Novel Pectin Binder for Satelliting Carbides to H13 Tool Steel for PBF-LB Processing

Abstract

:1. Introduction

1.1. Motivation

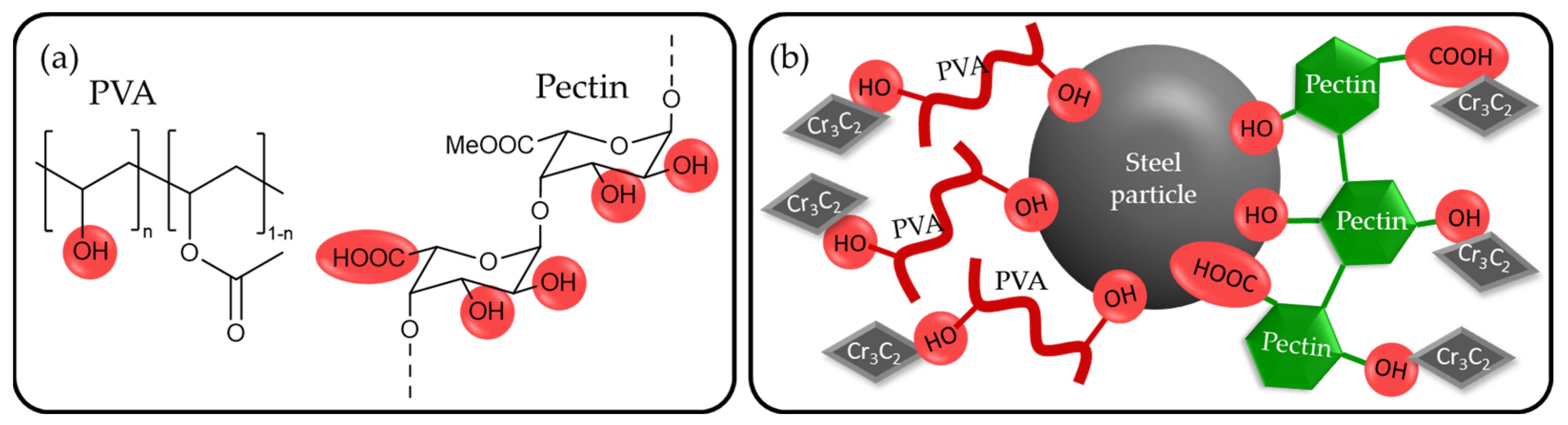

1.2. Polymer Binders: Polyvinyl Alcohol versus Pectin

2. Materials and Methods

2.1. Materials

2.2. Powder Feedstock Preparation

2.3. Binder and Feedstock Analysis

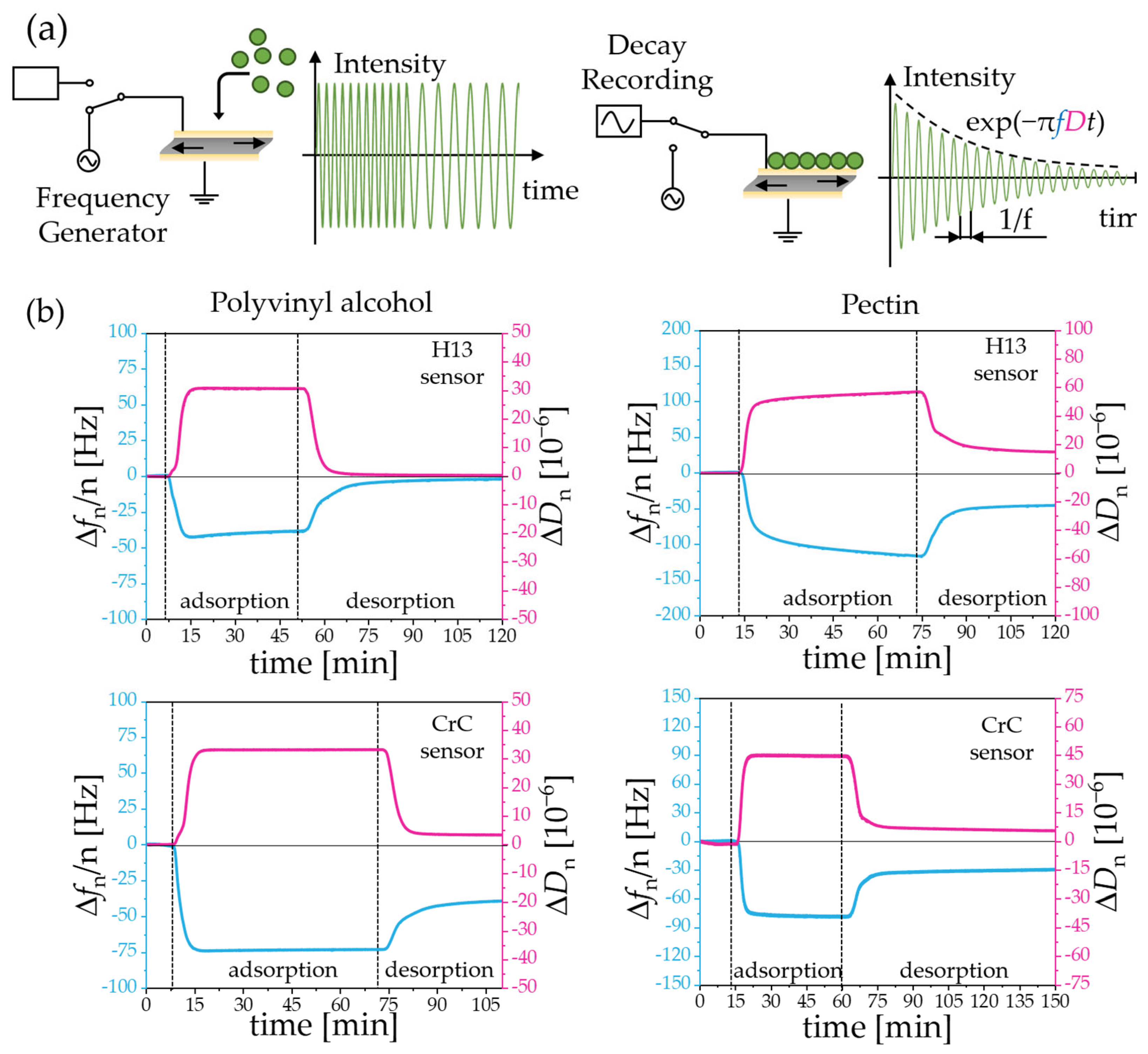

2.3.1. Quartz-Crystal Microbalance with Dissipation (QCM-D)

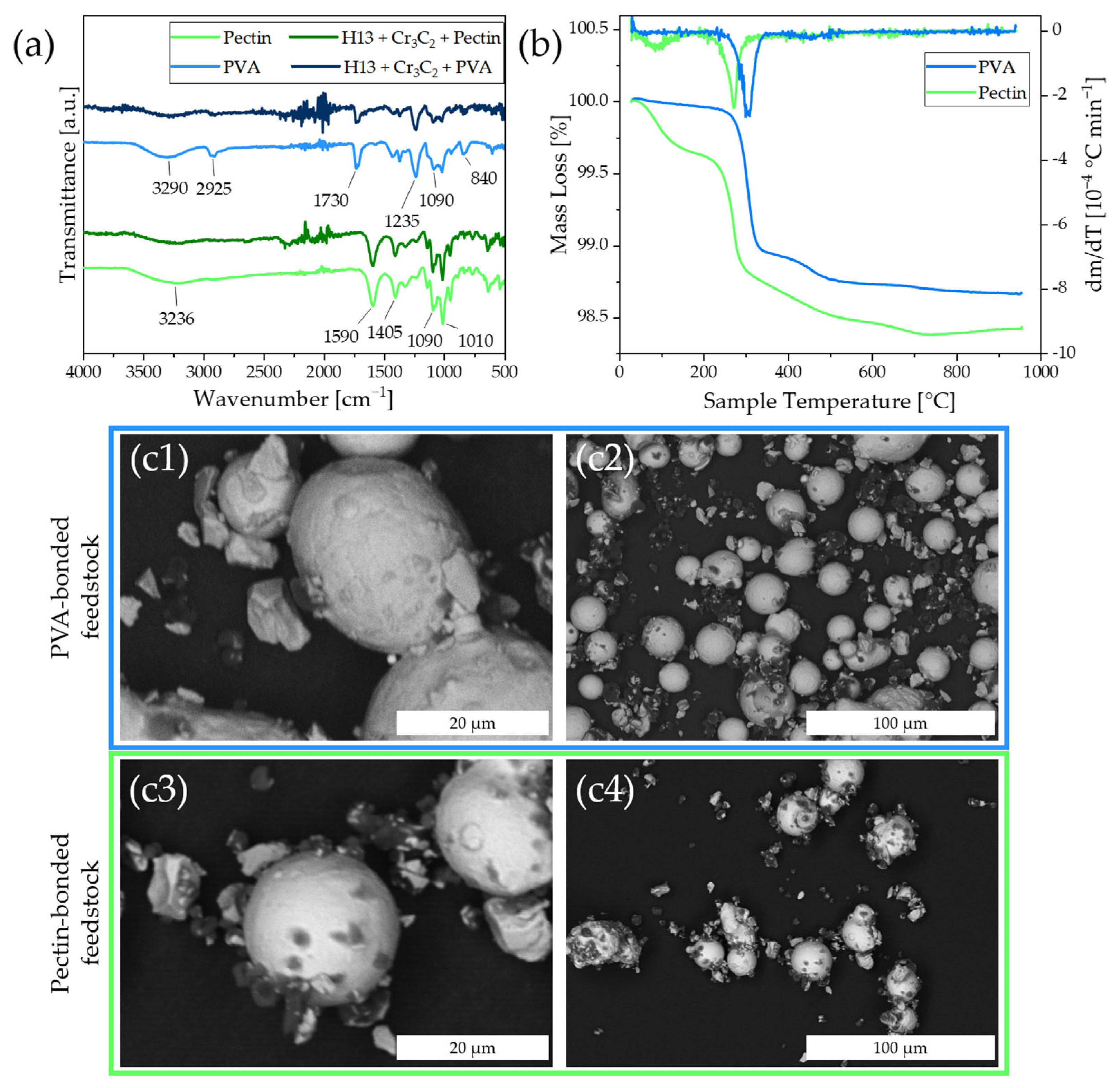

2.3.2. Attenuated Total Reflection Fourier Transform Infrared Spectroscopy (ATR-FTIR)

2.3.3. Thermogravimetric Analysis (TGA)

2.3.4. Scanning Electron Microscopy—Energy-Dispersive X-ray Spectroscopy (SEM-EDS)

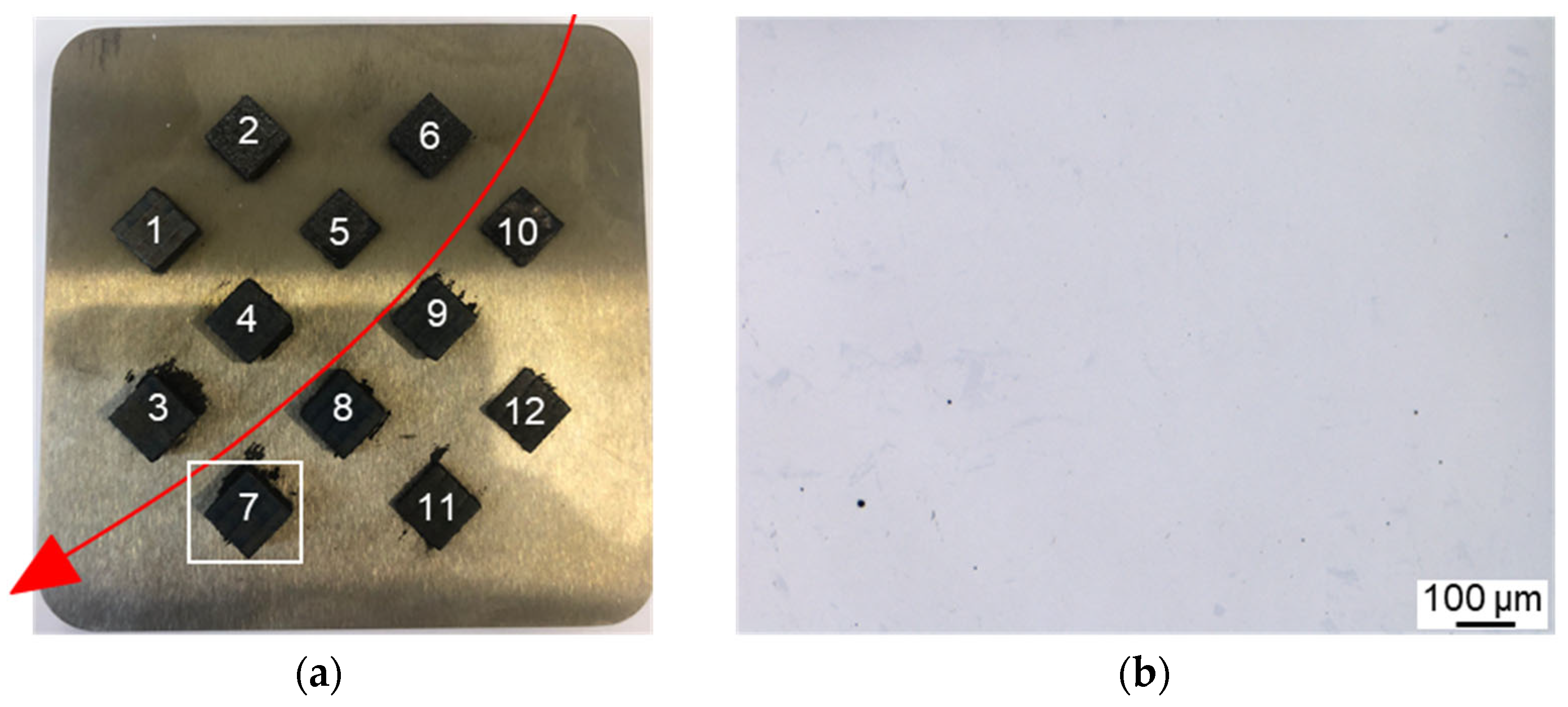

2.4. Powder Application and PBF-LB/M Processing

2.5. Microstructural Analysis

3. Results

3.1. QCM-D Reveals That Pectin Irreversibly Adsorbs to Steel, in Contrast to PVA

3.2. Spray Drying Yields Steel Powder Satellited with Chromium Carbide by PVA or Pectin

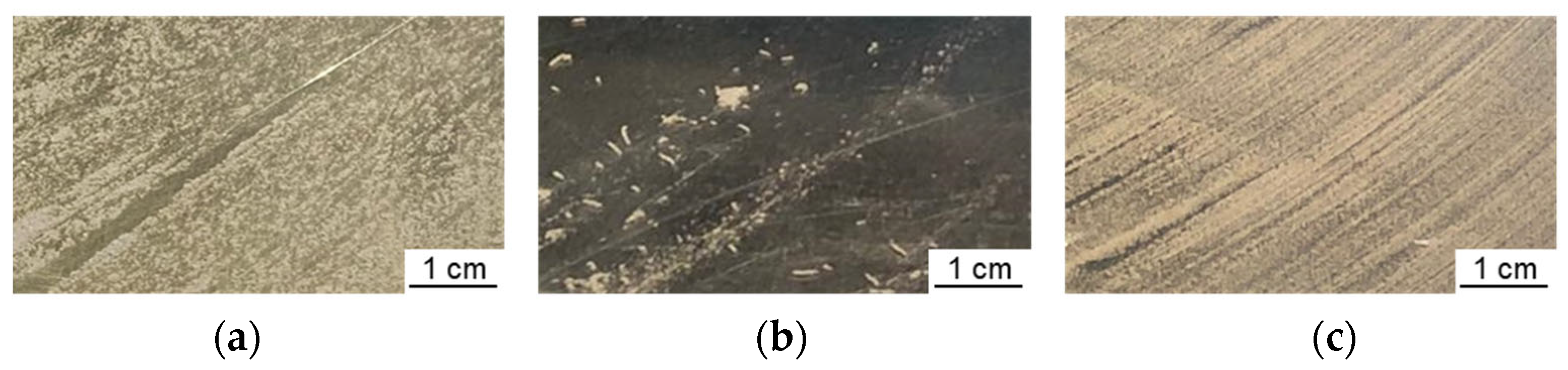

3.3. Powder Application and PBF-LB/M Processing

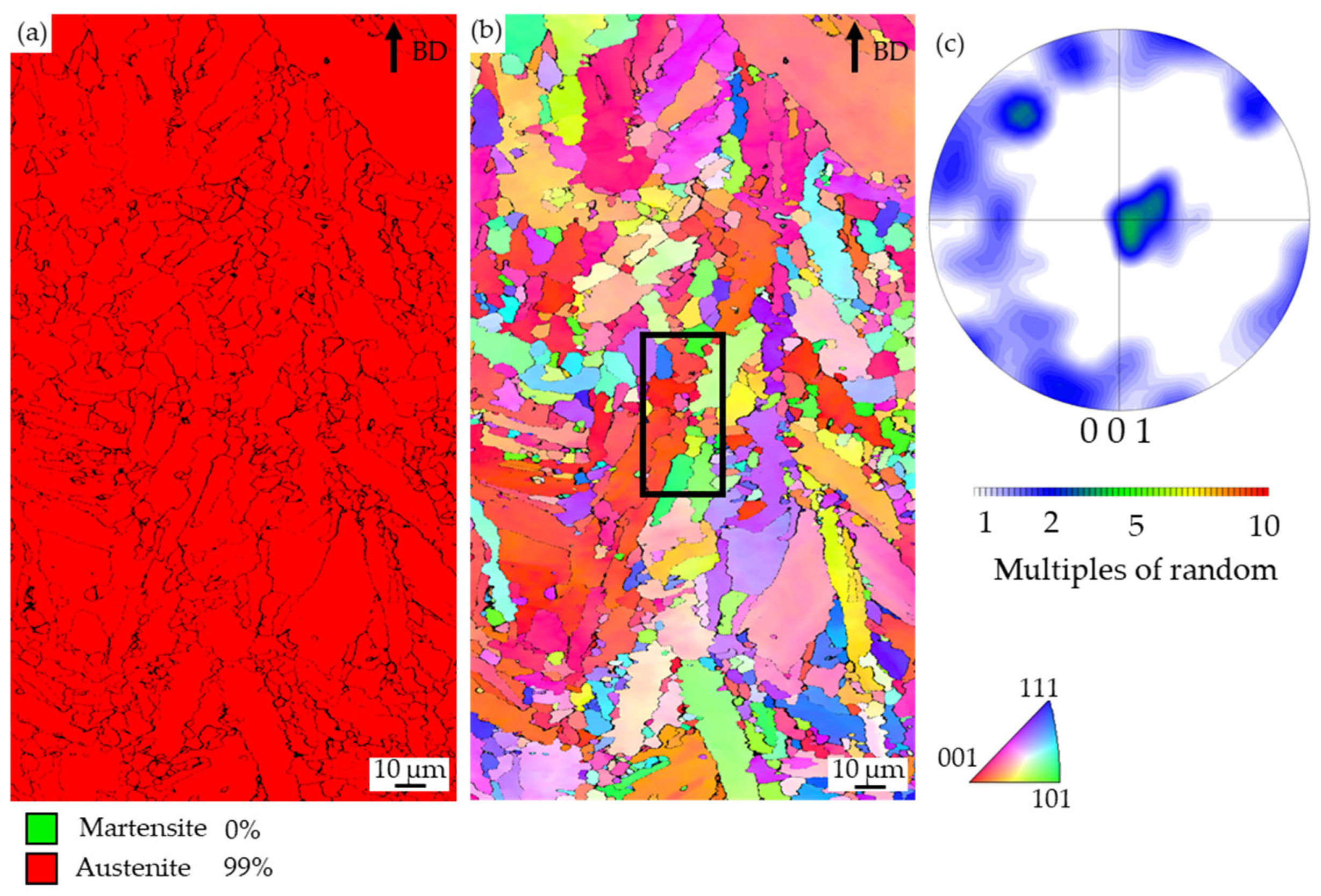

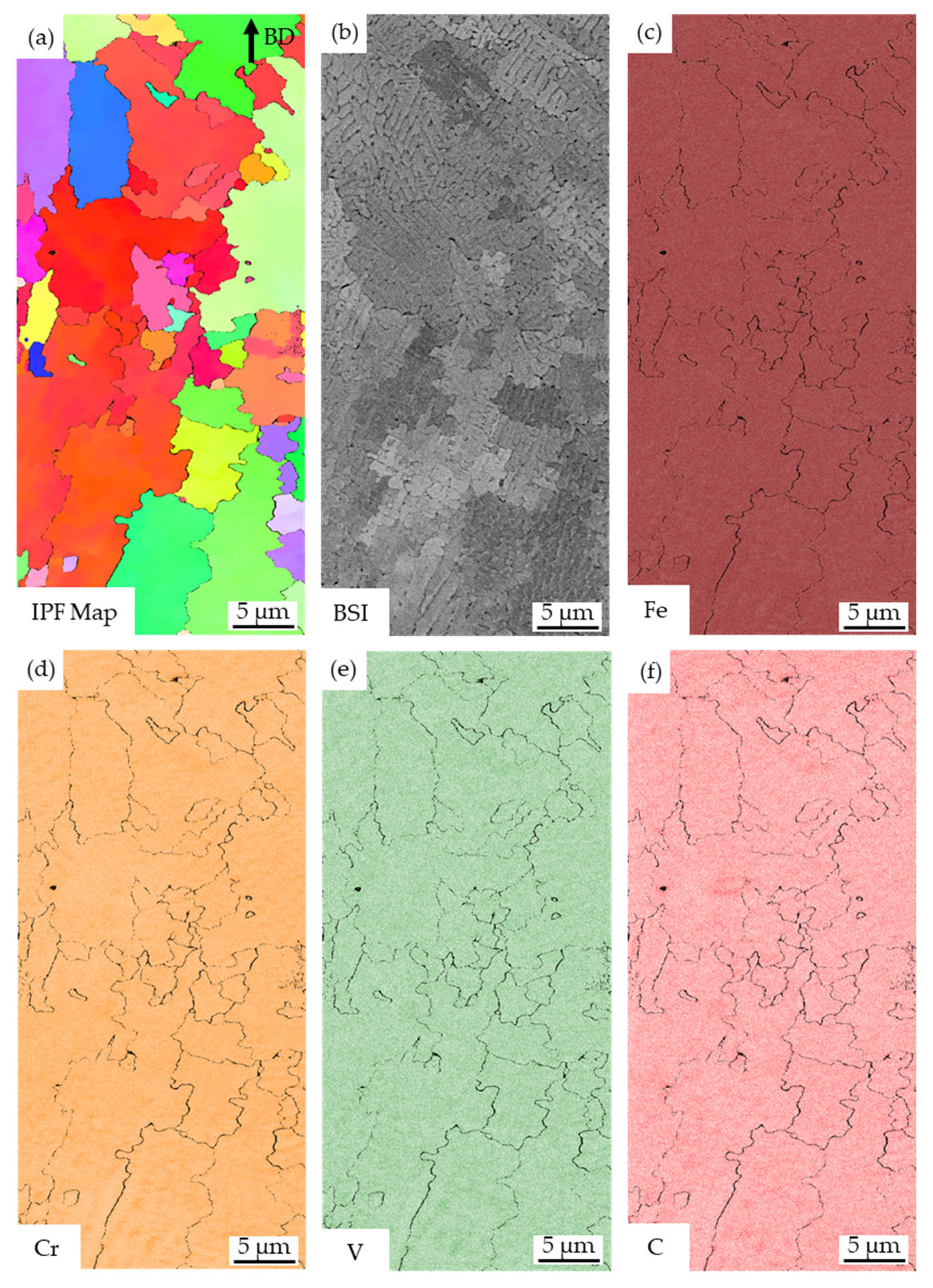

3.4. Microstructural Analysis

4. Discussion

4.1. Powder Feedstock—Preparation and Characteristics

4.2. Powder Application and PBF-LB/M Processing

4.3. Microstructure Analysis

5. Conclusions

- The potential of pectin as a biobased binder for the satelliting process was shown. It adsorbs on the surface of the steel and carbide and enhances the adhesion of small carbide particles to larger steel particles.

- The PVA-bonded alloy as a benchmark for the satelliting process shows significantly reduced processability at pre-heating temperatures of the substrate plate of 500 °C.

- The pectin-bonded alloy could be applied at 500 °C and specimens were built-up from the pectin-bonded alloy.

- The chemical gradients over the substrate plate related to the particle size can be reduced by using a by pectin satellited feedstock compared to a simple powder blend. The adhesion of the carbide particles to the steel particles via pectin is stable enough to endure the mechanical forces of the recoating unit on the feedstock.

- The carbon content within the specimens of the satellited feedstock is enhanced, possibly being a resulting effect of the organic nature of the binder. The binder content in this initial study is 2 wt.% and will be reduced in future studies. The effect of the carbon enrichment will be analyzed carefully.

- The processing parameters used provide adequate mixing of all alloying components in the melt pool. No cracks were found, the porosity lay well below 0.1% and the chemical composition was homogenous, and no C or Cr enrichments related to an inhomogeneous Cr3C2 distribution were found.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chou, C.-Y.; Pettersson, N.H.; Durga, A.; Zhang, F.; Oikonomou, C.; Borgenstam, A.; Odqvist, J.; Lindwall, G. Influence of solidification structure on austenite to martensite transformation in additively manufactured hot-work tool steels. Acta Mater. 2021, 215, 117044. [Google Scholar] [CrossRef] [PubMed]

- Qin, S.; Bo, Y.; Herzog, S.; Hallstedt, B.; Kaletsch, A.; Broeckmann, C. Influence of Process Parameters on Porosity and Hot Cracking of AISI H13 Fabricated by Laser Powder Bed Fusion. Powders 2022, 1, 184–193. [Google Scholar] [CrossRef]

- Katancik, M.; Mirzababaei, S.; Ghayoor, M.; Pasebani, S. Selective laser melting and tempering of H13 tool steel for rapid tooling applications. J. Alloys Compd. 2020, 849, 156319. [Google Scholar] [CrossRef]

- Geenen, K.; Röttger, A.; Feld, F.; Theisen, W. Microstructure, mechanical, and tribological properties of M3:2 high-speed steel processed by selective laser melting, hot-isostatic pressing, and casting. Addit. Manuf. 2019, 28, 585–599. [Google Scholar] [CrossRef]

- Kwok, C.; Cheng, F.; Man, H. Microstructure and corrosion behavior of laser surface-melted high-speed steels. Surf. Coat. Technol. 2007, 202, 336–348. [Google Scholar] [CrossRef]

- Lee, E.-S.; Park, W.-J.; Jung, J.Y.; Ahn, S. Solidification microstructure and M2C carbide decomposition in a spray-formed high-speed steel. Metall. Mater. Trans. A 1998, 29, 1395–1404. [Google Scholar] [CrossRef]

- Tang, G.; Xu, F.; Fan, G.; Ma, X.; Wang, L. Mechanisms of microstructure formations in M50 steel melted layer by high current pulsed electron beam. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2012, 288, 1–5. [Google Scholar] [CrossRef]

- da Fonseca, E.B.; Gabriel, A.H.G.; Araújo, L.C.; Santos, P.L.; Campo, K.N.; Lopes, E.S. Assessment of laser power and scan speed influence on microstructural features and consolidation of AISI H13 tool steel processed by additive manufacturing. Addit. Manuf. 2020, 34, 101250. [Google Scholar] [CrossRef]

- Köhler, M.L.; Ali, F.; Herzog, S.; Suwanpinij, P.; Kaletsch, A.; Broeckmann, C. Influence of Cr3C2 Additions to AISI H13 Tool Steel in the LPBF Process. Steel Res. Int. 2021, 117, 2100454. [Google Scholar]

- Mindt, H.W.; Megahed, M.; Lavery, N.P.; Holmes, M.A.; Brown, S.G.R. Powder Bed Layer Characteristics: The Overseen First-Order Process Input. Metall. Mater. Trans. A 2016, 47, 3811–3822. [Google Scholar] [CrossRef]

- Shaheen, M.Y.; Thornton, A.R.; Luding, S.; Weinhart, T. The influence of material and process parameters on powder spreading in additive manufacturing. Powder Technol. 2021, 383, 564–583. [Google Scholar] [CrossRef]

- Jacob, G.; Brown, C.U.; Donmez, A. The Influence of Spreading Metal Powders with Different Particle Size Distributions on the Powder Bed Density in Laser-Based Powder Bed Fusion Processes; US Department of Commerce, National Institute of Standards and Technology: Gaithersburg, MD, USA, 2018.

- Al-Thamir, M.; McCartney, D.G.; Simonelli, M.; Hague, R.; Clare, A. Processability of Atypical WC-Co Composite Feedstock by Laser Powder-Bed Fusion. Materials 2019, 13, 50. [Google Scholar] [CrossRef] [PubMed]

- Simonelli, M.; Aboulkhair, N.T.; Cohen, P.; Murray, J.W.; Clare, A.T.; Tuck, C.; Hague, R.J.M. A comparison of Ti-6Al-4V in-situ alloying in Selective Laser Melting using simply-mixed and satellited powder blend feedstocks. Mater. Charact. 2018, 143, 118–126. [Google Scholar] [CrossRef]

- Knieps, M.S.; Reynolds, W.J.; Dejaune, J.; Clare, A.T.; Evirgen, A. In-situ alloying in powder bed fusion: The role of powder morphology. Mater. Sci. Eng. A 2021, 807, 140849. [Google Scholar] [CrossRef]

- Gasper, A.; Catchpole-Smith, S.; Clare, A. In-situ synthesis of titanium aluminides by direct metal deposition. J. Mater. Process. Technol. 2017, 239, 230–239. [Google Scholar] [CrossRef]

- Sundar Raj, A.A.; Rubila, S.; Jayabalan, R.; Ranganathan, T.V. A Review on Pectin: Chemistry due to General Properties of Pectin and its Pharmaceutical Uses. Sci. Rep. 2012, 1, 550–553. [Google Scholar]

- Baker, M.I.; Walsh, S.P.; Schwartz, Z.; Boyan, B.D. A review of polyvinyl alcohol and its uses in cartilage and orthopedic applications. J. Biomed. Mater. Res. Part B Appl. Biomater. 2012, 100, 1451–1457. [Google Scholar] [CrossRef]

- Youssef, A.M.; Assem, F.M.; Abdel-Aziz, M.E.; Elaaser, M.; Ibrahim, O.A.; Mahmoud, M.; Abd El-Salam, M.H. Development of bionanocomposite materials and its use in coating of Ras cheese. Food Chem. 2019, 270, 467–475. [Google Scholar] [CrossRef]

- Ben Halima, N. Poly(vinyl alcohol): Review of its promising applications and insights into biodegradation. RSC Adv. 2016, 6, 39823–39832. [Google Scholar] [CrossRef]

- Zhou, Z.; Lennon, A.; Buchanan, F.; McCarthy, H.O.; Dunne, N. Binder jetting additive manufacturing of hydroxyapatite powders: Effects of adhesives on geometrical accuracy and green compressive strength. Addit. Manuf. 2020, 36, 101645. [Google Scholar] [CrossRef]

- Lankveld, J.; Lyklema, J. Adsorption of polyvinyl alcohol on the paraffin—Water interface. III. Emulsification of paraffin in aqueous solutions of polyvinyl alcohol and the properties of paraffin-in-water emulsions stabilized by polyvinyl alcohol. J. Colloid Interface Sci. 1972, 41, 475–483. [Google Scholar] [CrossRef]

- Yanez-Sanchez, S.I.; Lennox, M.D.; Therriault, D.; Favis, B.D.; Tavares, J.R. Model Approach for Binder Selection in Binder Jetting. Ind. Eng. Chem. Res. 2021, 60, 15162–15173. [Google Scholar] [CrossRef]

- Utela, B.; Storti, D.; Anderson, R.; Ganter, M. A review of process development steps for new material systems in three dimensional printing (3DP). J. Manuf. Process. 2008, 10, 96–104. [Google Scholar] [CrossRef]

- Kedir, W.M.; Deresa, E.M.; Diriba, T.F. Pharmaceutical and drug delivery applications of pectin and its modified nanocomposites. Heliyon 2022, 8, e10654. [Google Scholar] [CrossRef] [PubMed]

- Saha, D.; Bhattacharya, S. Hydrocolloids as thickening and gelling agents in food: A critical review. J. Food Sci. Technol. 2010, 47, 587–597. [Google Scholar] [CrossRef]

- Trikkaliotis, D.G.; Ainali, N.M.; Tolkou, A.K.; Mitropoulos, A.C.; Lambropoulou, D.A.; Bikiaris, D.N.; Kyzas, G.Z. Removal of Heavy Metal Ions from Wastewaters by Using Chitosan/Poly(Vinyl Alcohol) Adsorbents: A Review. Macromol 2022, 2, 403–425. [Google Scholar] [CrossRef]

- Wang, R.; Liang, R.; Dai, T.; Chen, J.; Shuai, X.; Liu, C. Pectin-based adsorbents for heavy metal ions: A review. Trends Food Sci. Technol. 2019, 91, 319–329. [Google Scholar] [CrossRef]

- Sriamornsak, P. Chemistry of pectin and its pharmaceutical uses: A review. Silpakorn Univ. Int. J. 2003, 3, 206–228. [Google Scholar]

- Fawzy, A.; Toghan, A.; Alqarni, N.; Morad, M.; Zaki, M.E.A.; Sanad, M.M.S.; Alakhras, A.I.; Farag, A.A. Experimental and Computational Exploration of Chitin, Pectin, and Amylopectin Polymers as Efficient Eco-Friendly Corrosion Inhibitors for Mild Steel in an Acidic Environment: Kinetic, Thermodynamic, and Mechanistic Aspects. Polymers 2023, 15, 891. [Google Scholar] [CrossRef]

- Abou-Elseoud, W.S.; Abdel-Karim, A.M.; Hassan, E.A.; Hassan, M.L. Enzyme- and acid-extracted sugar beet pectin as green corrosion inhibitors for mild steel in hydrochloric acid solution. Carbohydr. Polym. Technol. Appl. 2021, 2, 100072. [Google Scholar] [CrossRef]

- Wegst, M.; Wegst, C.W. Stahlschlüssel—Key to Steel 2019: Nachschlagewerk Dt./Engl./Franz, 25th ed.; Stahlschlüssel: Marbach am Neckar, Germany, 2019. [Google Scholar]

- Easley, A.D.; Ma, T.; Eneh, C.I.; Yun, J.; Thakur, R.M.; Lutkenhaus, J.L. A practical guide to quartz crystal microbalance with dissipation monitoring of thin polymer films. J. Polym. Sci. 2022, 60, 1090–1107. [Google Scholar] [CrossRef]

- Reid, M.S.; Marway, H.S.; Moran-Hidalgo, C.; Villalobos, M.; Cranston, E.D. Comparison of polyethylene glycol adsorption to nanocellulose versus fumed silica in water. Cellulose 2017, 24, 4743–4757. [Google Scholar] [CrossRef]

- Walton, D.E. The morphology of spray-dried particles a qualitative view. Dry. Technol. 2000, 18, 1943–1986. [Google Scholar] [CrossRef]

- Littringer, E.; Paus, R.; Mescher, A.; Schroettner, H.; Walzel, P.; Urbanetz, N. The morphology of spray dried mannitol particles—The vital importance of droplet size. Powder Technol. 2013, 239, 162–174. [Google Scholar] [CrossRef]

- Köhler, M.L.; Norda, M.; Herzog, S.; Kaletsch, A.; Petzoldt, F.; Broeckmann, C. Towards carbide-rich tool steels in PBF-LB/M: TiC additivation of AISI H13. Addit. Manuf. Lett. 2023, 6, 100143. [Google Scholar] [CrossRef]

- Gupta, B.; Agarwal, R.; Alam, M.S. Preparation and characterization of polyvinyl alcohol-polyethylene oxide-carboxymethyl cellulose blend membranes. J. Appl. Polym. Sci. 2012, 127, 1301–1308. [Google Scholar] [CrossRef]

- Einhorn-Stoll, U.; Kastner, H.; Urbisch, A.; Kroh, L.W.; Drusch, S. Thermal degradation of citrus pectin in low-moisture environment—Influence of acidic and alkaline pre-treatment. Food Hydrocoll. 2019, 86, 104–115. [Google Scholar] [CrossRef]

- Barbier, D. Extension of the Martensite Transformation Temperature Relation to Larger Alloying Elements and Contents. Adv. Eng. Mater. 2013, 16, 122–127. [Google Scholar] [CrossRef]

| Name | C | Si | Mn | Cr | Mo | V | Fe |

|---|---|---|---|---|---|---|---|

| AISIH13 nominal [32] | 0.35–0.42 | 0.8–1.2 | 0.25–0.5 | 4.8–5.5 | 1.2–1.5 | 0.85–1.15 | Bal. |

| AISI H13 as provided | 0.37 | 0.9 | 0.4 | 5.0 | 1.3 | 1.1 | Bal. |

| Cr3C2 nominal | 13.3 | - | - | 86.7 | - | - | - |

| H13 + 5% Cr3C2 calculated (ideal) | 1.1 | 0.9 | 0.5 | 9.4 | 1.2 | 1.0 | 86.0 |

| Name | EV | C | Si | Mn | Cr | Mo | V | Fe |

|---|---|---|---|---|---|---|---|---|

| [J/mm3] | [wt.%] | [wt.%] | [wt.%] | [wt.%] | [wt.%] | [wt.%] | [wt.%] | |

| Calculated AISI H13 + 5 wt.% Cr3C2 | 1.1 | 0.9 | 0.5 | 9.4 | 1.2 | 1.0 | 86.0 | |

| Specimen 7 AISI H13 + 5 wt.% Cr3C2 | 64 | 0.6 | 0.7 | 0.3 | 7.1 | 1.4 | 1.0 | 88.0 |

| Specimen 7 Pectin-bonded alloy with 5 wt.% Cr3C2 | 64 | 1.2 | 0.8 | 0.3 | 9.3 | 1.3 | 0.9 | 85.5 |

| Name | EV | C | Si | Mn | Cr | Mo | V | Fe |

|---|---|---|---|---|---|---|---|---|

| [J/mm3] | [wt.%] | [wt.%] | [wt.%] | [wt.%] | [wt.%] | [wt.%] | [wt.%] | |

| Calculated AISI H13 + 5 wt.% Cr3C2 | 1.1 | 0.9 | 0.5 | 9.4 | 1.2 | 1.0 | 86.0 | |

| Specimen 7 Pectin-bonded alloy with 5 wt.% Cr3C2 | 64 | 1.2 | 0.8 | 0.3 | 9.3 | 1.3 | 0.9 | 85.5 |

| Specimen 7 AISI H13 + 13 wt.% Cr3C2 | 64 | 1.0 | 0.8 | 0.3 | 9.7 | 1.3 | 1.0 | 85.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meyer, F.; Kolodzy, F.; Scheck, M.L.; Kaletsch, A.; Kharandiuk, T.; Pich, A.; Broeckmann, C. Novel Pectin Binder for Satelliting Carbides to H13 Tool Steel for PBF-LB Processing. Materials 2023, 16, 3649. https://doi.org/10.3390/ma16103649

Meyer F, Kolodzy F, Scheck ML, Kaletsch A, Kharandiuk T, Pich A, Broeckmann C. Novel Pectin Binder for Satelliting Carbides to H13 Tool Steel for PBF-LB Processing. Materials. 2023; 16(10):3649. https://doi.org/10.3390/ma16103649

Chicago/Turabian StyleMeyer, Fabian, Fabian Kolodzy, Marie Luise Scheck, Anke Kaletsch, Tetiana Kharandiuk, Andrij Pich, and Christoph Broeckmann. 2023. "Novel Pectin Binder for Satelliting Carbides to H13 Tool Steel for PBF-LB Processing" Materials 16, no. 10: 3649. https://doi.org/10.3390/ma16103649

APA StyleMeyer, F., Kolodzy, F., Scheck, M. L., Kaletsch, A., Kharandiuk, T., Pich, A., & Broeckmann, C. (2023). Novel Pectin Binder for Satelliting Carbides to H13 Tool Steel for PBF-LB Processing. Materials, 16(10), 3649. https://doi.org/10.3390/ma16103649