Deformation Behavior, a Flow Stress Model Considering the Contribution of Strain and Processing Maps in the Isothermal Compression of a Near-α Ti–3.3Al–1.5Zr–1.2Mo–0.6Ni Titanium Alloy

Abstract

:1. Introduction

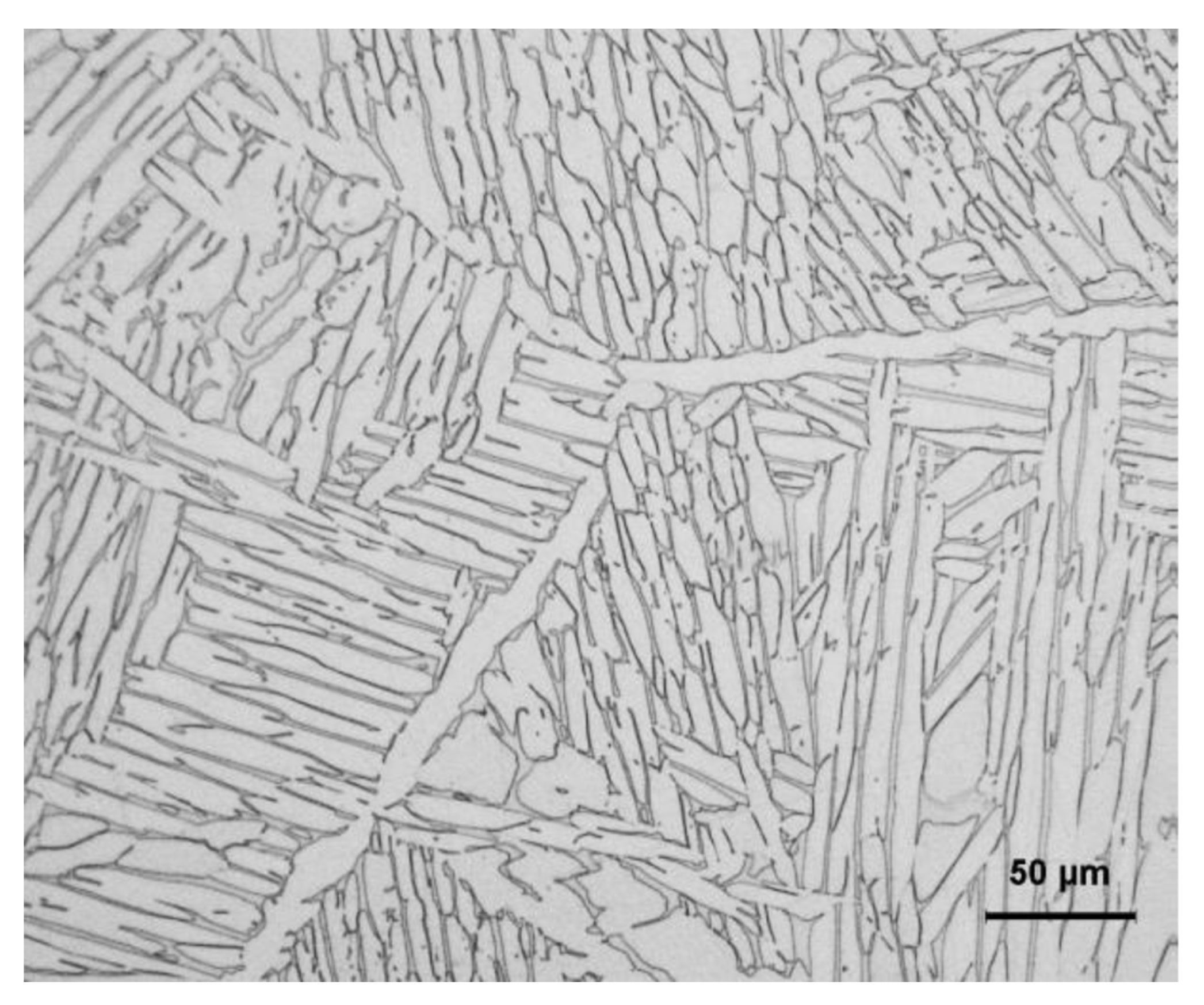

2. Materials and Methods

3. Results and Discussion

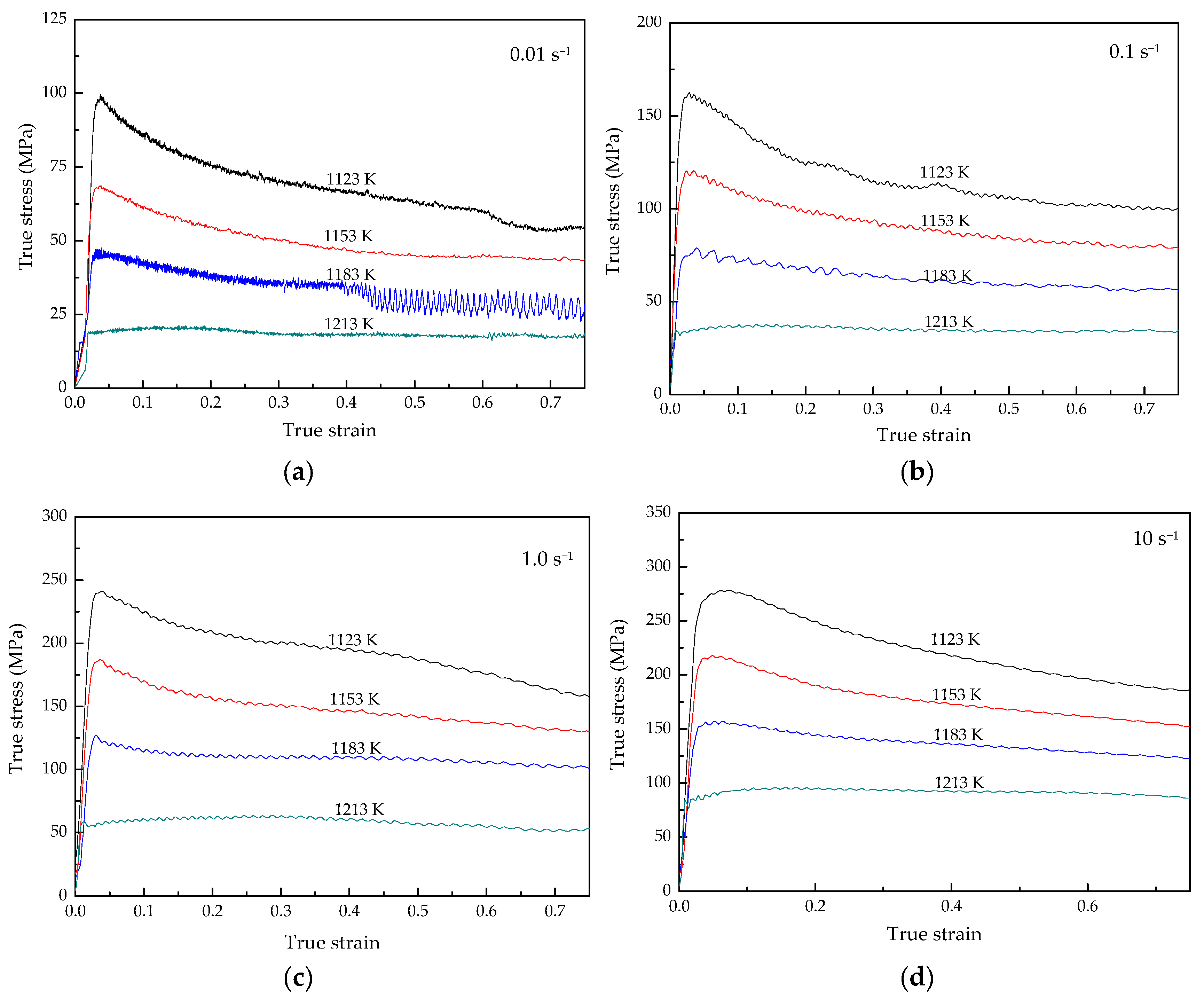

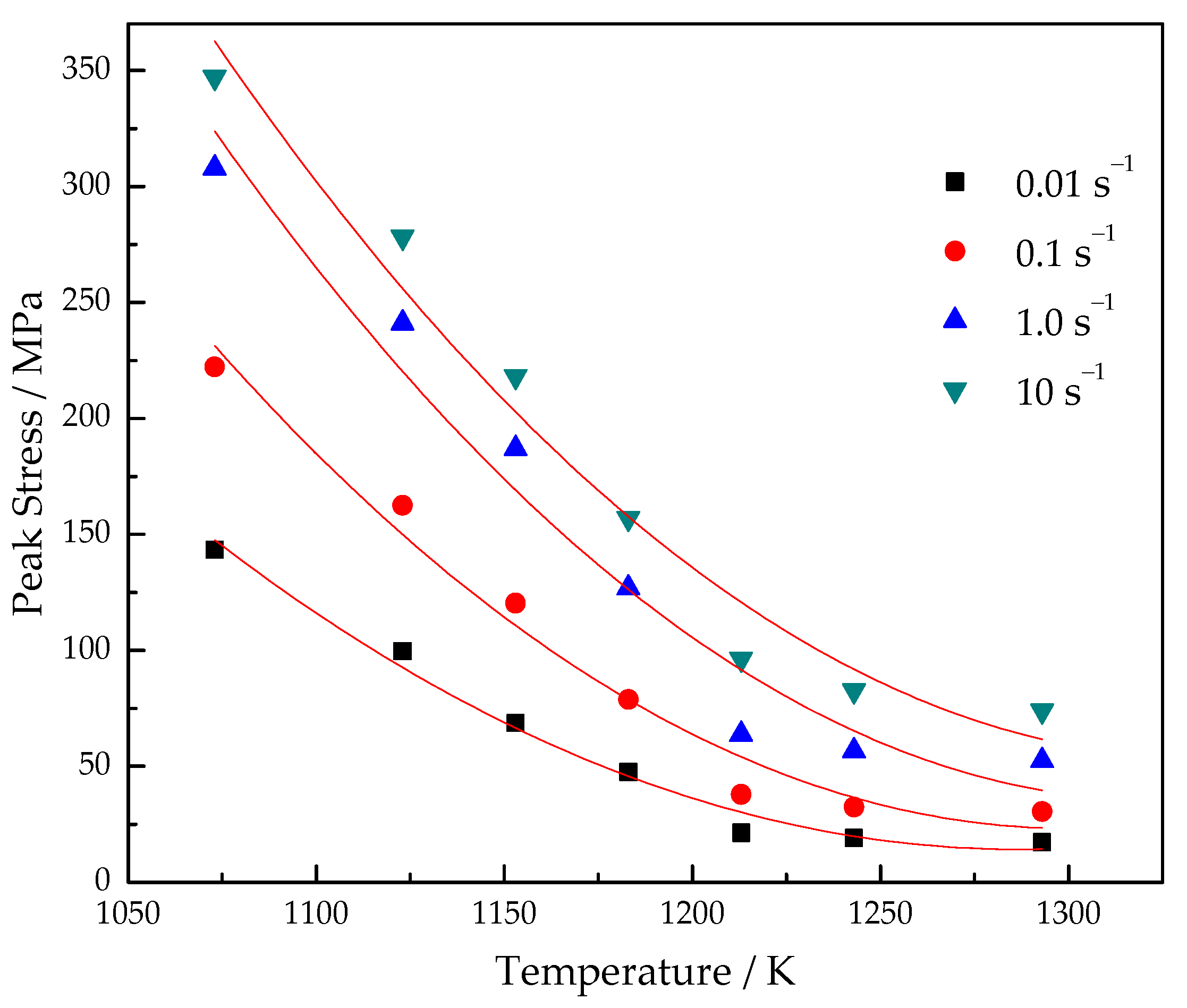

3.1. Deformation Behavior

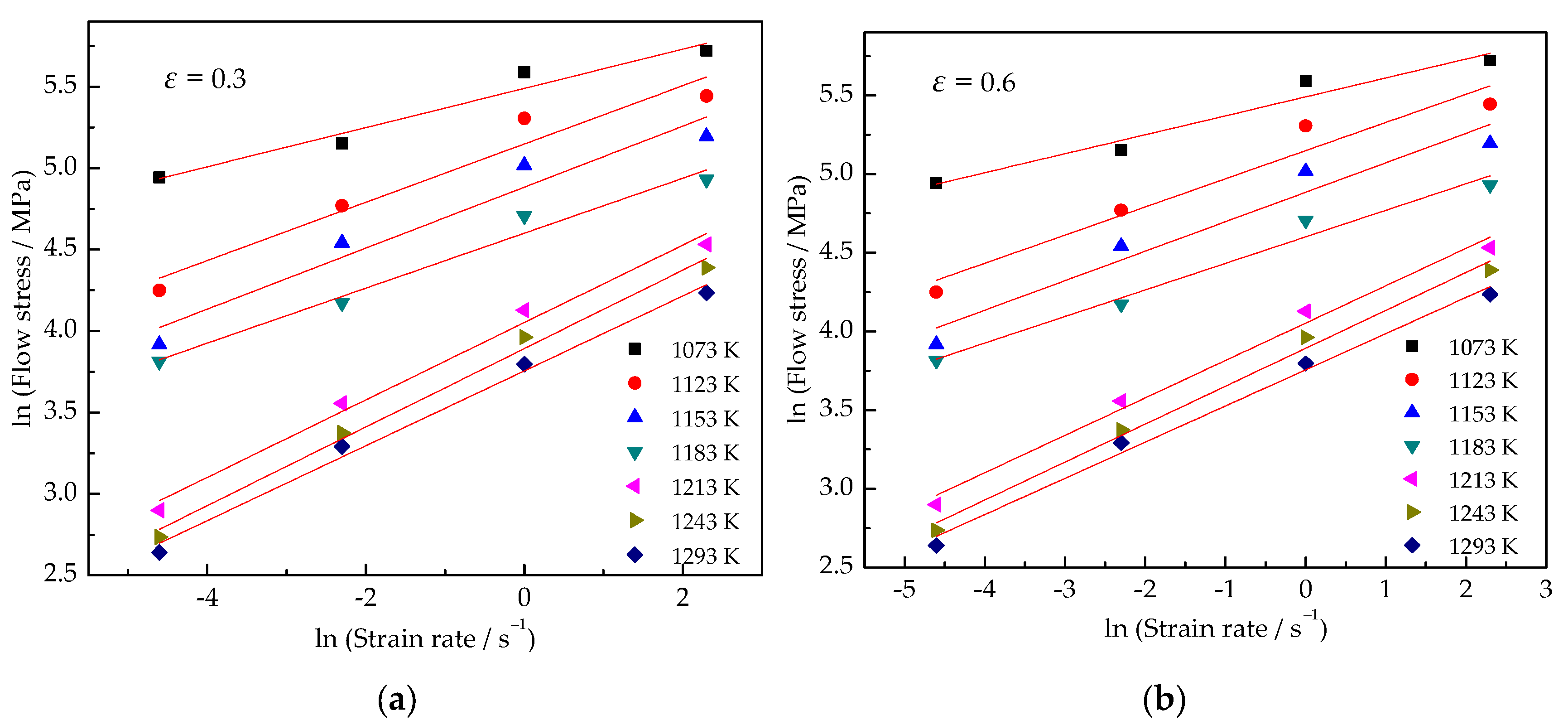

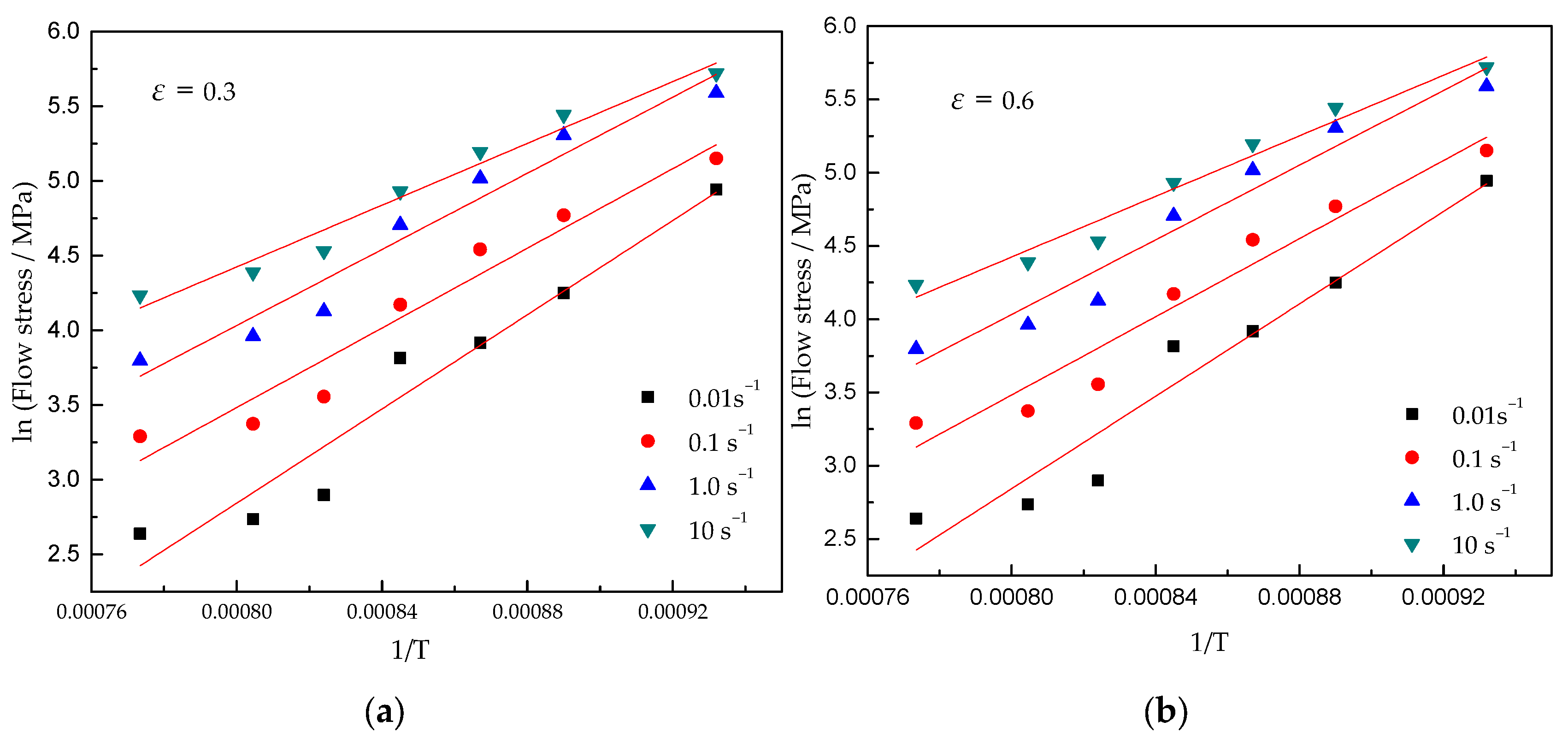

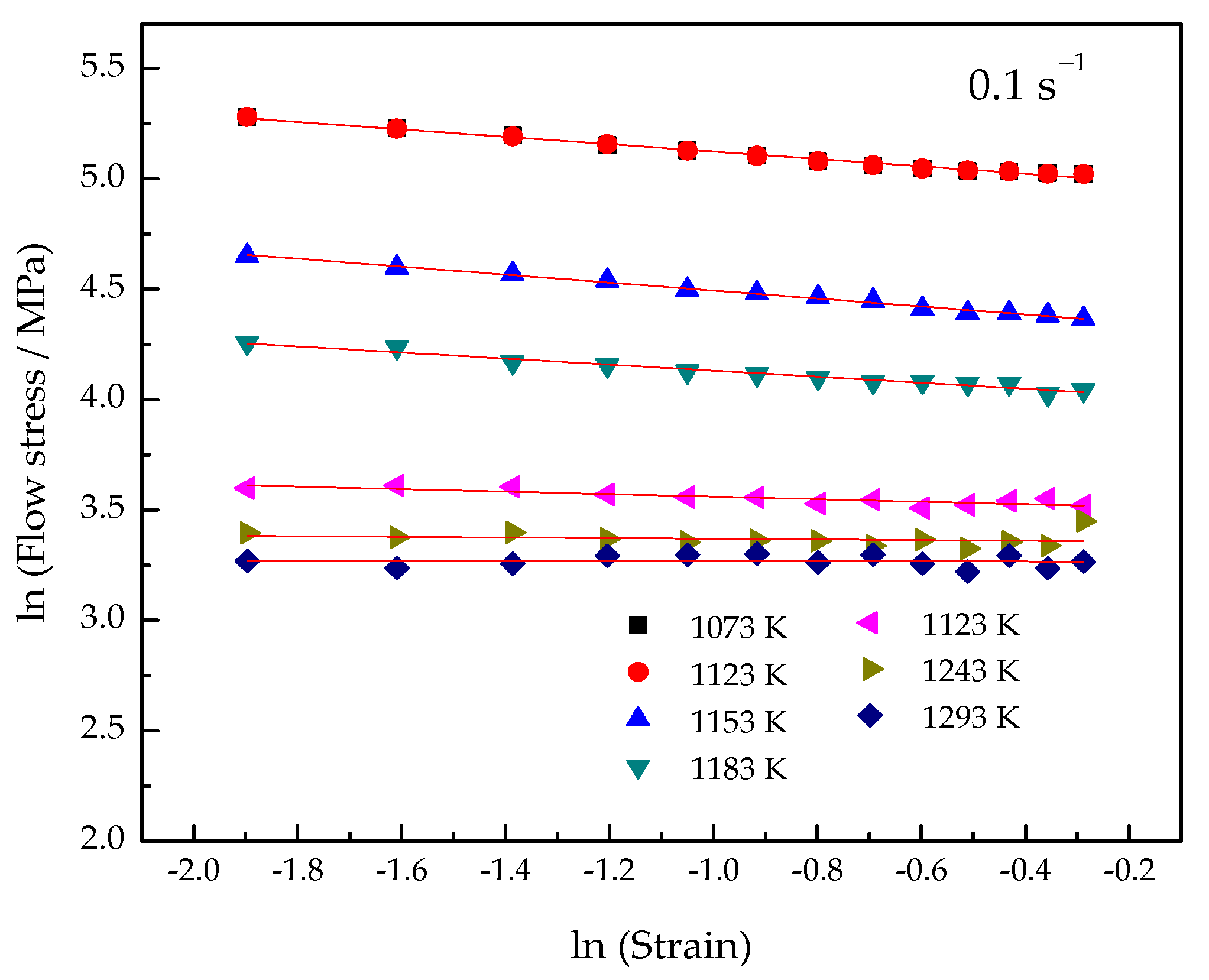

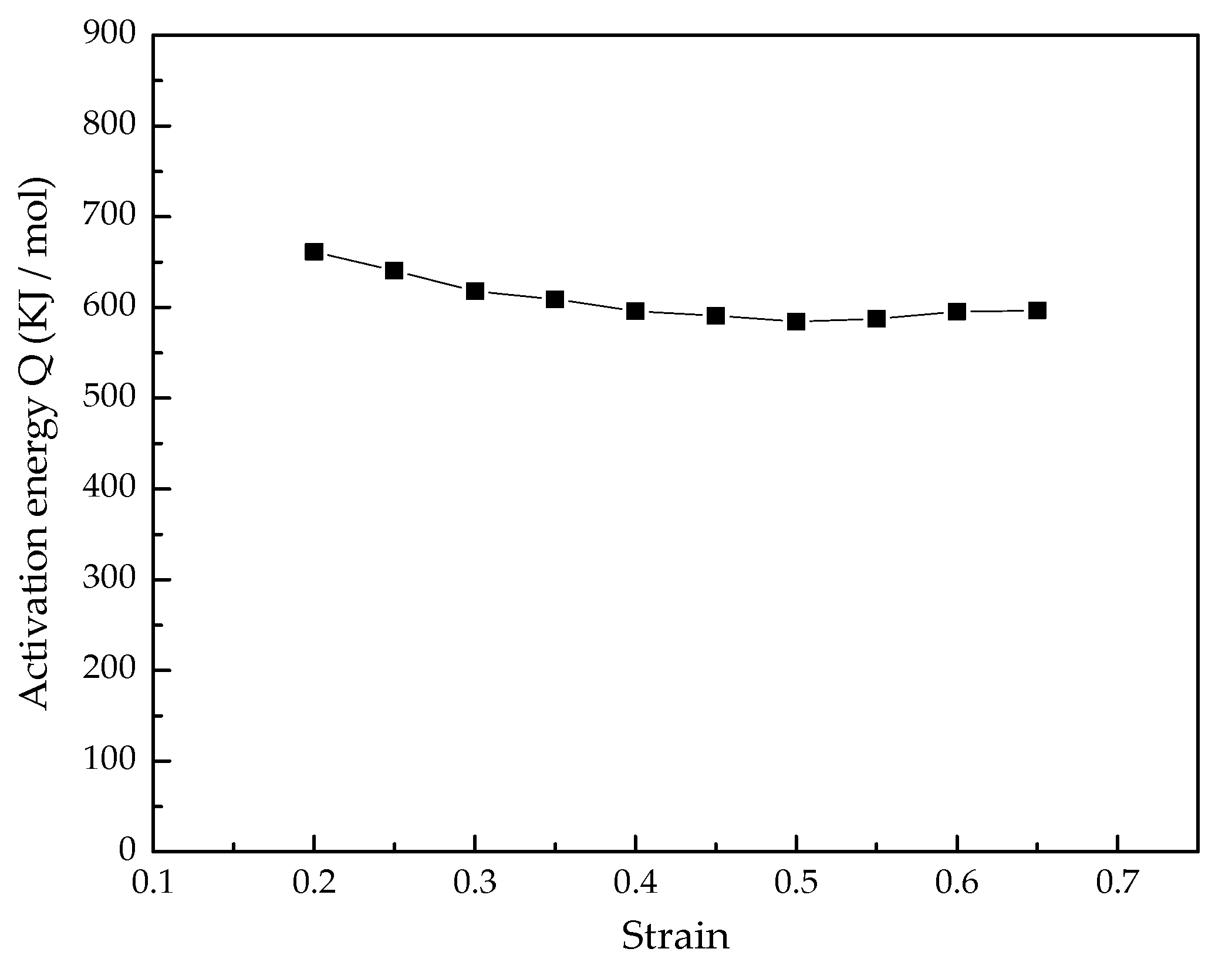

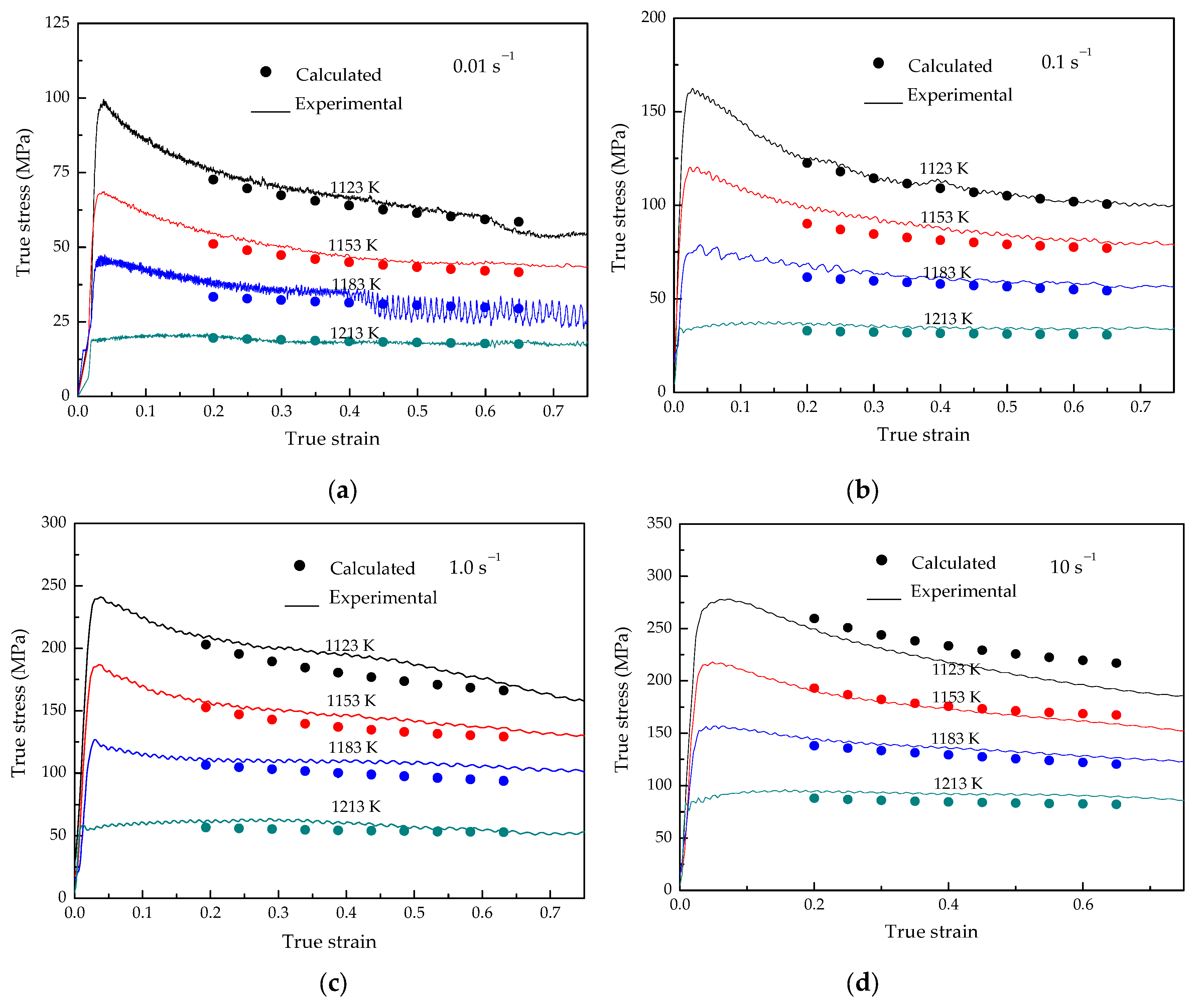

3.2. Flow Stress Model

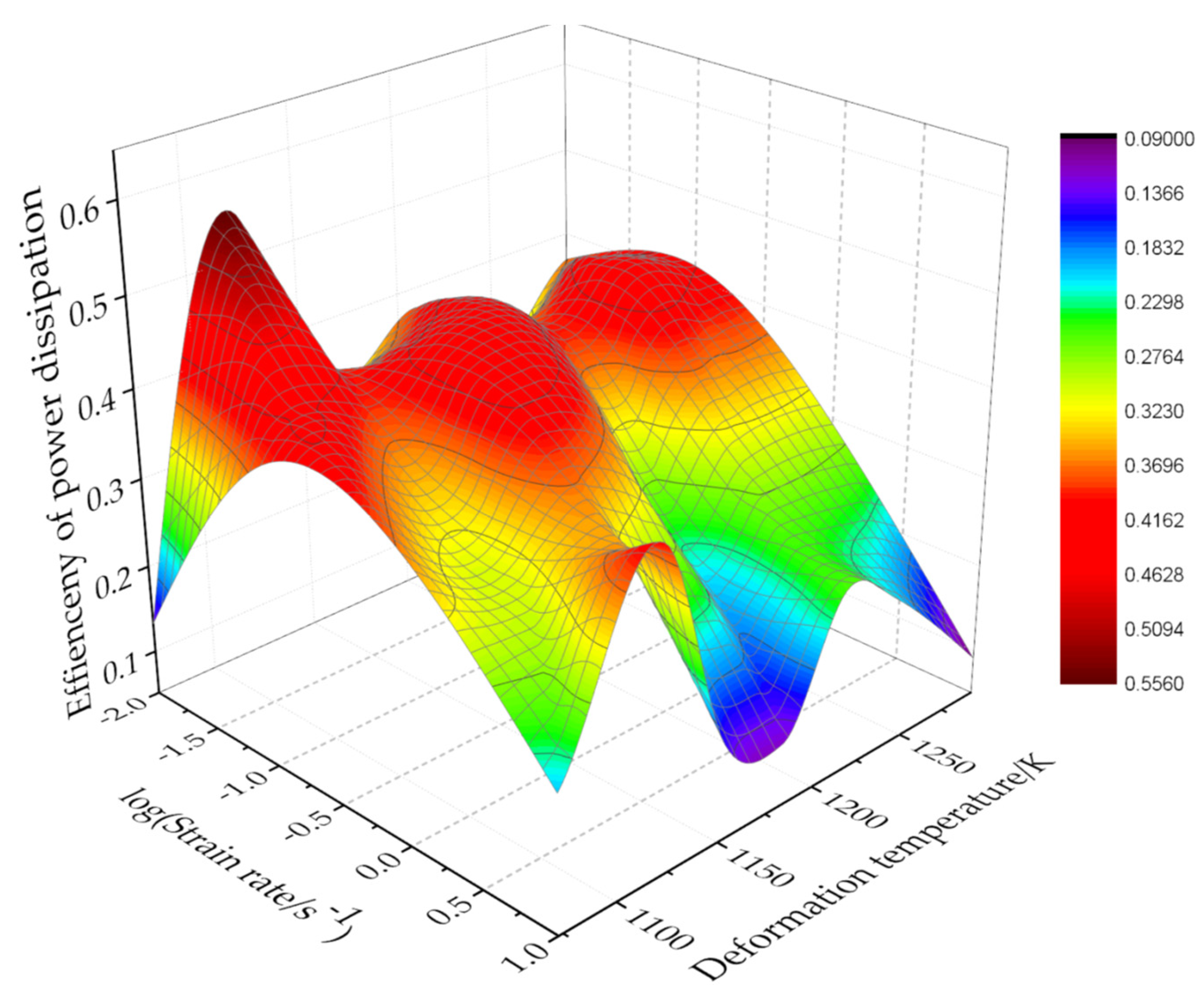

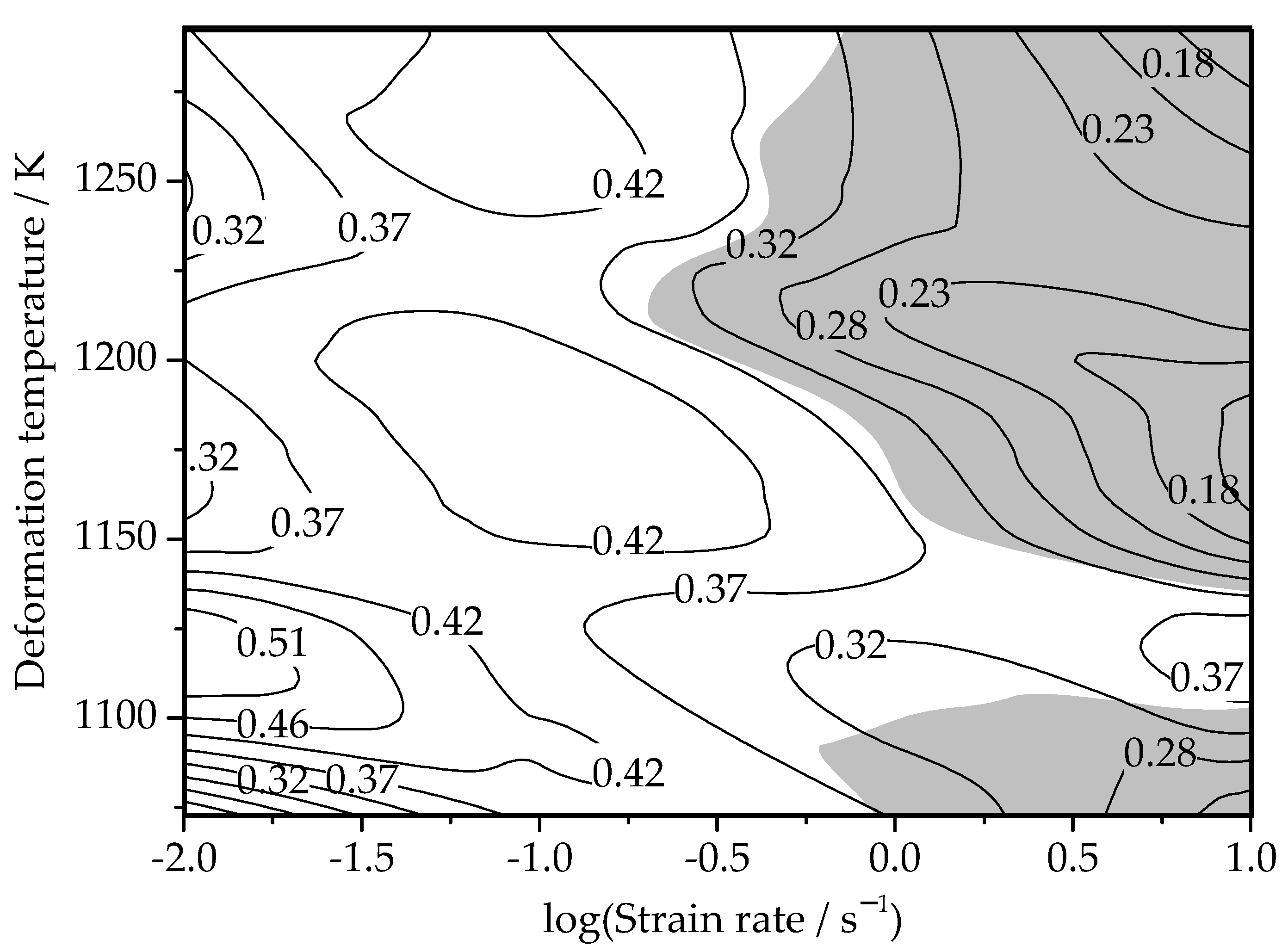

3.3. Processing Map

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Banerjee, D.; Williams, J.C. Perspectives on titanium science and technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Shugurov, A. Microstructure and mechanical properties of titanium alloys. Metals 2021, 11, 1617. [Google Scholar] [CrossRef]

- Zhang, L.; Pellegrino, A.; Townsend, D.; Petrinic, N. Strain rate and temperature dependent strain localization of a near α titanium alloy. Int. J. Impact Eng. 2020, 145, 103676. [Google Scholar] [CrossRef]

- Luo, M.; Lin, T.; Zhou, L.; Li, W.; Liang, Y.; Han, M.; Liang, Y. Deformation behavior and tensile properties of the semi-equiaxed microstructure in near alpha titanium alloy. Materials 2021, 14, 3380. [Google Scholar] [CrossRef] [PubMed]

- Dichtl, C.; Lunt, D.; Atkinson, M.; Thomas, R.; Plowman, A.; Barzdajn, B.; Sandala, R.; Fonseca, J.Q.D.; Preuss, M. Slip activity during low-stress cold creep deformation in a near-α titanium alloy. Acta Mater. 2022, 229, 117691. [Google Scholar] [CrossRef]

- Yasmeen, T.; Shao, Z.; Jiang, J. Constitutive modeling for the simulation of the superplastic forming of TA15 titanium alloy. Int. J. Mech. Sci. 2019, 164, 105178. [Google Scholar] [CrossRef]

- Mosleh, A.O.; Mikhaylovskaya, A.V.; Kotov, A.D.; Kwame, J.S. Experimental, modelling and simulation of an approach for optimizing the superplastic forming of Ti-6%Al-4%V titanium alloy. J. Manuf. Process. 2019, 45, 262–272. [Google Scholar] [CrossRef]

- Wang, F.; Shen, J.; Zhang, Y.; Ning, Y. A modified constitutive model for the description of the flow behavior of the Ti-10V-2Fe-3Al alloy during hot plastic deformation. Metals 2019, 9, 844. [Google Scholar] [CrossRef] [Green Version]

- MamdouhBadr, O.; Barlat, F.; Rolfe, B.; Lee, M.G.; Hodgson, P.; Weiss, M. Constitutive modelling of high strength titanium alloy Ti-6Al-4 V for sheet forming applications at room temperature. Int. J. Solids Struct. 2016, 80, 334–347. [Google Scholar]

- Yu, R.; Li, X.; Li, W.; Chen, J.; Guo, X.; Li, J. Application of four different models for predicting the high-temperature flow behavior of TG6 titanium alloy. Mater. Today Commun. 2021, 26, 102004. [Google Scholar] [CrossRef]

- Hajari, A.; Morakabati, M.; Abbasi, S.M.; Badri, H. Constitutive modeling for high-temperature flow behavior of Ti-6242S alloy. Mater. Sci. Eng. A 2017, 681, 103–113. [Google Scholar] [CrossRef]

- Cui, J.; Yang, H.; Sun, Z.; Li, H.; Li, Z.; Shen, C. Flow behavior and constitutive model using piecewise function of strain for TC11 alloy. Rare Met. Mat. Eng. 2012, 41, 397–401. [Google Scholar]

- Zeng, Z.; Jonsson, S.; Zhang, Y. Constitutive equations for pure titanium at elevated temperatures. Mater. Sci. Eng. A 2009, 505, 116–119. [Google Scholar] [CrossRef]

- Zhu, Y.; Zeng, W.; Sun, Y.; Feng, F.; Zhou, Y. Artificial neural network approach to predict the flow stress in the isothermal compression of as-cast TC21 titanium alloy. Comput. Mater. Sci. 2011, 50, 1785–1790. [Google Scholar] [CrossRef]

- Han, Y.; Zeng, W.; Zhao, Y.; Qi, Y.; Sun, Y. An ANFIS model for the prediction of flow stress of Ti600 alloy during hot deformation process. Comput. Mater. Sci. 2011, 50, 2273–2279. [Google Scholar] [CrossRef]

- Li, C.L.; Narayana, P.L.; Reddy, N.S.; Choi, S.W.; Yeom, J.T.; Hong, J.K.; Park, C.H. Modeling hot deformation behavior of low-cost Ti-2Al-9.2Mo-2Fe beta titanium alloy using a deep neural network. J. Mater. Sci. Technol. 2019, 35, 907–916. [Google Scholar] [CrossRef]

- Lin, Y.C.; Huang, J.; Li, H.B.; Chen, D.D. Phase transformation and constitutive models of a hot compressed TC18 titanium alloy in the α+β regime. Vacuum 2018, 157, 83–91. [Google Scholar] [CrossRef]

- Zhao, J.; Ding, H.; Zhao, W.; Huang, M.; Wei, D.; Jiang, Z. Modelling of the hot deformation behaviour of a titanium alloy using constitutive equations and artificial neural network. Comput. Mater. Sci. 2014, 92, 47–56. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Seshacharyulu, T. Processing maps for hot working of titanium alloys. Mater. Sci. Eng. A 1998, 243, 82–88. [Google Scholar] [CrossRef]

- Li, M.; Zhang, X. Optimization of TC11 alloy forging parameters using processing maps. Rare Met. 2011, 30, 222–226. [Google Scholar] [CrossRef]

- Lypchanskyi, O.; Sleboda, T.; Łukaszek-Sołek, A.; Zyguła, K.; Wojtaszek, M. Application of the strain compensation model and processing maps for description of hot deformation behavior of metastable β Titanium alloy. Materials 2021, 14, 2021. [Google Scholar] [CrossRef] [PubMed]

- Meng, Q.; Bai, C.; Xu, D. Flow behavior and processing map for hot deformation of ATI425 titanium alloy. J. Mater. Sci. Technol. 2018, 34, 679–688. [Google Scholar] [CrossRef]

- Morakabati, M.; Hajari, A. Hot working behavior of near alpha titanium alloy analyzed by mechanical testing and processing map. Trans. Nonferrous Met. Soc. China 2020, 30, 1560–1573. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Zhu, Z. Characterization of high-temperature deformation behavior and processing map of TB17 titanium alloy. J. Alloy. Compd. 2017, 692, 149–154. [Google Scholar] [CrossRef]

- Peng, W.; Zeng, W.; Wang, Q.; Yu, H. Characterization of high-temperature deformation behavior of as-cast Ti60 titanium alloy using processing map. Mater. Sci. Eng. A 2013, 571, 116–122. [Google Scholar] [CrossRef]

- Tsukamoto, G.; Kunieda, T.; Mitsuhara, M.; Nakashima, H. Effect of twinning deformation on work hardening in commercially pure titanium. Mater. Sci. Eng. A 2022, 840, 142907. [Google Scholar] [CrossRef]

- Jiang, X.Q.; Fan, X.G.; Zhan, M.; Wang, R.; Liang, Y.F. Microstructure dependent strain localization during primary hot working of TA15 titanium alloy: Behavior and mechanism. Mater. Des. 2021, 203, 109589. [Google Scholar] [CrossRef]

- Dang, K.; Wang, K.; Liu, G. Dynamic softening and hardening behavior and the micro-mechanism of a TC31 high temperature titanium alloy sheet within hot deformation. Materials 2021, 14, 6515. [Google Scholar] [CrossRef]

- Yasmeen, T.; Zhao, B.; Zheng, J.H.; Tian, F.; Lin, J.; Jiang, J. The study of flow behavior and governing mechanisms of a titanium alloy during superplastic forming. Mater. Sci. Eng. A 2020, 788, 139482. [Google Scholar] [CrossRef]

- Li, C.; Huang, L.; Zhao, M.; Guo, S.; Li, J. Hot deformation behavior and mechanism of a new metastable β titanium alloy Ti–6Cr–5Mo–5V–4Al in single phase region. Mater. Sci. Eng. A 2021, 814, 141231. [Google Scholar] [CrossRef]

- Li, J.; Wang, B.; Huang, H.; Fang, S.; Chen, P.; Shen, J. Unified modelling of the flow behaviour and softening mechanism of a TC6 titanium alloy during hot deformation. J. Alloy. Compd. 2018, 748, 1031–1043. [Google Scholar] [CrossRef]

- Wang, H.; Wang, C.; Li, M.; Ma, R.; Zhao, J. Constitutive equations for describing the hot compressed behavior of TC4–DT titanium alloy. Materials 2020, 13, 3424. [Google Scholar] [CrossRef] [PubMed]

| 3.94331 | 0.21924 | −0.01144 | −9.02243 × 10−4 | −0.05766 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, W.; Cao, J.; Hou, S.; Wang, G.; Li, Y.; Lang, S. Deformation Behavior, a Flow Stress Model Considering the Contribution of Strain and Processing Maps in the Isothermal Compression of a Near-α Ti–3.3Al–1.5Zr–1.2Mo–0.6Ni Titanium Alloy. Materials 2022, 15, 3346. https://doi.org/10.3390/ma15093346

Yu W, Cao J, Hou S, Wang G, Li Y, Lang S. Deformation Behavior, a Flow Stress Model Considering the Contribution of Strain and Processing Maps in the Isothermal Compression of a Near-α Ti–3.3Al–1.5Zr–1.2Mo–0.6Ni Titanium Alloy. Materials. 2022; 15(9):3346. https://doi.org/10.3390/ma15093346

Chicago/Turabian StyleYu, Weixin, Junhui Cao, Shusen Hou, Guanglong Wang, Yue Li, and Shaoting Lang. 2022. "Deformation Behavior, a Flow Stress Model Considering the Contribution of Strain and Processing Maps in the Isothermal Compression of a Near-α Ti–3.3Al–1.5Zr–1.2Mo–0.6Ni Titanium Alloy" Materials 15, no. 9: 3346. https://doi.org/10.3390/ma15093346

APA StyleYu, W., Cao, J., Hou, S., Wang, G., Li, Y., & Lang, S. (2022). Deformation Behavior, a Flow Stress Model Considering the Contribution of Strain and Processing Maps in the Isothermal Compression of a Near-α Ti–3.3Al–1.5Zr–1.2Mo–0.6Ni Titanium Alloy. Materials, 15(9), 3346. https://doi.org/10.3390/ma15093346