Substituting Resistance Spot Welding with Flexible Laser Spot Welding to Join Ultra-Thin Foil of Inconel 718 to Thick 410 Steel

Abstract

:1. Introduction

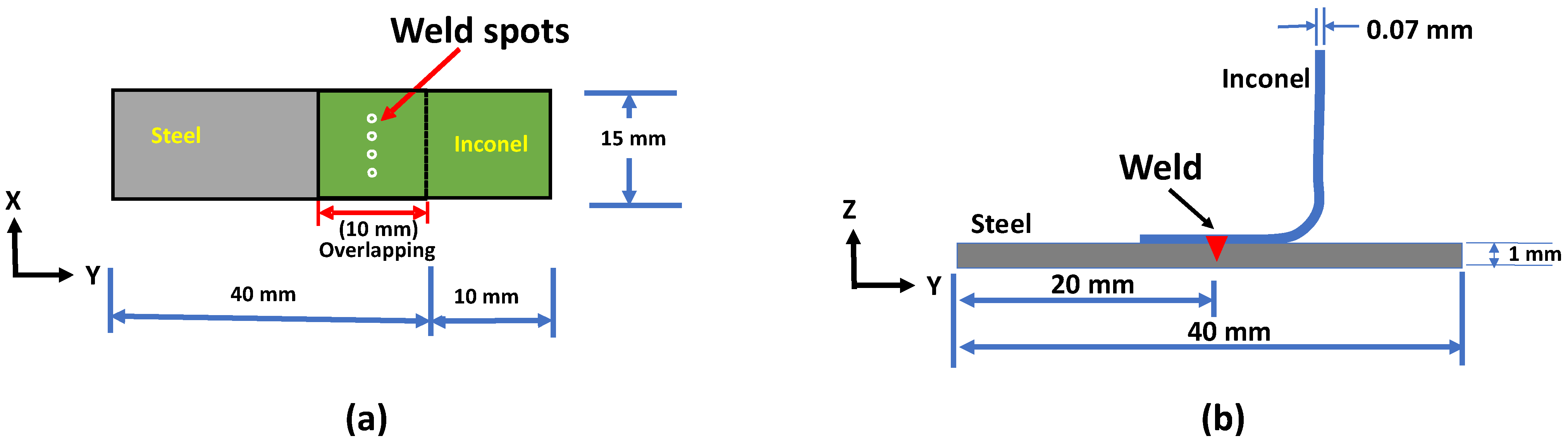

2. Experimental Setup and Procedure

3. Results and Discussions

3.1. Joint Strength Analysis

3.1.1. Micro-RSW Joint Strength

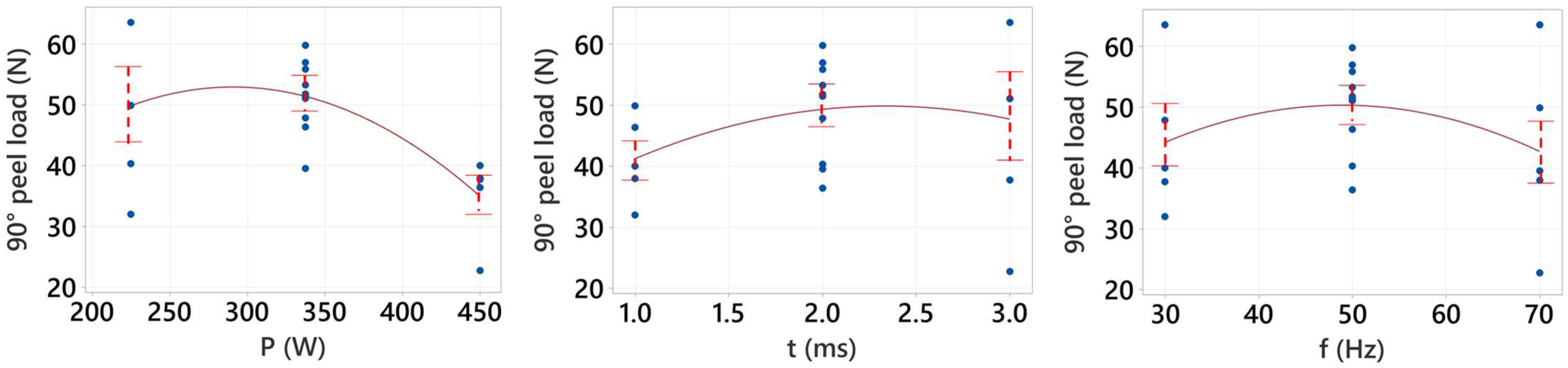

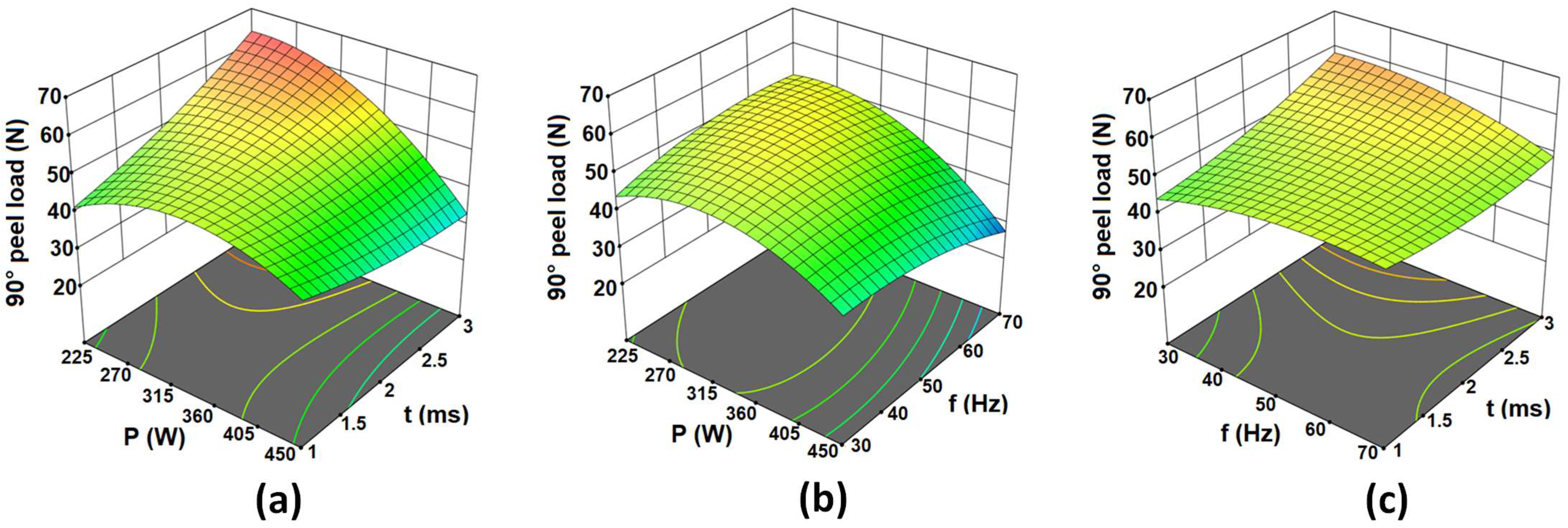

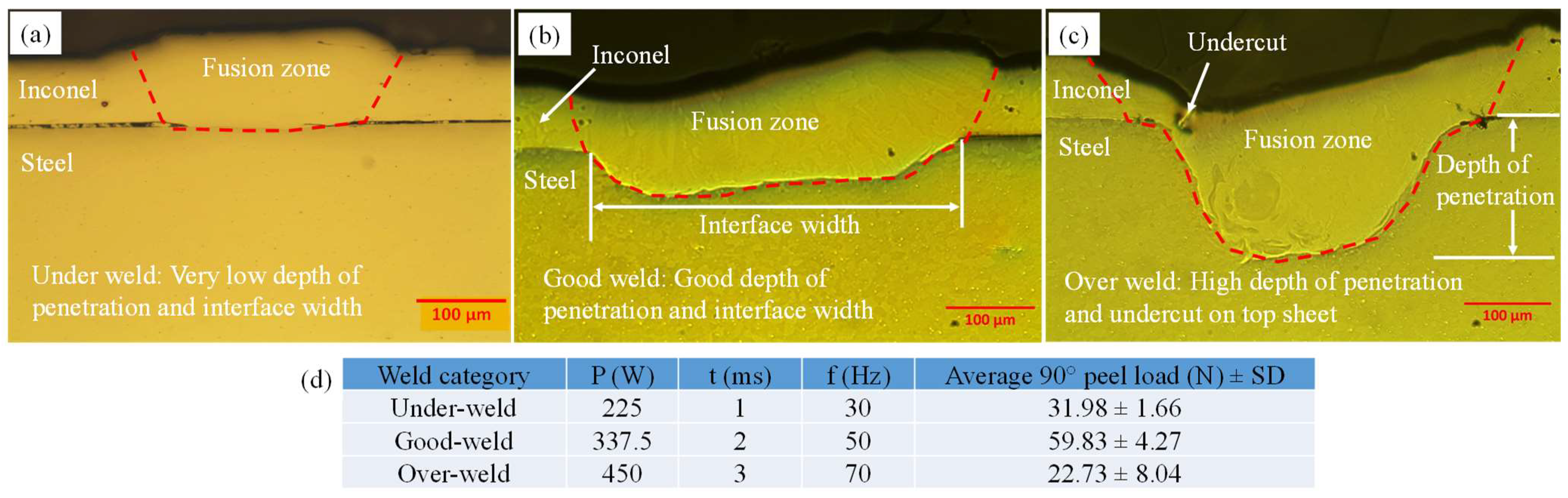

3.1.2. Laser-Welded Joint Strength

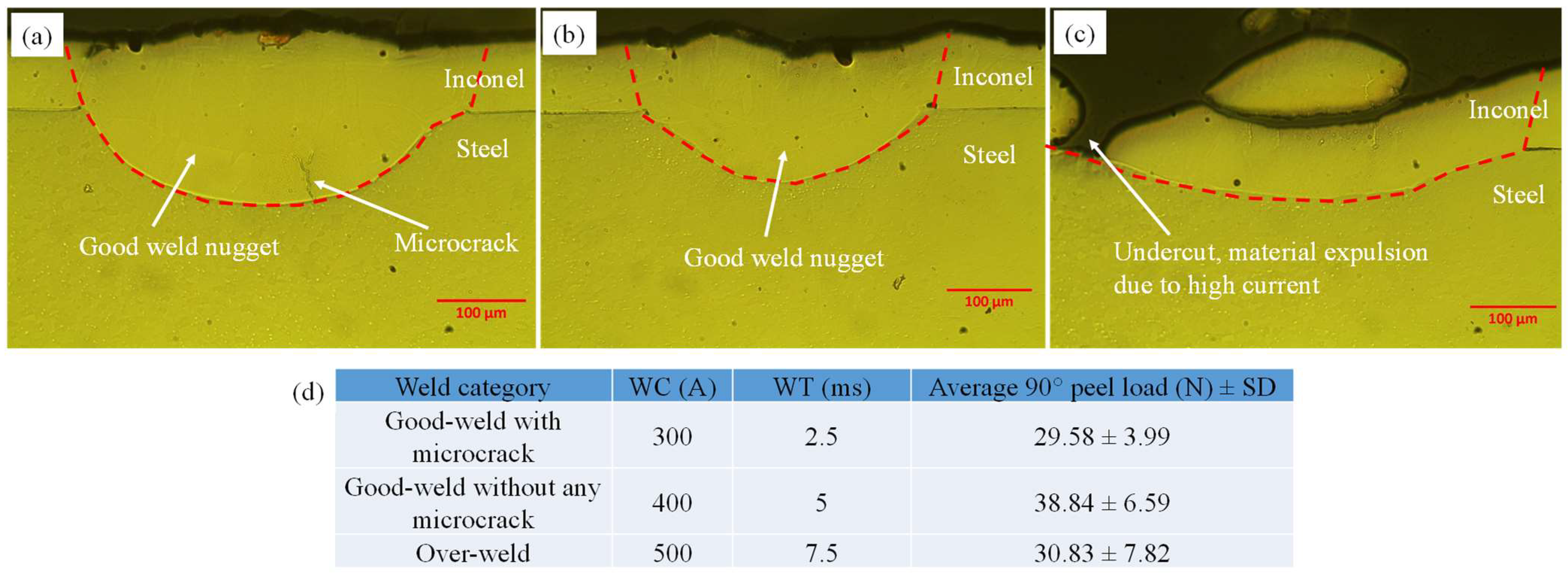

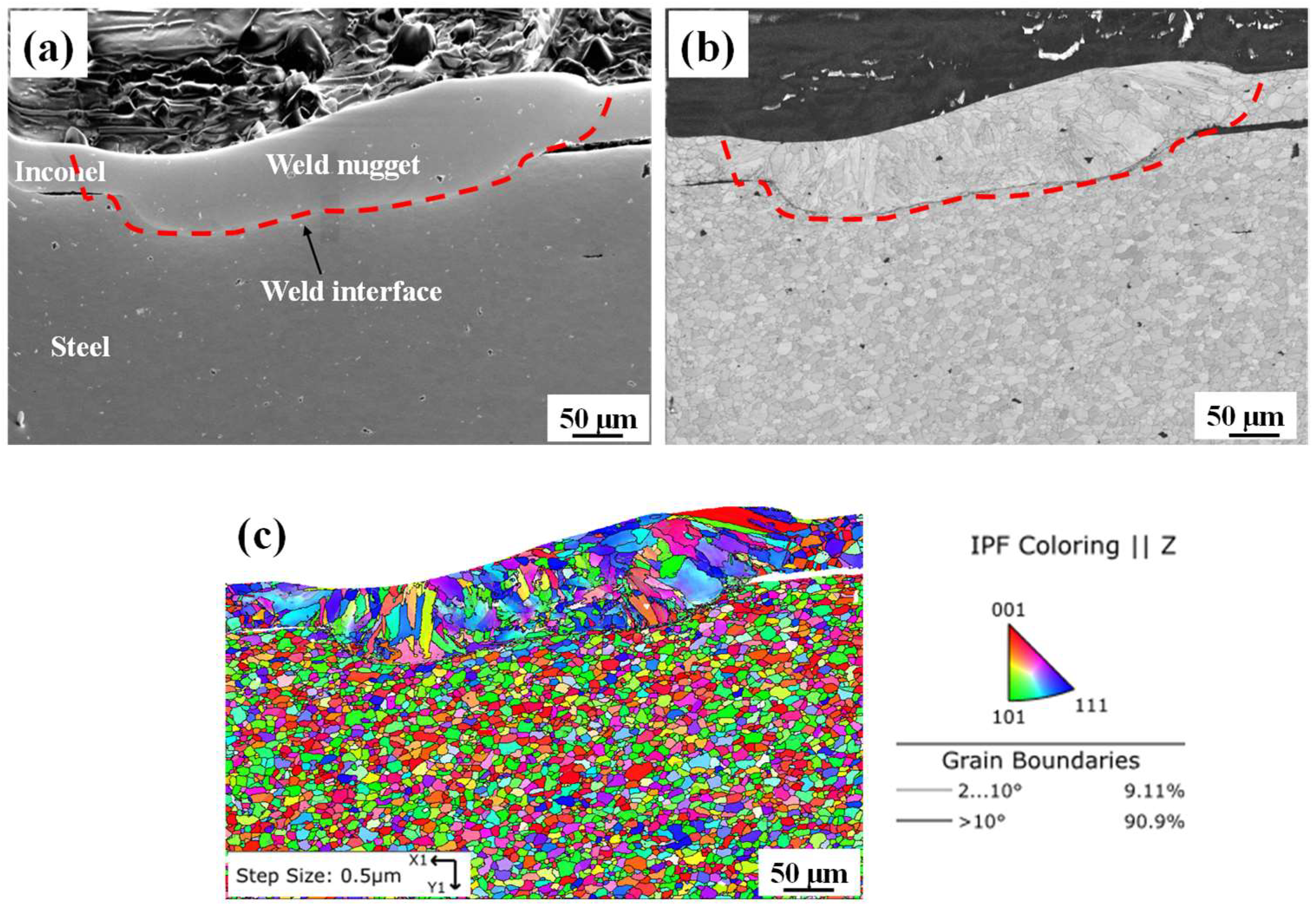

3.2. Metallographic Analysis

3.2.1. Micro-RSW Welding Process

3.2.2. Laser Welding Process

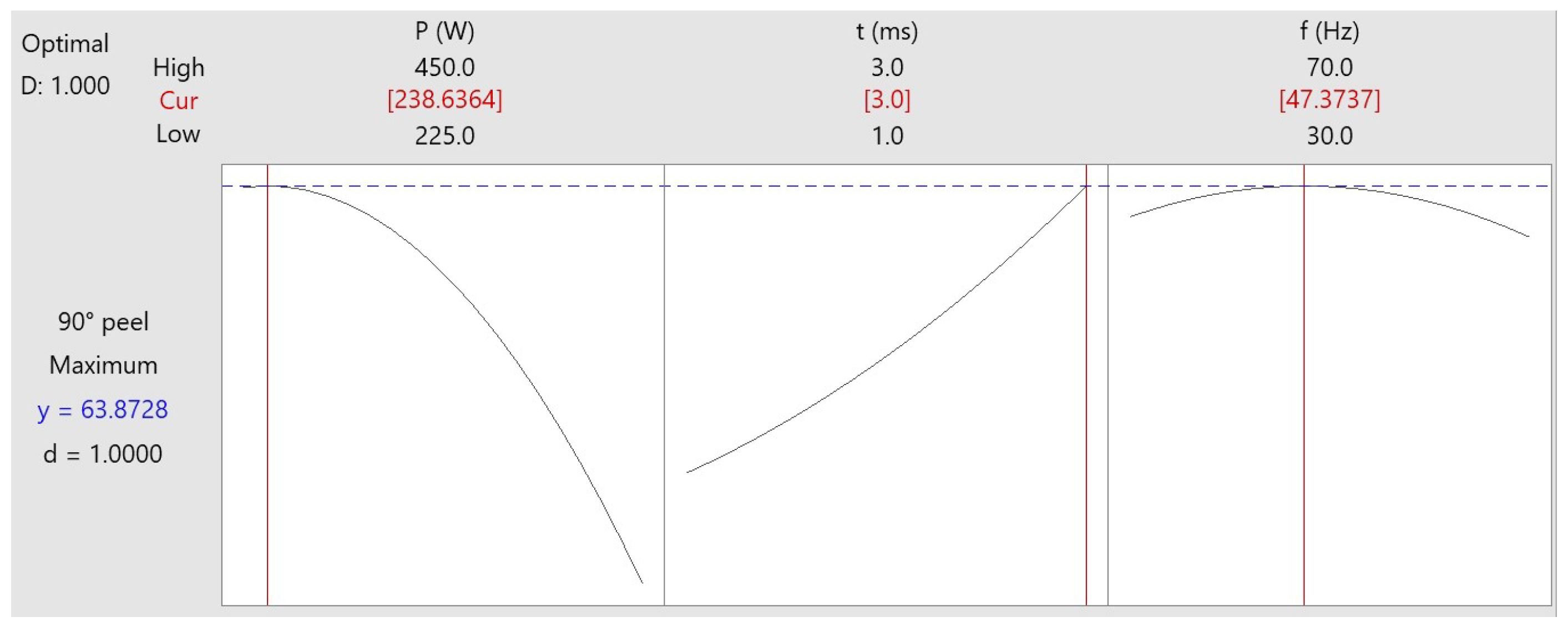

3.3. Detailed Analysis of Laser Welding Process Parameters

3.3.1. Confirmatory Tests

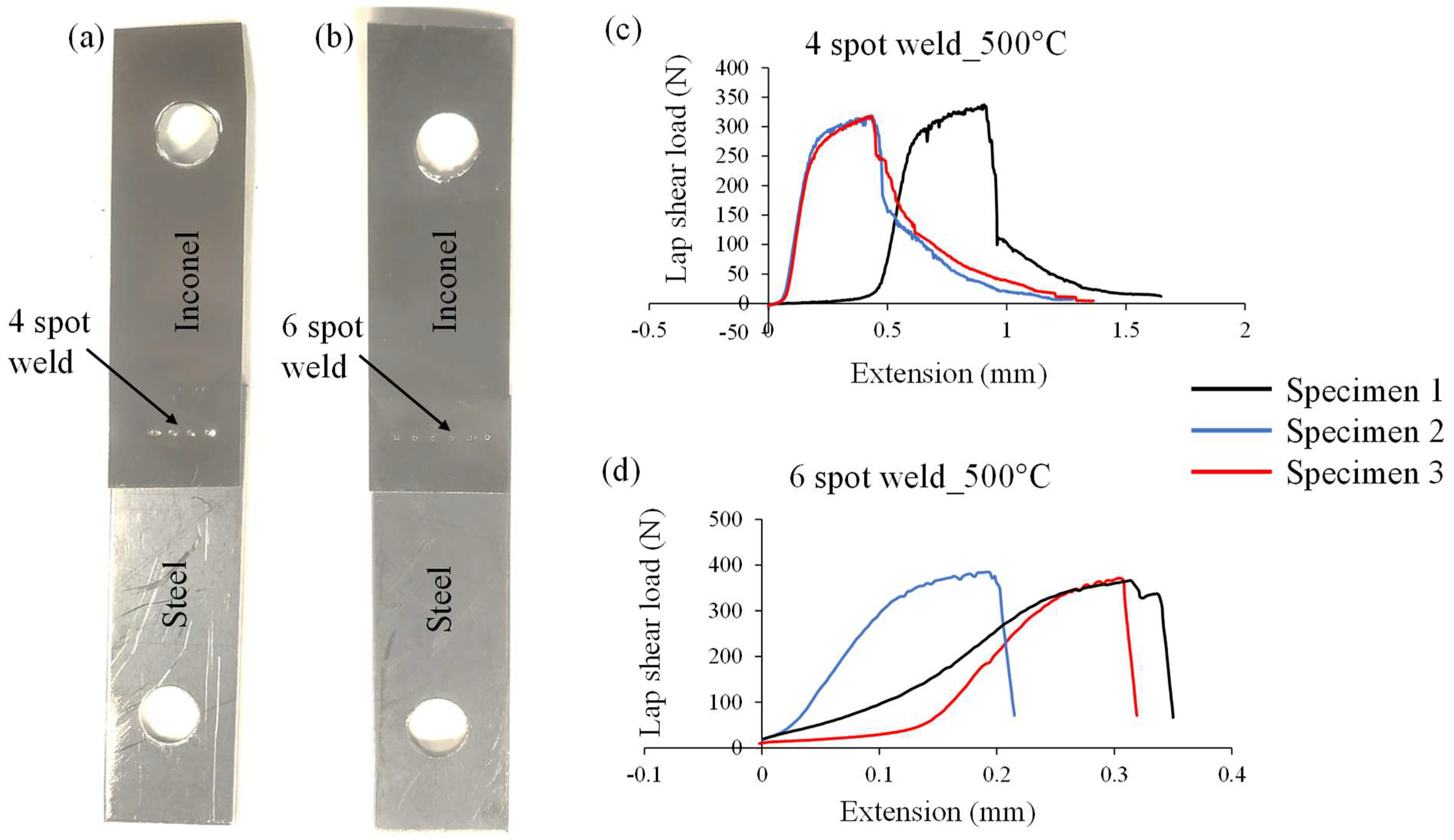

3.3.2. Ambient vs. Elevated Temperature Tests

4. Conclusions

- ➢

- From mean effect plots, it was found that for micro-RSW, the weld current had the most significant effect on the 90° peel load followed by weld time. Similarly, in the case of laser welding, laser power had a significant effect on the 90° peel load followed by pulse on time and pulse frequency within the selected working range of the process parameters.

- ➢

- The micro-RSW welded joints showed relatively lower weld strength than laser-welded joints under good-weld parametric conditions.

- ➢

- This paper identified the optimized process parameters for laser welding processes to achieve good weld for thin Inconel to steel joints.

- ➢

- The laser weld provided maximum joint strength of about 63.60 N which was significantly higher than the micro-RSW welding process of about 39.16 N.

- ➢

- For four spots of laser weld, the average lap shear load obtained for the laser welding of Inconel to steel joints at elevated temperature (324.59 N) was lower (about 17%) than the ambient temperature (390.31 N). Meanwhile, for six spots of laser weld, the average lap shear load (374.15 N) was about 4% lower than the average load at ambient temperature.

- ➢

- In further work, a detailed study may be conducted to establish the relationship of weld quality with laser seam shape instead of spot.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fotovvati, B.; Namdari, N.; Dehghanghadikolaei, A. On Coating Techniques for Surface Protection: A Review. J. Manuf. Mater. Process. 2019, 3, 28. [Google Scholar] [CrossRef] [Green Version]

- Das, A.; Fritz, R.; Finuf, M.; Masters, I. Blue laser welding of multi-layered AISI 316L stainless steel micro-foils. Opt. Laser Technol. 2020, 132, 106498. [Google Scholar] [CrossRef]

- Ventrella, V.A.; Berretta, J.R.; De Rossi, W. Application of pulsed Nd: YAG laser in thin foil microwelding. Int. J. Mater. Prod. Technol. 2014, 48, 194–204. [Google Scholar] [CrossRef]

- Kumar, N.; Masters, I.; Das, A. In-depth evaluation of laser-welded similar and dissimilar material tab-to-busbar electrical interconnects for electric vehicle battery pack. J. Manuf. Process. 2021, 70, 78–96. [Google Scholar] [CrossRef]

- Shah, R.K. Advances in Science and Technology of Compact Heat Exchangers. Heat Transf. Eng. 2006, 27, 3–22. [Google Scholar] [CrossRef]

- Jozwik, P.; Polkowski, W.; Bojar, Z. Applications of Ni3Al Based Intermetallic Alloys—Current Stage and Potential Perceptivities. Materials 2015, 8, 2537–2568. [Google Scholar] [CrossRef]

- Chludzinski, M.; dos Santos, R.E.; Churiaque, C.; Ortega-Iguña, M.; Sánchez-Amaya, J.M. Pulsed Laser Welding Applied to Metallic Materials—A Material Approach. Metals 2021, 11, 640. [Google Scholar] [CrossRef]

- Hong, Y.; Chang, B.; Peng, G.; Yuan, Z.; Hou, X.; Xue, B.; Du, D. In-process monitoring of lack of fusion in ultra-thin sheets edge welding using machine vision. Sensors 2018, 18, 2411. [Google Scholar] [CrossRef] [Green Version]

- Shaikh, U.F.; Das, A.; Barai, A.; Masters, I. Electro-Thermo-Mechanical Behaviours of Laser Joints for Electric Vehicle Battery Interconnects. In Proceedings of the 2019 Electric Vehicles International Conference (EV), Bucharest, Romania, 3–4 October 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar]

- Das, A.; Li, D.; Williams, D.; Greenwood, D. Weldability and shear strength feasibility study for automotive electric vehicle battery tab interconnects. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 54. [Google Scholar] [CrossRef] [Green Version]

- Rikka, V.R.; Sahu, S.R.; Roy, A.; Jana, S.N.; Sivaprahasam, D.; Prakash, R.; Gopalan, R.; Sundararajan, G. Tailoring micro resistance spot welding parameters for joining nickel tab to inner aluminium casing in a cylindrical lithium ion cell and its influence on the electrochemical performance. J. Manuf. Process. 2020, 49, 463–471. [Google Scholar] [CrossRef]

- Dong, S.; Kelkar, G.; Zhou, Y. Electrode sticking during micro-resistance welding of thin metal sheets. IEEE Trans. Electron. Packag. Manuf. 2002, 25, 355–361. [Google Scholar] [CrossRef]

- Ely, K.J.; Zhou, Y. Microresistance spot welding of Kovar, steel, and nickel. Sci. Technol. Weld. Join. 2001, 6, 63–72. [Google Scholar] [CrossRef]

- Dimatteo, V.; Ascari, A.; Fortunato, A. Continuous laser welding with spatial beam oscillation of dissimilar thin sheet materials (Al-Cu and Cu-Al): Process optimization and characterization. J. Manuf. Process. 2019, 44, 158–165. [Google Scholar] [CrossRef]

- Das, A.; Dale, T.; Masters, I.; Widanage, D. Feasibility of Fillet Edge Weld Using Laser Wobble Technique. Procedia CIRP 2020, 95, 846–851. [Google Scholar] [CrossRef]

- Li, B.; Shiu, B.W.; Lau, K.J. Robust fixture configuration design for sheet metal assembly with laser welding. J. Manuf. Sci. Eng. 2003, 125, 120–127. [Google Scholar] [CrossRef]

- Abe, N.; Funada, Y.; Imanaka, T.; Tsukamoto, M. Micro welding of thin stainless steel foil with a direct diode laser. Trans. JWRI 2005, 34, 19–23. [Google Scholar]

- Kim, J.; Kim, S.; Kim, K.; Jung, W.; Youn, D.; Lee, J.; Ki, H. Effect of beam size in laser welding of ultra-thin stainless steel foils. J. Mater. Process. Technol. 2016, 233, 125–134. [Google Scholar] [CrossRef]

- Kumar, N.; Mukherjee, M.; Bandyopadhyay, A. Comparative study of pulsed Nd:YAG laser welding of AISI 304 and AISI 316 stainless steels. Opt. Laser Technol. 2017, 88, 24–39. [Google Scholar] [CrossRef]

- Ion, J.C. Chapter 16—Keyhole Welding. In Laser Processing of Engineering Materials; Ion, J.C., Ed.; Butterworth-Heinemann: Oxford, UK, 2005; pp. 395–455. [Google Scholar]

- Ventrella, V.A.; Berretta, J.R.; de Rossi, W. Pulsed Nd:YAG laser seam welding of AISI 316L stainless steel thin foils. J. Mater. Process. Technol. 2010, 210, 1838–1843. [Google Scholar] [CrossRef]

- Kleine, K.F.; Fox, W.J.; Watkins, K.G. Micro Welding with Pulsed Single Mode Fiber Lasers; Laser Institute of America: San Francisco, CA, USA, 2004; p. M501. [Google Scholar]

- Gillner, A.; Holtkamp, J.; Hartmann, C.; Olowinsky, A.; Gedicke, J.; Klages, K.; Bosse, L.; Bayer, A. Laser applications in microtechnology. J. Mater. Process. Technol. 2005, 167, 494–498. [Google Scholar] [CrossRef]

- Tolinski, M. Lasers seal the deal in medical. Manuf. Eng. 2008, 140, LT14–LT20. [Google Scholar]

- Quazi, M.; Ishak, M.; Fazal, M.; Arslan, A.; Rubaiee, S.; Aiman, M.; Qaban, A.; Yusof, F.; Sultan, T.; Ali, M. A comprehensive assessment of laser welding of biomedical devices and implant materials: Recent research, development and applications. Crit. Rev. Solid State Mater. Sci. 2021, 46, 109–151. [Google Scholar] [CrossRef]

- Pakmanesh, M.R.; Shamanian, M. Optimization of pulsed laser welding process parameters in order to attain minimum underfill and undercut defects in thin 316L stainless steel foils. Opt. Laser Technol. 2018, 99, 30–38. [Google Scholar] [CrossRef]

- Kim, J.-D.; Kim, C.-J.; Chung, C.-M. Repair welding of etched tubular components of nuclear power plant by Nd:YAG laser. J. Mater. Process. Technol. 2001, 114, 51–56. [Google Scholar] [CrossRef]

- Ahmad, G.N.; Raza, M.S.; Singh, N.K.; Kumar, H. Experimental investigation on Ytterbium fiber laser butt welding of Inconel 625 and Duplex stainless steel 2205 thin sheets. Opt. Laser Technol. 2020, 126, 106117. [Google Scholar] [CrossRef]

- Ahmad, G.N.; Raza, M.S.; Singh, N.K.; Muvvala, G. Investigating the effect of process parameters on weld pool thermal history and mechanical properties of laser welded Inconel 625 and Duplex stainless steel 2205 dissimilar welds. Optik 2021, 248, 168134. [Google Scholar] [CrossRef]

- Yan, L.; Jam, J.E.; Beni, M.H.; Kholoud, M.J.; Baleanu, D.; Shahraki, M.E.; Ghaemi, F. Effect of laser welding parameters on the temperature distribution, microstructure and mechanical properties of dissimilar weld joint of Inconel 625 and stainless steel 304. Int. Commun. Heat Mass Transf. 2022, 131, 105859. [Google Scholar] [CrossRef]

- Srikanth, S.; Parthiban, A. Microstructural analysis of Nd:YAG laser welding for Inconel alloy. Mater. Today Proc. 2020, 21, 568–571. [Google Scholar] [CrossRef]

- Cheepu, M.; Kumar Reddy, Y.A.; Indumathi, S.; Venkateswarlu, D. Laser welding of dissimilar alloys between high tensile steel and Inconel alloy for high temperature applications. Adv. Mater. Process. Technol. 2020, 1–12. [Google Scholar] [CrossRef]

- Sidharth, D.; KV, P.P.; Rajendran, R.; Narayanan, S. Microstructure and properties of inconel 718 and AISI 416 laser welded joints. J. Mater. Process. Technol. 2019, 266, 52–62. [Google Scholar]

- Lertora, E.; Mandolfino, C.; Gambaro, C. Mechanical Behaviour of Inconel 718 Thin-Walled Laser Welded Components for Aircraft Engines. Int. J. Aerosp. Eng. 2014, 2014, 721680. [Google Scholar] [CrossRef]

- Lin, J.; Wang, X.; Lei, Y.; Wei, R.; Guo, F. Study on hot cracking in laser welded joints of inconel 718 alloy foils. J. Manuf. Process. 2021, 64, 1024–1035. [Google Scholar] [CrossRef]

- Vamsi Krishna, B.; Bandyopadhyay, A. Surface modification of AISI 410 stainless steel using laser engineered net shaping (LENSTM). Mater. Des. 2009, 30, 1490–1496. [Google Scholar] [CrossRef]

- Masomtob, M.; Sukondhasingha, R.; Becker, J.; Sauer, D.U. Parametric study of spot welding between Li-ion battery cells and sheet metal connectors. Eng. J. 2017, 21, 457–473. [Google Scholar] [CrossRef] [Green Version]

- Kumar, N.; Das, A.; Dale, T.; Masters, I. Laser wobble welding of fluid-based cooling channel joining for battery thermal management. J. Manuf. Process. 2021, 67, 151–169. [Google Scholar] [CrossRef]

- Kumar, N.; Mukherjee, M.; Bandyopadhyay, A. Study on laser welding of austenitic stainless steel by varying incident angle of pulsed laser beam. Opt. Laser Technol. 2017, 94, 296–309. [Google Scholar] [CrossRef]

- Dhara, S.; Das, A. Impact of ultrasonic welding on multi-layered Al–Cu joint for electric vehicle battery applications: A layer-wise microstructural analysis. Mater. Sci. Eng. A 2020, 791, 139795. [Google Scholar] [CrossRef]

| Materials | Thickness (mm) | Chemical Compositions (wt%) |

|---|---|---|

| IN 718 | 0.07 | Ni = 52.1, Cr = 17.69, Nb = 4.9, Mo = 2.9, C = 0.031, Fe = 20.7, Cu = 0.11, P = 0.09, Al = 0.29, Ti = 0.72, Co = 0.36, S = 0.012, Si = 0.1 and Mn = 0.2 |

| 410 steel | 1.0 | C = 0.15%, Mn = 1.00%, Si = 1.00%, Cr = 11.5–13.5%, P = 0.04%, S = 0.03% and Fe balance |

| Type of Joints | Varied Parameters | Fixed Parameters | Levels | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| Micro-RSW | Weld current (WC), A | ST = 50 ms; HT = 100 ms | 300 | 400 | 500 |

| Weld time (WT), ms | 2.5 | 5 | 7.5 | ||

| Laser weld | Laser power (P), W | Wobble amplitude = 0.5 mm Wobble frequency = 600 Hz | 225 | 337.5 | 450 |

| Pulse on time (t), ms | 1 | 2 | 3 | ||

| Pulse frequency (f), Hz | 30 | 50 | 70 | ||

| Experiment No. | Process Parameters | Response | |

|---|---|---|---|

| WC (A) | WT (ms) | Average 90° Peel Load (N) ± SD | |

| 1 | 400 | 7.5 | 29.00 ± 6.64 |

| 2 | 400 | 5 | 30.20 ± 10.32 |

| 3 | 500 | 2.5 | 35.52 ± 7.46 |

| 4 | 400 | 5 | 27.25 ± 1.02 |

| 5 | 300 | 5 | 30.84 ± 9.75 |

| 6 | 300 | 2.5 | 29.58 ± 3.99 |

| 7 | 500 | 7.5 | 30.83 ± 7.82 |

| 8 | 400 | 2.5 | 26.12 ± 6.33 |

| 9 | 400 | 5 | 38.84 ± 6.59 |

| 10 | 400 | 5 | 32.98 ± 4.59 |

| 11 | 500 | 5 | 39.16 ± 9.35 |

| 12 | 300 | 7.5 | 26.19 ± 7.36 |

| Experiment No. | Process Parameters | Response | ||

|---|---|---|---|---|

| P (W) | t (ms) | f (Hz) | Average 90° Peel Load (N) ± SD | |

| 1 | 337.5 | 1 | 50 | 46.37 ± 0.54 |

| 2 | 337.5 | 2 | 50 | 59.83 ± 4.27 |

| 3 | 450 | 1 | 30 | 40.03 ± 2.77 |

| 4 | 337.5 | 2 | 50 | 53.28 ± 7.26 |

| 5 | 337.5 | 2 | 50 | 51.79 ± 4.69 |

| 6 | 225 | 1 | 30 | 31.98 ± 1.66 |

| 7 | 337.5 | 2 | 70 | 39.58 ± 0.89 |

| 8 | 337.5 | 2 | 50 | 55.88 ± 2.90 |

| 9 | 337.5 | 2 | 50 | 56.96 ± 3.62 |

| 10 | 337.5 | 3 | 50 | 51.07 ± 1.02 |

| 11 | 450 | 2 | 50 | 36.41 ± 6.67 |

| 12 | 225 | 1 | 70 | 49.90 ± 6.74 |

| 13 | 337.5 | 2 | 30 | 47.90 ± 4.89 |

| 14 | 450 | 3 | 70 | 22.73 ± 8.04 |

| 15 | 225 | 3 | 70 | 63.58 ± 2.69 |

| 16 | 450 | 3 | 30 | 37.72 ± 5.24 |

| 17 | 450 | 1 | 70 | 37.97 ± 2.36 |

| 18 | 225 | 2 | 50 | 40.31 ± 3.59 |

| 19 | 337.5 | 2 | 50 | 51.48 ± 1.69 |

| 20 | 225 | 3 | 30 | 63.60 ± 4.24 |

| ANOVA Terms | Response | ||

|---|---|---|---|

| 90° Peel Load (N) | |||

| Source | F-Value | p-Value | Remarks |

| Model | 5.42 | 0.007 | Significant |

| P | 14.55 | 0.003 | Significant |

| t | 2.76 | 0.128 | Non-significant |

| f | 0.15 | 0.710 | Non-significant |

| 12.94 | 0.005 | Significant | |

| 4.00 | 0.073 | Non-significant | |

| 3.12 | 0.108 | Non-significant | |

| P2 | 5.06 | 0.048 | Significant |

| t2 | 0.28 | 0.607 | Non-significant |

| f2 | 0.65 | 0.439 | Non-significant |

| R2 | 83% | ||

| The Optimum Condition for PL (N) | Confirmatory Experimental Results | |Error%| | ||||

|---|---|---|---|---|---|---|

| Process Parameters | Values | PL (N) | Trials | PL (N) | Average ± SD | |

| P (W) | 238.63 | 63.87 | Test 1 | 66.39 | 65.4 ± 0.91 | 2.4 |

| t (ms) | 3 | Test 2 | 65.23 | |||

| f (Hz) | 47.37 | Test 3 | 64.58 | |||

| Test Condition | Lap Shear Force (N) | ||||

|---|---|---|---|---|---|

| Test 1 | Test 2 | Test 3 | Average PL ± SD | % Change From Ambient to Elevated Temperature | |

| Ambient temperature (23 °C) | 390.18 | 389.13 | 391.63 | 390.31 ± 1.25 | 16.84 |

| Elevated temperature (500 °C) | 337.44 | 317.98 | 318.36 | 324.59 ± 11.24 | |

| Test Condition | Lap Shear Load (N) | |||

|---|---|---|---|---|

| Sample 1 | Sample 2 | Sample 3 | Average Load ± SD | |

| Elevated temperature (500 °C) | 371.82 | 384.60 | 366.04 | 374.15 ± 9.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, N.; Dhara, S.; Masters, I.; Das, A. Substituting Resistance Spot Welding with Flexible Laser Spot Welding to Join Ultra-Thin Foil of Inconel 718 to Thick 410 Steel. Materials 2022, 15, 3405. https://doi.org/10.3390/ma15093405

Kumar N, Dhara S, Masters I, Das A. Substituting Resistance Spot Welding with Flexible Laser Spot Welding to Join Ultra-Thin Foil of Inconel 718 to Thick 410 Steel. Materials. 2022; 15(9):3405. https://doi.org/10.3390/ma15093405

Chicago/Turabian StyleKumar, Nikhil, Sisir Dhara, Iain Masters, and Abhishek Das. 2022. "Substituting Resistance Spot Welding with Flexible Laser Spot Welding to Join Ultra-Thin Foil of Inconel 718 to Thick 410 Steel" Materials 15, no. 9: 3405. https://doi.org/10.3390/ma15093405

APA StyleKumar, N., Dhara, S., Masters, I., & Das, A. (2022). Substituting Resistance Spot Welding with Flexible Laser Spot Welding to Join Ultra-Thin Foil of Inconel 718 to Thick 410 Steel. Materials, 15(9), 3405. https://doi.org/10.3390/ma15093405