Preliminary Feasibility Investigation on Reutilization of Recycled Crushed Clay Bricks from Construction and Demolition Waste for Cement-Stabilized Macadam

Abstract

:1. Introduction

2. Raw Materials and Methods

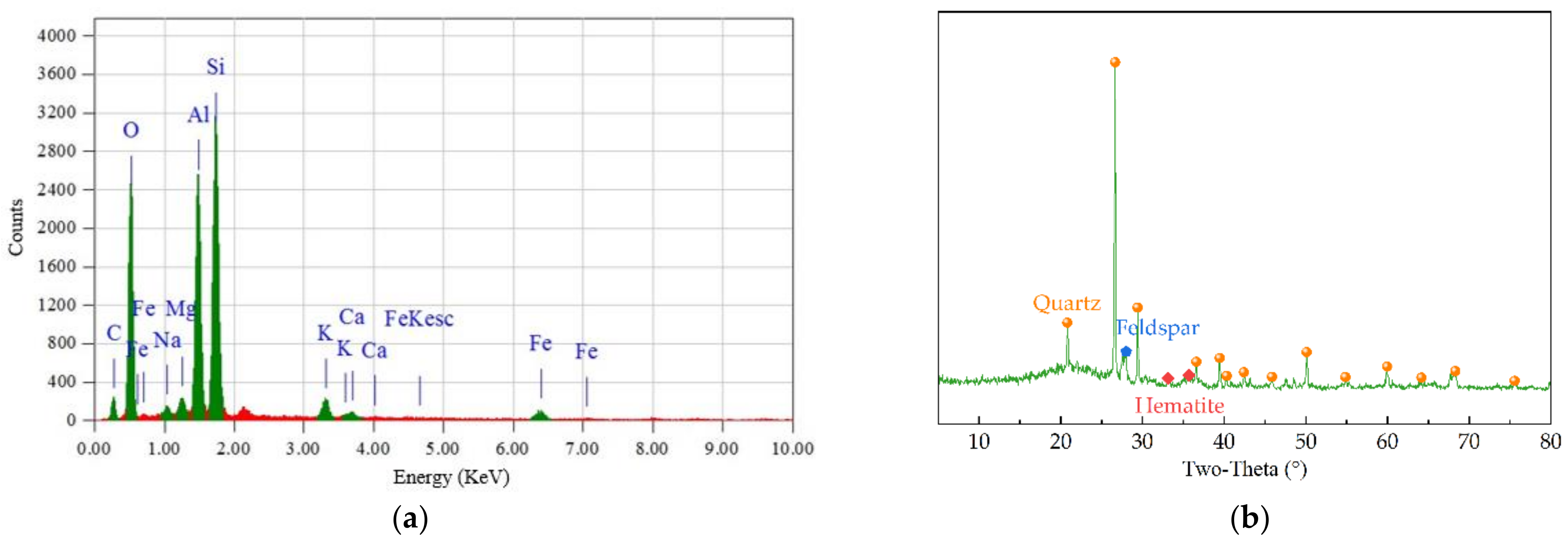

2.1. Raw Materials

2.2. Gradation Design and Samples Preparation

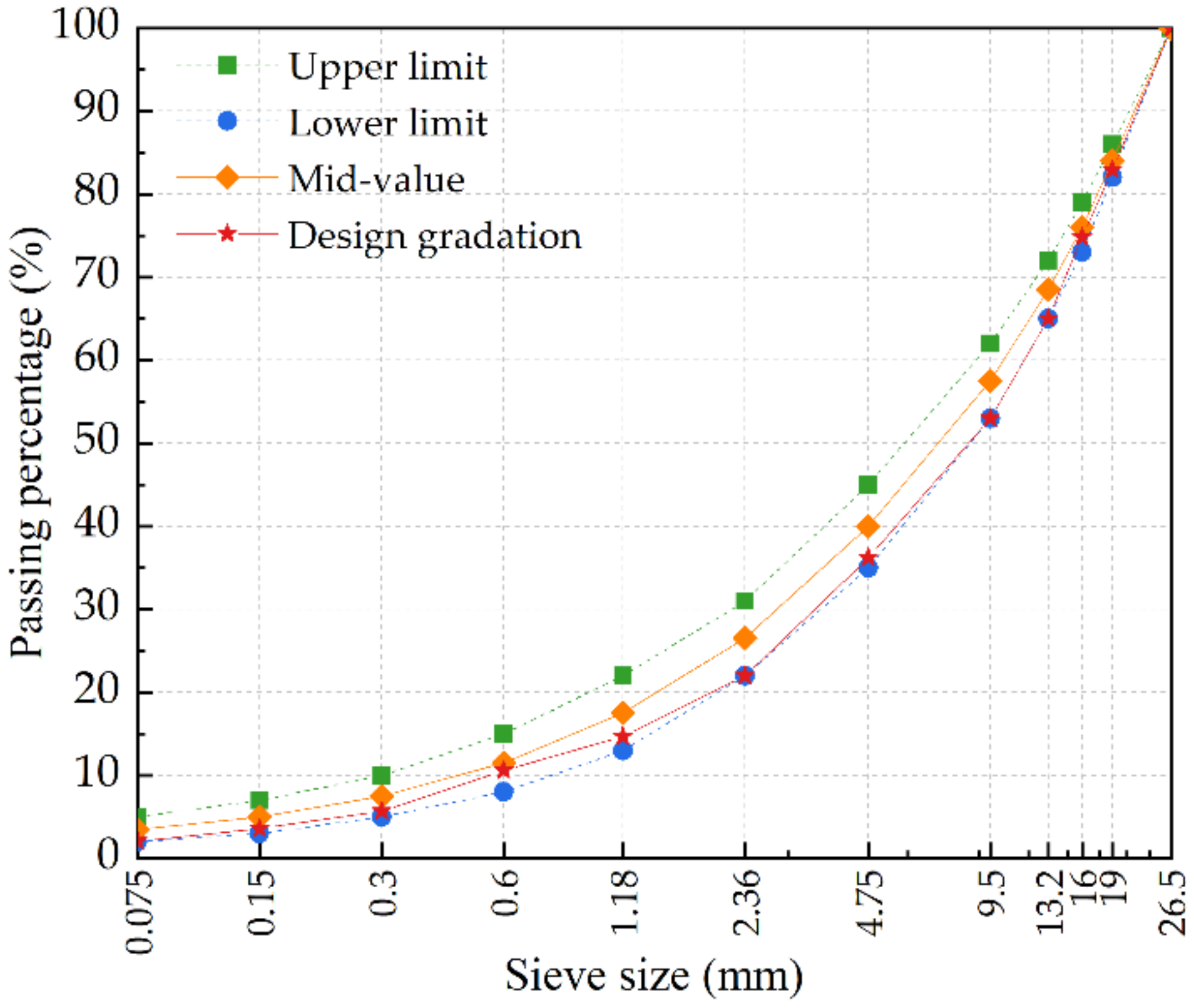

2.2.1. Aggregate Gradation

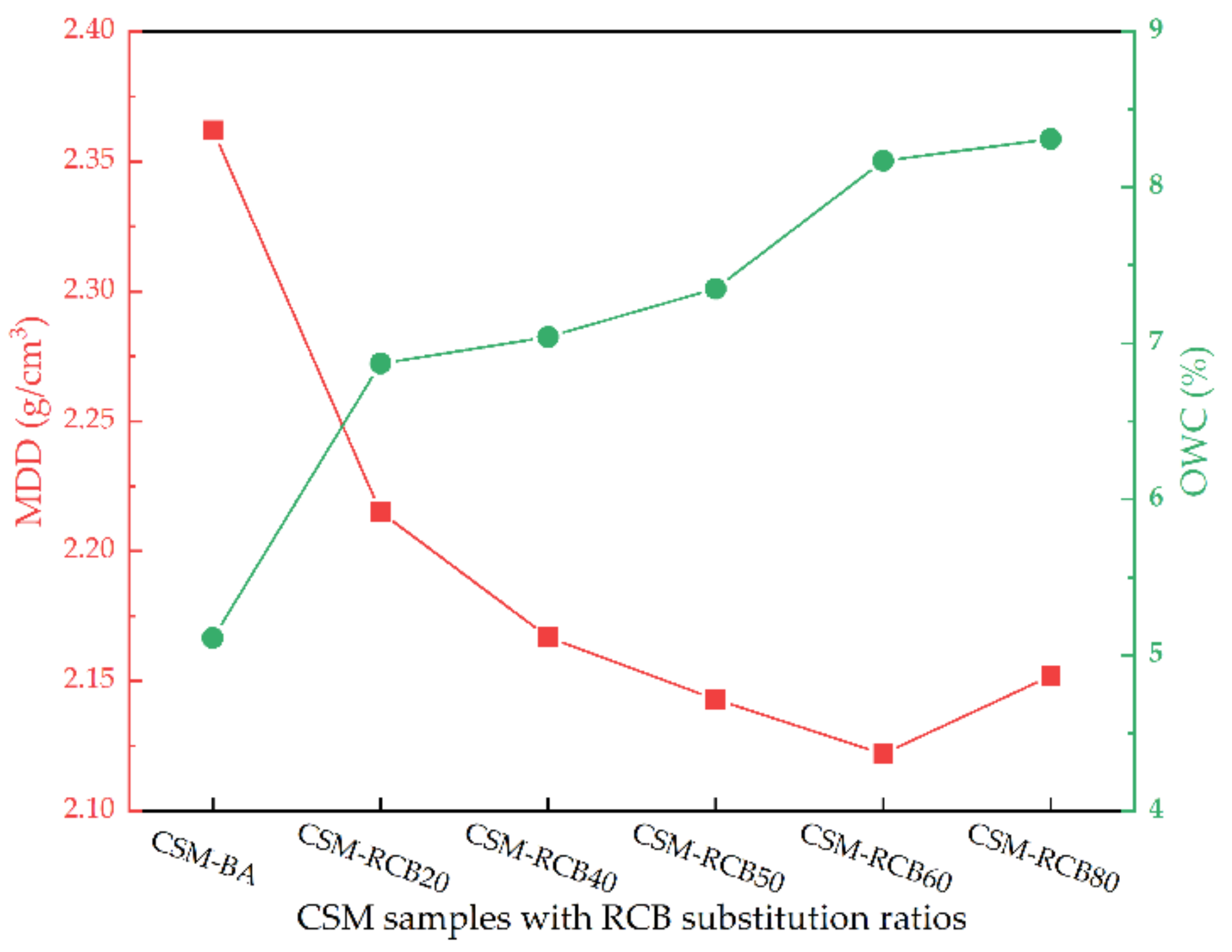

2.2.2. Mixture Design and Samples Preparation

2.3. Experimental Methods

2.3.1. Unconfined Compressive Strength

2.3.2. Indirect Tensile Strength

2.3.3. Dry Shrinkage

3. Results and Discussion

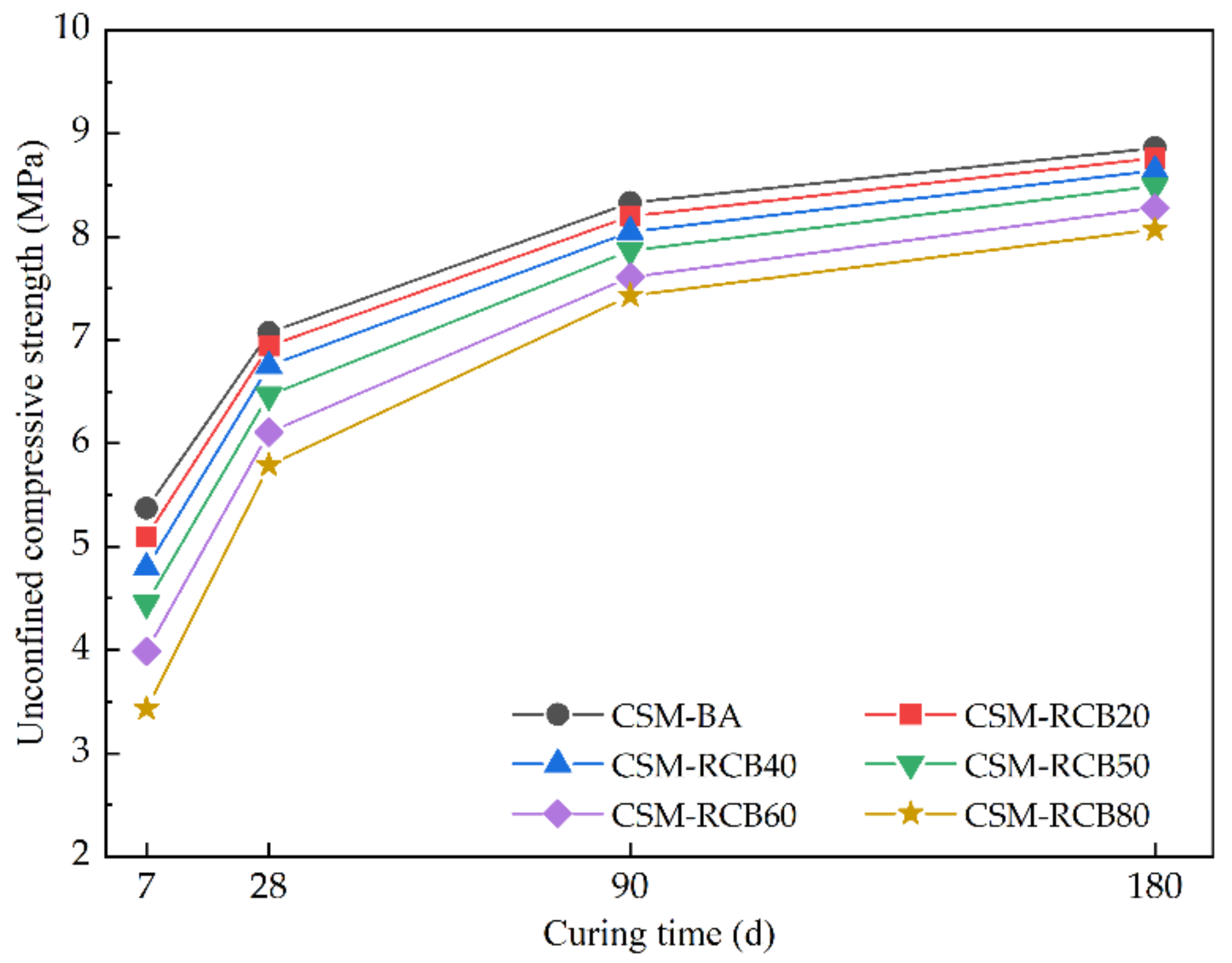

3.1. Unconfined Compressive Strength Testing

3.1.1. Analysis of Influence of RCB Substitution Ratios

3.1.2. Analysis of Influence of Curing Time

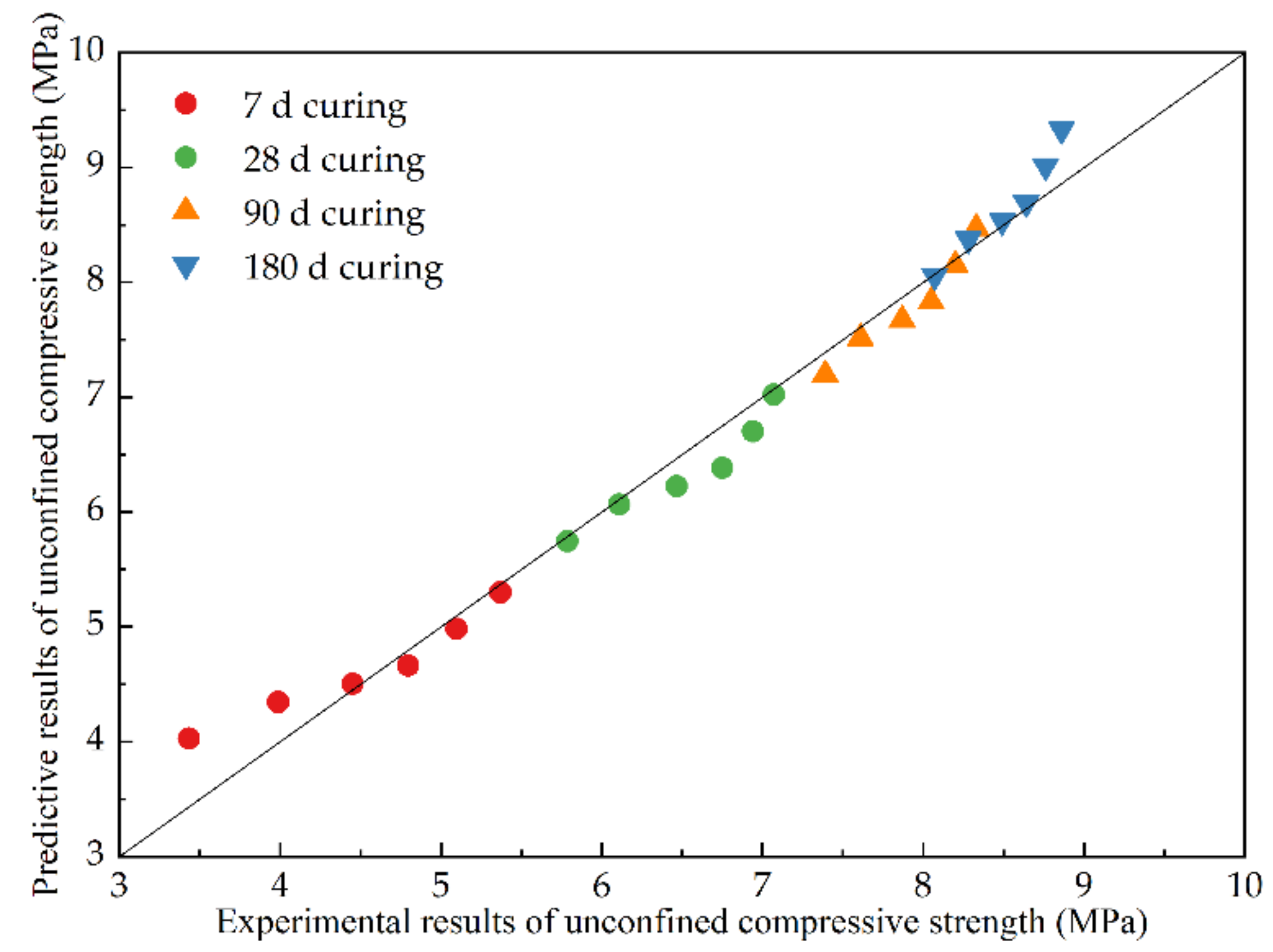

3.1.3. Regression Analysis of Unconfined Compressive Strength

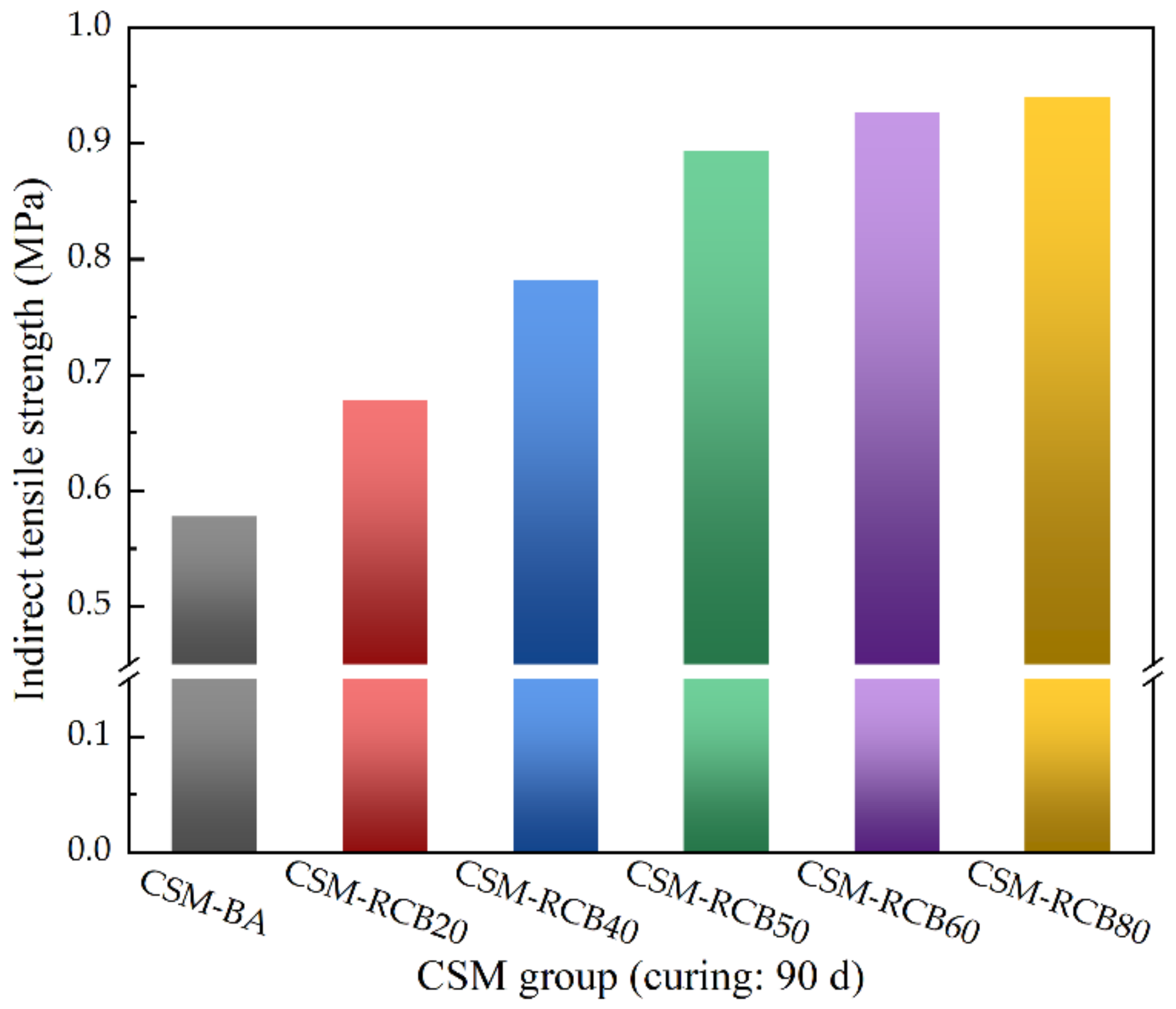

3.2. Indirect Tensile Strength Testing

3.3. Dry Shrinkage Testing

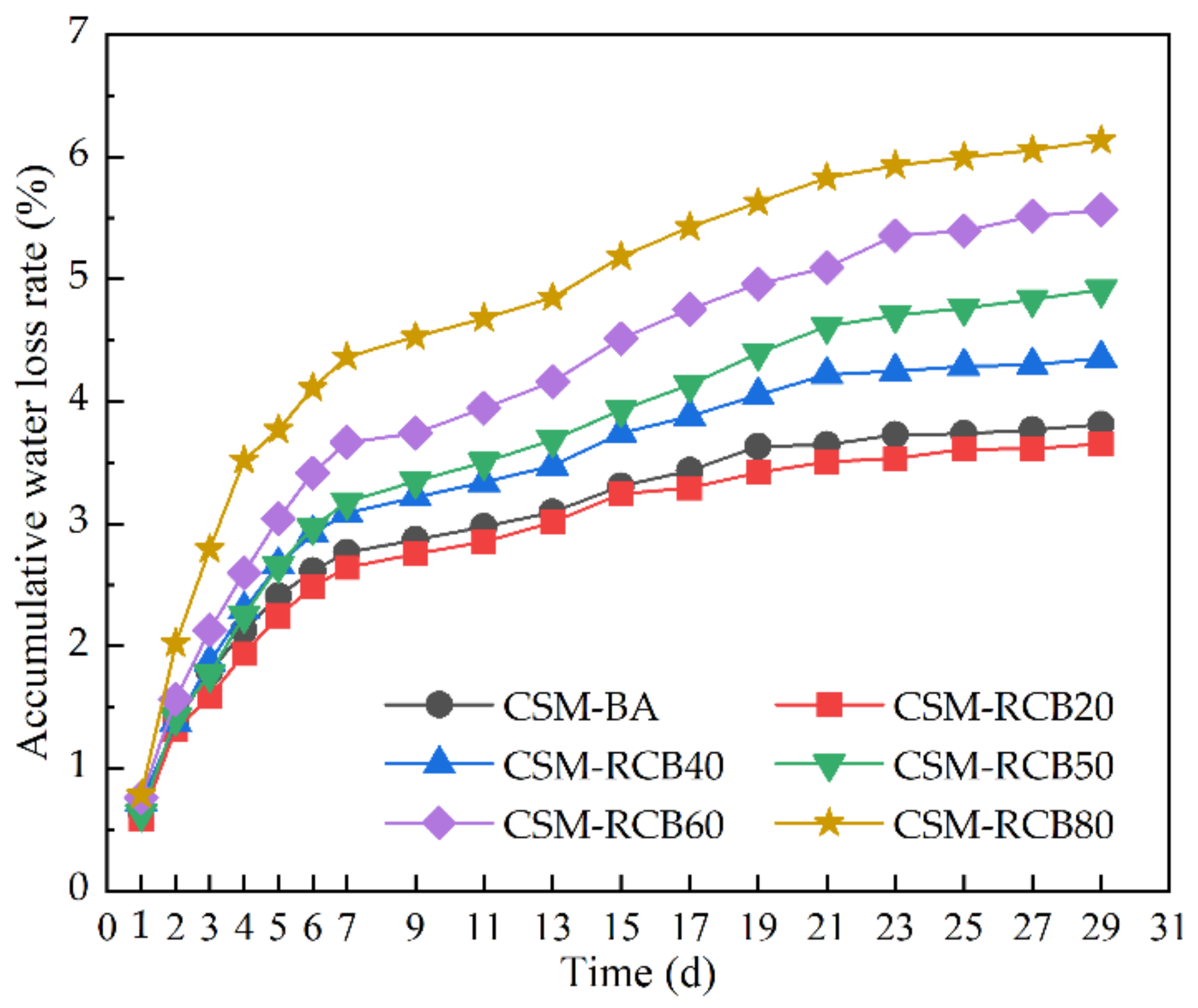

3.3.1. Analysis of Water Loss

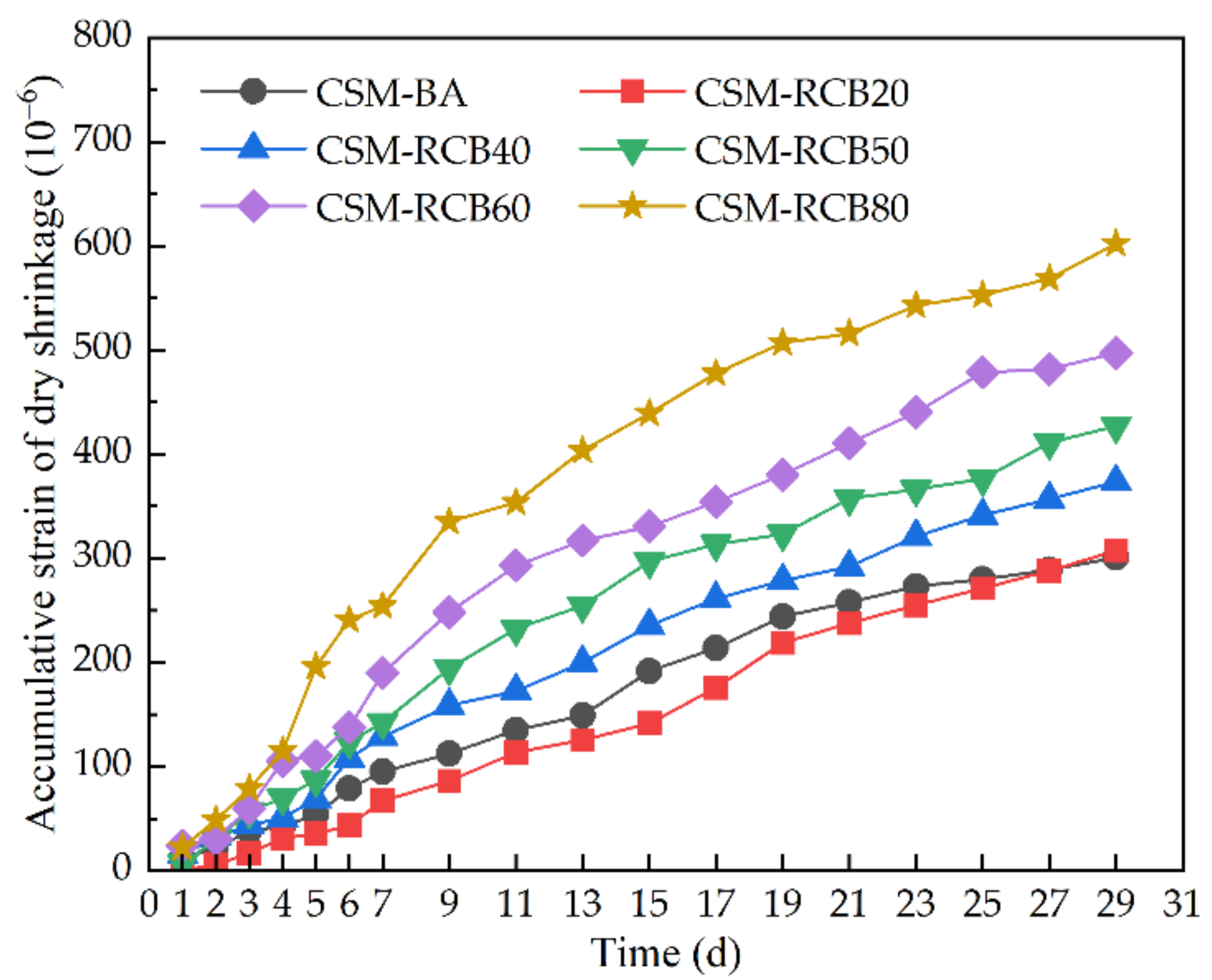

3.3.2. Analysis of Accumulative Strain of Dry Shrinkage

3.3.3. Relationship Analysis between Dry Shrinkage Strain and Water-Loss Rate

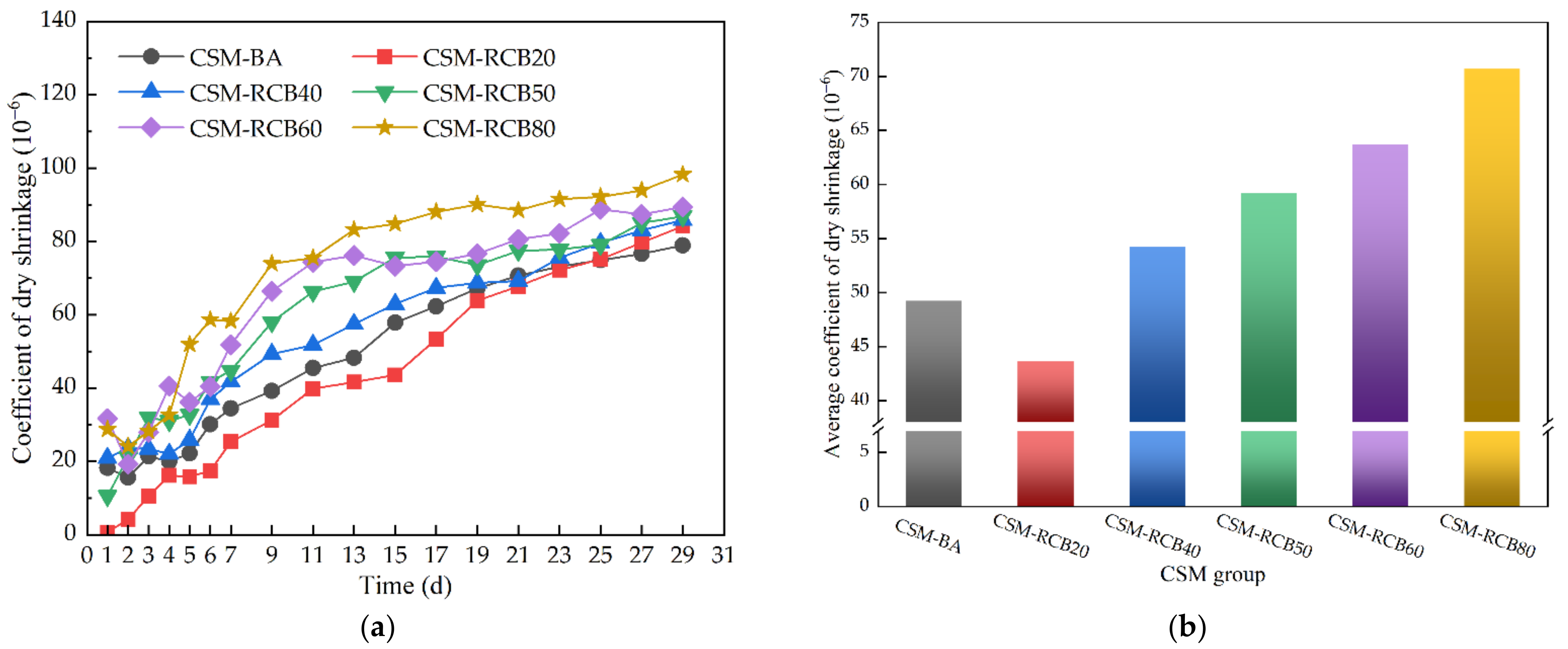

3.3.4. Analysis of Coefficient of Dry Shrinkage

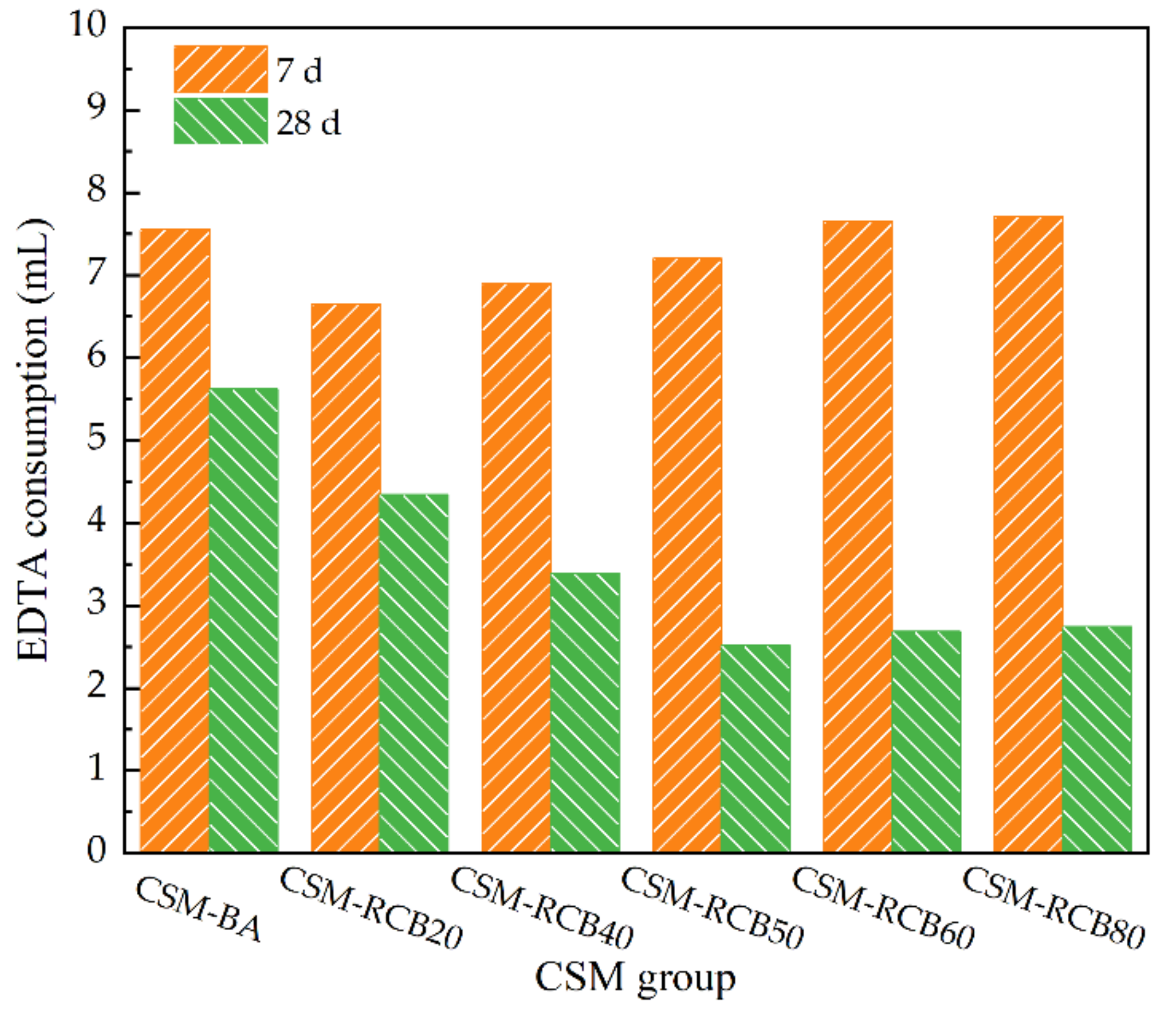

3.4. Strength Mechanism Analysis

4. Conclusions

- (1)

- The negative influence of RCB on the unconfined compressive strength of CSM would decrease gradually, varying the curing time due to a slower pozzolanic reaction rate. In contrast, the higher the RCB substitution ratio, the larger the indirect tensile strength at 90 d curing time of the late curing period.

- (2)

- Substituting RCB for natural aggregate resulted in an overall increasing accumulative water-loss rate, accumulative strain of dry shrinkage and average coefficient of dry shrinkage, except for the CSM with 20% RCB (i.e., CSM-RCB20), which obtained an excellent dry shrinkage property, and the average coefficient of dry shrinkage reached the minimum value.

- (3)

- CSM incorporating RCB with pozzolanic activity reacts very slowly to form the crystal structure, cementing into a whole and enhancing the interfacial transition zone, which has a positive effect on the strength of modified CSM mainly at later ages.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wong, C.L.; Mo, K.H.; Yap, S.P.; Alengaram, U.J.; Ling, T.C. Potential use of brick waste as alternate concrete-making materials: A review. J. Clean. Prod. 2018, 195, 226–239. [Google Scholar] [CrossRef]

- Arulrajah, A.; Piratheepan, J.; Disfani, M.M.; Bo, M.W. Geotechnical and geoenvironmental properties of recycled construction and demolition materials in pavement subbase applications. J. Mater. Civ. Eng. 2013, 25, 1077–1088. [Google Scholar] [CrossRef]

- Pappu, A.; Saxena, M.; Asolekar, S.R. Solid wastes generation in india and their recycling potential in building materials. Build. Environ. 2007, 42, 2311–2320. [Google Scholar] [CrossRef]

- Wu, J.D.; Guo, L.P.; Qin, Y.Y. Preparation and characterization of ultra-high-strength and ultra-high-ductility cementitious composites incorporating waste clay brick powder. J. Clean. Prod. 2021, 312, 127813. [Google Scholar] [CrossRef]

- Duan, H.B.; Li, J.H. Construction and demolition waste management: China’s lessons. Waste Manag. Res. 2016, 34, 397–398. [Google Scholar] [CrossRef] [Green Version]

- Gebremariam, A.T.; Vahidi, A.; Di Maio, F.; Moreno-Juez, J.; Vegas-Ramiro, I.; Lagosz, A.; Mroz, R.; Rem, P. Comprehensive study on the most sustainable concrete design made of recycled concrete, glass and mineral wool from C&D wastes. Constr. Build. Mater. 2021, 273, 121697. [Google Scholar] [CrossRef]

- Tang, D.W.; Zhang, X.B.; Hu, S.S.; Liu, X.Y.; Ren, X.; Hu, J.X.; Feng, Y. The reuse of red brick powder as a filler in styrene-butadiene rubber. J. Clean. Prod. 2020, 261, 120966. [Google Scholar] [CrossRef]

- Xuan, D.X.; Molenaar, A.A.A.; Houben, L.J.M. Compressive and indirect tensile strengths of cement-treated mix granulates with recycled masonry and concrete aggregates. J. Mater. Civ. Eng. 2012, 24, 577–585. [Google Scholar] [CrossRef]

- Li, L.G.; Lin, Z.H.; Chen, G.M.; Kwan, A.K.H.; Li, Z.H. Reutilization of clay brick waste in mortar: Paste replacement versus cement replacement. J. Mater. Civ. Eng. 2019, 31, 04019129. [Google Scholar] [CrossRef]

- Afshinnia, K.; Poursaee, A. The potential of ground clay brick to mitigate alkali-silica reaction in mortar prepared with highly reactive aggregate. Constr. Build. Mater. 2015, 95, 164–170. [Google Scholar] [CrossRef]

- Yang, J.A.; Du, Q.A.; Bao, Y.W. Concrete with recycled concrete aggregate and crushed clay bricks. Constr. Build. Mater. 2011, 25, 1935–1945. [Google Scholar] [CrossRef]

- Yan, K.Z.; Li, G.K.; You, L.Y.; Zhou, Y.B.; Wu, S.H. Performance assessments of open-graded cement stabilized macadam containing recycled aggregate. Constr. Build. Mater. 2020, 233, 117326. [Google Scholar] [CrossRef]

- Sun, Y.; Li, L.H. Strength assessment and mechanism analysis of cement stabilized reclaimed lime-fly ash macadam. Constr. Build. Mater. 2018, 166, 118–129. [Google Scholar] [CrossRef]

- Chhabra, R.S.; Ransinchung, G.D.R.N.; Islam, S.S. Performance analysis of cement treated base layer by incorporating reclaimed asphalt pavement material and chemical stabilizer. Constr. Build. Mater. 2021, 298, 123866. [Google Scholar] [CrossRef]

- Zhao, C.; Liang, N.; Zhu, X.; Yuan, L.; Zhou, B. Fiber-reinforced cement-stabilized macadam with various polyvinyl alcohol fiber contents and lengths. J. Mater. Civ. Eng. 2020, 32, 04020312. [Google Scholar] [CrossRef]

- Yan, K.Z.; Sun, H.; Gao, F.Q.; Ge, D.D.; You, L.Y. Assessment and mechanism analysis of municipal solid waste incineration bottom ash as aggregate in cement stabilized macadam. J. Clean. Prod. 2020, 244, 118750. [Google Scholar] [CrossRef]

- Zhang, J.H.; Li, C.; Ding, L.; Li, J. Performance evaluation of cement stabilized recycled mixture with recycled concrete aggregate and crushed brick. Constr. Build. Mater. 2021, 296, 123596. [Google Scholar] [CrossRef]

- Arulrajah, A.; Piratheepan, J.; Bo, M.W.; Sivakugan, N. Geotechnical characteristics of recycled crushed brick blends for pavement sub-base applications. Can. Geotech. J. 2012, 49, 796–811. [Google Scholar] [CrossRef]

- Arabani, M.; Moghadas Nejad, F.; Azarhoosh, A.R. Laboratory evaluation of recycled waste concrete into asphalt mixtures. Int. J. Pavement Eng. 2013, 14, 531–539. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, S.Y.; Ren, J.L.; Wang, Y.; Wang, C.G. Fatigue characteristics and prediction of cement-stabilized cold recycled mixture with road-milling materials considering recycled aggregate composition. Constr. Build. Mater. 2021, 301, 124122. [Google Scholar] [CrossRef]

- Poon, C.S.; Chan, D.X. Paving blocks made with recycled concrete aggregate and crushed clay brick. Constr. Build. Mater. 2006, 20, 569–577. [Google Scholar] [CrossRef]

- Adamson, M.; Razmjoo, A.; Poursaee, A. Durability of concrete incorporating crushed brick as coarse aggregate. Constr. Build. Mater. 2015, 94, 426–432. [Google Scholar] [CrossRef] [Green Version]

- Bektas, F.; Wang, K.; Ceylan, H. Effects of crushed clay brick aggregate on mortar durability. Constr. Build. Mater. 2009, 23, 1909–1914. [Google Scholar] [CrossRef]

- Khatib, J.M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Shao, J.; Gao, J.; Zhao, Y.; Chen, X. Study on the pozzolanic reaction of clay brick powder in blended cement pastes. Constr. Build. Mater. 2019, 213, 209–215. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Z.; Li, Y.; Shang, J. Cold recycling of lime-fly ash stabilized macadam mixtures as pavement bases and subbases. Constr. Build. Mater. 2018, 169, 306–314. [Google Scholar] [CrossRef]

- Ortega, J.M.; Letelier, V.; Solas, C.; Moriconi, G.; Climent, M.Á.; Sánchez, I. Long-term effects of waste brick powder addition in the microstructure and service properties of mortars. Constr. Build. Mater. 2018, 182, 691–702. [Google Scholar] [CrossRef] [Green Version]

- Liang, C.Y.; Wang, Y.; Song, W.Z.; Tan, G.J.; Li, Y.L.; Guo, Y.M. Potential activity of recycled clay brick in cement stabilized subbase. Appl. Sci. 2019, 9, 5208. [Google Scholar] [CrossRef] [Green Version]

- Yan, K.; Gao, F.; Sun, H.; Ge, D.; Yang, S. Effects of municipal solid waste incineration fly ash on the characterization of cement-stabilized macadam. Constr. Build. Mater. 2019, 207, 181–189. [Google Scholar] [CrossRef]

- Raavi, S.S.D.; Tripura, D.D. Predicting and evaluating the engineering properties of unstabilized and cement stabilized fibre reinforced rammed earth blocks. Constr. Build. Mater. 2020, 262, 120845. [Google Scholar] [CrossRef]

- Zhao, G.; She, W.; Yang, G.; Pan, L.; Cai, D.; Jiang, J.; Hu, H. Mechanism of cement on the performance of cement stabilized aggregate for high speed railway roadbed. Constr. Build. Mater. 2017, 144, 347–356. [Google Scholar] [CrossRef]

- Fan, S.; Wang, P. Effect of fly ash on drying shrinkage of thermal insulation mortar with glazed hollow beads. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2017, 32, 1352–1360. [Google Scholar] [CrossRef]

- Yang, J.; Liu, L.; Liao, Q.; Wu, J.; Li, J.; Zhang, L. Effect of superabsorbent polymers on the drying and autogenous shrinkage properties of self-leveling mortar. Constr. Build. Mater. 2019, 201, 401–407. [Google Scholar] [CrossRef]

- Yan, X.; Jiang, L.; Guo, M.; Chen, Y.; Zhu, P.; Jin, W.; Zha, J. Using edta-2na to inhibit sulfate attack in slag cement mortar under steam curing. Constr. Build. Mater. 2020, 265, 120324. [Google Scholar] [CrossRef]

| Aggregates | Apparent Specific Density | Water Absorption (%) | Flakiness Content (%) | Crushed Stone Value (%) | Liquid Limit (%) | Plasticity Index |

|---|---|---|---|---|---|---|

| Coarse BA | 2.735 | 1.24 | 9.57 | 21.63 | / | / |

| Fine BA | 2.689 | 1.73 | / | / | 18.06 | 4.34 |

| Coarse RCB | 2.331 | 17.36 | 9.97 | 41.53 | / | / |

| Fine RCB | 2.116 | 17.60 | / | / | 37.91 | 8.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, D.; Chu, W.; Wang, L.; Wang, W.; Wang, H.; Shangguan, X.; Cui, X. Preliminary Feasibility Investigation on Reutilization of Recycled Crushed Clay Bricks from Construction and Demolition Waste for Cement-Stabilized Macadam. Materials 2022, 15, 3171. https://doi.org/10.3390/ma15093171

Wu D, Chu W, Wang L, Wang W, Wang H, Shangguan X, Cui X. Preliminary Feasibility Investigation on Reutilization of Recycled Crushed Clay Bricks from Construction and Demolition Waste for Cement-Stabilized Macadam. Materials. 2022; 15(9):3171. https://doi.org/10.3390/ma15093171

Chicago/Turabian StyleWu, Dongxing, Wenchao Chu, Longlin Wang, Wensheng Wang, Haoyun Wang, Xuanhao Shangguan, and Xiang Cui. 2022. "Preliminary Feasibility Investigation on Reutilization of Recycled Crushed Clay Bricks from Construction and Demolition Waste for Cement-Stabilized Macadam" Materials 15, no. 9: 3171. https://doi.org/10.3390/ma15093171

APA StyleWu, D., Chu, W., Wang, L., Wang, W., Wang, H., Shangguan, X., & Cui, X. (2022). Preliminary Feasibility Investigation on Reutilization of Recycled Crushed Clay Bricks from Construction and Demolition Waste for Cement-Stabilized Macadam. Materials, 15(9), 3171. https://doi.org/10.3390/ma15093171