Material and Structural Functionalization of Knitted Fabrics for Sportswear

Abstract

:1. Introduction

2. Thermal Comfort of Knitted Sportswear

3. Experimental

3.1. Sample Preparation

3.1.1. Yarn Selection

3.1.2. Knitted Samples Preparation

3.2. Testing Methods

3.2.1. Yarn Testing

3.2.2. Knitted Fabric Testing

4. Results

4.1. Results of Yarn Testing

4.2. Results of Knitted Fabric Testing: Structural Parameters

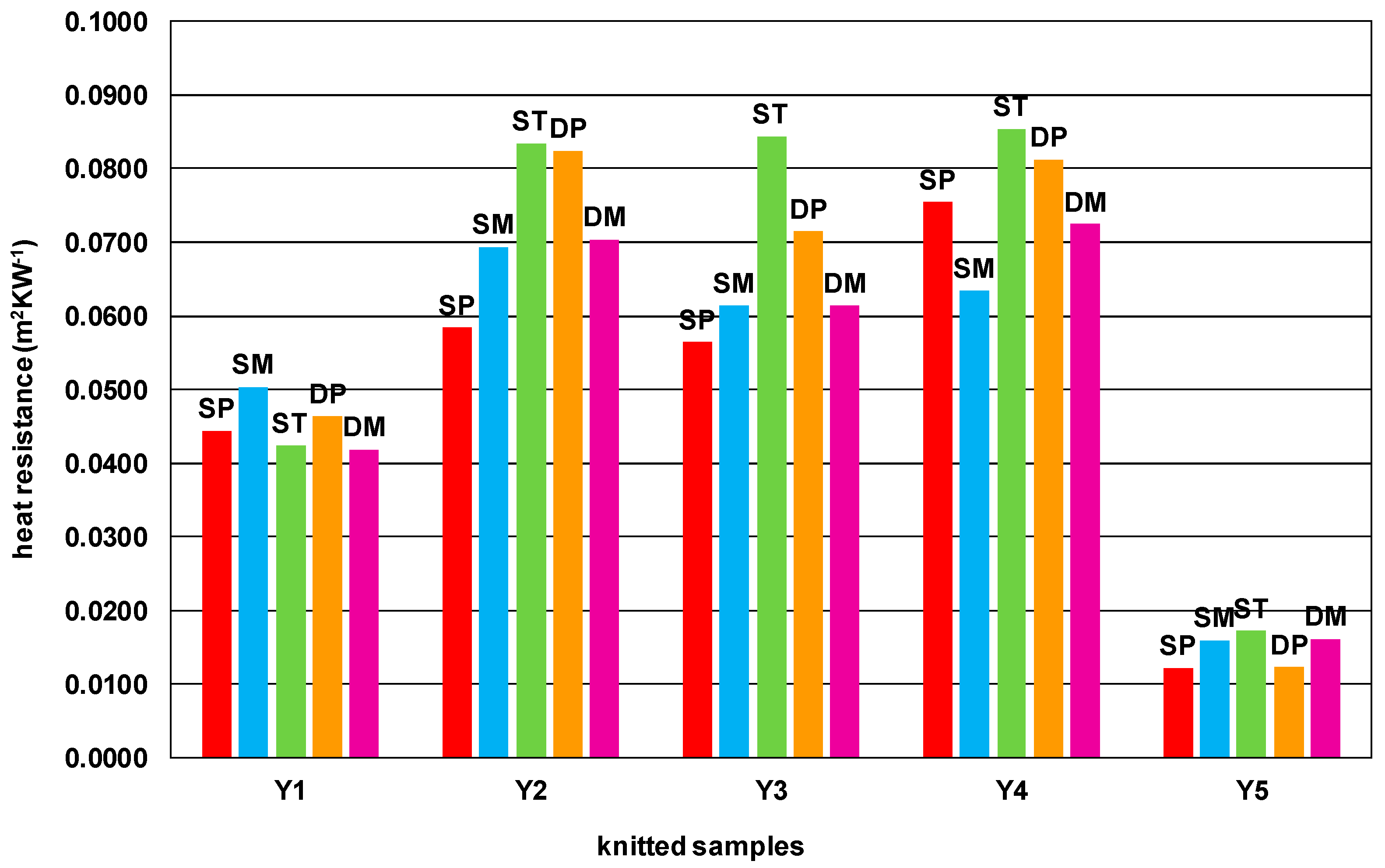

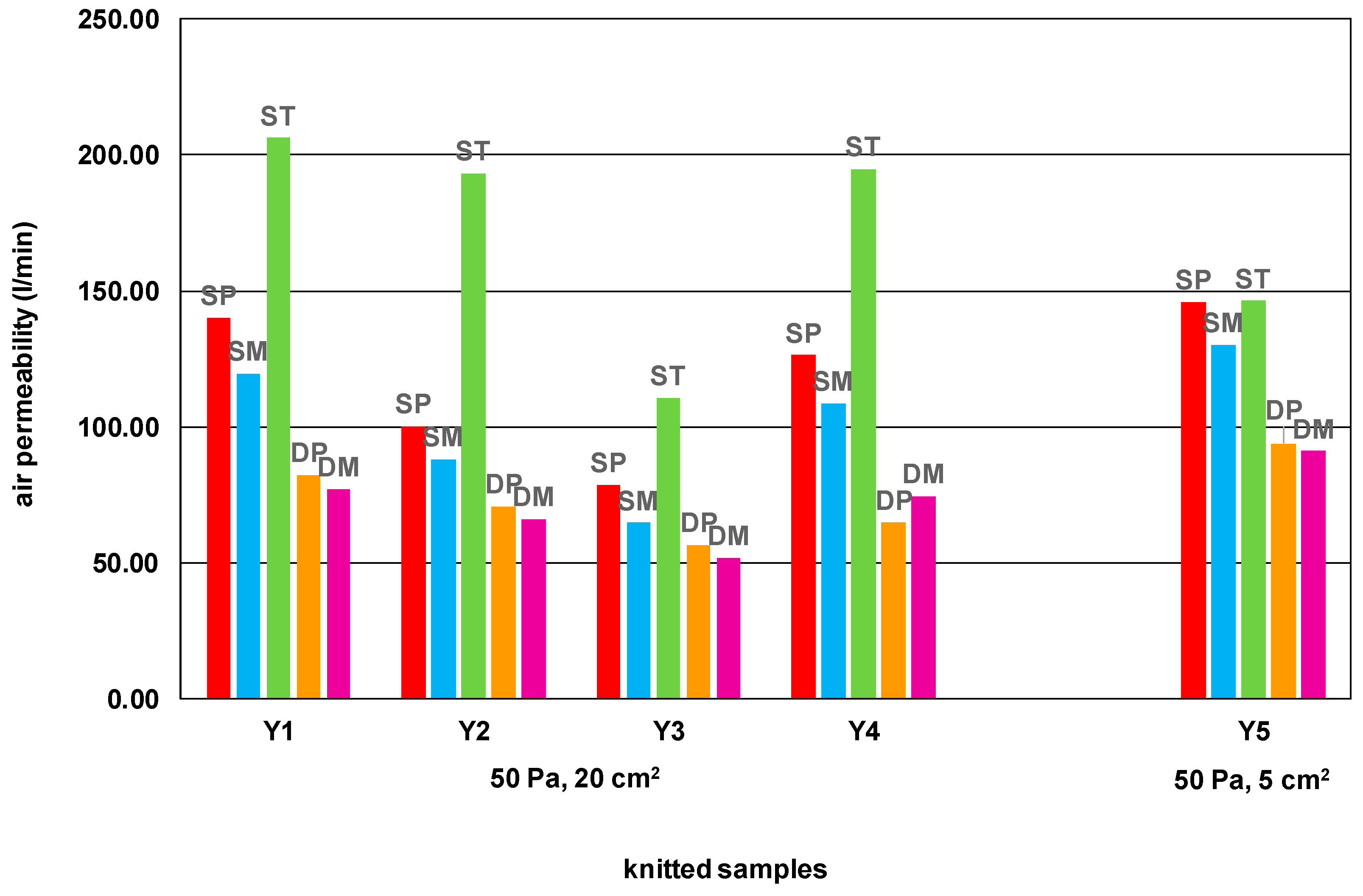

4.3. Results of Knitted Fabric Testing: Thermal Properties, Air Permeability, and Water Vapour Resistance

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

. This work has been fully supported by Croatian Science Foundation under the project IP-2020-02-5041 Textile Materials for Enhanced Comfort in Sports.

. This work has been fully supported by Croatian Science Foundation under the project IP-2020-02-5041 Textile Materials for Enhanced Comfort in Sports.Conflicts of Interest

References

- Black, S. Knitting: Fashion, Industry, Craft; V&A Publishing: London, UK, 2012; p. 83. [Google Scholar]

- Sportswear, Cambridge Dictionary. Available online: https://dictionary.cambridge.org/dictionary/english/sportswear (accessed on 1 June 2021).

- Sportswear, Merriam-Webster. Available online: https://www.merriam-webster.com/dictionary/sportswear (accessed on 1 June 2021).

- Athleisure, Merriam-Webster. Available online: https://www.merriam-webster.com/dictionary/athleisure (accessed on 1 June 2021).

- Athleisure, Cambridge Dictionary. Available online: https://dictionary.cambridge.org/dictionary/english/athleisure (accessed on 1 June 2021).

- Shishoo, R. (Ed.) Textiles in Sports; Woodhead Publishing: Cambridge, UK, 2005. [Google Scholar]

- Market for Sports Apparel Is Expected to Grow. Available online: https://textilefocus.com/market-sports-apparel-expected-grow (accessed on 3 June 2021).

- How Sportswear Became High Fashion, Origin. Available online: https://www.originoutside.com/insights/how-sportswear-became-high-fashion (accessed on 4 June 2021).

- Fourt, L.; Hollies, N.R.S. Clothing: Comfort and Functions; Marcel Decker Inc.: New York, NY, USA, 1970. [Google Scholar]

- Slater, K. Human Comfort; Charles, C., Ed.; Thomas Publisher: Springfield, IL, USA, 1985; p. 4. [Google Scholar]

- Ansi/Ashrae 55 Thermal Environmental Conditions for Human Occupancy; ASHRAE Standards Committee, The ASHRAE Board of Directors, and the American National Standards Institute: Atlanta, GA, USA, 2017; Available online: https://www.ashrae.org (accessed on 1 June 2021).

- Peng, Y.; Cui, Y. Advanced Textiles for Personal Thermal Management and Energy. Joule 2020, 4, 724–742. [Google Scholar] [CrossRef]

- Fan, J.; Hunter, L. Engineering Apparel Fabrics and Garments; Woodhead Publishing: Cambridge, UK, 2009; p. 212. [Google Scholar]

- Shishoo, R. (Ed.) Textiles for Sportswear; Woodhead Publishing: Cambridge, UK, 2015; p. 199. [Google Scholar]

- Oğlakcioğlu, N.; Marmarali, A. Thermal comfort properties of some knitted structures. Fibres Text. East. Eur. 2007, 15, 94–96. [Google Scholar]

- van Amber, R.R.; Wilson, C.A.; Laing, R.; Lowe, B.M. Thermal and moisture transfer properties of sock fabrics differing in fiber type, yarn, and fabric structure. Text. Res. J. 2015, 85, 1269–1280. [Google Scholar] [CrossRef]

- Uçar, N.; Yilmaz, T. Thermal properties of 1 × 1, 2 × 2, 3 × 3 rib knit fabrics. Fibres Text. East. Eur. 2004, 12, 34–38. [Google Scholar]

- Erdumlu, N.; Saricam, C. Investigating the effect of some fabric parameters on the thermal comfort properties of flat knitted acrylic fabrics for winter wear. Text. Res. J. 2017, 87, 1349–1359. [Google Scholar] [CrossRef]

- Senthilkumar, P.; Suganthi, T. Influence of tuck stitch in course direction on thermal comfort characteristics of layered knitted fabrics. Indian J. Fibre Text. Res. (IJFTR) 2019, 44, 163–172. [Google Scholar]

- Yang, Y.; Yu, X.; Chen, L.; Zhang, P. Effect of knitting structure and yarn composition on thermal comfort properties of bi-layer knitted fabrics. Text. Res. J. 2021, 91, 3–17. [Google Scholar] [CrossRef]

- Özdil, N.; Marmarali, A.; Kretzschmar, S.D. Effect of yarn properties on thermal comfort of knitted fabrics. Int. J. Therm. Sci. 2007, 46, 1318–1322. [Google Scholar] [CrossRef]

- Prakash, C.; Ramakrishnan, G.; Koushik, C.V. The effect of loop length and yarn linear density on the thermal properties of bamboo knitted fabric. Autex Res. J. 2011, 11, 102–105. [Google Scholar]

- Mishra, R.; Jamshaid, H.; Siddique Yosfani, S.H.; Hussain, S.; Nadeem, M.; Petru, M.; Tichy, M.; Muller, M. Thermo physiological comfort of single jersey knitted fabric derivatives. Fash. Text. 2021, 8, 1–22. [Google Scholar] [CrossRef]

- Oğlakcioğlu, N.; Çay, A.; Marmarali, A.; Mert, E. Characteristics of knitted structures produced by engineered polyester yarns and their blends in terms of thermal comfort. J. Eng. Fibers Fabr. 2015, 10, 32–41. [Google Scholar] [CrossRef] [Green Version]

- Sampath, M.B.; Arputharaj, A.; Senthilkumar, M.; Nalankilli, G. Analysis of thermal comfort characteristics of moisture management finished knitted fabrics made from different yarns. J. Ind. Text. 2011, 42, 19–33. [Google Scholar] [CrossRef]

- Gericke, A.; van der Pol, J. A comparative study of regenerated bamboo. cotton and viscose rayon fabrics. Part 1: Selected comfort properties. J. Fam. Ecol. Consum. Sci. 2010, 38, 63–73. [Google Scholar] [CrossRef]

- Gun, A.D. Dimensional. physical and thermal comfort properties of plain knitted fabrics made from modal viscose yarns having microfibers and conventional fibers. Fibers Polym. 2011, 12, 258–267. [Google Scholar] [CrossRef]

- Lizák, P.; Legerska, J.; Militký, J.; Mojumdar, S.C. Thermal transport characteristics of polypropylene fiber-based knitted fabrics. J. Therm. Anal. Calorim. 2012, 108, 837–841. [Google Scholar] [CrossRef]

- Majumdar, A.; Mukhopadhyay, S.; Yadav, R. Thermal properties of knitted fabrics made from cotton and regenerated bamboo cellulosic fibres. Int. J. Therm. Sci. 2010, 49, 2042–2048. [Google Scholar] [CrossRef]

- Bivainytė, A.; Mikučionienė, D.; Kerpauskas, P. Investigation on thermal properties of double-layered weft knitted fabrics. Mater. Sci. 2012, 18, 167–171. [Google Scholar] [CrossRef] [Green Version]

- Jhanji, Y.; Gupta, D.; Kothari, V.K. Effect of fibre, yarn and fabric variables on heat and moisture transport properties of plated knit. Indian J. Fibre Text. Res. 2017, 42, 255–256. [Google Scholar]

- Kaplan, S.; Yilmaz, B. Thermal Comfort Performances of Double-face Knitted Insulation Fabrics. Fibers Polym. 2022, 23, 537–545. [Google Scholar] [CrossRef]

- Kumar, S.; Boominathan, S.H.; Kirubakar Raj, D.V. Comparative Analysis on Thermo-physiological Behavior of Eri Silk, Wool and Bamboo Knitted Fabrics Toward Sportswear. J. Nat. Fibers 2021, 18, 1–12. [Google Scholar] [CrossRef]

- ISO 2060; Textiles—Yarn from Packages—Determination of Linear Density (Mass per Unit Length) by the Skein Method. International Organization for Standardization: Genève, Switzerland, 1994; p. 13.

- ISO 17202; Textiles—Determination of Twist in Single Spun Yarns—Untwist/Retwist Method. International Organization for Standardization: Genève, Switzerland, 2002; p. 10.

- ISO 2062; Textiles—Yarns from Packages—Determination of Single-End Breaking Force and Elongation at Break Using Constant Rate of Extension (CRE) Tester. International Organization for Standardization: Genève, Switzerland, 2009; p. 10.

- ISO 5084; Textiles—Determination of Thickness of Textiles and Textile Products. International Organization for Standardization: Genève, Switzerland, 1996; p. 5.

- Salopek Čubrić, I.; Skenderi, Z. Effect of finishing treatments on heat resistance of one- and two-layered fabrics. Fibers Polym. 2014, 15, 1635–1640. [Google Scholar] [CrossRef]

- Potočić Matković, V.M.; Salopek Čubrić, I.; Skenderi, Z. Thermal resistance of polyurethane-coated knitted fabrics before and after weathering. Text. Res. J. 2015, 84, 2015–2025. [Google Scholar] [CrossRef]

- Salopek Čubrić, I.; Skenderi, Z. Impact of Cellulose Materials Finishing on Heat and Water Vapor Resistance. Fibres Text. East. Eur. 2013, 21, 61–66. [Google Scholar]

- ISO 11092; Textiles—Physiological Effects—Measurement of Thermal and Water-Vapour Resistance under Steady-State Conditions (Sweating Guarded-Hotplate Test). International Organization for Standardization: Genève, Switzerland, 2014; p. 15.

- ISO 9237; Textiles—Determination of the Permeability of Fabrics to Air. International Organization for Standardization: Genève, Switzerland, 1995; p. 5.

- Engel, F.; Sperlich, B. (Eds.) Compression Garments in Sports: Athletic Performance and Recovery; Springer: Berlin/Heidelberg, Germany, 2016; p. 21. [Google Scholar]

- Spencer, D.J. Knitting Technology. A Comprehensive Handbook and Practical Guide, 3rd ed.; Woodhead Publishing: Cambridge, UK, 2001. [Google Scholar]

- Tellier-Loumagne, F. The Art of Knitting. Inspirational Stitches, Textures and Surfaces; Thames & Hudson: London, UK, 2005. [Google Scholar]

- ISO 8388; Knitted Fabrics—Types—Vocabulary. International Organization for Standardization: Genève, Switzerland, 1994; p. 85.

- Fabric Structures—Single Jersey and Its Derivatives—Part 1, Textile Guide. Available online: https://www.textileguide.info/2019/12/fabric-structures-single-jersey-and-its.html (accessed on 26 June 2021).

| Single Structures | DOUBLE Structures | ||||

|---|---|---|---|---|---|

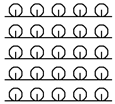

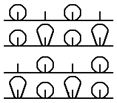

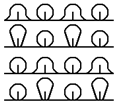

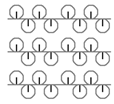

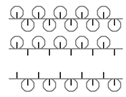

| Appearance front |  |  |  |  |  |

| Appearance back |  |  |  |  |  |

| Yarn path |  |  |  |  |  |

| Structure | Single plain | Single miss | Single tuck | Double plain | Double Milano |

| Designation | SP | SM | ST | DP | DM |

| Yarn Designation | Yarn Material Composition | Yarn Linear Density (tex) | Yarn Twist (m−1) | Number of Threads for Knitting | Yarn Tenacity (cNtex−1) | Yarn Elongation at Break (%) |

|---|---|---|---|---|---|---|

| Y1 | 100% Cotton | 29.1 | 661 | 2 | 13.90 | 5.20 |

| Y2 | 100% Wool | 68.6 | 88 | 1 | 5.25 | 2.90 |

| Y3 | 100% PAN (bouclé) | 72.3 | 10 | 1 | 4.66 | 12.55 |

| Y4 | 50% Wool 50% PAN | 71.4 | 114 | 1 | 12.23 | 14.30 |

| Y5 | 100% PA (filament) | 15.4 | - | 2 | 40.76 | 301.27 |

| Yarn Designation | Yarn Material Composition | Yarn Evenness–CVmass (%) | Yarn Hairiness | |||

|---|---|---|---|---|---|---|

| n1 (2 mm) | n2 (4 mm) | n3 (6 mm) | n4 (8 mm) | |||

| Y1 | 100% Cotton | 11.75 | 952 | 147 | 23 | 5 |

| Y2 | 100% Wool | 19.04 | 1604 | 494 | 156 | 88 |

| Y3 | 100% PAN (bouclé) | 12.04 | 1350 | 718 | 346 | 283 |

| Y4 | 50% Wool 50% PAN | 9.47 | 1804 | 535 | 174 | 95 |

| Y5 | 100% PA (filament) | - | - | - | - | - |

| Material Composition | Fabric Designation | Knitted Structure | Horizontal Density (cm−1) | Vertical Density (cm−1) | Mass per Unit Area (gm−2) | Thickness (mm) |

|---|---|---|---|---|---|---|

| Y1 100% Cotton | Y1 SP | single plain | 7.98 | 8.32 | 260.38 | 1.23 |

| Y1 SM | single miss | 7.88 | 8.32 | 287.17 | 1.37 | |

| Y1 ST | single tuck/single piqué | 5.32 | 6.68 | 267,35 | 1.54 | |

| Y1 DP | double plain | 6.40 | 9.08 | 433.40 | 1.92 | |

| Y1 DM | double Milano rib | 7.26 | 8.82 | 430.49 | 1.80 | |

| Y2 100% Wool | Y2 SP | single plain | 6.00 | 8.00 | 238.19 | 0.98 |

| Y2 SM | single miss | 6.70 | 7.76 | 281.49 | 1.22 | |

| Y2 ST | single tuck/single piqué | 4.66 | 6.64 | 286.40 | 1.85 | |

| Y2 DP | double plain | 5.76 | 8.76 | 438.49 | 2.00 | |

| Y2 DM | double Milano rib | 6.54 | 8.42 | 453.85 | 1.77 | |

| Y3 100% PAN | Y3 SP | single plain | 5.80 | 7.90 | 233.73 | 1.22 |

| Y3 SM | single miss | 6.36 | 7.92 | 267.36 | 1.52 | |

| Y3 ST | single tuck/single piqué | 4.62 | 5.72 | 250.79 | 1.78 | |

| Y3 DP | double plain | 5.16 | 8.72 | 459.36 | 2.28 | |

| Y3 DM | double Milano rib | 6.08 | 8.64 | 453.15 | 2.01 | |

| Y4 Wool/PAN | Y4 SP | single plain | 5.88 | 7.64 | 234.20 | 1.00 |

| Y4 SM | single miss | 6.44 | 7.62 | 263.41 | 1.24 | |

| Y4 ST | single tuck/single piqué | 4.68 | 6.80 | 299.42 | 1.89 | |

| Y4 DP | double plain | 5.82 | 8.88 | 471.54 | 2.06 | |

| Y4 DM | double Milano rib | 6.44 | 8.08 | 455.06 | 1.76 | |

| Y5 100% PA | Y5 SP | single plain | 5.52 | 8.20 | 92.68 | 0.58 |

| Y5 SM | single miss | 5.88 | 6.36 | 132.51 | 0.77 | |

| Y5 ST | single tuck/single piqué | 3.88 | 3.86 | 132.51 | 1.40 | |

| Y5 DP | double plain | 5.36 | 5.88 | 231.54 | 1.70 | |

| Y5 DM | double Milano rib | 6.02 | 5.16 | 216.42 | 1.44 |

| Yarn/Structure | Heat Resistance (m2 KW−1) | |||||

|---|---|---|---|---|---|---|

| SP | SM | ST | DP | DM | ||

| Single Plain | Single Miss | Single Tuck | Double Plain | Double Milano rib | ||

| Y1 | 100% Cotton | 0.0444 | 0.0504 | 0.0424 | 0.0464 | 0.0419 |

| Y2 | 100% Wool | 0.0584 | 0.0694 | 0.0834 | 0.0824 | 0.0704 |

| Y3 | 100% PAN | 0.0564 | 0.0614 | 0.0844 | 0.0714 | 0.0614 |

| Y4 | Wool/PAN | 0.0754 | 0.0634 | 0.0854 | 0.0812 | 0.0724 |

| Y5 | 100% PA | 0.0122 | 0.0160 | 0.0172 | 0.0123 | 0.0162 |

| Yarn/Structure | Air Permeability (l min−1) | |||||

|---|---|---|---|---|---|---|

| SP | SM | ST | DP | DM | ||

| Single Plain | Single Miss | Single Tuck | Double Plain | Double Milano rib | ||

| Y1 | 100% Cotton | 140.12 | 119.72 | 206.14 | 82.44 | 77.14 |

| Y2 | 100% Wool | 100.40 | 88.20 | 193.30 | 70.92 | 66.20 |

| Y3 | 100% PAN | 78.76 | 64.68 | 110.66 | 56.78 | 51.84 |

| Y4 | Wool/PAN | 126.18 | 108.74 | 194.86 | 64.90 | 74.60 |

| Y5 | 100% PA | 145.88 | 130.18 | 146.28 | 93.92 | 91.02 |

| Yarn/Structure | Water Vapour Resistance (m2 Pa W−1) | |||||

|---|---|---|---|---|---|---|

| SP | SM | ST | DP | DM | ||

| Single Plain | Single Miss | Single Tuck | Double Plain | Double Milano rib | ||

| Y1 | 100% Cotton | 3.7448 | 3.9135 | 5.6966 | 4.1322 | 3.9222 |

| Y2 | 100% Wool | 4.4758 | 2.0459 | 3.5071 | 2.4678 | 2.7070 |

| Y3 | 100% PAN | 3.5522 | 3.8274 | 4.8722 | 5.6936 | 4.9208 |

| Y4 | Wool/PAN | 3.7760 | 5.7246 | 3.1658 | 6.0944 | 5.7542 |

| Y5 | 100% PA | 0.6112 | 0.7075 | 0.5570 | 3.0855 | 1.3329 |

| Knitted Sample Structure | Correlation Coefficients | ||||||

|---|---|---|---|---|---|---|---|

| Linear Density | Yarn Hairiness (Length of Protruding Fibres) | Thickness | Mass per Unit Area | ||||

| 2 mm | 4 mm | 6 mm | 8 mm | ||||

| Single plain | 0.89241 | 0.98688 | 0.81619 | 0.63217 | 0.48558 | 0.63803 | 0.81236 |

| Single miss | 0.89081 | 0.96882 | 0.83147 | 0.66089 | 0.53297 | 0.79345 | 0.92944 |

| Single tuck | 0.99334 | 0.95358 | 0.95406 | 0.82584 | 0.70488 | 0.98268 | 0.82534 |

| Double plain | 0.95409 | 0.98832 | 0.88101 | 0.70842 | 0.56797 | 0.78978 | 0.90537 |

| Double Milano rib | 0.95421 | 0.99198 | 0.87418 | 0.69593 | 0.55038 | 0.70619 | 0.90318 |

| Knitted Sample Structure | Correlation Coefficients | ||||||

|---|---|---|---|---|---|---|---|

| Linear Density | Yarn Hairiness (Length of Protruding Fibres) | Thickness | Mass per Unit Area | ||||

| 2 mm | 4 mm | 6 mm | 8 mm | ||||

| Single plain | −0.80487 | −0.58298 | −0.89139 | −0.93040 | −0.91987 | −0.50103 | −0.44484 |

| Single miss | −0.81007 | −0.60602 | −0.90414 | −0.94283 | −0.93351 | −0.71800 | −0.50944 |

| Single tuck | −0.06720 | 0.30399 | −0.27054 | −0.52998 | −0.66410 | 0.14010 | 0.50699 |

| Double plain | −0.94761 | −0.84736 | −0.98875 | −0.94508 | −0.87497 | −0.97376 | −0.83646 |

| Double Milano rib | −0.81155 | −0.67561 | −0.90661 | −0.92479 | −0.90892 | −0.93086 | −0.76062 |

| Knitted Sample Structure | Correlation Coefficients | ||||||

|---|---|---|---|---|---|---|---|

| Linear Density | Yarn Hairiness (Length of Protruding Fibres) | Thickness | Mass per Unit Area | ||||

| 2 mm | 4 mm | 6 mm | 8 mm | ||||

| Single plain | 0.74784 | 0.90664 | 0.67931 | 0.49148 | 0.36833 | 0.79575 | 0.95664 |

| Single miss | 0.56481 | 0.72480 | 0.55035 | 0.43234 | 0.33876 | 0.67858 | 0.73407 |

| Single tuck | 0.37182 | 0.53672 | 0.43834 | 0.39050 | 0.37734 | 0.34807 | 0.70002 |

| Double plain | 0.47280 | 0.45394 | 0.55580 | 0.57826 | 0.55864 | 0.6553 | 0.54081 |

| Double Milano rib | 0.68288 | 0.761314 | 0.70517 | 0.62598 | 0.54825 | 0.7408 | 0.77297 |

| Knitted Sample Structure | Correlation Coefficient |

|---|---|

| Single plain | −0.51528 |

| Single miss | −0.69783 |

| Single tuck | 0.02073 |

| Double plain | −0.87624 |

| Double Milano rib | −0.71627 |

| Knitted Sample Structure | Multiple Linear Regression Equations | R2 | Significance F |

|---|---|---|---|

| Single plain | R = 0.0120697 + 3.24855 × 10−5 X1 + 9.05167 × 10−7 X2 | R2 = 0.97393 | Signif. F = 0.02606 |

| Single miss | R = 0.0018770 + 2.00342 × 10−5 X1 + 1.09454 × 10−4 X2 | R2 = 0.96437 | Signif. F = 0.03562 |

| Single tuck | R = 0.0699356 + 7.40042 × 10−5 X1 − 3.70694 × 10−4 X2 | R2 = 0.97055 | Signif. F = 0.02944 |

| Double plain | R = 0.0201838 + 4.54164 × 10−5 X1 − 3.27122 × 10−5 X2 | R2 = 0.97837 | Signif. F = 0.02162 |

| Double Milano rib | R = 0.0228920 + 3.71459 × 10−5 X1 − 3.19884 × 10−5 X2 | R2 = 0.98672 | Signif. F = 0.01327 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salopek Čubrić, I.; Potočić Matković, V.M.; Pavlović, Ž.; Pavko Čuden, A. Material and Structural Functionalization of Knitted Fabrics for Sportswear. Materials 2022, 15, 3306. https://doi.org/10.3390/ma15093306

Salopek Čubrić I, Potočić Matković VM, Pavlović Ž, Pavko Čuden A. Material and Structural Functionalization of Knitted Fabrics for Sportswear. Materials. 2022; 15(9):3306. https://doi.org/10.3390/ma15093306

Chicago/Turabian StyleSalopek Čubrić, Ivana, Vesna Marija Potočić Matković, Željka Pavlović, and Alenka Pavko Čuden. 2022. "Material and Structural Functionalization of Knitted Fabrics for Sportswear" Materials 15, no. 9: 3306. https://doi.org/10.3390/ma15093306

APA StyleSalopek Čubrić, I., Potočić Matković, V. M., Pavlović, Ž., & Pavko Čuden, A. (2022). Material and Structural Functionalization of Knitted Fabrics for Sportswear. Materials, 15(9), 3306. https://doi.org/10.3390/ma15093306