Tuning of the Titanium Oxide Surface to Control Magnetic Properties of Thin Iron Films

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Structural Characterization

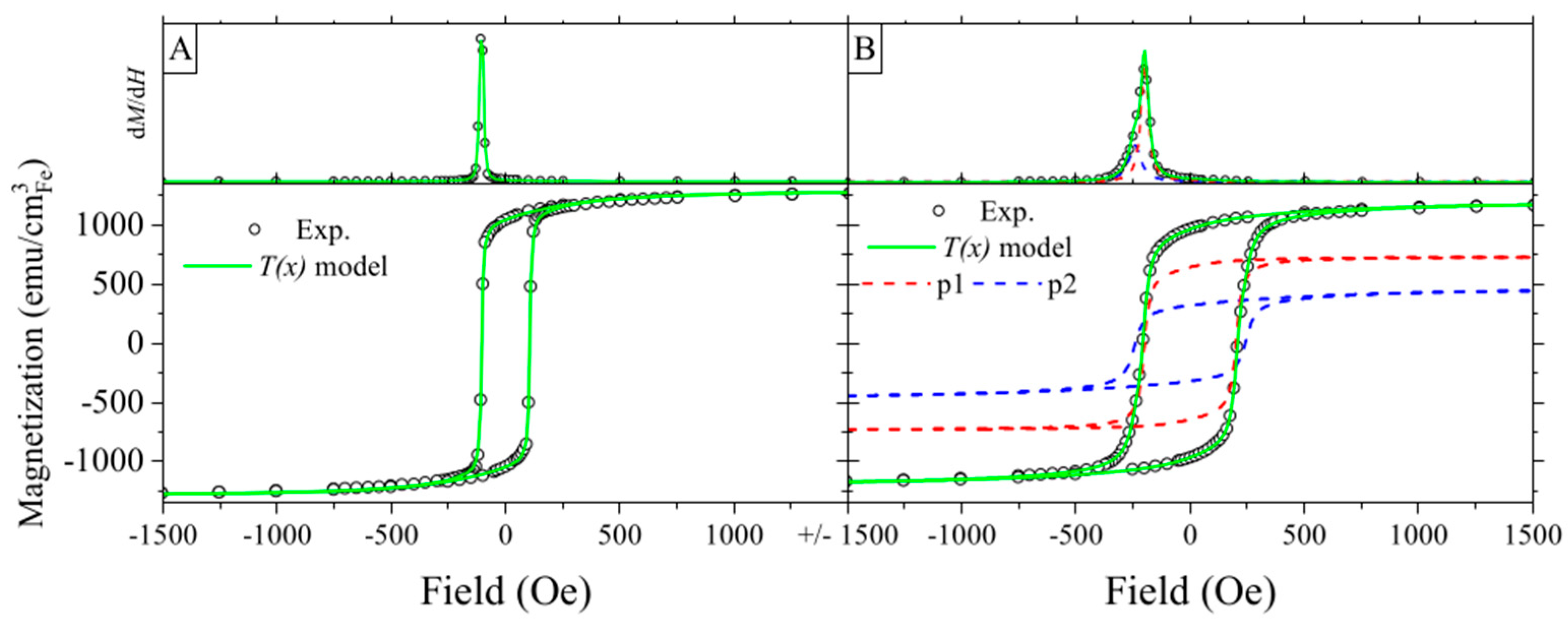

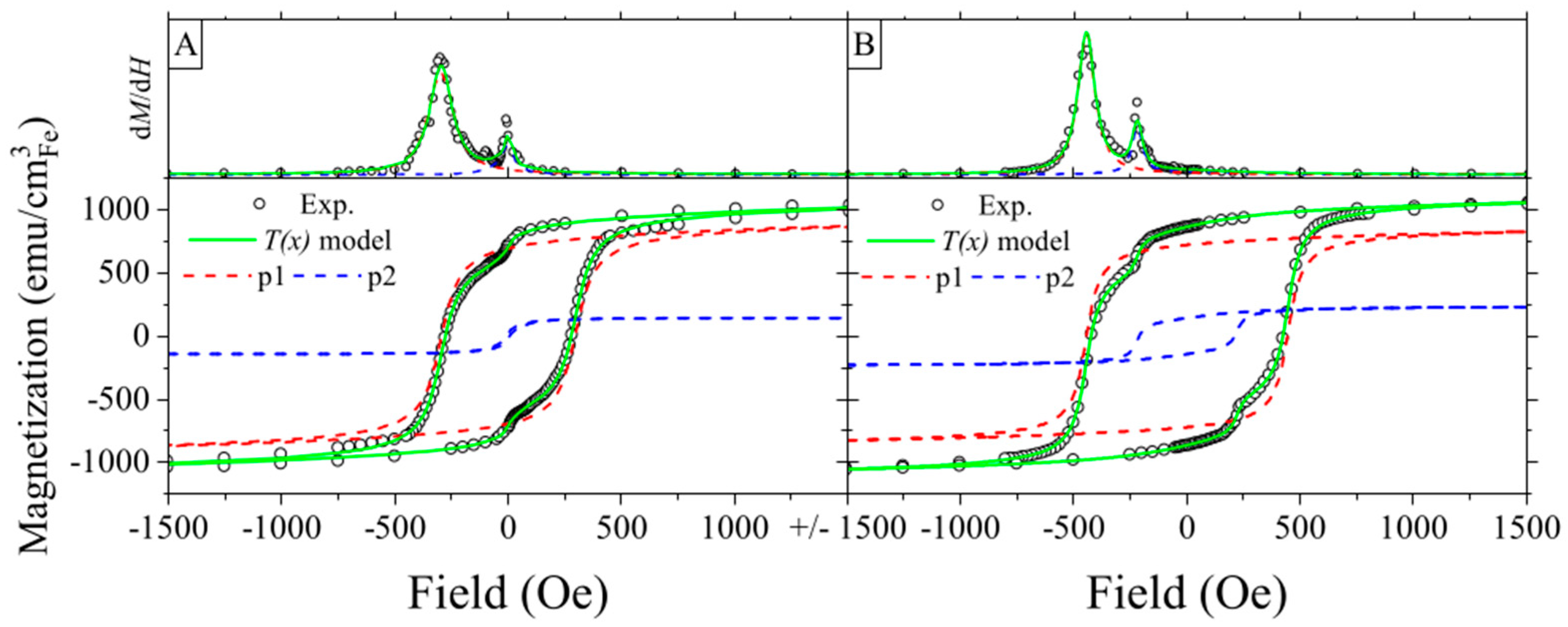

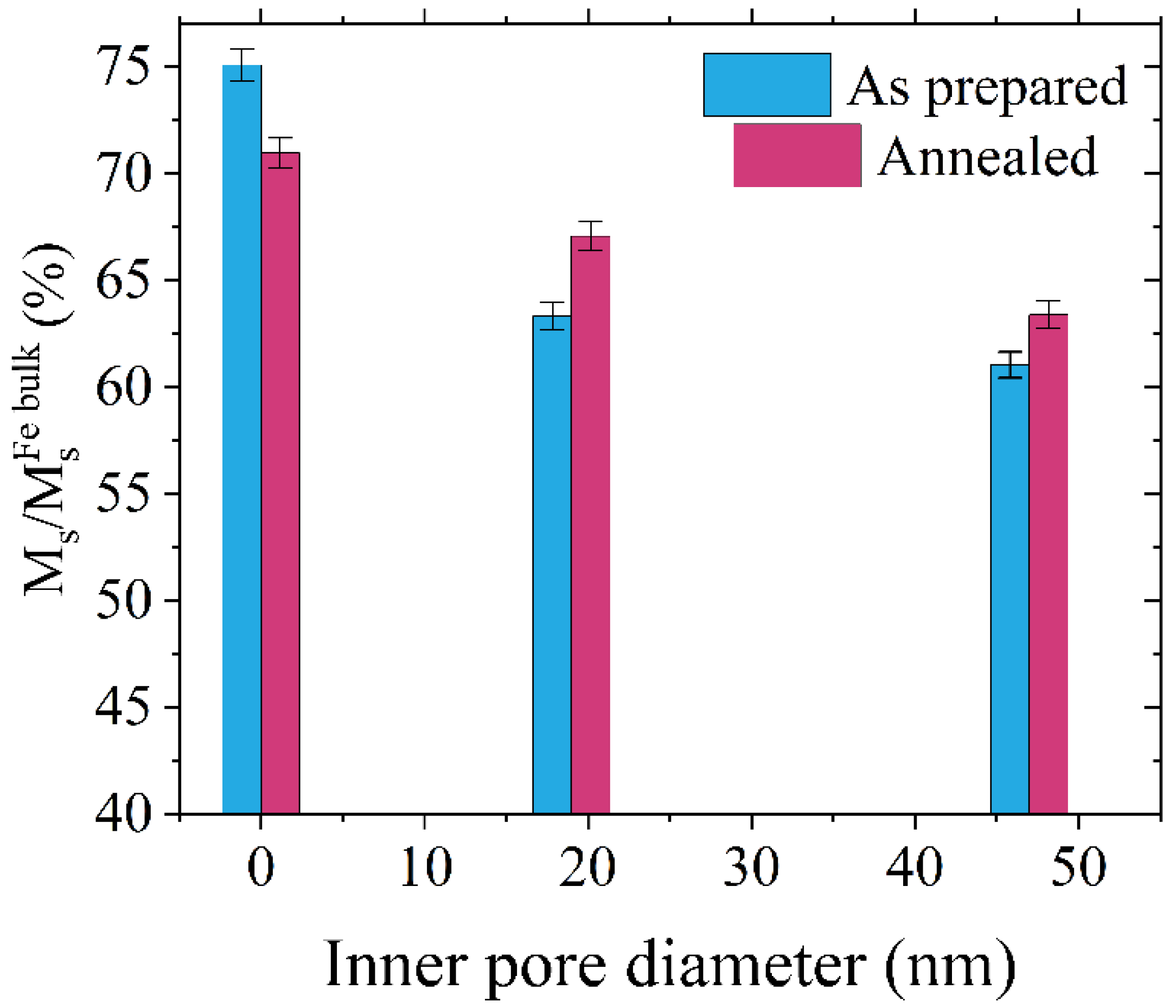

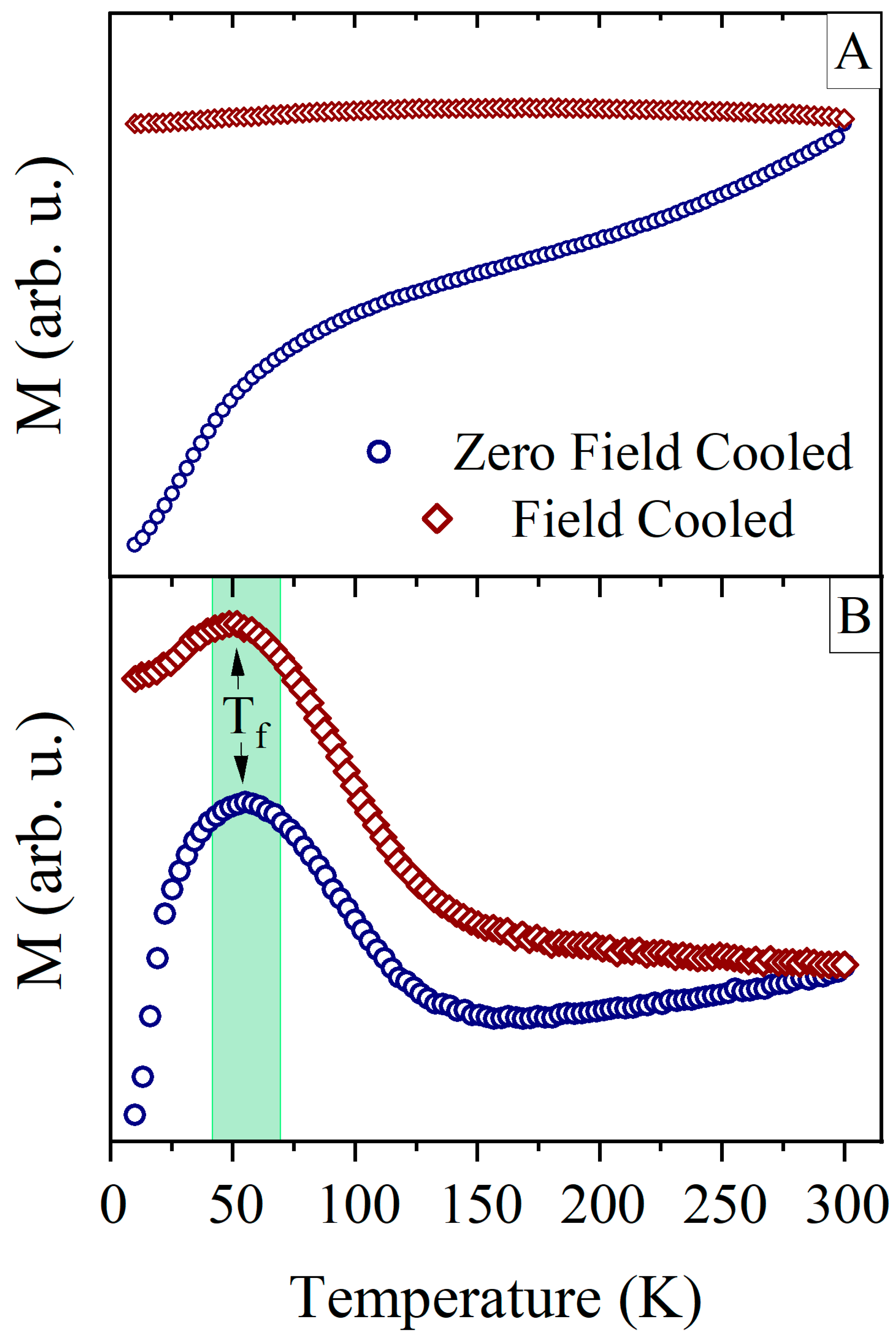

3.2. Magnetic Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yamanaka, S.; Kanki, T.; Kawai, T.; Tanaka, H. Enhancement of Spin Polarization in a Transition Metal Oxide Ferromagnetic Nanodot Diode. Nano Lett. 2011, 11, 343–347. [Google Scholar] [CrossRef] [PubMed]

- Zehner, J.; Soldatov, I.; Schneider, S.; Heller, R.; Khojasteh, N.B.; Schiemenz, S.; Fähler, S.; Nielsch, K.; Schäfer, R.; Leistner, K. Voltage-Controlled Deblocking of Magnetization Reversal in Thin Films by Tunable Domain Wall Interactions and Pinning Sites. Adv. Electron. Mater. 2020, 6, 2000406. [Google Scholar] [CrossRef]

- Chen, Z.; Yang, Q.; Tao, L.; Tsymbal, E.Y. Tsymbal Reversal of the magnetoelectric effect at a ferromagnetic metal/ferroelectric interface induced by metal oxidation. NPJ Comput. Mater. 2021, 7, 204. [Google Scholar] [CrossRef]

- Li, Y.; Cheng, H.; Wang, N.; Zhou, S.; Xie, D.; Li, T. Preparation and Microwave Absorption Properties of the Fe/TiO2/Al2O3 Composites. Nano 2018, 13, 1850125. [Google Scholar] [CrossRef] [Green Version]

- Ngo, T.D.; Chang, J.-W.; Lee, K.; Han, S.; Lee, J.S.; Kim, Y.H.; Jung, M.-H.; Doh, Y.-J.; Choi, M.-S.; Song, J.; et al. Polarity-tunable magnetic tunnel junctions based on ferromagnetism at oxide heterointerfaces. Nat. Commun. 2015, 6, 8035. [Google Scholar] [CrossRef] [Green Version]

- Song, C.; Cui, B.; Li, F.; Zhou, X.; Pan, F. Recent progress in voltage control of magnetism: Materials, mechanisms, and performance. Prog. Mater. Sci. 2017, 87, 33–82. [Google Scholar] [CrossRef] [Green Version]

- Krupinski, M.; Sobieszczyk, P.; Zieliński, P.; Marszałek, M. Magnetic reversal in perpendicularly magnetized antidot arrays with intrinsic and extrinsic defects. Sci. Rep. 2019, 9, 13276. [Google Scholar] [CrossRef] [Green Version]

- Perzanowski, M.; Krupinski, M.; Zarzycki, A.; Dziedzic, A.; Zabila, Y.; Marszalek, M. Exchange Bias in the [CoO/Co/Pd]10 Antidot Large Area Arrays. ACS Appl. Mater. Interfaces 2017, 9, 33250–33256. [Google Scholar] [CrossRef] [Green Version]

- Krupinski, M.; Hintermayr, J.; Sobieszczyk, P.; Albrecht, M. Control of magnetic properties in ferrimagnetic GdFe and TbFe thin films by He+ and Ne+ irradiation. Phys. Rev. Mater. 2021, 5, 024405. [Google Scholar] [CrossRef]

- Krupinski, M.; Bali, R.; Mitin, D.; Sobieszczyk, P.; Gregor-Pawlowski, J.; Zarzycki, A.; Böttger, R.; Albrecht, M.; Potzger, K.; Marszałek, M. Ion induced ferromagnetism combined with self-assembly for large area magnetic modulation of thin films. Nanoscale 2019, 11, 8930–8939. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Vega, V.; Caballero-Flores, R.; Prida, V.M.; Fernández, A. Influence of nanoholes array geometrical parameters on magnetic properties of Dy–Fe antidot thin films. Nanotechnology 2019, 30, 455703. [Google Scholar] [CrossRef] [PubMed]

- Prida, V.; Salaheldeen, M.; Pfitzer, G.; Hidalgo, A.; Vega, V.; González, S.; Teixeira, J.; Fernández, A.; Hernando, B. Template Assisted Deposition of Ferromagnetic Nanostructures: From Antidot Thin Films to Multisegmented Nanowires. Acta Phys. Pol. A 2017, 131, 822–827. [Google Scholar] [CrossRef]

- Papaioannou, E.; Kapaklis, V.; Patoka, P.; Giersig, M.; Fumagalli, P.; Garcia-Martin, A.; Ferreiro-Vila, E.; Ctistis, G. Magneto-optic enhancement and magnetic properties in Fe antidot films with hexagonal symmetry. Phys. Rev. B 2010, 81, 054424. [Google Scholar] [CrossRef] [Green Version]

- Maximenko, A.; Marszałek, M.; Chojenka, J.; Fedotova, J.; Jany, B.; Krok, F.; Morgiel, J.; Zarzycki, A.; Zabila, Y. Perforated alumina templates as a tool for engineering of CoPd film magnetic properties. J. Magn. Magn. Mater. 2019, 477, 182–189. [Google Scholar] [CrossRef]

- Maximenko, A.A.; Kasiuk, J.V.; Fedotova, J.; Marszałek, M.; Zabila, Y.; Chojenka, J. Magnetic properties of Co/Pd multilayered films on porous Al2O3 templates with developed cell substructure. Phys. Solid State 2017, 59, 1762–1770. [Google Scholar] [CrossRef]

- Yu, C.T.; Jiang, H.; Shen, L.; Flanders, P.J.; Mankey, G.J. The magnetic anisotropy and domain structure of permalloy antidot arrays. J. Appl. Phys. 2000, 87, 6322. [Google Scholar] [CrossRef] [Green Version]

- Salaheldeen, M.; Vega, V.; Ibabe, A.; Jaafar, M.; Asenjo, A.; Fernandez, A.; Prida, V.M. Tailoring of Perpendicular Magnetic Anisotropy in Dy13Fe87 Thin Films with Hexagonal Antidot Lattice Nanostructure. Nanomaterials 2018, 8, 227. [Google Scholar] [CrossRef] [Green Version]

- Michea, S.; Palma, J.L.; Lavín, R.; Briones, J.; Escrig, J.; Denardin, J.; Rodríguez-Suárez, R.L. Tailoring the magnetic properties of cobalt antidot arrays by varying the pore size and degree of disorder. J. Appl. Phys. D Appl. Phys. 2014, 47, 335001. [Google Scholar] [CrossRef] [Green Version]

- Rahman, M.T.; Shams, N.N.; Lai, C.H.; Fidler, J.; Suess, D. Co/Pt perpendicular antidotvarrays with engineered feature size and magnetic properties fabricated on anodicaluminum oxide templates. Phys. Rev. B. 2010, 81, 014418. [Google Scholar] [CrossRef]

- Béron, F.; Pirota, K.R.; Vega, V.; Prida, V.M.; Fernández, A.; Hernando, B.; Knobel, M. An effective method to probe local magnetostatic properties in a nanometric FePd antidot array. New J. Phys. 2011, 13, 013035. [Google Scholar] [CrossRef]

- Krupinski, M.; Sobieszczyk, P. Influence of angular orientation, shape, and arrangement of antidots on magnetic reversal in thin films with perpendicular magnetic anisotropy. J. Magn. Magn. Mater. 2021, 518, 167448. [Google Scholar] [CrossRef]

- Merazzo, K.J.; Leitao, D.C.; Jiménez, E.; Araujo, J.P.; Camarero, J.; Del Real, R.P.; Asenjo, A.; Vázquez, M. Geometry-dependent magnetization reversal mechanism in ordered Py antidot arrays. J. Phys. D Appl. Phys. 2011, 44, 505001. [Google Scholar] [CrossRef]

- Palma, J.; Gallardo, C.; Spinu, L.; Vargas, J.; Dorneles, L.; Denardin, J.; Escrig, J. Magnetic properties of Fe20 Ni80 antidots: Pore size and array disorder. J. Magn. Magn. Mater. 2013, 344, 8–13. [Google Scholar] [CrossRef]

- Martens, S.; Albrecht, O.; Nielsch, K.; Görlitz, D. Local modes and two magnon scattering in ordered permalloy antidot arrays. J. Appl. Phys. 2009, 105, 07C113. [Google Scholar] [CrossRef]

- Garad, H.; Usmani, S.; Barral, D.; David, P.; Cagnon, L.; Testemale, D.; Mannix, D.; Fettar, F.; Proux, O.; Rosa, A.; et al. Influence of the pore diameter in Cu/Co/Cu antidots: A XANES study. Phys. Rev. Mater. 2018, 2, 066001. [Google Scholar] [CrossRef]

- Rodríguez-Suárez, R.; Palma, J.; Burgos, E.; Michea, S.; Escrig, J.; Denardin, J.; Aliaga, C. Ferromagnetic resonance investigation in permalloy magnetic antidot arrays on alumina nanoporous membranes. J. Magn. Magn. Mater. 2014, 350, 88–93. [Google Scholar] [CrossRef]

- Barnard, J.A.; Butera, A.; Fujiwara, H.; Inturi, V.R.; Jarratt, J.D.; Klemmer, T.J.; Scharr, T.W.; Weston, J.L. High coercivity nanostructured networks. J. Appl. Phys. 1997, 81, 5467–5469. [Google Scholar] [CrossRef]

- Krupinski, M.; Perzanowski, M.; Maximenko, A.; Zabila, Y.; Marszałek, M. Fabrication of flexible highly ordered porous alumina templates by combined nanosphere lithography and anodization. Nanotechnology 2017, 28, 194003. [Google Scholar] [CrossRef]

- Indira, K.; Mudali, U.K.; Nishimura, T.; Rajendran, N. A Review on TiO2 Nanotubes: Influence of Anodization Parameters, Formation Mechanism, Properties, Corrosion Behavior, and Biomedical Applications. J. Bio-Tribo-Corros. 2015, 1, 28. [Google Scholar] [CrossRef] [Green Version]

- Sato, K.S.K.; Katayama-Yoshida, H.K.-Y.H. Stabilization of Ferromagnetic States by Electron Doping in Fe-, Co- or Ni-Doped ZnO. Jpn. J. Appl. Phys. 2001, 40, L334. [Google Scholar] [CrossRef]

- Sarkar, A.; Adhikari, R.; Das, A.K. Magnetic Schottky diode exploiting spin polarized transport in Co/p-Si heterostructure. Appl. Phys. Lett. 2012, 100, 262402. [Google Scholar] [CrossRef]

- Roundy, R.C.; Raikh, M.E. Spin injection from a ferromagnet into a semiconductor in the case of a rough interface. Phys. Rev. B 2015, 91, 045202. [Google Scholar] [CrossRef] [Green Version]

- Duvvuru, M.K.; Wu, L.; Lin, N.S.; Xu, T.; Vahabzadeh, S. Surface treatment of titanium by anodization and iron deposition: Mechanical and biological properties. J. Mater. Res. 2020, 35, 1290–1297. [Google Scholar] [CrossRef]

- Zarzycki, A.; Chojenka, J.; Perzanowski, M.; Marszalek, M. Electrical Transport and Magnetic Properties of Metal/Metal Oxide/Metal Junctions Based on Anodized Metal Oxides. Materials 2021, 14, 2390. [Google Scholar] [CrossRef]

- Takács, J. A phenomenological mathematical model of hysteresis. COMPEL 2001, 20, 1002–1015. [Google Scholar] [CrossRef]

- Macak, J.M.; Tsuchiya, H.; Ghicov, A.; Yasuda, K.; Hahn, R.; Bauer, S.; Schmuki, P. TiO2 nanotubes: Self-organized electrochemical formation, properties and applications. Curr. Opin. Solid State Mater. Sci. 2007, 11, 3–18. [Google Scholar] [CrossRef]

- Suh, I.-K.; Ohta, H.; Waseda, Y. High-temperature thermal expansion of six metallic elements measured by dilatation method and X-ray diffraction. J. Mater. Sci. 1998, 23, 757–760. [Google Scholar] [CrossRef]

- Rahimi, N.; Pax, R.A.; Gray, E.M. Review of functional titanium oxides. I: TiO2 and its modifications. Prog. Solid State Chem. 2016, 40, 86–105. [Google Scholar] [CrossRef]

- Kornilov, I.I.; Vavilova, V.V.; Fykin, L.E.; Ozerov, R.P.; Solowiev, S.P.; Smirnov, V.P. Neutron diffraction investigation of ordered structures in the titanium-oxygen system. Metall. Mater. Trans. B 1970, 1, 2569. [Google Scholar] [CrossRef]

- Rice, C.E.; Robinson, W.R. Structural changes in the solid solution (Ti1−xVx)2O3 as x varies from zero to one. J. Solid State Chem. 1997, 21, 145–154. [Google Scholar] [CrossRef]

- Hyun, Y.H.; Lee, Y.P.; Kudryavtsev, Y.V.; Gontarz, R. Properties of Au-Fe Disordered Alloy Films near the fcc-bcc Structural Transformation. J. Korean Phys. Soc. 2003, 43, 625–628. [Google Scholar]

- Zamponi, C.; Schürmann, U.; Jurgeleit, T.; Kienle, L.; Quandt, E. Microstructures of magnetron sputtered Fe–Au thin films. Int. J. Mater. Res. 2015, 106, 103–107. [Google Scholar] [CrossRef]

- Włodarski, Z. Classical and hyperbolic approximation of hysteresis loops. Phys. B Condens. Matter 2007, 389, 347–350. [Google Scholar] [CrossRef]

- Włodarski, Z. Application of different saturation curves in a mathematical model of hysteresis. COMPEL 2005, 24, 1367–1380. [Google Scholar] [CrossRef]

- Alam, S.; Anand, C.; Logudurai, R.; Balasubramanian, V.V.; Ariga, K.; Bose, A.C.; Mori, T.; Srinivasu, P.; Vinu, A. Comparative study on the magnetic properties of iron oxide nanoparticles loaded on mesoporous silica and carbon materials with different structure. Microporous Mesoporous Mater. 2009, 121, 178–184. [Google Scholar] [CrossRef]

- Kim, Y.K.; Oliveria, M. Magnetic properties of sputtered Fe thin films: Processing and thickness dependence. J. Appl. Phys. 1993, 74, 1233. [Google Scholar] [CrossRef]

- Shalyguina, E.; Mukasheva, M.; Abrosimova, N.; Kozlovskii, L.; Tamanis, E.; Shalygin, A. The influence of annealing on magnetic and magneto-optical properties of iron and nickel films. J. Magn. Magn. Mater. 2006, 300, 367–370. [Google Scholar] [CrossRef]

- Bensehil, I.; Kharmouche, A.; Bourzami, A. Synthesis, Structural, and Magnetic Properties of Fe Thin Films. J. Supercond. Nov. Magn. 2017, 30, 795–799. [Google Scholar] [CrossRef]

- Mebarki, M.; Ghebouli, B.; Fouad, O.A.; Ibrahim, I.A.; Layadi, A. Effect of deposition conditions on the magnetic properties of evaporated Fe thin films. Eur. Phys. J. Appl. Phys. 2017, 78, 10301. [Google Scholar] [CrossRef]

- Sukovatitsina, E.V.; Samardak, A.S.; Ognev, A.V.; Chebotkevich, L.A.; Sanaeian, M.R.; Nasirpouri, F. Dependence of the magnetic properties of nanocrystalline nickel films on grain size and surface morphology. Nanotechnol. Russ. 2014, 9, 723–727. [Google Scholar] [CrossRef]

- Cao, Y.; Xu, K.; Jiang, W.; Droubay, T.; Ramuhalli, P.; Edwards, D.; Johnson, B.R.; McCloy, J. Hysteresis in single and polycrystalline iron thin films: Major and minor loops, first order reversal curves, and Preisach modeling. J. Magn. Magn. Mater. 2015, 395, 361–375. [Google Scholar] [CrossRef]

- Skomski, R.; Coey, J.M.D. Giant energy product in nanostructured two-phase magnets. Phys. Rev. B 1993, 48, 15812. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goyal, R.; Arora, N.; Kapoor, A.; Lamba, S.; Annapoorni, S. Exchange hardening in FePt/Fe3Pt dual exchange spring magnet: Monte Carlo modeling. J. Alloys Compd. 2017, 695, 1014–1019. [Google Scholar] [CrossRef]

- Nguyen, T.A.; Fedotova, J.; Kasiuk, J.; Bayev, V.; Kupreeva, O.; Lazarouk, S.; Manh, D.; Vu, D.; Chung, S.; Åkerman, J.; et al. Effect of flattened surface morphology of anodized aluminum oxide templates on the magnetic properties of nanoporous Co/Pt and Co/Pd thin multilayered films. Appl. Surf. Sci. 2018, 427, 649–655. [Google Scholar] [CrossRef]

- Meydan, T.; Kockar, H. In-plane anisotropy and stress detection of films deposited by RC technique. Eur. Phys. J. B 2001, 24, 457–461. [Google Scholar] [CrossRef]

- Kockar, H. Rotation Speed-Induced Uniaxial In-Plane Anisotropy in Thin Films Deposited Onto a Rotating Substrate. J. Supercond. 2004, 17, 531–536. [Google Scholar] [CrossRef]

- Goyal, R.; Kapoor, A.; Lamba, S.; Annapoorni, S. Origin of open recoil curves in L10-A1 FePt exchange coupled nanocomposite thin film. J. Magn. Magn. Mater. 2016, 418, 200–205. [Google Scholar] [CrossRef]

- Kang, K.; Lewis, L.H.; Jiang, J.S.; Bader, S.D. Recoil hysteresis of Sm–Co/Fe exchange-spring bilayers. J. Appl. Phys. 2005, 98, 113906. [Google Scholar] [CrossRef]

- Vashisht, G.; Goyal, R.; Bala, M.; Ojha, S.; Annapoorni, S. Studies of Exchange Coupling in FeCo/L10-FePt Bilayer Thin Films. IEEE Trans. Magn. 2019, 55, 1–5. [Google Scholar] [CrossRef]

- Goll, D.; Seeger, M.; Kronmüller, H. Magnetic and microstructural properties of nanocrystalline exchange coupled PrFeB permanent magnets. J. Magn. Magn. Mater. 1998, 185, 49–60. [Google Scholar] [CrossRef]

- Harland, C.; Lewis, L.; Chen, Z.; Ma, B.-M. Exchange coupling and recoil loop area in Nd2Fe14B nanocrystalline alloys. J. Magn. Magn. Mater. 2004, 271, 53–62. [Google Scholar] [CrossRef]

- Rong, C.-B.; Liu, J.P. Effect of thermal fluctuations on the recoil loops of SmCo5/Fe nanocomposite system. J. Appl. Phys. 2009, 105, 07A714. [Google Scholar] [CrossRef] [Green Version]

- Ye, Q.-L.; Feng, C.-M.; Xu, X.-J.; Jin, J.-S.; Xia, A.-G.; Ye, G.-X. Anomalous hysteresis properties of iron films deposited on liquid surfaces. J. Appl. Phys. 2005, 98, 013906. [Google Scholar] [CrossRef]

- Bedanta, S.; Kleemann, W. Supermagnetism. J. Phys. D Appl. Phys. 2009, 42, 013001. [Google Scholar] [CrossRef]

- Del Bianco, A.L.; Hernando, D. Fiorani, Spin-Glass-Like Behaviour in Nanocrystalline Fe. Phys. Status Solidi A 2002, 189, 533–536. [Google Scholar] [CrossRef]

- Zheng, R.K.; Wen, G.H.; Fung, K.K.; Zhang, X.X. Training effect of exchange bias in γ−Fe2O3 coated Fe nanoparticles. Phys. Rev. B 2004, 69, 214431. [Google Scholar] [CrossRef] [Green Version]

- Martínez, B.; Obradors, X.; Balcells, L.; Rouanet, A.; Monty, C. Low Temperature Surface Spin-Glass Transition in γ-Fe2O3 Nanoparticles. Phys. Rev. Lett. 1998, 80, 181. [Google Scholar] [CrossRef]

- Del Bianco, L.; Hernando, A.; Multigner, M.; Prados, C.; Sánchez-López, J.C.; Fernández, A.; Conde, C.F.; Conde, A. Evidence of spin disorder at the surface–core interface of oxygen passivated Fe nanoparticles. J. Appl. Phys. 1998, 84, 2189. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chojenka, J.; Zarzycki, A.; Perzanowski, M.; Krupiński, M.; Fodor, T.; Vad, K.; Marszałek, M. Tuning of the Titanium Oxide Surface to Control Magnetic Properties of Thin Iron Films. Materials 2023, 16, 289. https://doi.org/10.3390/ma16010289

Chojenka J, Zarzycki A, Perzanowski M, Krupiński M, Fodor T, Vad K, Marszałek M. Tuning of the Titanium Oxide Surface to Control Magnetic Properties of Thin Iron Films. Materials. 2023; 16(1):289. https://doi.org/10.3390/ma16010289

Chicago/Turabian StyleChojenka, Juliusz, Arkadiusz Zarzycki, Marcin Perzanowski, Michał Krupiński, Tamás Fodor, Kálmán Vad, and Marta Marszałek. 2023. "Tuning of the Titanium Oxide Surface to Control Magnetic Properties of Thin Iron Films" Materials 16, no. 1: 289. https://doi.org/10.3390/ma16010289

APA StyleChojenka, J., Zarzycki, A., Perzanowski, M., Krupiński, M., Fodor, T., Vad, K., & Marszałek, M. (2023). Tuning of the Titanium Oxide Surface to Control Magnetic Properties of Thin Iron Films. Materials, 16(1), 289. https://doi.org/10.3390/ma16010289