Effects of Recycled Rubber Particles Incorporated as Partial Sand Replacement on Fresh and Hardened Properties of Cement-Based Concrete: Mechanical, Microstructural and Life Cycle Analyses

Abstract

:1. Introduction

2. Materials and Methods

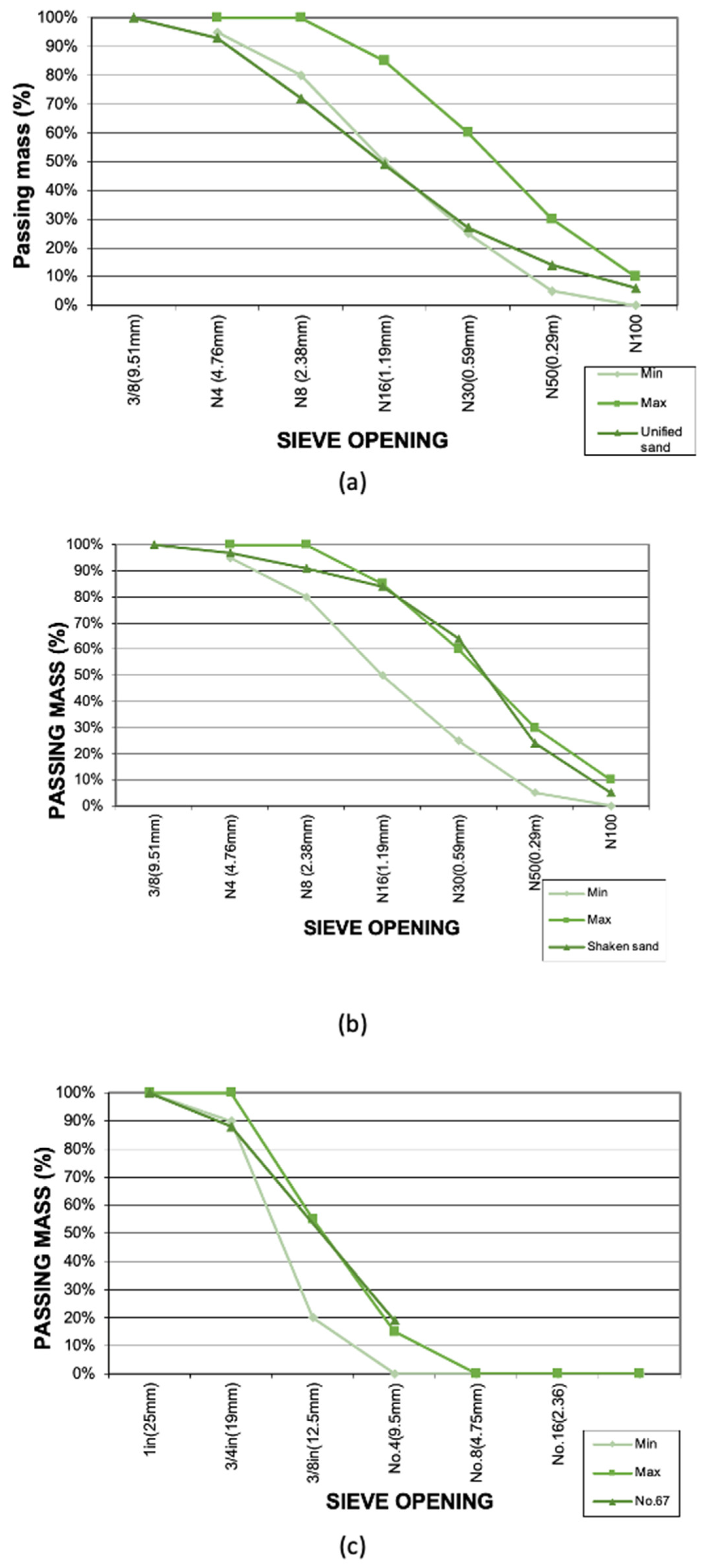

2.1. Materials

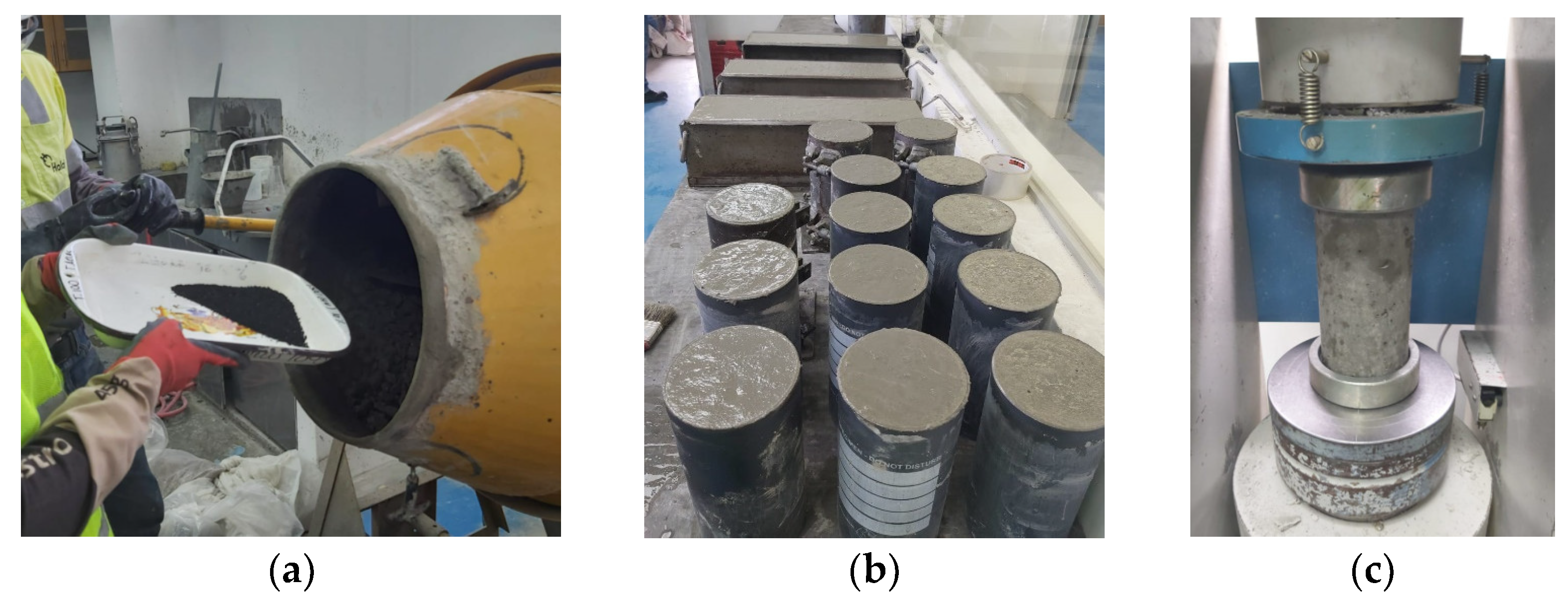

2.2. Methods

2.3. Fresh Concrete Tests

2.4. Hardened Concrete Tests

3. Results

3.1. Fresh Concrete Properties

3.1.1. Slump

3.1.2. Air Content

3.1.3. Density

3.2. Hardened Concrete Properties

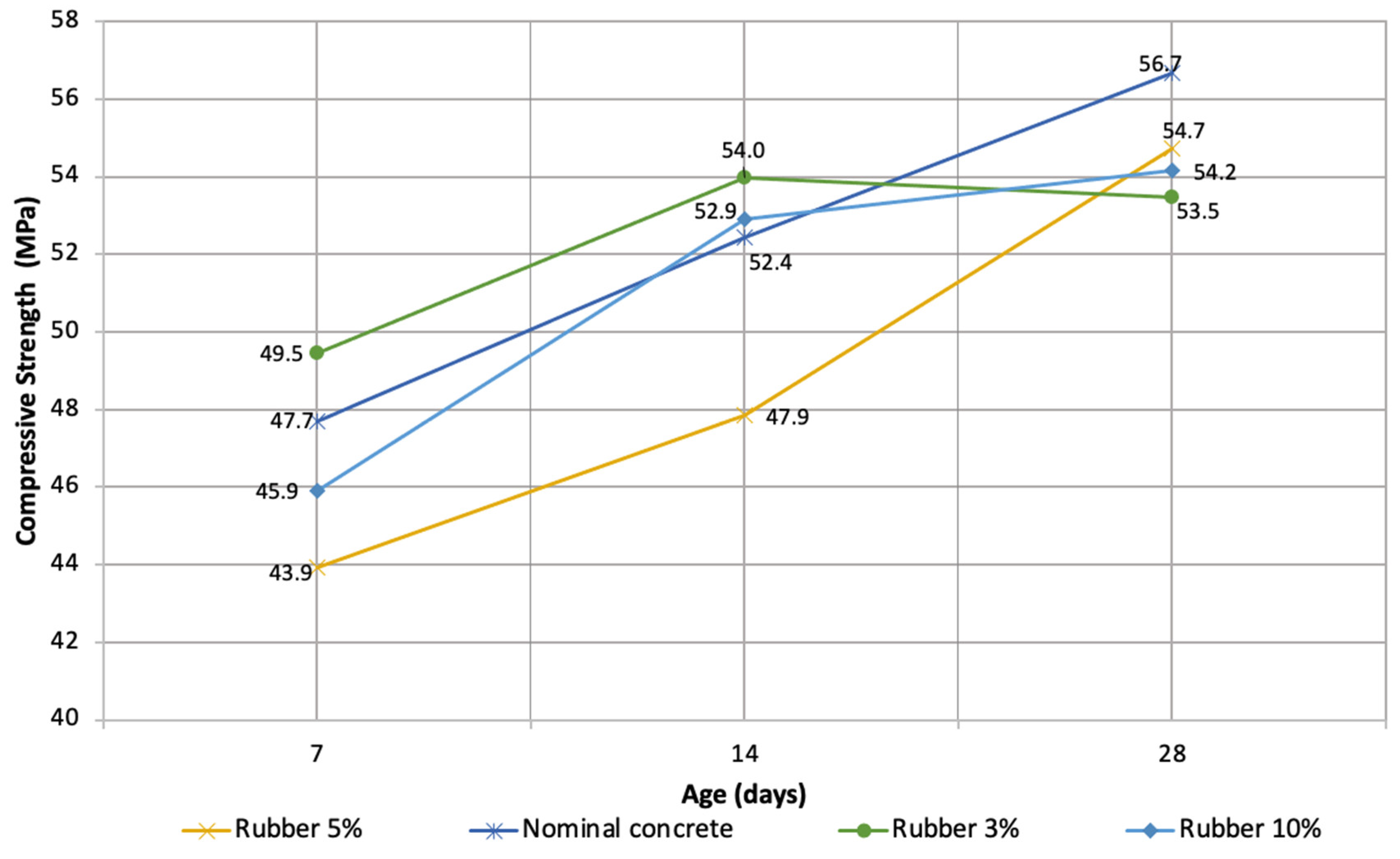

3.2.1. Compressive Strength

3.2.2. Flexural Strength

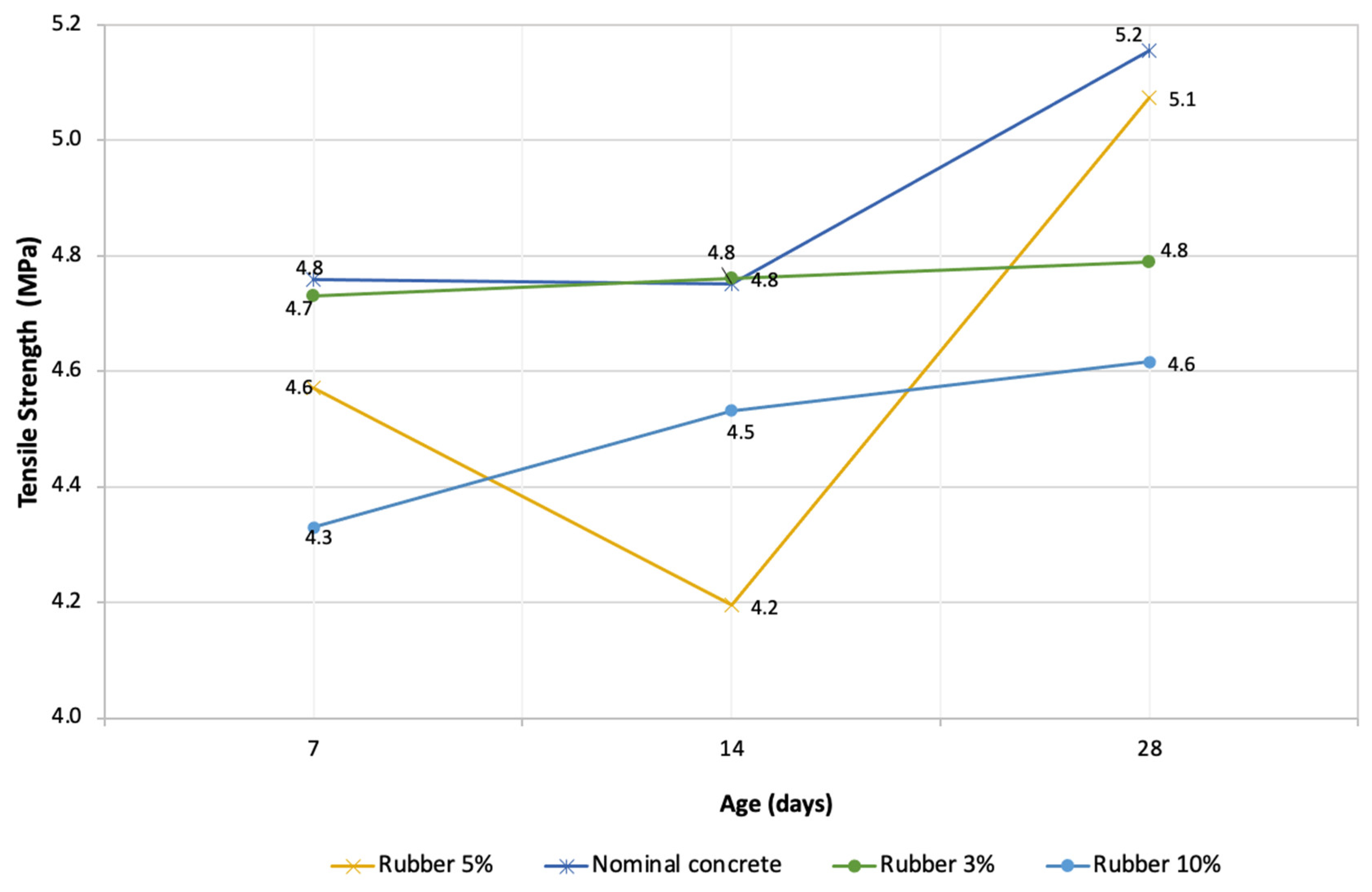

3.2.3. Tensile Strength

3.2.4. Modulus of Elasticity

3.2.5. Pulse Velocity

3.2.6. Rebound Number

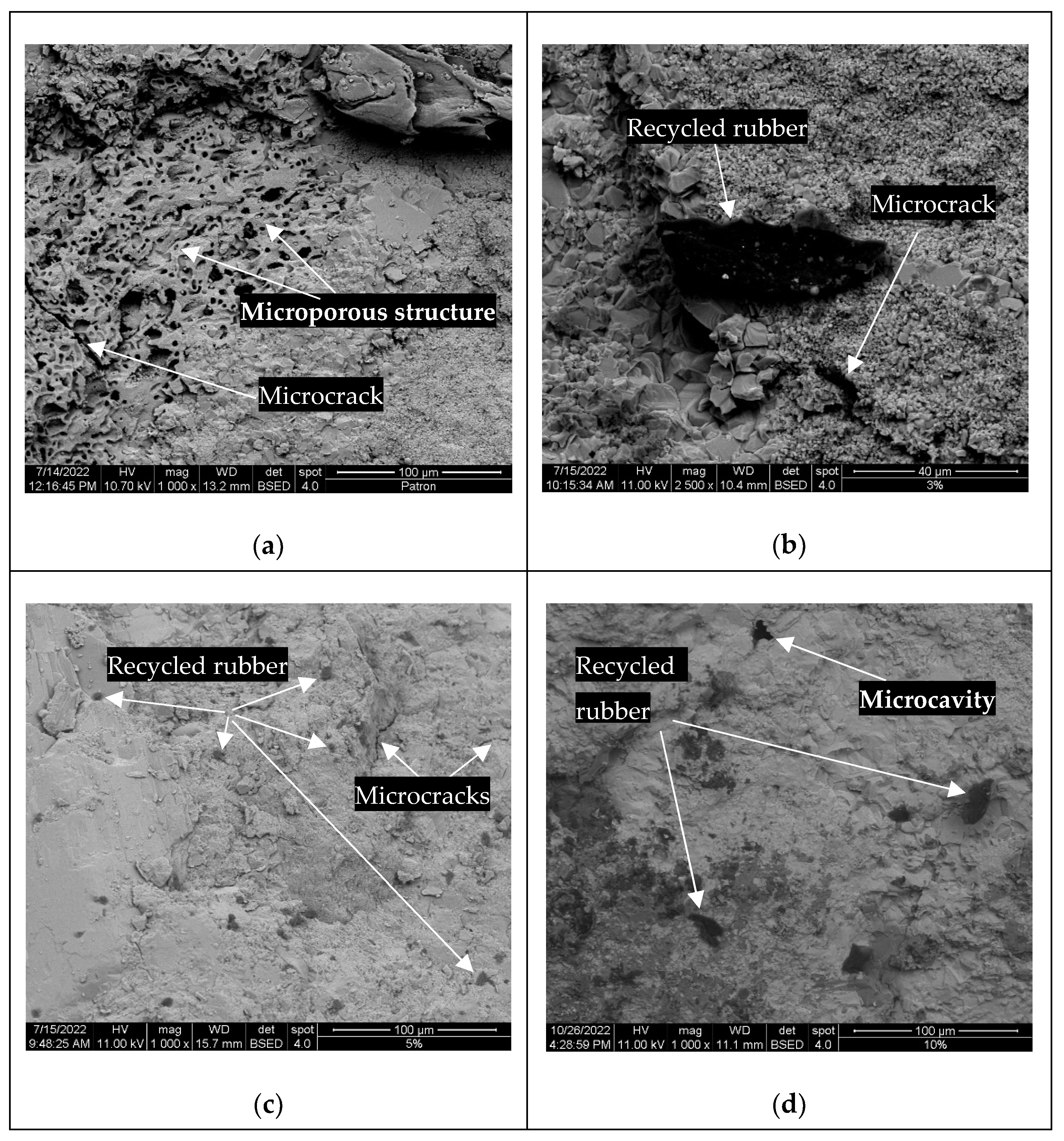

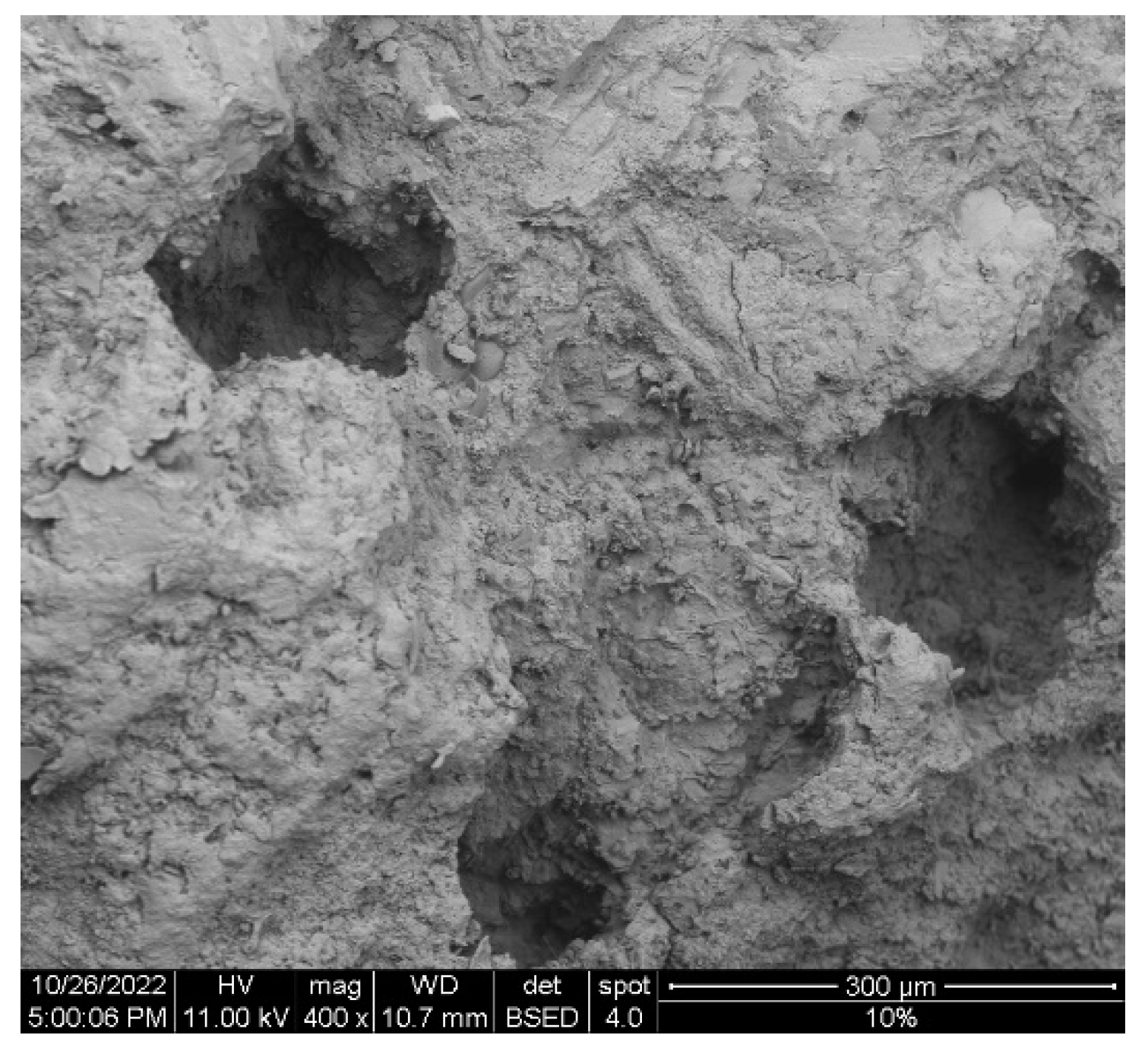

3.2.7. Microstructural Analysis

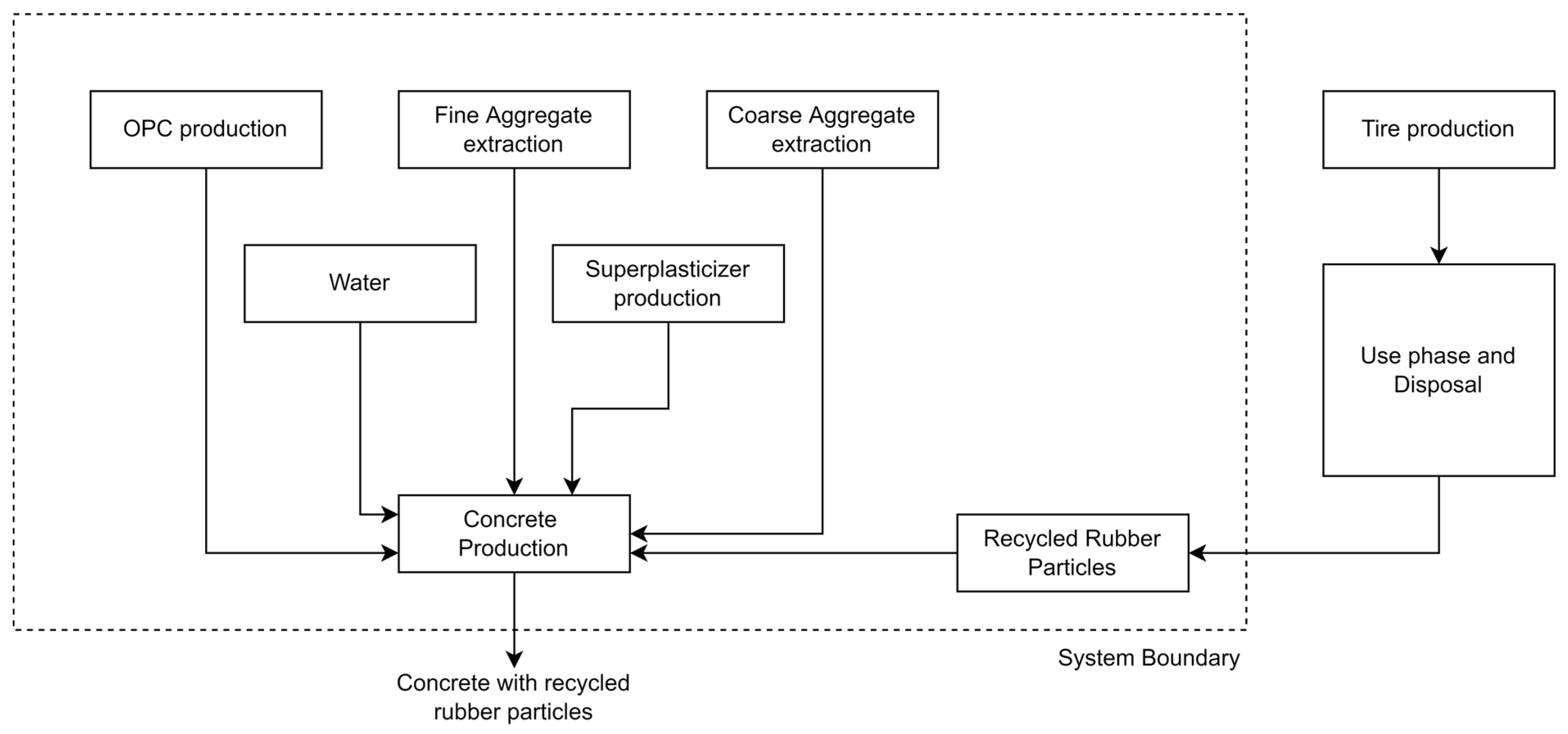

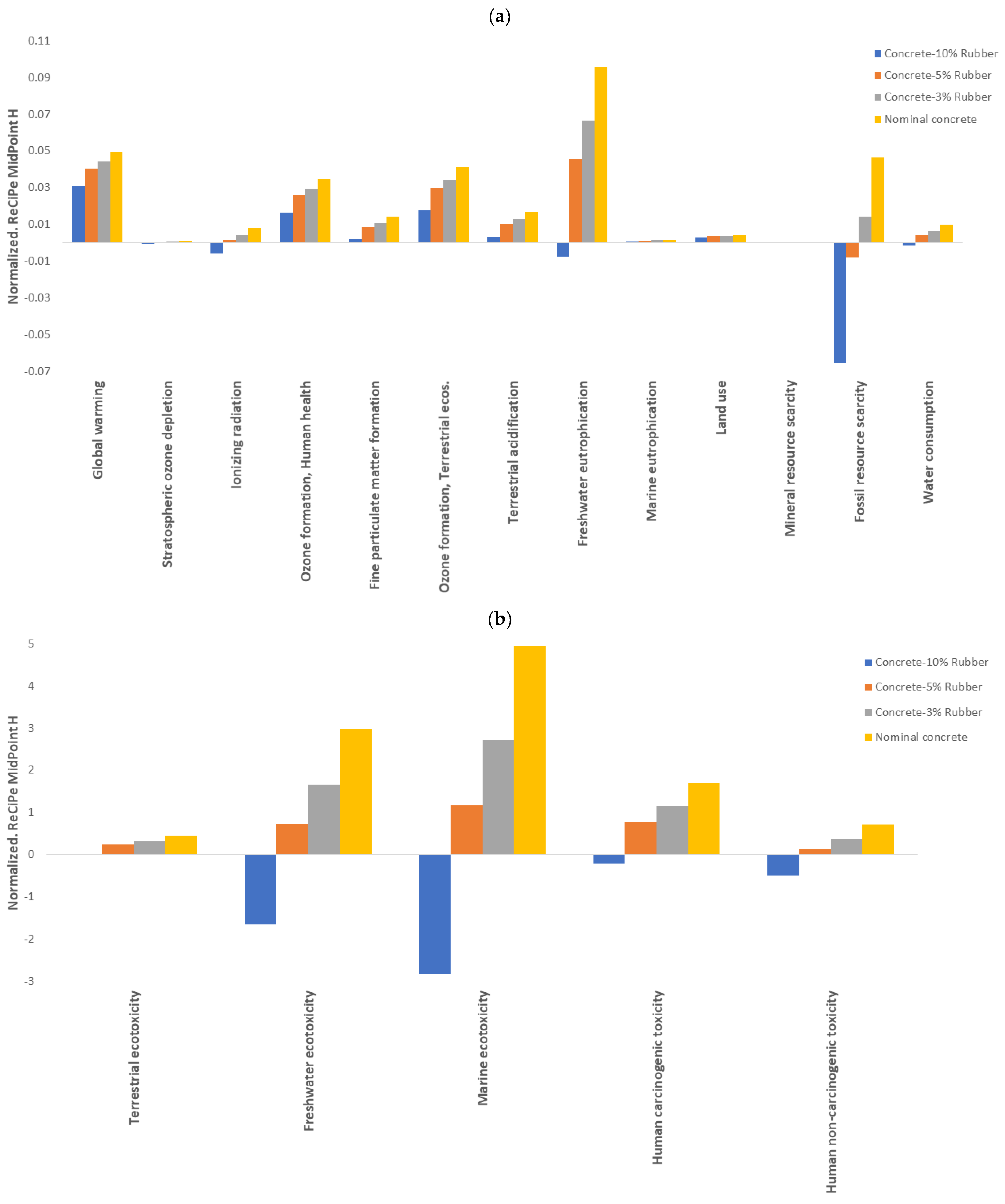

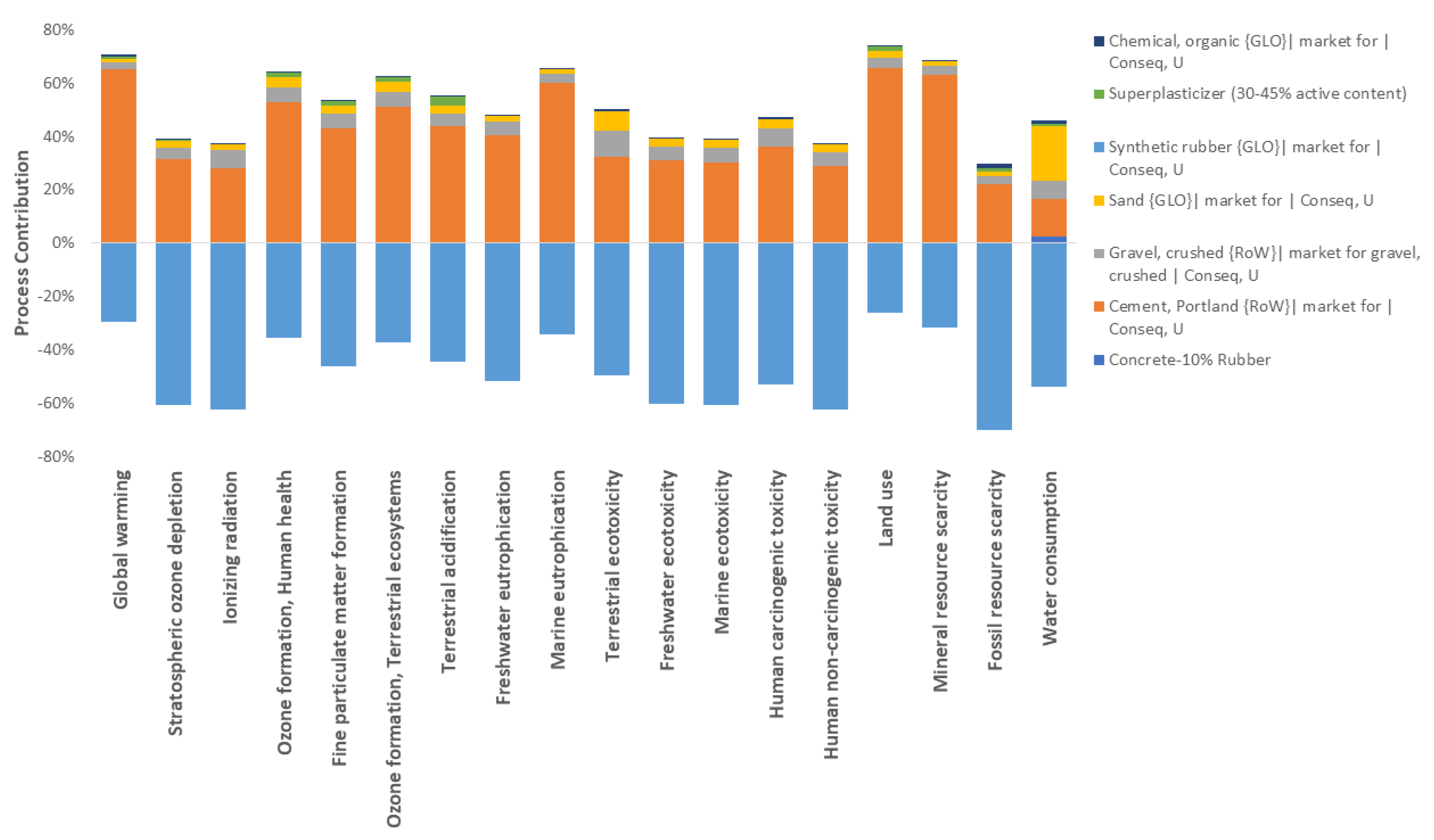

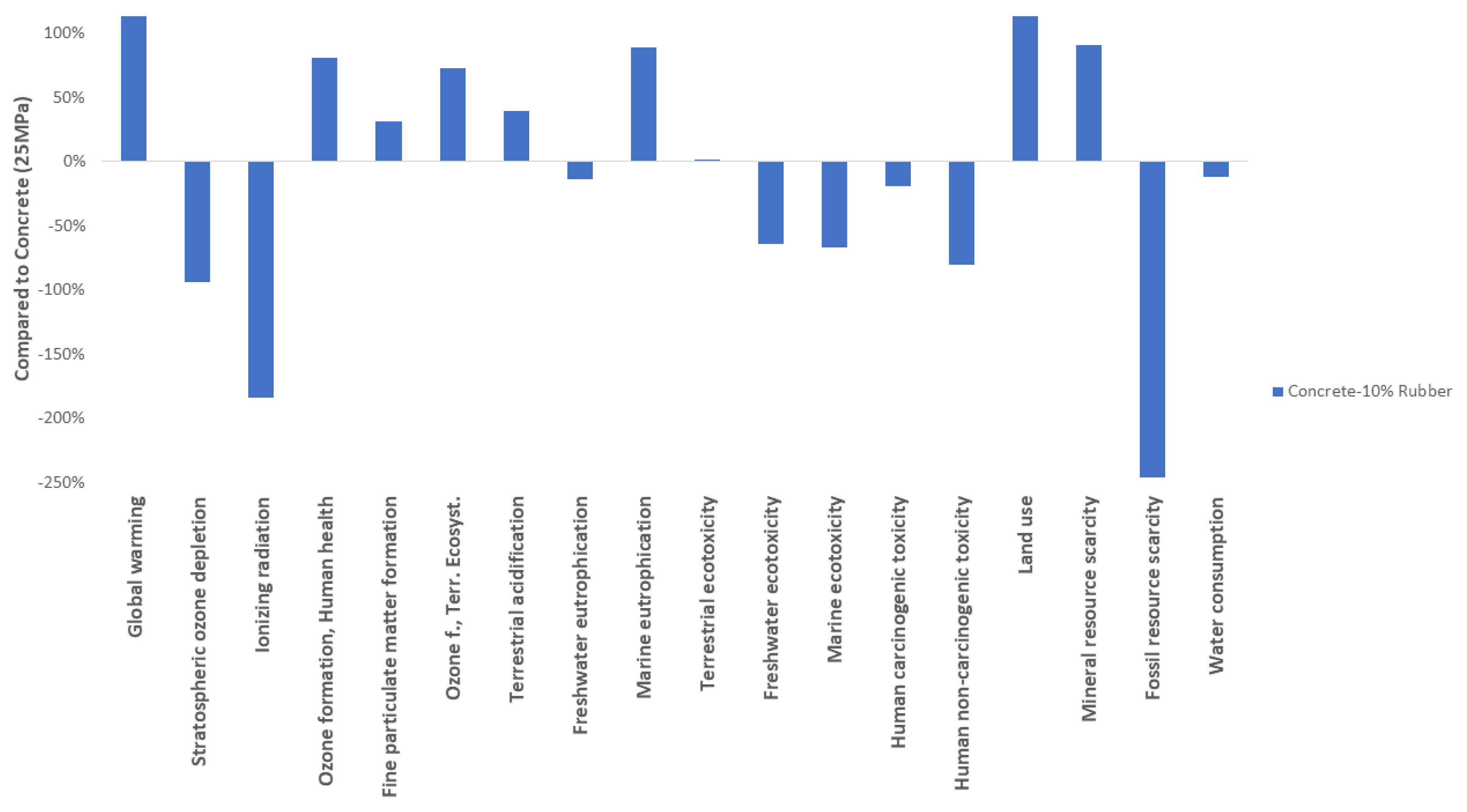

4. Life Cycle Assessment (LCA)

4.1. Inventory

4.2. Discussion

5. Conclusions

- Recycled rubber does not significantly alter the mechanical properties of fresh concrete and aged concrete for up to 28 days. Additionally, the use of recycled rubber can be used to reduce the environmental impact;

- Up to 5% of recycled rubber as a replacement for fine aggregate is feasible considering the mechanical properties of the desired concrete;

- The life cycle assessment showed a reduction of up to 40% in the global warming potential. In fact, the 15% recycled rubber concrete mix has a climate change indicator of approximately 245 kg of CO2 eq, which means that the global warming potential significantly decreases with the increase in the amount of recycled rubber used in the concrete as fine aggregate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ruddock, L.; Lopes, J. The construction sector and economic development: The ‘Bon curve’. Constr. Manag. Econ. 2006, 24, 717–723. [Google Scholar] [CrossRef]

- Harmsen, T.E. Diseño de Estructuras de Concreto Armado; PUCP, Fondo Editorial: Lima, Peru, 2005. [Google Scholar]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A. Environmental impact of cement production: Detail of the different processes and cement plant variability evaluation. J. Clean. Prod. 2010, 18, 478–485. [Google Scholar] [CrossRef]

- Alias, C.; Feretti, D.; Benassi, L.; Abbà, A.; Gelatti, U.; Sorlini, S.; Zerbini, I.; Piovani, G. The release of contaminants from steel slags and natural aggregates: Evaluation of toxicity and genotoxicity. Environ. Mol. Mutagen. 2020, 62, 66–77. [Google Scholar] [CrossRef] [PubMed]

- Sabău, M.; Bompa, D.V.; Silva, L.F. Comparative carbon emission assessments of recycled and natural aggregate concrete: Environmental influence of cement content. Geosci. Front. 2021, 12, 101235. [Google Scholar] [CrossRef]

- Prakash, R.; Divyah, N.; Srividhya, S.; Avudaiappan, S.; Amran, M.; Raman, S.N.; Guindos, P.; Vatin, N.I.; Fediuk, R. Effect of Steel Fiber on the Strength and Flexural Characteristics of Coconut Shell Concrete Partially Blended with Fly Ash. Materials 2022, 15, 4272. [Google Scholar] [CrossRef] [PubMed]

- Raman, S.; Ngo, T.; Mendis, P.; Mahmud, H. High-strength rice husk ash concrete incorporating quarry dust as a partial substitute for sand. Constr. Build. Mater. 2011, 25, 3123–3130. [Google Scholar] [CrossRef]

- Divyah, N.; Prakash, R.; Srividhya, S.; Sivakumar, A. Parametric study on lightweight concrete-encased short columns under axial compression-Comparison of design codes. Struct. Eng. Mech. 2022, 83, 387–400. [Google Scholar] [CrossRef]

- Barcelo, L.; Kline, J.; Walenta, G.; Gartner, E. Cement and carbon emissions. Mater. Struct. 2013, 47, 1055–1065. [Google Scholar] [CrossRef]

- Prakash, R.; Thenmozhi, R.; Raman, S.N. Mechanical characterisation and flexural performance of eco-friendly concrete produced with fly ash as cement replacement and coconut shell coarse aggregate. Int. J. Environ. Sustain. Dev. 2019, 18, 131–148. [Google Scholar] [CrossRef]

- Prakash, R.; Thenmozhi, R.; Raman, S.N.; Subramanian, C.; Divyah, N. An investigation of key mechanical and durability properties of coconut shell concrete with partial replacement of fly ash. Struct. Concr. 2020, 22, E985–E996. [Google Scholar] [CrossRef]

- Prakash, R.; Raman, S.N.; Subramanian, C.; Divyah, N. 6—Eco-friendly fiber-reinforced concretes. In Woodhead Publishing Series in Civil and Structural Engineering, Handbook of Sustainable Concrete and Industrial Waste Management; Woodhead Publishing: Sawston, UK, 2022; pp. 109–145. ISBN 9780128217306. [Google Scholar] [CrossRef]

- Prakash, R.; Thenmozhi, R.; Sudharshan, N.R. Fibre reinforced concrete containing waste coconut shell aggregate, fly ash and polypropylene fibre. Rev. Fac. De Ing. Univ. De Antioq. (REDIN) 2020, 33–42. Available online: https://www.redalyc.org/journal/430/43062873004/ (accessed on 25 January 2022). [CrossRef] [Green Version]

- Bedoya, C.; Dzul, L. El concreto con agregados reciclados como proyecto de sostenibilidad urbana. Rev. Ing. Construcción 2015, 30, 99–108. [Google Scholar] [CrossRef] [Green Version]

- Ghose, M.; Majee, S. Air pollution caused by opencast mining and its abatement measures in India. J. Environ. Manag. 2001, 63, 193–202. [Google Scholar] [CrossRef]

- Ghose, M.K. Effect of opencast mining on soil fertility. JSIR 2004, 63, 1006–1009. [Google Scholar]

- Garcia-Troncoso, N.; Xu, B.; Probst-Pesantez, W. Development of Concrete Incorporating Recycled Aggregates, Hydrated Lime and Natural Volcanic Pozzolan. Infrastructures 2021, 6, 155. [Google Scholar] [CrossRef]

- Kambli, P.S.; Mathapati, S.R.; Student, P.G. Application of coconut shell as coarse aggregate in concrete: A technical review. IJERA 2014, 4, 498–501. [Google Scholar]

- Keshavarz, Z.; Mostofinejad, D. Porcelain and red ceramic wastes used as replacements for coarse aggregate in concrete. Constr. Build. Mater. 2019, 195, 218–230. [Google Scholar] [CrossRef]

- Olanipekun, E.; Olusola, K.; Ata, O. A comparative study of concrete properties using coconut shell and palm kernel shell as coarse aggregates. Build. Environ. 2006, 41, 297–301. [Google Scholar] [CrossRef]

- Debieb, F.; Kenai, S. The use of coarse and fine crushed bricks as aggregate in concrete. Constr. Build. Mater. 2008, 22, 886–893. [Google Scholar] [CrossRef]

- Eo, S.-H.; Yi, S.-T. Effect of oyster shell as an aggregate replacement on the characteristics of concrete. Mag. Concr. Res. 2015, 67, 833–842. [Google Scholar] [CrossRef]

- Bamigboye, G.O.; Okara, O.; Bassey, D.E.; Jolayemi, K.J.; Ajimalofin, D. The use of Senilia senilis seashells as a substitute for coarse aggregate in eco-friendly concrete. J. Build. Eng. 2020, 32, 101811. [Google Scholar] [CrossRef]

- Karolina, R.; Syahrizal; Putra, M.; Prasetyo, T.A. Optimization of the Use of Volcanic Ash of Mount Sinabung Eruption as the Substitution for Fine Aggregate. Procedia Eng. 2015, 125, 669–674. [Google Scholar] [CrossRef] [Green Version]

- Hasan-Ghasemi, A.; Nematzadeh, M. Tensile and compressive behavior of self-compacting concrete incorporating PET as fine aggregate substitution after thermal exposure: Experiments and modeling. Constr. Build. Mater. 2021, 289, 123067. [Google Scholar] [CrossRef]

- Al-Jabri, K.S.; Al-Saidy, A.H.; Taha, R. Effect of copper slag as a fine aggregate on the properties of cement mortars and concrete. Constr. Build. Mater. 2010, 25, 933–938. [Google Scholar] [CrossRef]

- Ullah, K.; Qureshi, M.I.; Ahmad, A.; Ullah, Z. Substitution potential of plastic fine aggregate in concrete for sustainable production. Structures 2021, 35, 622–637. [Google Scholar] [CrossRef]

- Ruslan, H.N.; Muthusamy, K.; Ariffin, N.F.; Wahab, M.M.A.; Mohamad, N. Effect of crushed cockle shell as partial fine aggregate replacement on workability and strength of lightweight concrete. Mater. Today Proc. 2021, 48, 1826–1830. [Google Scholar] [CrossRef]

- Gupta, T.; Chaudhary, S.; Sharma, R.K. Assessment of mechanical and durability properties of concrete containing waste rubber tire as fine aggregate. Constr. Build. Mater. 2014, 73, 562–574. [Google Scholar] [CrossRef]

- Dawood, A.O.; Al-Khazraji, H.; Falih, R.S. Physical and mechanical properties of concrete containing PET wastes as a partial replacement for fine aggregates. Case Stud. Constr. Mater. 2020, 14, e00482. [Google Scholar] [CrossRef]

- Garcia-Troncoso, N.; Baykara, H.; Cornejo, M.H.; Riofrio, A.; Tinoco-Hidalgo, M.; Flores-Rada, J. Comparative mechanical properties of conventional concrete mixture and concrete incorporating mining tailings sands. Case Stud. Constr. Mater. 2022, 16, e01031. [Google Scholar] [CrossRef]

- Althoey, F.; Hosen, A. Physical and Mechanical Characteristics of Sustainable Concrete Comprising Industrial Waste Materials as a Replacement of Conventional Aggregate. Sustainability 2021, 13, 4306. [Google Scholar] [CrossRef]

- Cement Premium. Available online: https://www.portaldirecta.com/portaldirecta/ec/CEMENTO_PREMIUM_G.pdf (accessed on 20 November 2022).

- Idriss, L.K.; Gamal, Y.A.S. Properties of Rubberized Concrete Prepared from Different Cement Types. Recycling 2022, 7, 39. [Google Scholar] [CrossRef]

- Asutkar, P.; Shinde, S.; Patel, R. Study on the behaviour of rubber aggregates concrete beams using analytical approach. Eng. Sci. Technol. Int. J. 2017, 20, 151–159. [Google Scholar] [CrossRef] [Green Version]

- ASTM C1157; Standard Performance Specification for Hydraulic Cement. ASTM International: West Conshohocken, PA USA, 2020.

- ASTM C-33; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA USA, 2008.

- ASTM C-494 Type D; Standard Specification for Chemical Admixtures for Concrete: Water-Reducing and Retarding Admixtures. ASTM International: West Conshohocken, PA, USA, 2017.

- Sika Retarder. Available online: https://ecu.sika.com/content/dam/dms/ec01/f/Sika_Retarder_PDS.pdf (accessed on 20 November 2021).

- ASTM C—494 Type A and F; Standard Specification for Chemical Admixtures for Concrete: Water-Reducing Admixtures and Water-Reducing, High Range Admixtures. ASTM International: West Conshohocken, PA, USA, 2017.

- Vargas-Moreno, K. Evaluación de las Propiedades Mecánicas del Hormigón Con Fibras de Caucho Comparado Con el Hormigón Simple. Undergraduate Thesis, Universidad de Especialidades Espiritu Santo, Samborondon, Ecuador, 2022. [Google Scholar]

- Datasheet form ECSASE.S.A. Available online: https://www.ecsade.com (accessed on 26 February 2022).

- ASTM C566; Standard Test Method for Total Evaporable Moisture Content of Aggregate by Drying. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C127; Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C136; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2019.

- ACI 211.1-91; Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. ASTM International: West Conshohocken, PA, USA, 2002.

- ASTM C31; Standard Practice for Making and Curing Concrete Test Specimens in the Field. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C192; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C143; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C138; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C231; Standard Practice for Use of Unbonded Caps in Determination of Compressive Strength of Hardened Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C496; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C78; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C469; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C597; Standard Test Method for Pulse Velocity Through Concrete. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C805; Standard Test Method for Rebound Number of Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2018.

- Hormigon Hidraulico Especificaciones. 120–2014. Available online: https://es.scribd.com/document/399590432/NC-120 (accessed on 15 November 2021).

- Ling, T.-C. Prediction of density and compressive strength for rubberized concrete blocks. Constr. Build. Mater. 2011, 25, 4303–4306. [Google Scholar] [CrossRef]

- Stallings, K.A.; Durham, S.A.; Chorzepa, M.G. Effect of cement content and recycled rubber particle size on the performance of rubber-modified concrete. Int. J. Sustain. Eng. 2018, 12, 189–200. [Google Scholar] [CrossRef]

- Bisht, K.; Ramana, P. Evaluation of mechanical and durability properties of crumb rubber concrete. Constr. Build. Mater. 2017, 155, 811–817. [Google Scholar] [CrossRef]

- Ho, A.C.; Turatsinze, A.; Hameed, R.; Vu, D.C. Effects of rubber aggregates from grinded used tyres on the concrete resistance to cracking. J. Clean. Prod. 2012, 23, 209–215. [Google Scholar] [CrossRef]

- Yahya, Z.; Abdullah, M.M.A.B.; Ramli, N.M.; Burduhos-Nergis, D.D.; Razak, R.A. Influence of Kaolin in Fly Ash Based Geopolymer Concrete: Destructive and Non-Destructive Testing. IOP Conf. Ser. Mater. Sci. Eng. 2018, 374. [Google Scholar] [CrossRef]

- ISO/TC 207/SC 5; ISO 14040: Environmental Management–Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- European Commission; Joint Research Centre; Institute for Environment and Sustainability. 2010 International Reference Life Cycle Data System (ILCD) Handbook—General guide for Life Cycle Assessment—Detailed Guidance; European Commission: Brussels, Belgium, 2011. [Google Scholar] [CrossRef]

- Pré-Sustainability B.V. 2019 SimaPro Software v9.0. Available online: https://simapro.com/ (accessed on 26 February 2022).

- European Federation of Concrete Admixture Associations (EFCA). Environmental Declaration Superplasticizing Admixtures; Environmental Consultant INTRON B.V.: Sittard, The Netherlands, 2002; Available online: https://swe.sika.com/dms/getdocument.get/60b7f6a6-92fc-36b7-ae01-45e0c48e395d/SuperplasticizerED.pdf (accessed on 26 February 2022).

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Riofrio, A.; Alcivar, T.; Baykara, H. Environmental and Economic Viability of Chitosan Production in Guayas-Ecuador: A Robust Investment and Life Cycle Analysis. ACS Omega 2021, 6, 23038–23051. [Google Scholar] [CrossRef]

- Gravina, R.J.; Xie, T. Toward the development of sustainable concrete with Crumb Rubber: Design-oriented Models, Life-Cycle-Assessment and a site application. Constr. Build. Mater. 2022, 315, 125565. [Google Scholar] [CrossRef]

- Fiksel, J.; Bakshi, B.; Baral, A.; Guerra, E.; DeQuervain, B. Comparative life cycle assessment of beneficial applications for scrap tires. Clean Technol. Environ. Policy 2010, 13, 19–35. [Google Scholar] [CrossRef]

- Nascimento, F.; Gouveia, B.; Dias, F.; Ribeiro, F.; Silva, M.A. A method to select a road pavement structure with life cycle assessment. J. Clean. Prod. 2020, 271, 122210. [Google Scholar] [CrossRef]

| Chemical Composition | Portland cement clinker Gypsum Natural pozzolans |

| Physical properties | Change in length per autoclave −0.04% Setting time, Vicat method: 150 min |

| Air content of the mortar: 3% Minimum compressive strength

|

| Nominal Concrete | Rubber 3% | Rubber 5% | Rubber 10% | |

|---|---|---|---|---|

| Cement | 10.92 | 11.06 | 11.85 | 11.85 |

| No.67 | 24.63 | 24.94 | 27.02 | 26.75 |

| River sand | 17.79 | 16.73 | 17.06 | 14.88 |

| Crushed sand | 8.65 | 8.30 | 8.38 | 7.27 |

| Rubber | 0.00 | 0.53 | 0.95 | 1.89 |

| Water | 3.92 | 3.65 | 3.75 | 4.13 |

| Superplasticizer | 0.055 | 0.055 | 0.059 | 0.059 |

| Retarder | 0.131 | 0.133 | 0.142 | 0.142 |

| Property | Slump [mm] | Air Content [%] | Density [kg/m3] |

|---|---|---|---|

| Nominal | 220 | 2.0 | 2360 |

| 3% | 215 | 2.0 | 2355 |

| 5% | 220 | 1.5 | 2360 |

| 10% | 220 | 1.3 | 2364 |

| Property | Compressive Strength (MPa) | Splitting Tensile Strength (MPa) | Flexural Strength (MPa) | |||||

|---|---|---|---|---|---|---|---|---|

| Age (days) | 7 | 14 | 28 | 7 | 14 | 28 | 7 | 28 |

| Nominal | 47.679 | 52.422 | 56.679 | 4.759 | 4.752 | 5.155 | 4.46 | 5.05 |

| 3% | 49.456 | 53.957 | 53.481 | 4.731 | 4.761 | 4.789 | 4.21 | 5.35 |

| 5% | 43.939 | 47.863 | 54.720 | 4.571 | 4.195 | 5.074 | 4.78 | 4.69 |

| 10% | 45.892 | 52.910 | 54.159 | 4.330 | 4.532 | 4.616 | 5.4 | 5.33 |

| Design | Modulus of Elasticity [GPa] |

|---|---|

| Nominal concrete | 32.91 |

| 3% | 31.76 |

| 5% | 30.43 |

| 10% | 23.15 |

| Property | Ultrasonic Pulse Velocity (km/s) | Rebound Number | Average Compressive Strength (MPa) |

|---|---|---|---|

| Nominal | 4.504 | 50.00 | 56.50 |

| 3% | 5.239 | 49.80 | 56.20 |

| 5% | 4.518 | 54.00 | 63.20 |

| 10% | 4.500 | 50.80 | 57.80 |

| Products | ||

| Nominal concrete | 66.096 | kg |

| Resources | ||

| Water, unspecified natural origin, EC | 3.92 | l |

| Materials/fuels | ||

| Cement, Portland {RoW}|market for|Conseq, U | 10.96 | kg |

| Gravel, crushed {RoW}|market for gravel, crushed|Conseq, U | 24.63 | kg |

| Sand {GLO}| market for|Conseq, U | 26.44 | kg |

| Synthetic rubber {GLO}|market for|Conseq, U | 0 | kg |

| Superplasticizer (30–45% active content) | 0.131 | kg |

| Chemical, organic {GLO}|market for|Conseq, U | 0.055 | kg |

| Impact Indicator | Unit | Concrete-10% Rubber | Concrete-5% Rubber | Concrete-3% Rubber | Nominal Concrete |

|---|---|---|---|---|---|

| Global warming | kg CO2 eq | 2.44 × 102 | 3.34 × 102 | 3.46 × 102 | 3.96 × 102 |

| Stratospheric ozone depletion | kg CFC11 eq | −1.97 × 10−5 | 2.14 × 10−5 | 3.55 × 10−5 | 7.59 × 10−5 |

| Ionizing radiation | kBq Co-60 eq | −5.45 | −1.52 | 5.78 × 10−2 | 3.96 |

| Ozone formation, Human health | kg NOx eq | 4.95 × 10−1 | 7.22 × 10−1 | 7.59 × 10−1 | 7.17 × 10−1 |

| Fine particulate matter formation | kg PM2.5 eq | 8.84 × 10−2 | 2.50 × 10−1 | 2.94 × 10−1 | 3.64 × 10−1 |

| Ozone formation, Terrestrial ecosystems | kg NOx eq | 4.79 × 10−1 | 7.28 × 10−1 | 7.73 × 10−1 | 7.31 × 10−1 |

| Terrestrial acidification | kg SO2 eq | 2.10 × 10−1 | 4.84 × 10−1 | 5.55 × 10−1 | 6.92 × 10−1 |

| Freshwater eutrophication | kg P eq | 1.74 × 10−2 | 4.76 × 10−2 | 5.58 × 10−2 | 6.23 × 10−2 |

| Marine eutrophication | kg N eq | −1.69 × 10−3 | 5.54 × 10−4 | 1.36 × 10−3 | 7.78 × 10−3 |

| Terrestrial ecotoxicity | kg 1,4-DCB | −9.41 | 2.11 × 102 | 2.79 × 102 | 4.66 × 102 |

| Freshwater ecotoxicity | kg 1,4-DCB | −4.68 | −2.44 × 10−1 | 1.44 | 3.66 |

| Marine ecotoxicity | kg 1,4-DCB | −6.22 | −2.39 × 10−1 | 2.03 | 5.11 |

| Human carcinogenic toxicity | kg 1,4-DCB | −1.82 | 1.45 | 2.58 | 4.73 |

| Human non-carcinogenic toxicity | kg 1,4-DCB | −1.24 × 102 | 3.79 | 5.17 × 101 | 1.06 × 102 |

| Land use | m2a crop eq | 6.96 | 1.20 × 101 | 1.31 × 101 | 2.66 × 101 |

| Mineral resource scarcity | kg Cu eq | 8.30 × 10−1 | 1.15 | 1.19 | 2.05 |

| Fossil resource scarcity | kg oil eq | −6.62 × 101 | −6.88 | 1.60 × 101 | 4.57 × 101 |

| Water consumption | m3 | −1.37 | 2.63 × 10−1 | 8.71 × 10−1 | 2.64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garcia-Troncoso, N.; Acosta-Calderon, S.; Flores-Rada, J.; Baykara, H.; Cornejo, M.H.; Riofrio, A.; Vargas-Moreno, K. Effects of Recycled Rubber Particles Incorporated as Partial Sand Replacement on Fresh and Hardened Properties of Cement-Based Concrete: Mechanical, Microstructural and Life Cycle Analyses. Materials 2023, 16, 63. https://doi.org/10.3390/ma16010063

Garcia-Troncoso N, Acosta-Calderon S, Flores-Rada J, Baykara H, Cornejo MH, Riofrio A, Vargas-Moreno K. Effects of Recycled Rubber Particles Incorporated as Partial Sand Replacement on Fresh and Hardened Properties of Cement-Based Concrete: Mechanical, Microstructural and Life Cycle Analyses. Materials. 2023; 16(1):63. https://doi.org/10.3390/ma16010063

Chicago/Turabian StyleGarcia-Troncoso, Natividad, Samantha Acosta-Calderon, Jorge Flores-Rada, Haci Baykara, Mauricio H. Cornejo, Ariel Riofrio, and Katherine Vargas-Moreno. 2023. "Effects of Recycled Rubber Particles Incorporated as Partial Sand Replacement on Fresh and Hardened Properties of Cement-Based Concrete: Mechanical, Microstructural and Life Cycle Analyses" Materials 16, no. 1: 63. https://doi.org/10.3390/ma16010063

APA StyleGarcia-Troncoso, N., Acosta-Calderon, S., Flores-Rada, J., Baykara, H., Cornejo, M. H., Riofrio, A., & Vargas-Moreno, K. (2023). Effects of Recycled Rubber Particles Incorporated as Partial Sand Replacement on Fresh and Hardened Properties of Cement-Based Concrete: Mechanical, Microstructural and Life Cycle Analyses. Materials, 16(1), 63. https://doi.org/10.3390/ma16010063