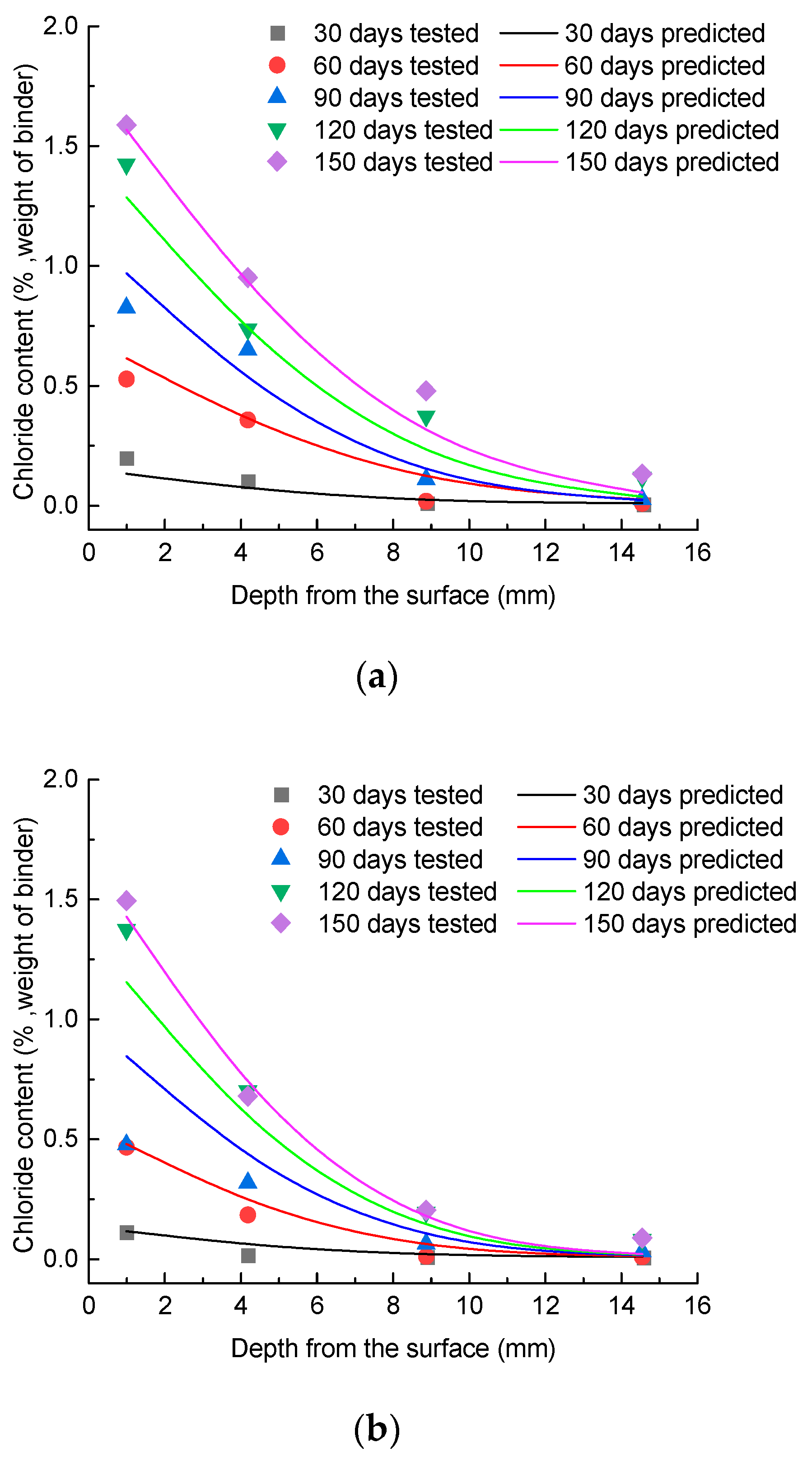

3.2. Chloride Diffusion Model

3.3. Model Validation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tadayon, M.H.; Shekarchi, M.; Tadayon, M. Long-term field study of chloride ingress in concretes containing pozzolans exposed to severe marine tidal zone. Constr. Build. Mater. 2016, 123, 611–616. [Google Scholar] [CrossRef]

- Jin, W.L.; Zhao, Y.X. The Durability of Concrete Sturcture; Science Press: Beijing, China, 2002; Volume 6, pp. 50–53. (In Chinese) [Google Scholar]

- Hussain, S.E.; Rasheeduzzafar, S.E.; Al-Musallam, A. Factors affecting threshold chloride for reinforcement corrosion in concrete. Cem. Concr. Res. 1995, 25, 1543–1555. [Google Scholar] [CrossRef]

- Cai, Y.K.; Xu, Y.M.; Zhao, Y.; Ma, X.B. Extrapolating short-term corrosion test results to field exposures in different environments. Corros. Sci. 2021, 186, 109455. [Google Scholar] [CrossRef]

- Manera, M.; Vennesland, Ø.; Bertolini, L. Chloride threshold for rebar corrosion in concrete with addition of silica fume. Corros. Sci. 2008, 50, 554–560. [Google Scholar] [CrossRef]

- Melchers, R.E.; Li, C.Q. Reinforcement corrosion initiation and activation times in concrete structures exposed to severe marine environments. Cem. Concr. Res. 2009, 39, 1068–1076. [Google Scholar] [CrossRef]

- David, T.; Naga, P.V.; Ceki, H. Standardizing test to quantify chloride threshold of steel in concrete. ACI Mater. J. 2021, 118, 177–187. [Google Scholar]

- Zhen, C.; Alice, A. Concrete cover cracking and service life prediction of reinforced concrete structures in corrosive environments. Constr. Build. Mater. 2018, 159, 652–671. [Google Scholar]

- Qu, F.L.; Liu, G.R.; Zhao, S.B. Mechanical properties of non-uniformly corroded steel bars based on length characterization. J. Build. Mater. 2016, 19, 566–570. (In Chinese) [Google Scholar]

- Zhang, L.; Niu, D.; Wen, B.; Luo, D. Concrete protective layer cracking caused by non-uniform corrosion of reinforcements. Materials 2019, 12, 4245. [Google Scholar] [CrossRef] [Green Version]

- Cairns, J.; Du, Y.; Law, D. Structural performance of corrosion-damaged concrete beams. Mag. Concr. Res. 2008, 60, 359–370. [Google Scholar] [CrossRef]

- Otieno, M.; Beushausen, H.; Alexander, M. Chloride-induced corrosion of steel in cracked concrete–Part I: Experimental studies under accelerated and natural marine environments. Cem. Concr. Res. 2016, 79, 373–385. [Google Scholar] [CrossRef]

- Xue, W.; Chen, J.; Xu, F.; Jiang, A.Y. Corrosion development of carbon steel grids and shear connectors in cracked composite beams exposed to wet–dry cycles in chloride environment. Materials 2018, 11, 479. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luo, Y.; Niu, D.; Su, L. Chloride diffusion property of hybrid basalt–polypropylene fibre-reinforced concrete in a chloride–sulphate composite environment under drying–wetting cycles. Materials 2021, 14, 1138. [Google Scholar] [CrossRef] [PubMed]

- Hong, K.; Hooton, R. Effects of fresh water exposure on chloride contaminated concrete. Cem. Concr. Res. 2000, 30, 1199–1207. [Google Scholar] [CrossRef]

- Liu, P.; Yu, Z.W.; Lu, Z.H. Predictive convection zone depth of chloride in concrete under chloride environment. Cem. Concr. Compos. 2016, 72, 257–267. [Google Scholar] [CrossRef]

- Gao, Y.H.; Zhang, J.Z.; Zhang, S.; Zhang, Y.R. Probability distribution of convection zone depth of chloride in concrete in a marine tidal environment. Constr. Build Mater. 2017, 140, 485–495. [Google Scholar] [CrossRef]

- Hong, K.; Hooton, R.D. Effects of cyclic chloride exposure on penetration of concrete cover. Cem. Concr. Res. 1999, 29, 1379–1386. [Google Scholar] [CrossRef]

- Gang, X.; Yun, P.L.; Yi-Biao, S.; Ke, X. Chloride ion transport mechanism in concrete due to wetting and drying cycles. Struct. Concr. 2015, 16, 289–296. [Google Scholar] [CrossRef]

- Huang, Y.; Wie, J.; Dong, R.; Zeng, H. Chloride ion transmission model under the drying-wetting cycles and its solution. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2014, 29, 445–450. [Google Scholar] [CrossRef]

- Lai, J.; Cai, J.; Chen, Q.J.; He, A.; Wei, M.Y. Influence of crack width on chloride penetration in concrete subjected to alternating wetting–drying cycles. Materials 2020, 13, 3801. [Google Scholar] [CrossRef]

- Ye, H.L.; Jin, X.Y.; Fu, C.Q.; Jin, N.G.; Xu, Y.B.; Huang, T. Chloride penetration in concrete exposed to cyclic drying-wetting and carbonation. Constr. Build. Mater. 2016, 112, 457–463. [Google Scholar] [CrossRef]

- Alawi, A.-S.K.A.; Al-Zahrani, M.M.; Maslehuddin, M.; Baghabra, A.-A.O.S.; Al-Dulaijan, S.U. Chloride diffusion models for Type I and fly ash cement concrete exposed to field and laboratory conditions. Mar. Struct. 2021, 76, 102900. [Google Scholar] [CrossRef]

- Luping, T.; Nilsson, L.-O. Rapid determination of the chloride diffusivity in concrete by applying an electrical field. Mater. J. 1992, 89, 40–53. [Google Scholar]

- Huang, D.G.; Niu, D.T.; Su, L.; Liu, Y.H.; Guo, B.B.; Xia, Q.; Peng, G. Diffusion behavior of chloride in coral aggregate concrete in marine salt-spray environment. Constr. Build. Mater. 2022, 316, 125878. [Google Scholar] [CrossRef]

- Pack, S.W.; Jung, M.S.; Song, H.W.; Kim, S.H.; Ann, K.Y. Prediction of time dependent chloride transport in concrete structures exposed to a marine environment. Cem. Concr. Res. 2010, 40, 302–312. [Google Scholar] [CrossRef]

- Ann, K.Y.; Ahn, J.H.; Ryou, J.S. The importance of chloride content at the concrete surface in assessing the time to corrosion of steel in concrete structures. Constr. Build. Mater. 2009, 23, 239–245. [Google Scholar] [CrossRef]

- Erik, P.N.; Mette, R.G. Chloride diffusion in partially saturated cementitious material. Cem. Concr. Res. 2003, 33, 133–138. [Google Scholar]

- GB/T 50081—2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Ministry of Construction of the People’s Republic of China: Beijing, China, 2019.

- Lin, G.; Liu, Y.; Xiang, Z. Numerical modeling for predicting service life of reinforced concrete structures exposed to chloride environments. Cem. Concr. Compos. 2010, 32, 571–579. [Google Scholar] [CrossRef]

- Wang, L.; Bao, J. Investigation on chloride penetration into unsaturated concrete under short-term sustained tensile loading. Mater. Struct. 2017, 50, 227. [Google Scholar] [CrossRef]

- Li, K.F.; Li, C.Q.; Chen, Z.Y. Influential depth of moisture transport in concrete subject to drying–wetting cycles. Cem. Concr. Compos. 2009, 31, 693–698. [Google Scholar] [CrossRef]

- Otieno, M.; Golden, G.; Alexander, M.G.; Beushausen, H. Acceleration of steel corrosion in concrete by cyclic wetting and drying: Effect of drying duration and concrete quality. Mater. Struct. 2019, 52, 50. [Google Scholar] [CrossRef]

- Crank, J. The Mathematics of Diffusion, 2nd ed.; Oxford Press: London, UK, 1975. [Google Scholar]

- Liu, Z.Y.; Wang, Y.C.; Wang, J.P.; Liu, C.; Jiang, J.Y.; Li, H.J. Experiment and simulation of chloride ion transport and binding in concrete under the coupling of diffusion and convection. J. Build. Eng. 2022, 45, 103610. [Google Scholar] [CrossRef]

- ACI Committee 365. Service-Life Prediction: State of the Art Report. Manual of Concrete Practice; Part 5; American Concrete Institute: Indianapolis, IN, USA, 2000. [Google Scholar]

- Petcherdchoo, A. Time dependent models of apparent diffusion coefficient and surface chloride for chloride transport in fly ash concrete. Constr. Build. Mater. 2013, 38, 497–507. [Google Scholar] [CrossRef]

- Kassir, M.K.; Ghosn, M. Chloride-induced corrosion of reinforced concrete bridge decks. Cem. Concr. Res. 2002, 32, 139–143. [Google Scholar] [CrossRef]

- Olsson, N.; Baroghel, B.V.; Nilsson, L.O. Non-saturated ion diffusion in concrete-A new approach to evaluate conductivity measurements. Cem. Concr. Compos. 2013, 40, 40–47. [Google Scholar] [CrossRef]

- Nygaard, P.V.; Geiker, M.R. A method for measuring the chloride threshold level required to initiate reinforcement corrosion in concrete. Mater. Struct. 2005, 38, 489–494. [Google Scholar] [CrossRef]

- Guimarães, A.T.C.; Climent, M.A.; Vera, G.D.; Vicente, F.J.; Rodrigues, F.T.; Andrade, C. Determination of chloride diffusivity through partially saturated Portland cement concrete by a simplified procedure. Constr. Build. Mater. 2011, 25, 785–790. [Google Scholar] [CrossRef]

- Climent, M.A.; Vera, G.D.; López, J.F.; Viqueira, E.; Andrade, C. A test method for measuring chloride diffusion coefficients through non-saturated concrete. Part I: The instantaneous plane source diffusion case. Cem. Concr. Res. 2002, 32, 1113–1123. [Google Scholar] [CrossRef]

- Boddy, A.; Bentz, E.; Thomas, M.D.A. An overview and sensitivity study of a multimechanistic chloride transport model. Cem. Concr. Res. 1999, 29, 827–837. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Guo, S.; Yan, B.C.; Liu, Z.; Wang, Y.C.; Yuan, C.K. Experimental and analytical investigation on chloride ions transport in concrete considering the effect of dry-exposure radio under diurnal tidal environment. Constr. Build. Mater. 2022, 328, 127138. [Google Scholar] [CrossRef]

- Wu, L.J.; Li, W.; Yu, X.N. Time-dependent chloride penetration in concrete in marine environments. Constr. Build. Mater. 2017, 152, 406–413. [Google Scholar] [CrossRef]

| CaO (%) | SiO2 (%) | MgO (%) | SO3 (%) | Al2O3 (%) | Fe2O3 (%) | Density (g/cm3) | Surface Area (m2/kg) | Loss (%) |

|---|---|---|---|---|---|---|---|---|

| 60.41 | 21.65 | 3.46 | 2.24 | 4.67 | 2.98 | 3.15 | 337 | 2.74 |

| Concrete Grade | Cement | Fine Aggregate | Coarse Aggregate | Water | Superplasticizer |

|---|---|---|---|---|---|

| C40 | 478 | 1172 | 632 | 167 | 6.8 |

| Group No. | State of Solution | Erosion Progress |

|---|---|---|

| S-W | static | long-term immersion |

| F-W | flowing | long-term immersion |

| F-DW | flowing | dry–wet cycles |

| Exposure Condition | D0 (10−12 m2/s) | m | R2 | |

|---|---|---|---|---|

| S-W | 4.50 | 0.98 | 0.59 | 0.926 |

| F-W | 5.60 | 0.97 | 0.98 | 0.876 |

| F-DW | 5.19 | 0.97 | 0.97 | 0.906 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, F.; Zhang, J.; Liu, G.; Zhao, S. Experimental Study on Chloride Ion Diffusion in Concrete Affected by Exposure Conditions. Materials 2022, 15, 2917. https://doi.org/10.3390/ma15082917

Qu F, Zhang J, Liu G, Zhao S. Experimental Study on Chloride Ion Diffusion in Concrete Affected by Exposure Conditions. Materials. 2022; 15(8):2917. https://doi.org/10.3390/ma15082917

Chicago/Turabian StyleQu, Fulai, Jinkai Zhang, Guirong Liu, and Shunbo Zhao. 2022. "Experimental Study on Chloride Ion Diffusion in Concrete Affected by Exposure Conditions" Materials 15, no. 8: 2917. https://doi.org/10.3390/ma15082917

APA StyleQu, F., Zhang, J., Liu, G., & Zhao, S. (2022). Experimental Study on Chloride Ion Diffusion in Concrete Affected by Exposure Conditions. Materials, 15(8), 2917. https://doi.org/10.3390/ma15082917