Assessment of Woodcrete Using Destructive and Non-Destructive Test Methods

Abstract

1. Introduction

2. Materials and Methods

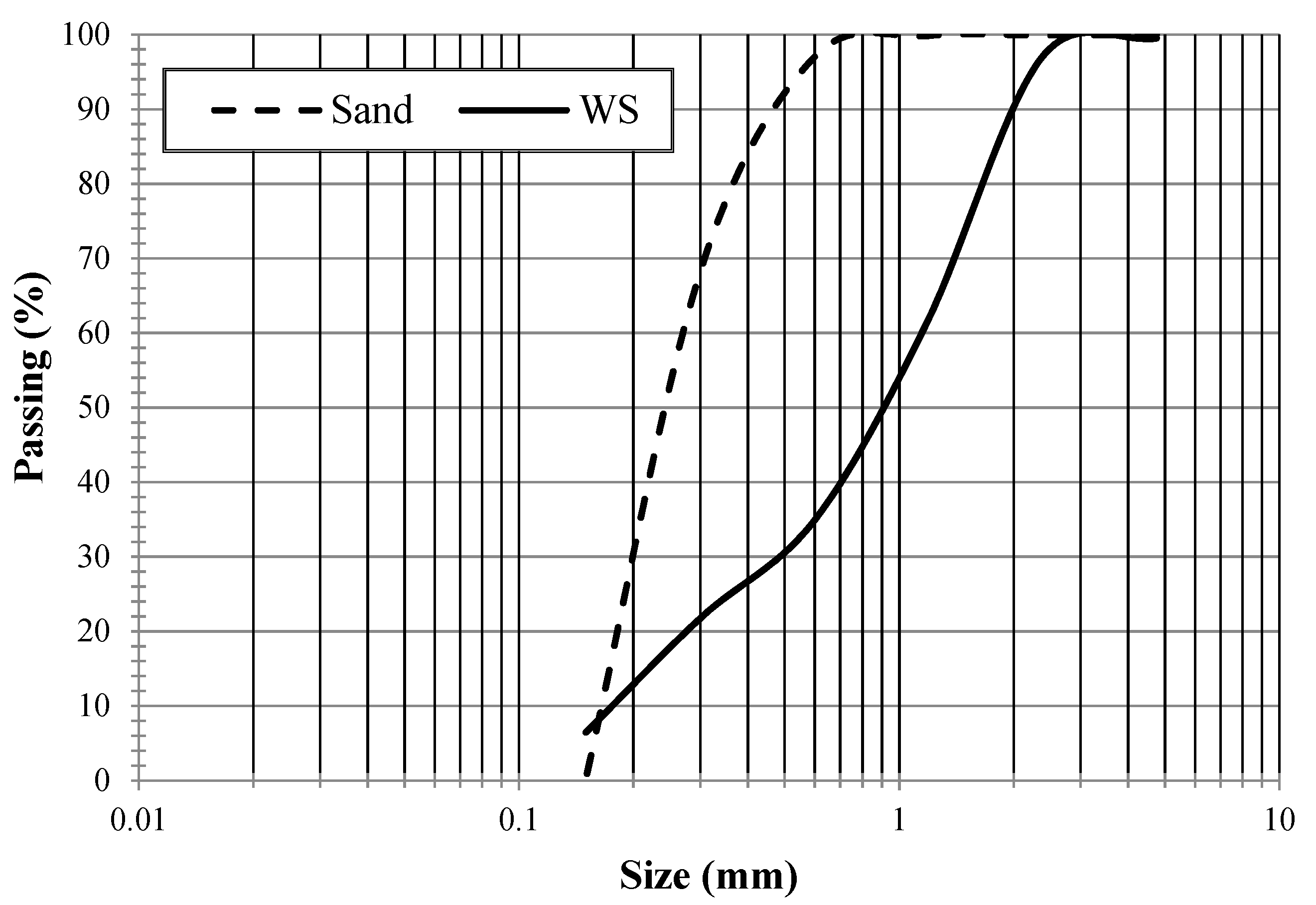

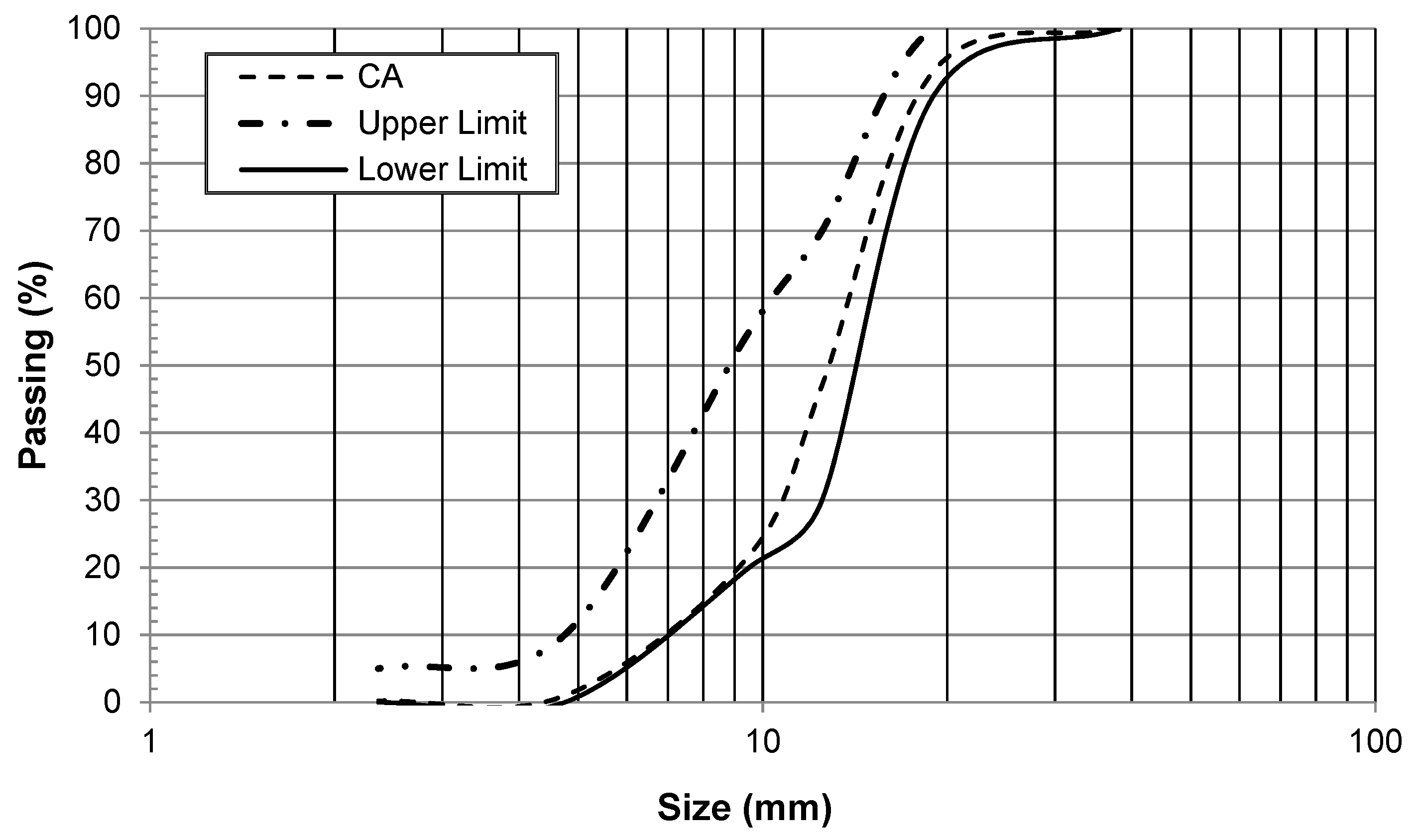

2.1. Materials Utilized

2.2. Methodology

2.3. Test Procedures

2.3.1. Ultrasonic Pulse Velocity Test (UPV)

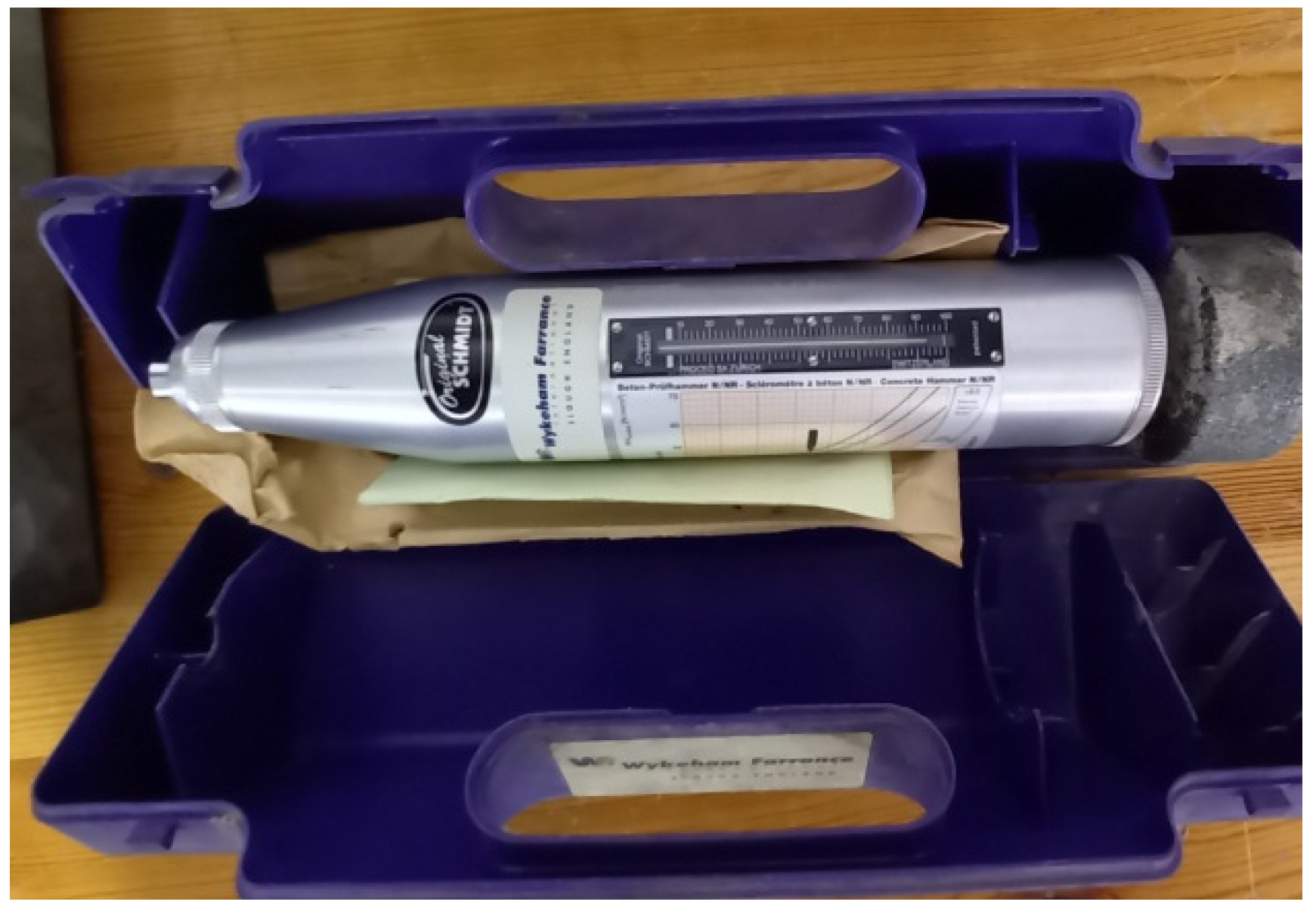

2.3.2. Rebound Hammer Test

2.3.3. Compressive Test

3. Results and Discussion

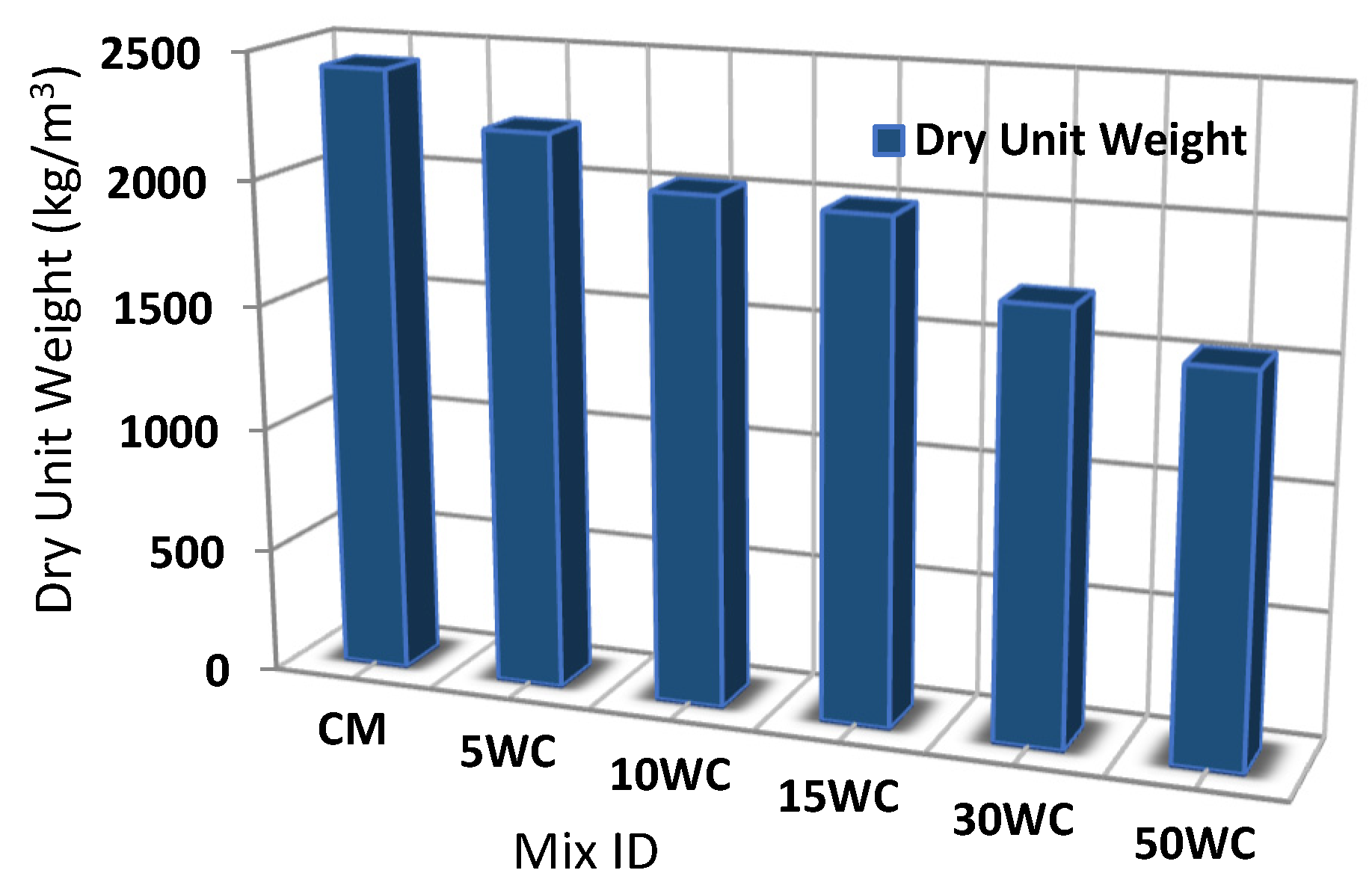

3.1. The Effect of Wood Shavings on Dry Unit Weight

3.2. The Effect of Wood Shavings on Absorption

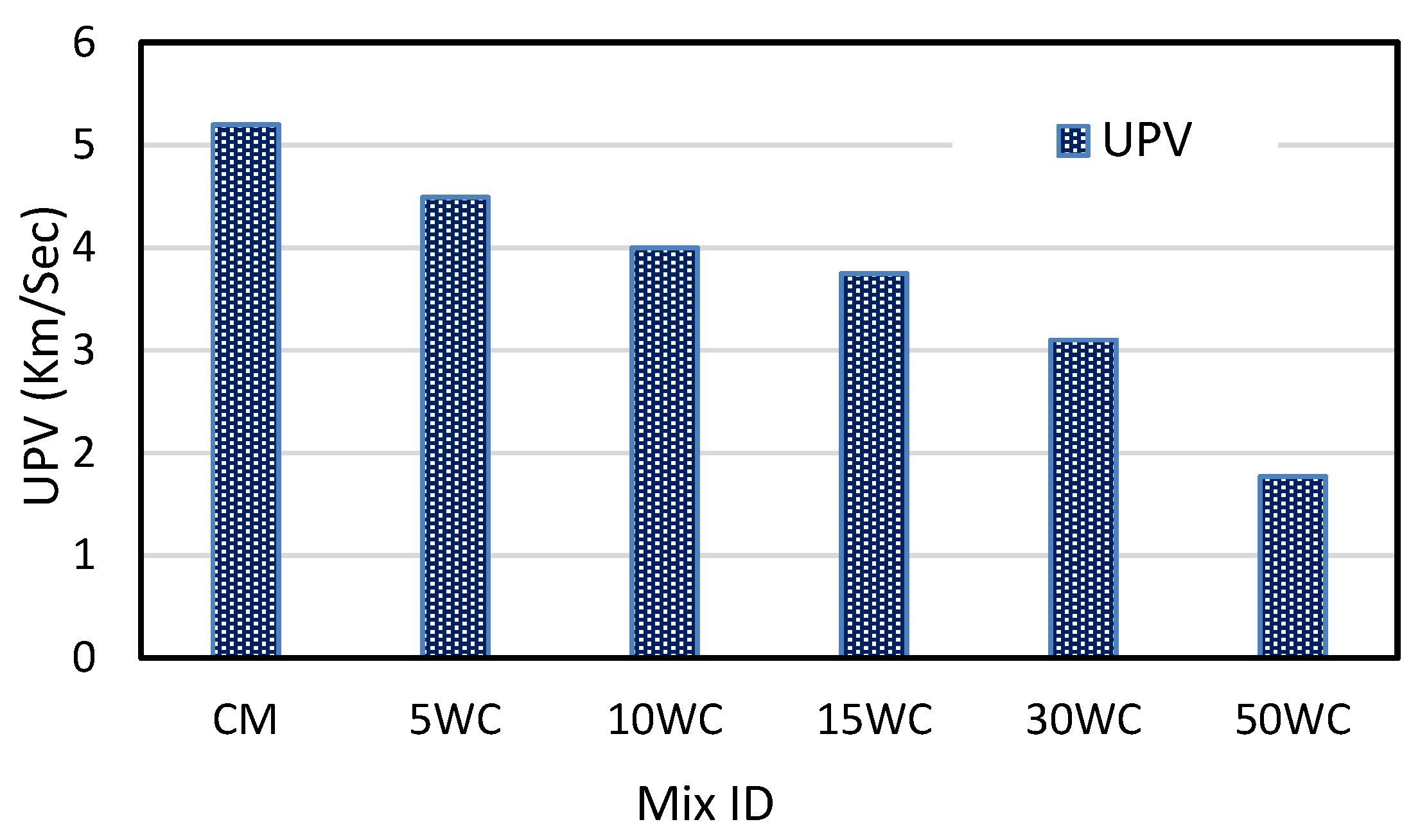

3.3. The Effect of Wood Shavings on Ultra Pulse Velocity

3.4. The Effect of Wood Shavings on Rebound Number

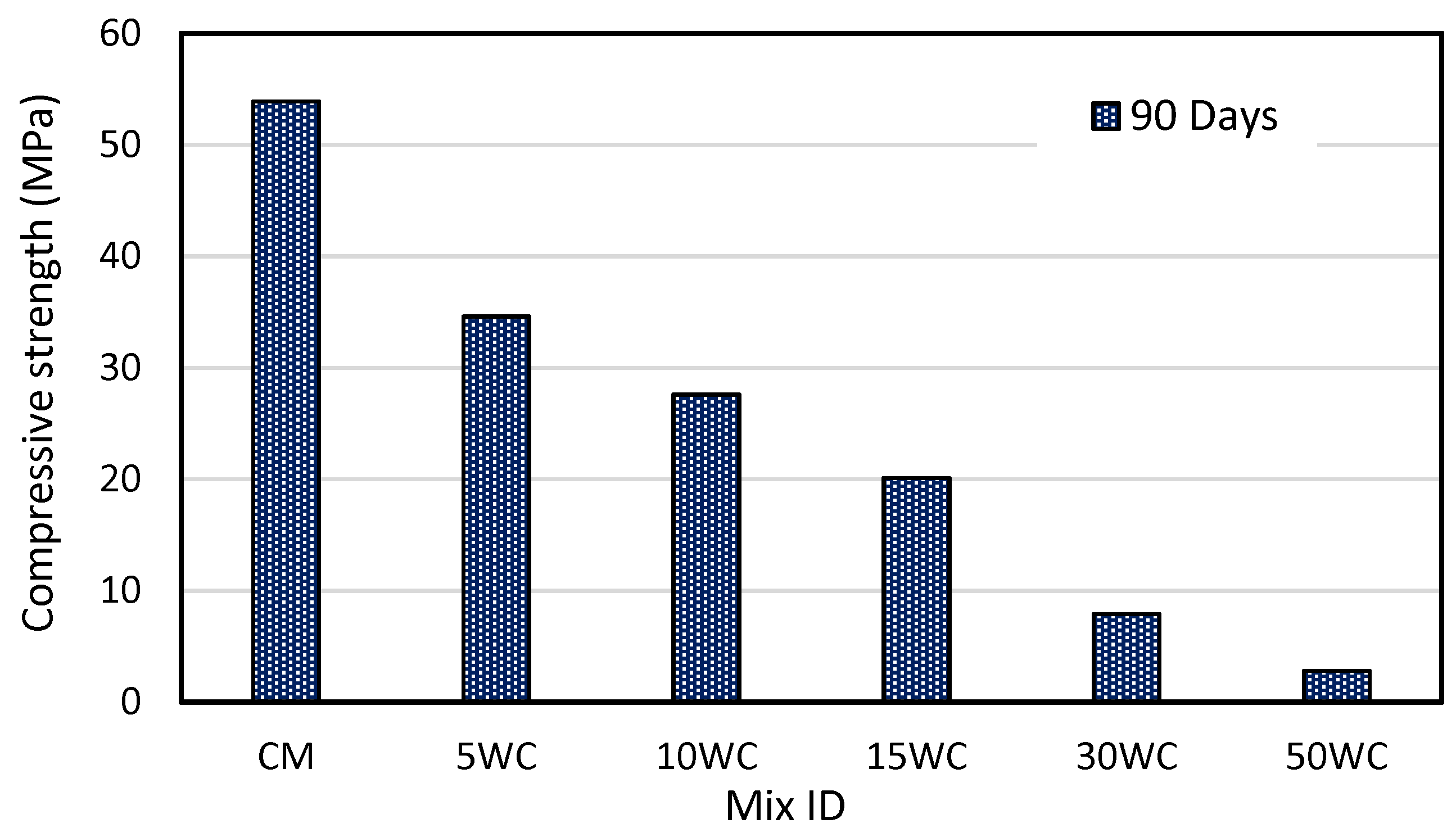

3.5. The Effect of Wood Shavings on Compressive Strength

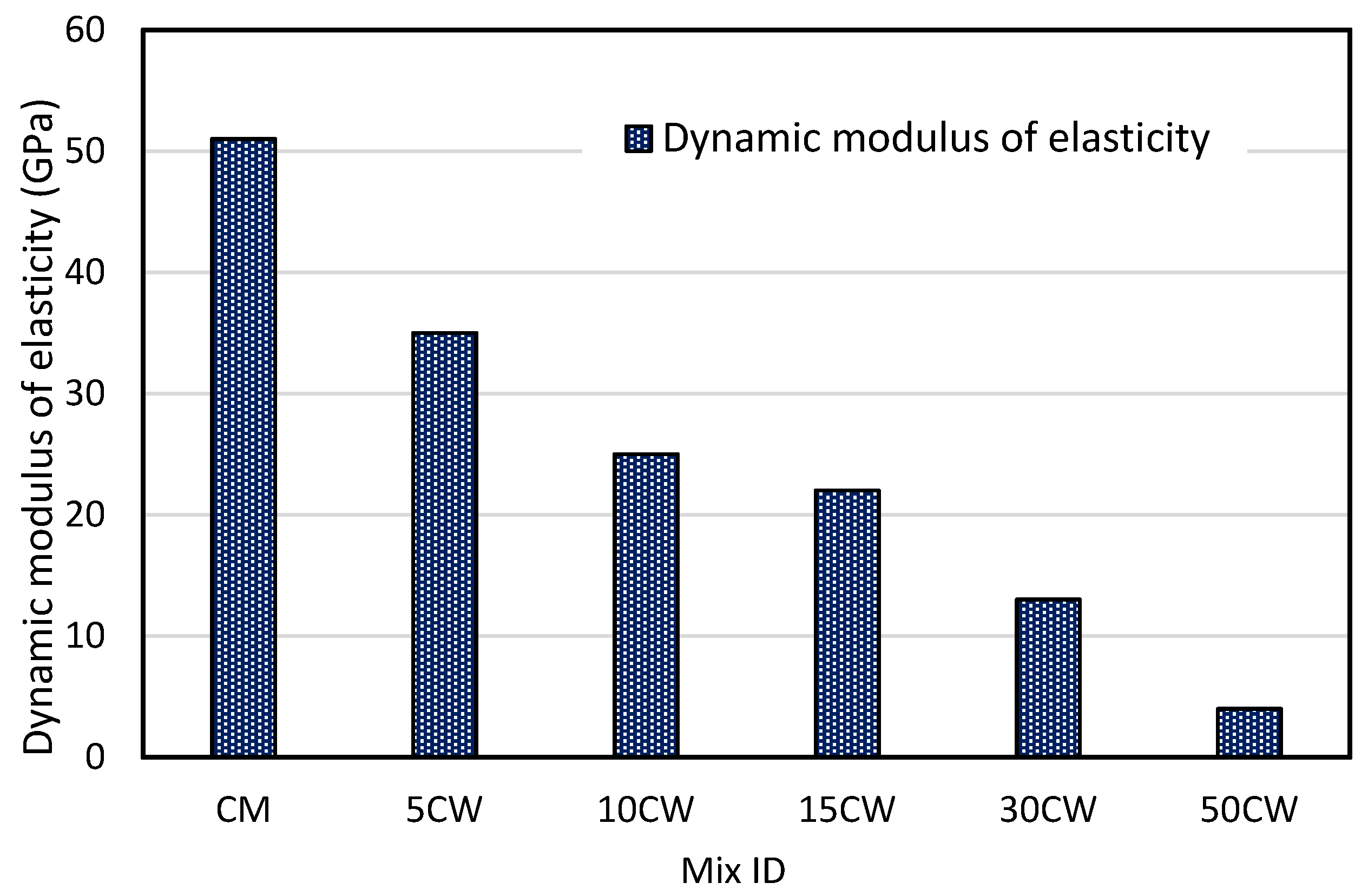

3.6. The Effect of WS on the Dynamic Modulus of Elasticity

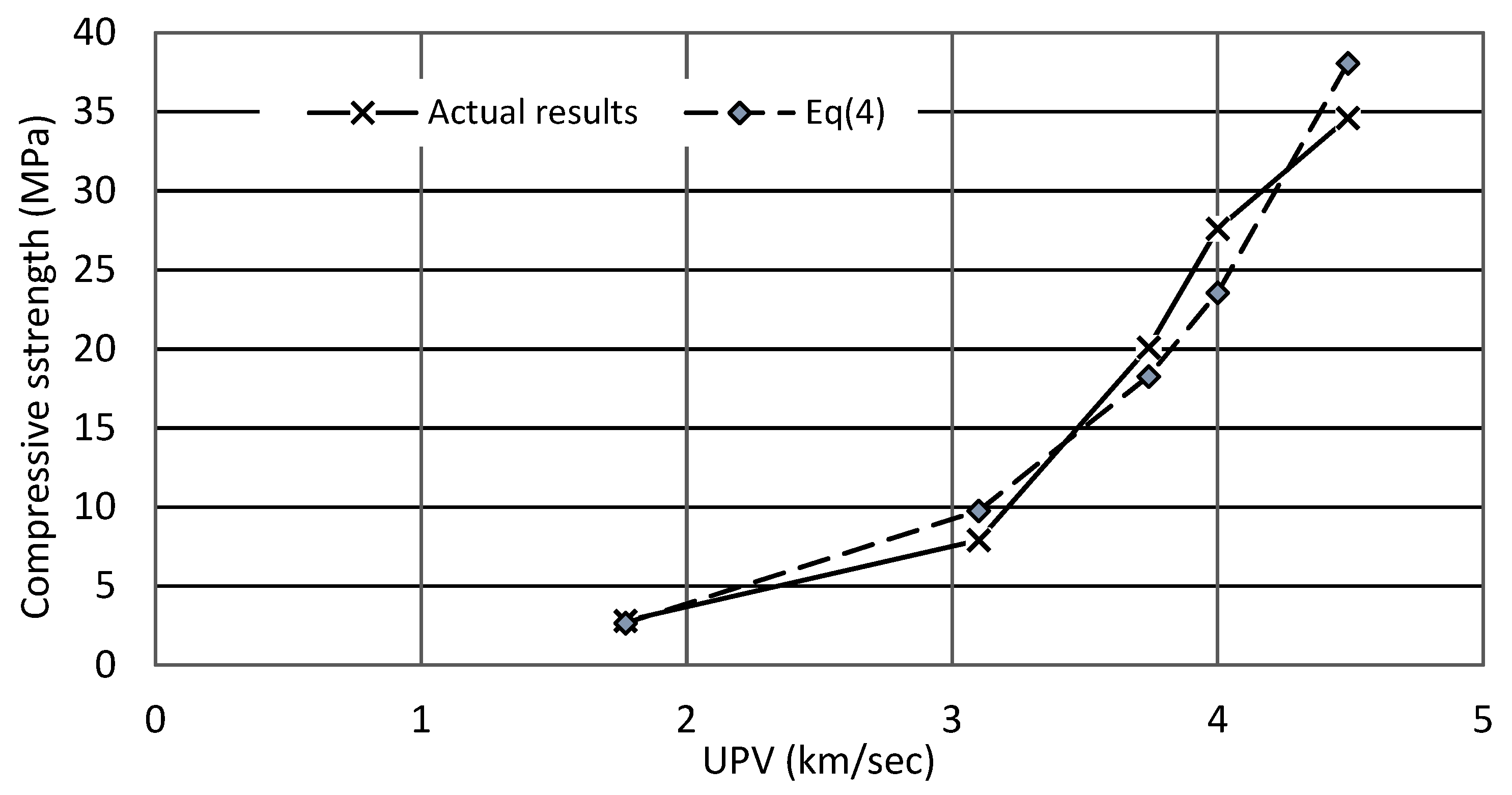

3.7. Relation between Compressive Strength and UPV

3.8. Relation between Compressive Strength and Rebound Hammer Strength

3.9. Combined Methods Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Poole, A.; Sims, I. Geology, Aggregates and Classification. Advanced Concrete Technology-Constituent Materials; Newman, J., Seng-Choo, B., Eds.; Elsevier Ltd.: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Fadiel, A. A review of properties of concrete containing crumb rubber from used tires. In Proceedings of the 13th Arab Structural Engineering Conference, Blida, Algeria, 13–15 December 2015. (In Arabic). [Google Scholar]

- Özkan, Ö.; Yüksel, I.; Muratoğlu, Ö. Strength properties of concrete incorporating coal bottom ash and granulated blast furnace slag. Waste Manag. 2007, 27, 161–167. [Google Scholar] [CrossRef] [PubMed]

- Lim, S.K.; Tan, C.S.; Li, B.; Ling, T.C.; Hossain, M.U.; Poon, C.S. Utilizing high volumes quarry wastes in the production of lightweight foamed concrete. Constr. Build. Mater. 2017, 151, 441–448. [Google Scholar] [CrossRef]

- Singh, M.; Choudhary, K.; Srivastava, A.; Sangwan, K.S.; Bhunia, D. A study on environmental and economic impacts of using waste marble powder in concrete. J. Build. Eng. 2017, 13, 87–95. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Abdullahi, M.; Hoong, C.K. Statistical models for concrete containing wood chipping as partial replacement to fine aggregate. Constr. Build. Mater. 2014, 55, 13–19. [Google Scholar] [CrossRef]

- Islam, G.S.; Rahman, M.; Kazi, N. Waste glass powder as partial replacement of cement for sustainable concrete practice. Int. J. Sustain. Built Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Mazzoli, A.; Siddique, R. Characterization of lightweight mortars containing wood processing by-products waste. Constr. Build. Mater. 2016, 123, 281–289. [Google Scholar] [CrossRef]

- Ashish, D.K. Feasibility of waste marble powder in concrete as partial substitute ion of cement and sand amalgam for sustainable growth. J. Build. Eng. 2018, 15, 236–242. [Google Scholar] [CrossRef]

- Abu-Lebdeh, T.; Fini, E.; Fadiel, A. Thermal conductivity of rubberized gypsum board. Am. J. Eng. Appl. Sci. 2014, 7, 12–22. [Google Scholar] [CrossRef]

- Fadiel, A.; Abu-Lebdeh, T. Mechanical Properties of Concrete Including Wood Shavings as Fine Aggregates. Am. J. Eng. Appl. Sci. 2021, 14, 478–487. [Google Scholar] [CrossRef]

- Fadiel, A. Use of Crumb Rubber to Improve Thermal Efficiency of Construction Materials. Master’s Thesis, North Carolina A&T State University, Greensboro, NC, USA, 2013. [Google Scholar]

- Fadiel, A.; Al Rifaie, F.; Abu-Lebdeh, T.; Fini, E. Use of crumb rubber to improve thermal efficiency of cement-based materials. Am. J. Eng. Appl. Sci. 2014, 7, 1–11. [Google Scholar] [CrossRef]

- Zheng, L.; Huo, X.S.; Yuan, Y. Strength, modulus of elasticity, and brittleness index of rubberized concrete. J. Mater. Civ. Eng. 2008, 20, 692–699. [Google Scholar] [CrossRef]

- Ganjian, E.; Khorami, M.; Maghsoudi, A.A. Scrap-tyre-rubber replacement for aggregate and filler in concrete. Constr. Build. Mater. 2009, 23, 1828–1836. [Google Scholar] [CrossRef]

- Agar-Ozbek, A.S.; Weeheijim, J.; Schlangen, E.; Bruegel, K.V. Investigating porous concrete with improved strength: Testing at different scales. Constr. Build. Mater. 2013, 41, 480–490. [Google Scholar] [CrossRef]

- Belytschko, T.; Black, T. Elastic crack growth in finite element with minimal remeshing. Int. J. Numer. Methods Eng. 1999, 45, 601–620. [Google Scholar] [CrossRef]

- Brake, N.A.; Allahdadi, H.; Adam, F. Flexural strength and fracture size effects of pervious concrete. Constr. Build. Mater. 2016, 113, 536–543. [Google Scholar] [CrossRef]

- Deppe, H.J. On the production and application of cement-bonded wood chipboards. In Proceedings of the 8th Washington State Symposium on Particleboard, Pullman, WA, USA, 26–28 March1974; pp. 267–286. [Google Scholar]

- Gunasekaran, K.; Annadurai, R.; Kumar, P.S. Study on reinforced lightweight coconut shell concrete beam behavior under flexure. Mater. Des. 2013, 46, 157–167. [Google Scholar] [CrossRef]

- Hameury, S.; Lundstrôm, T. Contribution of indoor exposed massive wood to a good indoor climate: In situ measurement campaign. Energy Build. 2004, 36, 281–292. [Google Scholar] [CrossRef]

- Kaya, F.K. Thermal and mechanical properties of concretes with styropor. J. Appl. Math. Phys. 2014, 2, 310–315. [Google Scholar] [CrossRef][Green Version]

- Kevern, J.T.; Biddle, D.; Cao, Q. Effects of macro synthetic fibers on pervious concrete properties. J. Mater. Civ. Eng. 2015, 27, 06014031. [Google Scholar] [CrossRef]

- Khelifa, M.; Auchet, S.; Méausoone, P.-J.; Celzard, A. Finite element analysis of flexural strengthening of timber beams with carbon fiber-reinforced polymers. Eng. Struct. 2015, 101, 364–375. [Google Scholar] [CrossRef]

- Koohestani, B.; Koubaa, A.; Tikou, B.T.; Bussière, B.; Bouzahzah, H. Experimental investigation of mechanical and microstructural properties of cemented paste backfill containing maple-wood filler. Constr. Build. Mater. 2016, 121, 222–228. [Google Scholar] [CrossRef]

- Kunzel, H.M.; Holm, A.; Sedlbauer, K.; Antretter, F.; Ellinger, M. Moisture Buffering Effect of Interior Linings Made from Wood or Wood-Based Products; IBP Report HTB-04/2004/e; Fraunhofer-Institute for Building Physics: Stuttgart, Germany, 2004. [Google Scholar]

- Machín, A.; Fontánez, K.; Arango, J.C.; Ortiz, D.; De León, J.; Pinilla, S.; Nicolosi, V.; Petrescu, F.I.; Morant, C.; Márquez, F. One-Dimensional (1D) Nanostructured Materials for Energy Applications. Materials 2021, 14, 2609. [Google Scholar] [CrossRef] [PubMed]

- Naik, T.R.; Kraus, R.N.; Siddique, R. CLSM containing mixtures of coal ash and a new pozzolanic material. ACI Mater. J. 2003, 100, 208–215. [Google Scholar]

- Okino, E.Y.A.; Souza, M.R.; Santana, M.A.E.; Alves, M.V.S.; Sousa, M.E.; Teixeira, D.E. Cement-bonded wood particleboard with a mixture of eucalypt and rubberwood. Cem. Concr. Compos. 2004, 26, 729–734. [Google Scholar] [CrossRef]

- Prusty, J.K.; Patro, S.K. Properties of fresh and hardened concrete using agro-waste as partial replacement of coarse aggregate—A review. Constr. Build. Mater. 2015, 82, 101–113. [Google Scholar] [CrossRef]

- Siddique, R. Utilization of wood ash in concrete manufacturing. Resour. Conserv. Recycl. 2012, 67, 27–33. [Google Scholar] [CrossRef]

- Sudin, R.; Swamy, N. Bamboo and wood fibre cement composites for sustainable infrastructure regeneration. J. Mater. Sci. 2006, 41, 6917–6924. [Google Scholar] [CrossRef]

- Tittelein, P.; Cloutier, A.; Bissonnette, B. Design of a low-density wood-cement particleboard for interior wall finish. Cem. Concr. Compos. 2012, 34, 218–222. [Google Scholar] [CrossRef]

- Udoeyo, F.F.; Inyang, H.; Young, D.T.; Oparadu, E.E. Potential of wood waste ash as an additive in concrete. J. Mater. Civ. Eng. 2006, 18, 605–611. [Google Scholar] [CrossRef]

- Nagrockienė, D.; Daugėla, A. Investigation into the properties of concrete modified with biomass combustion fly ash. Constr. Build. Mater. 2018, 174, 369–375. [Google Scholar] [CrossRef]

- Praveenkumar, T.R.; Vijayalakshmi, M.M.; Meddah, M.S. Strengths and durability performances of blended cement concrete with TiO2 nanoparticles and rice husk ash. Constr. Build. Mater. 2019, 217, 343–351. [Google Scholar] [CrossRef]

- Raheem, A.A.; Ige, A.I. Chemical composition and physicomechanical characteristics of sawdust ash blended cement. J. Build. Eng. 2019, 21, 404–408. [Google Scholar] [CrossRef]

- Ren, J.; Lai, Y.; Gao, J. Exploring the influence of SiO2 and TiO2 nanoparticles on the mechanical properties of concrete. Constr. Build. Mater. 2018, 175, 277–285. [Google Scholar] [CrossRef]

- Ikotun, B.D.; Raheem, A.A. Characteristics of Wood Ash Cement Mortar Incorporating Green-Synthesized Nano-TiO2. Int. J. Concr. Struct. Mater. 2021, 15, 19. [Google Scholar] [CrossRef]

- Coxworth, B. Wood Waste Makes Recycled Concrete Stronger Than Ever. 2020. Available online: https://newatlas.com/environment/wood-waste-recycled-concrete/ (accessed on 1 January 2022).

- Bederina, M.; Laidoudi, B.; Goullieux, A.; Khenfer, M.M.; Bali, A.; Queneudec, M. Effect of the treatment of wood shavings on the physico-mechanical characteristics of wood sand concretes. Construct. Build. Mater. 2009, 23, 1311–1315. [Google Scholar] [CrossRef]

- ASTM C597-09; Standard Test Method for Pulse Velocity through Concrete. ASTM International: West Conshohocken, PA, USA, 2009.

- Trtnik, G.; Kavčič, F.; Turk, G. Prediction of concrete strength using ultrasonic pulse velocity and artificial neural networks. Ultrasonics 2009, 49, 53–60. [Google Scholar] [CrossRef]

- Helal, J.; Sofi, M.; Mendis, P. Non-destructive testing of concrete: A review of methods. Electron. J. Struct. Eng. 2015, 14, 97–105. [Google Scholar]

- Lee, B.J.; Kee, S.H.; Oh, T.; Kim, Y.Y. Evaluating the dynamic elastic modulus of concrete using shear-wave velocity measurements. Adv. Mater. Sci. Eng. 2017, 2017, 1651753. [Google Scholar] [CrossRef]

- Ndagi, A.; Umar, A.A.; Hejazi, F.; Jaafar, M.S. Non-destructive assessment of concrete deterioration by ultrasonic pulse velocity: A review. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 357, p. 012015. [Google Scholar]

- ASTM C805/C805M-08; Standard Test Method for Rebound Number of Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2018.

- Neville, M. Properties of Concrete: Fourth and Final Edition, 4th ed.; Wiley: Hoboken, NJ, USA, 1996; 844p, ISBN 978-0470235270. Available online: https://www.amazon.com/Properties-Concrete-Adam-M-Neville/dp/0470235276 (accessed on 1 January 2022).

- Shang, H.S.; Yi, T.H.; Yang, L.S. Experimental study on the compressive strength of big mobility concrete with nondestructive testing method. Adv. Mater. Sci. Eng. 2012, 2012, 345214. [Google Scholar] [CrossRef]

- BS EN 12390-3:2009; Testing Hardened Concrete. Part 3: Compressive Strength of Test Specimens. British Standard Institution: London, UK, 2009.

- Qurashi, M.A.; Shah, S.A.R.; Farhan, M.; Taufiq, M.; Khalid, W.; Arshad, H.; Waseem, M. Sustainable Design and Engineering: A Relationship Analysis between Digital Destructive and Non-Destructive Testing Process for Lightweight Concrete. Processes 2019, 7, 791. [Google Scholar] [CrossRef]

- Salman, M.M.; Al-Amawee, A.H. The ratio between static and dynamic modulus of elasticity in normal and high strength concrete. J. Eng. Dev. 2006, 10, 163–174. [Google Scholar]

- Petrescu, R.V.V.; Aversa, R.; Akash, B.; Bucinell, R.; Corchado, J.; Kozaitis, S.P.; Abu-Lebdeh, T.M.; Apicella, A.; Petrescu, F.I.T. Testing by Non-Destructive Control. Am. J. Eng. Appl. Sci. 2017, 10, 568–583. [Google Scholar] [CrossRef][Green Version]

- Duan, Y.; Zhang, H.; Sfarra, S.; Avdelidis, N.P.; Loutas, T.H.; Sotiriadis, G.; Kostopoulos, V.; Fernandes, H.; Petrescu, F.I.; Ibarra-Castanedo, C.; et al. On the Use of Infrared Thermography and Acousto—Ultrasonics NDT Techniques for Ceramic-Coated Sandwich Structures. Energies 2019, 12, 2537. [Google Scholar] [CrossRef]

| Property | Value | Standard |

|---|---|---|

| Normal consistency (%) | 27.5 | --- |

| Initial setting time, (min) | 115 | >45 |

| Final setting time, (min) | 220 | <375 |

| Soundness, (mm) | 1 | <10 |

| Fineness (%) | 94.2 | |

| Specific Gravity | 3.15 | |

| Compressive strength, (MPa) | 3 days = 17 | 12 MPa |

| 7 days = 30.5 | 19 MPa |

| Oxide Composition | Weight (%) |

|---|---|

| CaO | 63.56 |

| SiO2 | 20.29 |

| Al2O3 | 5.65 |

| Fe2O3 | 3.3 |

| MgO | 2.06 |

| SO3 | 2.7 |

| Na2O | 0.19 |

| K2O | 0.85 |

| Cl | 0.007 |

| TiO2 | 0.34 |

| MnO | 0.043 |

| Property | Fine Aggregate | Wood Shavings | Coarse Aggregate |

|---|---|---|---|

| Specific gravity | 2.67 | 1.18 | 2.59 |

| Absorption (%) | 0.3 | 19 | 1.4 |

| Bulk density (kg/m3) | 1767 | 465 | 1534 |

| Impact value (%) | --- | --- | 16.4 |

| Crushing Value | --- | --- | 24 |

| Mix ID | Dry Unit Weight | UPV | Rebound Hammer Strength | Compressive Strength |

|---|---|---|---|---|

| Kg/m3 | Km/Sec | (MPa) | (MPa) | |

| CM | 2426.7 ± 9.9 | 5.2 ± 0.18 | 54.5 ± 0.90 | 53.9 ± 0.25 |

| 5WC | 2217.4 ± 5.13 | 4.49 ± 0.13 | 31 ± 0.90 | 34.6 ± 0.90 |

| 10WC | 2022.7 ± 3.02 | 4 ± 0.23 | 22.5 ± 0.66 | 27.6 ± 0.75 |

| 15WC | 1994.7 ± 3.28 | 3.75 ± 0.07 | 18.8 ± 0.50 | 20.1 ± 1.08 |

| 30WC | 1706 ± 1.55 | 3.1 ± 0.35 | 15.7 ± 0.45 | 7.9 ± 0.66 |

| 50WC | 1530.4 ± 6.07 | 1.77 ± 0.09 | 10 ± 0.50 | 2.8 ± 0.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fadiel, A.A.M.; Abu-Lebdeh, T.; Petrescu, F.I.T. Assessment of Woodcrete Using Destructive and Non-Destructive Test Methods. Materials 2022, 15, 3066. https://doi.org/10.3390/ma15093066

Fadiel AAM, Abu-Lebdeh T, Petrescu FIT. Assessment of Woodcrete Using Destructive and Non-Destructive Test Methods. Materials. 2022; 15(9):3066. https://doi.org/10.3390/ma15093066

Chicago/Turabian StyleFadiel, Ashraf A.M., Taher Abu-Lebdeh, and Florian Ion T. Petrescu. 2022. "Assessment of Woodcrete Using Destructive and Non-Destructive Test Methods" Materials 15, no. 9: 3066. https://doi.org/10.3390/ma15093066

APA StyleFadiel, A. A. M., Abu-Lebdeh, T., & Petrescu, F. I. T. (2022). Assessment of Woodcrete Using Destructive and Non-Destructive Test Methods. Materials, 15(9), 3066. https://doi.org/10.3390/ma15093066