Water versus Oil Lubrication of Laser-Textured Ti6Al4V Alloy upon Addition of MoS2 Nanotubes for Green Tribology

Abstract

:1. Introduction

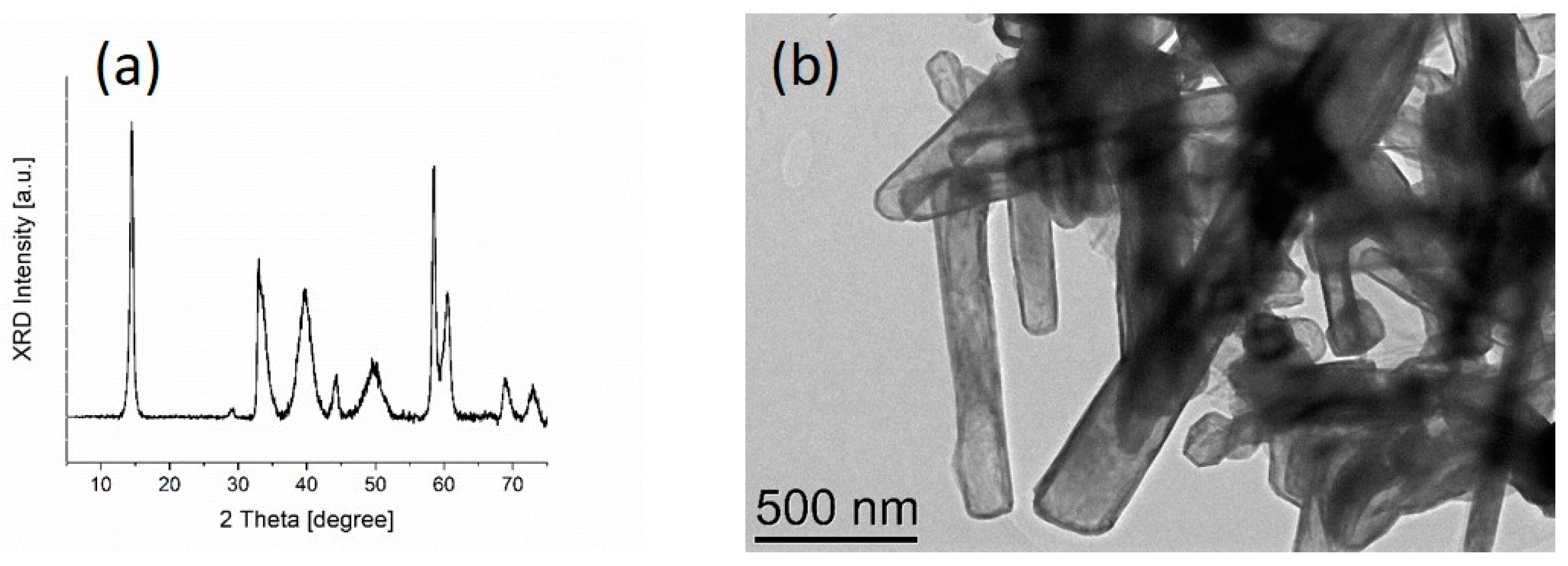

2. Materials and Methods

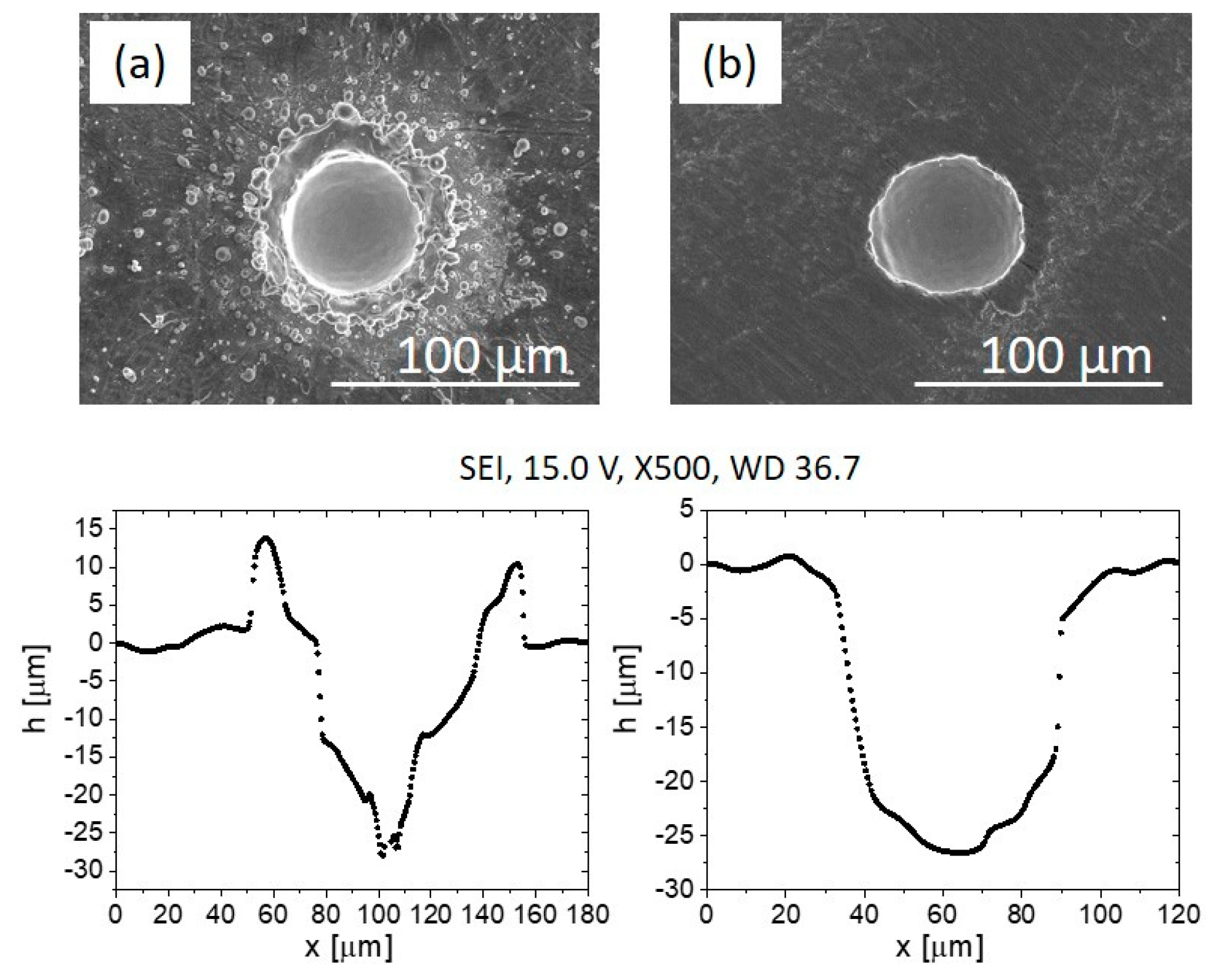

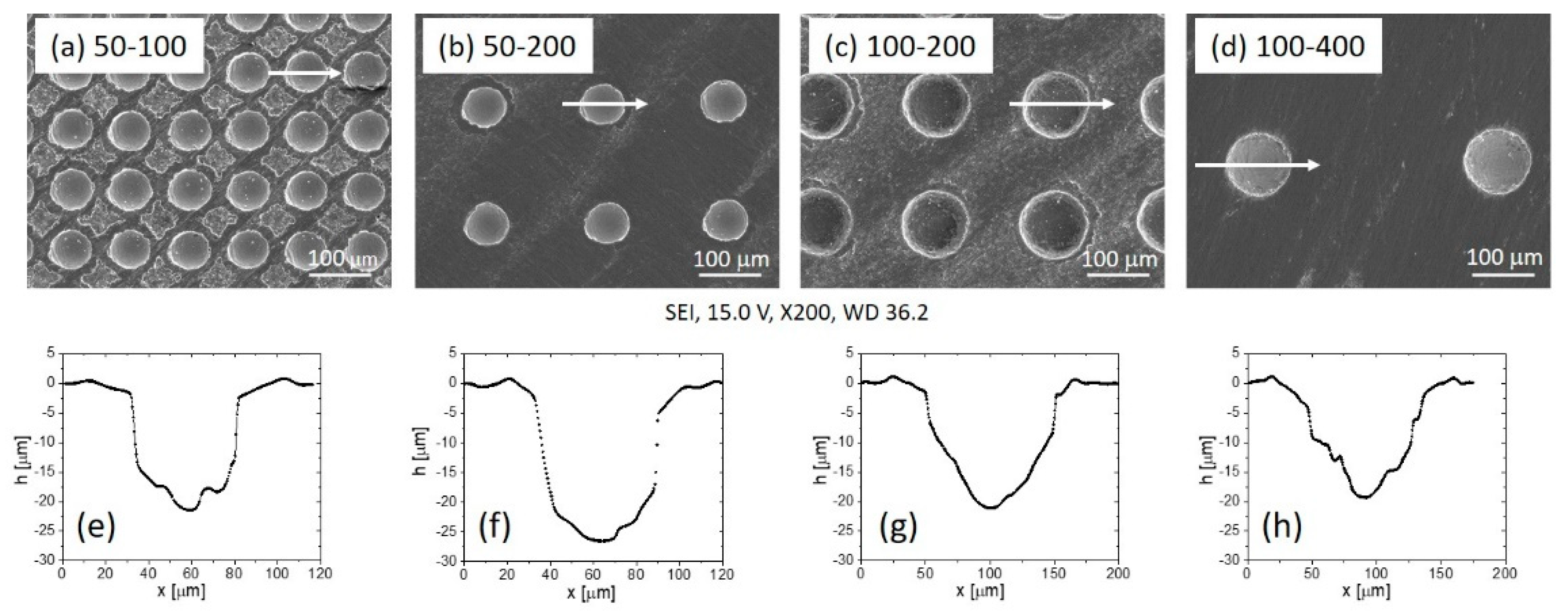

3. Results and Discussion

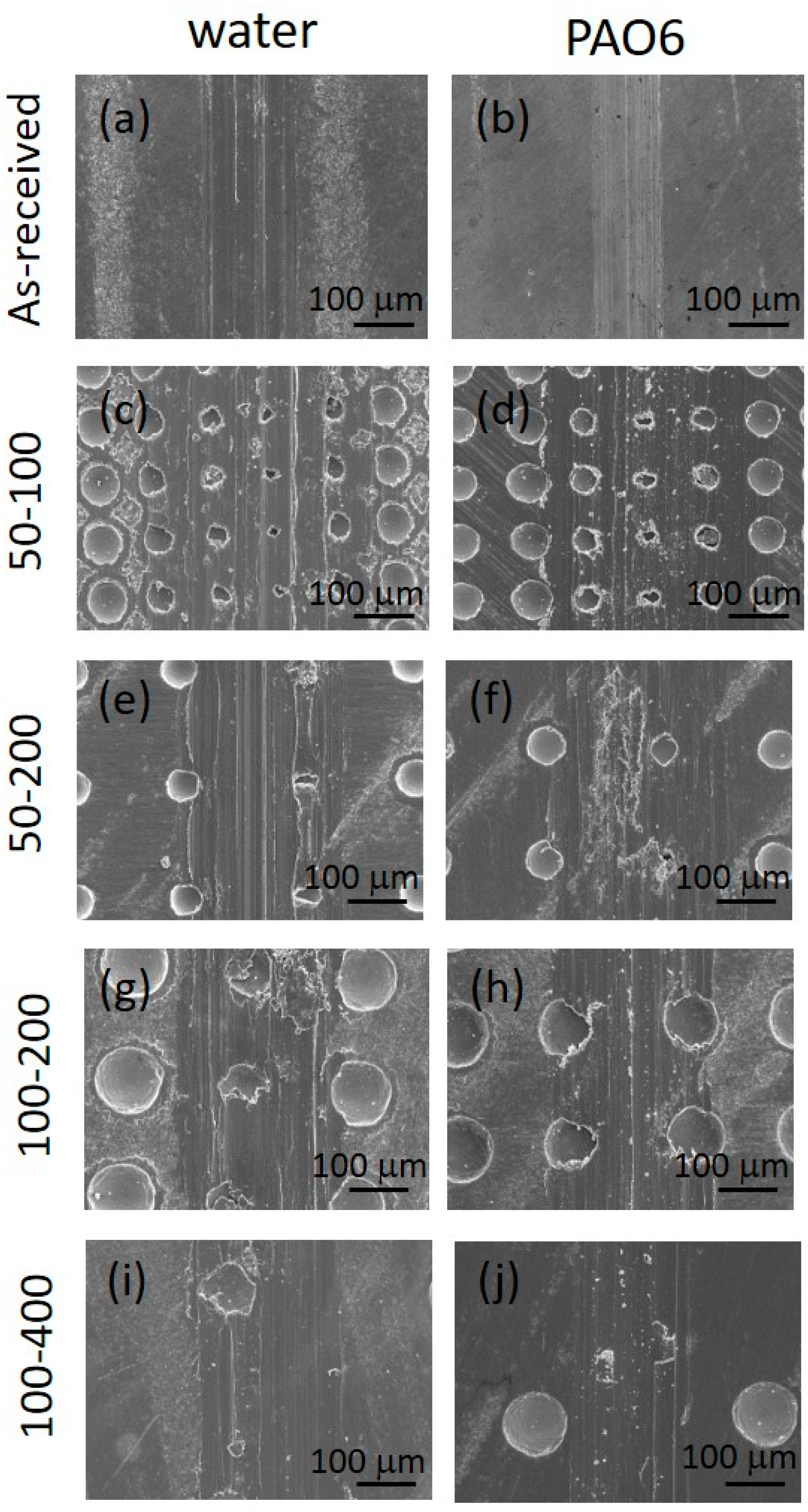

3.1. Surface Morphology

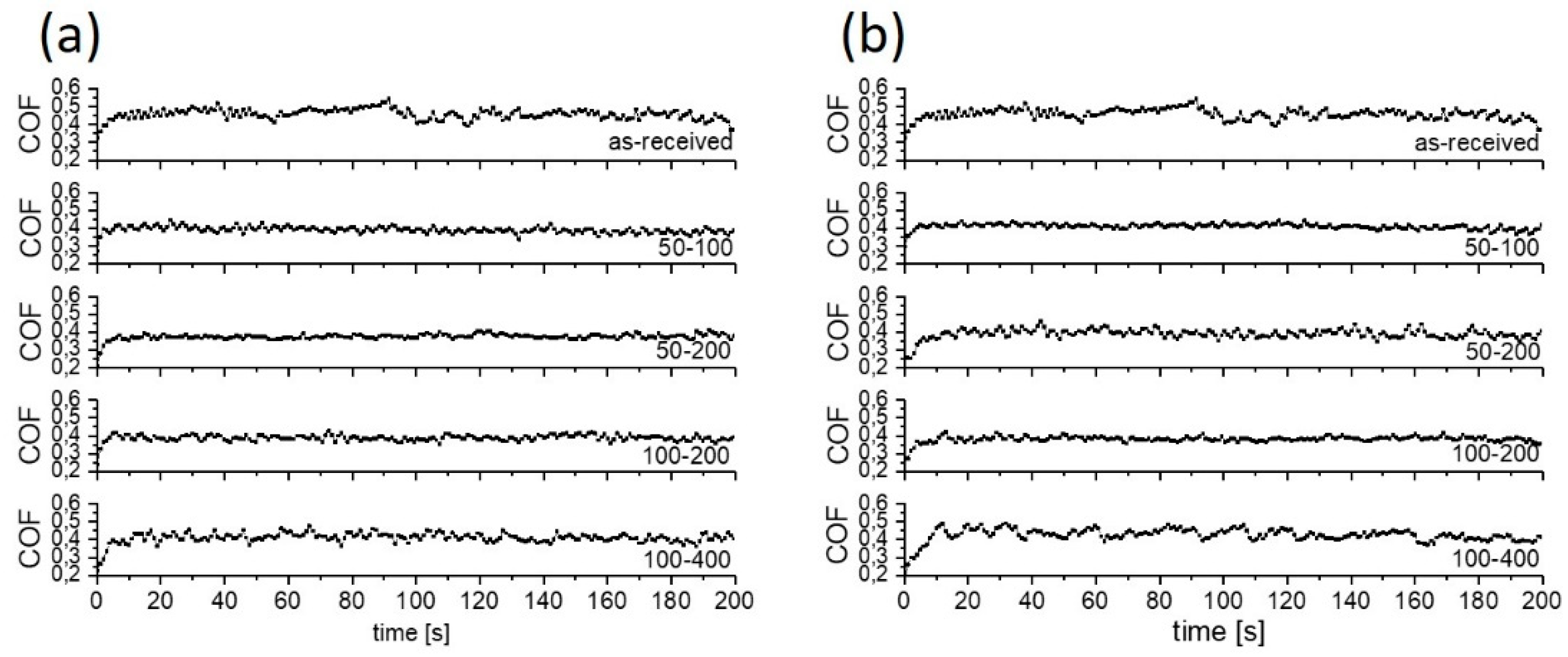

3.2. Tribological Testing

3.2.1. Coefficient of Friction

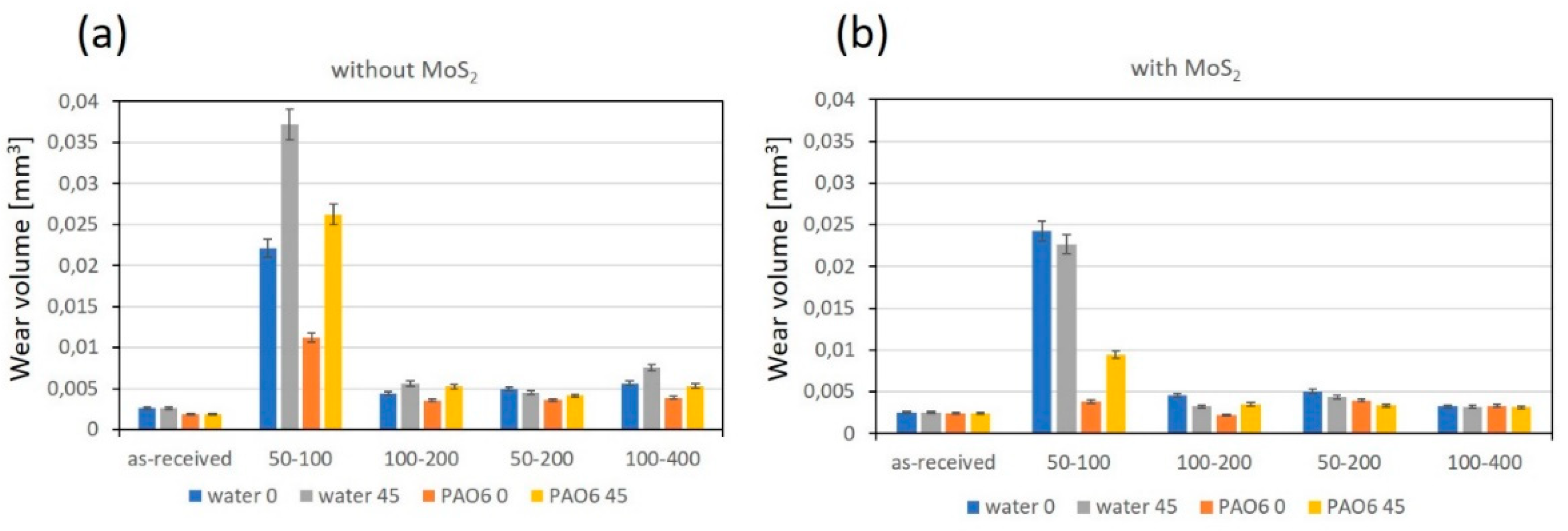

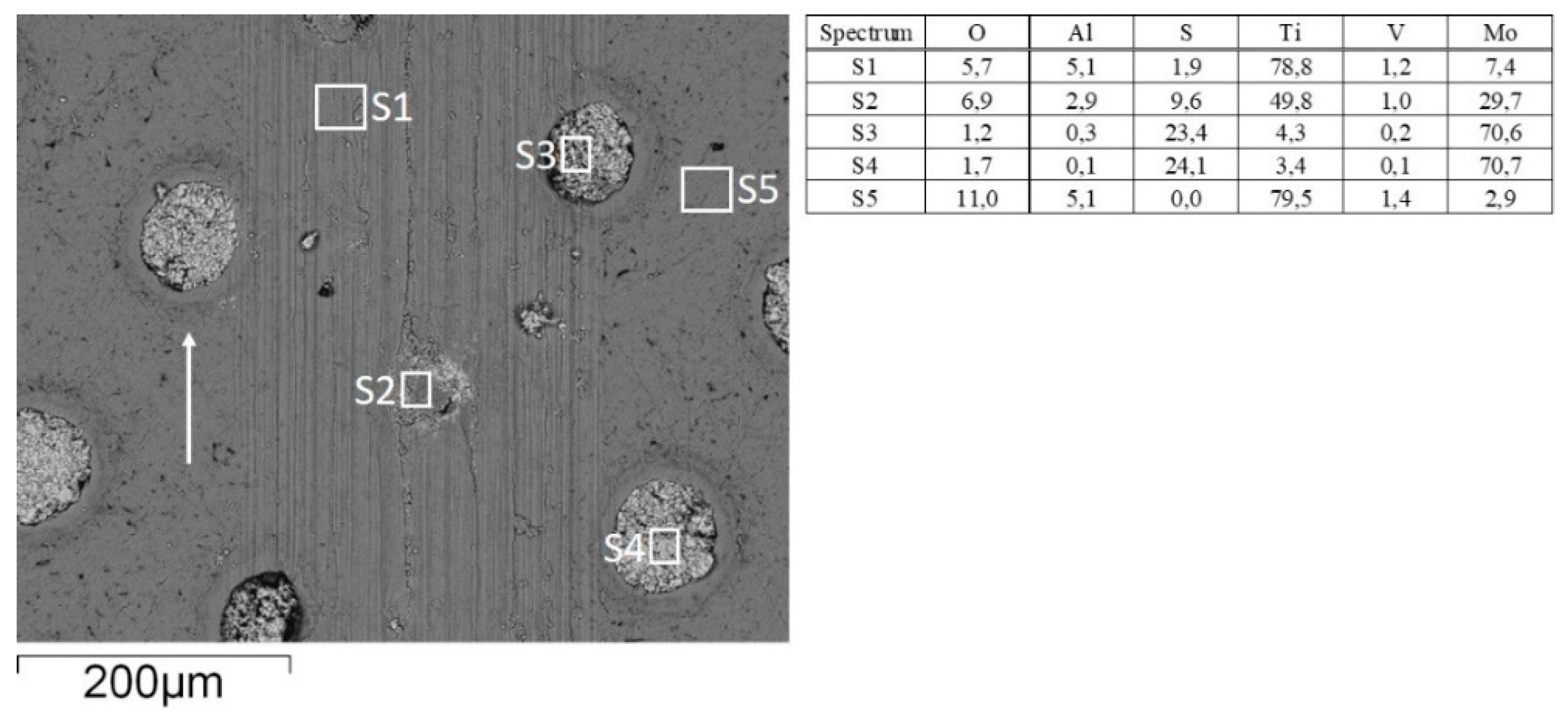

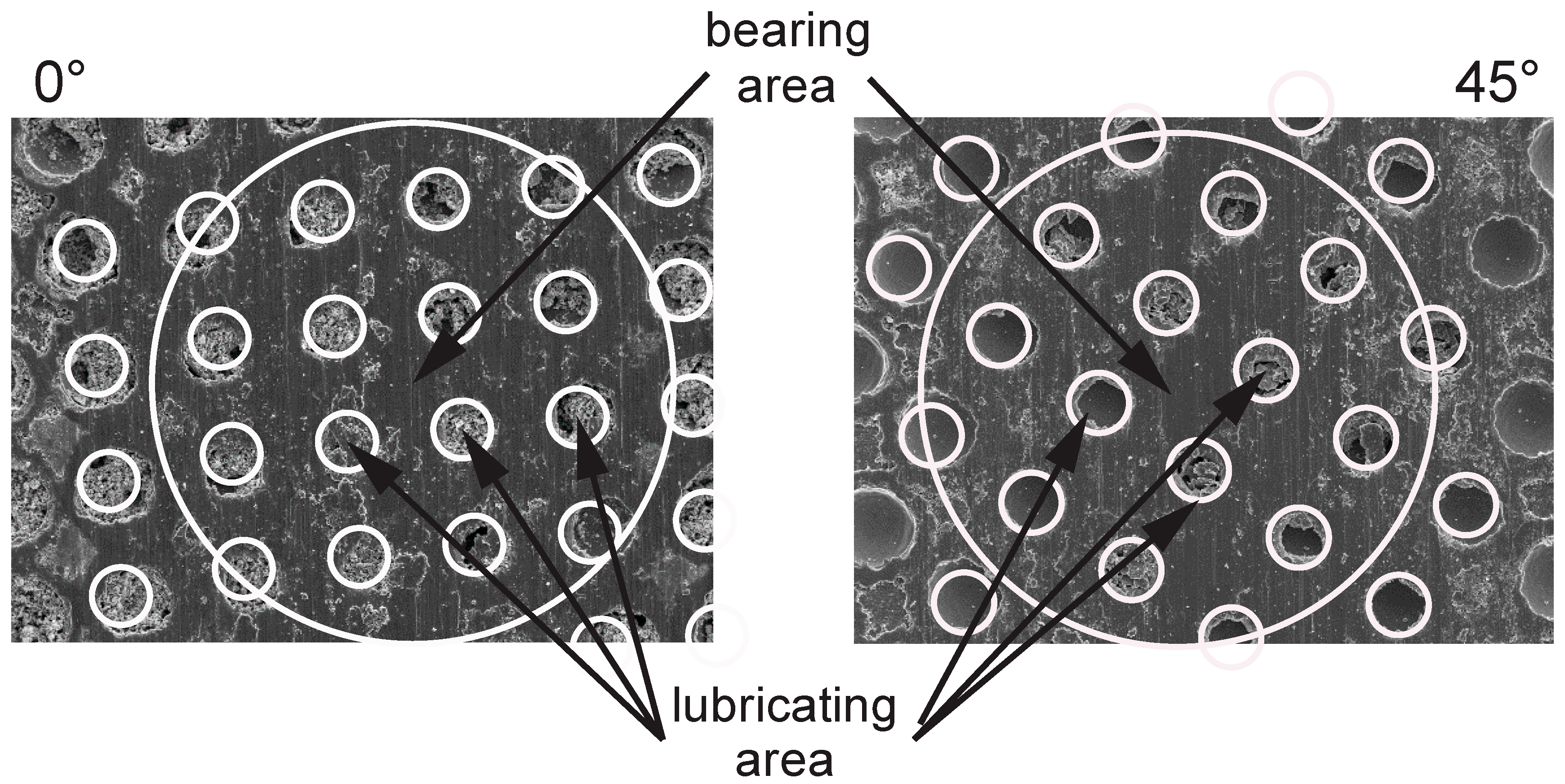

3.2.2. Wear

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meng, Y.; Xu, J.; Jin, Z.; Prakash, B.; Hu, Y. A review of recent advances in tribology. Friction 2020, 8, 221–300. [Google Scholar] [CrossRef] [Green Version]

- Khadem, M.; Penkov, O.V.; Yang, H.-K.; Kim, D.-E. Tribology of multilayer coatings for wear reduction: A review. Friction 2017, 5, 248–262. [Google Scholar] [CrossRef] [Green Version]

- Babu, D.P.; Vignesh, S.; Vignesh, M.; Balamurugan, C. Enhancement of wear resistance of Ti-6Al-4V alloy by picosecond laser surface micro texturing process. J. Cent. South Univ. 2018, 25, 1836–1848. [Google Scholar] [CrossRef]

- Salguero, J.; Del Sol, I.; Vazquez-Martinez, J.M.; Schertzer, M.J.; Iglesias, P. Effect of laser parameters on the tribological behavior of Ti6Al4V titanium microtextures under lubricated conditions. Wear 2019, 426–427, 1272–1279. [Google Scholar] [CrossRef]

- Zhu, Y.; Zou, J.; Chen, X.; Yang, H. Tribology of selective laser melting processed parts: Stainless steel 316 L under lubricated conditions. Wear 2016, 350–351, 46–55. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Dai, Y.; Luo, J. Tribological properties of titanium alloys under lubrication of SEE oil and aqueous solutions. Tribol. Int. 2017, 109, 40–47. [Google Scholar] [CrossRef]

- Amanov, A.; Sasaki, S. A study on the tribological characteristics of duplex-treated Ti–6Al–4V alloy under oil-lubricated sliding conditions. Tribol. Int. 2013, 64, 155–163. [Google Scholar] [CrossRef]

- Zhou, F.; Wang, X.; Kato, K.; Dai, Z. Friction and wear property of a-CNx coatings sliding against Si3N4 balls in water. Wear 2007, 63, 1253–1258. [Google Scholar] [CrossRef]

- Matta, C.; Joly-Pottuz, L.; De Barros Bouchet, M.I.; Martin, J.M.; Kano, M.; Zhang, Q.; Goddard, W.A., III. Superlubricity and tribochemistry of polyhydric alcohols. Phys. Rev. B 2008, 78, 085436. [Google Scholar] [CrossRef] [Green Version]

- Klein, J.; Kumacheva, E.; Mahalu, D.; Perahia, D.; Fetters, L.J. Reduction of frictional forces between solid surfaces bearing polymer brushes. Nature 1994, 370, 634–636. [Google Scholar] [CrossRef]

- Guo, Z.-W.; Yuan, C.-Q.; Bai, X.-Q.; Yan, X.-P. Experimental Study on Wear Performance and Oil Film Characteristics of Surface Textured Cylinder Liner in Marine Diesel Engine. Chin. J. Mech. Eng. 2018, 31, 52. [Google Scholar] [CrossRef] [Green Version]

- Nosonovsky, M.; Bhushan, B. Green tribology: Principles, research areas and challenges. Trans. Trans. Soc. A 2010, 368, 4677–4694. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sahu, J.; Panda, K.; Gupta, B.; Kumar, N.; Manojkumar, P.A.; Kamruddin, M. Enhanced tribo-chemical properties of oxygen functionalized mechanically exfoliated hexagonal boron nitride nanolubricant additives. Mater. Chem. Phys. 2018, 207, 412–422. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, Z.; Dearn, K.D.; Dong, Y.; You, T.; Hu, X. Thermo-tribological behaviour of microgels for improved aqueous lubrication for steel/UHMWPE contact. Tribol. Int. 2019, 130, 63–73. [Google Scholar] [CrossRef]

- Wojciechowski, L.; Kubiak, K.J.; Mathia, T.G. Roughness and wettability of surfaces in boundary lubricated scuffing wear. Tribol. Int. 2016, 93, 593–601. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Shen, M.X.; Cai, Z.B.; Peng, J.F.; Zhu, M.H. Study on dual rotary fretting wear behavior of Ti6Al4V titanium alloy. Wear 2017, 376–377, 670–679. [Google Scholar] [CrossRef]

- Aniołek, K.; Kupka, M.; Barylski, A. Sliding wear resistance of oxide layers formed on a titanium surface during thermal oxidation. Wear 2016, 356–357, 23–29. [Google Scholar] [CrossRef]

- Vazquez-Martinez, J.M.; Botana, M.; Botana, F.J.; Del Sol, I.; Salguero, J.; Marcos, M. Thermal laser oxidation based texturing as finishing treatment for improving surface properties of UNS R56400. Procedia Manuf. 2017, 13, 372–379. [Google Scholar] [CrossRef]

- Hu, T.; Hu, L. Tribological Properties of Lubricating Films on the Al-Si Alloy Surface via Laser Surface Texturing. Tribol. Trans. 2011, 54, 800–805. [Google Scholar] [CrossRef]

- Grabowski, A.; Florian, T.; Wieczorek, J.; Adamiak, M. Structuring of the Ti6Al4V alloy surface by pulsed laser remelting. Appl. Surf. Sci. 2021, 535, 147618. [Google Scholar] [CrossRef]

- Surya, M.S.; Prasanthi, G.; Kumar AKSridhar, V.K.; Gugulothu, S.K. Optimization of cutting parameters while turning Ti6Al4V using response surface methodology and machine learning technique. Int. J. Interact. Des. Manuf. 2021, 15, 453–462. [Google Scholar] [CrossRef]

- Bhaduri, D.; Batal, A.; Dimov, S.S.; Zhang, Z.; Dong, H.; Fallqvist, M.; M’Saoubi, R. On Design and Tribological Behaviour of Laser Textured Surfaces. Procedia CIRP 2017, 60, 20–25. [Google Scholar] [CrossRef]

- Liang, L.; Yuan, J.; Li, X.; Yang, F.; Jiang, L. Wear behavior of the micro-grooved texture on WC-Ni3Al cermet prepared by laser surface texturing. Int. J. Refract. Met. Hard Mater. 2018, 72, 211–222. [Google Scholar] [CrossRef]

- Manuel Vazquez Martinez, J.; Del Sol Illana, I.; Iglesias Victoria, P.; Salguero, J. Assessment the Sliding Wear Behavior of Laser Microtexturing Ti6Al4V under Wet Conditions n.d. Coatings 2019, 9, 67. [Google Scholar] [CrossRef] [Green Version]

- Conradi, M.; Kocijan, A.; Klobčar, D.; Podgornik, B. Tribological response of laser-textured Ti6Al4V alloy under dry conditions and lubricated with Hank’s solution. Tribol. Int. 2021, 160, 107049–107058. [Google Scholar] [CrossRef]

- Kogovšek, J.; Remškar, M.; Mrzel, A.; Kalin, M. Influence of surface roughness and running-in on the lubrication of steel surfaces with oil containing MoS2 nanotubes in all lubrication regimes. Tribol. Int. 2013, 61, 40–47. [Google Scholar] [CrossRef]

- Conradi, M.; Kocijan, A.; Klobčar, D.; Godec, M. Influence of Laser Texturing on Microstructure, Surface and Corrosion Properties of Ti-6Al-4V. Metals 2020, 10, 1504. [Google Scholar] [CrossRef]

- Wang, X.; Adachi, K.; Otsuka, K.; Kato, K. Optimization of the surface texture for silicon carbide sliding in water. Appl. Surf. Sci 2006, 253, 1282–1286. [Google Scholar] [CrossRef]

- Kovalchenko, A.; Ajayi, O.; Erdemir, A.; Fenske, G.; Etsion, I. The Effect of Laser Texturing of Steel Surfaces and Speed-Load Parameters on the Transition of Lubrication Regime from Boundary to Hydrodynamic. Tribol. Trans. 2004, 47, 299–307. [Google Scholar] [CrossRef]

- Sahoo, R.R.; Biswas, S.K. Deformation and friction of MoS2 particles in liquid suspensions used to lubricate sliding contact. Thin Solid Films 2010, 518, 5995–6005. [Google Scholar] [CrossRef]

- Jazaa, Y.; Lan, T.; Padalkar, S.; Sundararajan, S. The Effect of Agglomeration Reduction on the Tribological Behavior of WS2 and MoS2 Nanoparticle Additives in the Boundary Lubrication Regime. Lubricatns 2018, 6, 106. [Google Scholar] [CrossRef] [Green Version]

- Vakili-Nezhaad, G.; Dorany, A. Effect of Single-Walled Carbon Nanotube on the Viscosity of Lubricants. Energy Procedia 2012, 14, 512–517. [Google Scholar] [CrossRef] [Green Version]

- Wagner, J.J.; Jenson, A.D.; Sundararajan, S. The effect of contact pressure and surface texture on running-in behavior of case carburized steel under boundary lubrication. Wear 2017, 376–337, 7851–7857. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Conradi, M.; Podgornik, B.; Kocijan, A.; Remškar, M.; Klobčar, D. Water versus Oil Lubrication of Laser-Textured Ti6Al4V Alloy upon Addition of MoS2 Nanotubes for Green Tribology. Materials 2022, 15, 2974. https://doi.org/10.3390/ma15092974

Conradi M, Podgornik B, Kocijan A, Remškar M, Klobčar D. Water versus Oil Lubrication of Laser-Textured Ti6Al4V Alloy upon Addition of MoS2 Nanotubes for Green Tribology. Materials. 2022; 15(9):2974. https://doi.org/10.3390/ma15092974

Chicago/Turabian StyleConradi, Marjetka, Bojan Podgornik, Aleksandra Kocijan, Maja Remškar, and Damjan Klobčar. 2022. "Water versus Oil Lubrication of Laser-Textured Ti6Al4V Alloy upon Addition of MoS2 Nanotubes for Green Tribology" Materials 15, no. 9: 2974. https://doi.org/10.3390/ma15092974

APA StyleConradi, M., Podgornik, B., Kocijan, A., Remškar, M., & Klobčar, D. (2022). Water versus Oil Lubrication of Laser-Textured Ti6Al4V Alloy upon Addition of MoS2 Nanotubes for Green Tribology. Materials, 15(9), 2974. https://doi.org/10.3390/ma15092974