An Empirical Dilatancy Model for Coarse-Grained Soil under the Influence of Freeze–Thaw Cycles

Abstract

:1. Introduction

2. Development of an Empirical Model for CGS under Different FTCs

3. Results and Discussion

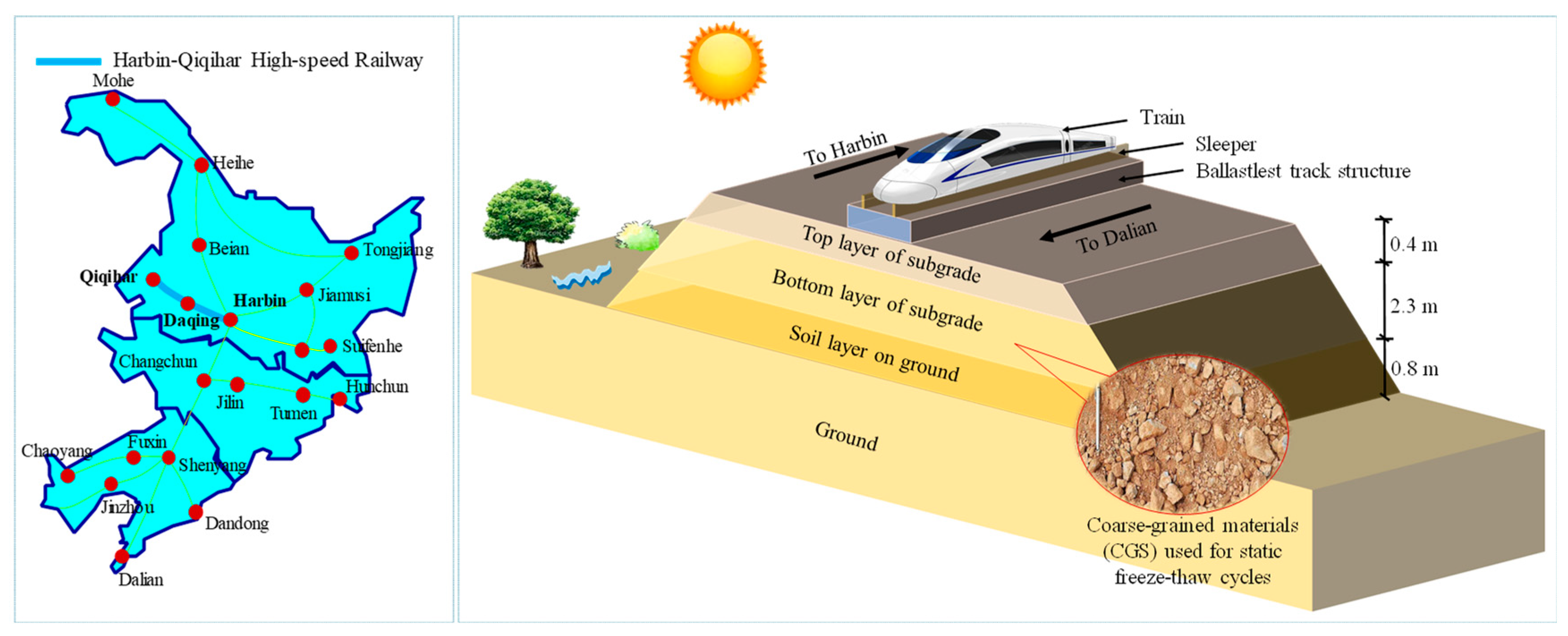

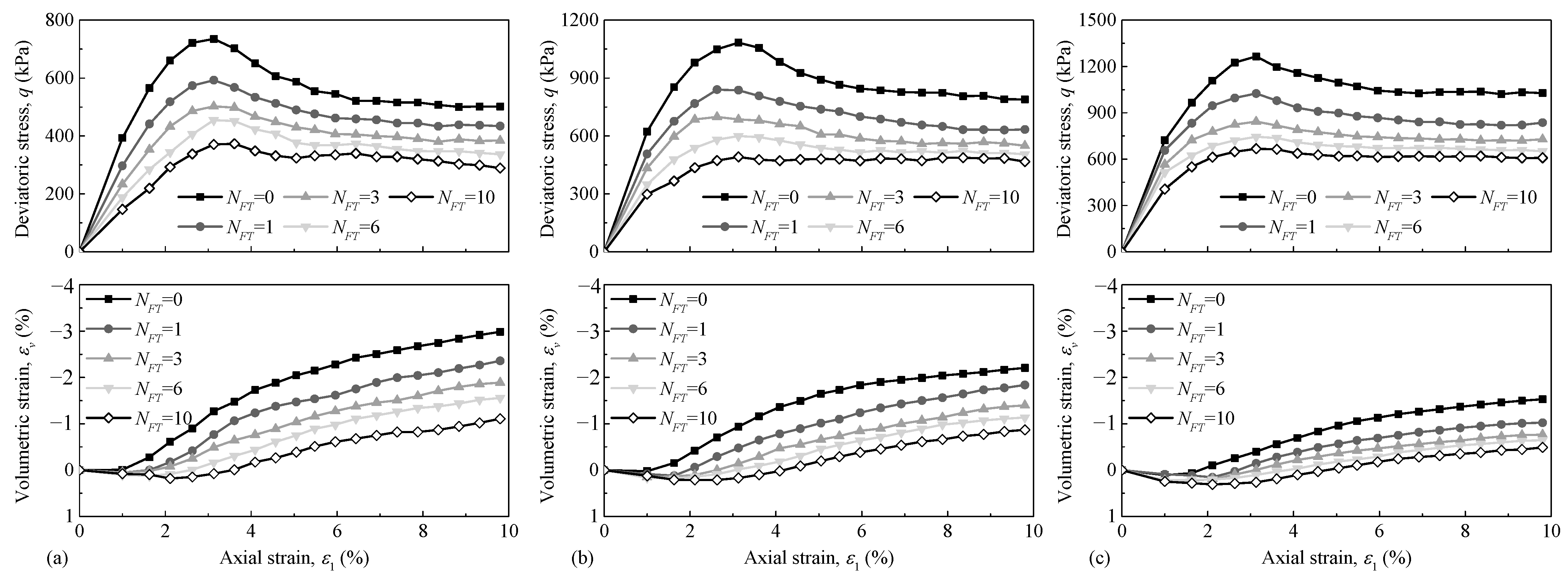

3.1. Static Freeze–Thaw Triaxial Test

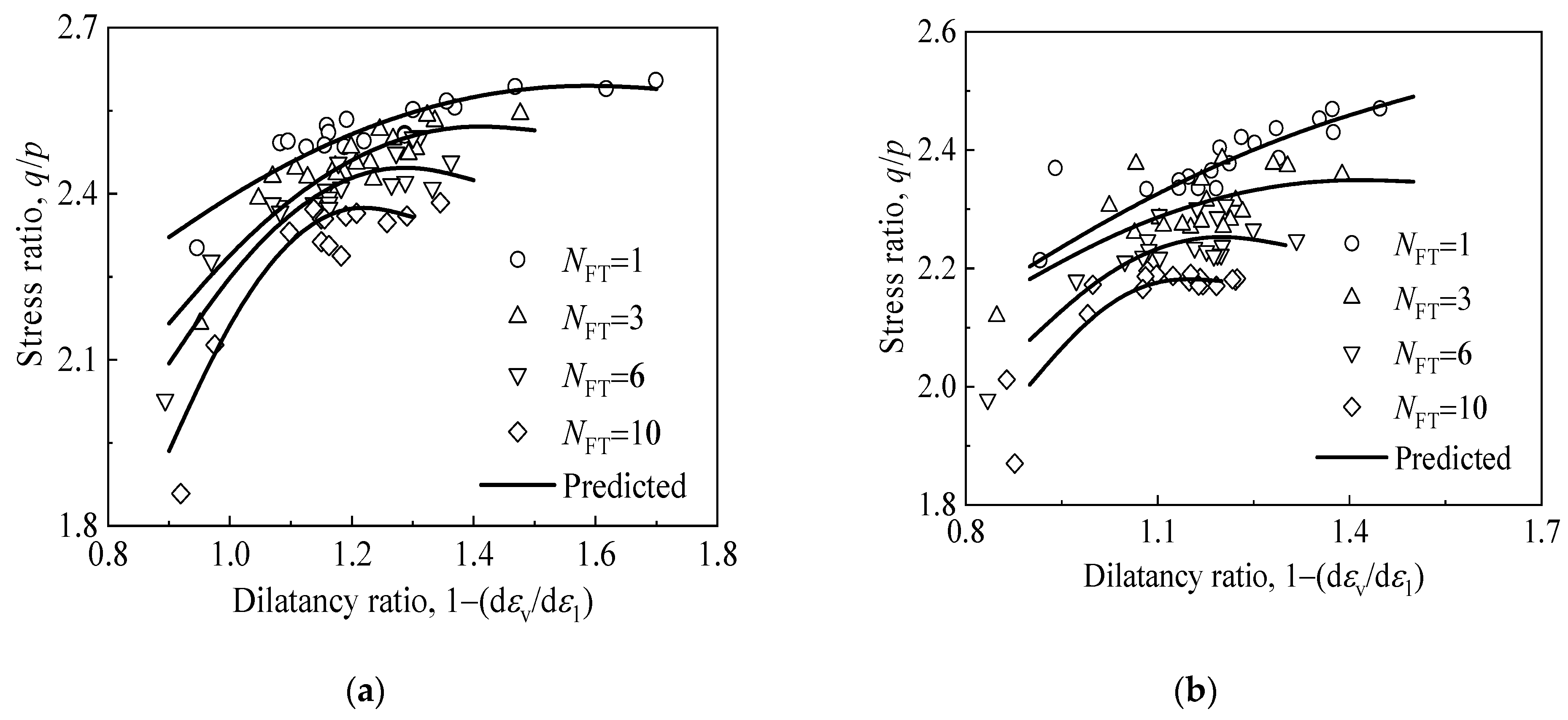

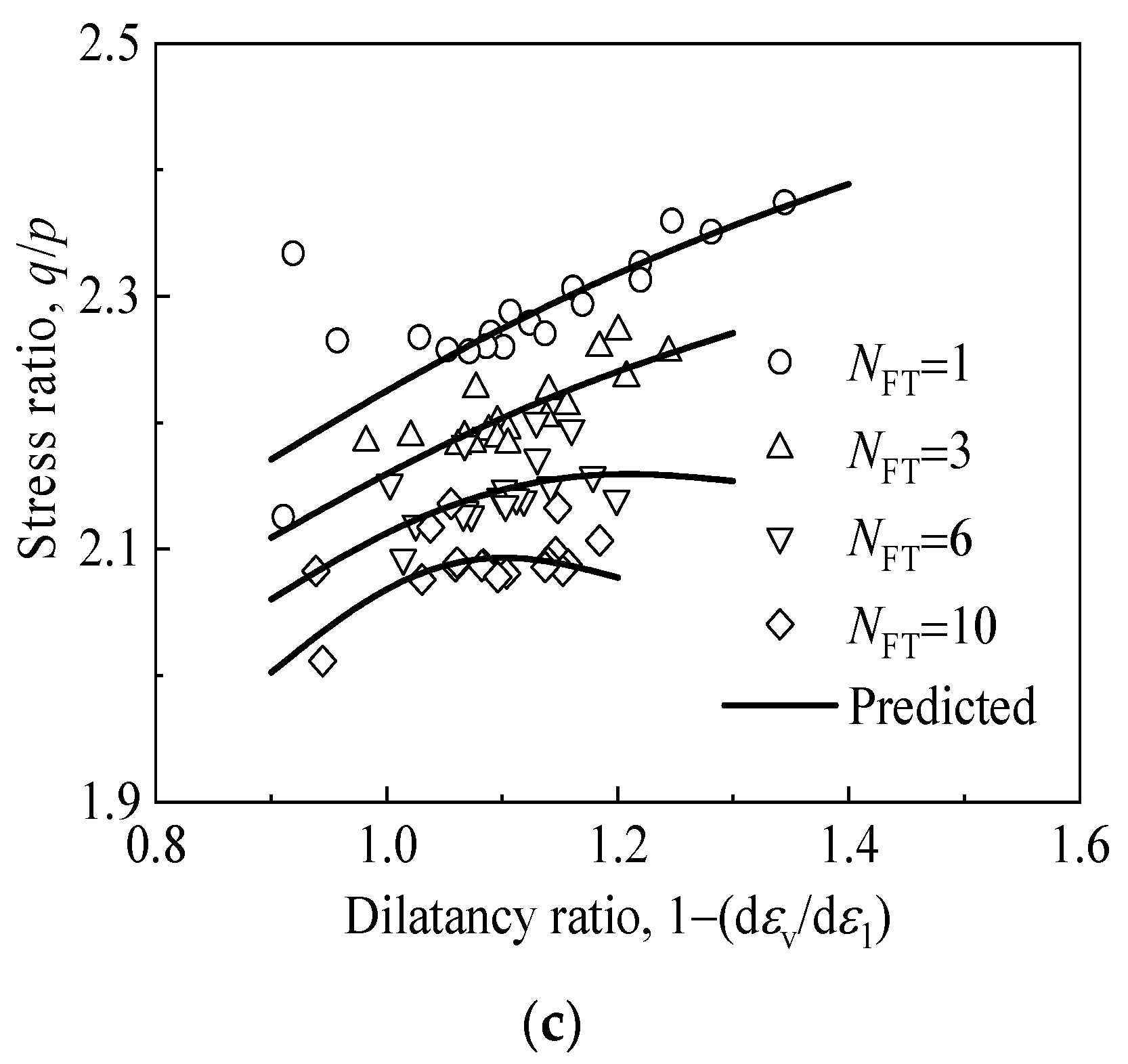

3.2. An Empirical Dilatancy Model for CGS Considering FTCs

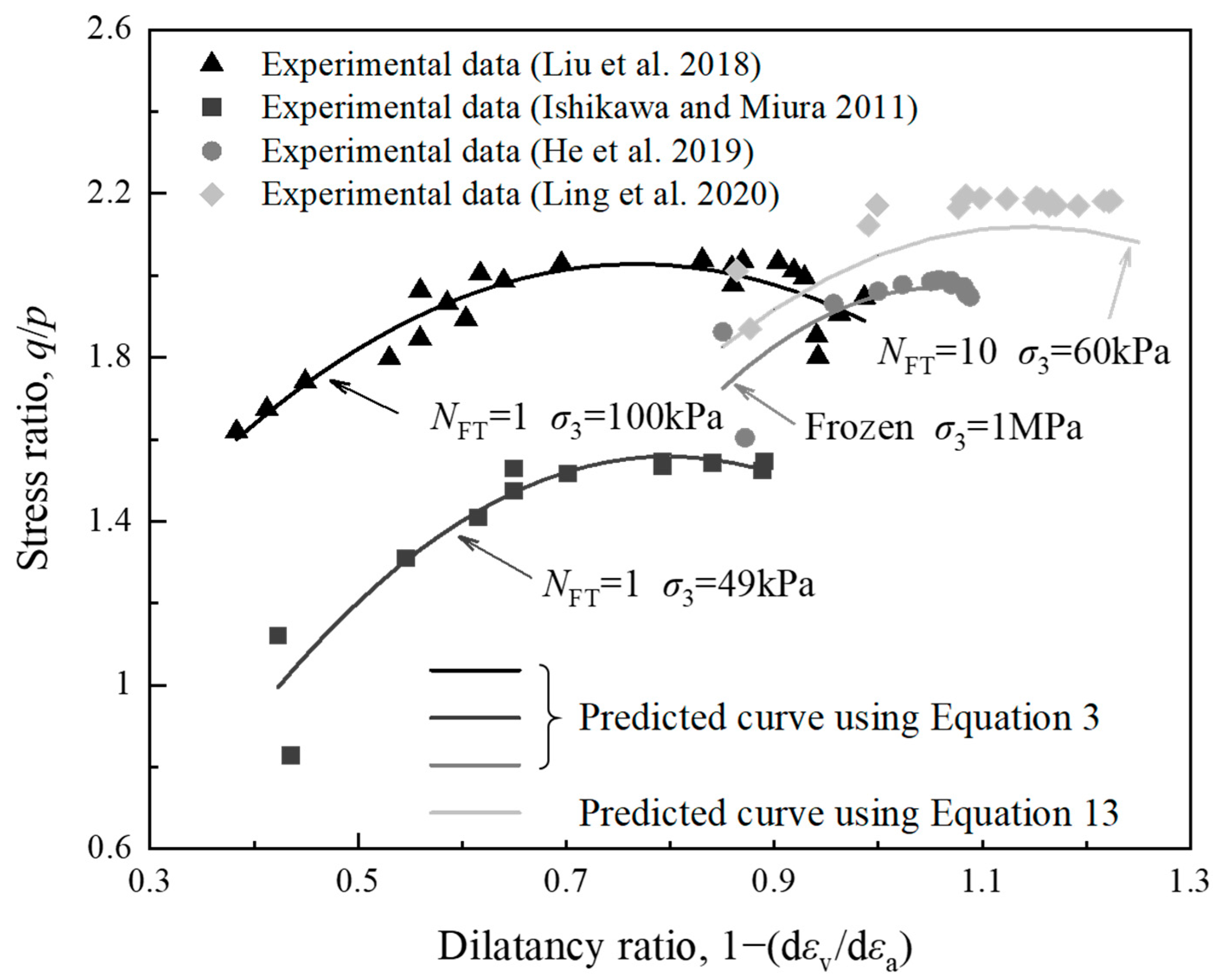

3.3. Validation of the Proposed Equation with the Literature

4. Conclusions

- (1)

- An empirical dilatancy model of CGS considering FTCs was proposed to represent the dilatancy of CGS. The relationship between the stress ratio and the dilatancy ratio can be well-captured by a second-order polynomial fitting. The values of the empirical constants a, b and c introduced in this model depend on the FTCs and σ3.

- (2)

- The best fit a and c values increase in the form of an exponential function with increasing σ3, while b values exhibit the opposite trend. On the other hand, the changing law of the a and b values increase with increasing FTCs following a form of an exponential function. Meanwhile, c values exhibit the opposite trend. It is interesting to note that the a, b, and c values vary between −0.37 and −4.53, 1.82 and 11.03, −4.32 and 1.41, respectively.

- (3)

- The prediction performance of the proposed model was verified using experimental data, and the validity and applicability of the proposed model was validated. The minimum value of the biggest determination coefficient R2 is 0.816 except for sandy soil under frozen state, which show that the proposed non-linear stress-dilatancy equation capture the test data well for the FTC conditions.

- (4)

- Further research is needed to address the limitations in the present study; for instance, certain aspects related to stress-induced anisotropy, the effects of creep, long-term cyclic loading and the influence of particle breakage will need to be investigated in the future as an extension of the proposed model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Taylor, D.W. Fundamentals of Soil Mechanics; LWW: Philadelphia, PA, USA, 1948. [Google Scholar]

- Rowe, P.W. The stress-dilatancy relation for static equilibrium of an assembly of particles in contact. Proc. R. Soc. Lond. A Math. Phys. Sci. 1962, 269, 500–527. [Google Scholar] [CrossRef]

- Rowe, P.W. The relation between the shear strength of sands in triaxial compression, plane strain and direct. Géotechnique 1969, 19, 75–86. [Google Scholar] [CrossRef]

- Wroth, C.P.; Bassett, R.H. A stress–Strain relationship for the shearing behaviour of a sand. Géotechnique 1965, 15, 32–56. [Google Scholar] [CrossRef]

- Bolton, M.D. The strength and dilatancy of sands. Géotechnique 1986, 36, 65–78. [Google Scholar] [CrossRef] [Green Version]

- Houlsby, G.T. How the Dilatancy of Soils Affects Their Behaviour; University of Oxford: Oxford, UK, 1991. [Google Scholar]

- Mitchell, J.K.; Soga, K. Fundamentals of Soil Behavior; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Ling, X.Z.; Zhang, F.; Li, Q.L.; An, L.S.; Wang, J.H. Dynamic shear modulus and damping ratio of frozen compacted sand subjected to freeze–thaw cycle under multi-stage cyclic loading. Soil Dyn. Earthq. Eng. 2015, 76, 111–121. [Google Scholar] [CrossRef]

- Lai, Y.M.; Yang, Y.G.; Chang, X.X.; Li, S.Y. Strength criterion and elastoplastic constitutive model of frozen silt in generalised plastic mechanics. Int. J. Plast. 2010, 26, 1461–1484. [Google Scholar] [CrossRef]

- Liu, Y.; Deng, H.W.; Xu, J.B.; Tian, G.L.; Deng, J.R. Association study on the pore structure and mechanical characteristics of coarse-grained soil under freeze–thaw cycles. Minerals 2022, 12, 314. [Google Scholar] [CrossRef]

- Li, S.Z.; Ye, Y.S.; Tang, L.; Cai, D.G.; Tian, S.; Ling, X.Z. Experimental study on the compaction characteristics and evaluation method of coarse-grained materials for subgrade. Materials 2021, 14, 6972. [Google Scholar] [CrossRef]

- Andrzejuk, W.; Danuta, B.H.; Jacek, G. Physical properties of mineral and recycled aggregates used to mineral-asphalt mixtures. Materials 2019, 12, 3437. [Google Scholar] [CrossRef] [Green Version]

- Huang, S.; Liu, Q.; Cheng, A.; Liu, Y. A statistical damage constitutive model under freeze-thaw and loading for rock and its engineering application. Cold Reg. Sci. Technol. 2018, 145, 142–150. [Google Scholar] [CrossRef]

- Liu, J.; Chang, D.; Yu, Q. Influence of freeze-thaw cycles on mechanical properties of a silty sand. Eng. Geol. 2016, 210, 23–32. [Google Scholar] [CrossRef]

- Liu, Q.; Huang, S.; Kang, Y.; Liu, X. A prediction model for uniaxial compressive strength of deteriorated rocks due to freeze–thaw. Cold Reg. Sci. Technol. 2015, 120, 96–107. [Google Scholar] [CrossRef]

- Tang, L.; Cong, S.; Geng, L.; Ling, X.Z.; Gan, F.D. The effect of freeze-thaw cycling on the mechanical properties of expansive soils. Cold Reg. Sci. Technol. 2018, 145, 197–207. [Google Scholar] [CrossRef]

- Güllü, H.; Khudir, A. Effect of freeze–Thaw cycles on unconfined compressive strength of fine-grained soil treated with jute fiber, steel fiber and lime. Cold Reg. Sci. Technol. 2014, 106–107, 55–65. [Google Scholar] [CrossRef]

- Chu, J. Strain Softening Behaviour of Granular Soils under Strain Path Testing. Ph.D. Thesis, University of New South Wales, Sydney, NSW, Australia, 1991. [Google Scholar]

- Chen, X.B.; Zhang, J.S. Effect of clay invasion on shear behavior and dilatancy of unbound aggregate subbase. Transp. Geotech. 2016, 6, 16–25. [Google Scholar] [CrossRef]

- SarojiniAmma, B.K.; Indraratna, B.; Vinod, J.S. A semi-empirical dilatancy model for ballast fouled with plastic fines. Geomech. Geoeng. 2018, 14, 12–17. [Google Scholar] [CrossRef]

- Chen, J.; Indraratna, B.; Vinod, J.S.; Ngo, N.T.; Gao, R.; Liu, Y. Stress-dilatancy behaviour of fouled ballast: Experiments and DEM modelling. Granul. Matter. 2021, 23, 90. [Google Scholar] [CrossRef]

- He, J.; Luo, F.; Zhu, Z.; Zhang, Y.; Ling, C.; Zou, Z. An elastoplastic constitutive model for frozen sandy soil considering particle breakage. Eur. J. Environ. Civ. Eng. 2019, 26, 320–344. [Google Scholar] [CrossRef]

- Ling, X.; Tian, S.; Tang, L.; Li, S. A damage-softening and dilatancy prediction model of coarse-grained materials considering freeze–thaw effects. Transp. Geotech. 2020, 22, 100307. [Google Scholar] [CrossRef]

- Tian, S.; Indraratna, B.; Tang, L.; Qi, Y.; Ling, X. A semi-empirical elasto-plastic constitutive model for coarse-grained materials that incorporates the effects of freeze–thaw cycles. Transp. Geotech. 2020, 24, 100373. [Google Scholar] [CrossRef]

- Ishikawa, T.; Miura, S. Influence of freeze–Thaw action on deformation-strength characteristics and particle crushability of volcanic coarse-grained soils. Soils Found. 2011, 51, 785–799. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Huang, R.; Liu, E.; Hou, F. Mechanical behaviour and constitutive model of tailing soils subjected to freeze-thaw cycles. Eur. J. Environ. Civ. Eng. 2021, 25, 673–695. [Google Scholar] [CrossRef]

| Confining Pressure, σ3 (kPa) | FTC, NFT (−) | a | b | c | R2 |

|---|---|---|---|---|---|

| 30 | 1 | −0.5822 | 1.8480 | 1.1303 | 0.825 |

| 3 | −1.3870 | 3.9102 | −0.2301 | 0.808 | |

| 6 | −2.4030 | 6.1883 | −1.5292 | 0.869 | |

| 10 | −4.5342 | 11.0304 | −4.3194 | 0.909 | |

| 60 | 1 | −0.3523 | 1.3240 | 1.2973 | 0.856 |

| 3 | −0.6427 | 1.8171 | 1.0671 | 0.543 | |

| 6 | −2.0180 | 4.8403 | −0.6425 | 0.823 | |

| 10 | −3.3690 | 7.6584 | −2.1612 | 0.845 | |

| 90 | 1 | −0.2907 | 1.1040 | 1.4135 | 0.539 |

| 3 | −0.3732 | 1.2260 | 1.3086 | 0.875 | |

| 6 | −1.0870 | 2.6253 | 0.5784 | 0.786 | |

| 10 | −2.4421 | 5.3794 | −0.8606 | 0.899 |

| Fitting Equations | Regression Coefficients | Values |

|---|---|---|

| −3.2310 | ||

| −0.0122 | ||

| 8.5480 | ||

| −0.0132 | ||

| 8.0590 | ||

| 0.0031 | ||

| 0.2898 | ||

| 0.2024 | ||

| 0.3517 | ||

| 0.1745 | ||

| 1.2390 | ||

| −0.0451 |

| Source of Experimental Data | Material | FTC | Confining Pressure, σ3 (kPa) | R2 | |||

|---|---|---|---|---|---|---|---|

| Liu et al. [16] | Tailing soil | NFT = 1 | 100 | −2.892 | 4.440 | 0.324 | 0.816 |

| Ishikawa and Miura [17] | Volcanic coarse-grained soil | NFT = 1 | 49 | −4.017 | 6.409 | −0.998 | 0.889 |

| He et al. [18] | Sandy soil | Frozen | 1000 | −5.514 | 11.710 | −4.246 | 0.633 |

| Ling et al. [14] | Coarse-grained soil | NFT = 1 | 60 | −3.408 | 7.797 | −2.339 | 0.845 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, Y.; Cai, D.; Tian, S.; Yan, H.; Ling, X.; Tang, L.; Wu, Y. An Empirical Dilatancy Model for Coarse-Grained Soil under the Influence of Freeze–Thaw Cycles. Materials 2022, 15, 3167. https://doi.org/10.3390/ma15093167

Ye Y, Cai D, Tian S, Yan H, Ling X, Tang L, Wu Y. An Empirical Dilatancy Model for Coarse-Grained Soil under the Influence of Freeze–Thaw Cycles. Materials. 2022; 15(9):3167. https://doi.org/10.3390/ma15093167

Chicago/Turabian StyleYe, Yangsheng, Degou Cai, Shuang Tian, Hongye Yan, Xianzhang Ling, Liang Tang, and Yike Wu. 2022. "An Empirical Dilatancy Model for Coarse-Grained Soil under the Influence of Freeze–Thaw Cycles" Materials 15, no. 9: 3167. https://doi.org/10.3390/ma15093167