High Energy Storage Density in Nanocomposites of P(VDF-TrFE-CFE) Terpolymer and BaZr0.2Ti0.8O3 Nanoparticles

Abstract

:1. Introduction

2. Materials and Methods

3. Results

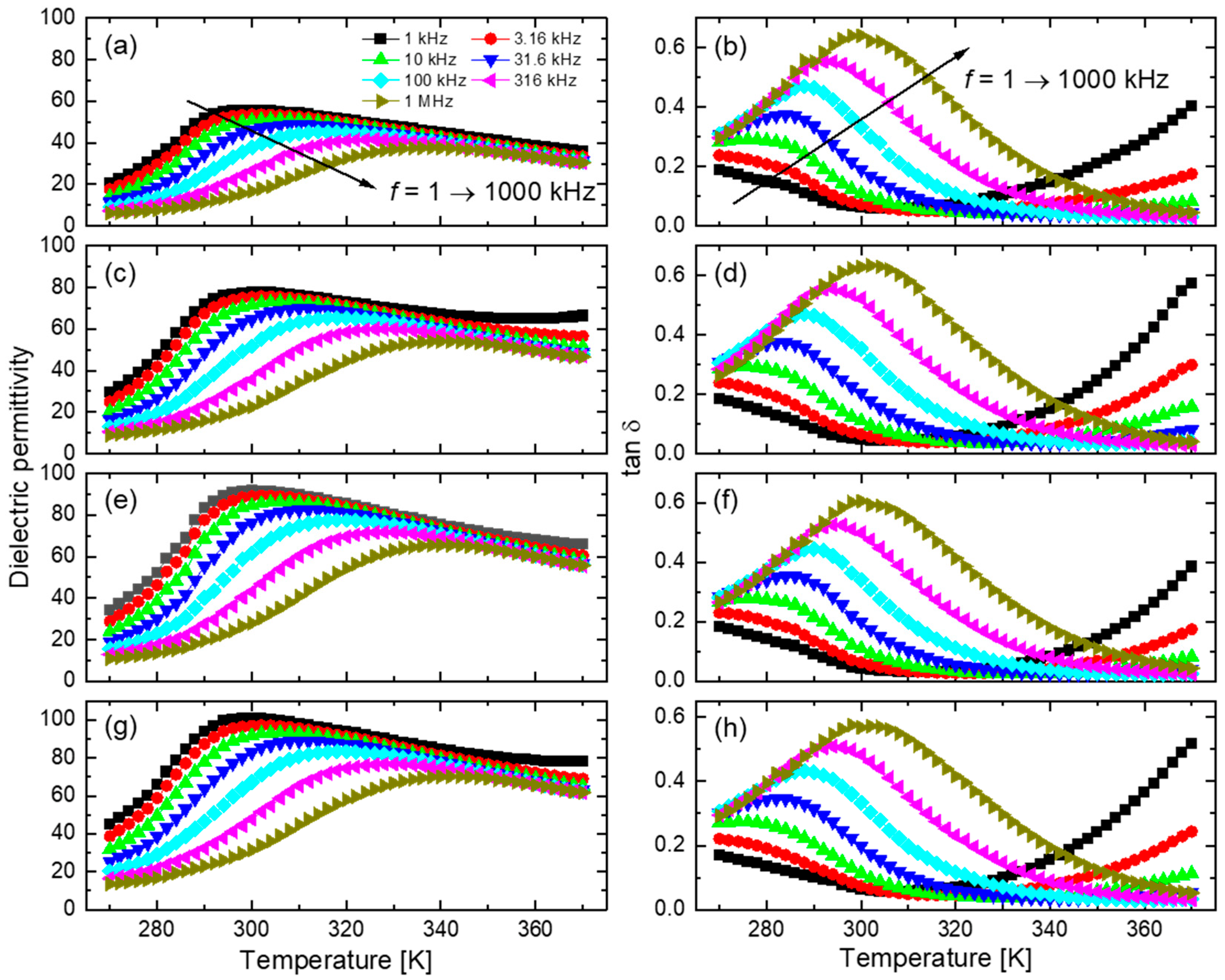

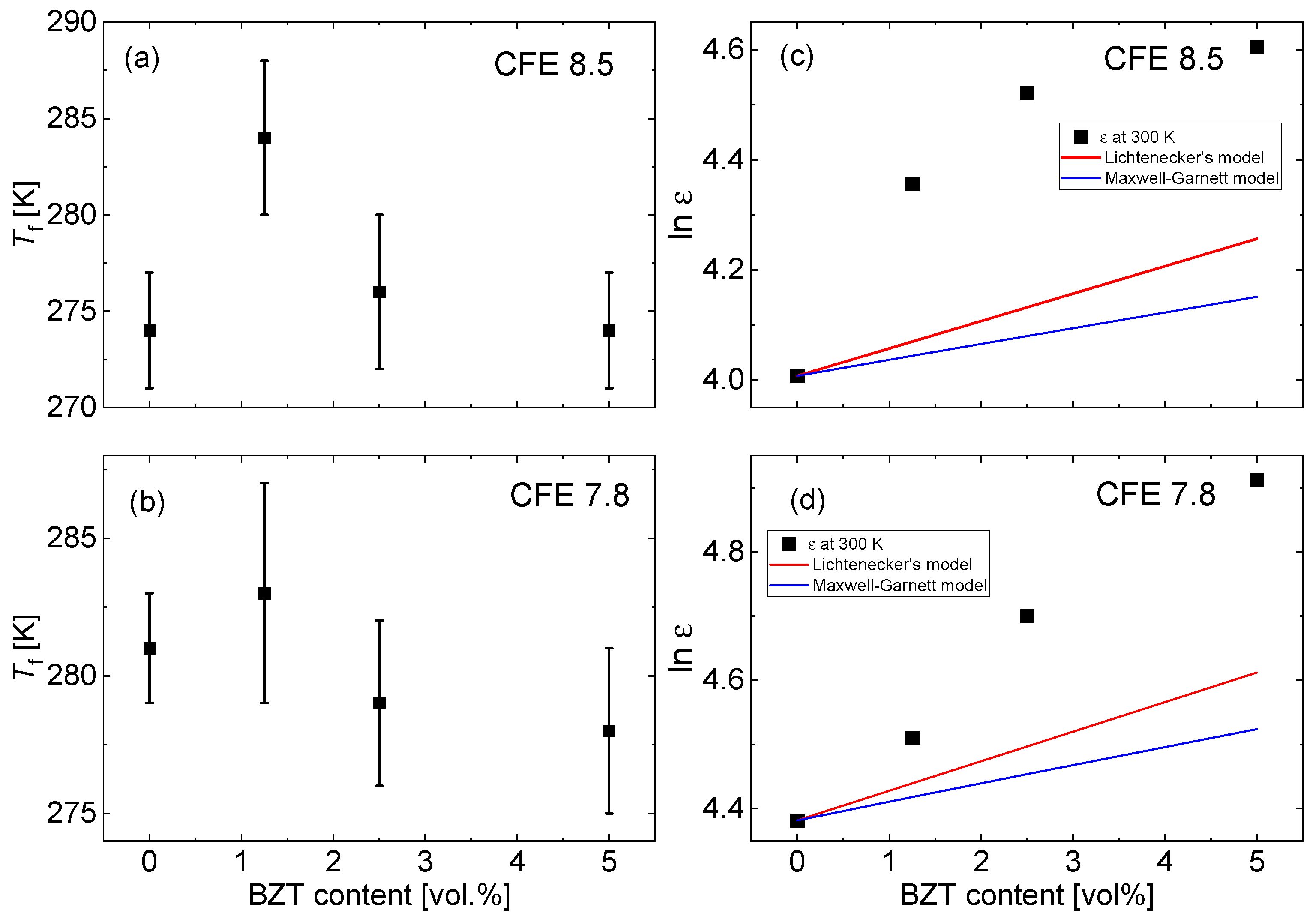

3.1. Dielectric Properties

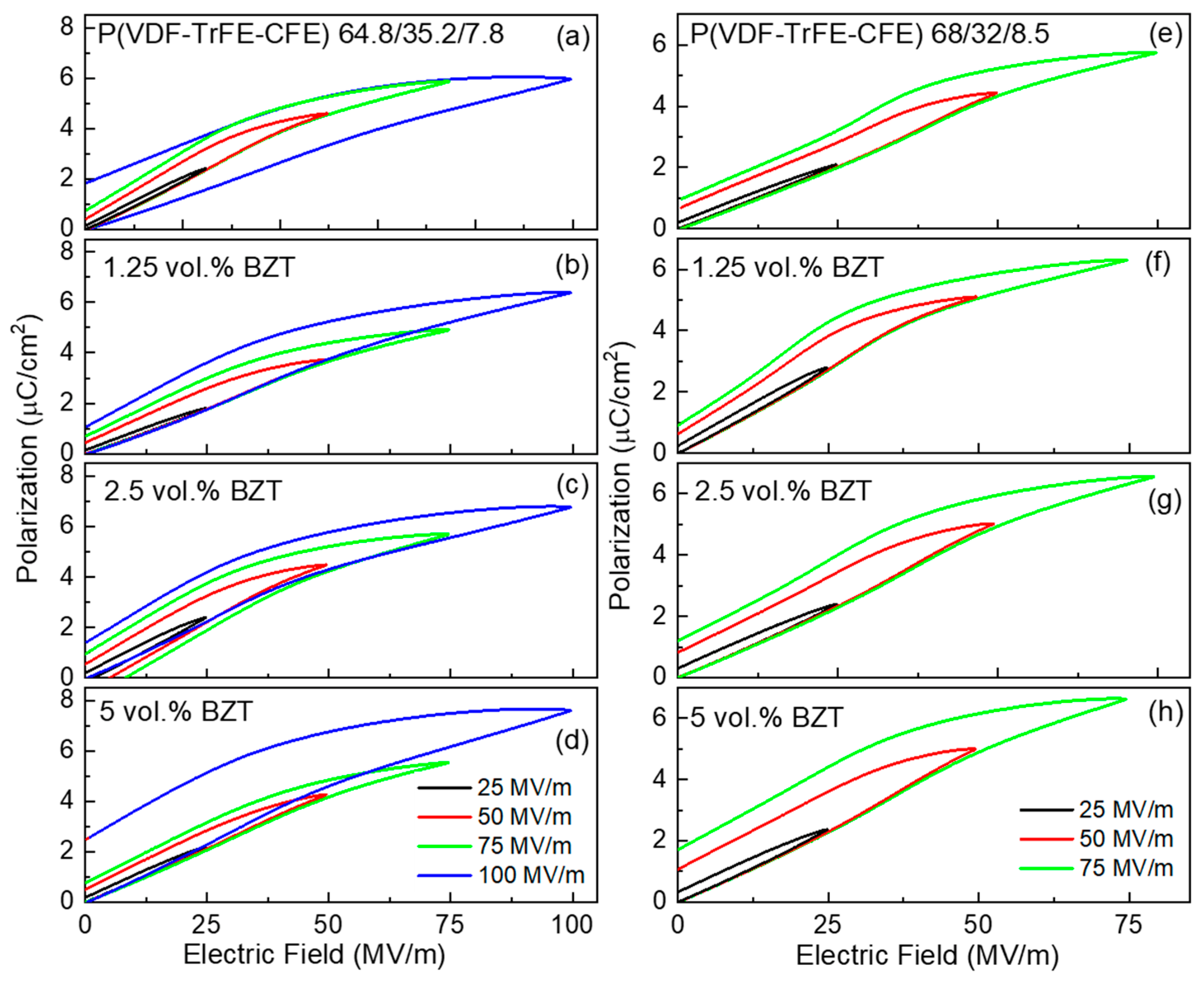

3.2. Polarization Hysteresis Loops

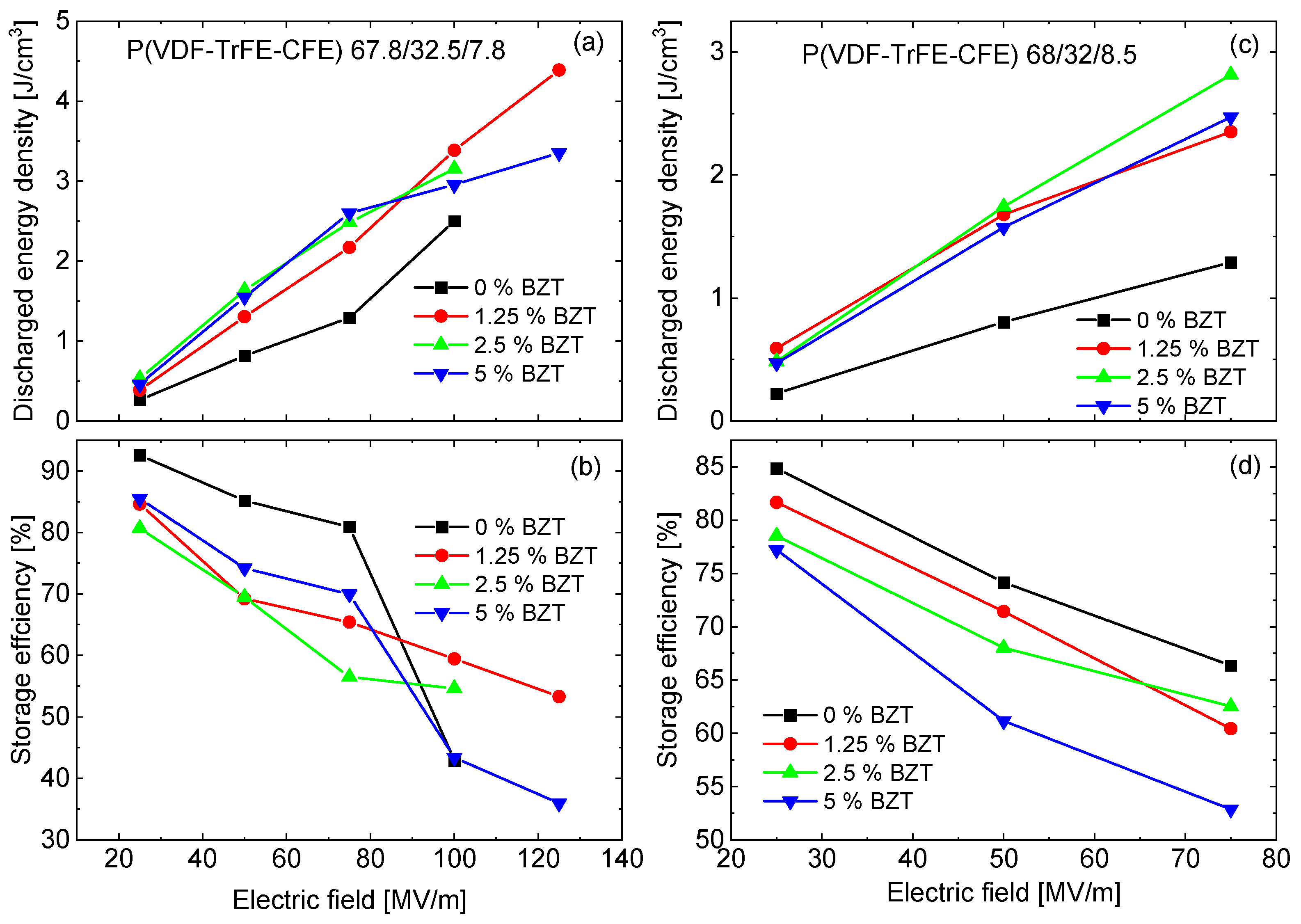

3.3. Energy Storage Properties

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, Z.; Wang, Z.; Tian, Y.; Wang, G.; Wang, W.; Yang, M.; Wang, X.; Zhang, F.; Pu, Y. Progress, outlook, and challenges in lead-free energy-storage ferroelectrics. Adv. Electron. Mater. 2020, 6, 1900698. [Google Scholar] [CrossRef]

- Nalwa, H.S. Ferroelectric Polymers: Chemistry: Physics, and Applications, 1st ed.; Taylor & Francis Inc.: Boca Raton, FL, USA, 1995. [Google Scholar]

- Wang, Y.; Zhou, X.; Chen, Q.; Chu, B.; Zhang, Q.M. Recent development of high energy density polymers for dielectric capacitors. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1036–1042. [Google Scholar] [CrossRef]

- Zhu, L. Exploring strategies for high dielectric constant and low loss polymer dielectrics. J. Phys. Chem. Lett. 2014, 5, 3677–3687. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.-H.; Jung, H.-B.; Lim, J.-H.; Ji, S.-Y.; Choi, D.H.; Jeong, D.-Y. Configurational approach to the enhancement of the dielectric properties and energy density of Polyvinylidene Fluoride-based polymer composites. J. Phys. D Appl. Phys. 2020, 53, 375502. [Google Scholar] [CrossRef]

- Li, C.; Shi, L.; Yang, W.; Zhou, Y.; Li, X.; Zhang, C.; Yang, Y. All polymer dielectric films for achieving high energy density film capacitors by blending Poly(Vinylidene Fluoride-Trifluoroethylene-Chlorofluoroethylene) with aromatic polythiourea. Nanoscale Res. Lett. 2020, 15, 36. [Google Scholar] [CrossRef]

- Thuau, D.; Kallitsis, K.; Ha, S.; Bargain, F.; Soulestin, T.; Pecastaings, G.; Tencé-Girault, S.; Santos, F.D.D.; Hadziioannou, G. High and temperature-independent dielectric constant dielectrics from PVDF-Based terpolymer and copolymer blends. Adv. Electron. Mater. 2020, 6, 1901250. [Google Scholar] [CrossRef]

- Shvartsman, V.V.; Lupascu, D.C. Lead-free relaxor ferroelectrics. J. Am. Ceram. Soc. 2012, 95, 1–26. [Google Scholar] [CrossRef]

- Yang, Z.; Du, H.; Jin, L.; Poelman, D. High-performance lead-free bulk ceramics for electrical energy storage applications: Design strategies and challenges. J. Mater. Chem. A 2021, 9, 18026–18085. [Google Scholar] [CrossRef]

- Palneedi, H.; Peddigari, M.; Hwang, G.-T.; Jeong, D.-Y.; Ryu, J. High-performance dielectric ceramic films for energy storage capacitors: Progress and outlook. Adv. Funct. Mater. 2018, 28, 1803665. [Google Scholar] [CrossRef]

- Kleemann, W. The relaxor enigma—Charge disorder and random fields in ferroelectrics. J. Mater. Sci. 2006, 41, 129–136. [Google Scholar] [CrossRef]

- Bokov, A.A.; Ye, Z.-G. Recent progress in relaxor ferroelectrics with perovskite structure. J. Mater. Sci. 2006, 41, 31–52. [Google Scholar] [CrossRef]

- Viehland, D.; Jang, S.J.; Cross, L.E.; Wuttig, M. Freezing of the polarization fluctuations in lead magnesium niobate relaxors. J. Appl. Phys. 1990, 68, 2916–2921. [Google Scholar] [CrossRef]

- Klein, R.J.; Xia, F.; Zhang, Q.M.; Bauer, F. Influence of composition on relaxor ferroelectric and electromechanical properties of Poly(Vinylidene Fluoride-Trifluoroethylene-Chlorofluoroethylene). J. Appl. Phys. 2005, 97, 94105. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Q. Ferroelectric polymers and their energy-related applications. Macromol. Chem. Phys. 2016, 217, 1228–1244. [Google Scholar] [CrossRef]

- Yang, L.; Li, X.; Allahyarov, E.; Taylor, P.L.; Zhang, Q.M.; Zhu, L. Novel polymer ferroelectric behavior via crystal isomorphism and the nanoconfinement effect. Polymer 2013, 54, 1709–1728. [Google Scholar] [CrossRef] [Green Version]

- Gadinski, M.R.; Li, Q.; Zhang, G.; Zhang, X.; Wang, Q. Understanding of relaxor ferroelectric behavior of Poly(Vinylidene Fluoride-Trifluoroethylene-Chlorotrifluoroethylene) terpolymers. Macromolecules 2015, 48, 2731–2739. [Google Scholar] [CrossRef]

- Hambal, Y.; Shvartsman, V.V.; Lewin, D.; Huat, C.H.; Chen, X.; Michiels, I.; Zhang, Q.M.; Lupascu, D.C. Effect of composition on polarization hysteresis and energy storage ability of P(VDF-TrFE-CFE) relaxor terpolymers. Polymers 2021, 13, 1343. [Google Scholar] [CrossRef]

- Chu, B.; Zhou, X.; Ren, K.; Neese, B.; Lin, M.; Wang, Q.; Bauer, F.; Zhang, Q.M. A dielectric polymer with high electric energy density and fast discharge speed. Science 2006, 313, 334–336. [Google Scholar] [CrossRef]

- Huang, H.; Scott, J.F. Ferroelectric Materials for Energy Applications; Wiley-VCH: Weinhaim, Germany, 2018. [Google Scholar]

- Streibl, M.; Karmazin, R.; Moos, R. Materials and applications of polymer films for power capacitors with special respect to nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 2429. [Google Scholar] [CrossRef]

- Solnyshkin, A.V.; Kislova, I.L.; Morsakov, I.M.; Belov, A.N.; Shevyakov, V.I.; Kiselev, D.A.; Shvartsman, V.V. Dielectric properties of composite based on ferroelectric copolymer of poly(vinylidene fluoride-trifluoroethylene) and ferroelectric ceramics of barium lead zirconate titanate. J. Adv. Dielectr. 2017, 7, 1720003. [Google Scholar] [CrossRef] [Green Version]

- Feng, X.; Wang, M.; Li, L.; Yang, Z.; Cao, M.; Cheng, Z.-Y. Enhanced thermal and pyroelectric properties in 0–3 TGS:PVDF composites doped with graphene for infrared application. J. Adv. Dielectr. 2017, 7, 1750006. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Y.; Zhou, M.; Shen, Z.; Zhang, X.; Pan, H.; Lin, Y.-H. Ferroelectric polymers and their nanocomposites for dielectric energy storage applications. APL Mater. 2021, 9, 020905. [Google Scholar] [CrossRef]

- Tsutsumi, N.; Tanaka, R.; Kinashi, K.; Sakai, W. Re-evaluation of the energy density properties of VDF ferroelectric thin-film capacitors. ACS Omega 2020, 5, 30468–30477. [Google Scholar] [CrossRef]

- Tang, H.; Lin, Y.; Sodano, H.A. Ultra high energy density nanocomposite capacitors using surface-functionalized BaTiO3 nanowires and PVDF-TrFE-CFE. In Proceedings of the Behavior and Mechanics of Multifunctional Materials and Composites 2012, San Diego, CA, USA, 12–15 March 2012; p. 834206. [Google Scholar] [CrossRef]

- Tang, H.; Lin, Y.; Sodano, H.A. Synthesis of high aspect ratio BaTiO3 nanowires for high energy density nanocomposite capacitors. Adv. Energy Mater. 2013, 3, 451–456. [Google Scholar] [CrossRef]

- Shen, Y.; Shen, D.; Zhang, X.; Jiang, J.; Dan, Z.; Song, Y.; Lin, Y.; Lia, M.; Nan, C.-W. High energy density of polymer nanocomposites at a low electric field induced by modulation of their topological-structure. J. Mater. Chem. A 2016, 4, 8359–8365. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, C.; Feng, Y.; Zhang, T.; Chen, Q.; Chi, Q.; Liu, L.; Wang, X.; Lei, Q. Energy storage enhancement of P(VDF-TrFE-CFE)-based composites with double-shell structured BZCT nanofibers of parallel and orthogonal configurations. Nano Energy 2019, 66, 104195. [Google Scholar] [CrossRef]

- Xue, J.; Zhang, T.; Zhang, C.; Zhang, Y.; Feng, Y.; Zhang, Y.; Chi, Q. Excellent energy storage performance for P(VDF-TrFE-CFE) composites by filling core–shell structured inorganic fibers. J. Mater. Sci. Mater. Electron. 2020, 31, 21128–21141. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, T.; Zhang, C.; Feng, Y.; Zhang, Y.; Zhang, Y.; Chi, Q.; Wang, X.; Lei, Q. Improved energy storage performance of P(VDF-TrFE-CFE) multilayer films by utilizing inorganic functional layers. ACS Appl. Energy Mater. 2021, 4, 11726–11734. [Google Scholar] [CrossRef]

- Ye, H.; Jiang, H.; Luo, Z.; Xu, L. Elastic interface in few-layer graphene/poly(vinylidenefluoride-trifluoroethylene-chlorofluoroethylene) nanocomposite with improved polarization. J. Appl. Polym. Sci. 2022, 139, e52030. [Google Scholar] [CrossRef]

- Zhu, M.-H.; Yu, Q.-C.; Song, H.-G.; Chen, T.-X.; Chen, J.-M. Rational design of high-energy-density polymer composites by machine learning approach. ACS Appl. Energy Mater. 2021, 4, 1449–1458. [Google Scholar] [CrossRef]

- Simon, A.; Ravez, J.; Ma glione, M. The crossover from a ferroelectric to a relaxor state in lead-free solid solutions. J. Phys. Condens. Matter. 2004, 16, 963–970. [Google Scholar] [CrossRef]

- Shvartsman, V.V.; Zhai, J.; Kleemann, W. The dielectric relaxation in solid solutions BaTi1-xZrxO3. Ferroelectrics 2009, 379, 77–85. [Google Scholar] [CrossRef]

- Baek, C.; Wang, J.E.; Ryu, S.; Kim, J.-H.; Jeong, C.K.; Park, K.-I.; Kim, D.K. Facile hydrothermal synthesis of BaZrxTi1−xO3 nanoparticles and their application to a lead-free nanocomposite generator. RSC Adv. 2017, 7, 2851–2856. [Google Scholar] [CrossRef] [Green Version]

- Shanshan, G.; Escobar Castillo, M.; Shvartsman, V.V.; Karabasov, M.; Lupascu, D.C. Electrocaloric effect in P(VDF-TrFE)/barium zirconium titanate composites. In Proceedings of the 2019 IEEE International Symposium on Applications of Ferroelectrics (ISAF), Lausanne, Switzerland, 14–19 July 2019; pp. 1–3. [Google Scholar] [CrossRef]

- Hambal, Y.; Menze, K.-H.; Shvartsman, V.V.; Lupascu, D.C. Directly measured electrocaloric effect in relaxor polymer nanocomposites. In Proceedings of the 2021 IEEE International Symposium on Applications of Ferroelectrics (ISAF), Sidney, Australia, 16–21 May 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Aziguli, H.; Chen, X.; Liu, Y.; Yang, G.; Yu, P.; Wang, Q. Enhanced electrocaloric effect in lead-free organic and inorganic relaxor ferroelectric composites near room temperature. Appl. Phys. Lett. 2018, 112, 193902. [Google Scholar] [CrossRef]

- Hu, X.; Yi, K.; Liu, Y.; Chu, B. High energy density dielectrics based on PVDF-based polymers. Energy Technol. 2018, 6, 849–864. [Google Scholar] [CrossRef]

- Chen, X.-Z.; Li, X.; Qian, X.-S.; Lin, M.; Wu, S.; Shen, Q.-D.; Zhang, Q.-M. A nanocomposite approach to tailor electrocaloric effect in ferroelectric polymer. Polymer 2013, 54, 5299–5302. [Google Scholar] [CrossRef]

- Asandulesa, M.; Kostromin, S.; Tameev, A.; Aleksandrov, A.; Bronnikov, S. Molecular dynamics and conductivity of a PTB7:PC71BM photovoltaic polymer blend: A dielectric spectroscopy study. ACS Appl. Polym. Mater. 2021, 3, 4869–4878. [Google Scholar] [CrossRef]

- Indra Devi, P.; Ramachandran, K. Dielectric studies on hybridised PVDF-Zno nanocomposites. J. Exp. Nanosci. 2011, 6, 281–293. [Google Scholar] [CrossRef]

- Feng, Y.; Li, W.L.; Hou, Y.F.; Yu, Y.; Cao, W.P.; Zhang, T.D.; Fei, W.D. Enhanced dielectric properties of PVDF-HFP/BaTiO3-nanowire composites induced by interfacial polarization and wire-shape. J. Mater. Chem. C 2015, 3, 1250–1260. [Google Scholar] [CrossRef]

- Bunget, I.; Popescu, M. Physics of Solid Dielectrics; Elsevier: Amsterdam, The Netherlands, 1984; pp. 249–252. [Google Scholar]

- Liu, T.; Pang, Y.; Zhu, M.; Kobayashi, S. Microporous Co@CoO nanoparticles with superior microwave absorption properties. Nanoscale 2014, 6, 2447–2454. [Google Scholar] [CrossRef] [Green Version]

- Thakur, Y.; Zhang, T.; Iacob, C.; Yang, T.; Bernholc, J.; Chen, L.Q.; Runt, J.; Zhang, Q.M. Enhancement of the dielectric response in polymer nanocomposites with low dielectric constant fillers. Nanoscale 2017, 9, 10992–10997. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Chen, X.; Thakur, Y.; Lu, B.; Zhang, Q.; Runt, J.; Zhang, Q.M. A highly scalable dielectric metamaterial with superior capacitor performance over a broad temperature. Sci. Adv. 2020, 6, eaax6622. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Filler | Morphology | Fraction | Electric Field (MV/m) | Discharged Energy Density (J/cm3) | Reference |

|---|---|---|---|---|---|

| Ba(Zr,Ti)O3 | Nanoparticles | 2.5 vol.% | 75 | 2.8 | This work |

| Ba(Zr,Ti)O3 | Nanoparticles | 1.25 vol.% | 125 | 4.5 | This work |

| Ba(Zr,Ti)O3 | Intralayer | 75/125 | 1.3/2.2 | [31] | |

| SrTiO3 | Nanofibers | 7 vol.% | 75/125 | 1.0/2.2 | [30] |

| BaTiO3 | Nanowires | 17.5 vol.% | 75 | 1.6 | [26] |

| BaTiO3 | Nanowires | 17.5 vol.% | 100 | 2.0 | [27] |

| BaTiO3@TiO2 | Nanofibers | 10 wt.% | 150 | 2.9 | [28] |

| (Ba,Ca)(Zr,Ti)O3 | Nanofibers | 3 vol.% | 75/125 | 1.0/1.3 | [29] |

| Graphene | Sheets | 0.5 wt.% | 125 | 1.2 | [32] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hambal, Y.; Shvartsman, V.V.; Michiels, I.; Zhang, Q.; Lupascu, D.C. High Energy Storage Density in Nanocomposites of P(VDF-TrFE-CFE) Terpolymer and BaZr0.2Ti0.8O3 Nanoparticles. Materials 2022, 15, 3151. https://doi.org/10.3390/ma15093151

Hambal Y, Shvartsman VV, Michiels I, Zhang Q, Lupascu DC. High Energy Storage Density in Nanocomposites of P(VDF-TrFE-CFE) Terpolymer and BaZr0.2Ti0.8O3 Nanoparticles. Materials. 2022; 15(9):3151. https://doi.org/10.3390/ma15093151

Chicago/Turabian StyleHambal, Yusra, Vladimir V. Shvartsman, Ivo Michiels, Qiming Zhang, and Doru C. Lupascu. 2022. "High Energy Storage Density in Nanocomposites of P(VDF-TrFE-CFE) Terpolymer and BaZr0.2Ti0.8O3 Nanoparticles" Materials 15, no. 9: 3151. https://doi.org/10.3390/ma15093151