Abstract

With the rapid development of urbanization, the construction industry consumes a lot of cement and produces a large amount of construction waste. To overcome this situation, the rational use of recycled aggregate produced from waste concrete is one of solutions. In some countries, the building industry has approved the use of recycled coarse aggregates in concrete, with some limits. However, practically all existing standards and regulations prohibit the use of recycled fine aggregate (RFA) in concrete. Therefore, study on improving the performance of RFA concrete is vital. In this study, the effects of fly ash and GGBS on concrete with RFA were investigated. Compressive strength, pore structure, drying shrinkage and accelerated carbonation were tested. The correlation between the pore structure and properties of concrete was analyzed. The results show that adding fly ash and GGBS to RFA concrete increased its compressive strength, modified pore structure, reduced drying shrinkage, and even achieved higher compressive strength and lower drying shrinkage than normal concrete. The compressive strength was mainly affected by the capillary pores, and the carbonation was mainly affected by the gel pores.

1. Introduction

Since the beginning of the 21st century, concrete has been a widely used building material, with yearly production estimated at 10 billion m3 [1]. Aggregate includes coarse aggregate (gravel) and fine aggregate (sand), accounting for about 60–80% of the total volume of concrete [2]. Because of the extensive use of concrete, the demand for aggregates has greatly increased [3], and the production of fine aggregates by crushing gravel has a high energy cost and causes problems with fresh concrete because of high angularity [4,5]. However, the demolition of old buildings generates a large amount of construction waste, at 850 to 880 Mt/year in the European Union [6,7], 317 Mt/year in the US, and 77 Mt/year in Japan [8]. Therefore, the rational use of recycled aggregate produced from waste concrete can simultaneously solve problems with building material supply and disposal. The building industry has previously approved the use of recycled coarse aggregates in concrete, with some limits, and in some countries, full substitution is permitted in certain circumstances. However, practically all existing standards and regulations prohibit the use of recycled fine aggregate (RFA) in the manufacturing of concrete and mortar [9].

Several studies have been conducted on the properties of RFA concrete. Gholampour et al. [10] studied concrete containing 25, 50, and 100% RFA, and their results showed that the compressive strength of the concrete decreased as the replacement rate of RFA increased, although the strength of concrete containing 25% RFA was slightly increased. Kirthik et al. [11] showed that increasing the content of RFA in concrete decreased its durability, and the best RFA content was 30%, which decreased shrinkage and porosity by 14% and 25%, respectively, and increased resistance to chlorine penetration by 21%. Khatib et al. [12] studied concrete containing 0, 25, 50, and 100% RFA, and showed that concrete containing 100% and 25% RFA had 30% and 15% lower compressive strength, respectively, compared with normal concrete, and increasing the RFA content increased shrinkage. The chloride permeability of concrete increases with the RFA content, whereas incorporating fly ash decreases chloride permeability [13,14,15,16,17]. Lovato et al. [18] reported that the carbonation depth of concrete increased with the content of RFA. Evangelista et al. [19] showed that in concrete containing 30% and 100% RFA, the carbonation depth increased by 40% and 100%, respectively, compared with normal concrete. Bu et al. [20] reviewed the literature on the durability of concrete containing RFA and found that the durability of concrete decreased as the replacement rate of RFA increased; for concrete containing 100% RFA, the drying shrinkage of was twice that of ordinary concrete and the carbonation depth increased by about 110%. The density and mechanical properties of concrete decreases as the RFA content increases [21,22]. In summary, exceeding an RFA content in concrete of 30% has several negative effects, including increased shrinkage, decreased compressive strength, decreased carbonation resistance, and increased water absorption. This has greatly limited the application of RFA in concrete, so finding a method that can modify the properties of RFA concrete should expand its applications in practical engineering.

On the other hand, some studies have shown that the application of cementitious materials in concrete can improve durability, reduce long-term deformation, and modify the pore structure. It has been reported that cementitious materials enhance the workability, improve the performance of concrete at high temperatures, and inhibit the alkali-aggregate reaction [23]. Fly ash can be used instead of OPC to decrease porosity and reduce average pore size. Additionally, the volume of the gel’s pores (less than 0.01 μm) increases with the fly ash content [24]. The fly ash content in concrete is about 20%, and its compressive strength is the largest [25]. Adding fly ash to concrete reduces porosity and changes water absorptivity and chloride permeability [26]. High replacement volumes of fly ash increase resistance to chloride penetration substantially [27]. A fly ash content of 50% in concrete mixes offers benefits such as high resistance to chloride and sulfate attack, reduced alkali-silica expansion, and low heat generation [28]. The addition of fly ash to concrete can also reduce the creep [29,30] and drying shrinkage of concrete [26,31]. Özbay et al. [32] found that using GGBS in concrete increases the long-term mechanical properties of concrete. Additionally, using GGBS improves the deformation of concrete and increases the durability of concrete. Adding GGBS to concrete can reduce the porosity and modify the pore structure of the concrete [33]. Concrete containing GGBS tends to have lower shrinkage and creep than ordinary concrete [34,35,36,37]. In addition, some scholars have studied the use of cementitious materials in recycled aggregate concrete (fine and coarse). Qureshi et al. [38] studied recycled coarse aggregate concrete containing 20% fly ash and 30% GGBS, and their results showed that the concrete containing 20% fly ash and 30% GGBS had 2–10% and 5–12% higher compressive strength, respectively. Ahmad et al. [39] reported that the addition of GGBS to recycled coarse aggregate concrete can significantly increase its slump and strength. Kurad et al. [40] analyzed the effect of fly ash on concrete containing recycled fine and coarse aggregate and showed that the concrete had lower initial strength, but fly ash had little effect on its the strength. Ali et al. [41] showed that recycled coarse aggregate concrete containing 20–40% fly ash had a higher compressive strength at 180 days than control concrete. It has also been reported that fly ash improves mechanical properties and significantly reduces water absorption and chloride penetration of recycled coarse aggregate concrete [42]. Kou et al. [43] reported that GGBS and FA had great contributions to the performance of recycled coarse aggregate concrete. Anastasiou et al. [44] studied RFA concrete containing fly ash and showed that fly ash improves long-term strength and decreases water penetration under pressure, and chloride ion penetration. In conclusion, using cementitious materials such as fly ash or GGBS in concrete can improve durability, reduce long-term deformation, and modify pore structure. However, most researchers paid attention to recycled coarse aggregate. Research on the effect of cementitious materials on RFA concrete is still insufficient and requires further investigation. In addition, studies on the effect of GGBS and fly ash have mainly focused on mechanical properties and durability, and little research has been done on microscopic pore structure.

The purpose of this study was to enhance the compressive strength and durability performance of RFA concrete by adding cementitious materials, and to analyze the influence of microstructure on the mechanical properties and durability of RFA concrete. The optimal addition rate of fly ash or GGBS in RFA concrete was obtained. After adding supplementary cementitious materials, RFA concrete had higher strength and lower drying shrinkage than ordinary concrete. In addition, the influence of pore volume of different pore diameters on the compressive strength and durability of RFA concrete was analyzed. The micropores in RFA concrete were divided into harmful pores, small harmful pores, and harmless pores according to diameter. The results of this study will provide a basis for the application of RFA in practical engineering.

2. Materials and Experimental Program

2.1. Materials Properties

Sea sand (S) and M standard RFA conforming to JIS A 5022 [45] were used as fine aggregate. RFA was made from waste concrete after crushing, grinding and classifying. Crushed stone aggregate was used for coarse aggregate (G). Table 1 shows the physical properties of the fine and coarse aggregates.

Table 1.

Properties of fine and coarse aggregates.

OPC as defined in JIS R 5210 [46], supplementary cementitious materials were fly ash (FA) conforming to Class II in JIS A 6201 [47], fly ash with a higher carbon content from a local power plant that had its carbon content reduced by the floatation method (modified fly ash [MFA]), and GGBS as defined in JIS A 6206 [48]. The properties of cement, FA, MFA, and GGBS are shown in Table 2.

Table 2.

Properties of the cement, FA, MFA, and GGBS.

2.2. Mix Proportions

The mix proportions of the concrete cast in this experiment are shown in Table 3. The design strength of concrete was 27 MPa, according to JASS 5 [49], water-binder ratio was set to 0.55, the unit water volume was 180 kg/m3, and the unit coarse aggregate amount was 945 kg/m3. A total of 12 concrete mixes were prepared: the control concrete, concrete containing sea sand replaced with RFA (50% by volume), four mixes containing cement replaced with FA or MFA (10% and 15% by weight), two mixes containing cement replaced with GGBS (30% and 45% by weight), and four mixes with cement replaced (30% and 45% by weight) by FA and GGBS using ternary binders (the ratio of FA to GGBS was 1 or 0.5). In the process of concrete production, the aggregates were all surface dry.

Table 3.

Mix proportions.

2.3. Experiment Method

According to JIS A 1108 [50], testing for compressive strength was performed on cylindrical specimens that were 100 mm in diameter and 200 mm in height. The specimens were cast in a mold and kept for 24 h in a room at 20 °C and 60% RH before demolding. The specimens were then cured in water at 20 °C until the age required for the test. The compressive strength was tested at 7, 28, and 91 days. In order to avoid impact loads on concrete specimens, the loading rate was set at 0.6 ± 0.4 MPa per second. Three specimens were tested for each group, and the average value was taken.

The “Method of measurement for length change of mortar and concrete” described in JIS A 1129-2 [51] was used to conduct the drying shrinkage test, and prismatic specimens measuring 100 × 100 × 400 mm were cast. The specimens were demolded 1 day after casting, and then cured in water at 20 °C for 7 days. After 7 days, a stainless-steel chip was attached to both ends of the specimens, and the length of the specimen was measured as the base length. The specimens were then cured in a constant humidity and temperature chamber (20 ± 1.0 °C; RH, 60 ± 5%) and tested after 182 days.

The accelerated carbonation experiment was conducted according to JIS A1153 [52] using 40 × 40 × 160 mm test specimens. The specimens were cured in water at 20 °C for 4 weeks, and then placed in a thermo-hygrostat at 20 °C and 60% relative humidity for 4 weeks. After curing, the specimens were placed in a carbonation chamber at a CO2 concentration of 2.0%, 20 °C, and RH of 65% for 7, 28, 56, and 91 days. The depth of carbonation was tested at a specified age by splitting the specimen at right angles to the length direction and immediately spraying the split surface with 1% phenolphthalein solution to measure the depth-stained red purple. The carbonation depth of was measured at five points on each side (total of 10 points), and the average was taken as the carbonation depth. The carbonation depth was modelled by Equation (1):

where Xc is carbonation depth (mm), t is carbonation age (weeks), and K is the carbonation coefficient (mm/weeks 0.5).

Xc = K√t

Porosity was measured by mercury intrusion porosimetry (MIP). The samples were prepared by crushing a specimen (φ100 × 200 mm) that had been cured in water at 20 °C to the specific material age and sieving the powder to obtain particles of 2.5 to 5.0 mm. The hydration reaction was stopped by immersion in acetone, and then the powder was dried under vacuum for 72 h before use. The porosity was tested at 7, 28, and 91 days to investigate the development of the pore structure of concrete.

3. Results and Discussion

3.1. Compressive Strength

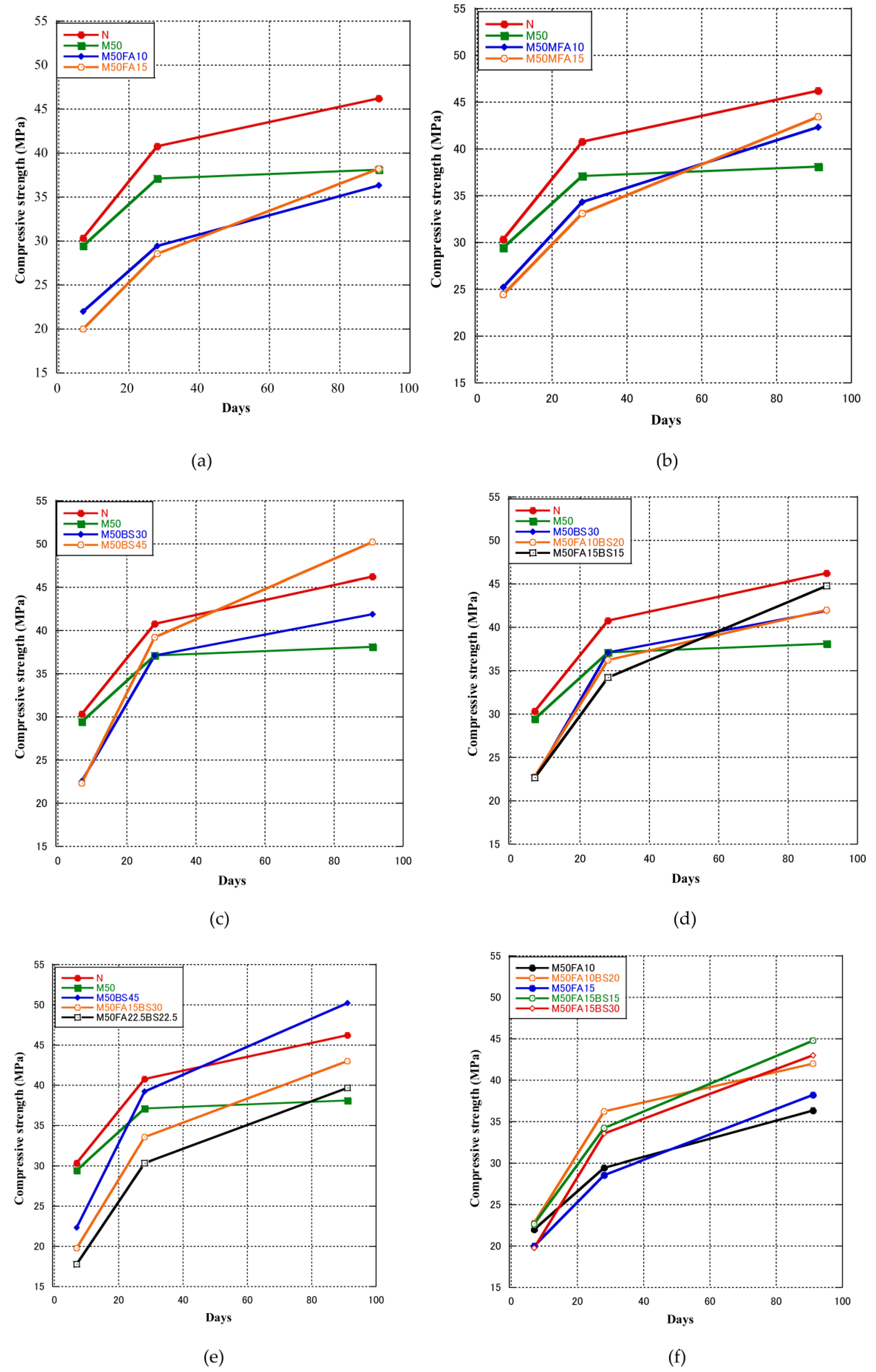

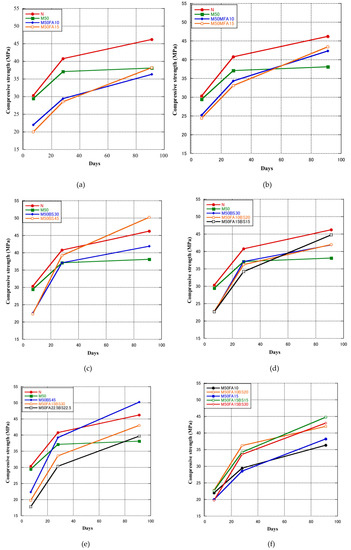

Figure 1a,b shows the compressive strength of RFA concrete containing only FA or MFA. The concrete containing 50% RFA had lower compressive strength than the control concrete. Compared with the control concrete, the compressive strength at 7, 28, and 91 days decreased by 2.8, 8.9, and 17.6%, respectively. Khatib [12] reported that when sand was substituted with RFA, the long-term strength was systematically decreased. At a replacement level of 100%, this reduction might approach 30%. A reduction of only 15% resulted from a replacement level of 25%. This was attributable to RFA’s porous structure and higher water absorption [24]. The FA specimens, consisting of RFA concrete containing FA, had a lower compressive strength than the M50 concrete at 7 and 28 days, and the MFA specimens showed similar results. The compressive strength of the concrete containing 15% FA was lower than that of the concrete containing 10% FA at 7 and 28 days. However, the decrease of compressive strength at 91 days was not significant. These decreases can be attributed to fly ash’s diluting effect and early-stage poor reactivity [53,54,55,56,57]. The results are in good agreement with the results of some previous studies, which showed that the long-term mechanical characteristics of fly ash concrete had clearly improved [54,58,59,60]. The RFA concrete specimens containing MFA had a higher 91-day compressive strength than the M50 concrete. Compared with M50 concrete, the compressive strength of MFA10 and MFA15 concrete at 91 days increased by 10.93% and 14.04%, respectively. Therefore, the removal of unburned carbon from fly ash by flotation is an effective method for using fly ash with high carbon content in concrete. As shown in Table 2, MFA had a larger specific surface area than ordinary fly ash, which may be an important reason for the better performance of MFA than ordinary fly ash. In addition, the 91-day compressive strength of M50FA10 concrete was 4.8% lower than that of M50 concrete, whereas that of M50FA15 concrete was similar. According to previous studies, the results showed that the reaction degree of fly ash varied depending on the fly ash properties, from less than 4% at 3 days to 9–23% at 28 days to 26–33% at 180 days [53,61,62,63,64].

Figure 1.

Compressive strength of concrete with cementitious materials.

The pozzolanic reaction between fly ash and Ca(OH)2 might result in abundant CSH, resulting in modified pore structure and improved long-term strength, which is ultimately responsible for the improvement in the mechanical performance [56,63,65]. The results of pore structure in this experiment also indicated the pozzolanic reaction.

Figure 1c shows the compressive strength of RFA concrete containing only GGBS. The compressive strengths of M50BS30 and M50BS45 were lower than that of the M50 and control concrete at 7 days. The 28-day compressive strengths of M50BS30 and M50BS45 were higher than that of M50, but lower than that of the control concrete. Both M50BS30 and M50BS45 had a higher 91-day compressive strength than M50, and M50BS45 had a higher 91-day compressive strength than the control concrete. Therefore, using GGBS in RFA concrete decreased the 7-day compressive strength, but did not affect the 28-day compressive strength. In addition, GGBS increased the 91-day compressive strength, and the compressive strength increased with the GGBS content. Some studies also reported similar results [37,66,67]; the early strength of GGBS concrete was lower, and with the increase of curing time, the compressive strength of GGBS concrete increased faster than that of the normal concrete. The compressive strength increases of GGBS concrete took longer due to the slow pozzolanic reaction [66,68]. As shown in Table 2, GGBS has a larger specific surface area and higher CaO content than fly ash. The GGBS group exhibited higher compressive strength than the fly ash group due to the higher CaO content and larger specific surface area of GGBS, which resulted in a better pozzolanic reaction rate in GGBS-based concrete.

Figure 1d shows that the compressive strength of RFA concrete containing 30% blended cementitious materials was lower at 7 and 28 days than M50 concrete. The compressive strengths of M50BS30, M50FA10BS20, and M50FA15BS15 concrete were around 23% lower than that of M50 concrete at 7 days, although at 28 days those of M50FA10BS20 and M50FA15BS15 concrete were 2.6% and 7.9% lower, respectively, and that of M50BS30 was similar. However, at 91 days, RFA concrete containing 30% blended cementitious materials had a higher compressive strength than M50 concrete. Compared with M50 concrete, the compressive strengths of M50BS30, M50FA10BS20, and M50FA15BS15 concrete increased by 9.8, 10.2, and 17.5%, respectively. Figure 1e shows that the concrete containing 45% blended cementitious materials. In addition, M50BS45 concrete had a 7-day compressive strength 24.1% lower than that of M50, a 28-day compressive strength 5.7% higher than that of M50 and similar to that of N, and a 91-day compressive strength 31.6% higher than M50 and 8.5% higher than N.M50BS45 was the only specimen that had a higher compressive strength than N at 91 days, and had the highest compressive strength at 91 days in this experiment. Compared with M50, the 7-day compressive strengths of M50FA15BS30 and M50FA22.5BS22.5 were 32.9% and 39.8% lower, and the 28-day compressive strengths were 9.8% and 18.4% lower, respectively. The compressive strength of every mixture proportion was higher than that of M50 at 91 days; M50BS45, M50FA15BS30, and M50FA22.5BS22.5 concrete were 31.6, 12.6, and 4.0% higher, respectively. Zhao et al. [69] researched concrete containing 30, 40, and 50% cementitious materials (fly ash and GGBS) and showed that the compressive strength of concrete decreased with the increase of cementitious materials content. In addition, the 28-day compressive strength increased with the increase of fly ash content at the same content of cementitious materials content. Gesoğlu et al. [70] found that concrete incorporating 10% fly ash and 10% GGBS had the highest compressive strength. Experimental results showed that adding cementitious materials to recycled aggregate concrete helps to increase its strength; especially M50BS45 and M50FA15BS15 exhibited higher and similar compressive strength than normal concrete, respectively. Therefore, it can be said that adding GGBS and fly ash can increase the compressive strength of RFA concrete, but the mixing ratio of GGBS and fly ash needs further study.

Figure 1f shows the compressive strength of RFA concrete with constant FA content (10% and 15%). In RFA concrete containing 10–15% FA, adding 15–30% GGBS resulted in the 7-day compressive strength being similar, the 28-day compressive strength increased by about 20%, and the 91-day compressive strength increased by about 15% compared with M50FA10, M50FA15 specimens. Therefore, adding GGBS to concrete containing FA can address the problem of low 28-day compressive strength of FA concrete and increase the 91-day compressive strength.

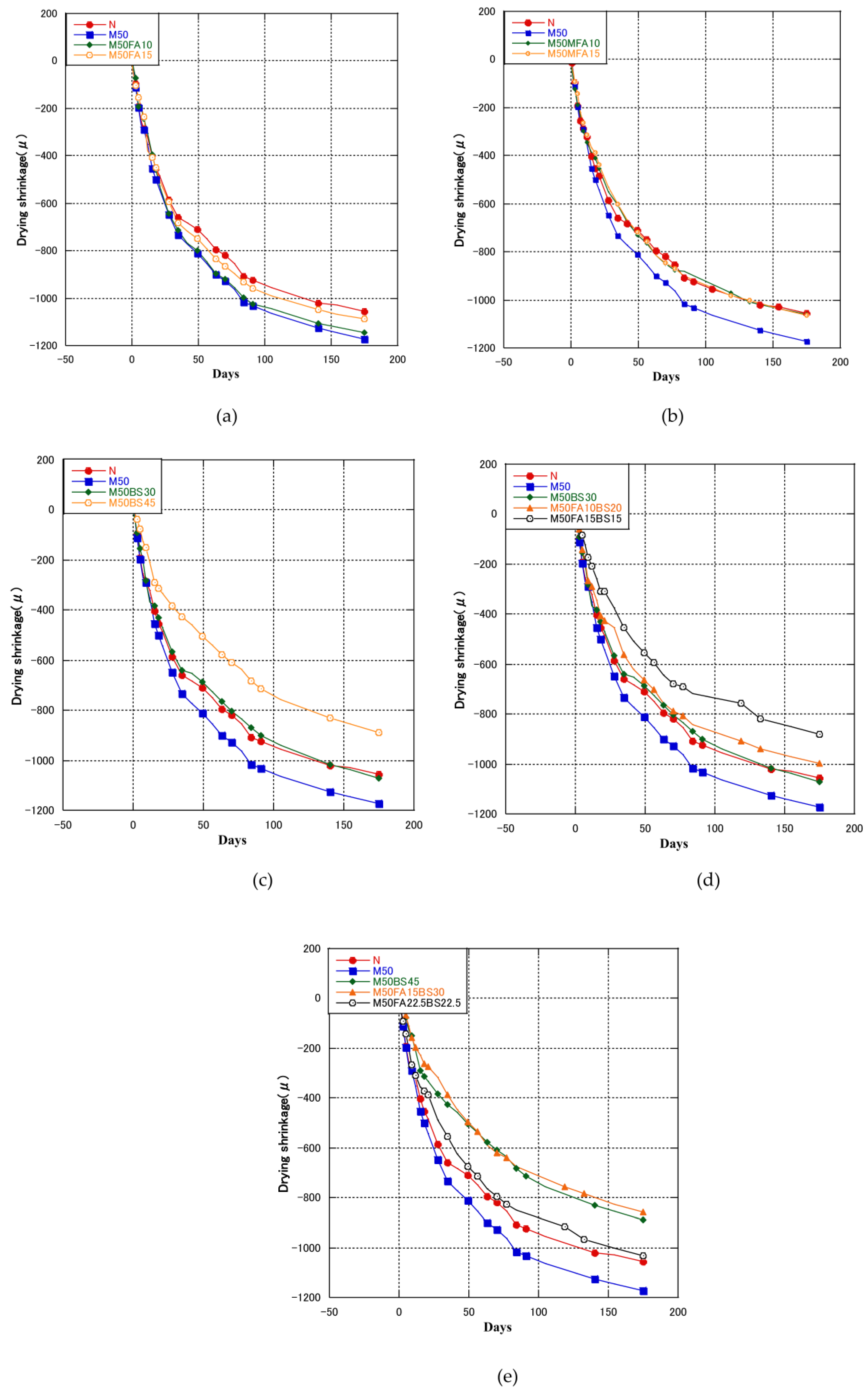

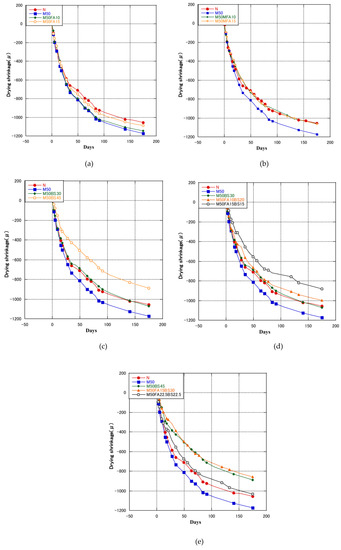

3.2. Drying Shrinkage

Figure 2a shows the drying shrinkage of the FA specimens. The drying shrinkage of M50 developed quickly, diverged from the control concrete after 1 week, and was 10.85% higher after 182 days, Kirthika et al. [11] reported the similar results. It is common knowledge that the greatest cause of drying shrinkage is the water content of the concrete mixture [71]. The higher drying shrinkage of RFA concrete was due, in part, to RFA’s higher water absorption, and because a large amount of fines in the pores and gaps of coarse particles of RFA increased the paste volume of the concrete [2]. The drying shrinkage of RFA concrete containing FA was suppressed compared with M50; the drying shrinkages of M50FA10 and M50FA15 were 2.3% and 7.1% lower after 182 days, respectively. Thus, adding FA to RFA concrete decreased the drying shrinkage and the decrease was greater as the FA content increased. Figure 2b shows the drying shrinkage of the MFA specimens. Both M50MFA10 and M50MFA15 concrete had lower drying shrinkages than M50, which were similar to that of the control concrete. Compared with M50, the drying shrinkages of M50MFA10 and M50MFA15 were 9.5% and 9.3% lower at 182 days, respectively. Saha et al. [26], and Wang et al. [72] also reported similar results in that the drying shrinkage decreased with increasing fly ash content. Adding fly ash to concrete lowered the cement concentration and delayed the development of shrinkage, which caused a modest reduction in early drying shrinkage [31,73]. The results of pore structure in this experiment showed that fly ash modified the pore structure of concrete, which inhibited evaporation of water and reduced drying shrinkage.

Figure 2.

Drying shrinkage of concrete with cementitious materials.

Figure 2c shows the drying shrinkage of the GGBS specimens. GGBS reduced the drying shrinkage considerably. The drying shrinkage of M50BS30 at 182 days was 8.6% lower than that of M50, and was similar to that of the control concrete. Furthermore, at 182 days, the drying shrinkage of M50BS45 was the lowest, was 24% lower than that of M50 and 15.8% lower than that of the control concrete. Some studies also reported similar results [37,74,75], adding GGBS inhibited the development of drying shrinkage of concrete. Adding GGBS to concrete reduced the porosity and modified the pore structure of the concrete [33,76]. On the one hand, GGBS had a larger specific surface area than fly ash, and on the other hand, GGBS had a higher CaO content than fly ash, so the activity of GGBS was higher, and the inhibition effect on drying shrinkage was greater.

Figure 2d shows the drying shrinkage of the 30% blended cementitious materials specimens. The cementitious materials reduced the drying shrinkage, and the mixture of GGBS and FA had a greater effect. The drying shrinkage of M50FA10BS20 and M50FA15BS15 at 182 days was 14.8% and 24.7% lower than that of M50, and 5.6% and 16.5% lower than that of the control concrete, respectively. Figure 2e shows the drying shrinkage results of 45% blended cementitious material specimens. In contrast to the 30% blended cementitious material specimens, M50FA15BS30 had a similar 182-day drying shrinkage compared to M50BS45, whereas the 182-day shrinkage value of M50FA22.5BS22.5 was 16.2% higher than that of M50BS45. Therefore, for a cementitious materials content of 30–45%, the reduction in drying shrinkage was higher for GGBS mixed with FA, although FA contents higher than 15% increased the drying shrinkage.

Zhao et al. [69] reported that comparing concrete with the simultaneous addition of fly ash and GGBS to cement-only concrete, shrinkage was reduced by 15%. Weng et al. [77] studied concrete with binary cementitious materials (FA, GGBS) and showed that drying shrinkage of concrete was less with binary FA and GGBS than with GGBS alone. Due to GGBS’s fineness and hydration activity, which aid in the formation of a compact microstructure and stop water evaporating from the concrete, drying shrinkage of concrete is significantly reduced [77]. Adding fly ash or GGBS to concrete promoted the hydration of cement and modified the microstructure of concrete, lowing permeability of free water, so that drying shrinkage decreased significantly [69].

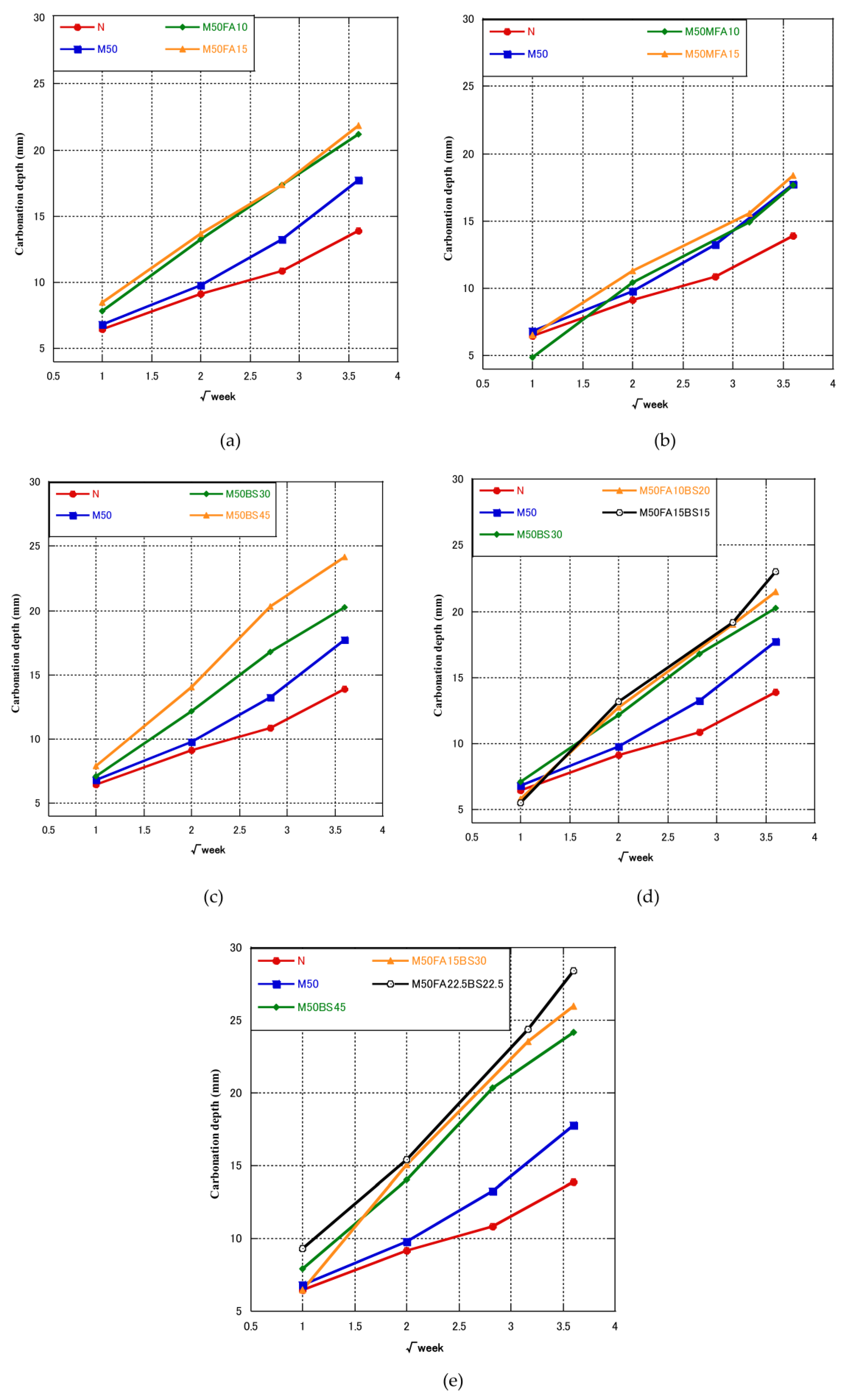

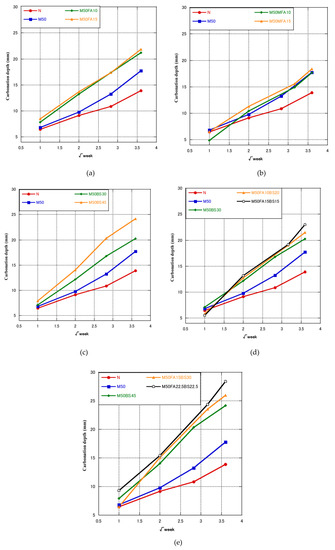

3.3. Accelerated Carbonation

The accelerated carbonation experiment results are shown in Figure 3a–e. The carbonation depth of M50 was about 27.8% greater than that of the normal concrete at 91 days, probably due to the higher porosity of the concrete. Therefore, RFA decreased the carbonation resistance. Some studies reported that the carbonation depth of RFA concrete likewise rises with the recycled aggregate replacement level [18,19] because concrete with RFA has higher porosity than normal concrete, which makes it easier for atmospheric CO2 to diffuse into concrete.

Figure 3.

Carbonation depth of concrete with cementitious material.

Figure 3a,b shows the results of the FA and MFA groups. Increasing the FA content increased the carbonation depth at 91 days, regardless of whether it was MFA or class II FA. Compared with the M50 concrete, the carbonation depths of M50FA10, M50FA15, M50MFA10, and M50MFA15 were 19.8, 22.9, 1.65, and 4.92% higher, respectively. Some research reported similar results and showed that the depth of carbonation increased as FA quantity increased [78,79,80]. This was due to the lower content of available Ca(OH)2 in fly ash concrete compared to normal concrete [81,82], which resulted in faster carbonation of the C-S-H bond [83].

Figure 3c show the results of GGBS group. The results were similar to concrete containing FA. Increasing the GGBS content increased the carbonation depth at 91 days. Compared with the M50 concrete, the carbonation depths of M50BS30 and M50BS45 were 14.2% and 31.6% higher, respectively. It was reported that with up to 20% GGBS content, the carbonation of GGBS concrete was similar to that of normal concrete, while with a GGBS content over 20%, carbonation depth increased with the increase of GGBS content [84]. Sulapha et al. [85] also reported that concrete with GGBS exhibited lower resistance to carbonation than conventional concrete.

Figure 3d,e shows the results of the blended admixture (FA, GGBS) group. Increasing the blended admixture content (FA and GGBS) increased the carbonation depth at 91 days. In concrete containing 30% and 45% blend admixtures, increasing the FA content increased the carbonation depth, and M50FA22.5BS22.5 had the highest carbonation depth. Therefore, FA had a greater effect on carbonation than GGBS, although after 7 days, specimens containing FA had a smaller carbonation depth. Jones et al. [86] studied concrete containing ternary binders, and showed that compared to regular concrete, concrete incorporating GGBS and fly ash showed noticeably greater rates of rapid carbonation. On average, carbonation depths for the concrete made with GGBS and fly ash mixes were 2.5 times greater than those for regular concrete, and as the cement replacement level was raised, carbonation rates increased [86].

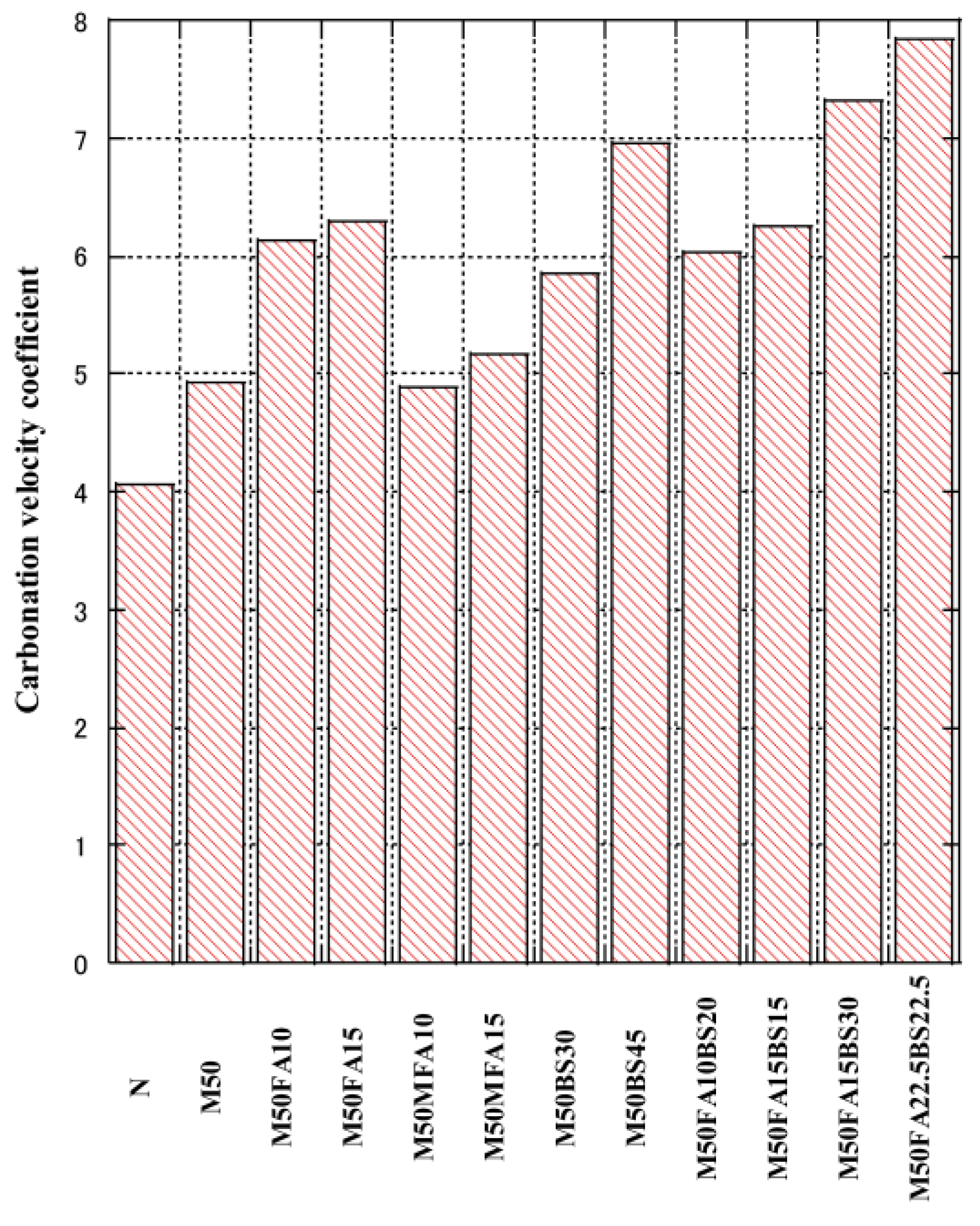

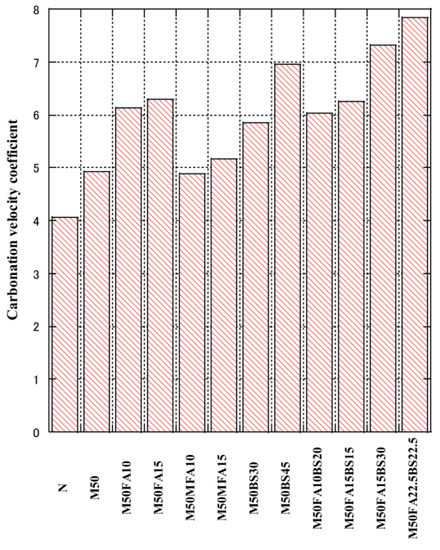

Figure 4 shows the carbonation velocity coefficients. The incorporation of FA, GGBS, and RFA increased the carbonation velocity coefficient. In the RFA concrete containing 30% and 45% blended admixtures, the carbonation depth increased with the FA content. Generally, increasing the content of mineral admixture increases the carbonation depth of concrete. This is mainly because the pozzolanic reaction consumes a large amount of Ca(OH)2, resulting in a decrease in the pH of the concrete [87]. When the FA content was constant, adding GGBS to the concrete increased the carbonization velocity coefficient.

Figure 4.

Carbonation velocity coefficient.

When the total FA and GGBS content was constant, increasing the FA content increased the carbonation velocity coefficient.

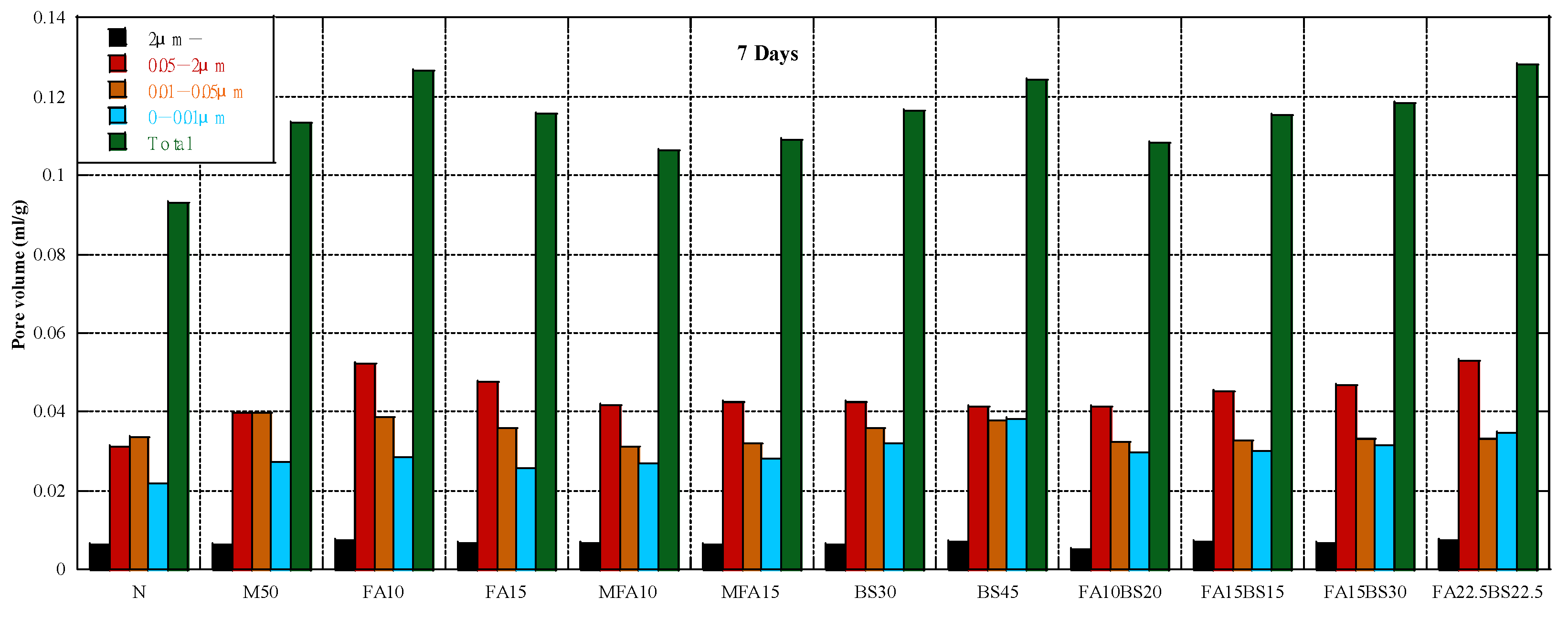

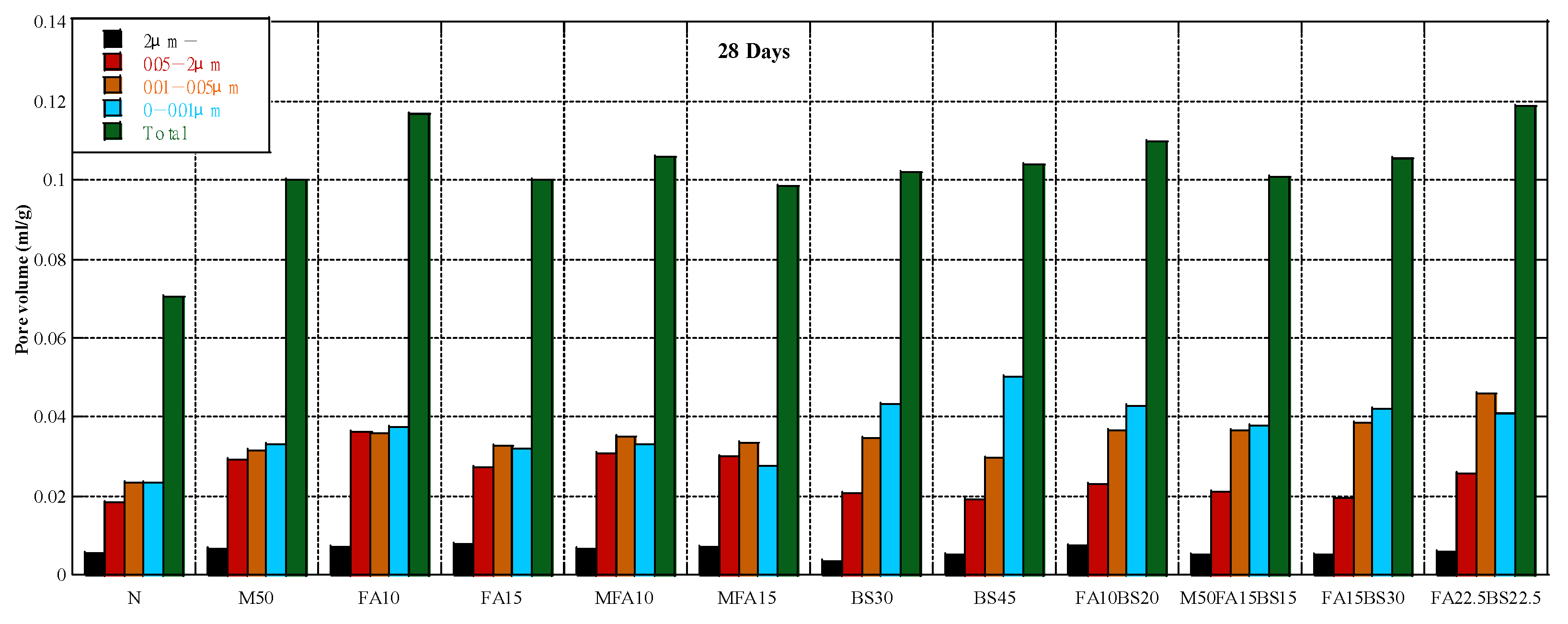

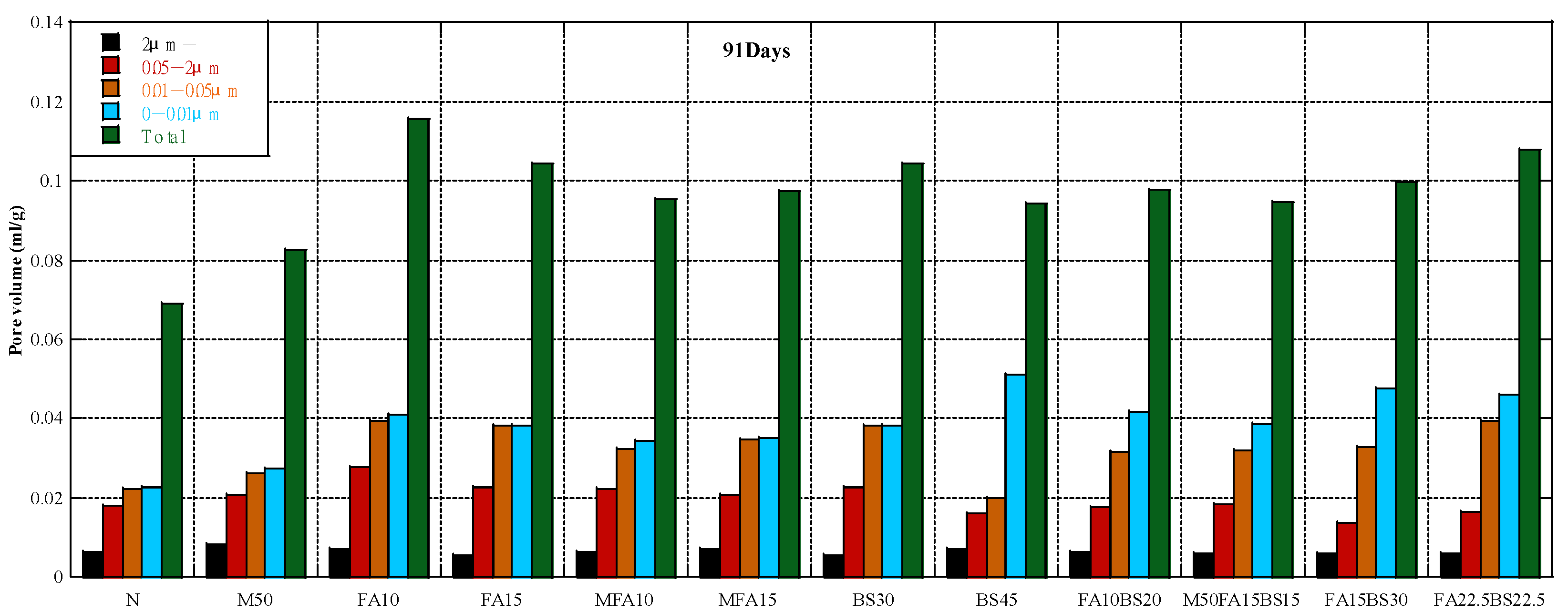

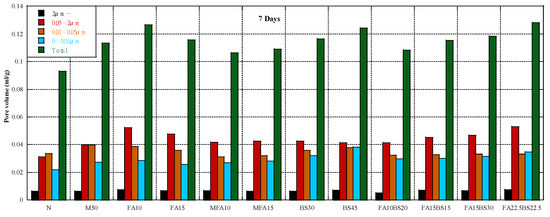

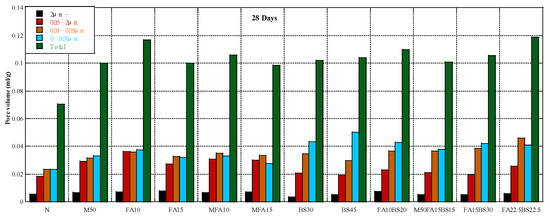

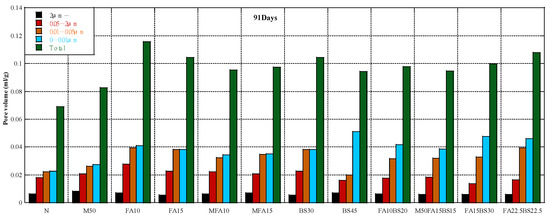

3.4. Pore Structure

Figure 5 shows the cumulative pore volume at 7 days. The concrete containing RFA had a higher pore volume, especially for pore diameters of 0.05–2 µm. The concrete containing class II FA had a higher pore volume than M50 concrete, whereas the concrete containing MFA had a lower pore volume. Thus, the properties of FA strongly affect the pore volume of concrete. The concrete containing GGBS had a higher pore volume than M50 concrete, and the pore volume increased with the GGBS content. The concrete containing the blended admixtures had a lower pore volume when the admixture content was 30% compared with concrete containing only GGBS, and the ratio of FA to GGBS of 1:2 was better than 1:1. Figure 6 shows the cumulative pore volume at 28 days. The effect of RFA on the pore volume of concrete was similar to the effect at 7 days, and the concrete containing RFA had a higher pore volume than the control concrete. The pore volume at 28 days was much lower than that at 7 days due to the hydration of the cement and cementitious materials. The concrete containing fly ash had different results; that containing class II FA had a higher volume than the control concrete, whereas that containing MFA had a lower pore volume. For concrete containing GGBS, the change in cumulative pore volume was negligible, but the pore volume between 0.05 and 2 µm was considerably lower. For concrete containing the blended admixture, concrete containing FA and GGBS had a higher pore volume than concrete containing only GGBS, especially for pore diameters of 0.01–0.05 µm. When the cementitious materials content was constant, the pore volume increased with the FA content. Figure 7 shows the cumulative pore volume at 91 days. The pore volume of M50 was higher than that in the control concrete. The pore volume of RFA concrete containing FA was larger than that in the M50 concrete, but the volume of pores between 0.05 and 2 µm did not change much, mainly due to the increase in the volume of pores less than 0.05 µm, regardless of whether the FA was class II FA or MFA. This may be due to the pozzolanic reaction and the tiny aggregate effect of FA [71]. Poon et al. [88] also reported that replacing cement with fly ash increased porosity but decreased average pore size of the pastes. Other studies reported similar results [89,90]. The total pore volume of concrete containing GGBS was larger than that of M50 concrete, but the 0.05–2 µm pore volume was smaller than that of M50 concrete, mainly due to the increase in the volume of pores less than 0.05 µm.

Figure 5.

Pore structure at 7 days.

Figure 6.

Pore structure at 28 days.

Figure 7.

Pore structure at 91 days.

The pore volume of concrete containing 30% cementitious materials did not change substantially, whereas that containing 45% cementitious materials was different. The total pore volume of concrete containing the blended admixture was larger than that containing only GGBS; while the volume of the pores at 0.05–2 µm did not change much, the volume of the pores at 0.01–0.05 µm increased. The experimental results prove that the activity of pozzolanic reaction of GGBS is greater than that of fly ash, so the pore volume of concrete mixed with GGBS only had a higher pore volume at pore diameters of less than 0.01 µm. Furthermore, we found that the incorporation of GGBS decreased the volume of pores with a diameter greater than 0.01, and the incorporation of fly ash had little effect on the volume of pores. with a diameter of 0.05–2µm but increased the volume of pores with a diameter of 0.01–0.05µm.

Based on MIP-determined trials, Mindess et al. [91] defined capillary pores as being greater than 0.01 μm, and gel pores as being less than 0.01 μm. PK Mehta [92] analyzed pore size in four ranges: less than 4.5 nm, 4.5–50 nm, 50–100 nm, and greater than 100 nm. Wu and Lian [93] examined four ranges of pores: pores under 20 nm, between 20 and 50 nm, 50 and 200 nm and those over 200 nm. It was reported that the strength of mortar was mainly affected by capillary pores, and the durability was mainly affected by gel pores [94].

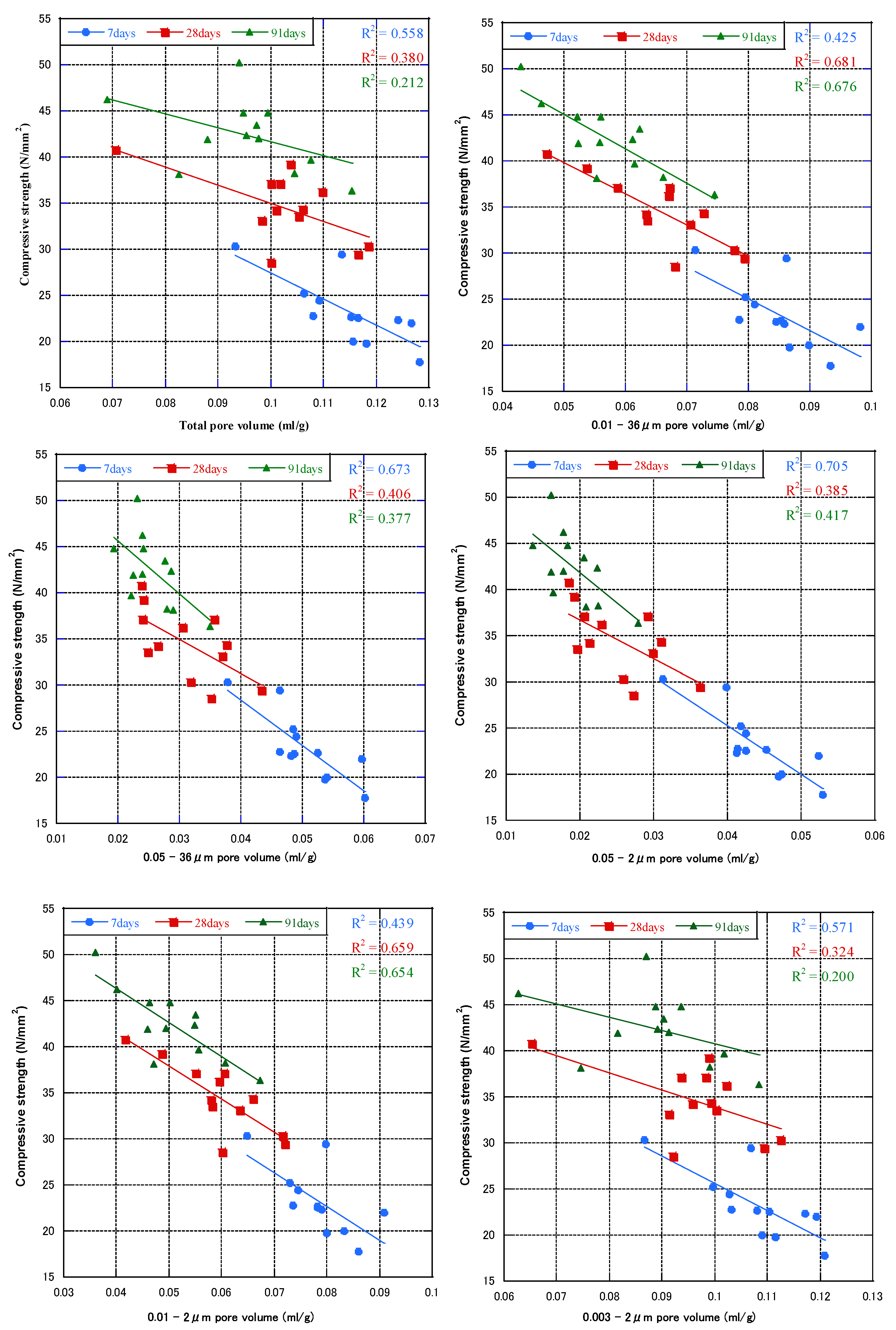

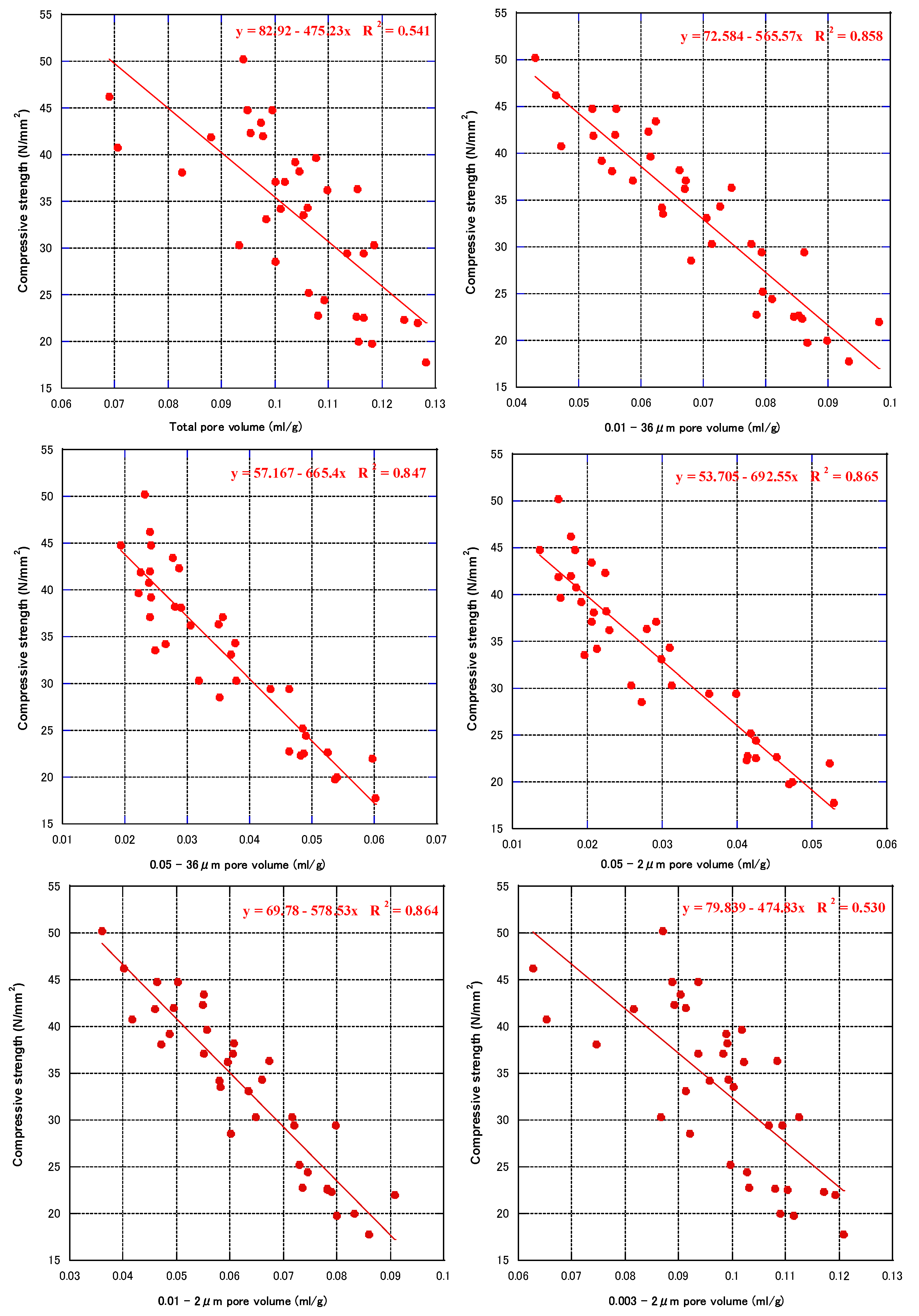

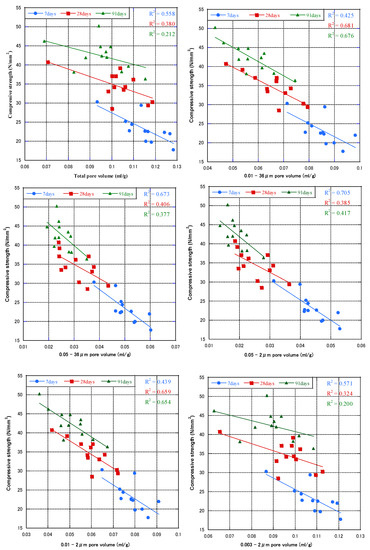

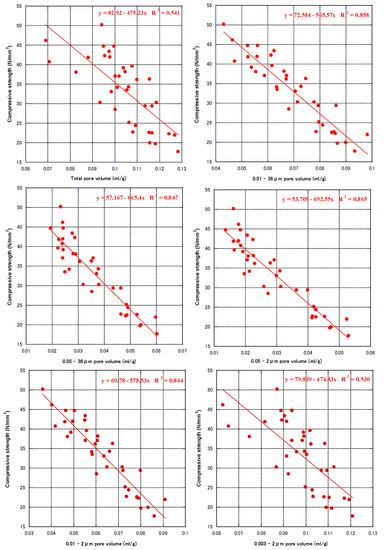

Based on the relationship between pore volume and pore diameter, we analyzed the correlation between the compressive strength of concrete at each age and the total pore volumes of 0.01–36, 0.05–36, 0.003–2, 0.01–2, and 0.05–2 μm. Figure 8 shows the relationship between compressive strength and cumulative pore volume at each age (all mix proportions). In all pore size ranges, the compressive strength tended to increase as the pore volume decreased. For the 28-day and 91-day compressive strength, the correlation coefficients (R2) for the 0.01–36 µm pore volume were the highest. However, the 7-day compressive strength had a good correlation with the 0.05–2 μm pore volume. In Figure 9, regardless of the age and mix proportions of the specimens, all the compressive strength and cumulative pore volumes obtained were fitted. The compressive strength had a low correlation with the total pore volume and pore volume of 0.003–2 μm. Furthermore, compressive strength was linearly related to pore volumes larger than 0.01 or 0.05 μm. This showed that pores with a diameter of less than 0.01 μm had no effect on the compressive strength of concrete, pores with a diameter of 0.01–0.05 μm had weak effect on the compressive strength of concrete, and pores with a diameter greater than 0.05 μm had a greater effect on the strength of concrete. The correlation coefficient between the 0.05–2 μm pore volume and the compressive strength had the largest R2 of 0.87. Therefore, for the compressive strength, pores with a diameter greater than 0.05 μm can be termed harmful pores, 0.01–0.05 μm small harmful pores, and less than 0.01 μm harmless pores.

Figure 8.

Relationship between pore volume and compressive strength at each age.

Figure 9.

Relationship between pore volume and compressive strength (all mixes and ages).

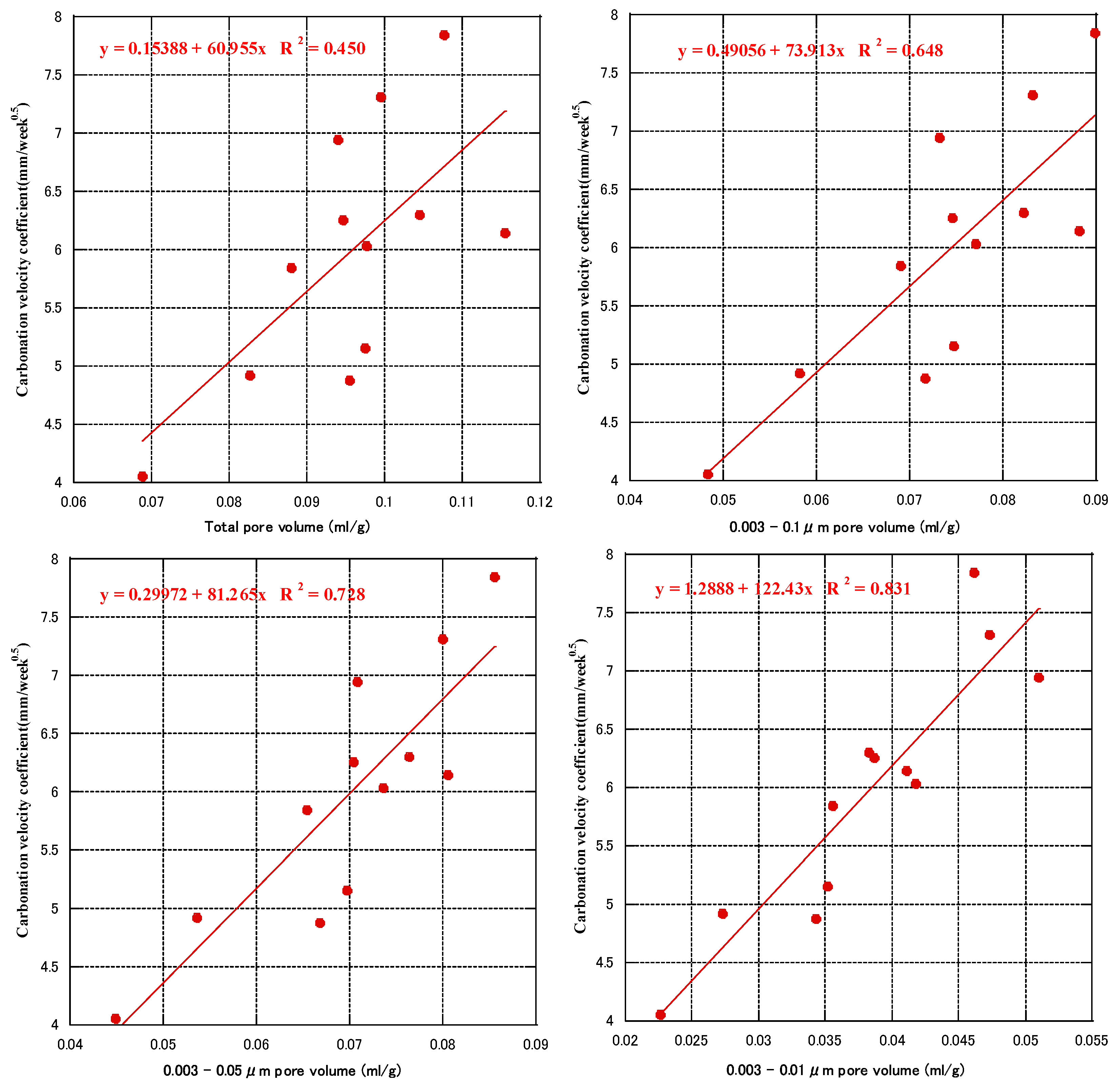

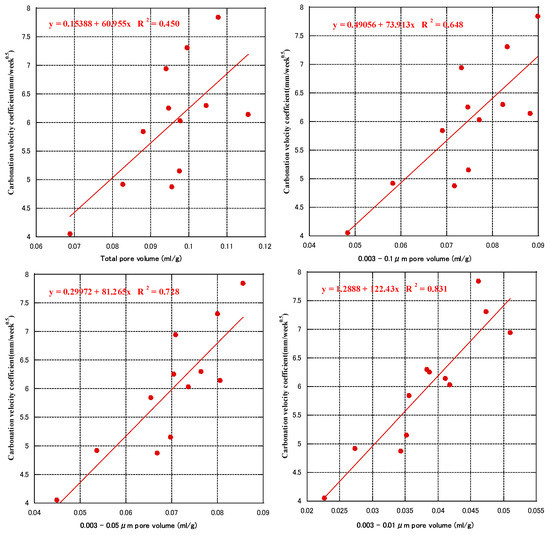

Figure 10 shows the correlation between carbonation velocity coefficient and cumulative pore volume obtained from the MIP tests at 91 days (total pore volumes, pore volumes of 0.003–0.1, 0.003–0.05, and 0.003–0.01 μm), respectively. The correlation between cumulative pore volume and carbonation velocity coefficient increased gradually with the decrease of pore diameter. The correlation between the carbonation velocity coefficient and 0.003–0.01 μm pore volume was the highest, with R2 of 0.83. Thus, the carbonation velocity coefficient of concrete was linearly related to the volume of pores with diameters less than 0.01 µm.

Figure 10.

Relationship between cumulative pore volume and carbonation velocity coefficient.

4. Conclusions

- Adding fly ash and GGBS to RFA concrete increased its compressive strength. M50BS45 and M50FA15BS15 exhibited similar 91-day compressive strengths with normal concrete. Therefore, the compressive strength of RFA concrete can be effectively improved by the use of cementitious materials.

- Replacement of cement with fly ash or GGBS significantly decreased the drying shrinkage of the RFA concrete. The drying shrinkage of all specimens in this experiment reached the level of ordinary concrete, and even lower than that of ordinary concrete. M50FA15BS15 showed 16.5% lower drying shrinkage, M50BS45 and M50FA15BS30 showed around 25% lower drying shrinkage than normal concrete.

- Increasing the cementitious (fly ash and GGBS) materials content decreased the carbonation resistance of RFA concrete. Fly ash had a greater effect on carbonation than GGBS.

- Incorporating FA or GGBS into concrete modified the pore structure of concrete, and reduced the volume of capillaries larger than 0.05 μm. In addition, the compressive strength was mainly affected by capillary pores (greater than 0.01 μm or 0.05 μm), and the carbonation was mainly affected by gel pores (less than 0.01 μm).

- For compressive strength, pores with a diameter greater than 0.05 μm are considered harmful pores, 0.01–0.05 μm are considered small harmful pores, and less than 0.01 μm are considered harmless pores.

Author Contributions

Conceptualization, Z.L. and K.T.; methodology, Z.L.; validation, K.T., H.K., H.S., S.L. and Q.H.; formal analysis, Z.L.; investigation, Z.L. and K.T.; resources, K.T., H.K. and H.S., S.L. and Q.H.; data curation, Z.L.; writing—original draft preparation, Z.L.; writing—review and editing, Z.L.; visualization, Z.L.; supervision, K.T.; project administration, K.T.; funding acquisition, K.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was financially supported by the Environmental Restoration and Conservation Agency (ERCA) JPMEERF20213G03 “Demonstration Development of Recycling Technology for Woody Biomass Combustion Ash for Geopolymer Concrete”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy restrictions.

Acknowledgments

The authors acknowledge the assistance in this work provided by Eiji Mikura.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Evangelista, L.; Guedes, M.; de Brito, J.; Ferro, A.; Pereira, M. Physical, chemical and mineralogical properties of fine recycled aggregates made from concrete waste. Construct. Build. Mater. 2015, 86, 178–188. [Google Scholar] [CrossRef]

- Kumar, G.S. Influence of fluidity on mechanical and permeation performances of recycled aggregate mortar. Constr. Build. Mater. 2019, 213, 404–412. [Google Scholar] [CrossRef]

- Elavenil, S.; Vijaya, B. Manufactured sand, a solution and an alternative to river sand and in concrete manufacturing. J. Eng. Comput. Appl. Sci. 2013, 2, 20–24. [Google Scholar]

- Villalobos, S.; Lange, D.A.; Roesler, J.R. Evaluation, Testing and Comparison between Crushed Manufactured Sand and Natural Sand; Technical Note; University of Illinois, Department of Civil Enviroment Eng.: Champaign, IL, USA, 2005; p. 15. [Google Scholar]

- Fischer, C.; Werge, M. EU as a recycling society. In European Topic Centre on Resource Waste Management; Working Paper 2/2009; European Topic Centre on Sustainable Consumption and Production: Copenhagen, Denmark, 2009. [Google Scholar]

- Sáez, P.V.; Merino, M.; Del, R.; Porras-Amores, C. Managing construction and demolition (C&D) waste—A European perspective. In International Conference on Petroleum and Sustainable Development; IPCBEE: Dubai, United Arab Emirates, 2011; pp. 27–31. [Google Scholar]

- CSI. The Cement Sustainability Initiative. Recycling Concrete: Executive Summary; CSI: Geneva, Switzerland, 2009. [Google Scholar]

- Gonçalves, P.; de Brito, J. Recycled aggregate concrete (RAC)—Comparative analysis of existing specifications. Mag. Concr. Res. 2010, 62, 339–346. [Google Scholar] [CrossRef]

- Gholampour, A.; Zheng, J.; Ozbakkaloglu, T. Development of waste-based concretes containing foundry sand, recycled fine aggregate, ground granulated blast furnace slag and fly ash. Constr. Build. Mater. 2021, 267, 121004. [Google Scholar] [CrossRef]

- Kirthika, S.K.; Singh, S.K. Durability studies on recycled fine aggregate concrete. Constr. Build. Mater. 2020, 250, 118850. [Google Scholar] [CrossRef]

- Khatib, J.M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Abbas, A.; Fathifazl, G.; Isgor, O.B.; Razaqpur, A.G.; Fournier, B.; Foo, S. Durability of recycled aggregate concrete designed with equivalent mortar volume method. Cem. Concr. Compos. 2009, 31, 555–563. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Influence of mineral additions on the performance of 100% recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2869–2876. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Fan, Y.; Huang, X. An overview of study on recycled aggregate concrete in China (1996–2011). Constr. Build. Mater. 2012, 31, 364–383. [Google Scholar] [CrossRef]

- Somna, R.; Jaturapitakkul, C.; Amde, A.M. Effect of ground fly ash and ground bagasse ash on the durability of recycled aggregate concrete. Cem. Concr. Compos. 2012, 34, 848–854. [Google Scholar] [CrossRef]

- Ann, K.Y.; Moon, H.Y.; Kim, Y.B.; Ryou, J. Durability of recycled aggregate concrete using pozzolanic materials. Waste Manag. 2008, 28, 993–999. [Google Scholar] [CrossRef]

- Lovato, P.S.; Possan, E.; Dal Molin, D.C.C.; Masuero, Â.B.; Ribeiro, J.L.D. Modeling of mechanical properties and durability of recycled aggregate concretes. Constr. Build. Mater. 2012, 26, 437–447. [Google Scholar] [CrossRef]

- Evangelista, L.; De Brito, J.M.C.L. Durability performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2010, 32, 9–14. [Google Scholar] [CrossRef]

- Bu, C.; Liu, L.; Lu, X.; Zhu, D.; Sun, Y.; Yu, L.; OuYang, Y.; Cao, X.; Wei, Q. The Durability of recycled fine aggregate Concrete: A Review. Materials 2022, 15, 1110. [Google Scholar] [CrossRef]

- Martínez-García, R.; de Rojas, M.S.; Jagadesh, P.; López-Gayarre, F.; Morán-del-Pozo, J.M.; Juan-Valdes, A. Effect of pores on the mechanical and durability properties on high strength recycled fine aggregate mortar. Case Stud. Constr. Mater. 2022, 16, e01050. [Google Scholar] [CrossRef]

- Martínez-García, R.; Rojas, M.I.S.D.; Pozo, J.M.M.D.; Fraile-Fernández, F.J.; Juan-Valdés, A. Evaluation of mechanical characteristics of cement mortar with fine recycled concrete aggregates (FRCA). Sustainability 2021, 13, 414. [Google Scholar] [CrossRef]

- Jiang, X.; Xiao, R.; Bai, Y.; Huang, B.; Ma, Y. Influence of waste glass powder as a supplementary cementitious material (SCM) on physical and mechanical properties of cement paste under high temperatures. J. Clean. Prod. 2022, 340, 130778. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T. Effect of fly ash fineness on compressive strength and pore size of blended cement paste. Cem. Concr. Compos. 2005, 27, 425–428. [Google Scholar] [CrossRef]

- Moradi, N.; Tavana, M.H.; Habibi, M.R.; Amiri, M.; Moradi, M.J.; Farhangi, V. Predicting the Compressive Strength of Concrete Containing Binary Supplementary Cementitious Material Using Machine Learning Approach. Materials 2022, 15, 5336. [Google Scholar] [CrossRef] [PubMed]

- Saha, A.K. Effect of class F fly ash on the durability properties of concrete. Sustain. Environ. Res. 2018, 28, 25–31. [Google Scholar] [CrossRef]

- Moffatt, E.G.; Thomas, M.D.; Fahim, A. Performance of high-volume fly ash concrete in marine environment. Cem. Concr. Res. 2017, 102, 127–135. [Google Scholar] [CrossRef]

- De Maeijer, P.K.; Craeye, B.; Snellings, R.; Kazemi-Kamyab, H.; Loots, M.; Janssens, K.; Nuyts, G. Effect of ultra-fine fly ash on concrete performance and durability. Constr. Build. Mater. 2020, 263, 120493. [Google Scholar] [CrossRef]

- Ross, A.D. Some problems in concrete construction. Mag. Concr. Res. 1960, 12, 27–34. [Google Scholar] [CrossRef]

- Bamforth, P. In situ measurement of the effect of partial Portland cement replacement using either fly ash or ground granulated blast-furnace slag on the performance of mass concrete. Proc. Inst. Civ. Eng. 1980, 69, 777–800. [Google Scholar] [CrossRef]

- Kristiawan, S.A.; Aditya, M.T.M. Effect of high volume fly ash on shrinkage of self-compacting concrete. Procedia Eng. 2015, 125, 705–712. [Google Scholar] [CrossRef]

- Özbay, E.; Erdemir, M.; Durmuş, H.İ. Utilization and efficiency of ground granulated blast furnace slag on concrete properties–A review. Constr. Build. Mater. 2016, 105, 423–434. [Google Scholar] [CrossRef]

- Li, K.; Zeng, Q.; Luo, M.; Pang, X. Effect of self-desiccation on the pore structure of paste and mortar incorporating 70% GGBS. Constr. Build. Mater. 2014, 51, 329–337. [Google Scholar] [CrossRef]

- El-Chabib, H.; Syed, A. Properties of Self-Consolidating Concrete Made with High Volumes of Supplementary Cementitious Materials. J. Mater. Civ. Eng. 2013, 25, 1579–1586. [Google Scholar] [CrossRef]

- Darquennes, A.; Rozière, E.; Khokhar, M.I.A.; Turcry, P.; Loukili, A.; Grondin, F. Long-term deformations and cracking risk of concrete with high content of mineral additions. Mater. Struct. 2012, 45, 1705–1716. [Google Scholar] [CrossRef]

- Brooks, J.J.; Wainwright, P.J.; Boukendakji, M. Influence of Slag Type and Replacement Level on Strength Elasticity, Shrinkage and Creep of Concrete. Spec. Publ. 1992, 132, 1325–1342. [Google Scholar]

- Liu, Z.; Takasu, K.; Koyamada, H.; Suyama, H. A study on engineering properties and environmental impact of sustainable concrete with fly ash or GGBS. Constr. Build. Mater. 2022, 316, 125776. [Google Scholar] [CrossRef]

- Qureshi, L.A.; Ali, B.; Ali, A. Combined effects of supplementary cementitious materials (silica fume, GGBS, fly ash and rice husk ash) and steel fiber on the hardened properties of recycled aggregate concrete. Constr. Build. Mater. 2020, 263, 120636. [Google Scholar] [CrossRef]

- Ahmad, J.; Martínez-García, R.; Szelag, M.; De-Prado-Gil, J.; Marzouki, R.; Alqurashi, M.; Hussein, E.E. Effects of Steel Fibers (SF) and Ground Granulated Blast Furnace Slag (GGBS) on Recycled Aggregate Concrete. Materials 2021, 14, 7497. [Google Scholar] [CrossRef]

- Kurad, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Effect of incorporation of high volume of recycled concrete aggregates and fly ash on the strength and global warming potential of concrete. J. Clean. Prod. 2017, 166, 485–502. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A.; Nawaz, M.A.; Aslam, H.M.U. Combined influence of fly ash and recycled coarse aggregates on strength and economic performance of concrete. Civ. Eng. J. 2019, 5, 832–844. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A.; Shah SH, A.; Rehman, S.U.; Hussain, I.; Iqbal, M. A step towards durable, ductile and sustainable concrete: Simultaneous incorporation of recycled aggregates, glass fiber and fly ash. Constr. Build. Mater. 2020, 251, 118980. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Anastasiou, E.; Filikas, K.G.; Stefanidou, M. Utilization of fine recycled aggregates in concrete with fly ash and steel slag. Constr. Build. Mater. 2014, 50, 154–161. [Google Scholar] [CrossRef]

- JIS A 5022; Recycled Aggregate Concrete-Class M. Japanese Industrial Standard Committee: Tokyo, Japan, 2018.

- JIS R 5210; Portland Cement. Japanese Industrial Standard Committee: Tokyo, Japan, 2019.

- JIS A 6201; Fly Ash for Use in Concrete. Japanese Industrial Standard Committee: Tokyo, Japan, 2015.

- JIS A 6206; Ground Granulated Blast-Furnace Slag for Concrete. Japanese Industrial Standard Committee: Tokyo, Japan, 2013.

- Japanese Architectural Standard Specification JASS 5 Reinforced Concrete Work, Japan. Available online: www.aij.or.jp/jpn/databox/2020/public_jass5-01.pdf (accessed on 20 December 2022).

- JIS A 1108; Method of Test for Compressive Strength of Concrete. Japanese Industrial Standard Committee: Tokyo, Japan, 2018.

- JIS A 1129-2; Method of Measurement for Length Change of Mortar and Concrete- Part 2: Method with Contact-Type Strain Gauge. Japanese Industrial Standard Committee: Tokyo, Japan, 2010.

- JIS A 1153; Method of Accelerated Carbonation Test for Concrete. Japanese Industrial Standard Committee: Tokyo, Japan, 2022.

- Termkhajornkit, P.; Nawa, T.; Nakai, M.; Saito, T. Effect of fly ash on autogenous shrinkage. Cem. Concr. Res. 2005, 35, 473–482. [Google Scholar] [CrossRef]

- Hu, X.; Shi, Z.G.; Shi, C.J.; Wu, Z.M.; Tong, B.H.; Ou, Z.H.; de Schutter, G. Drying shrinkage and cracking resistance of concrete made with ternary cementitious components. Constr. Build. Mater. 2017, 149, 406–415. [Google Scholar] [CrossRef]

- Atis, C.D. Heat evolution of high-volume fly ash concrete. Cem. Concr. Res. 2002, 32, 751–756. [Google Scholar] [CrossRef]

- Wang, L.; Yang, H.Q.; Zhou, S.H.; Chen, E.; Tang, S.W. Mechanical properties, long-term hydration heat, shrinkage behavior and crack resistance of dam concrete designed with low heat Portland (LHP) cement and fly ash. Constr. Build. Mater. 2018, 187, 1073–1091. [Google Scholar] [CrossRef]

- Yin, B.; Kang, T.; Kang, J.; Chen, Y.; Wu, L.; Du, M. Investigation of the hydration kinetics and microstructure formation mechanism of fresh fly ash cemented filling materials based on hydration heat and volume resistivity characteristics. Appl. Clay Sci. 2018, 166, 146–158. [Google Scholar] [CrossRef]

- Yoon, Y.S.; Won, J.P.; Woo, S.K. Enhanced durability performance of fly ash concrete for concrete-faced rockfill dam application. Cem. Concr. Res. 2002, 32, 23–30. [Google Scholar] [CrossRef]

- Bouzoubaâ, N.; Zhang, M.H.; Malhotra, V.M. Mechanical properties and durability of concrete made with high-volume fly ash blended cements using a coarse fly ash. Cem. Concr. Res. 2001, 31, 1393–1402. [Google Scholar] [CrossRef]

- De Matos, P.R.; Foiato, M.; Prudencio, L.R., Jr. Studies of the physical properties of hardened Portland cement paste—Part 8. The freezing of water in hardened Portland cement paste. Constr. Build. Mater. 2019, 203, 282–293. [Google Scholar]

- Termkhajornkit, P.; Nawa, T.; Kurumisawa, K. Effect of water curing conditions on the hydration degree and compressive strengths of fly ash–cement paste. Cem. Concr. Compos. 2006, 28, 781–789. [Google Scholar] [CrossRef]

- Jiang, D.B.; Li, X.G.; Lv, Y.; Zhou, M.K.; Li, C.J. Utilization of limestone powder and fly ash in blended cement: Rheology, strength and hydration characteristics. Constr. Build. Mater. 2020, 232, 117228. [Google Scholar] [CrossRef]

- Poon, C.S.; Lam, L.; Wong, Y.L. A study on high strength concrete prepared with large volumes of low calcium fly ash. Cem. Concr. Res. 2000, 30, 447–455. [Google Scholar] [CrossRef]

- Sakai, E.; Miyahara, S.; Ohsawa, S.; Lee, S.H.; Daimon, M. Hydration of fly ash cement. Cem. Concr. Res. 2005, 35, 1135–1140. [Google Scholar] [CrossRef]

- Oner, A.; Akyuz, S.; Yildiz, R. An experimental study on strength development of concrete containing fly ash and optimum usage of fly ash in concrete. Cem. Concr. Res. 2005, 35, 1165–1171. [Google Scholar] [CrossRef]

- Oner, A.; Akyuz, S. An experimental study on optimum usage of GGBS for the compressive strength of concrete. Cem. Concr. Compos. 2007, 29, 505–514. [Google Scholar] [CrossRef]

- Shariq, M.; Prasad, J.; Masood, A. Effect of GGBFS on time dependent compressive strength of concrete. Constr. Build. Mater. 2010, 24, 1469–1478. [Google Scholar] [CrossRef]

- Brooks, J.J.; Al-Kaisi, A.F. Early strength development of Portland and slag cement concretes cured at elevated temperatures. Mater. J. 1990, 87, 503–507. [Google Scholar]

- Zhao, Y.; Gong, J.; Zhao, S. Experimental study on shrinkage of HPC containing fly ash and ground granulated blast-furnace slag. Constr. Build. Mater. 2017, 155, 145–153. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E.; Özbay, E. Properties of self-compacting concretes made with binary, ternary, and quaternary cementitious blends of fly ash, blast furnace slag, and silica fume. Constr. Build. Mater. 2009, 23, 1847–1854. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Longman: London, UK, 1995; Volume 4. [Google Scholar]

- Wang, L.; Yu, Z.; Liu, B.; Zhao, F.; Tang, S.; Jin, M. Effects of fly ash dosage on shrinkage, crack resistance and fractal characteristics of face slab concrete. Fractal Fract. 2022, 6, 335. [Google Scholar] [CrossRef]

- Altoubat, S.; Talha Junaid, M.; Leblouba, M.; Badran, D. Effectiveness of fly ash on the restrained shrinkage cracking resistance of self-compacting concrete. Cem. Concr. Compos. 2017, 79, 9–20. [Google Scholar] [CrossRef]

- Yuan, J.; Lindquist, W.; Darwin, D.; Browning, J. Effect of slag cement on drying shrinkage of concrete. ACI Mater. J. 2015, 112, 267–276. [Google Scholar] [CrossRef]

- Li, J.; Yao, Y. A study on creep and drying shrinkage of high performance concrete. Cem. Concr. Res. 2001, 31, 1203–1206. [Google Scholar] [CrossRef]

- Yang, J.; Huang, J.; He, X.; Su, Y.; Tan, H.; Chen, W.; Wang, X.; Strnadel, B. Segmented fractal pore structure covering nano- and micro-ranges in cementing composites produced with GGBS. Constr. Build. Mater. 2019, 225, 1170–1182. [Google Scholar] [CrossRef]

- Weng, J.R.; Liao, W.C. Microstructure and shrinkage behavior of high-performance concrete containing supplementary cementitious materials. Constr. Build. Mater. 2021, 308, 125045. [Google Scholar] [CrossRef]

- Ignjatovic, I.; Carevic, V.; Sas, Z.; Dragas, J. High Volume Fly Ash Concrete: Part 2: Durability and Radiological Properties. In Proceedings of the Macedonian Association of Structural Engineers of the 17th International Symposium, Ohrid, Macedonia, 4–7 October 2017; pp. 700–709. [Google Scholar]

- Ashraf, W. Carbonation of cement-based materials: Challenges and opportunities. Constr. Build. Mater. 2016, 120, 558–570. [Google Scholar] [CrossRef]

- Lu, C.F.; Wang, W.; Li, Q.T.; Hao, M.; Xu, Y. Effects of micro-environmental climate on the carbonation depth and the pH value in fly ash concrete. J. Clean. Prod. 2018, 181, 309–317. [Google Scholar] [CrossRef]

- Liu, J.; Qiu, Q.; Chen, X.; Wang, X.; Xing, F.; Han, N.; He, Y. Degradation of fly ash concrete under the coupled effect of carbonation and chloride aerosol ingress. Corros. Sci. 2016, 112, 364–372. [Google Scholar] [CrossRef]

- Younsi, A.; Turcry, P.; Aït-Mokhtar, A.; Staquet, S. Accelerated carbonation of concrete with high content of mineral additions: Effect of interactions between hydration and drying. Cem. Concr. Res. 2013, 43, 25–33. [Google Scholar] [CrossRef]

- Castellote, M.; Fernandez, L.; Andrade, C.; Alonso, C. Chemical changes and phase analysis of OPC pastes carbonated at different CO2 concentrations. Mater. Struct. 2009, 42, 515–525. [Google Scholar] [CrossRef]

- Lye, C.-Q.; Dhir, R.K.; Ghataora, G.S. Carbonation resistance of GGBS concrete. Mag. Concr. Res. 2016, 68, 936–969. [Google Scholar] [CrossRef]

- Sulapha, P.; Wong, S.F.; Wee, T.H.; Swaddiwudhipong, S. Carbonation of concrete containing cementitious materials. J. Mater. Civ. Eng. 2003, 15, 134–143. [Google Scholar] [CrossRef]

- Jones, M.; Dhir, R.; Magee, B. Concrete containing ternary blended binders: Resistance to chloride ingress and carbonation. Cem. Concr. Res. 1997, 27, 825–831. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Carbonation of concrete made with high amount of fly ash and recycled concrete aggregates for utilization of CO2. J. CO2 Util. 2019, 29, 12–19. [Google Scholar] [CrossRef]

- Poon, C.S.; Lam, L.; Wong, Y.L. Effects of Fly Ash and Silica Fume on Interfacial Porosity of Concrete. J. Mater. Civ. Eng. 1999, 11, 197–205. [Google Scholar] [CrossRef]

- Yu, Z.; Ma, J.; Ye, G.; van Breugel, K.; Shen, X. Effect of fly ash on the pore structure of cement paste under a curing period of 3 years. Constr. Build. Mater. 2017, 144, 493–501. [Google Scholar] [CrossRef]

- Yu, Z.; Ni, C.; Tang, M.; Shen, X. Relationship between water permeability and pore structure of Portland cement paste blended with fly ash. Constr. Build. Mater. 2018, 175, 458–466. [Google Scholar] [CrossRef]

- Mindess, S.; Young, F.; Darwin, D. Concrete 2nd Edition; Technical Documents; Prentice Hall: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Mehta, P.; Monteiro, P. Concrete Microstructure, Properties and Materials; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Wu, Z.; Lian, H. High Performance Concrete; China Railway Publication House: Beijing, China, 1999. [Google Scholar]

- Ho, H.-L.; Huang, R.; Lin, W.-T.; Cheng, A. Pore-structures and durability of concrete containing pre-coated fine recycled mixed aggregates using pozzolan and polyvinyl alcohol materials. Constr. Build. Mater. 2018, 160, 278–292. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).