Study of Abrasive Water Jet Machining as a Texturing Operation for Thin Aluminium Alloy UNS A92024

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material and Machining Process

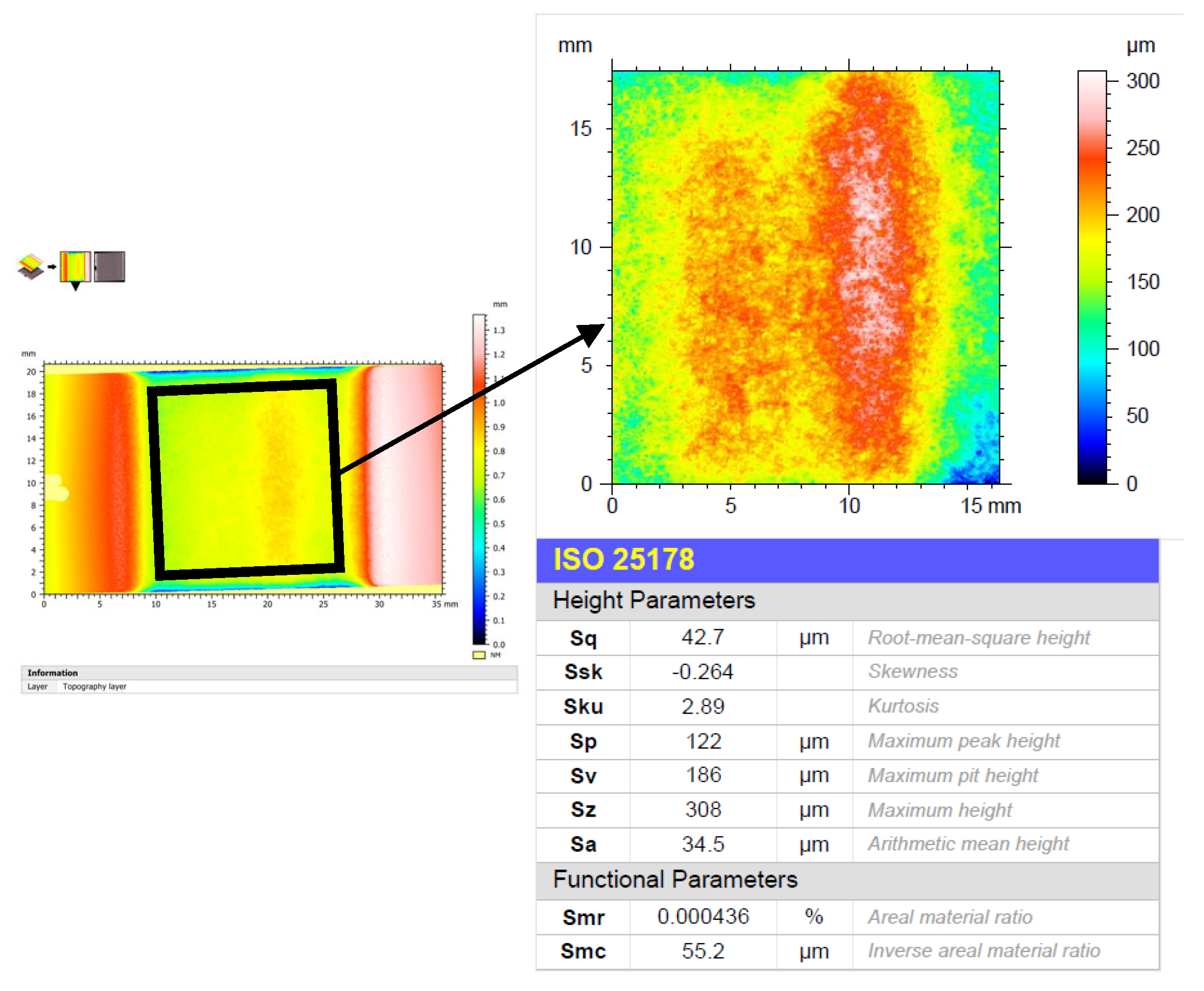

2.2. Test Evaluation

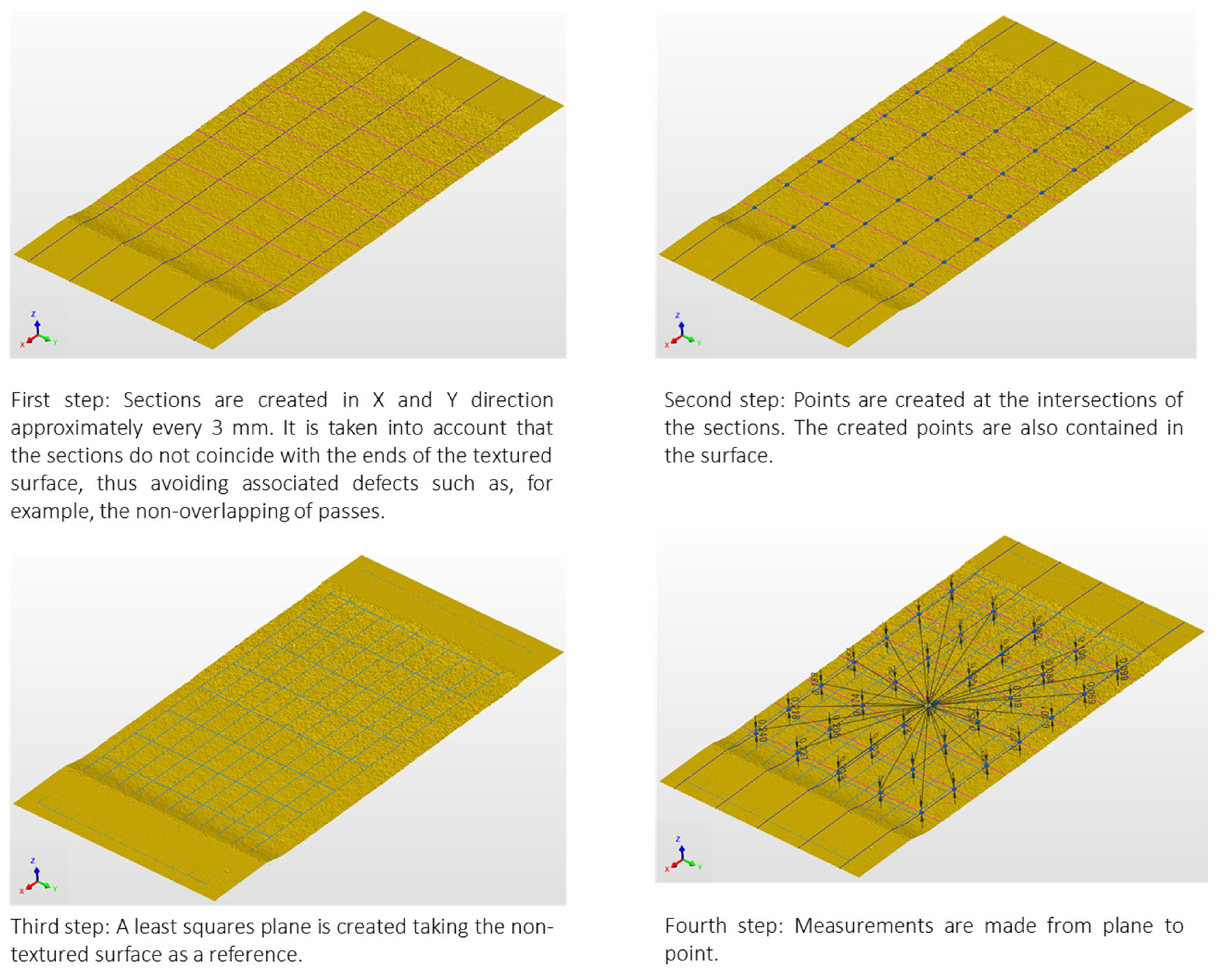

2.3. Data Processing

3. Results

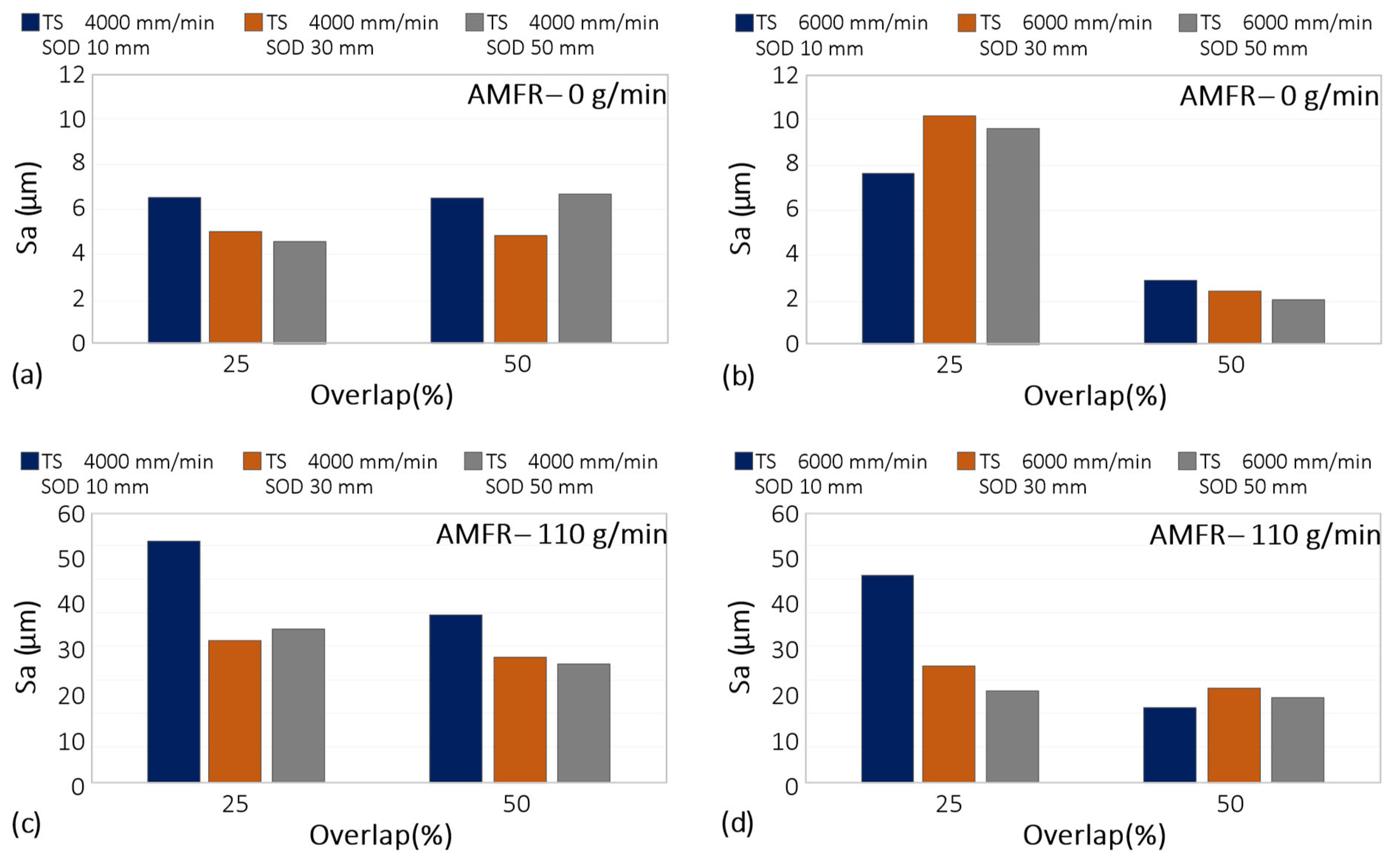

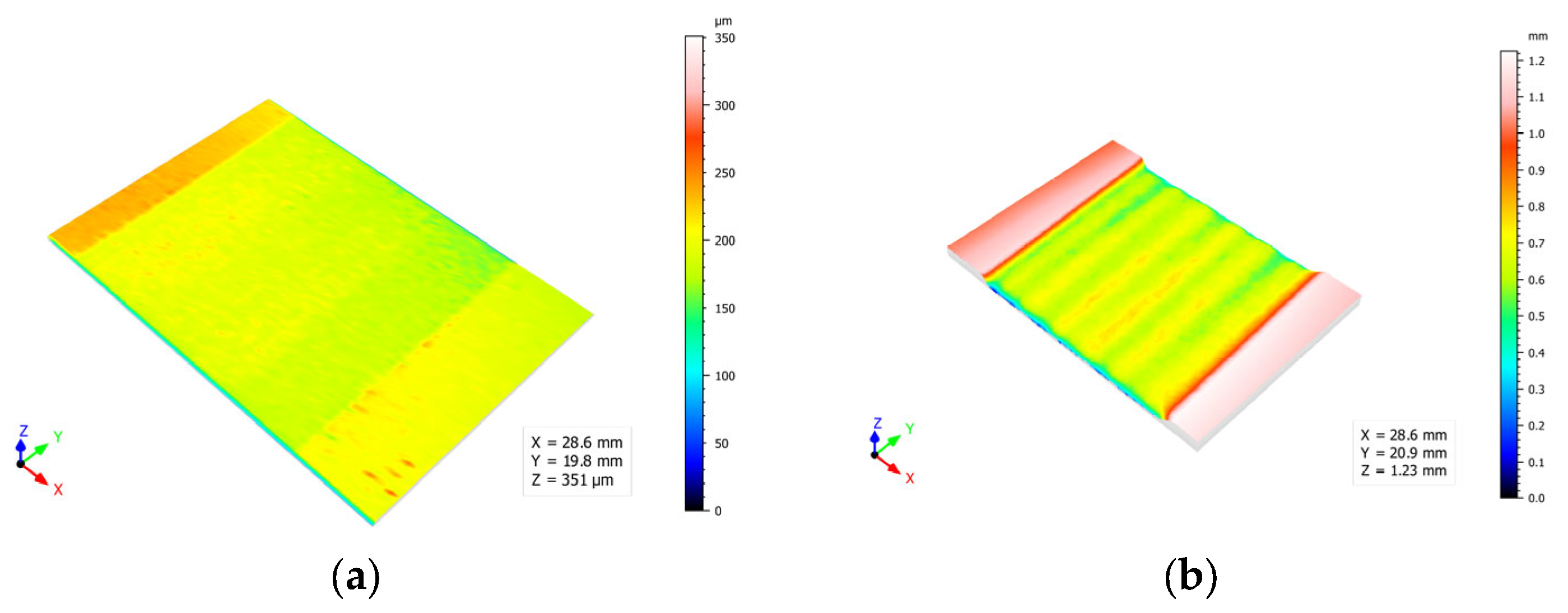

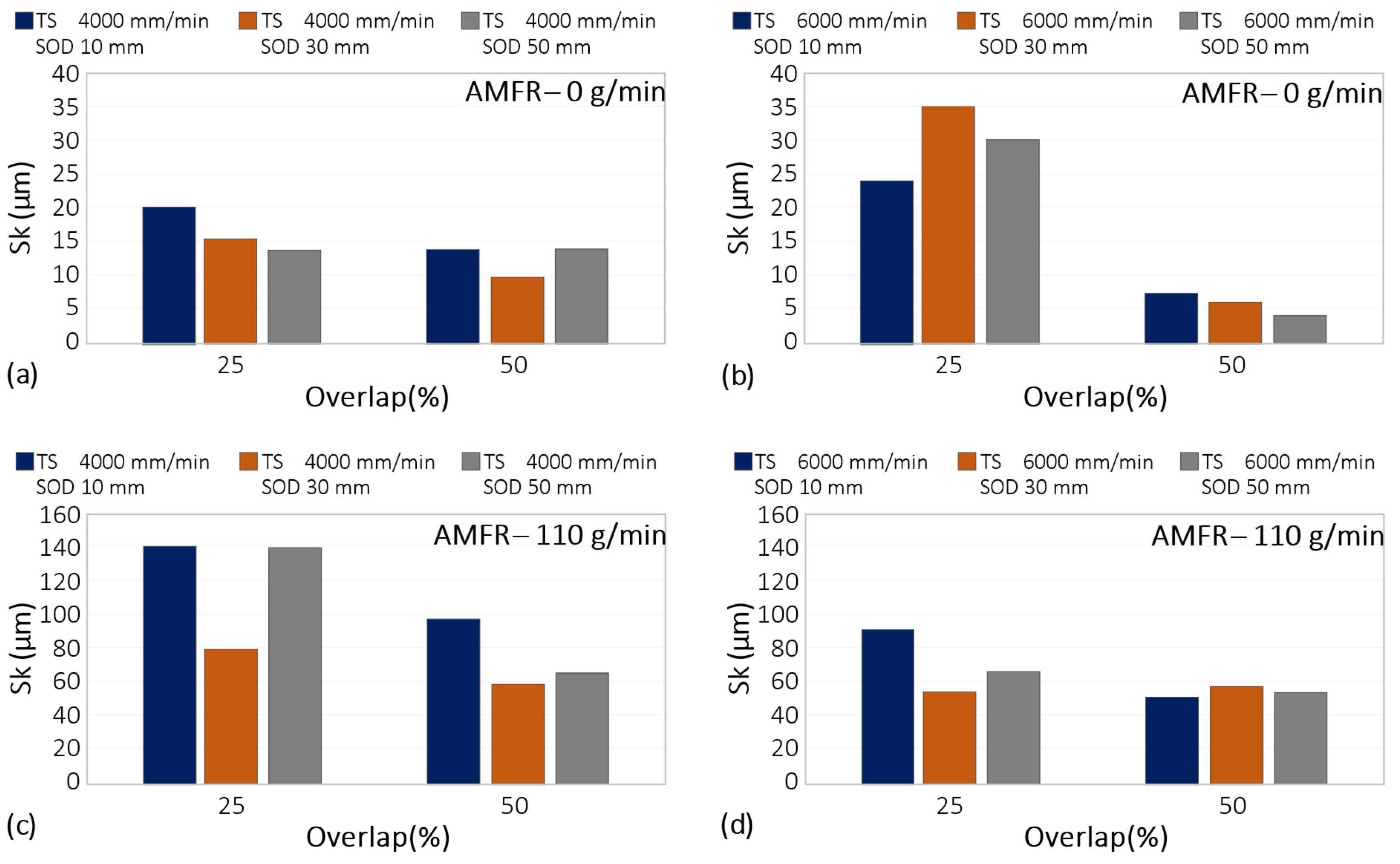

3.1. Experimental Results in Abrasive Waterjet Texturing

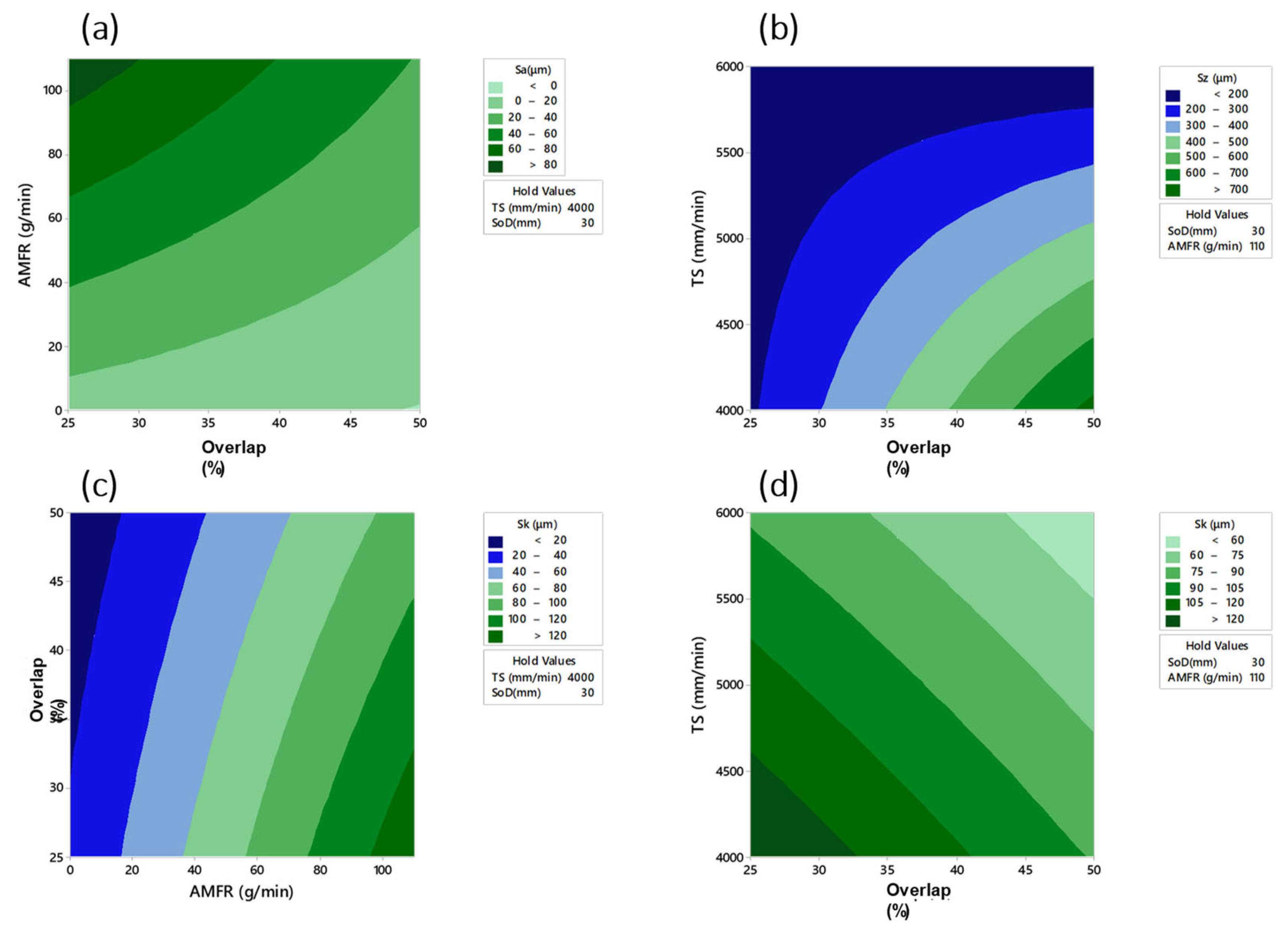

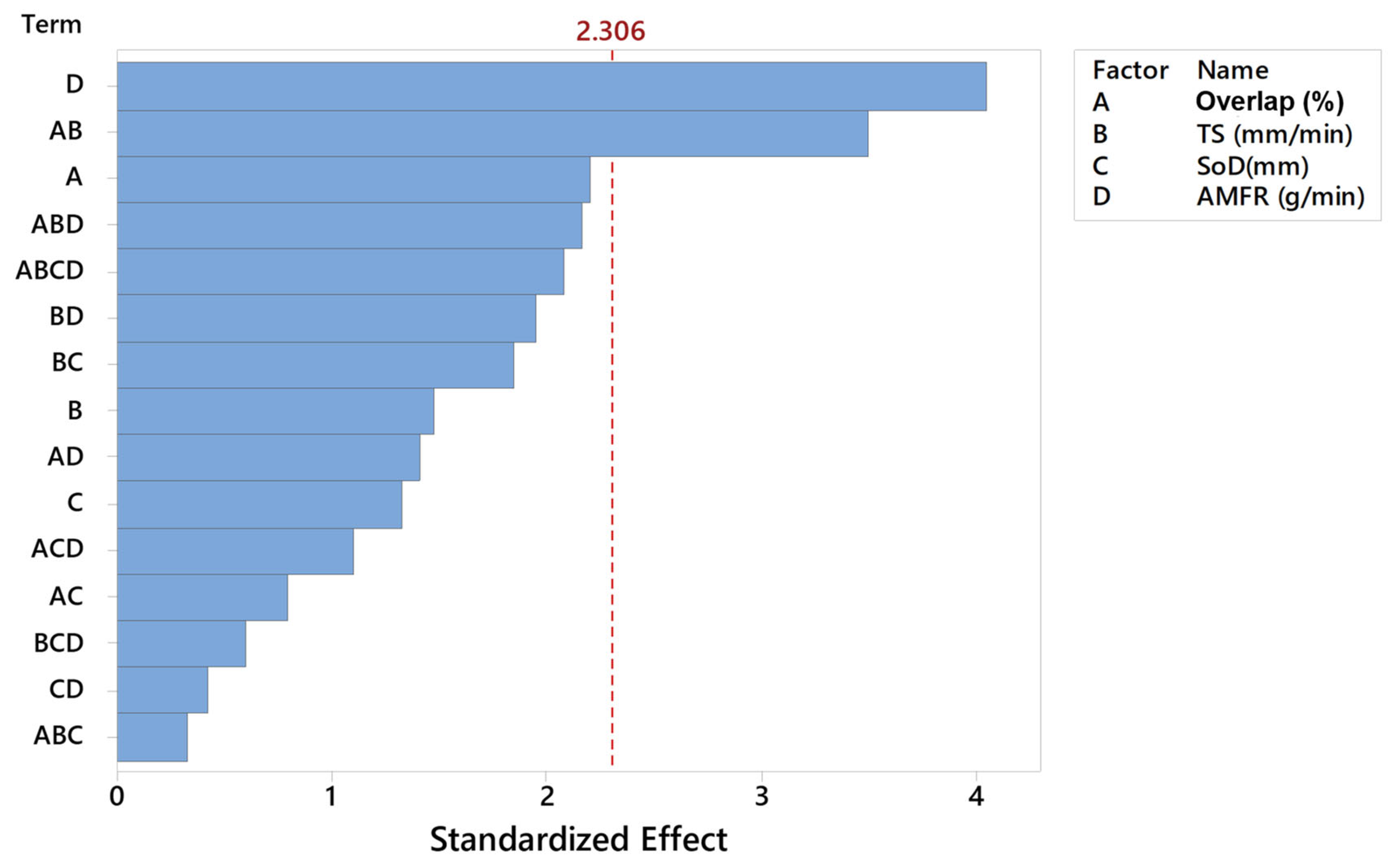

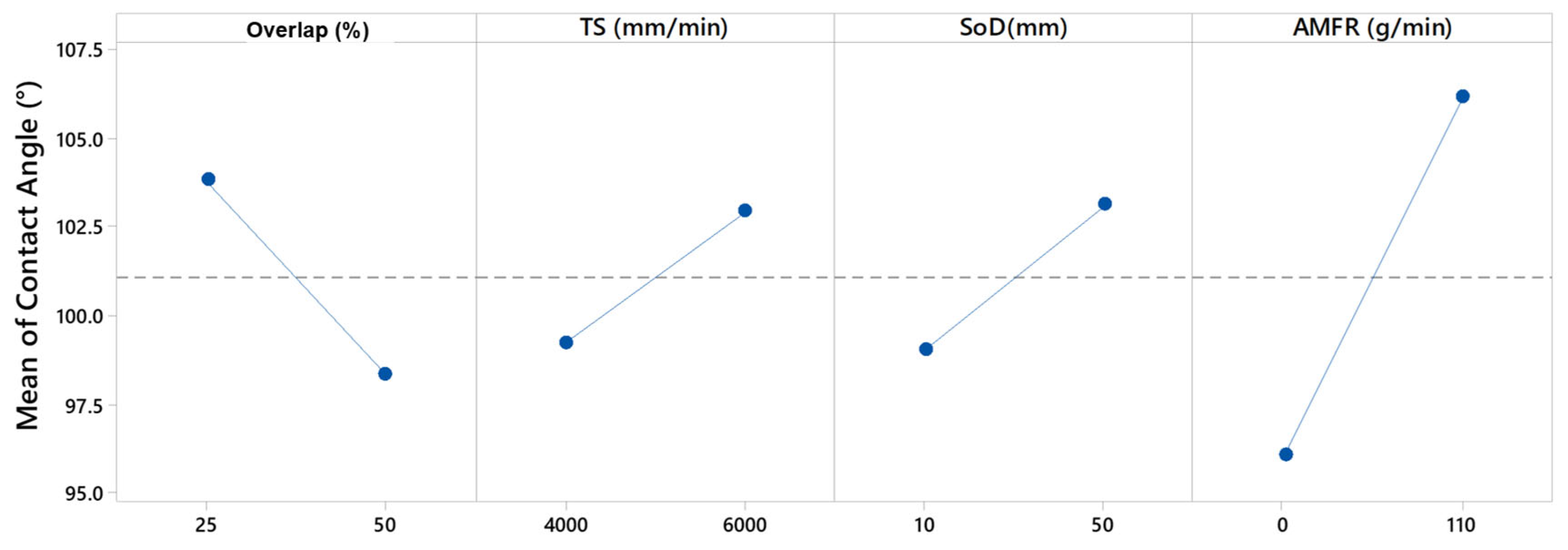

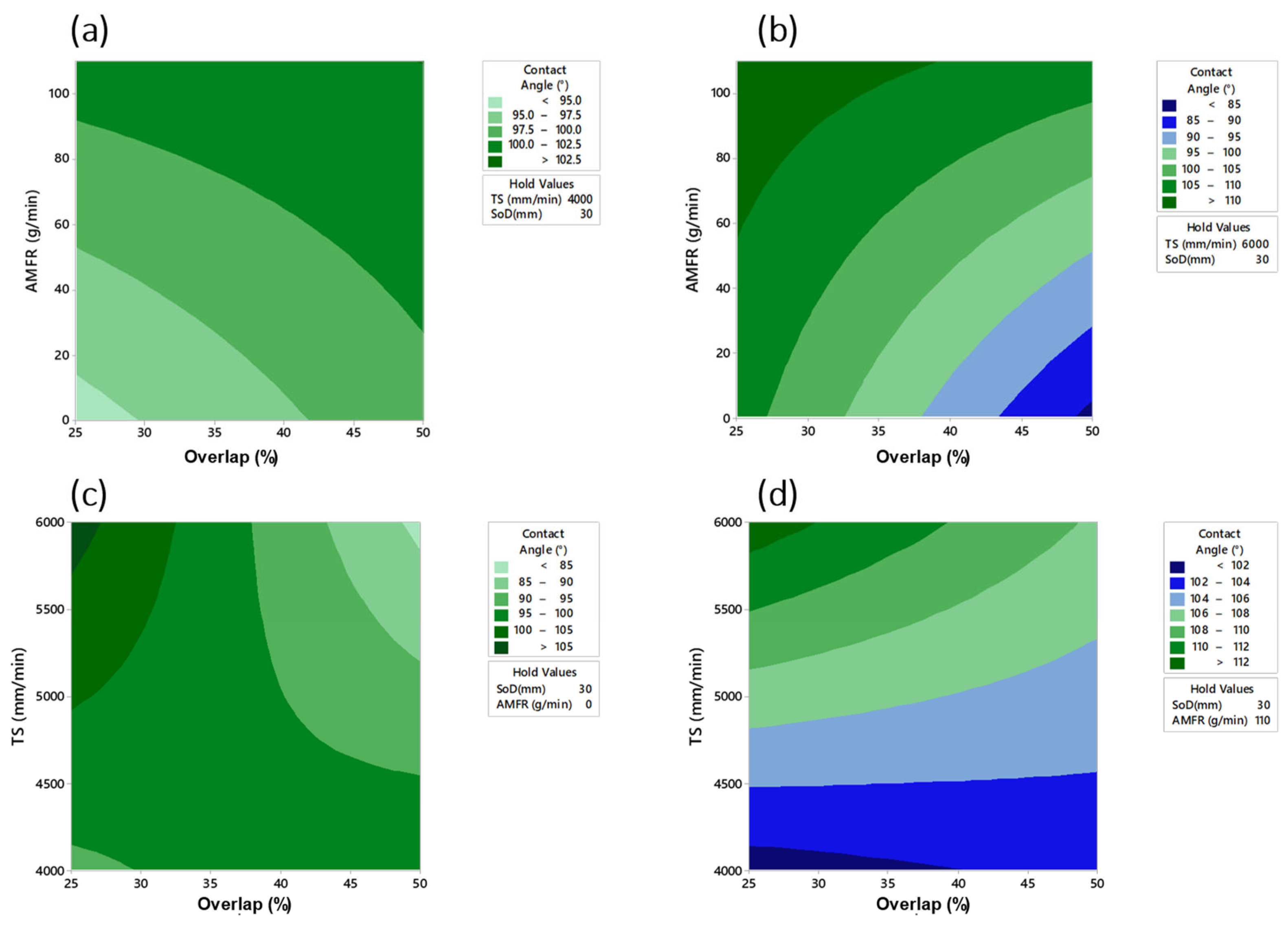

3.2. Statistical Analysis of Experimental Results and Contour Plots

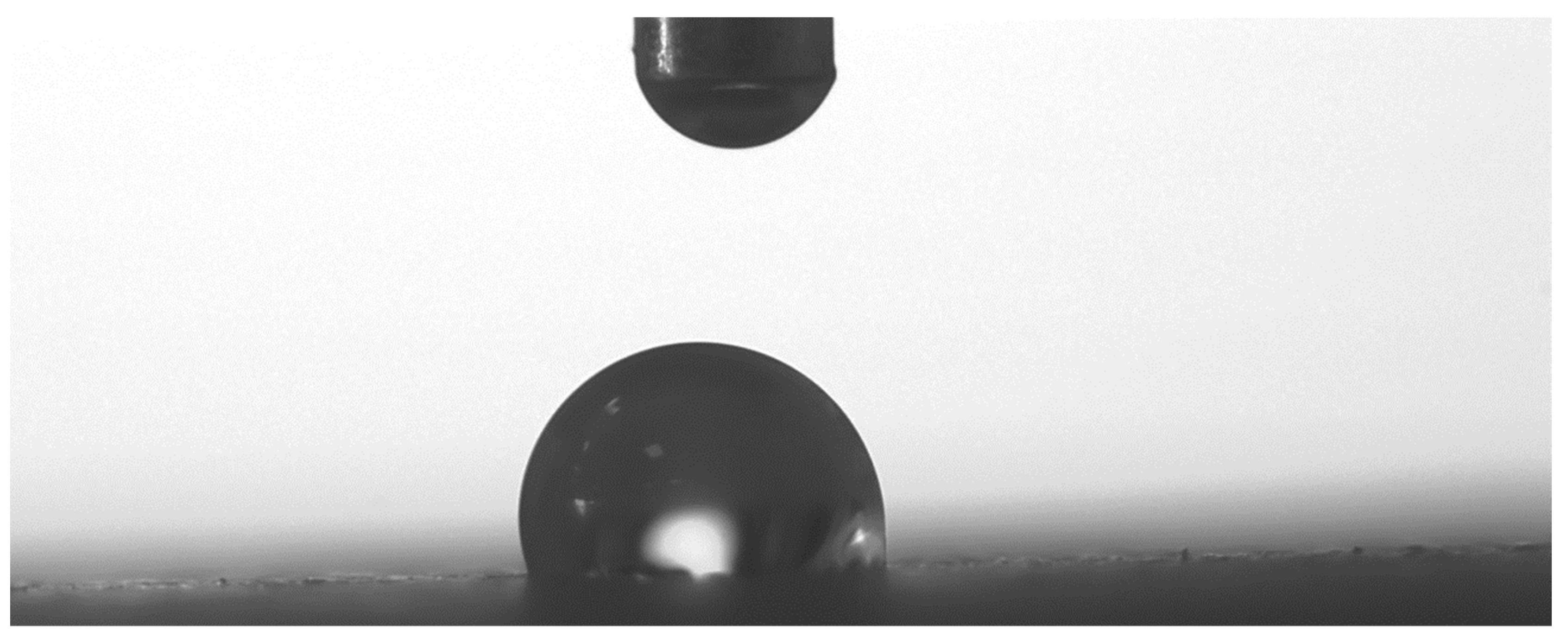

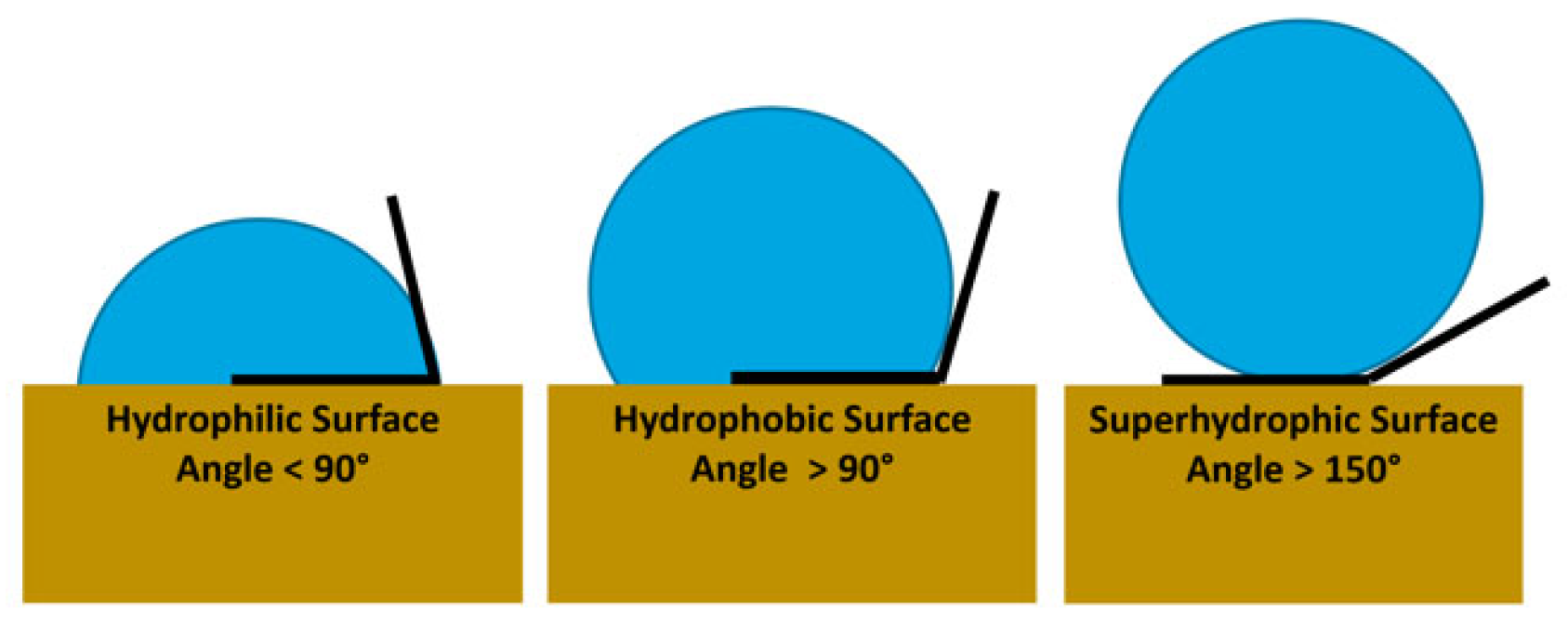

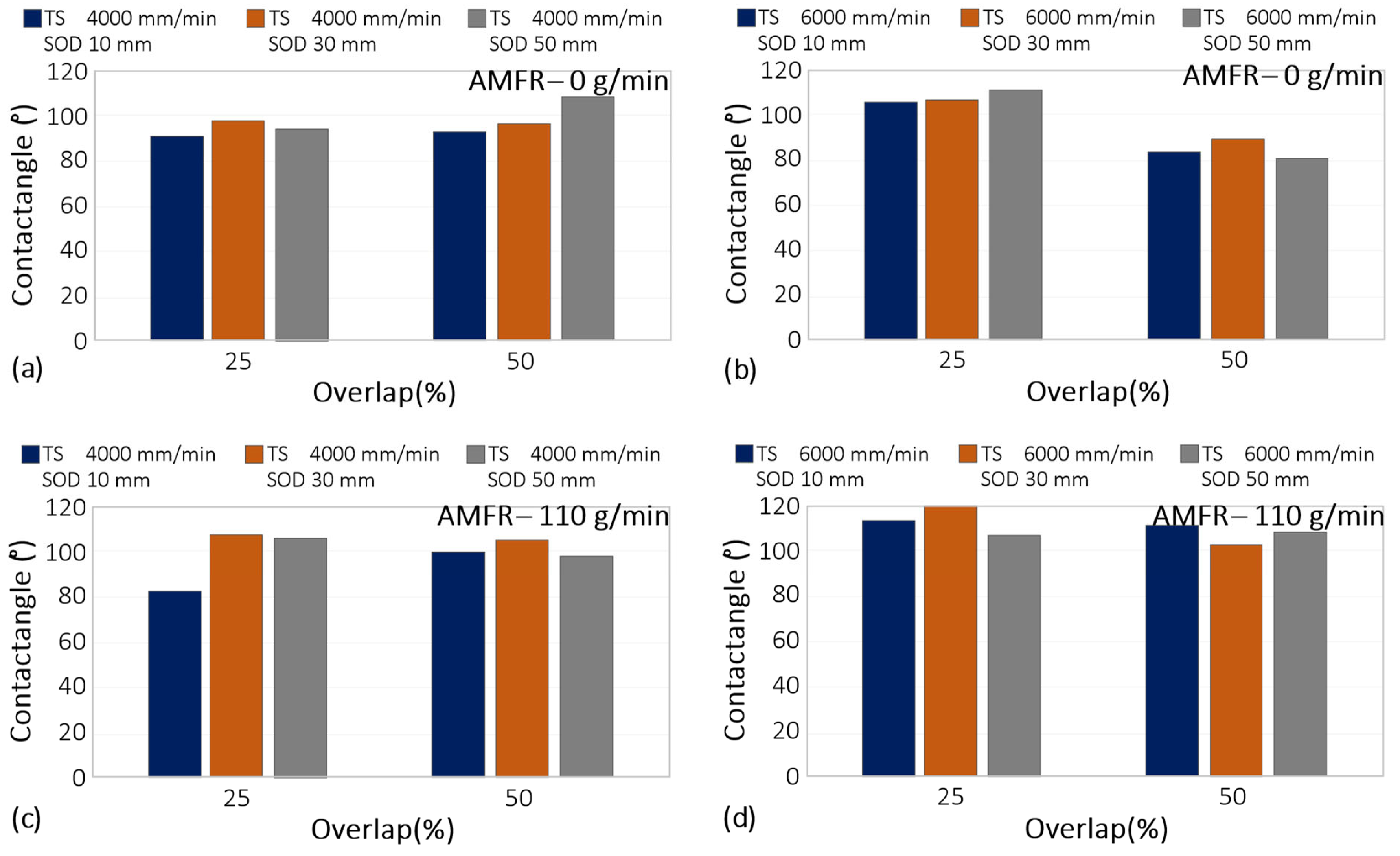

3.3. Wettability

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cirillo, P.; Marino, A.; Natale, C.; Di Marino, E.; Chiacchio, P.; De Maria, G. A Low-Cost and Flexible Solution for One-Shot Cooperative Robotic Drilling of Aeronautic Stack Materials. IFAC-PapersOnLine 2017, 50, 4602–4609. [Google Scholar] [CrossRef]

- Gómez-Parra, A.; Álvarez-Alcón, M.; Salguero, J.; Batista, M.; Marcos, M. Analysis of the Evolution of the Built-Up Edge and Built-Up Layer Formation Mechanisms in the Dry Turning of Aeronautical Aluminium Alloys. Wear 2013, 302, 1209–1218. [Google Scholar] [CrossRef]

- Lawcock, G.; Ye, L.; Mai, Y.W.; Sun, C.T. The Effect of Adhesive Bonding between Aluminum and Composite Prepreg on the Mechanical Properties of Carbon-Fiber-Reinforced Metal Laminates. Compos. Sci. Technol. 1997, 57, 35–45. [Google Scholar] [CrossRef]

- Cano, R.J.; Loos, A.C.; Jensen, B.J.; Britton, S.M.; Tuncol, G.; Long, K. Epoxy/Glass and Polyimide (LaRCTM PETI-8)/Carbon Fiber Metal Laminates Made by the VARTM Process. SAMPE J. 2011, 47, 50–58. [Google Scholar]

- Huang, Z.; Sugiyama, S.; Yanagimoto, J. Adhesive-Embossing Hybrid Joining Process to Fiber-Reinforced Thermosetting Plastic and Metallic Thin Sheets. Procedia Eng. 2014, 81, 2123–2128. [Google Scholar] [CrossRef]

- Martinsen, K.; Hu, S.J.; Carlson, B.E. Joining of Dissimilar Materials. CIRP Ann. Manuf. Technol. 2015, 64, 679–699. [Google Scholar] [CrossRef]

- Zhang, K.; Yang, Z.; Li, Y. A Method for Predicting the Curing Residual Stress for CFRP/Al Adhesive Single-Lap Joints. Int. J. Adhes. Adhes. 2013, 46, 7–13. [Google Scholar] [CrossRef]

- Samaei, M.; Zehsaz, M.; Chakherlou, T.N. Experimental and Numerical Study of Fatigue Crack Growth of Aluminum Alloy 2024-T3 Single Lap Simple Bolted and Hybrid (Adhesive/Bolted) Joints. Eng. Fail. Anal. 2016, 59, 253–268. [Google Scholar] [CrossRef]

- Higgins, A. Adhesive Bonding of Aircraft Structures. Int. J. Adhes. Adhes. 2000, 20, 367–376. [Google Scholar] [CrossRef]

- Srinivas Reddy, P.; Ravi Kumar, P.; Prasad, D.V.S.S.S.V.; Saroja Rani, B.; Narayana Gupta, C.L.; Daniel Das, A.; Subbiah, R. Effect of Parameters and Surface Analysis on Eglin Steel by Shot Blasting Method. Mater. Today Proc. 2022, 72, 2833–2836. [Google Scholar] [CrossRef]

- Campos Bernardes, P.; Andrade Araújo, E.; dos Santos Pires, A.C.; Felício Queiroz Fialho, J.; Aparecida Lelis, C.; de Andrade, N.J. Work of Adhesion of Dairy Products on Stainless Steel Surface. Braz. J. Microbiol. 2012, 43, 1261–1268. [Google Scholar] [CrossRef]

- Islam, M.S.; Tong, L.; Falzon, P.J. Influence of Metal Surface Preparation on Its Surface Profile, Contact Angle, Surface Energy and Adhesion with Glass Fibre Prepreg. Int. J. Adhes. Adhes. 2014, 51, 32–41. [Google Scholar] [CrossRef]

- Rudawska, A. Surface Treatment Methods. In Surface Treatment in Bonding Technology; Academic Press: Cambridge, MA, USA, 2019; pp. 47–62. [Google Scholar] [CrossRef]

- Sorrentino, L.; Polini, W.; Bellini, C.; Parodo, G. Surface Treatment of CFRP: Influence on Single Lap Joint Performances. Int. J. Adhes. Adhes. 2018, 85, 225–233. [Google Scholar] [CrossRef]

- Mamalis, D.; Obande, W.; Koutsos, V.; Blackford, J.R.; Ó Brádaigh, C.M.; Ray, D. Novel Thermoplastic Fibre-Metal Laminates Manufactured by Vacuum Resin Infusion: The Effect of Surface Treatments on Interfacial Bonding. Mater. Des. 2019, 162, 331–344. [Google Scholar] [CrossRef]

- Vishnoi, M.; Kumar, P.; Murtaza, Q. Surface Texturing Techniques to Enhance Tribological Performance: A Review. Surf. Interfaces 2021, 27, 101463. [Google Scholar] [CrossRef]

- Wang, H.; Tian, L.; Zheng, J.; Yang, D.; Zhang, Z. The Synergetic Effects of Laser Texturing and Super-Hydrophobic Coatings on Improving Wear Properties of Steel. Tribol. Int. 2022, 173, 107657. [Google Scholar] [CrossRef]

- Bañon, F.; Sambruno, A.; Batista, M.; Simonet, B.; Salguero, J. Surface Quality and Free Energy Evaluation of S275 Steel by Shot Blasting, Abrasive Water Jet Texturing and Laser Surface Texturing. Metals 2020, 10, 290. [Google Scholar] [CrossRef]

- Bañon, F.; Montaño, R.; Vazquez-Martinez, J.M.; Salguero, J. Free Surface Energy Evaluation in the Laser Texturing of a Carbon Steel S275. Procedia CIRP 2022, 108, 72–76. [Google Scholar] [CrossRef]

- Kumar, S.P.; Shata, A.S.; Kumar, K.V.P.; Sharma, R.; Munnur, H.; Rinawa, M.L.; Kumar, S.S. Effect on Abrasive Water Jet Machining of Aluminum Alloy 7475 Composites Reinforced with CNT Particles. Mater. Today Proc. 2022, 59, 1463–1471. [Google Scholar] [CrossRef]

- Gowthama, K.; Somashekar, H.M.; Suresha, B.; Rajole, S.; Ravindran, N. Optimization of Abrasive Water Jet Machining Process Parameters of Al 7071 Using Design of Experiments. Mater. Today Proc. 2022, 52, 2102–2108. [Google Scholar] [CrossRef]

- Chaturvedi, C.; Rao, P.S.; Khan, M.Y. Optimization of Process Variable in Abrasive Water Jet Machining (AWJM) of Ti-6Al-4V Alloy Using Taguchi Methodology. Mater. Today Proc. 2021, 47, 6120–6127. [Google Scholar] [CrossRef]

- Kovacevic, R. Surface Texture in Abrasive Waterjet Cutting. J. Manuf. Syst. 1991, 10, 32–40. [Google Scholar] [CrossRef]

- Artaza, T.; Alberdi, A.; Olite, J.; Latapia, J.L.; Gil, D.; Suarez, A.; Rivero, A. Abrasive Waterjet Texturing as a Method to Enhance the Embedment of Metallic Inserts in Composite Materials. Procedia Eng. 2015, 132, 724–731. [Google Scholar] [CrossRef]

- Arola, D.; McCain, M.L.; Kunaporn, S.; Ramulu, M. Waterjet and Abrasive Waterjet Surface Treatment of Titanium: A Comparison of Surface Texture and Residual Stress. Wear 2001, 249, 943–950. [Google Scholar] [CrossRef]

- Sambruno, A.; Bañon, F.; Salguero, J.; Simonet, B.; Batista, M. Kerf Taper Defect Minimization Based on Abrasive Waterjet Machining of Low Thickness Thermoplastic Carbon Fiber Composites C/TPU. Materials 2019, 12, 4192. [Google Scholar] [CrossRef]

- Sourd, X.; Zitoune, R.; Hejjaji, A.; Salem, M.; Crouzeix, L.; Lamouche, D. Multi-Scale Analysis of the Generated Damage When Machining Pockets of 3D Woven Composite for Repair Applications Using Abrasive Water Jet Process: Contamination Analysis. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106118. [Google Scholar] [CrossRef]

- Bañon, F.; Sambruno, A.; Gómez, A.; Mayuet, P.F. Preliminary Study of Abrasive Water Jet Texturing on Low Thickness UNS A92024 Alloy Sheets. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1193, 012027. [Google Scholar] [CrossRef]

- Pahuja, R.; Ramulu, M.; Hashish, M. Integration of Jetting Technology in Metal Additive Manufacturing. In Proceedings of the 24th International Conference on Water Jetting, Manchester, UK, 5–6 September 2018; pp. 23–35. [Google Scholar]

- Sourd, X.; Zitoune, R.; Crouzeix, L.; Coulaud, M. Influence of the Texturing Quality Consecutive to Abrasive Water Jet Machining on the Adhesive Properties in Mode I of 3D Woven Composite Assemblies. Compos. B Eng. 2022, 242, 110091. [Google Scholar] [CrossRef]

- Ibrahim, A.; Papini, M. Controlled Depth Micro-Abrasive Waterjet Milling of Aluminum Oxide to Fabricate Micro-Molds Containing Intersecting Free-Standing Structures. Precis. Eng. 2022, 75, 24–36. [Google Scholar] [CrossRef]

- Popan, A.; Balc, N.; Carean, A.; Luca, A.; Miron, A. Research on Abrasive Water Jet Milling of the Planar Surfaces, Slots and Profiles. Appl. Mech. Mater. 2015, 760, 409–414. [Google Scholar] [CrossRef]

- Hejjaji, A.; Zitoune, R.; Toubal, L.; Crouzeix, L.; Collombet, F. Influence of Controlled Depth Abrasive Water Jet Milling on the Fatigue Behavior of Carbon/Epoxy Composites. Compos. Part. A Appl. Sci. Manuf. 2019, 121, 397–410. [Google Scholar] [CrossRef]

- Pal, V.K.; Tandon, P. Identification of the Role of Machinability and Milling Depth on Machining Time in Controlled Depth Milling Using Abrasive Water Jet. Int. J. Adv. Manuf. Technol. 2013, 66, 877–881. [Google Scholar] [CrossRef]

- ISO 25178; Geometrical Product Specifications (GPS)—Surface Texture: Areal. ISO: Geneva, Switzerland, 2021.

- ISO 16610-61; Geometrical Product Specification (GPS)—Filtration—Part 61: Linear Areal Filters—Gaussian Filters. ISO: Geneva, Switzerland, 2015.

- Yuan, Y.; Lee, T.R. Contact Angle and Wetting Properties. In Surface Science Techniques; Springer Series in Surface Sciences; Springer: Berlin/Heidelberg, Germany, 2013; Volume 51, ISBN 978-3-642-34242-4. [Google Scholar]

- Botana-Galvín, M.; Blanco, G.; González-Rovira, L.; Rodríguez, M.A.; Botana, F.J. Adhesive Behaviour of Carbon Fibre Reinforced Plastic Panels Manufactured Using Woven and Unidirectional Tape after Ultraviolet Laser Surface Treatment. J. Compos. Mater. 2018, 52, 853–865. [Google Scholar] [CrossRef]

- Lou, S.; Zhu, Z.; Zeng, W.; Majewski, C.; Scott, P.J.; Jiang, X. Material Ratio Curve of 3D Surface Topography of Additively Manufactured Parts: An Attempt to Characterise Open Surface Pores. Surf. Topogr. 2021, 9, 015029. [Google Scholar] [CrossRef]

- Kovács, Z.F.; Viharos, Z.J.; Kodácsy, J. Improvements of Surface Tribological Properties by Magnetic Assisted Ball Burnishing. Surf. Coat. Technol. 2022, 437, 128317. [Google Scholar] [CrossRef]

- Wojciechowski, L.; Kubiak, K.J.; Mathia, T.G. Roughness and Wettability of Surfaces in Boundary Lubricated Scuffing Wear. Tribol. Int. 2016, 93, 593–601. [Google Scholar] [CrossRef]

- Arifvianto, B.; Suyitno; Mahardika, M. Effect of Sandblasting and Surface Mechanical Attrition Treatment on Surface Roughness, Wettability, and Microhardness Distribution of AISI 316L. Key Eng. Mater. 2011, 462–463, 738–743. [Google Scholar] [CrossRef]

| Al | Cu | Mg | Mn | Si | Fe | Zn | Ti | Cr | Others |

|---|---|---|---|---|---|---|---|---|---|

| Rest | 3.80–4.90 | 1.20–1.80 | 0.30–0.90 | ≤0.50 | ≤0.50 | ≤0.25 | ≤0.15 | ≤0.10 | ≤0.15 |

| Modulus of Elasticity | 73.1 GPa |

|---|---|

| Hardness, Vickers | 137 |

| Ultimate Tensile Strength, UTS | 469 MPa |

| Tensile Yield Strength | 324 MPa |

| Poisson’s Ratio | 0.33 |

| Fatigue Strength (R.R Moore Test) | 138 MPa |

| Parameters | |||

|---|---|---|---|

| AMFR (g/min) | 0 | 110 | |

| Overlap % | 25% | 50% | |

| SoD (mm) | 10 | 30 | 50 |

| TS (mm/min) | 4000 | 6000 | |

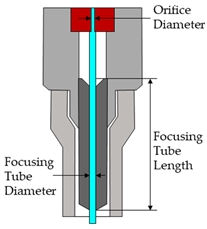

| Orifice Diameter (mm) | Focusing Tube Diameter (mm) | Focusing Tube Length (mm) |  |

| 0.25 | 0.76 | 380 | |

| Abrasive Size (µm) | Abrasive Type | Pressure (MPa) | |

| 500 | Garnet | 80 |

| DF | Adj SC | Adj MC | F-Value | p-Value | |

|---|---|---|---|---|---|

| Sa | |||||

| Model | 10 | 14,380.6 | 1438.1 | 1.87 | 0.254 |

| Overlap (%) | 1 | 1893.8 | 1893.8 | 2.46 | 0.177 |

| TS (mm/min) | 1 | 1588.1 | 1588.1 | 2.07 | 0.21 |

| SoD(mm) | 1 | 180.3 | 180.3 | 0.23 | 0.649 |

| AMFR (g/min) | 1 | 6186 | 6186 | 8.05 | 0.036 |

| Error | 5 | 3844.5 | 768.9 | ||

| Total | 15 | 18,225.2 | |||

| Sz | |||||

| Model | 10 | 1,013,053 | 101,305 | 8.12 | 0.016 |

| Overlap (%) | 1 | 238,897 | 238,897 | 19.14 | 0.007 |

| TS (mm/min) | 1 | 329,440 | 329,440 | 26.4 | 0.004 |

| SoD(mm) | 1 | 1670 | 1670 | 0.13 | 0.729 |

| AMFR (g/min) | 1 | 2223 | 2223 | 0.18 | 0.691 |

| Error | 5 | 62,392 | 12,478 | ||

| Total | 15 | 1,075,445 | |||

| Sk | |||||

| Model | 10 | 29,740.9 | 2974.1 | 13.95 | 0.005 |

| Overlap (%) | 1 | 2861.1 | 2861.1 | 13.42 | 0.015 |

| TS (mm/min) | 1 | 1708 | 1708 | 8.01 | 0.037 |

| SoD(mm) | 1 | 188.1 | 188.1 | 0.88 | 0.391 |

| AMFR (g/min) | 1 | 22,017.1 | 22,017.1 | 103.29 | 0 |

| Error | 5 | 1065.8 | 213.2 | ||

| Total | 15 | 30,806.7 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 15 | 2162.33 | 144.156 | 3.87 | 0.03 |

| Overlap (%) | 1 | 180.06 | 180.062 | 4.84 | 0.059 |

| TS(mm/min) | 1 | 80.58 | 80.582 | 2.17 | 0.179 |

| SoD(mm) | 1 | 65.38 | 65.383 | 1.76 | 0.222 |

| AMFR (g/min) | 1 | 610.13 | 610.132 | 16.4 | 0.004 |

| Error | 8 | 297.69 | 37.211 | ||

| Total | 23 | 2460.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bañon, F.; Sambruno, A.; Mayuet, P.F.; Gómez-Parra, Á. Study of Abrasive Water Jet Machining as a Texturing Operation for Thin Aluminium Alloy UNS A92024. Materials 2023, 16, 3843. https://doi.org/10.3390/ma16103843

Bañon F, Sambruno A, Mayuet PF, Gómez-Parra Á. Study of Abrasive Water Jet Machining as a Texturing Operation for Thin Aluminium Alloy UNS A92024. Materials. 2023; 16(10):3843. https://doi.org/10.3390/ma16103843

Chicago/Turabian StyleBañon, Fermin, Alejandro Sambruno, Pedro F. Mayuet, and Álvaro Gómez-Parra. 2023. "Study of Abrasive Water Jet Machining as a Texturing Operation for Thin Aluminium Alloy UNS A92024" Materials 16, no. 10: 3843. https://doi.org/10.3390/ma16103843

APA StyleBañon, F., Sambruno, A., Mayuet, P. F., & Gómez-Parra, Á. (2023). Study of Abrasive Water Jet Machining as a Texturing Operation for Thin Aluminium Alloy UNS A92024. Materials, 16(10), 3843. https://doi.org/10.3390/ma16103843