Evaluation of Strength Properties of Sand Stabilized with Wood Fly Ash (WFA) and Cement

Abstract

1. Introduction

2. State of the Art

3. Objective of This Study

4. Experimental Section

4.1. Stabilized Mixture Composition

4.1.1. Determination of Optimum WFA Amount in Stabilized Mixtures

4.1.2. Designing the Composition of Stabilization Mixtures

5. Test Methods

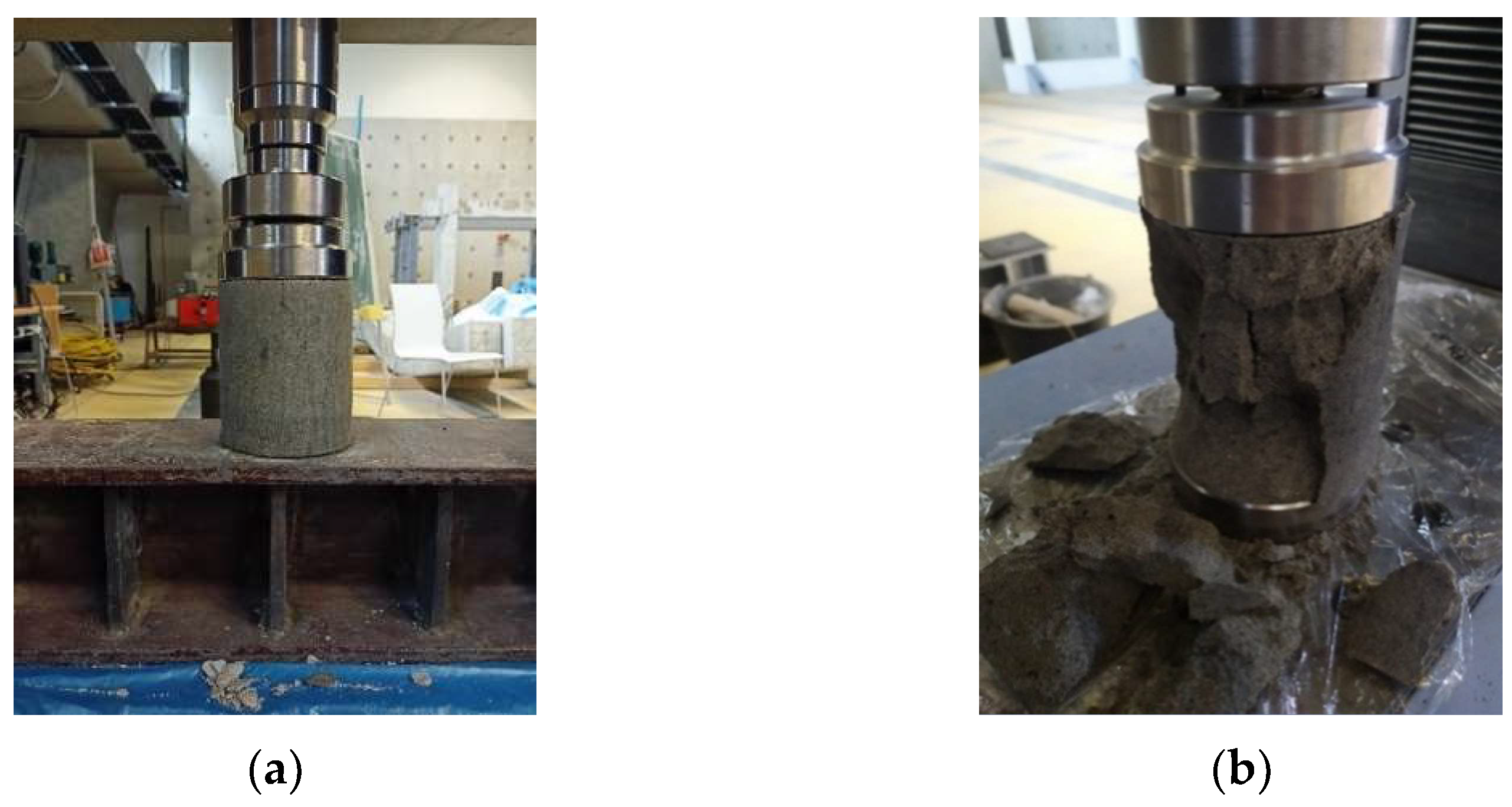

5.1. Compressive Strength Test

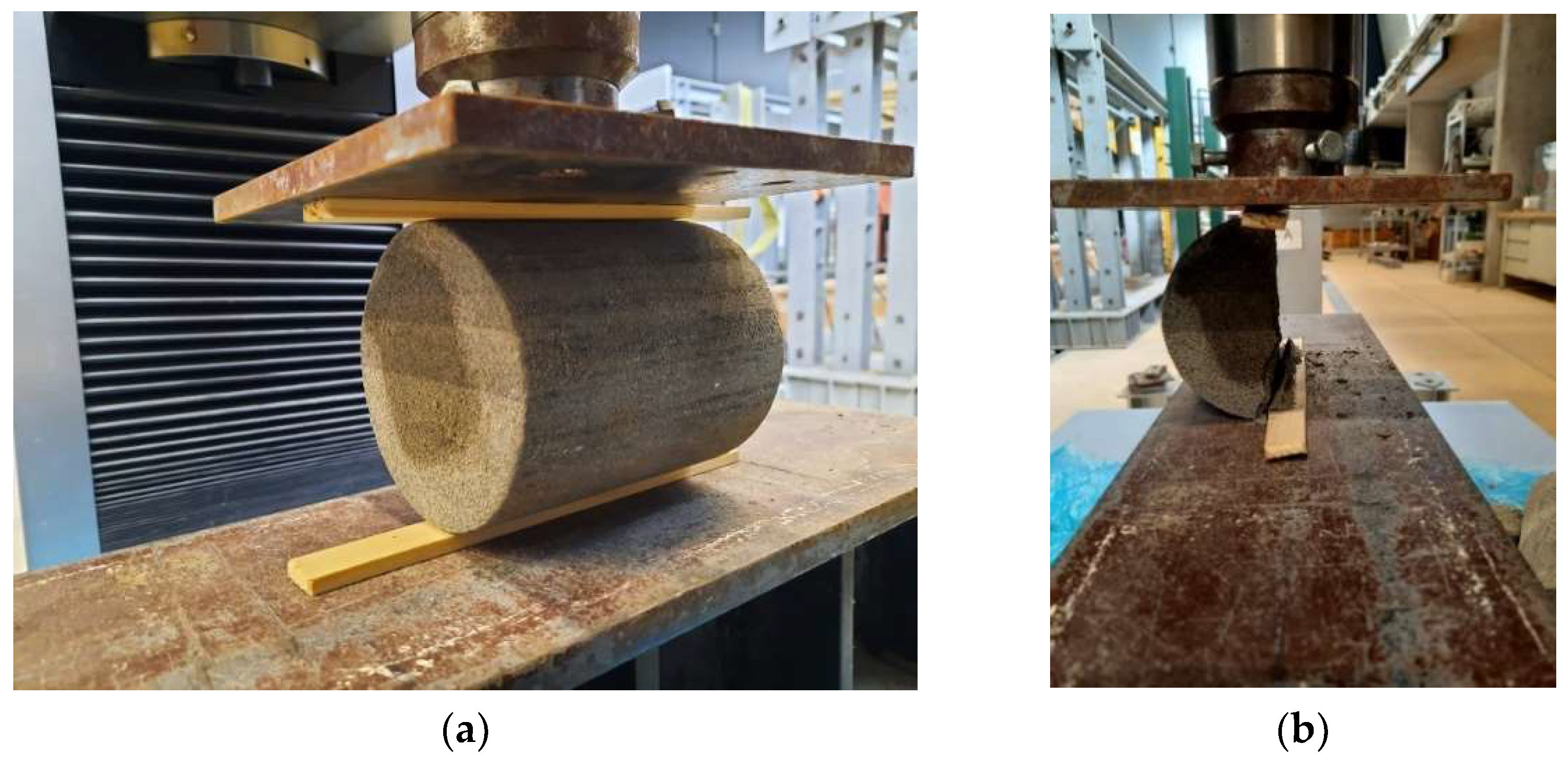

5.2. Tensile Strength Test

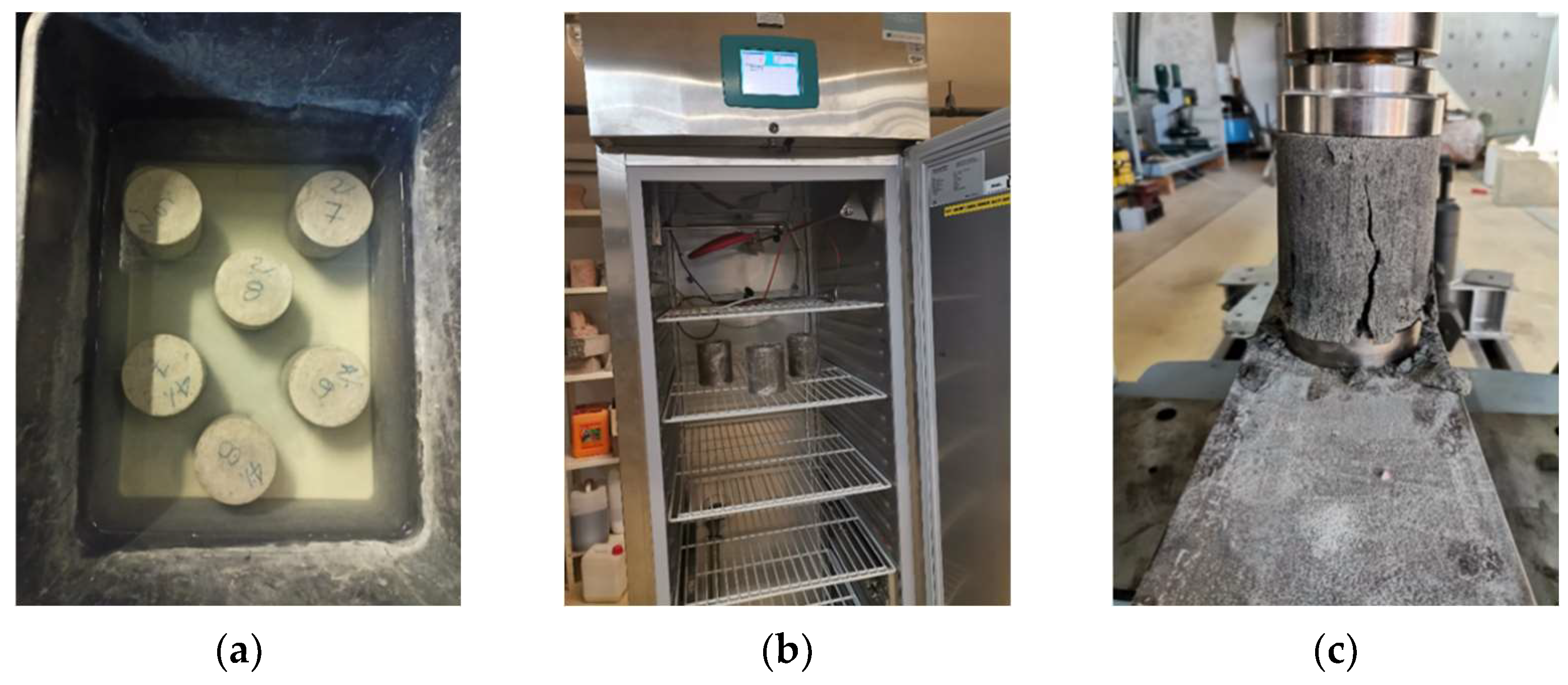

5.3. Testing of Resistance to Freezing and Thawing

6. Results Analysis and Discussion

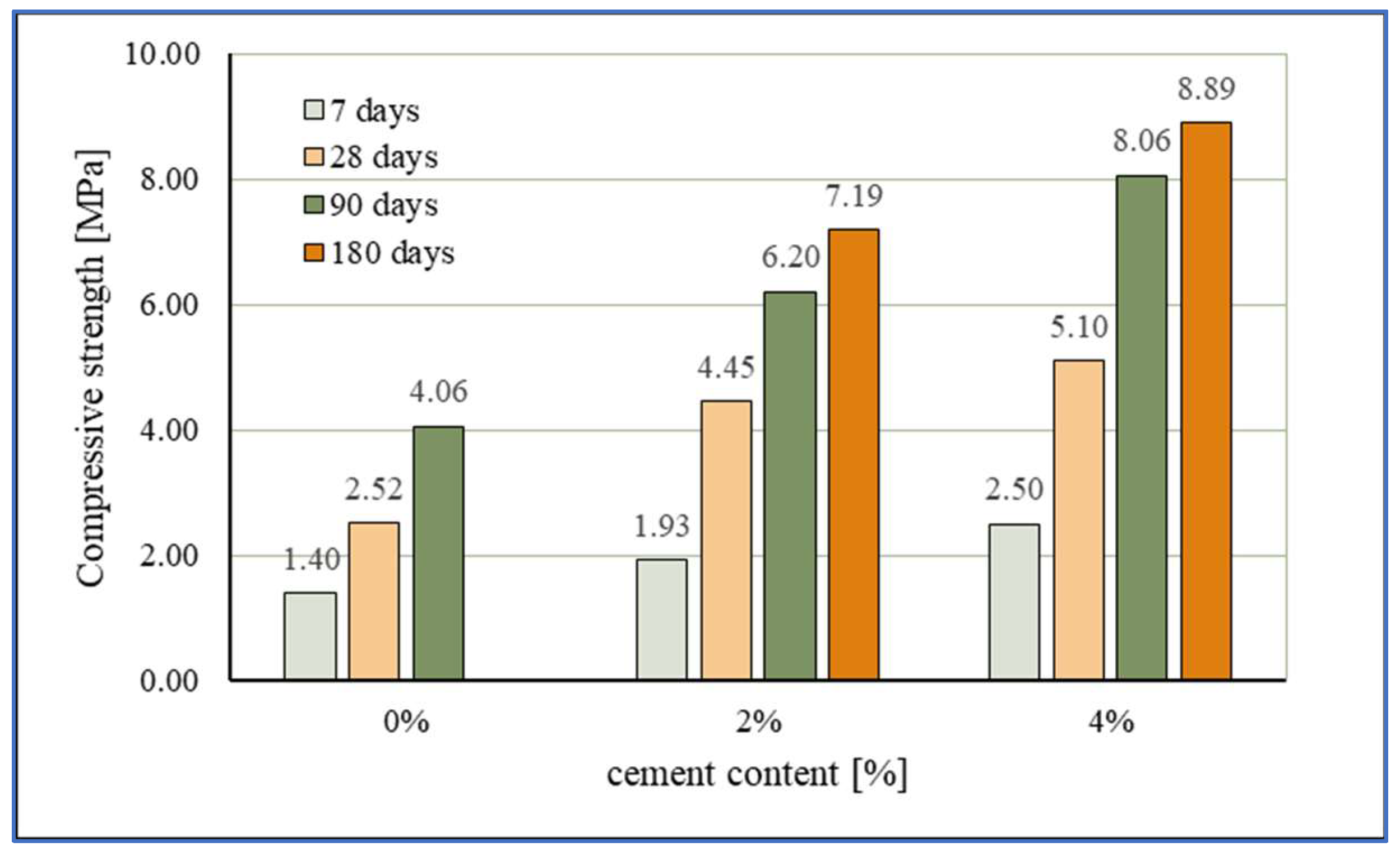

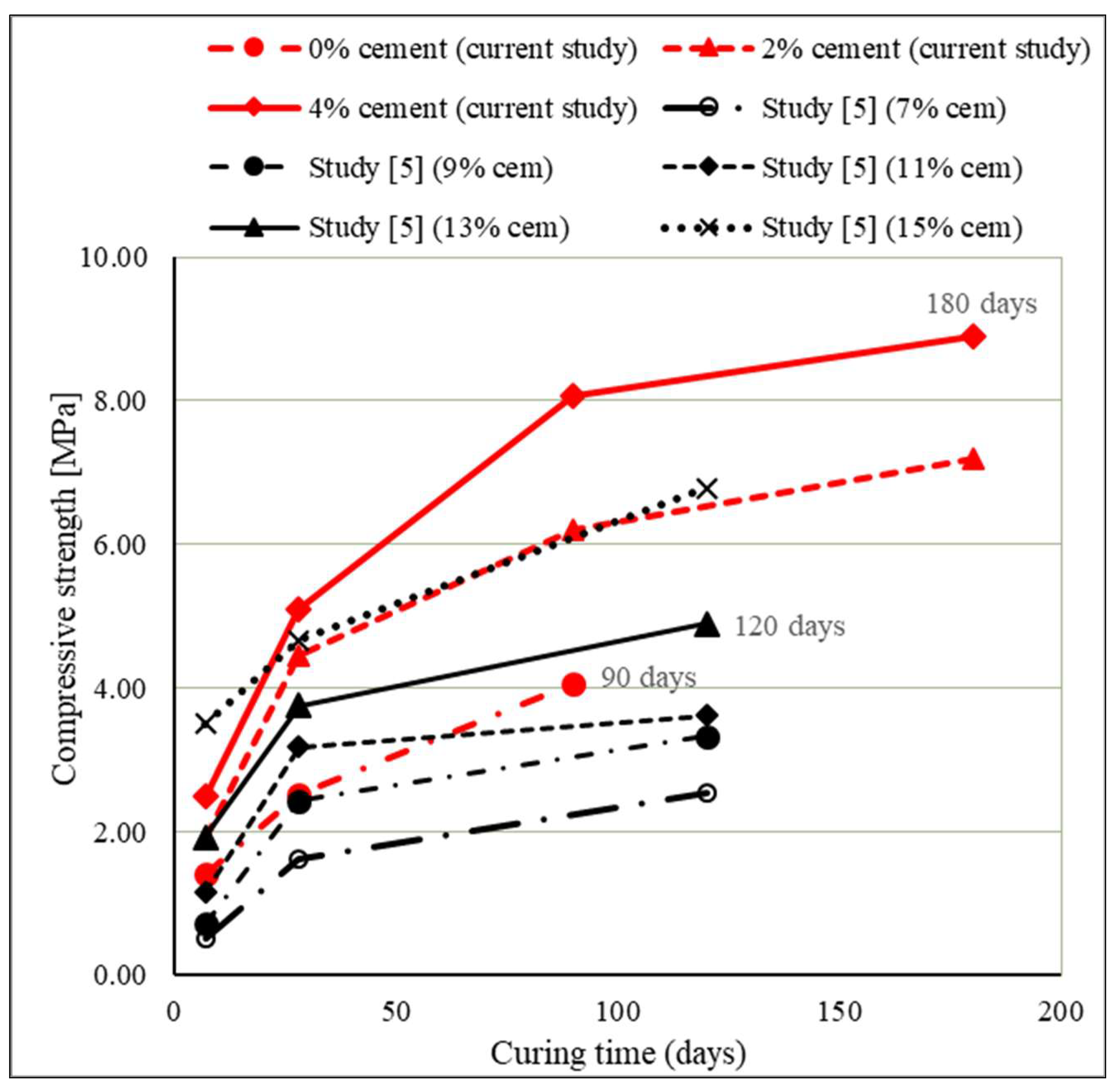

6.1. Analysis of Compressive Strength Results

6.2. The Comparison of Values of Compressive Strengths of Stabilized Mixtures with the Criteria Prescribed by the Applicable Croatian Technical Regulations

6.3. Analysis of Indirect Tensile Strength Results

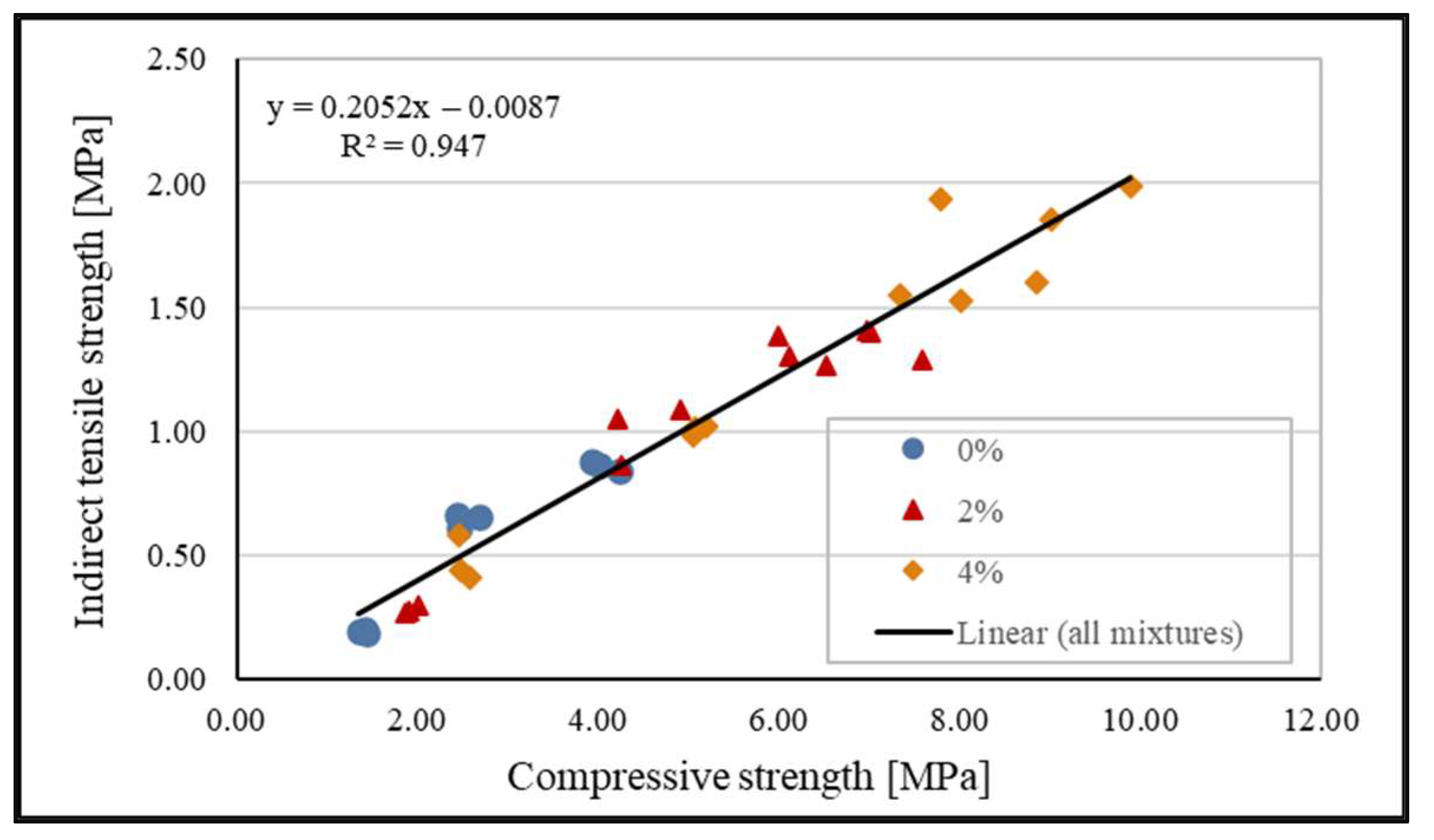

6.4. Correlations between Compressive and Indirect Tensile Strength

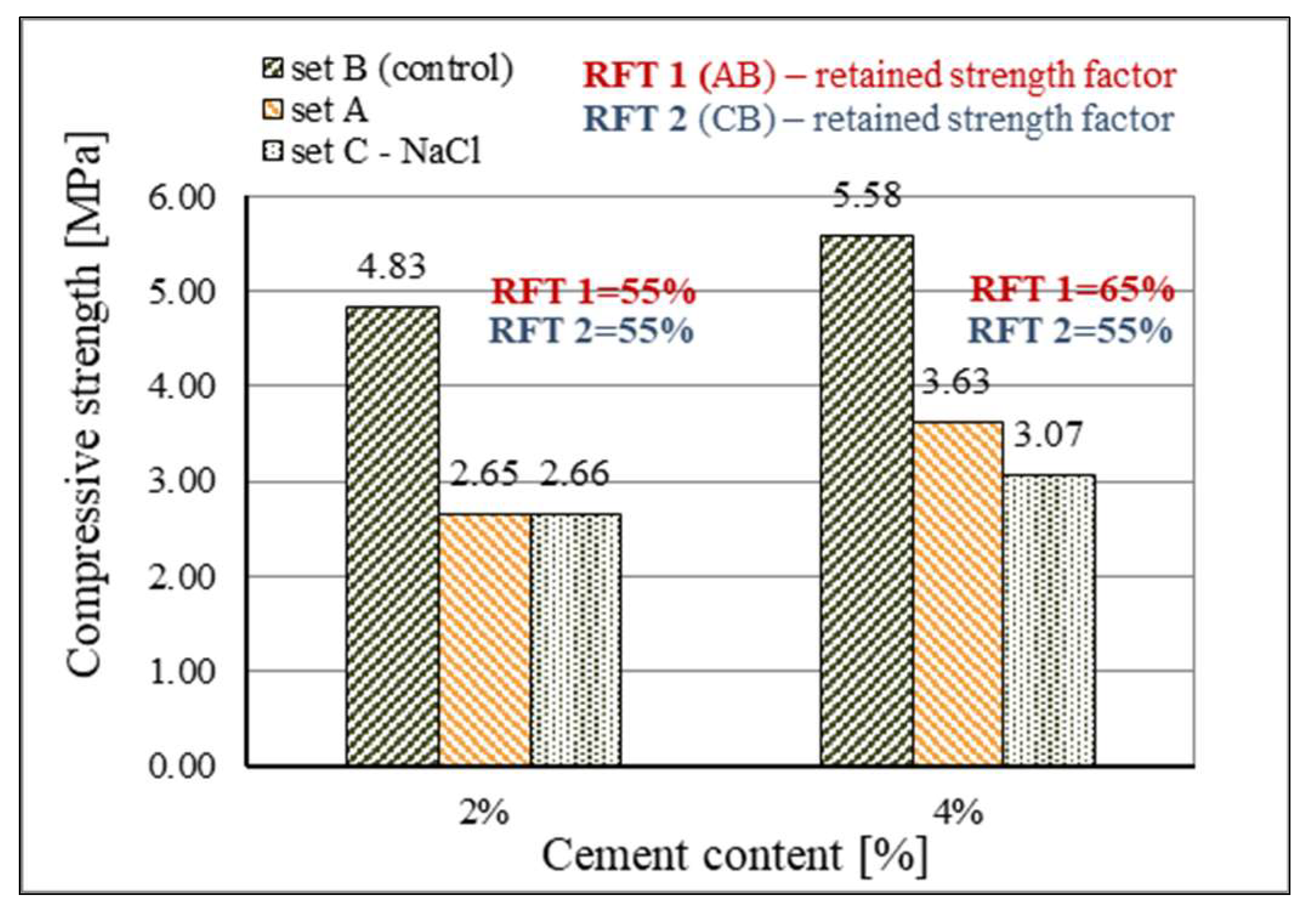

6.5. The Results of Resistance to Freezing and Thawing

7. Conclusions

- (1)

- WFA with a considerable content of CaO (46.91 mass %) has a stabilization effect on the sand mixture and improves the load bearing capacity of the mixture expressed by the CBR index. The CBR index increases considerably with an increase in the content of ash in the mixture (10%, 20%, 30%) both due to the filler effect and through hydraulic binding between minerals in sand and WFA. The greatest value of CBR (90.70%) was achieved by mixtures of sand and 30% WFA, which is three times more than the bearing ratio of pure sand (CBR = 27.44%).

- (2)

- WFA in the mixture of sand improves compressive strength, so that the mixtures with 0% cement achieved compressive strength values of 1.4 MPa (7 days) to 4.06 MPa (90 days). These results indicate the development of hydraulic and pozzolanic reactions between sand and WFA, but further research is necessary to clearly define the reactions and minerals that occur. By adding a small quantity of the cement (2% and 4%), the hydraulic reaction is even more intensive and results in higher values of compressive strength. According to the proposed classification based on a minimum compressive strength for new construction based on recycled materials [76], stabilizing mixtures with 0% and 2% cement belong to Group B: strong (min 1.5 MPa) whilst the mixture with 4% cement belongs to Group A: very strong (min 4.5 MPa).

- (3)

- The comparison of the values of compressive strengths after 7 and 28 days with the criteria of the Croatian technical regulations (prescribed for mixtures stabilized exclusively with cement) showed that the mixtures with 4% cement meet the conditions for application in the upper and bottom base layers of the pavement structure. The mixtures with 2% cement can be used for the construction of the subbase layers, as well as the mixtures without cement.

- (4)

- The trend of the indirect tensile strength development for all stabilized mixtures and durations of curing is very similar to that of compressive strengths. The stabilized mixture with 0% cement achieved the values of indirect tensile strength from 0.2 MPa (7 days) to 0.86 MPa (90 days). The average increase in indirect tensile strength of the mixtures with 4% cement in comparison with the mixtures with 0% cement, for curing of 7 to 90 days, amounts to 75.55%, almost the same value as in the relation of compressive strengths of the mixture.

- (5)

- For compressive and indirect tensile strengths of mixtures, the model of the correlation ft = a * fc + b was analyzed. The results obtained show that the linear correlation between indirect tensile strength and compressive strength of stabilization mixtures is very strong, and coefficients of determination are very high (R2 = 0.90–0.947). The average correlation of indirect tensile strength in relation to compressive strength for all the tested mixtures and all the durations of curing amounts to 20%.

- (6)

- The mixture with 4% cement has a satisfactory resistance to freezing, and it can be used for the construction of load-bearing layers of pavement structures in a region with a continental climate, such as the area of eastern Croatia.

- (7)

- In addition to a significant contribution to achieving the required mechanical properties of mixtures, it is necessary to emphasize that the environmental and economic benefits of WFA in load-bearing layers of a pavement structure are reflected in:

- (I)

- The rationalization of costs of stabilized load-bearing layers through savings in cement and sand amount. WFA is a cost-free material, and with the replacement of 30% of sand with WFA and the decrease in cement content from the standard amount of 8% to 4%, the construction costs of pavement structure are reduced.

- (II)

- A reduction in the quantity of this waste material at landfills. The daily quantities of WFA that are produced are significant and they are mostly deposited in landfills. Depositing in landfills is demanding and expensive and takes up valuable space, so reuse/recycling is strongly encouraged.

- (III)

- Protection of natural aggregates. Clear requirements for conservation and protection of non-renewable sources of natural aggregates is stated in the sustainable development guidelines and the usage of WFA means a lower requirement for the exploitation of natural aggregates.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Commission. COST 333 Developement of New Bituminous Pavement Design Method. Final Report of the Action; European Commission: Brussels, Belgium, 1999; pp. 130–137. ISBN 92-828-6796-X. [Google Scholar]

- Barišić, I.; Rukavina, T.; Dimter, S. Cement stabilizations—characterization of materials and design criteria. Građevinar 2011, 63, 135–142. [Google Scholar]

- Little, D.N.; Scullion, T.; Kota, P.B.V.S.; Bhuiyan, J. Guidelines for Mixture Design and Tickness Design for Stabilized Bases and subgrades; Texas Transportation Institute: College Station, TX, USA, 1995. [Google Scholar]

- Dimter, S.; Rukavina, T.; Barišić, I. Alternative, environmentally acceptable materials in road construction. In Handbook of Research on Advancements in Environmental Engineering; Gaurina-Međimurec, N., Ed.; IGI Global: Hershey, PA, USA, 2014; pp. 557–583. [Google Scholar]

- Institute of Civil Engineering. Study of The Possibilities of Application of Sand in Construction of Roadso Slavonia and Baranja Region; Institute of Civil Engineering, Faculty of Civil Engineering in Osijek: Osijek, Croatia, 1990; p. 105. (In Croatian) [Google Scholar]

- Bošnjak, J. Constructing of the roads with sand. In Proceedings of the 1st Croatian Congress of Roads, Croatian Road Society—Via Vita, Opatija, Croatia, 23–25 October 1995; pp. 536–543, (In Croatian with English Summary). [Google Scholar]

- Dimter, S. Properties of Stabilized Mixtures for Road Construction. Ph.D. Thesis, University of Zagreb, Faculty of Civil Engineering, Zagreb, Croatia, 2005; 156p. (In Croatian with English Summary). [Google Scholar]

- Dimter, S.; Zagvozda, M.; Tonc, T.; Šimun, M. Construction of economical pavement structures with wood ash. In Proceedings of the 30th International Baltic Road Conference, Riga, Latvia, 23–24 August 2021; pp. 1–7. [Google Scholar]

- Zagvozda, M.; Dimter, S.; Rukavina, T.; Grubeša, I.N. Possibilities for using bioash in road construction. Građevinar 2018, 70, 393–402. [Google Scholar] [CrossRef]

- Dimter, S.; Rukavina, T.; Dragčević, V. Strength Properties of Fly Ash Stabilized Mixtures. Road Mater. Pavement Des. 2011, 12, 687–697. [Google Scholar] [CrossRef][Green Version]

- Ksaibati, K.; Conklin, T. Field Performance Evaluation of Cement-Treated Bases with and Without Fly Ash; Transportation Research Bord: Washington, DC, USA, 1994; Record No. 1440. [Google Scholar]

- Hadi Shirazi, P. Field and Lab Evaluation of the Use of Lime Fly Ash to Replace Soil Cement as a Base Course; Report No. 303; Louisiana Transportation Research Center: Baton Rouge, LA, USA, 1997. [Google Scholar] [CrossRef]

- Dimter, S.; Rukavina, T.; Minažek, K. Estimation of elastic properties of fly ash—Stabilized mixtures using nondestructive evaluation methods. Constr. Build. Mater. 2016, 102, 505–514. [Google Scholar] [CrossRef]

- Dimter, S.; Rukavina, T.; Barišić, I. Application of the ultrasonic method in evaluation of properties of stabilized mixture. Baltic J. Road Bridge Eng. 2011, 6, 177–184. [Google Scholar] [CrossRef]

- Sear, L.K.A. Properties and Use of Coal Fly Ash. A Valuable Industrial by Product; Thomas Telford Publishing: London, UK, 2001; p. 261. ISBN 0727730150. [Google Scholar]

- Maher, M.H.; Balaguru, P.N. Properties of flowable high-volume fly ash-cement composite. J. Mater. Civil Eng. 1993, 5, 212–225. [Google Scholar] [CrossRef]

- Zenieris, P.; Laguros, J.G. Fly ash as a binder in aggregate base course. Mater. Res. Soc. Simp. Proc. 1988, 113, 231–241. [Google Scholar] [CrossRef]

- Sobhan, K.; Jesick, M.R.; Dedominicis, E.J.; McFadden, J.P.; Cooper, K.A.; Roe, J.R. A Soil-Cement-Fly Ash Pavement Base Course Reinforced with Recycled Plastic Fibers. In Proceedings of the Transportation Research Board, 78th Annual Meeting, Washington, DC, USA, 10–14 January 1999; pp. 1–12. [Google Scholar]

- Simatupang, M.; Mangalla, L.K.; Edwin, R.S.; Putra, A.A.; Azikin, M.T.; Aswad, N.H.; Mustika, W. The Mechanical Properties of Fly-Ash-Stabilized Sands. Geosciences 2020, 10, 132. [Google Scholar] [CrossRef]

- Mahvash, S.; López-Querol, S.; Bahadori-Jahromi, A. Effect of class F fly ash on fine sand compaction through soil stabilization. Heliyon 2017, 3, e00274, ISSN 2405-8440. [Google Scholar] [CrossRef]

- Mahvash, S.; López-Querol, S.; Bahadori-Jahromi, A. Effect of fly ash on the bearing capacity of stabilised fine sand. Proc. Inst. Civ. Eng.-Ground Improv. 2018, 171, 82–95. [Google Scholar] [CrossRef]

- Chenari, R.J.; Fatahi, B.; Ghorbani, A.; Alamoti, M.N. Evaluation of strength properties of cement stabilized sand mixed with EPS beads and fly ash. Geomech. Eng. 2018, 14, 533–544. [Google Scholar] [CrossRef]

- Lav, A.H.; Lav, M.A.; Goktepe, A.B. Analysis and design of stabilized fly ash as pavement base material. Fuel 2006, 85, 2359–2370. [Google Scholar] [CrossRef]

- Lav, M.A.; Lav, A.H. Effects of stabilization on resilient characteristics of fly ash as pavement material. Constr. Build. Mater. 2014, 54, 10–16. [Google Scholar] [CrossRef]

- Forteza, R.; Far, M.; Seguı, C.; Cerda, V. Characterization of bottom ash in municipal solid waste incinerators for its use in road base. Waste Manag. 2004, 24, 899–909. [Google Scholar] [CrossRef]

- Marieta, C.; Guerrero, A.; Cascante, I.L. Municipal solid waste incineration fly ash to produce eco-friendly binders for sustainable building construction. Waste Manag. 2021, 120, 114–124. [Google Scholar] [CrossRef]

- Šķēls, P.; Bondars, K.; Plonis, R.; Haritonovs, V.; Paeglītis, A. Usage of Wood Fly Ash in Stabilization of Unbound Pavement Layers and Soils. In Proceedings of the 13th Baltic Sea Geotechnical Conference, Vilnius, Lithuania, 22–24 September 2016; pp. 122–125. Available online: https://www.researchgate.net/publication/309015822_Usage_of_Wood_Fly_Ash_in_Stabilization_of_Unbound_Pavement_Layers_and_Soils (accessed on 2 December 2021). [CrossRef]

- Šķēls, P.; Bondars, K.; Haritonovs, V. Wood fly ash stabilization of unbound pavement layers. In Proceedings of the 19th International Conference on Soil Mechanics and Geotechnical Engineering (ICSMGE 2017), Seoul, Korea, 17–21 September 2017; pp. 2014–2017. [Google Scholar]

- Vestin, J.; Arm, M.; Nordmark, D.; Lagerkvist, A.; Hallgren, P.; Lind, B. Fly ash as a road construction material. In Proceedings of the WASCON 2012, Gothenburg, Sweden, 30 May–1 June 2012; pp. 1–8. [Google Scholar]

- Bohrn, G.; Stampfer, K. Untreated Wood Ash as a Structural Stabilizing Material in Forest Roads. Croat. J. For. Eng. 2014, 35, 81–90. [Google Scholar]

- Kaakkurivaara, T.; Kolisoja, P.; Uusitalo, J.; Vuorimies, N. Fly Ash in Forest Road Rehabilitation. Croat. J. For. Eng. 2009, 37, 119–130. [Google Scholar]

- Sarkkinen, M.; Luukkonen, T.; Kemppainen, K. A wasterock and bioash mixture as a road stabilization product. In Proceedings of the 3rd Edition of the International Conference on Wastes: Solution, Treatments and Opportunities, Viana do Castelo, Portugal, 14–16 September 2015; pp. 283–288. [Google Scholar]

- Cabrera, M.; Agrela, F.; Ayuso, J.; Galvin, A.P.; Rosales, J. Feasible use of biomass bottom ash in the manufacture of cement treated recycled materials. Mater. Struct. 2015, 49, 3227–3238. [Google Scholar] [CrossRef]

- Cabrera, M.; Rosales, J.; Ayuso, J.; Estaire, J.; Agrela, F. Feasibility of using olive biomass bottom ash in the sub-bases of roads and rural paths. Constr. Build. Mater. 2018, 181, 266–275. [Google Scholar] [CrossRef]

- Behak, L.; Musso, M. Performance of Low-Volume Roads with Wearing Course of Silty Sand Modified with Rice Husk Ash and Lime. Transp. Res. Procedia 2016, 18, 93–99, ISSN 2352-1465. [Google Scholar] [CrossRef]

- Cabrera, M.; Díaz-López, J.L.; Agrela, F.; Rosales, J. Eco-Efficient Cement-Based Materials Using Biomass Bottom Ash: A Review. Appl. Sci. 2020, 10, 8026. [Google Scholar] [CrossRef]

- Sáez del Bosque, I.F.; Sánchez de Rojas, M.I.; Asensio, E.; Frías, M.; Medina, C. Industrial waste from biomass-fired electric power plants as alternative pozzolanic material. In Waste and Byproducts in Cement-Based Materials. Innovative Sustainable Materials for a Circular Economy; de Brito, J., Thomas, C., Medina, C., Agrela, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 243–283. ISBN 9780128208953/9780128205495. [Google Scholar] [CrossRef]

- Zagvozda, M.; Rukavina, T.; Dimter, S. Wood bioash effect as lime replacement in the stabilisation of different clay subgrades. Int. J. Pavement Eng. 2020, 1–11. [Google Scholar] [CrossRef]

- Hinojosa, M.J.R.; Galvín, A.P.; Agrela, F.; Perianes, M.; Barbudo, A. Potential use of biomass bottom ash as alternative construction material: Conflictive chemical parameters according to technical regulations. Fuel 2014, 128, 248–259. [Google Scholar] [CrossRef]

- Zagvozda, M.; Dimter, S.; Rukavina, T.; Estokova, A. Ecological aspect of bioashes as road building material. In Proceedings of the 5th International Conference on Road and Rail Infrastructures-CETRA 2018, Zadar, Croatia, 17–19 May 2018. [Google Scholar] [CrossRef]

- Sigvardsen, N.M.; Kirkelund, G.M.; Jensen, P.E.; Geiker, M.R.; Ottosen, L.M. Impact of production parameters on physiochemical characteristics of wood ash for possible utilisation in cement-based materials. Resour. Conserv. Recycl. 2019, 145, 230–240. [Google Scholar] [CrossRef]

- Sigvardsen, N.M.; Geiker, M.R.; Ottosen, L.M. Phase development and mechanical response of low-level cement replacements with wood ash and washed wood ash. Constr. Build. Mater. 2020, 269, 121234. [Google Scholar] [CrossRef]

- Sigvardsen, N.M.; Geiker, M.R.; Ottosen, L.M. Reaction mechanisms of wood ash for use as a partial cement replacement. Constr. Build. Mater. 2021, 286, 122889. [Google Scholar] [CrossRef]

- Cherian, C.; Siddidua, S. Engineering and environmental evaluation for utilization of recycled pulp mill fly ash as binder in sustainable road construction. J. Clean. Prod. 2021, 298, 126758. [Google Scholar] [CrossRef]

- Demirbas, A. Potential applications of renewable energy sources, biomass combustion problems in boiler power systems and combustion related environmental issues. Prog. Energy Combust. Sci. 2005, 31, 171–192. [Google Scholar] [CrossRef]

- Directorate-General for Energy (European Commission), Navigant. Technical Assistance in Realisation of the 5th Report on Progress of Renewable Energy in the EU. Analysis of Bioenergy Supply and Demand in the EU (Task 3): Final Report; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- Zagvozda, M.; Dimter, S.; Rukavina, T. The potential of bioash for utilization in road construction in eastern Croatia. Sel. Sci. Pap. J. Civ. Eng. 2017, 12, 121–127. [Google Scholar] [CrossRef]

- Milovanović, B.; Štirmer, N.; Carević, I.; Baričević, A. Wood biomass ash as a raw material in concrete industry. Građevinar 2019, 71, 504–514. [Google Scholar] [CrossRef]

- Dimter, S.; Zagvozda, M.; Milovanović, B.; Šimun, M. Usage of Wood Ash in Stabilization of Unbound Pavement Layers. Road and Rail Infrastructure VI. In Proceedings of the 6th International Conference on Road and Rail Infrasturcture, Pula, Croatia, 20–22 May 2020; pp. 981–987. [Google Scholar] [CrossRef]

- Carević, I.; Baričević, A.; Štirmer, N.; Šantek Bajto, J. Correlation between physical and chemical properties of wood biomass ash and cement composites performances. Constr. Build. Mater. 2020, 256, 119450. [Google Scholar] [CrossRef]

- Carević, I.; Štirmer, N.; Serdar, M.; Ukrainczyk, N. Effect of wood biomass ash storage on the properties of cement composites. Materials 2021, 14, 1632. [Google Scholar] [CrossRef] [PubMed]

- Dimter, S.; Šimun, M.; Zagvozda, M.; Rukavina, T. Laboratory evaluation of the properties of asphalt mixture with wood ash filler. Materials 2021, 3, 575. [Google Scholar] [CrossRef] [PubMed]

- Gabrijel, I.; Jelčić Rukavina, M.; Štirmer, N. Influence of Wood Fly Ash on Concrete Properties through Filling Effect Mechanism. Materials 2021, 14, 7164. [Google Scholar] [CrossRef]

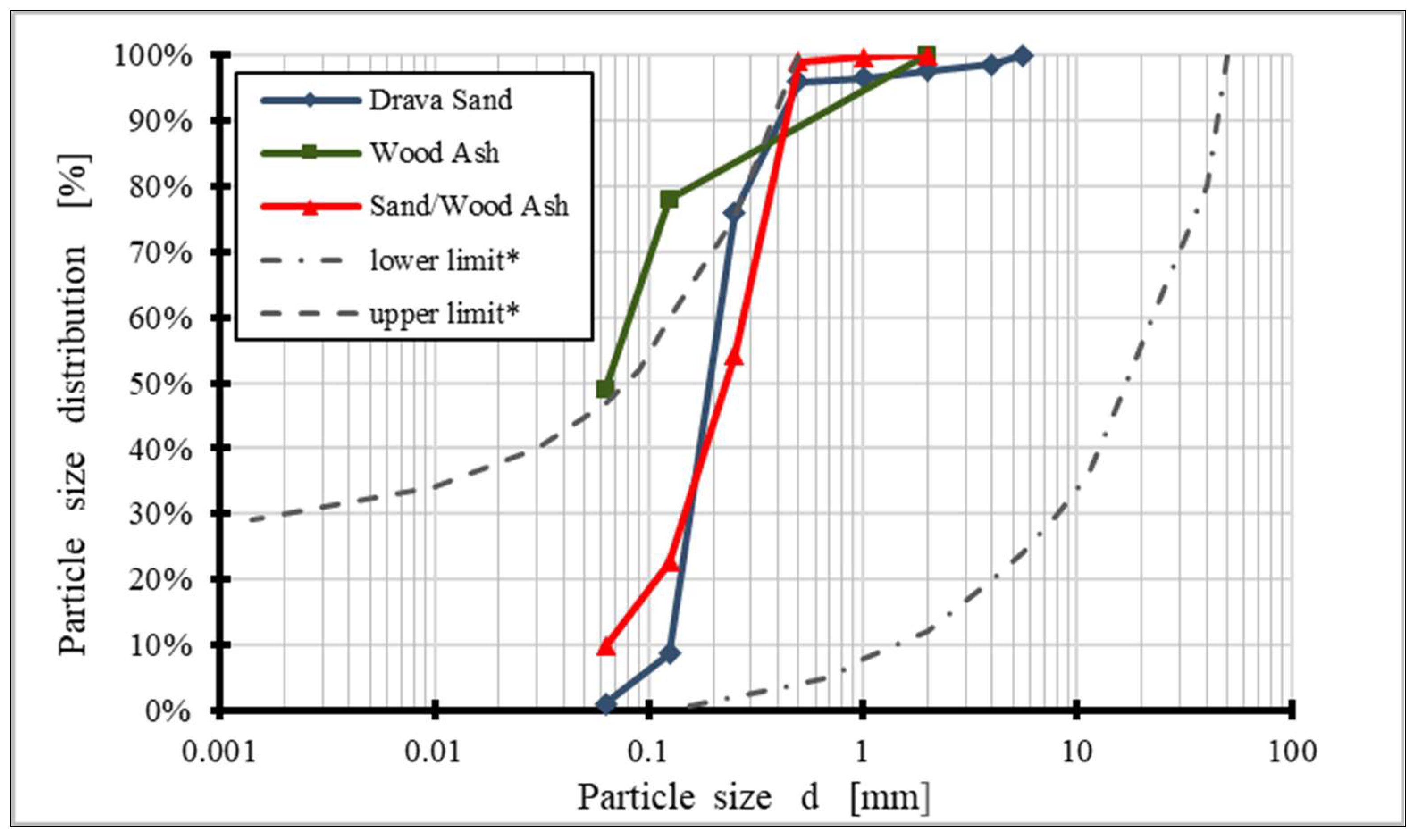

- HRN EN ISO 17892-4:2008; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 4: Determination of Particle Size Distribution. CEN: Brussels, Belgium; ISO: Geneva, Switzerland, 2008.

- HRN U.E9.024; Highway Design and Construction. Construction of Pavement Base Courses Stabilized by Means of Portland Cement and Similar Chemicals. The Croatian Standards Institute: Zagreb, Croatia. (In Croatian)

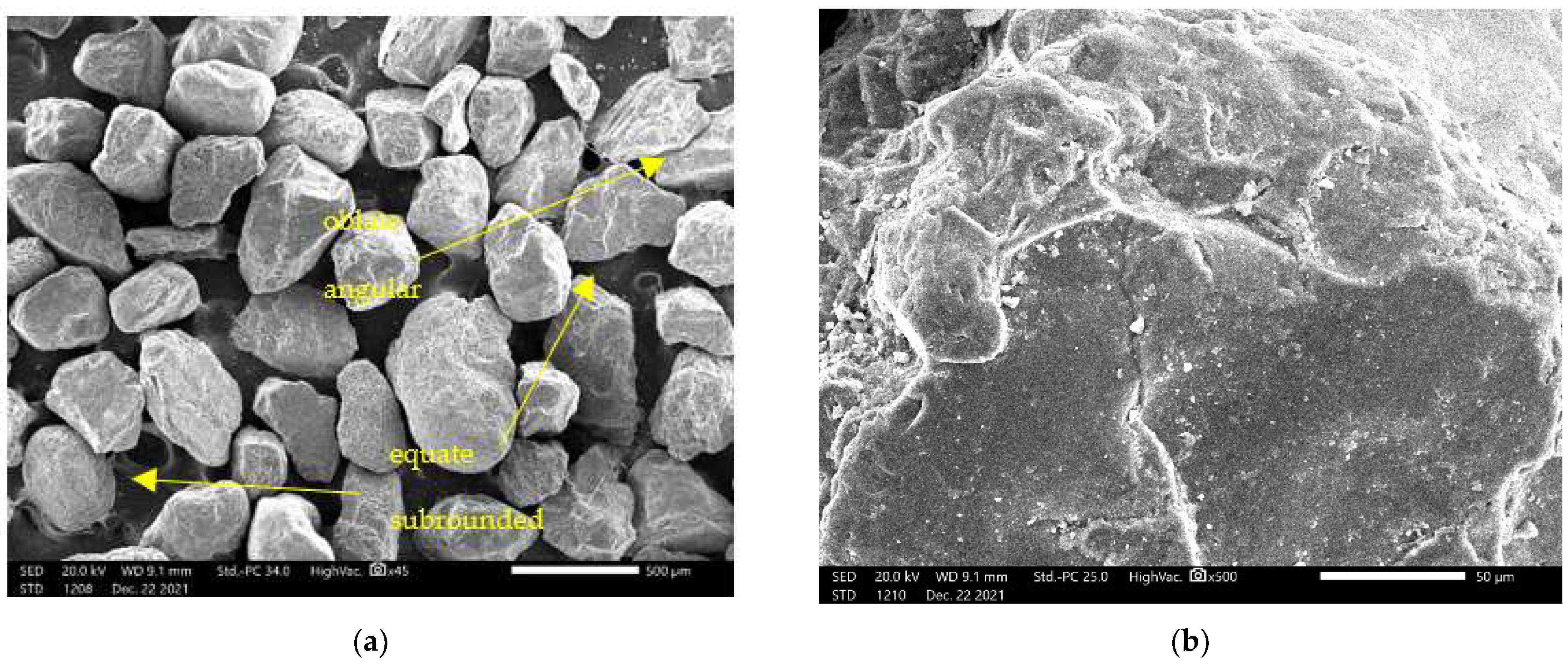

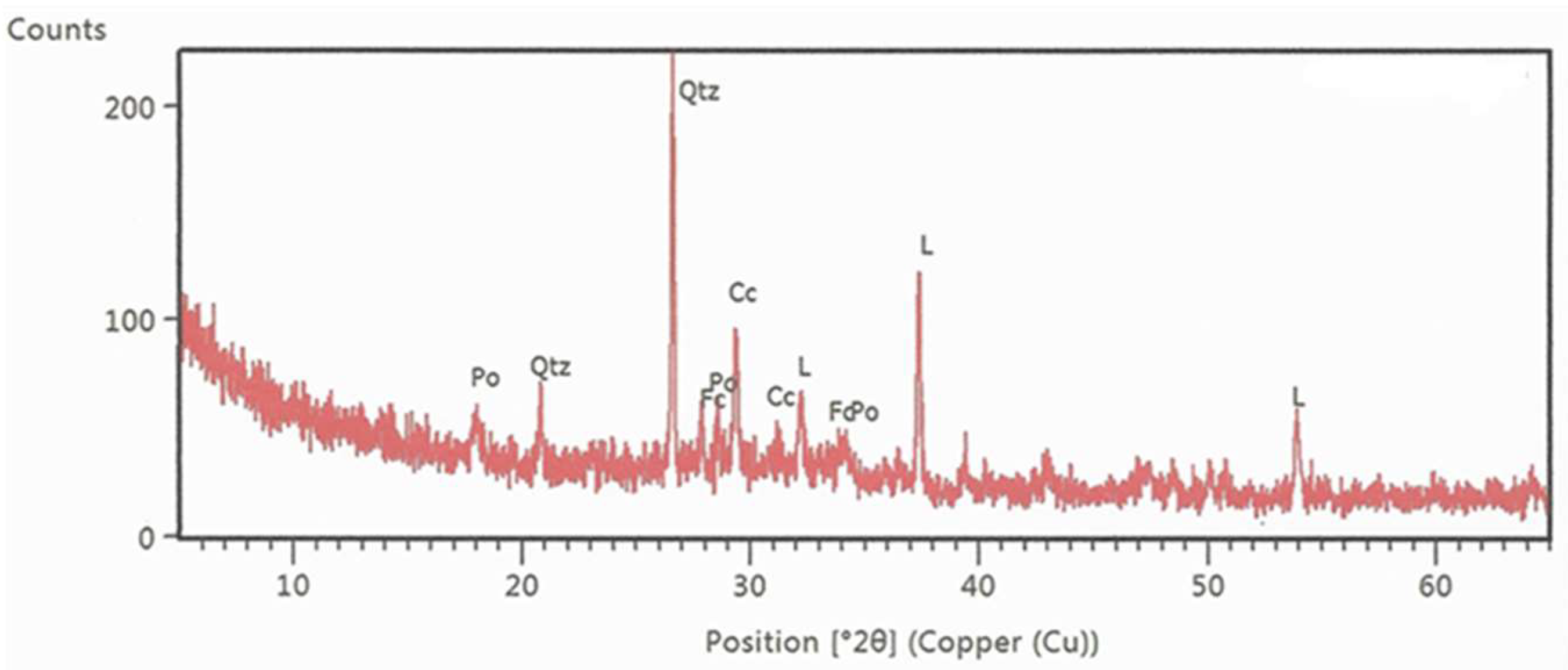

- Croatian Geological Survey. Testing Report on the Mineral Composition of Sand by X-Ray Diffraction Method (XRD) No. 24/21; Croatian Geological Survey: Zagreb, Croatia, 2021. [Google Scholar]

- Guideline on the Use of Sand in Road Construction in the SADC Region AFCAP/GEN/028/C, InfraAfrica (Pty) Ltd., Botswana CSIR, South Africa TRL Ltd., UK Roughton International, UK CPP Botswana (Pty) Ltd., May 2013. Available online: https://assets.publishing.service.gov.uk/media/57a08a39e5274a27b20004bb/AFCAP-GEN028-C-Sand-in-Road-Construction-Final-Guideline.pdf (accessed on 3 December 2021).

- Shalabi, F.I.; Mazher, J.; Khan, K.; Alsuliman, M.; Almustafa, I.; Mahmoud, W.; Alomran, N. Cement-Stabilized Waste Sand as Sustainable Construction Materials for Foundations and Highway Roads. Materials 2019, 12, 600. [Google Scholar] [CrossRef]

- HRN EN 14227-4:2013; Hydraulically Bound Mixtures—Specifications—Part 4: Fly Ash for Hydraulically Bound Mixtures. CEN: Brussels, Belgium, 2013.

- HRN EN 933-10:2009; Tests for Geometrical Properties of Aggregates—Part 10: Assessment of Fines—Grading of Filler Aggregates (Air Jet Sieving). CEN: Brussels, Belgium, 2009.

- HRN EN 450-1:2013; Fly Ash for Concrete—Part 1: Definition, Specifications and Conformity Criteria. CEN: Brussels, Belgium, 2013.

- Croatian Geological Survey. Testing Report on the Mineral Composition of Ash Samples by X-Ray Diffraction Method (XRD) No. 65/19; Croatian Geological Survey: Zagreb, Croatia, 2019. [Google Scholar]

- HRN EN 197-1:2012; Part 1: Composition, Specifications and Conformity Criteria for Common Cements. CEN: Brussels, Belgium, 2012.

- HRN EN 13286-2:2010; Unbound and Hydraulically Bound Mixtures—Part 2: Test Methods for Laboratory Reference Density and Water Content—Proctor Compaction. CEN: Brussels, Belgium, 2010.

- HRN EN 13286-47:2012; Unbound and Hydraulically Bound Mixtures—Part 47: Test Method for the Determination of California Bearing Ratio, Immediate Bearing Index and Linear Swelling. CEN: Brussels, Belgium, 2012.

- HRN EN 13286-41:2003; Unbound and Hydraulically Bound Mixtures—Part 41: Test Method for the Determination of the Compressive Strength of Hydraulically Bound Mixtures. CEN: Brussels, Belgium, 2003.

- HRN EN 13286-42:2003; Unbound and Hydraulically Bound Mixtures—Part 42: Test Method for the Determination of the Indirect Tensile Strength of Hydraulically Bound Mixtures. CEN: Brussels, Belgium, 2003.

- HRS CEN/TS 13286-54; Unbound and Hydraulically Bound Mixtures—Part 54: Test Method for the Determination of Frost Susceptibility. Resistance to Freezing and Thawing of Hydraulically Bound Mixtures. CEN: Brussels, Belgium, 2014.

- HRN EN 1367-1:2008; Tests for Thermal and Weathering Properties of Aggregates—Part 1: Determination of Resistance to Freezing and Thawing. CEN: Brussels, Belgium, 2008.

- ASTM D5239-98; Characterizing Fly Ash for Use in Soil Stabilization. ASTM: West Conshohocken, PA, USA, 1998.

- ASTM D6726-99a; Standard Test Method for Using pH to Estimate the Soil-Lime Proportion Requirement for Soil Stabilization. ASTM: West Conshohocken, PA, USA, 1999.

- Bell, F.G. Lime stabilization of clay minerals and soils. Eng. Geol. 1996, 42, 223–237. [Google Scholar] [CrossRef]

- Enríquez, E.; Torres-Carrasco, M.; Cabrera, M.J.; Muñoz, D.; Fernández, J.F. Towards more sustainable building based on modified Portland cements through partial substitution by engineered feldspars. Constr. Build. Mater. 2021, 269, 121334. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, J.Y.; Kim, Y.H.; Kim, D.; Kim, J.; Han, J.G. Evaluating the eco-compatibility of mortars with feldspar-based fine aggregate. Case Stud. Constr. Mater. 2022, 16, e00781. [Google Scholar] [CrossRef]

- Pratt, A. Cementitious Compositions Containing Feldspar and Pozzolanic Particulate Material, and Method of Making Said Compositin. U.S. Patent Patent No.: US 8,066,813 B2, 29 November 2011. [Google Scholar]

- Lahtinen, P. Fly Ash Mixtures as Flexible Structure Materials for Low-Volume Roads. Helsinki, Finnish Road Administration, Uusimaa Region. Finnra Reports 70. 2001. Available online: http://lib.tkk.fi/Diss/2001/isbn9512257076/isbn9512257076.pdf (accessed on 15 December 2021).

- Institute of Civil Engineering of Croatia. Pavement Structure. In General Technical Requirements for Road Work (GTR); IGH: Zagreb, Croatia, 2001; Volume 3. (In Croatian) [Google Scholar]

- Parylak, K. Influence of Particle Structure on Properties of Fly Ash and Sand. Mater. Sci. 1992, 1031–1041. [Google Scholar]

- ASTM C593-95; Standard Specification for Fly Ash and Other Pozzolans for Use with Lime. ASTM: West Conshohocken, PA, USA, 2000.

| Physical Properties | UCSC | Density (Mg/m3) | Color | D10 (mm) | D30 (mm) | D60 (mm) | Cu | Cc |

|---|---|---|---|---|---|---|---|---|

| SP | 2.68 | Grayish-Brown | 0.13 | 0.16 | 0.22 | 1.68 | 0.895 | |

| Mineralogical properties | type of mineral | quartz | calcite | dolomite | feldspars | clay minerals | ||

| mass % | 71 | 2 | 2 | 25 | 1.2 |

| Components | MgO | Al2O3 | SiO2 | P2O5 | SO3 | K2O | CaO |

|---|---|---|---|---|---|---|---|

| mass % | 3.06 | 0.44 | 4.05 | 2.90 | 1.59 | 2.82 | 46.9 |

| Initial Time Setting (min) | Stability of Volume According to Le Chatelier (mm) | Unconfined Compressive Strength (2, 28 Days) (MPa) | SO3 (%) | Cl (%) |

|---|---|---|---|---|

| 200 | 0.4 | 16.0; 42.0 | 3.20 | 0.009 |

| Test | Amount of WFA in Mixtures | ||||

|---|---|---|---|---|---|

| 0% | 10% | 20% | 30% | ||

| CBR 1 | % | 27.44 | 48.99 | 52.69 | 82.09 |

| CBR 2 | % | 18.96 | 59.39 | 56.82 | 90.70 |

| Linear swelling | % | 0.02 | 0.08 | 0.22 | 0.64 |

| Mix No. | Mixture Composition | OMC [%] | MDD [g/cm3] |

|---|---|---|---|

| 1 | (70% sand + 30% WA) + 0% cem | 13.50 | 1.72 |

| 2 | (70% sand + 30% WA) + 2% cem | 12.69 | 1.73 |

| 3 | (70% sand + 30% WA) + 4% cem | 11.61 | 1.70 |

| Drava Sand | 14.20 | 1.64 |

| Mix No. | Days of Curing | Model | Coefficient of Determination R2 |

|---|---|---|---|

| 1 | 7, 28, 90 | a = 0.2428 b = 0.0777 | 0.9078 |

| 2 | 7, 28, 90, 180 | a = 0.2089 b = 0.0411 | 0.9227 |

| 3 | 7, 28, 90, 180 | a = 0.2075 b = 0.0323 | 0.9435 |

| All mixtures | a = 0.2052 b = 0.0087 | 0.9470 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dimter, S.; Zagvozda, M.; Tonc, T.; Šimun, M. Evaluation of Strength Properties of Sand Stabilized with Wood Fly Ash (WFA) and Cement. Materials 2022, 15, 3090. https://doi.org/10.3390/ma15093090

Dimter S, Zagvozda M, Tonc T, Šimun M. Evaluation of Strength Properties of Sand Stabilized with Wood Fly Ash (WFA) and Cement. Materials. 2022; 15(9):3090. https://doi.org/10.3390/ma15093090

Chicago/Turabian StyleDimter, Sanja, Martina Zagvozda, Tea Tonc, and Miroslav Šimun. 2022. "Evaluation of Strength Properties of Sand Stabilized with Wood Fly Ash (WFA) and Cement" Materials 15, no. 9: 3090. https://doi.org/10.3390/ma15093090

APA StyleDimter, S., Zagvozda, M., Tonc, T., & Šimun, M. (2022). Evaluation of Strength Properties of Sand Stabilized with Wood Fly Ash (WFA) and Cement. Materials, 15(9), 3090. https://doi.org/10.3390/ma15093090