Facile Synthesis of Island-like ZrO2-VO2 Composite Films with Enhanced Thermochromic Performance for Smart Windows

Abstract

:1. Introduction

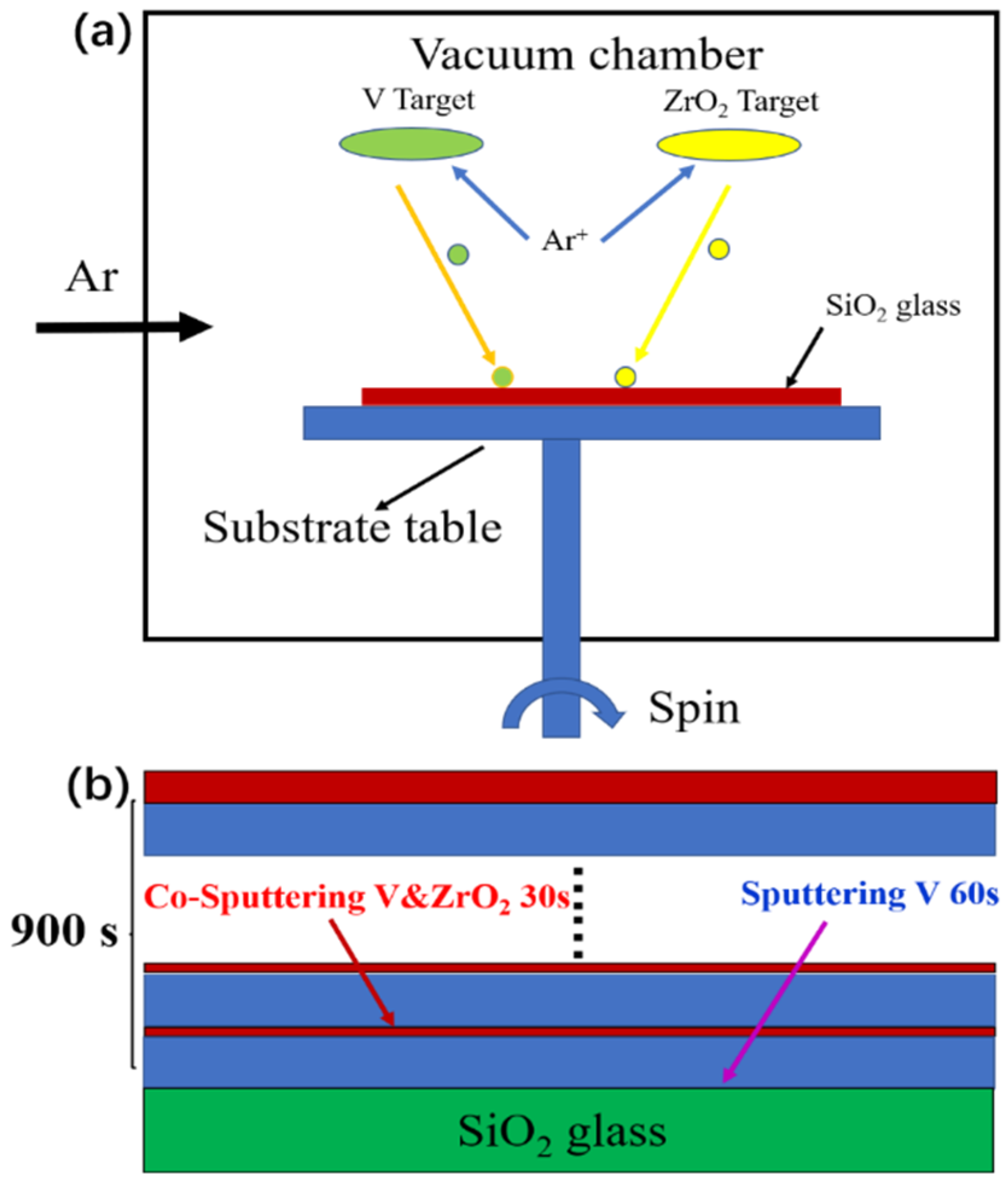

2. Materials and Methods

3. Results and Discussion

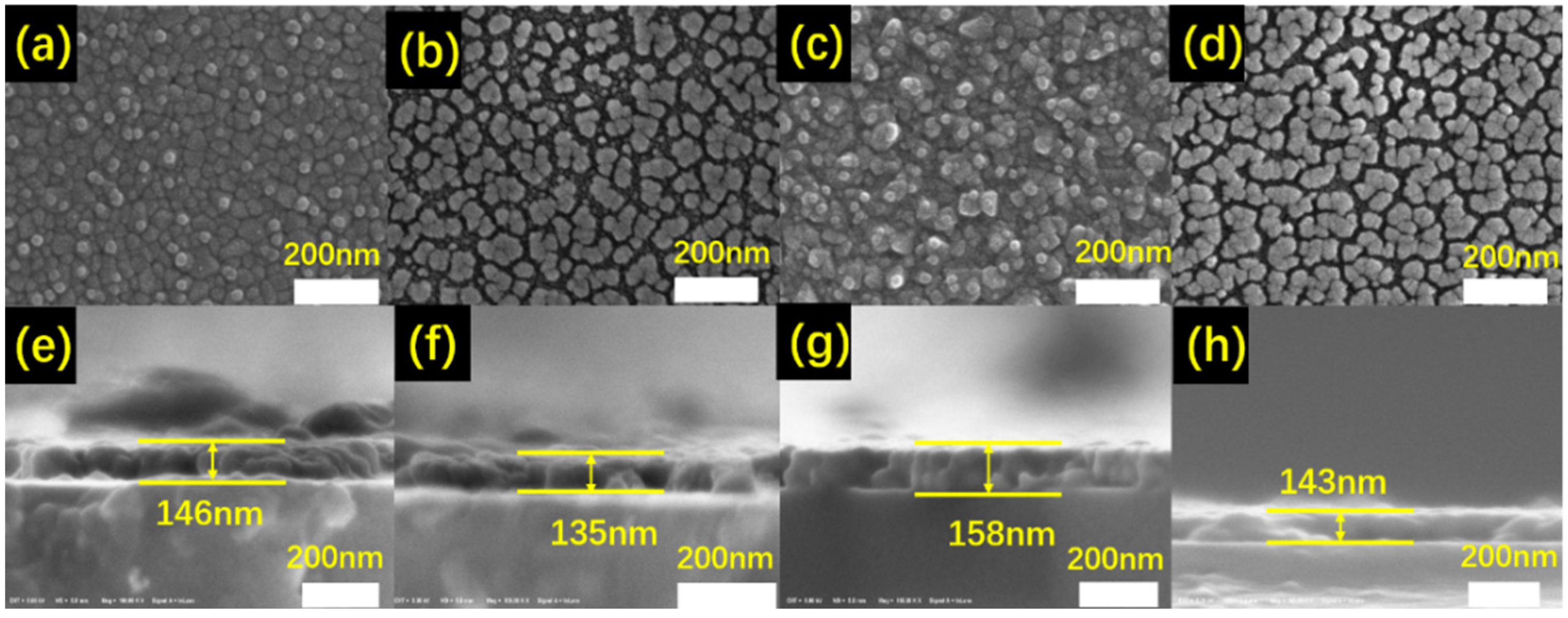

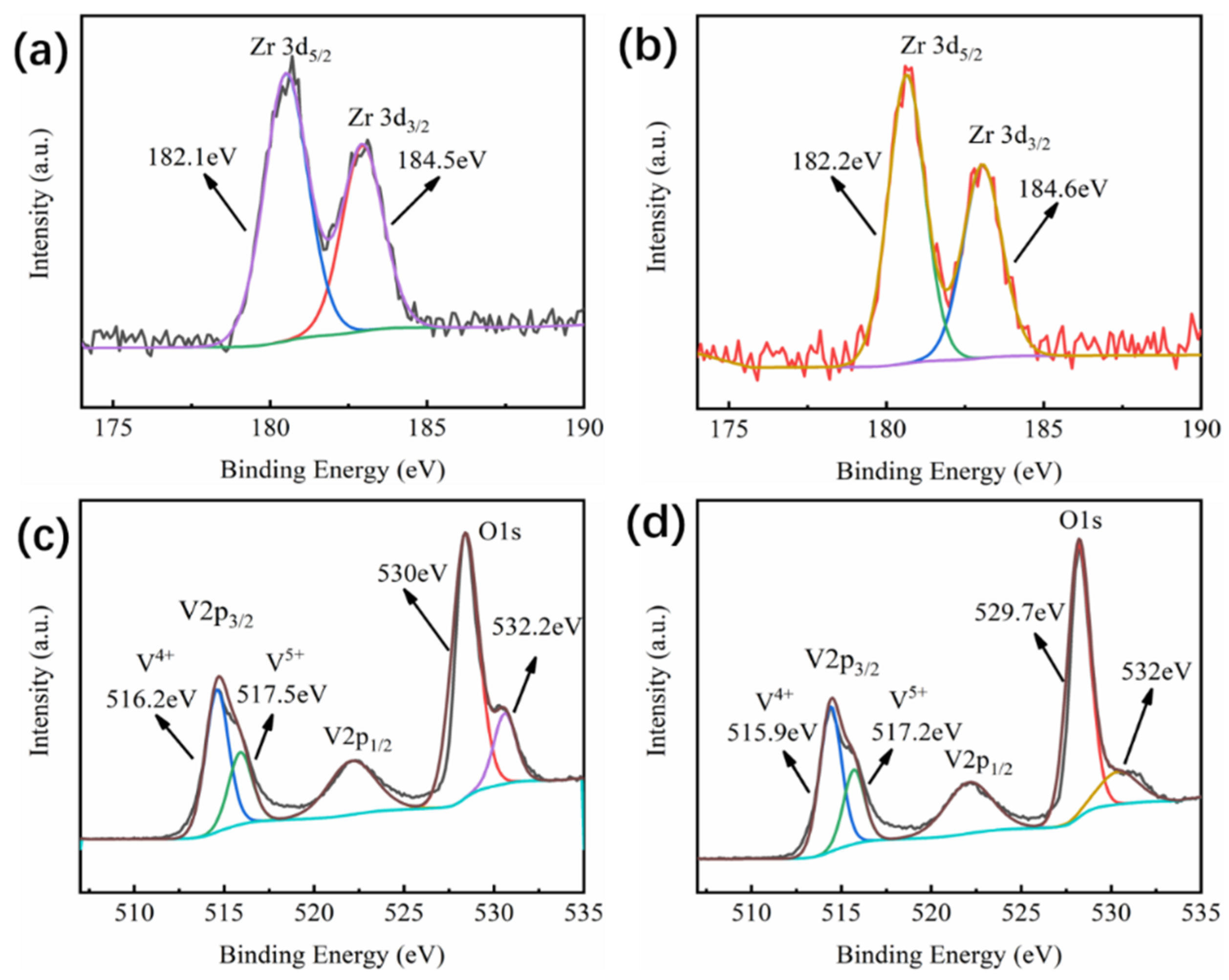

3.1. Structures of the Films before and after Acid-Solution Treatment

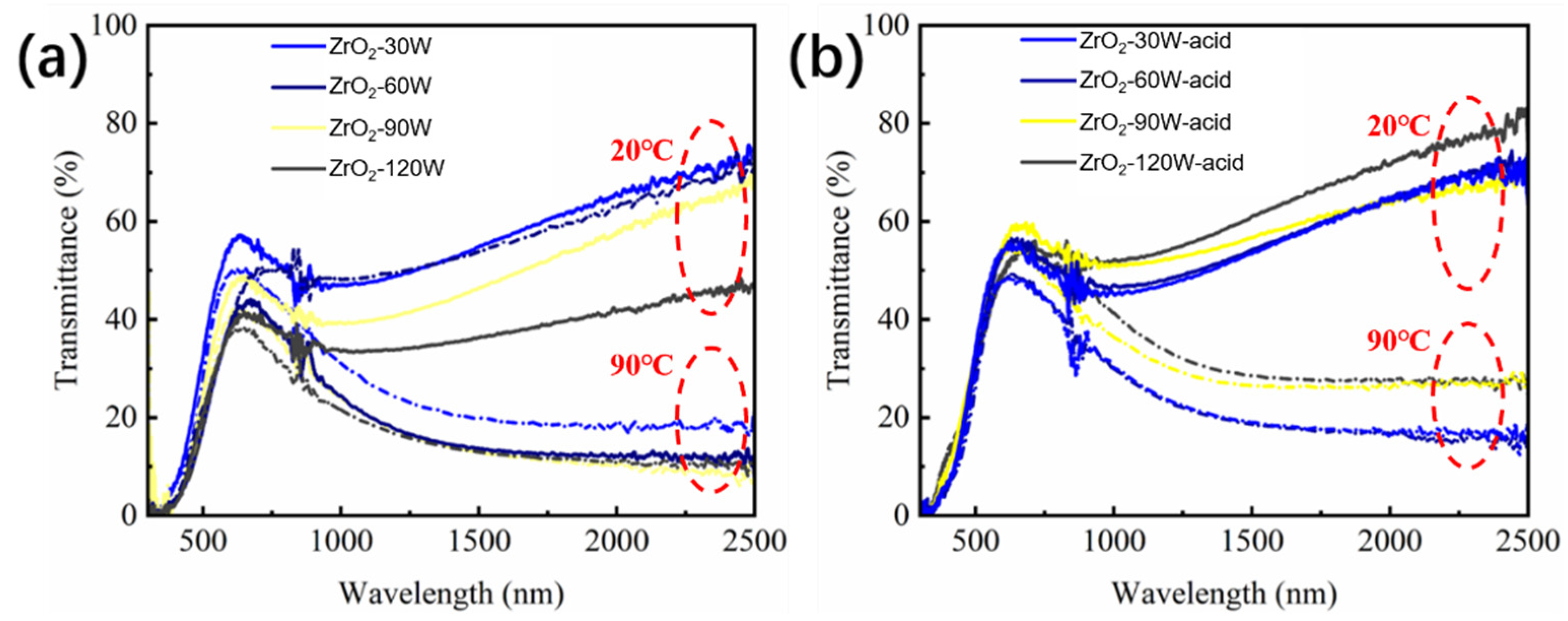

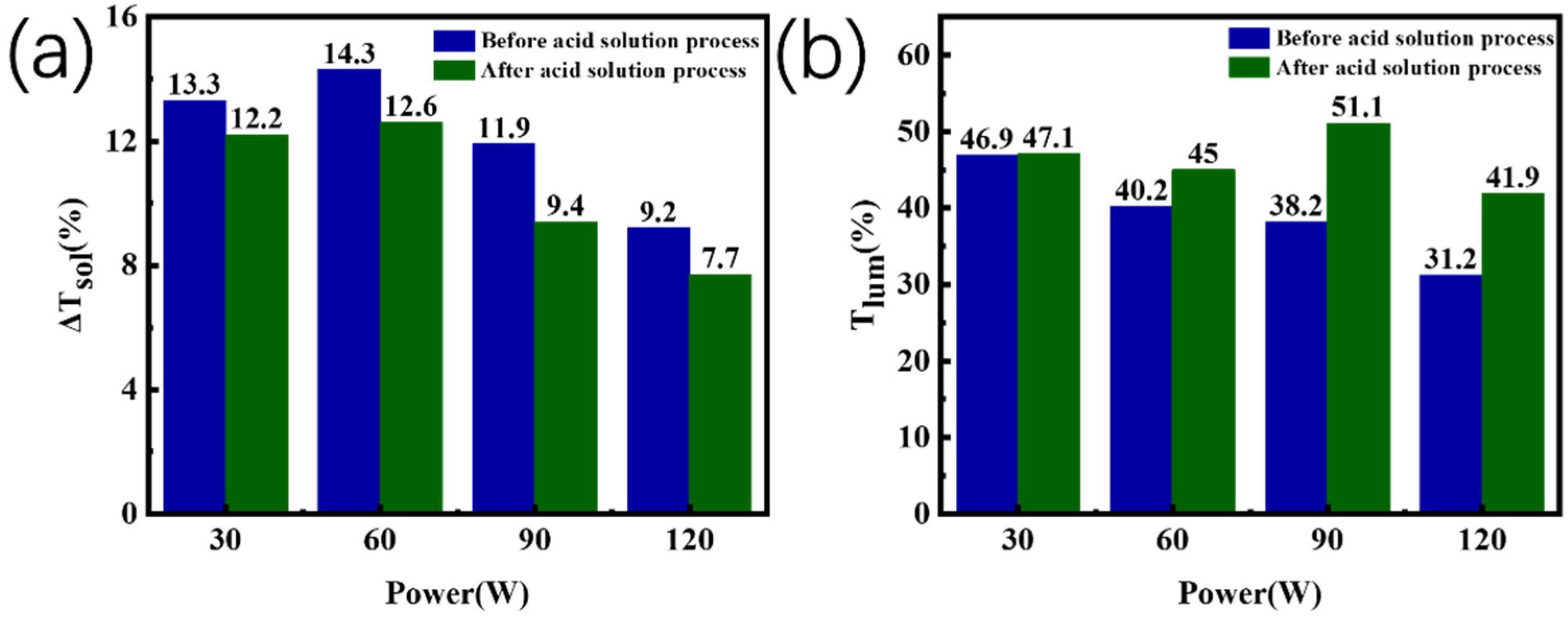

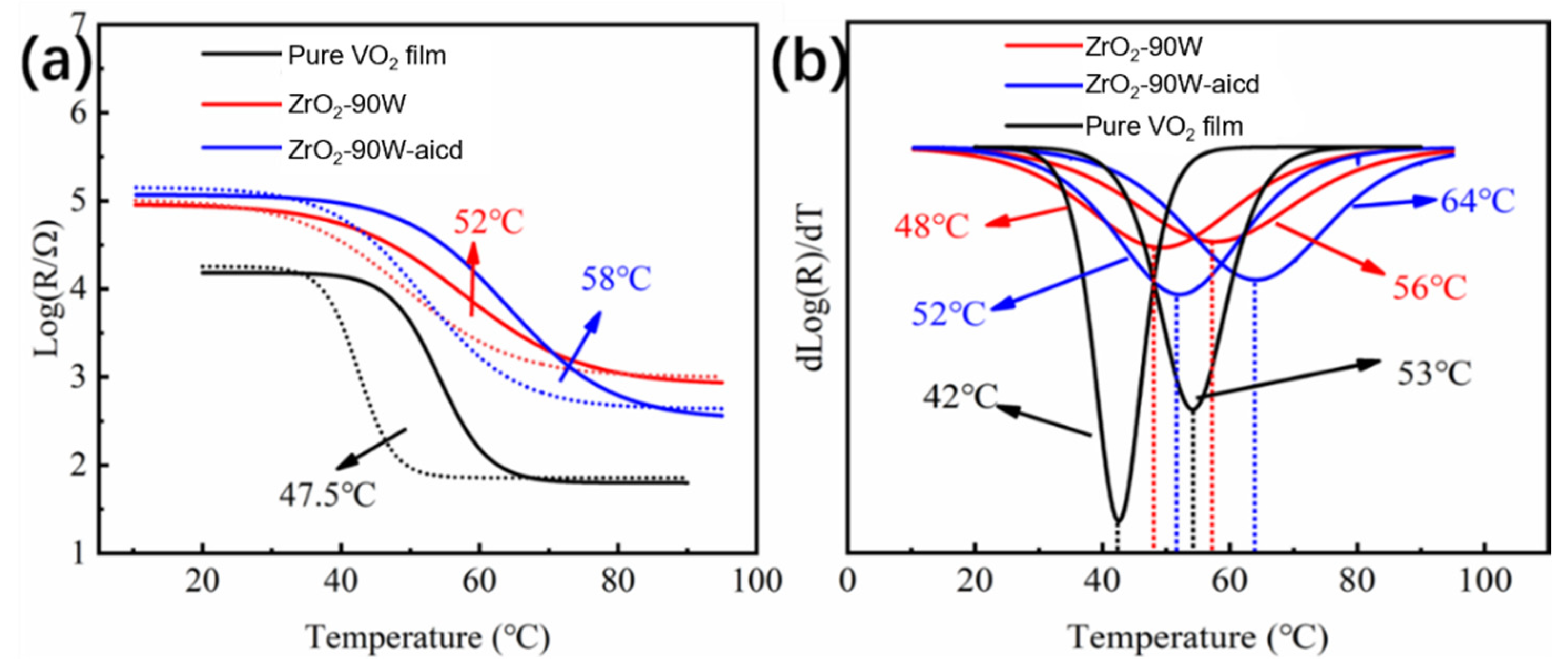

3.2. Thermochromic Properties of VO2-Based Films

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cui, Y.; Ke, Y.; Liu, C.; Chen, Z.; Wang, N.; Zhang, L.; Yang, Z.; Zhou, Y.; Wang, S.; Gao, Y.; et al. Thermochromic VO2 for energy-efficient smart windows. Joule 2018, 2, 1707–1746. [Google Scholar] [CrossRef] [Green Version]

- Tang, K.; Dong, K.; Li, J.; Gordon, M.P.; Reichertz, F.G.; Kim, H.; Rho, Y.; Wang, Q.; Lin, C.; Javey, A.; et al. Temperature-adaptive radiative coating for all-season household thermal regulation. Science 2021, 374, 1504–1509. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Jiang, T.; Meng, Y.; Yang, R.; Tan, G.; Long, Y. Scalable thermochromic smart windows with passive radiative cooling regulation. Science 2021, 374, 1501–1504. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Li, G.; Long, Y. Hydrothermal Synthesis of Thermochromic VO2 for Energy-Efficient Windows. In Vanadium Dioxide-Based Thermochromic Smart Windows; Jenny Stanford Publishing: Dubai, United Arab Emirates, 2021; pp. 179–214. [Google Scholar]

- Zong, H.; Zhou, D.; Yan, L.; Liu, H.; Wu, J.; Hu, Q.; Kang, C.; Li, M. ZrO2/VO2/ZrO2 sandwich structure with improved optical properties and weatherability for smart window application. Appl. Phys. A 2021, 127, 472. [Google Scholar] [CrossRef]

- Guo, H.; Wang, Y.G.; Fu, H.R.; Jain, A.; Chen, F.G. Combined negative thermal expansion and anti-reflective effects of ZrW2O8 layer on the VO2 films with an enhanced luminous transmittance. Sol. Energy Mater. Sol. Cells 2020, 211, 110528. [Google Scholar] [CrossRef]

- Sang, J.; Zhu, W.; Feng, Y.; Liu, Y.; Shang, J.; Sun, J.; Guo, L.; Zhang, Y.; Zhao, S.; Chigrinov, V.; et al. Smart Windows with a VO2 Thin Film as a Conductive Layer for Efficient and Independent Dual-Band Modulation. ACS Appl. Electron. Mater. 2021, 3, 4882–4890. [Google Scholar] [CrossRef]

- Guo, H.; Wang, Y.G.; Jain, A.; Fu, H.R.; Chen, F.G. Preparation of W/Zr co-doped VO2 with improved microstructural and thermochromic properties. J. Alloy. Compd. 2021, 878, 160352. [Google Scholar] [CrossRef]

- Song, J.; Zhao, Y.; Sun, L.; Luo, Q.; Xu, H.; Wang, C.; Xin, H.; Wu, W.; Ma, F. VO2/ATO nanocomposite thin films with enhanced solar modulation and high luminous transmittance for smart windows. Ceram. Int. 2022, 48, 15868–15876. [Google Scholar] [CrossRef]

- Zou, Z.; Zhang, Z.; Xu, J.; Li, G.; Xiong, R.; Liu, Y.; Shi, J. Phase transition mechanism and application of silicon-doped VO2 thin films to smart windows. J. Mater. Sci. Mater. Electron. 2021, 32, 23825–23833. [Google Scholar] [CrossRef]

- Liang, J.; Wang, S.; Lei, D.; Wang, Z.; Li, X. Enhanced visible and tunable infrared transmittance of W-doped VO2/SiO2/PVP composite films for smart windows. Opt. Mater. 2021, 121, 111485. [Google Scholar] [CrossRef]

- Wang, C.; Li, N.; Tu, Y.; Zhang, J.; Schmid, M.; Yin, G. Thermochromic VO2 films with periodic meshes for smart windows: Analysis of optical properties. Opt. Commun. 2021, 500, 127330. [Google Scholar] [CrossRef]

- Shen, N.; Chen, S.; Shi, R.; Niu, S.; Amini, A.; Cheng, C. Phase transition hysteresis of tungsten doped VO2 synergistically boosts the function of smart windows in ambient conditions. ACS Appl. Electron. Mater. 2021, 3, 3648–3656. [Google Scholar] [CrossRef]

- Ren, H.; Chen, S.; Chen, Y.; Luo, Z.; Zhou, J.; Zheng, X.; Wang, L.; Li, B.; Zou, C. Wet-Etching Induced Abnormal Phase Transition in Highly Strained VO2/TiO2 (001) Epitaxial Film. Phys. Status Solidi (RRL) Rapid Res. Lett. 2018, 12, 1700320. [Google Scholar] [CrossRef]

- Savorianakis, G.; Mita, K.; Shimizu, T.; Konstantinidis, S.; Voué, M.; Maes, B. VO2 nanostripe-based thin film with optimized color and solar characteristics for smart windows. J. Appl. Phys. 2021, 129, 185306. [Google Scholar] [CrossRef]

- Lv, X.; Chai, X.; Lv, L.; Cao, Y.; Zhang, Y.; Song, L. Preparation of porous Mo-doped VO2 films via atomic layer deposition and post annealing. Jpn. J. Appl. Phys. 2021, 60, 085501. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, Z.J.; Li, D.L.; Li, J.B.; Zhao, Y.J.; Jin, H.B. Infrared Switching of Self-Heating VO2/ITO Films for Smart Window. Trans. Tech. Publ. Ltd. 2021, 1034, 123–131. [Google Scholar]

- Xu, F.; Cao, X.; Shao, Z.; Sun, G.; Long, S.; Chang, T.; Luo, H.; Jin, P. Highly enhanced thermochromic performance of VO2 film using “movable” antireflective coatings. ACS Appl. Mater. Interfaces 2019, 11, 4712–4718. [Google Scholar] [CrossRef] [PubMed]

- Riapanitra, A.; Asakura, Y.; Yin, S. One-step hydrothermal synthesis and thermochromic properties of chlorine-doped VO2(M) for smart window application. Funct. Mater. Lett. 2020, 13, 1951008. [Google Scholar] [CrossRef]

- Liu, S.; Tso, C.Y.; Lee, H.H.; Du, Y.W.; Yu, K.M.; Feng, S.P.; Huang, B. Self-Densified Optically Transparent VO2 Thermochromic Wood Film for Smart Windows. ACS Appl. Mater. Interfaces 2021, 13, 22495–22504. [Google Scholar] [CrossRef]

- Wang, C.; Xu, H.; Wang, C.; Liu, T.; Yang, S.; Nie, Y.; Guo, X.; Ma, X.; Jiang, X. Preparation of VO2 (M) nanoparticles with exemplary optical performance from VO2 (B) nanobelts by ball milling. J. Alloy. Compd. 2021, 877, 159888. [Google Scholar] [CrossRef]

- Wang, N.; Cui, Y.; Gao, Y.; Long, Y. Effect of doping on the thermochromic performance of VO2. In Vanadium Dioxide-Based Thermochromic Smart Windows; Jenny Stanford Publishing: Dubai, United Arab Emirates, 2021; pp. 35–61. [Google Scholar]

- Derkaoui, I.; Benkhali, M.; Khenfouch, M.; Rezzouk, A. Vanadium dioxide thin films for smart windows: Numerical study and improvement of their optical properties. Newest Updates Phys. Sci. Res. 2021, 3, 54–62. [Google Scholar]

- Jin, H.; Li, J. Sol-gel synthesis of thermochromic VO2 coatings. In Vanadium Dioxide-Based Thermochromic Smart Windows; Jenny Stanford Publishing: Dubai, United Arab Emirates, 2021; pp. 327–360. [Google Scholar]

- Xiao, X. Antireflection for the performance of VO2 thermochromic thin films. In Vanadium Dioxide-Based Thermochromic Smart Windows; Jenny Stanford Publishing: Dubai, United Arab Emirates, 2021; pp. 101–122. [Google Scholar]

- Liu, H.; Zong, H.; Yan, L.; Zhou, D.; Yin, Y.; Cao, G.; Bian, L.; Kang, C.; Li, M. SnO2/VO2/SnO2 tri-layer thermochromic films with high luminous transmittance, remarkable solar modulation ability and excellent hydrophobicity grown on glass substrates. Infrared Phys. Technol. 2021, 113, 103648. [Google Scholar] [CrossRef]

- Won Youn, J.; Lee, S.J.; Kim, K.S.; Up Kim, D.; Han, J.W. A Study on the Coating Characteristics of VO2 Nanoparticle Thin Film with Various Conditions of Ultrasonic Spray Coater. J. Nanosci. Nanotechnol. 2021, 21, 3010–3015. [Google Scholar] [CrossRef] [PubMed]

- Sirvent, P.; Pérez, G.; Guerrero, A. Efficient VO2 (M) synthesis to develop thermochromic cement-based materials for smart building envelopes. Mater. Chem. Phys. 2021, 269, 124765. [Google Scholar] [CrossRef]

- Kim, H.J.; Choi, Y.H.; Lee, D.; Lee, I.H.; Choi, B.K.; Phark, S.H.; Chang, Y. Enhanced passive thermal stealth properties of VO2 thin films via gradient W doping. Appl. Surf. Sci. 2021, 561, 150056. [Google Scholar] [CrossRef]

- Li, B.; Liu, J.; Tian, S.; Liu, B.; Yang, X.; Yu, Z.; Zhao, X. VO2-ZnO composite films with enhanced thermochromic properties for smart windows. Ceram. Int. 2020, 46, 2758–2763. [Google Scholar] [CrossRef]

- Li, B.; Yao, J.; Tian, S.; Fang, Z.; Wu, S.; Liu, B.; Gong, X.; Tao, H.; Zhao, X. A facile one-step annealing route to prepare thermochromic W doped VO2 (M) particles for smart windows. Ceram. Int. 2020, 46, 18274–18280. [Google Scholar] [CrossRef]

- Long, S.; Cao, X.; Huang, R.; Xu, F.; Li, N.; Huang, A.; Sun, G.; Bao, S.; Luo, H.; Jin, P. Self-template synthesis of nanoporous VO2-based films: Localized surface plasmon resonance and enhanced optical performance for solar glazing application. ACS Appl. Mater. Interfaces 2019, 11, 22692–22702. [Google Scholar] [CrossRef]

- Houska, J.; Rezek, J.; Cerstvy, R. Dependence of the ZrO2 growth on the crystal orientation: Growth simulations and magnetron sputtering. Appl. Surf. Sci. 2022, 572, 151422. [Google Scholar] [CrossRef]

- Kang, L.; Gao, Y.; Luo, H.; Chen, Z.; Du, J.; Zhang, Z. Nanoporous thermochromic VO2 films with low optical constants, enhanced luminous transmittance and thermochromic properties. ACS Appl. Mater. Interfaces 2011, 3, 135–138. [Google Scholar] [CrossRef]

- Xu, G.; Jin, P.; Tazawa, M.; Yoshimura, K. Optimization of antireflection coating for VO2-based energy efficient window. Sol. Energy Mater. Sol. Cells 2004, 83, 29–37. [Google Scholar] [CrossRef]

- Lee, S.J.; Choi, D.S.; Kang, S.H.; Yang, W.S.; Nahm, S.; Han, S.H.; Kim, T. VO2/WO3-based hybrid smart windows with thermochromic and electrochromic properties. ACS Sustain. Chem. Eng. 2019, 7, 7111–7117. [Google Scholar] [CrossRef]

- Li, B.; Tian, S.; Wang, Z.; Liu, B.; Gong, X.; Zhao, X. Thermochromic Ta Doped VO2 Films: Enhanced Luminous Transmittance, Significantly Depressed Phase Transition Temperature and Hysteresis Width. Appl. Surf. Sci. 2021, 568, 150959. [Google Scholar] [CrossRef]

- Wang, Z.; Li, B.; Tian, S.; Liu, B.; Zhao, X.; Zhou, X.; Tang, G.; Pang. Acid Solution Processed VO2-Based Composite Films with Enhanced Thermochromic Properties for Smart Windows. Materials 2021, 14, 4927. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, B.; Wang, Z.; Tian, S.; Liu, B.; Zhao, X.; Li, N.; Sankar, G.; Wang, S. Facile Preparation of Zn2V2O7–VO2 Composite Films with Enhanced Thermochromic Properties for Smart Windows. ACS Appl. Electron. Mater. 2021, 3, 2224–2232. [Google Scholar] [CrossRef]

- Zong, H.; Geng, C.; Zhang, C.; Liu, H.; Wu, J.; Yu, Z.; Cao, G.; Kang, C.; Li, M. Tuning the electrical and optical properties of ZrxOy/VO2 thin films by controlling the stoichiometry of ZrxOy buffer layer. Appl. Surf. Sci. 2019, 487, 138–145. [Google Scholar] [CrossRef]

- Jung, Y.; Han, H.; Sharma, A.; Jeong, J.; Parkin, S.S.; Poon, J.K. Integrated Hybrid VO2–Silicon Optical Memory. ACS Photon. 2022, 9, 217–223. [Google Scholar] [CrossRef]

- Kim, J.; Paik, T. Recent Advances in Fabrication of Flexible, Thermochromic Vanadium Dioxide Films for Smart Windows. Nanomaterials 2021, 11, 2674. [Google Scholar] [CrossRef]

- Kang, J.; Liu, J.; Shi, F.; Dong, Y.; Jiang, S. The thermochromic characteristics of Zn-doped VO2 that were prepared by the hydrothermal and post-annealing process and their polyurethane composite films. Ceram. Int. 2021, 47, 15631–15638. [Google Scholar] [CrossRef]

- Wang, N.; Duchamp, M.; Dunin-Borkowski, R.; Liu, S.; Zeng, X.; Cao, X.; Long, Y. Terbium-Doped VO2 Thin Films: Reduced Phase Transition Temperature and Largely Enhanced Luminous Transmittance. Langmuir 2016, 32, 759–764. [Google Scholar] [CrossRef]

- Ke, Y.; Wen, X.; Zhao, D.; Che, R.; Xiong, Q.; Long, Y. Controllable Fabrication of Two-Dimensional Patterned VO2 Nanoparticle, Nanodome, and Nanonet Arrays with Tunable Temperature-Dependent Localized Surface Plasmon Resonance. ACS Nano 2018, 11, 7542–7551. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Xia, F.; Yao, J.; Zhu, T.; Xia, H.; Yang, G.; Liu, B.; Gao, Y. Facile synthesis, formation mechanism and thermochromic properties of W-doped VO2 (M) nanoparticles for smart window applications. J. Mater. Chem. C 2020, 8, 13396–13404. [Google Scholar] [CrossRef]

| Sample | Sputtering Pressure | Preparation of VO2 Thin Films | Preparation of ZrO2 Thin Films | Acid Treatment | ||

|---|---|---|---|---|---|---|

| Sputtering Power | Sputtering Time | Sputtering Power | Sputtering Time | |||

| Pure VO2 film | 1 × 103 Pa | 90 W | 15 min | 9 times for 30 s each time | ||

| ZrO2-30 W | 30 W | |||||

| ZrO2-60 W | 60 W | |||||

| ZrO2-90 W | 90 W | |||||

| ZrO2-120 W | 120 W | |||||

| ZrO2-30 W-acid | 30 W | 20-s | ||||

| ZrO2-60 W-acid | 60 W | |||||

| ZrO2-90 W-acid | 90 W | |||||

| ZrO2-120 W-acid | 120 W | |||||

| Sputtering Power of ZrO2 (W) | ZrO2-VO2 Composite Film before Acid-Solution Process | ZrO2-VO2 Composite Film after Acid-Solution Process | ||

|---|---|---|---|---|

| Tlum (%) | ΔTsol (%) | Tlum (%) | ΔTsol (%) | |

| 0 | 28.2 | 12.4 | - | - |

| 30 | 46.9 | 13.3 | 47.1 | 12.2 |

| 60 | 40.2 | 14.3 | 45.0 | 12.6 |

| 90 | 38.2 | 11.9 | 51.1 | 9.4 |

| 120 | 31.2 | 9.2 | 41.9 | 7.7 |

| Thermochromic Properties | Reference | ||

|---|---|---|---|

| System | Tlum (%) | ΔTsol (%) | |

| VO2 | 39.93 | 9.95 | Sang et al. [7] |

| VO2 | 55.0 | 18.0 | Kim et al. [42] |

| W/Zr-doped VO2 | 60.7 | 10.6 | Guo et al. [8] |

| Zn-doped VO2 | 41.3 | 15.3 | Kang et al. [43] |

| Terbium-doped VO2 film | 54.0 | 8.3 | Wang et al. [44] |

| Two-dimensional nanostructure VO2 film | 61.3 | 11.9 | Long et al. [45] |

| W-doped VO2 film | 61.7 | 11.7 | Zhang et al. [46] |

| Island-like ZrO2-VO2 composite films | 45.0 51.1 | 12.6 9.4 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Wang, Z.; Li, B.; Liu, B.; Zhao, X.; Tang, G.; Zeng, D.; Tian, S. Facile Synthesis of Island-like ZrO2-VO2 Composite Films with Enhanced Thermochromic Performance for Smart Windows. Materials 2023, 16, 273. https://doi.org/10.3390/ma16010273

Wu J, Wang Z, Li B, Liu B, Zhao X, Tang G, Zeng D, Tian S. Facile Synthesis of Island-like ZrO2-VO2 Composite Films with Enhanced Thermochromic Performance for Smart Windows. Materials. 2023; 16(1):273. https://doi.org/10.3390/ma16010273

Chicago/Turabian StyleWu, Jiahao, Zhe Wang, Bin Li, Baoshun Liu, Xiujian Zhao, Gen Tang, Dawen Zeng, and Shouqin Tian. 2023. "Facile Synthesis of Island-like ZrO2-VO2 Composite Films with Enhanced Thermochromic Performance for Smart Windows" Materials 16, no. 1: 273. https://doi.org/10.3390/ma16010273