Weldability Assessment of Various Steels by Hard-Facing

Abstract

:1. Introduction

2. Literature Review

3. Theoretical Weldability Estimates and Preheating Temperature Calculations

3.1. Base Metals

3.2. Weldability Estimates and Preheating Temperature Calculations

4. Experimental Investigation on Samples

4.1. The Filler Metals

4.2. Preparation and Hard-Facing of the Samples

5. Results

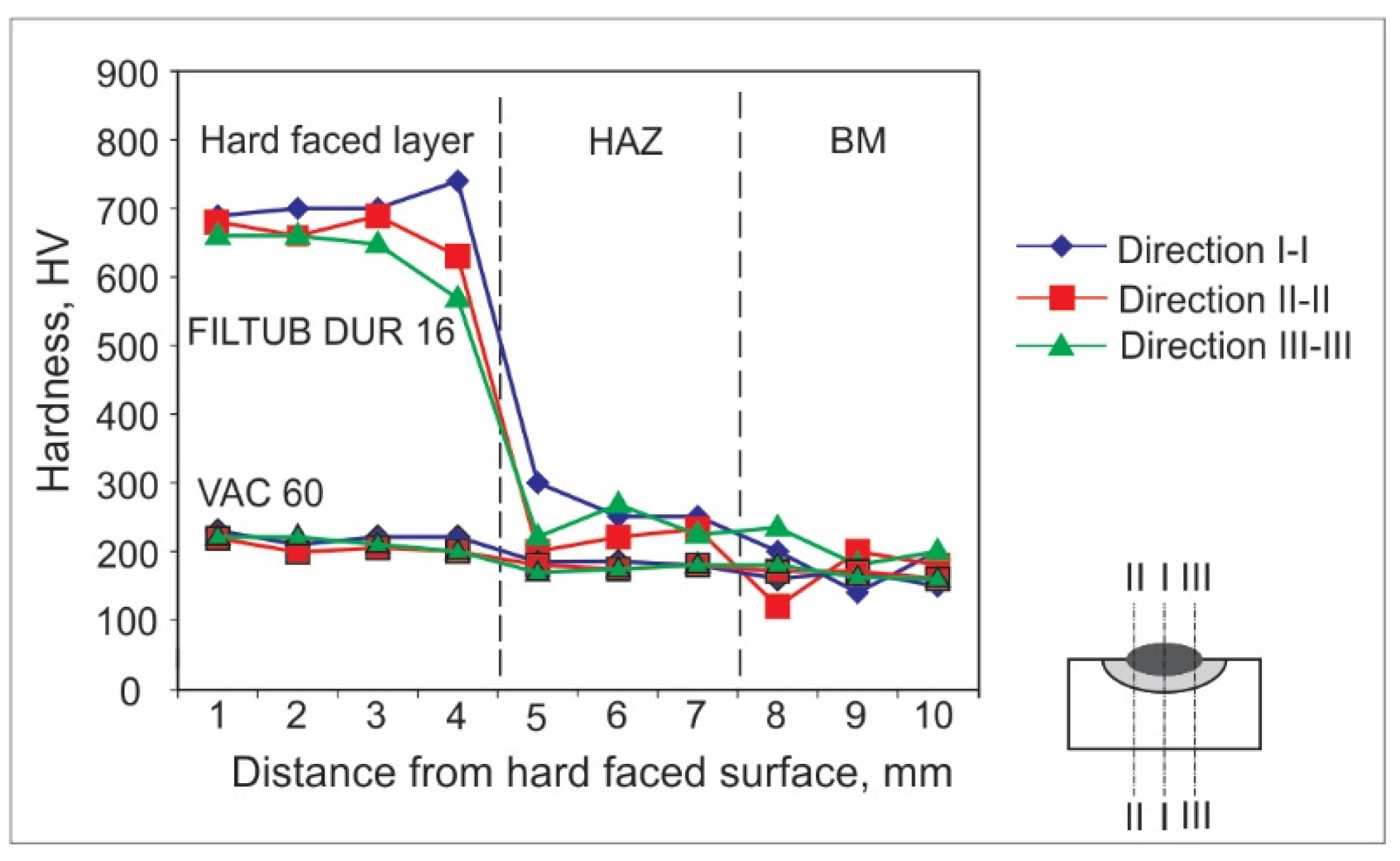

5.1. Hardness Measurements

5.2. Microstructure Analysis

6. Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ilić, M. Theoretical-Experimental Estimation of the Carbon and Alloyed Steels Weldability. Master’s Thesis, Faculty of Engineering, University of Kragujevac, Kragujevac, Serbia, 2021. (In Serbian). [Google Scholar]

- Arsić, D.; Lazić, V.; Sedmak, A.; Nikolić, R.; Aleksandrović, S.; Djordjević, M.; Bakić, R. Selection of the optimal hard-facing (HF) technology of damaged forging dies based on cooling time t8/5. Metalurgija—Metallurgy 2016, 55, 103–106. [Google Scholar]

- Lazić, V.; Arsić, D.; Nikolić, R.R.; Aleksandrović, S.; Djordjević, M.; Hadzima, B. Estimate of weldability and selection of optimal welding technology for the cover of a tube girder made of the C-Mn high strength steel. In Proceedings of the XLIV International conference WELDING 2016, Tatranska Lomnica, Slovakia, 9–11 November 2016. [Google Scholar]

- Arsić, D.; Lazić, V.; Mitrović, S.; Džunić, D.; Aleksandrović, S.; Djordjević, M.; Nedeljković, B. Tribological behavior of four types of filler metals for hard-facing under dry conditions. Ind. Lubr. Trib. 2016, 68, 729–736. Available online: https://www.emerald.com/insight/content/doi/10.1108/ILT-10-2015-0156/full/html (accessed on 11 March 2022). [CrossRef]

- Tolf, E.; Hedegard, J. Resistance nut welding: Improving the weldability and joint properties of ultra high strength steels. Weld. World 2007, 51, 28–36. [Google Scholar] [CrossRef]

- Talas, S. The assessment of carbon equivalent formulas in predicting the properties of steel weld metals. Mat. Des. 2010, 31, 2649–2653. [Google Scholar] [CrossRef]

- Chang, C.; Chen, Y.; Wu, W. Microstructural and abrasive characteristics of high carbon Fe–Cr–C hard-facing alloy. Trib. Int. 2010, 43, 929–934. [Google Scholar] [CrossRef]

- Lin, C.M.; Chang, C.M.; Chen, J.H.; Wu, W. The Effects of additive elements on the microstructure characteristics and mechanical properties of Cr–Fe–C hard-facing alloys. J. Alloys Compd. 2010, 498, 30–36. [Google Scholar] [CrossRef]

- Liu, D.; Liu, R.; Wei, Y.; Ma, Y.; Zhu, K. Microstructure and Wear Properties of Fe–15Cr–2.5Ti–2C–xB wt.% hard-facing alloys. Appl. Surf. Sci. 2013, 271, 253–259. [Google Scholar] [CrossRef]

- Tolf, E. Challenges in Resistance Welding of Ultra High Strength Steels. Licentiate Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2015. [Google Scholar]

- Schipaanboord, W.N.; Marquering, J.; Bruce, W.A. Benefits of low-yield weld filler metals for safe welding on live gas transmission pipelines. Weld. World 2015, 59, 97–118. [Google Scholar] [CrossRef]

- Cabrilo, A.; Geric, K. Weldability of High Hardness armor steel. Adv. Mater. Res. 2016, 1138, 79–84. [Google Scholar] [CrossRef]

- Dobosy, A.; Lukács, J. The effect of the welding parameters on the properties of thermomechanically rolled high strength steels. In Proceedings of the MultiScience—XXX, microCAD International Multidisciplinary Scientific Conference, Miskolc, Hungary, 21–22 April 2016. [Google Scholar] [CrossRef]

- Han, X.; DiGiovanni, C.; McDermid, J.; Biro, E.; Zhou, N.Y. Effect of internal oxidation on the weldability of CMnSi steels. Weld. World 2019, 63, 1633–1639. [Google Scholar] [CrossRef]

- Vicen, M.; Bronček, J.; Nový, F. Investigation of tribological properties of CarbonX coating deposited on 100Cr6 steel. Prod. Eng. Arch. 2019, 25, 52–55. [Google Scholar] [CrossRef] [Green Version]

- Trško, L.; Lago, J.; Jambor, M.; Nový, F.; Bokůvka, O.; Florková, Z. Microstructure and residual stress analysis of Strenx 700 MC welded joint. Prod. Eng. Arch. 2020, 26, 41–44. [Google Scholar] [CrossRef]

- Królicka, A.; Szczepa, Ł.; Konat, Ł.; Stawicki, T.; Kostencki, P. The Influence of Microstructure on Abrasive Wear Micro-Mechanisms of the Claddings Produced by Welding Used in Agricultural Soil. Materials 2020, 13, 1920. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Czuprynski, A. Comparison of Properties of Hard-faced Layers Made by a Metal-Core-Covered Tubular Electrode with a Special Chemical Composition. Materials 2020, 13, 5445. [Google Scholar] [CrossRef]

- Tomków, J.; Fydrych, D.; Rogalski, G. Dissimilar underwater wet welding of HSLA steels. Int. J. Adv. Manuf. Technol. 2020, 109, 717–725. [Google Scholar] [CrossRef]

- Tomków, J.; Fydrych, J.; Wilk, K. Effect of Electrode Waterproof Coating on Quality of Underwater Wet Welded Joints. Materials 2020, 13, 2947. [Google Scholar] [CrossRef] [PubMed]

- Tomków, J. Weldability of Underwater Wet-Welded HSLA Steel: Effects of Electrode Hydrophobic Coatings. Materials 2021, 14, 1364. [Google Scholar] [CrossRef] [PubMed]

- Marković, S.; Arsić, D.; Nikolić, R.; Lazić, V.; Ratković, N.; Hadzima, B.; Szmidla, J.; Ulewicz, R. Analysis of the welding type and filler metal influence on performance of a regenerated gear. Materials 2021, 14, 1496. [Google Scholar] [CrossRef] [PubMed]

- Marković, S.; Arsić, D.; Nikolić, R.R.; Lazić, V.; Hadzima, B.; Milovanović, V.; Dwornicka, R.; Ulewicz, R. Exploitation characteristics of teeth flanks of gears regenerated by three hard-facing procedures. Materials 2021, 14, 4203. [Google Scholar] [CrossRef]

- Konat, L. Technological, Microstructural and Strength Aspects of Welding and Post-Weld Heat Treatment of Martensitic, Wear-Resistant Hardox 600 Steel. Materials 2021, 14, 4541. [Google Scholar] [CrossRef]

- Jilleh, A.; Babu, N.K.; Thota, V.; Anis, A.L.; Harun, M.K.; Talari, M.K. Micro-structural and wear investigation of high chromium white cast iron hard-facing alloys deposited on carbon steel. J. Alloys Compd. 2021, 857, 157472. [Google Scholar] [CrossRef]

- EN 10025-5:2005; Hot Rolled Products of Structural Steels—Part 5: Technical Delivery Conditions for Structural Steels with Improved Atmospheric Corrosion Resistance. European Committee for Standardization: Brussels, Belgium, 2005. Available online: https://standards.iteh.ai/catalog/standards/cen/15e78c18-b8a2-4aad-bf74-abc0d230b956/en-10025-5-2004 (accessed on 12 March 2018).

- Tanasković, D.; Petrović, S.; Đorđević, B.; Matavž, A.; Mijatović, T. Algorithm for defining quality of base material for repair welding. Struct. Int. Life 2021, 21, 279–284. [Google Scholar]

- Jovanović, M.; Lazić, V.; Adamović, D. Technology of Welding—Handbook; Faculty of Mechanical Engineering in Kragujevac: Kragujevac, Serbia, 2011. (In Serbian) [Google Scholar]

- Séférian, D. Métallurgie de la Soudure; Dunod: Paris, France, 1965. [Google Scholar]

- Tanasković, D.; Đorđević, B.; Gajin, M.; Aranđelović, M.; Gostović, N.; Milovanović, N. Repair welding procedure and techno-economic analysis of burner pipe. Struct. Int. Life 2021, 21, 85–90. [Google Scholar]

- SŽ-Elektrode Jesenice. Catalogue of Filler Materials—Welding Consumables; Slovenske Železnice: Jesenice, Slovenia, 2019. [Google Scholar]

| No. | Article | Subject of Research | Main Conclusions/Contributions |

|---|---|---|---|

| [5] | Tolf and Hedegard (2007) | Possibility for improving the ultra HSS weldability in projection welding | By increasing the BM strength, the weldability and ductility of the joints become limited: the welding time vs the welding current balance is needed to avoid undersizing of the weld. |

| [6] | Talas (2010) | Assessment of carbon equivalent formulas | CE equations correlate highly with yield stress (YS), ultimate tensile strength (UTS), hardness (HRD), and elongation (EL%); thus, they are suitable for predicting mechanical and microstructural properties of steel weld metals. |

| [7] | Chang, Chen, and Wu (2010) | Microstructural and abrasive characteristics of the high carbon HF Fe-Cr-C alloys | Primary (Cr, Fe)7C3 carbide fraction increased with increased graphite addition, while their size decreased due to the increase in their nucleation rate. |

| [8] | Lin et al. (2010) | Influence of V, Mo, and Ni addition on the primary carbides’ morphology and mechanical properties and eutectic colonies in the Cr-Fe-C HF alloys | Adding vanadium, molybdenum, and nickel does not affect the morphologies of the primary carbides; however, their addition produces high-performance Cr-Fe-C hard-facing alloys. |

| [9] | Liu et al. (2013) | Influence of the boron content on the alloy’s microstructure and wear properties in HF of a mild steel | With an increase in boron content, the carbide average diameter increased from 9 to 20 (mm) and the carbide volume fraction (CVF) increased from 14.10 to 36.00%, causing an increase in the alloy’s hardness and abrasive wear resistance. |

| [10] | Tolf (2015) | Various parameters of the projection welding | The electrode force is an important parameter that must be correctly set to avoid excessive weld deformation. |

| [11] | Schipaanboord, Marquering, and Bruce (2015) | Application of low-yield filler metals for the safe welding of live gas pipelines | The parent material had to be buttered up with a low-yield electrode with at least two layers to avoid dilution with carbon, manganese, and silicon in the weld pool. |

| [2] | Arsić et al. (2016a) | Selecting the optimal HF technology based on the t8/5 cooling time | The weldability estimate can be reliably performed by use of continuous cooling transformation (CCT) diagrams based on use of the calculated t8/5 cooling time. |

| [3] | Lazić et al. (2016) | Weldability estimates for the C-Mn HSS | Optimal welding technology defined for HF of the tube girder cover made of the said steel. |

| [4] | Arsić et al. (2016b) | Testing of four filler metals under dry conditions | Evaluated tribological behavior of HF layers executed by different filler metals to define the optimal HF conditions. |

| [12] | Cabrilo and Geric (2016) | Weldability of the high hardness armor (HHA) Protac 500 steel | The optimal technology was defined by varying the welding procedures, filler metals, and heat treatment regimes. |

| [13] | Dobosy and Lukacs (2016) | Welding parameters effects on properties of the welded structures made of thermomechanically rolled HSS | All the welding parameters can be used within the wide range of values since their modification had a small effect on the properties of welded joints. |

| [14] | Han et al. (2019) | Weldability of dual-phase CMnSi steels in the resistance spot welding. | Due to formation of the internal (sub-surface) oxides during annealing, the surface oxide formation is suppressed and the resistance spot welding of the steel surface coated with zinc is affected. |

| [15] | Vicen, Bronček, and Novy (2019) | Possibilities of reducing the friction coefficient of bearing steel 100Cr6 | Reducing the 100Cr6 bearing steel friction by coating with CarbonX DLC (diamond like) resulted in reduced wear and increased service time of the coated components. |

| [16] | Trško et al. (2020) | Weldability of the high-strength low-alloy (HSLA) steel Strenx® 700 MC | The WM microstructure consisted of a fine acicular ferrite and the BM structure of a fine-grain rolled structure with Ti, Nb, and V carbides. The heat affected zone (HAZ) was less than 1 mm wide with significantly coarsened grains of polyhedral ferrite and carbides. |

| [17] | Krolicka et al. (2020) | Microstructure and wear behavior of claddings (Fe-Cr-C-Nb) on coulters, produced by commercial welding alloys | The claddings consisted of hypereutectic, near-eutectic, and hypoeutectic layers, with different primary M7C3 carbide content. The near-eutectic layer exhibited the most advantageous mechanical behavior. |

| [18] | Czuprynski (2020) | Abrasion resistance of the HF layer produced by the self-developed covered tubular electrode | Wear-resistance of 11 commercially produced plates were tested to obtain one with properties closest to those obtained by the new electrode. |

| [19] | Tomkow, Fydrych, and Rogalski (2020) | Various aspects of the wet-welding of the HSLA S460N steel | Effects of application of the waterproof coatings to electrodes on S460N steel’s weldability. |

| [20] | Tomkow and Fydrych (2020) | The hydrophobic coatings can reduce the hardness in the welded joints HAZ. | |

| [21] | Tomkow (2021) | The temper bead welding (TBW) method can be applied for the wet-welding of this steel. | |

| [1] | Ilić (2021) | Weldability of carbon and alloyed steels | To correctly obtain/evaluate weldability of a certain material, all the aspects must be taken into account. |

| [22] | Markovic et al. (2021a) | Influence of the FM type on performance of the regenerated cylindrical spur gears | The “hard” FM produces better characteristics for individual reparatory HF, while for the batch reparation of numerous damaged gears, “soft” FM hard-facing, followed by cementation and heat treatment, is more convenient. |

| [23] | Markovic et al. (2021b) | Influential phenomena during regeneration of parts to reverse their working ability loss | Filler metal types, the teeth geometrical accuracy, microstructure, and micro hardness were compared to properties of new gears’ teeth flanks. |

| [24] | Konat (2021) | Technological and structural aspects of welded joints of the Hardox 600 steel | The welding leads to formation of a wide HAZ, with structures favoring the reduction of abrasion resistance and deterioration of plastic properties, while increasing the susceptibility to brittle fracture. New effective welding technology is proposed. |

| [25] | Jilleh et al. (2021) | Microstructural development during solidification and the wear behavior of four hypereutectic white cast iron (WCI) HF deposits, on the carbon steel (SJ235RG2). | Addition of the MC carbide-forming alloying elements to the filler metal caused the grain refinement of the primary pro-eutectic M7C3 carbide, while the further grain refinement was caused by increased content of carbide formers (Nb, Mo). The deposits’ wear resistance increased with increased content of alloying elements in the filler metal. |

| Base Metal | Chemical Composition, % | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | P | S | N | Si | Mn | Cu | Mo | Cr | |

| S235JR | 0.17 | 0.05 | 0.05 | 0.007 | / | / | / | / | / |

| S355J2G3 | 0.23 | 0.035 | 0.035 | / | 0.6 | 1.7 | 0.6 | / | / |

| C45 | 0.42–0.5 | 0.045 | 0.045 | / | 0.04 | 0.5–0.8 | / | / | / |

| 42CrMo4 | 0.38–0.45 | 0.035 | 0.0035 | / | 0.15–0.4 | 0.5–0.8 | / | 0.15–0.3 | 0.9–1.2 |

| Base Metal | Property | Microstructure | |||||

|---|---|---|---|---|---|---|---|

| Rm (MPa) | Reh (MPa) | A5 % | Z % | KV (J) | Hardness (HB) | ||

| S235JR | 370–450 | 220–240 | 18–25 | / | 27 | 130–145 | Ferrite–pearlite |

| S355J2G3 | 370–450 | 220–240 | 18–25 | / | 27 | 130–145 | Ferrite–pearlite |

| C45 | 700–850 | 500 | 14 | 30 | 32 | 334–340 | Tempered structure, predominantly tempered martensite * |

| 42CrMo4 | 1100–1300 | 900 | 10 | 40 | 34 | 298–305 | Tempered structure, fine pearlite with ferrite at grain boundaries |

| Carbon Equivalent (CE) | Weldability | Preheating |

|---|---|---|

| <0.35 | Excellent | Not necessary |

| 0.36–0.40 | Very good | Recommended |

| 0.41–0.45 | Good | Necessary |

| 0.46–0.50 | Fair | Necessary |

| >0.50 | Poor | Necessary |

| Base Metal | Preheating Temperature, Tp (°C) | |

|---|---|---|

| Calculated | Adopted | |

| S355J2G3 | ~107 | 110 |

| C45 | ~218 | 220 |

| 42CrMo4 | ~269 | 270 |

| Electrode Designation | Chemical Composition, % | ||||

|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | |

| EVB 50 | 0.08 | 0.6 | 1.0 | - | - |

| E DUR 600 | 0.5 | - | - | 7.5 | - |

| FILTUB DUR 16 | 0.45 | 0.6 | 1.6 | 5.5 | 0.8 |

| VAC 60 | 0.08 | 0.9 | 1.5 | - | - |

| Electrode Designation | Mechanical Properties of Pure Weld Metal | ||||

|---|---|---|---|---|---|

| Rm (MPa) | ReH (MPa) | A5, % | KV (J) | Hardness (HRC) | |

| EVB 50 | 510–610 | >440 | >24 | >47 | - |

| E DUR 600 | - | - | - | - | 57–62 |

| FILTUB DUR 16 | - | - | - | - | 57–62 |

| VAC 60 | 510–590 | >410 | >22 | >47 | - |

| Filler Metal Mark | Electrode Diameter de (mm) | Current, I (A) | Working Voltage U (V) | Speed, vz (mm/s) | Driving Energy, ql (J/mm) |

|---|---|---|---|---|---|

| EVB 50 | 3.25 | 100–150 | 20–23 | 1.19–2.20 | 2016.8–2545.5 |

| E DUR 600 | 3.25 | 100–150 | 20–23 | 1.19–2.20 | 2016.8–2545.5 |

| Filler Metal Mark | Protective Gas Flow (L/min) | Wire Diameter dw (mm) | Current, I (A) | Working Voltage, U (V) | Speed, vz (mm/s) | Driving Energy, ql (J/mm) |

|---|---|---|---|---|---|---|

| EVB 50 | 16–20 | 1.2 | 130–150 | 23–28 | 35–80 | 3187.5–1333.0 |

| E DUR 600 | 16–20 | 1.2 | 130–150 | 23–28 | 35–80 | 3187.5–1333.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arsić, D.; Lazić, V.; Nikolić, R.R.; Sczygiol, N.; Krstić, B.; Ivković, D.; Hadzima, B.; Pastorek, F.; Ulewicz, R. Weldability Assessment of Various Steels by Hard-Facing. Materials 2022, 15, 3082. https://doi.org/10.3390/ma15093082

Arsić D, Lazić V, Nikolić RR, Sczygiol N, Krstić B, Ivković D, Hadzima B, Pastorek F, Ulewicz R. Weldability Assessment of Various Steels by Hard-Facing. Materials. 2022; 15(9):3082. https://doi.org/10.3390/ma15093082

Chicago/Turabian StyleArsić, Dušan, Vukić Lazić, Ružica R. Nikolić, Norbert Sczygiol, Božidar Krstić, Djordje Ivković, Branislav Hadzima, Filip Pastorek, and Robert Ulewicz. 2022. "Weldability Assessment of Various Steels by Hard-Facing" Materials 15, no. 9: 3082. https://doi.org/10.3390/ma15093082

APA StyleArsić, D., Lazić, V., Nikolić, R. R., Sczygiol, N., Krstić, B., Ivković, D., Hadzima, B., Pastorek, F., & Ulewicz, R. (2022). Weldability Assessment of Various Steels by Hard-Facing. Materials, 15(9), 3082. https://doi.org/10.3390/ma15093082