Examination of the Corrosion Behavior of Shape Memory NiTi Material for Biomedical Applications

Abstract

1. Introduction

The Novelty of the Study

2. Materials and Methods

2.1. Microstructure Test

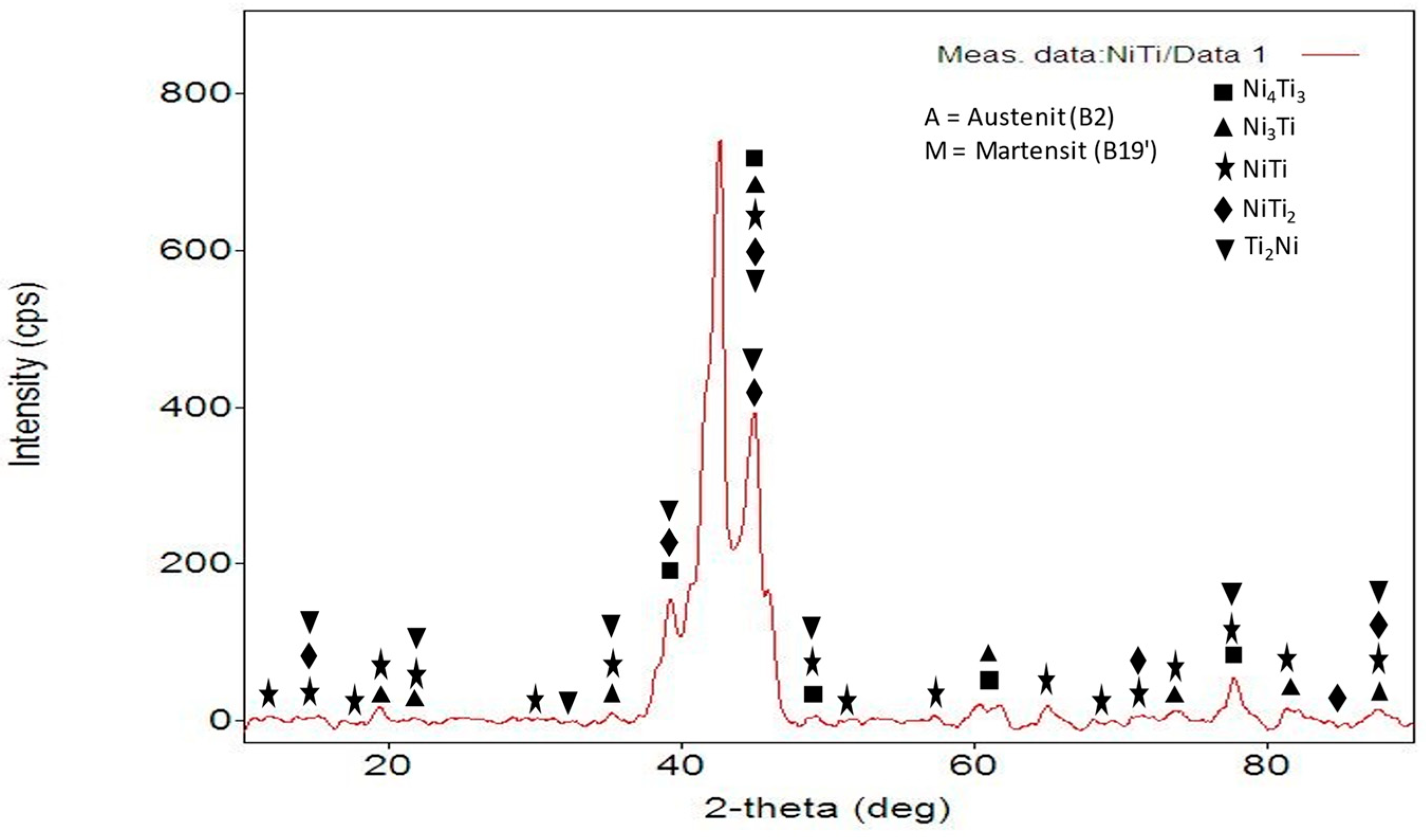

2.2. X-ray Diffraction

2.3. Corrosion Test

2.3.1. Immersion Test

2.3.2. Potentiodynamic Polarization Test

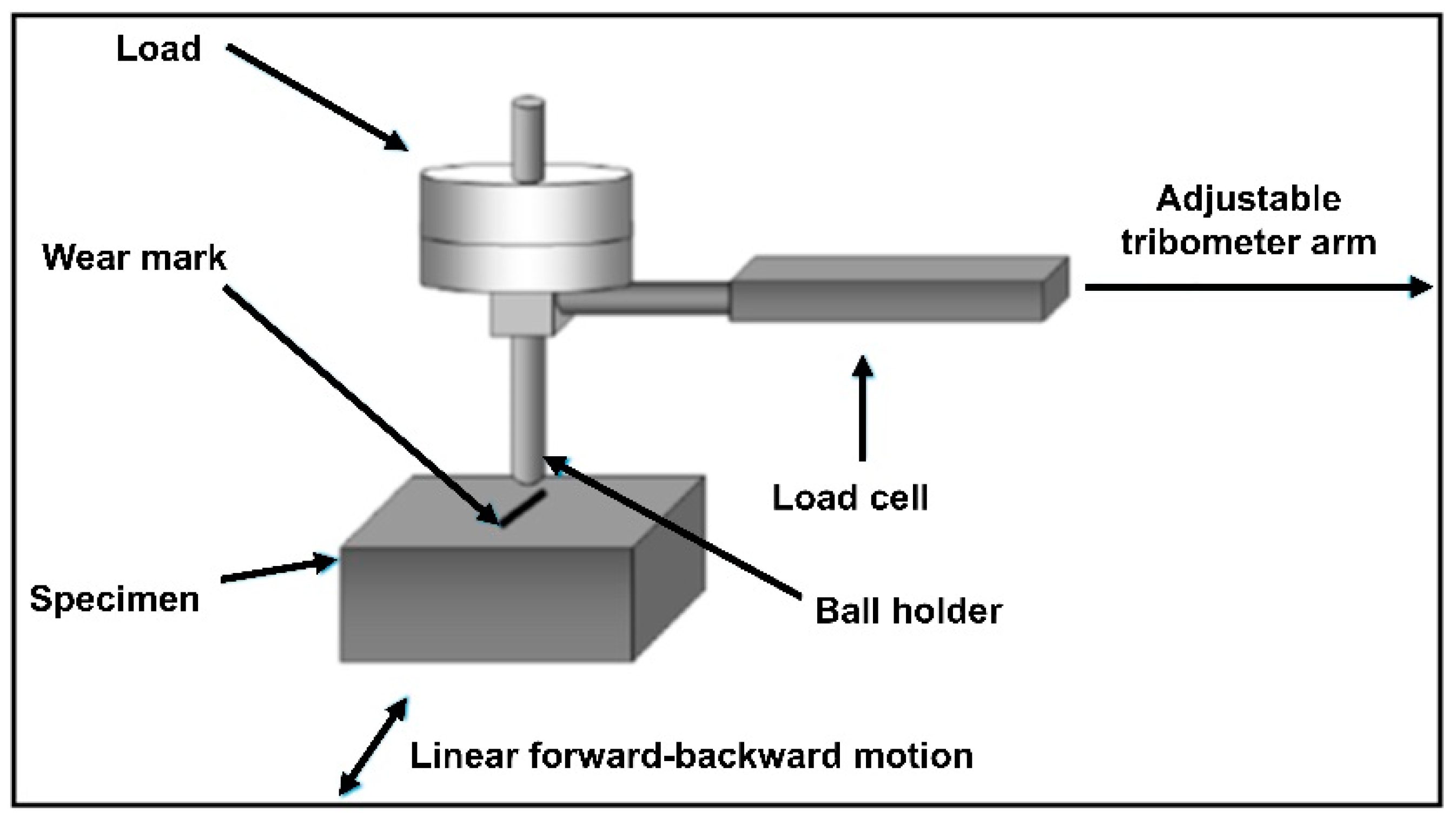

2.4. Wear Test

3. Results

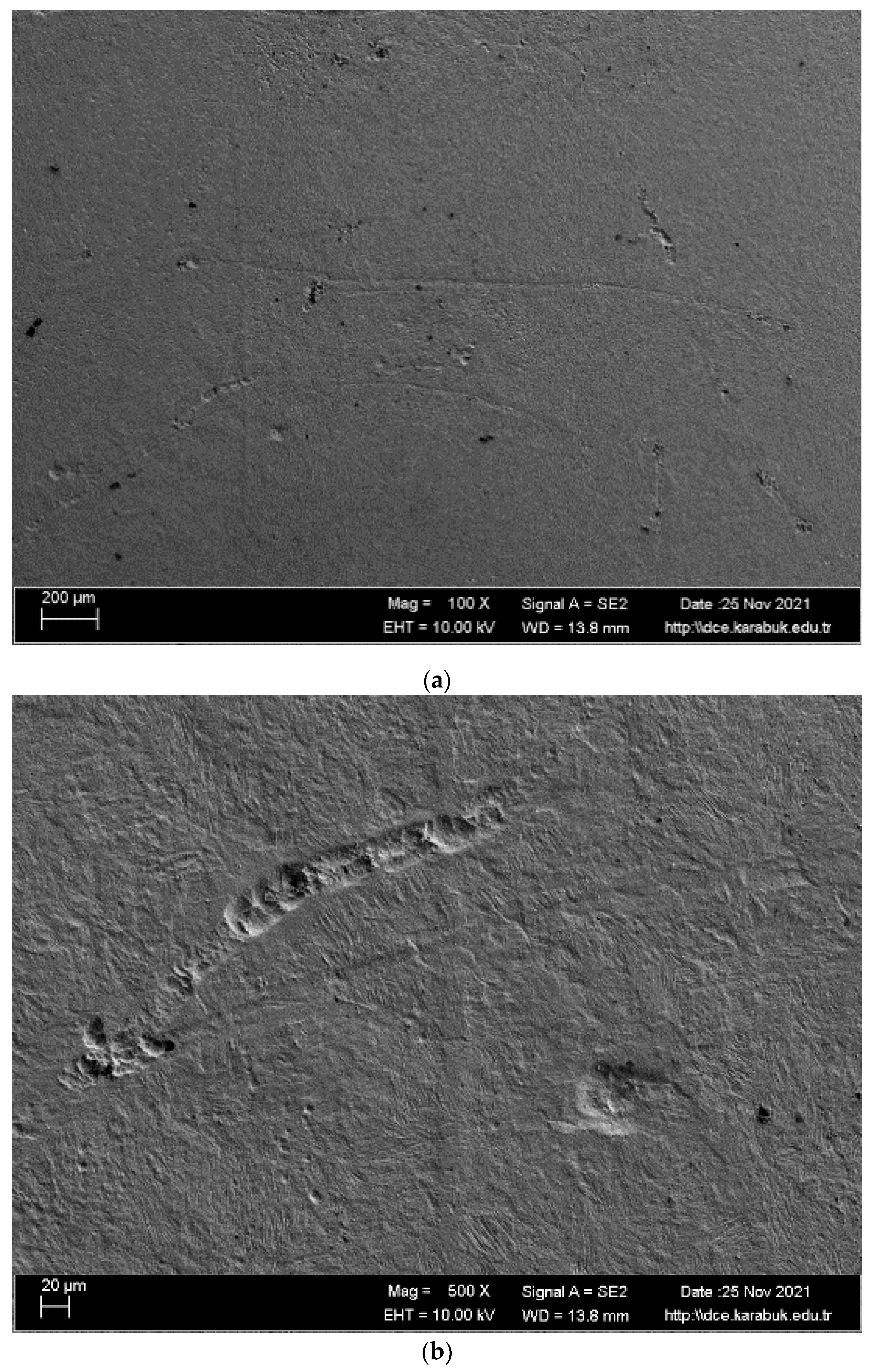

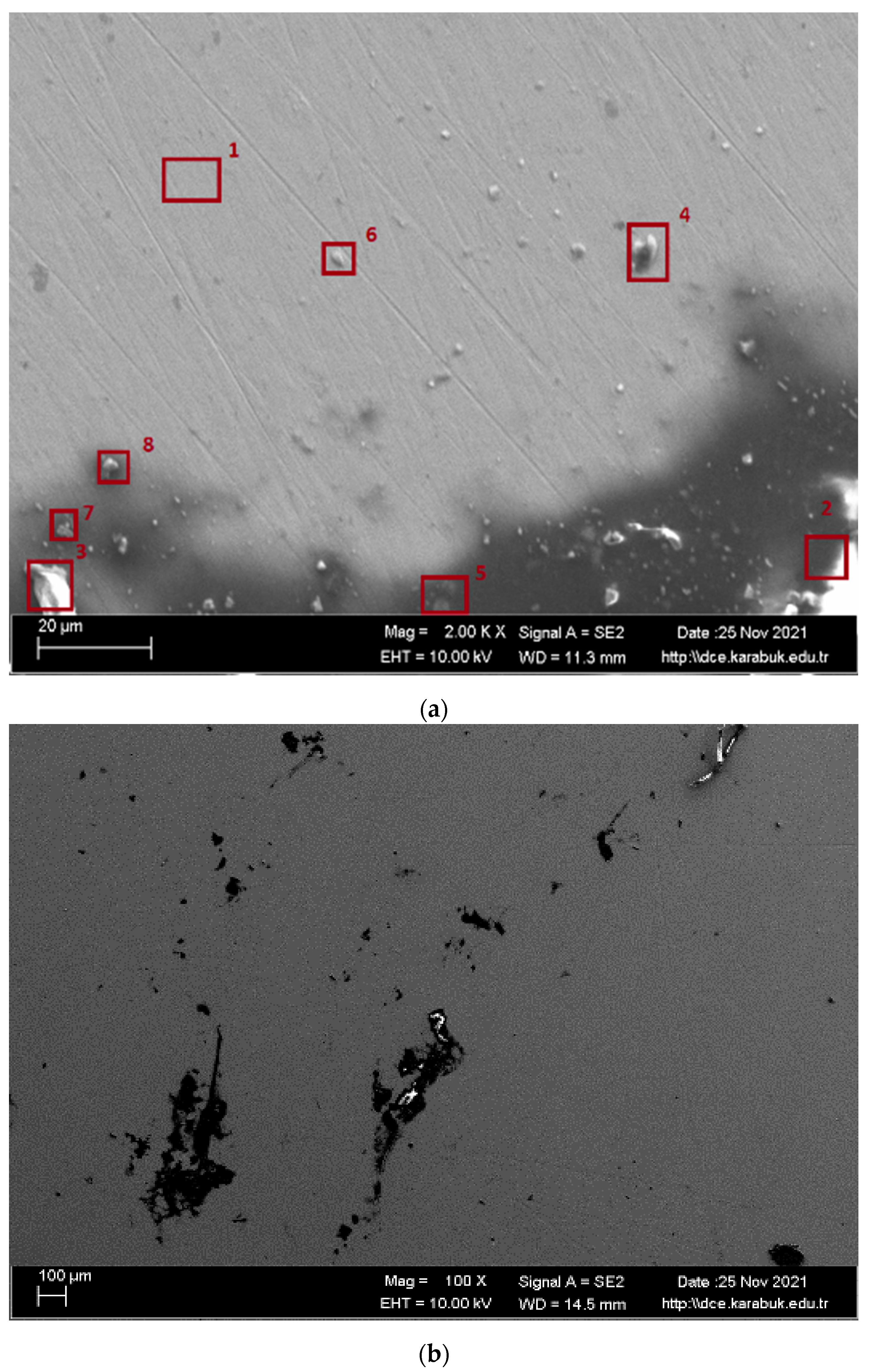

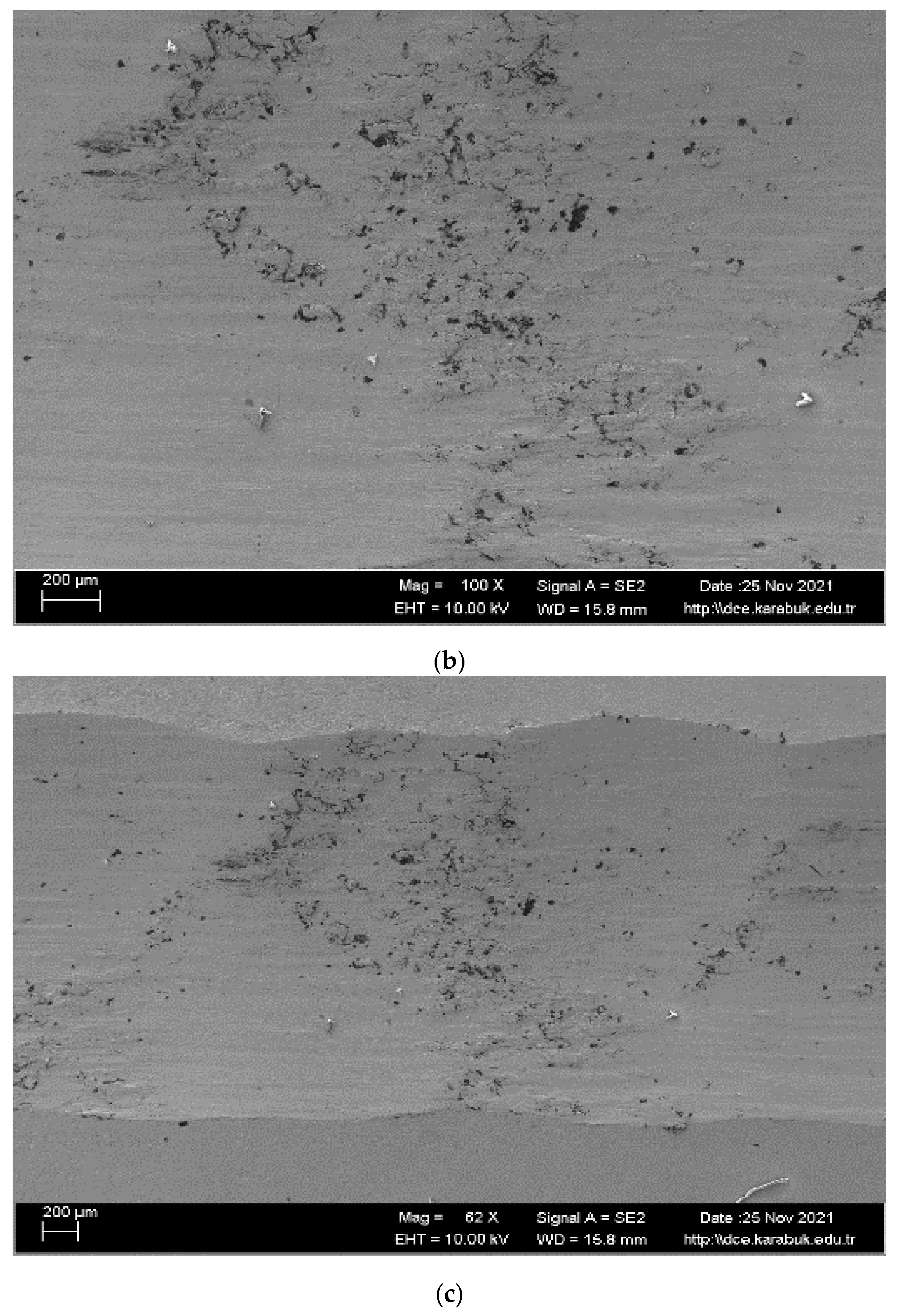

3.1. Mıcrostructural Results

XRD Analysis

3.2. Corrosion Test Results

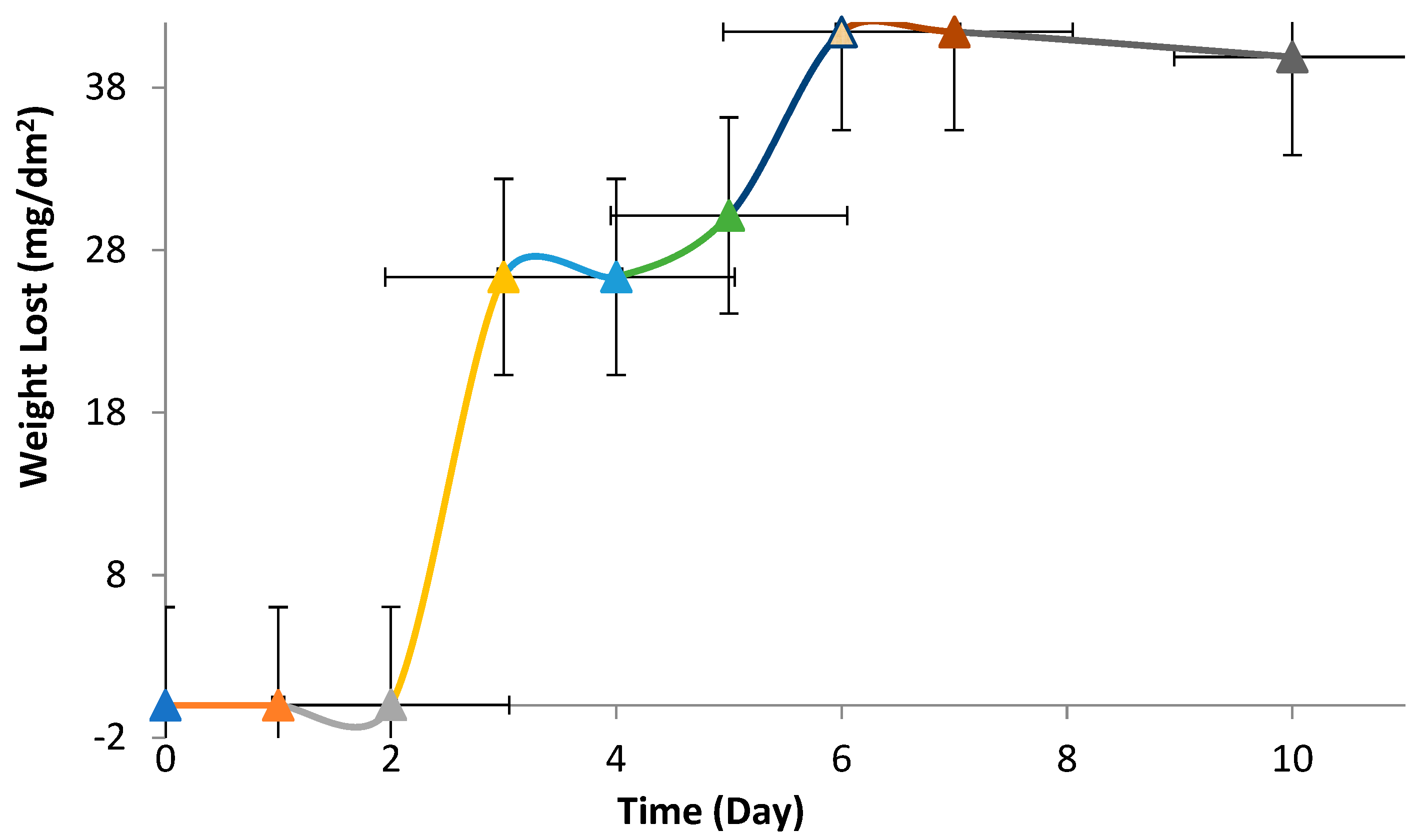

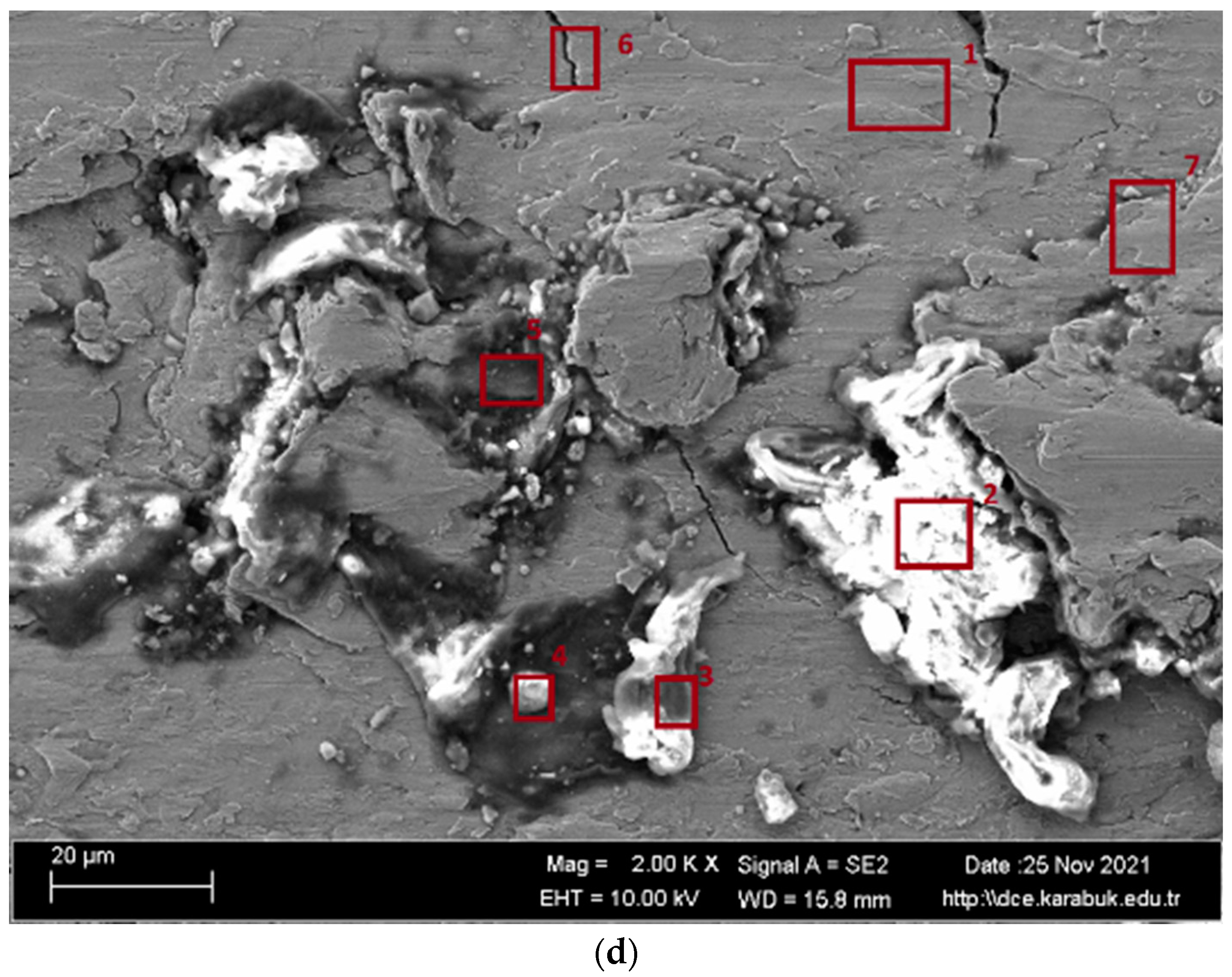

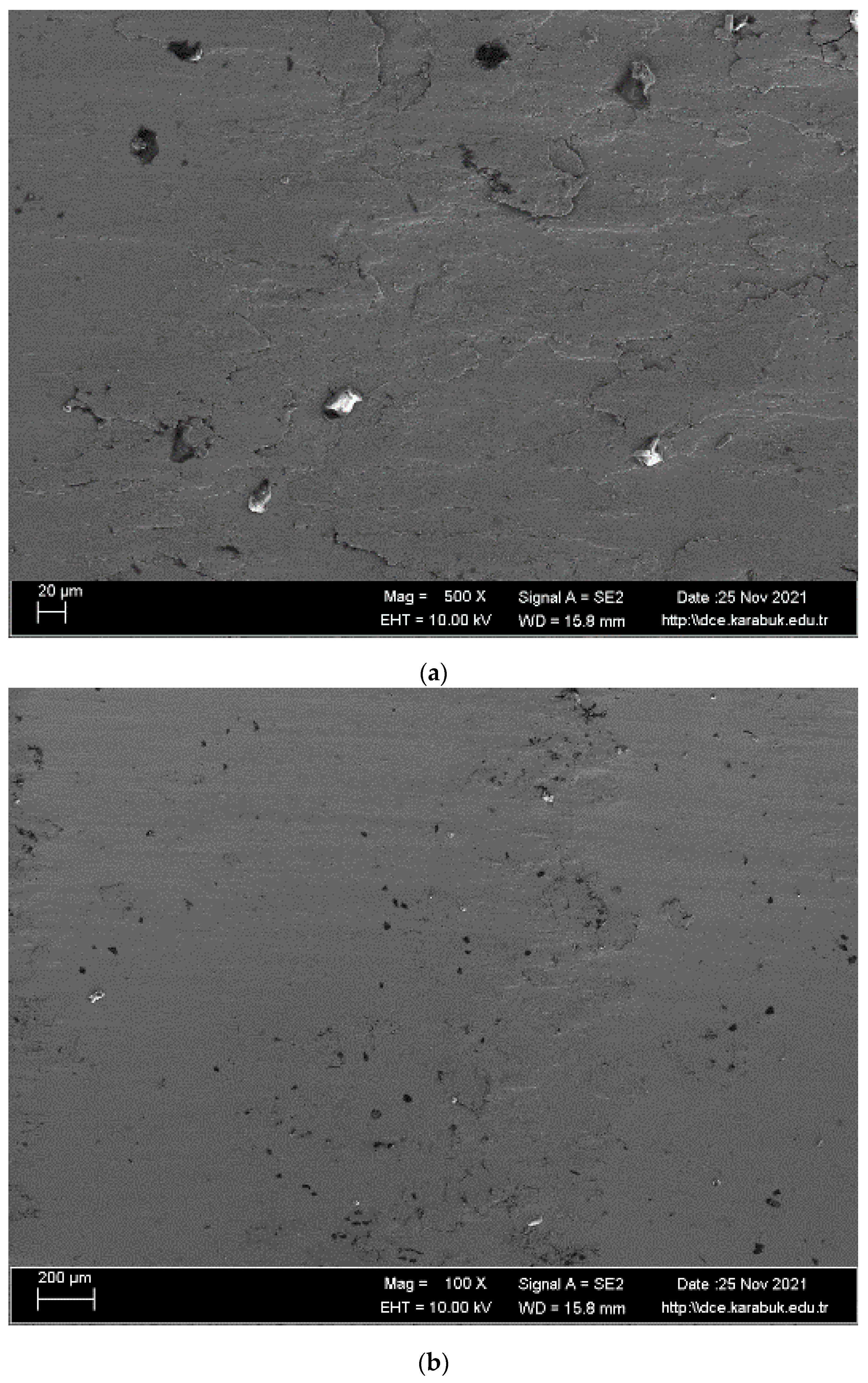

3.2.1. Immersion Corrosion Tests Results

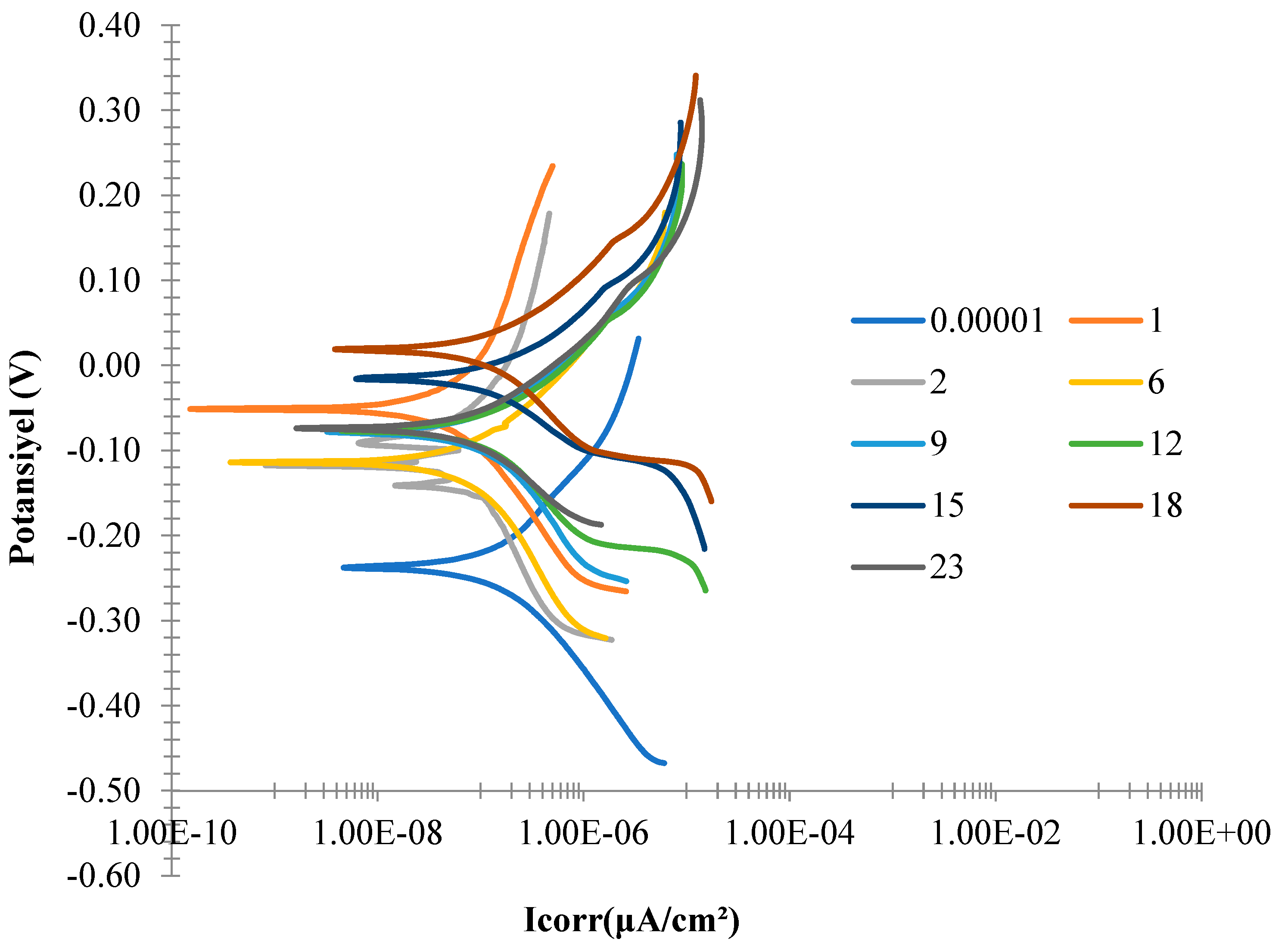

3.2.2. Potentiodynamic Corrosion Tests Results

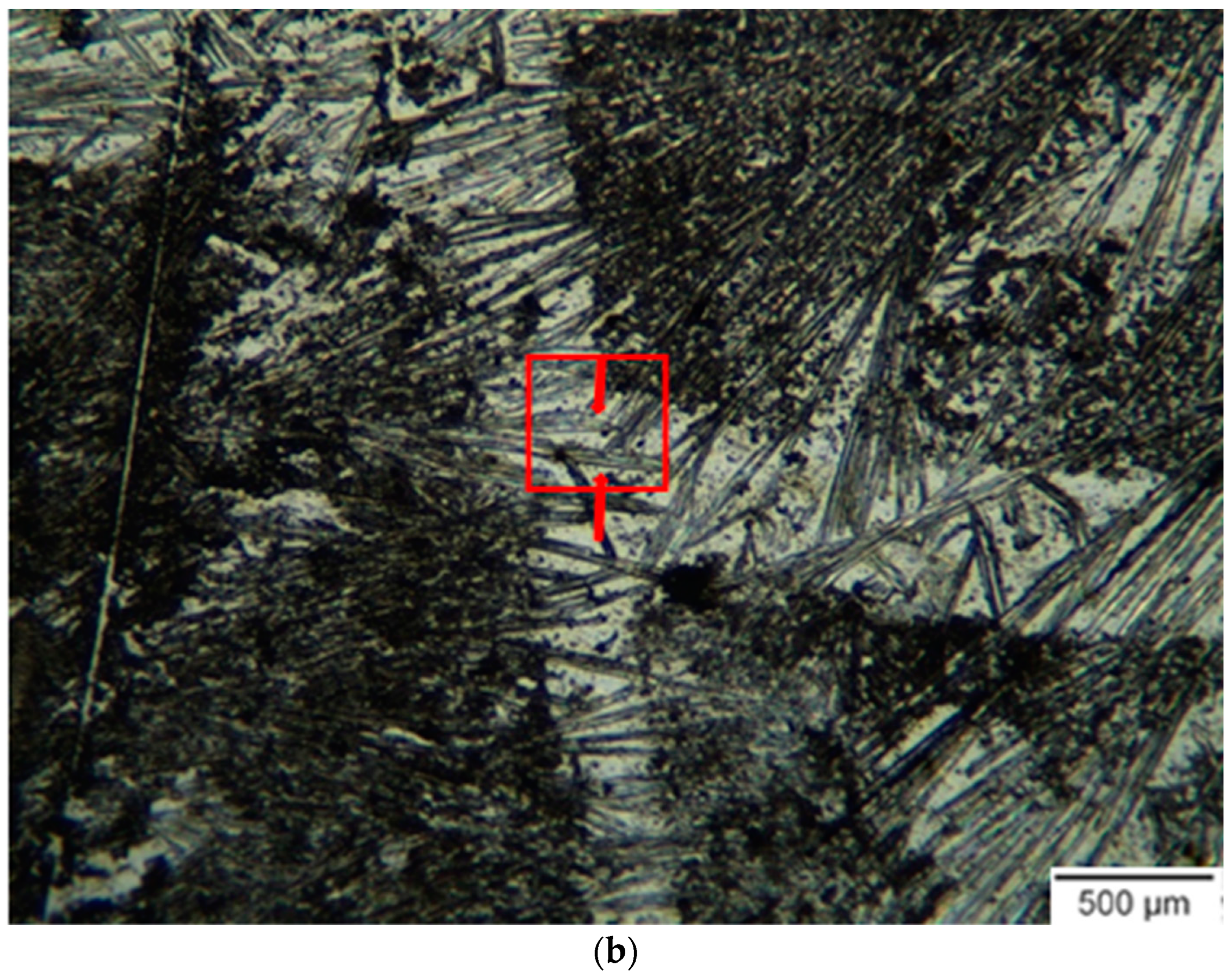

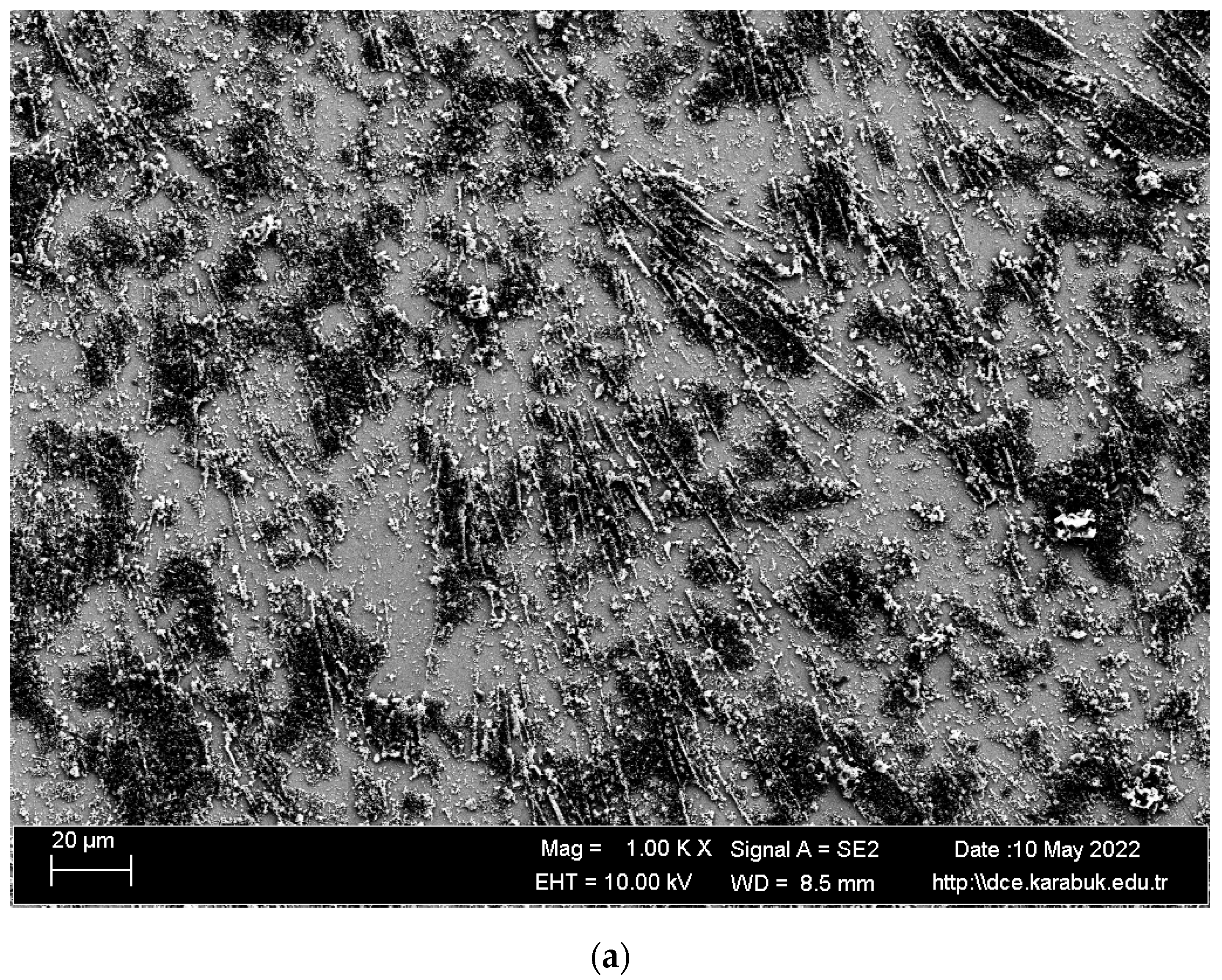

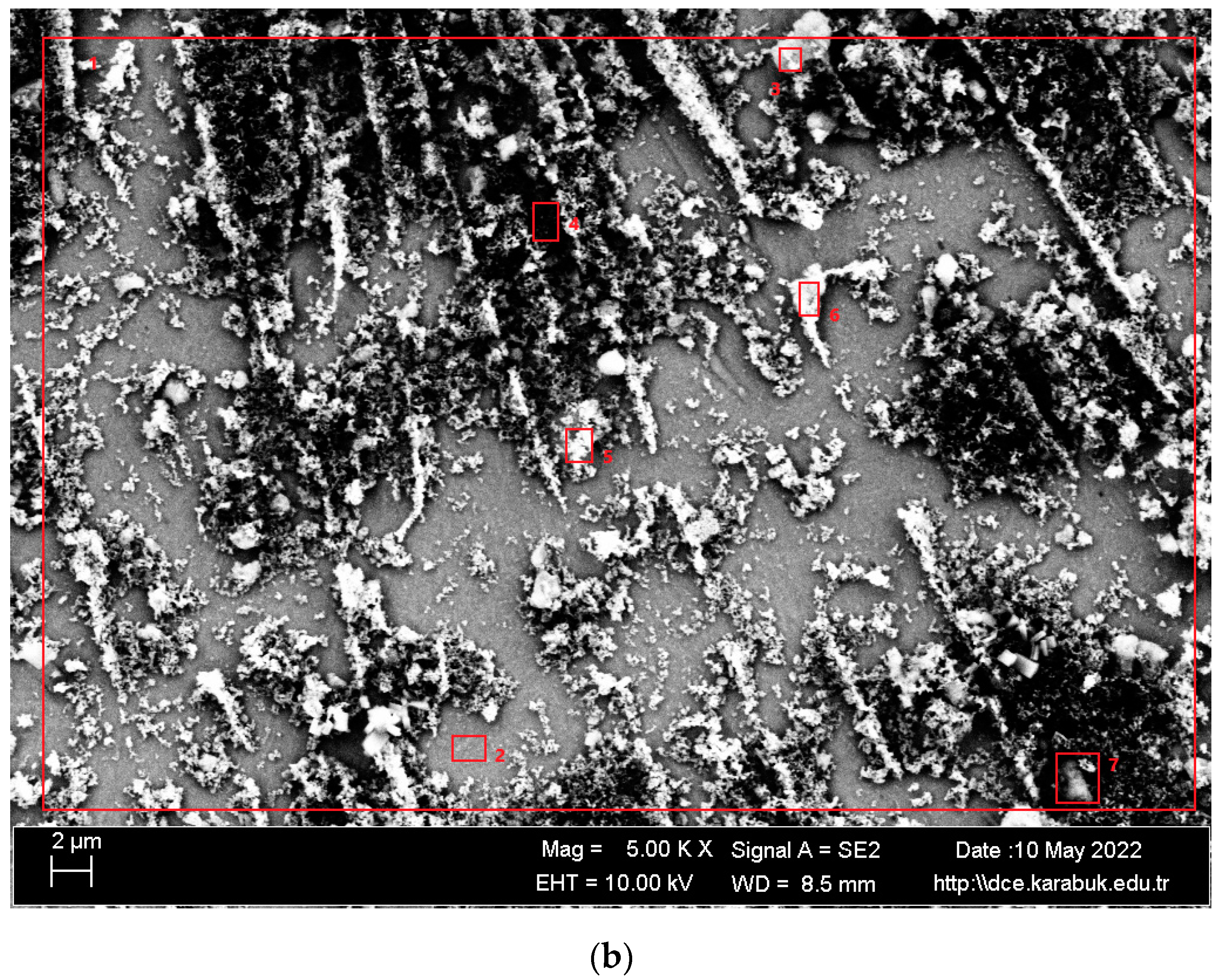

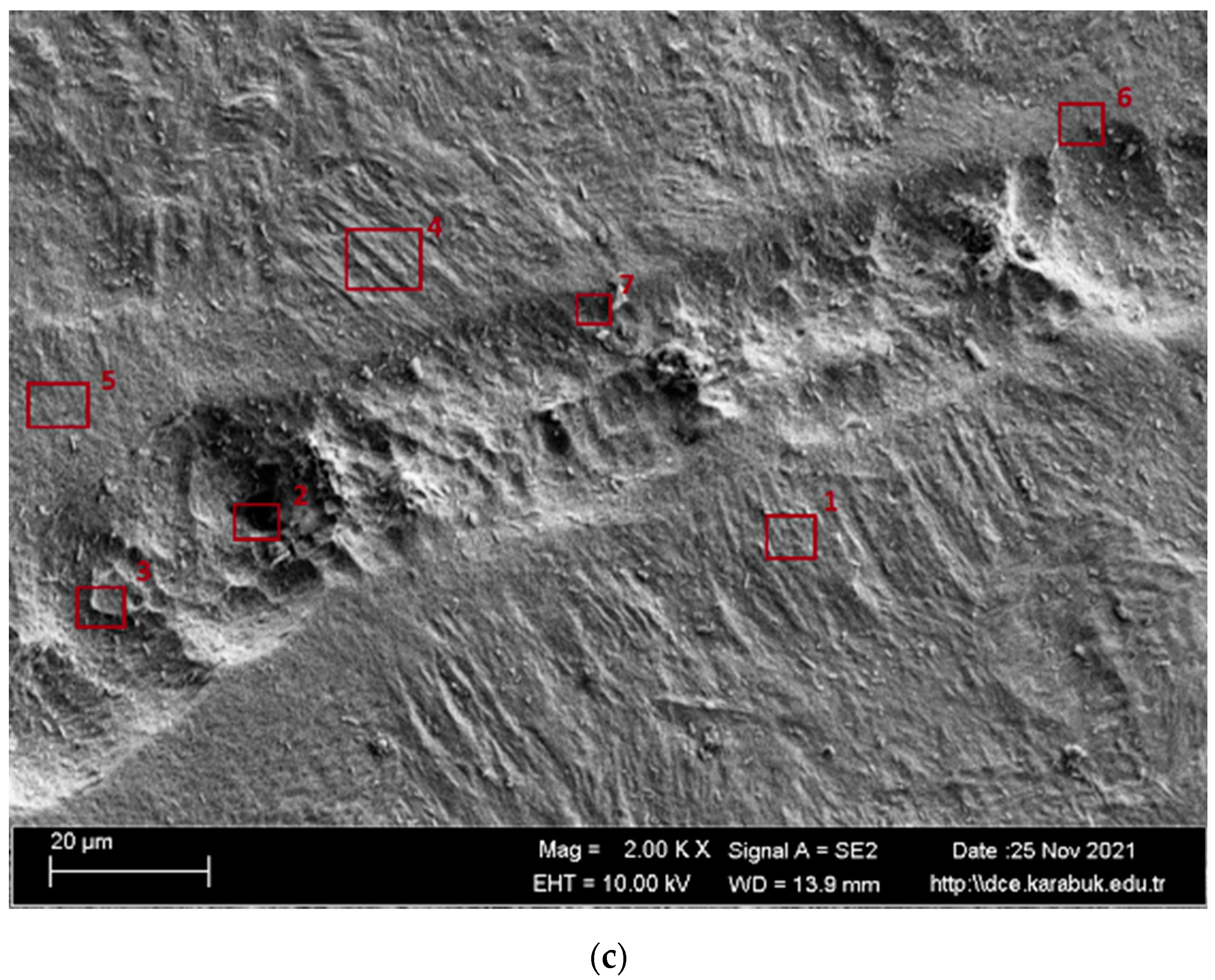

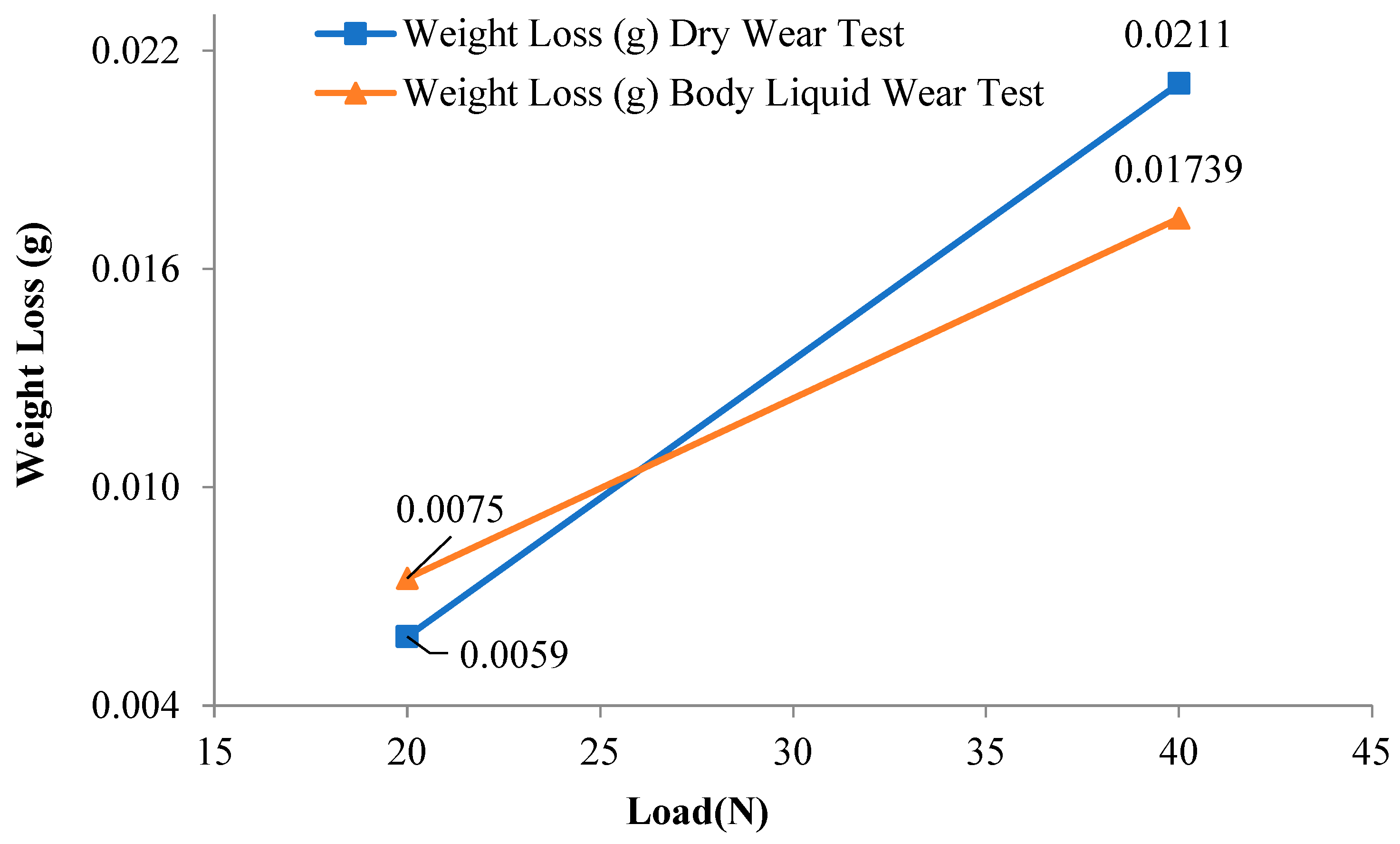

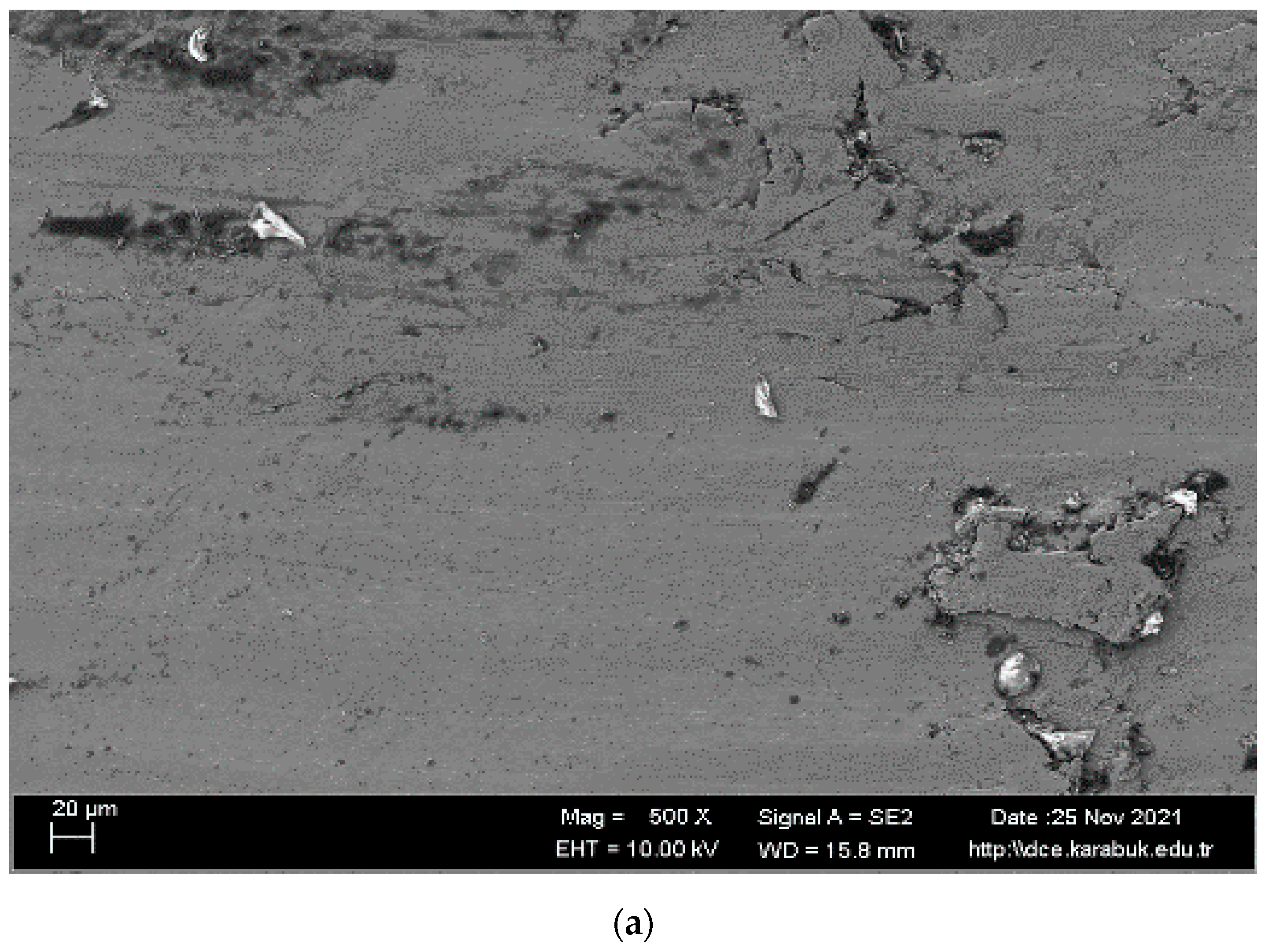

3.3. Wear Test Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Stöckel, D. The Shape Memory Effect-Phenomenon, Alloys and Applications. Proc. Shape Mem. Alloys Power Syst. 1995, 1, 1–13. [Google Scholar]

- Sathiya, P.; Ramesh, T. Experimental Investigation and Characterization of Laser Welded NiTinol Shape Memory Alloys. J. Manuf. Processes 2017, 25, 253–261. [Google Scholar]

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A Review of Shape Memory Alloy Research, Applications and Opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Dagdelen, F.; Aydogdu, Y. Transformation Behavior in NiTi20Ta and NiTi20Nb SMAs: Transformation Temperatures, Microstructure and Micro-Hardness. J. Therm. Anal. Calorim. 2019, 136, 637–642. [Google Scholar] [CrossRef]

- Auricchio, F.; Bonetti, E.; Scalet, G.; Ubertini, F. Theoretical and Numerical Modeling of Shape Memory Alloys Accounting for Multiple Phase Transformations and Martensite Reorientation. Int. J. Plast. 2014, 59, 30–54. [Google Scholar] [CrossRef]

- Centralgaheart Need Know Heart Stent. Available online: http://centralgaheart.com/need-know-heart-stent/ (accessed on 12 February 2023).

- McCracken, J.M.; Donovan, B.R.; White, T.J. Materials as Machines. Adv. Mater. 2020, 32, 1906564. [Google Scholar] [CrossRef]

- Tabesh, M. Finite Element Analysis of Shape Memory Alloy Biomedical Devices. Ph.D. Thesis, University of Toledo, Toledo, OH, USA, 2010. [Google Scholar]

- Castleman, L.S.; Motzkin, S.M.; Alicandri, F.P.; Bonawit, V.L.; Johnson, A.A. Biocompatibility of Nitinol Alloy as an Implant Material. J. Biomed. Mater. Res. 1976, 10, 695–731. [Google Scholar] [CrossRef]

- Buehler, W.J.; Wang, F.E. A Summary of Recent Research on the Nitinol Alloys and Their Potential Application in Ocean Engineering. Ocean Eng. 1968, 1, 105–120. [Google Scholar] [CrossRef]

- Zhang, L.C.; Chen, L.Y. A Review on Biomedical Titanium Alloys: Recent Progress and Prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef]

- Spruit, D.; Bongaarts, P.J.M.; Malten, K.E. Dermatological Effects of Nickel. In Nickel in the Environment; Wiley: New York, NY, USA, 1980; pp. 601–609. [Google Scholar]

- Di Tola, M.; Marino, M.; Amodeo, R.; Tabacco, F.; Casale, R.; Portaro, L.; Borghini, R.; Cristaudo, A.; Manna, F.; Rossi, A.; et al. Immunological Characterization of the Allergic Contact Mucositis Related to the Ingestion of Nickel-Rich Foods. Immunobiology 2014, 219, 522–530. [Google Scholar] [CrossRef]

- Cavani, A.; Mei, D.; Guerra, E.; Corinti, S.; Giani, M.; Pirrotta, L.; Puddu, P.; Girolomoni, G. Patients with Allergic Contact Dermatitis to Nickel and Nonallergic Individuals Display Different Nickel-Specific T Cell Responses. Evidence for the Presence of Effector CD8+ and Regulatory CD4+ T Cells. J. Investig. Dermatol. 1998, 111, 621–628. [Google Scholar] [CrossRef] [PubMed]

- Sager, A.; Esen, I.; Ahlatçi, H.; Turen, Y. Characterization and Corrosion Behavior of Composites Reinforced with ZK60, AlN, and SiC Particles. Eng. Sci. Technol. Int. J. 2023, 41, 101389. [Google Scholar] [CrossRef]

- Wisbey, A.; Gregson, P.J.; Peter, L.M.; Tuke, M. Effect of Surface Treatment on the Dissolution of Titanium-Based Implant Materials. Biomaterials 1991, 12, 470–473. [Google Scholar] [CrossRef] [PubMed]

- Pappas, M.J.; Makris, G.; Buechel, F.F. Titanium Nitride Ceramic Film against Polyethylene. A 48 Million Cycle Wear Test. Clin. Orthop. Relat. Res. 1995, 317, 64–70. [Google Scholar]

- Zhang, L.C.; Chen, L.Y.; Wang, L. Surface Modification of Titanium and Titanium Alloys: Technologies, Developments, and Future Interests. Adv. Eng. Mater. 2020, 22, 1901258. [Google Scholar] [CrossRef]

- Wang, H.; Wu, W.; Wang, F.; Yang, D. Dry Sliding Wear of Cu-Based Shape. Available online: https://www.ams.org.cn/EN/Y1991/V27/I6/50 (accessed on 12 February 2023).

- Richman, R.H.; Rao, A.S.; Kung, D. Cavitation Erosion of NiTi Explosively Welded to Steel. Wear 1995, 181, 80–85. [Google Scholar] [CrossRef]

- Liang, Y.N.; Li, S.Z.; Jin, Y.B.; Jin, W.; Li, S. Wear Behavior of a TiNi Alloy. Wear 1996, 198, 236–241. [Google Scholar] [CrossRef]

- Lin, H.C.; Liao, H.M.; He, J.L.; Lin, K.M.; Chen, K.C. Wear Characteristics of Ion-Nitrided Ti50Ni50 Shape Memory Alloys. Surf. Coat. Technol. 1997, 92, 178–189. [Google Scholar] [CrossRef]

- Gall, K.; Juntunen, K.; Maier, H.J.; Sehitoglu, H.; Chumlyakov, Y.I. Instrumented Micro-Indentation of NiTi Shape-Memory Alloys. Acta Mater. 2001, 49, 3205–3217. [Google Scholar] [CrossRef]

- Liu, R.; Li, D.Y.; Xie, Y.S.; Llewellyn, R.; Hawthorne, H.M. Indentation Behavior of Pseudoelastic TiNi Alloy. Scr. Mater. 1999, 41, 691–696. [Google Scholar] [CrossRef]

- Hornbogen, E. Ausforming of NiTi. J. Mater. Sci. 1999, 34, 599–606. [Google Scholar] [CrossRef]

- Li, D.Y. A New Type of Wear-Resistant Material: Pseudo-Elastic TiNi Alloy. Wear 1998, 221, 116–123. [Google Scholar] [CrossRef]

- Li, D.Y. Exploration of TiNi Shape Memory Alloy for Potential Application in a New Area: Tribological Engineering. Smart Mater. Struct. 2000, 9, 717. [Google Scholar] [CrossRef]

- Jin, J.; Wang, H. Wear Resistance of NiTi Alloy. Acta Metall. Sin. 1988, 1, 76–81. [Google Scholar]

- Abedini, M.; Ghasemi, H.M.; Nili Ahmadabadi, M. Tribological Behavior of NiTi Alloy in Martensitic and Austenitic States. Mater. Des. 2009, 30, 4493–4497. [Google Scholar] [CrossRef]

- Li, Y.; Schreiber, P.; Schneider, J.; Greiner, C. Tribological Mechanisms of Slurry Abrasive Wear. Friction 2023, 11, 1079–1093. [Google Scholar] [CrossRef]

- Callister, W.D. Mechanical Properties of Metals. In Materials Science and Engineering An Introduction; John Wiley and Sons, Inc.: New York, NY, USA, 1994. [Google Scholar]

- Tekin, E. Demirdışı Metaller ve Alaşımlarının Uygulamalı Optik Metalografisi, 2nd ed.; Baskı SEGEM Yayın: Ankara, Turkey, 1984. [Google Scholar]

- Muratoǧlu, M.; Aksoy, M. Abrasive Wear of 2124Al-SiC Composites in the Temperature Range 20–200 °C. J. Mater. Process. Technol. 2006, 174, 272–276. [Google Scholar] [CrossRef]

- Kaya, I.; Tobe, H.; Karaca, H.E.; Basaran, B.; Nagasako, M.; Kainuma, R.; Chumlyakov, Y. Effects of Aging on the Shape Memory and Superelasticity Behavior of Ultra-High Strength Ni54Ti46 Alloys under Compression. Mater. Sci. Eng. A 2016, 678, 93–100. [Google Scholar] [CrossRef]

- Morawiec, H.; Stroz, D.; Goryczka, T.; Chrobak, D. Two-Stage Martensitic Transformation in a Deformed and Annealed NiTi Alloy. Scr. Mater. 1996, 35, 485–490. [Google Scholar] [CrossRef]

- Kuang, C.-H.; Chien, C.; Wu, S.-K. Multistage Martensitic Transformation in High Temperature Aged Ti48Ni52 Shape Memory Alloy. Intermetallics 2015, 67, 12–18. [Google Scholar] [CrossRef]

- Mathew, Y.; Babu, B.G. A Real Time Experimental Set up to Analyse Automatic Actuation of a Fire Sprinkler Using a Shape Memory Alloy (NiTinol). Trans. Famena 2015, 39, 9–22. [Google Scholar]

- Bouzoubaa, A.; Costa, D.; Diawara, B.; Audiffren, N.; Marcus, P. Insight of DFT and Atomistic Thermodynamics on the Adsorption and Insertion of Halides onto the Hydroxylated NiO (1 1 1) Surface. Corros. Sci. 2010, 52, 2643–2652. [Google Scholar] [CrossRef]

- Costa, D.; Garrain, P.-A.; Diawara, B.; Marcus, P. Biomolecule- Biomaterial Interaction: A DFT-D Study of Glycine Adsorption and Self-Assembly on Hydroxylated Cr2O3 Surfaces. Langmuir 2011, 27, 2747–2760. [Google Scholar] [CrossRef]

- Islam, M.M.; Diawara, B.; Marcus, P.; Costa, D. Synergy between Iono-Covalent Bonds and van Der Waals Interactions in SAMs Formation: A First-Principles Study of Adsorption of Carboxylic Acids on the Zn-ZnO (0 0 0 1) Surface. Catal. Today 2011, 177, 39–49. [Google Scholar] [CrossRef]

- Cisse, O.; Savadogo, O.; Wu, M.; Yahia, L. Effect of Surface Treatment of NiTi Alloy on Its Corrosion Behavior in Hanks’ Solution. J. Biomed. Mater. Res. 2002, 61, 339–345. [Google Scholar] [CrossRef]

- Balci, E.; Dagdelen, F.; Qader, I.N.; Kok, M. Effects of Substituting Nb with V on Thermal Analysis and Biocompatibility Assessment of Quaternary NiTiNbV SMA. Eur. Phys. J. Plus 2021, 136, 145. [Google Scholar] [CrossRef]

- Sager, A.; Esen, I.; Ahlatçi, H.; Turen, Y. Dry Wear Behaviour of the New ZK60/AlN/SiC Particle Reinforced Composites. Materials 2022, 15, 8582. [Google Scholar] [CrossRef]

| Mass Percent (%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Spectrum | H | C | O | Na | Mg | Cl | K | Ca | Ti | Ni | Cu |

| 1 | 0.03 | 2.15 | 48.57 | 0.33 | 0.39 | 0 | 0.13 | 0.04 | 20.92 | 27.35 | 0.09 |

| 2 | 0 | 0.02 | 3.83 | 0.28 | 0.08 | 0.07 | 0.16 | 0 | 39.38 | 56.17 | 0 |

| 3 | 0.09 | 9.3 | 48.99 | 0.7 | 0.69 | 0.09 | 0 | 0.07 | 11.27 | 27.94 | 0.87 |

| 4 | 0.12 | 1.69 | 61.92 | 0.31 | 0.35 | 0 | 0 | 0 | 17.37 | 18.24 | 0 |

| 5 | 0.01 | 3.03 | 44.5 | 0.25 | 0.12 | 0.19 | 0.01 | 0 | 20.45 | 31.44 | 0 |

| 6 | 0.02 | 3 | 41.71 | 0.49 | 0.32 | 0.04 | 0 | 0 | 22 | 32.14 | 0.28 |

| 7 | 0.05 | 5.49 | 59.33 | 0.36 | 0.39 | 0 | 0.01 | 0.08 | 15.24 | 18.81 | 0.24 |

| Mean value: | 0.04 | 3.53 | 44.12 | 0.39 | 0.33 | 0.06 | 0.05 | 0.03 | 20.95 | 30.3 | 0.21 |

| Sigma: | 0.04 | 3.03 | 19.24 | 0.16 | 0.2 | 0.07 | 0.07 | 0.04 | 8.95 | 12.69 | 0.32 |

| Sigma means: | 0.02 | 1.15 | 7.27 | 0.06 | 0.08 | 0.03 | 0.03 | 0.01 | 3.38 | 4.79 | 0.12 |

| Mass Percent (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Spectrum | C | O | Na | Mg | K | Ca | Ti | Ni | Cu |

| 1 | 5.04 | 25.53 | 2.12 | 1.58 | 0.29 | 0.00 | 52.24 | 13.20 | 0.00 |

| 2 | 63.40 | 11.19 | 0.56 | 0.25 | 0.11 | 0.01 | 19.42 | 4.80 | 0.27 |

| 3 | 5.51 | 28.33 | 2.92 | 1.66 | 0.40 | 0.74 | 46.48 | 12.86 | 1.11 |

| 4 | 4.04 | 30.04 | 2.50 | 1.44 | 0.00 | 0.05 | 50.26 | 10.42 | 1.26 |

| 5 | 2.30 | 27.40 | 2.80 | 2.50 | 0.00 | 0.12 | 51.24 | 13.64 | 0.00 |

| 6 | 5.54 | 25.09 | 1.85 | 0.73 | 0.21 | 0.82 | 51.96 | 13.45 | 0.35 |

| 7 | 11.74 | 26.93 | 1.26 | 0.30 | 0.20 | 1.11 | 48.46 | 10.01 | 0.00 |

| Mean value: | 13.94 | 24.93 | 2.00 | 1.21 | 0.17 | 0.41 | 45.72 | 11.20 | 0.43 |

| Sigma: | 22.01 | 6.29 | 0.86 | 0.82 | 0.15 | 0.47 | 11.78 | 3.18 | 0.54 |

| Sigma means: | 8.62 | 2.38 | 0.32 | 0.31 | 0.06 | 0.18 | 4.45 | 1.20 | 0.20 |

| Mass Percent (%) | |||||

|---|---|---|---|---|---|

| Spectrum | C | O | Ti | Ni | Cu |

| 1 | 13.78 | 34.90 | 41.61 | 9.71 | 0.00 |

| 2 | 82.10 | 17.06 | 0.86 | 0.00 | 0.00 |

| 3 | 78.67 | 20.51 | 0.66 | 0.00 | 0.16 |

| 4 | 44.29 | 26.30 | 23.97 | 5,44 | 0.00 |

| 5 | 49.01 | 15.68 | 28.28 | 7.04 | 0.00 |

| 6 | 74.36 | 19.85 | 5.43 | 0.34 | 0.02 |

| 7 | 60.28 | 30.62 | 7.99 | 1.08 | 0.03 |

| Mean value: | 57.50 | 23.56 | 15.54 | 3.37 | 0.03 |

| Sigma: | 24.16 | 7.23 | 15.86 | 3.98 | 0.06 |

| Sigma mean: | 9.13 | 2.73 | 6.00 | 1.50 | 0.02 |

| Mass Percent (%) | |||||

|---|---|---|---|---|---|

| Spectrum | C | O | Ti | Ni | Cu |

| 1 | 15.15 | 33.98 | 41.95 | 8.85 | 0.05 |

| 2 | 68.23 | 27.63 | 3.96 | 0.04 | 0.14 |

| 3 | 72.71 | 27.28 | 0.01 | 0.00 | 0.00 |

| Mean value: | 52.03 | 29.63 | 15.31 | 2.96 | 0.07 |

| Sigma: | 32.02 | 3.77 | 23.16 | 5.09 | 0.07 |

| Sigma mean: | 18.48 | 2.18 | 13.37 | 2.94 | 0.04 |

| Mass Percent (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Spectrum | C | O | Na | Mg | K | Ca | Ti | Ni | Cu |

| 1 | 10.54 | 32.38 | 2.57 | 1.88 | 0.56 | 0.49 | 41.13 | 10.45 | 0.00 |

| 2 | 54.64 | 38.93 | 4.58 | 0.47 | 0.42 | 0.65 | 0.11 | 0.20 | 0.00 |

| 3 | 58.67 | 33.75 | 4.46 | 0.85 | 0.91 | 0.58 | 0.51 | 0.07 | 0.20 |

| 4 | 31.03 | 10.95 | 54.85 | 1.42 | 0.67 | 0.34 | 0.45 | 0.00 | 0.29 |

| 5 | 43.14 | 39.46 | 2.80 | 1.15 | 0.68 | 0.70 | 11.85 | 0.08 | 0.14 |

| 6 | 15.93 | 33.73 | 2.67 | 1.02 | 0.67 | 0.57 | 36.51 | 8.77 | 0.14 |

| 7 | 24.56 | 37.82 | 3.76 | 0.85 | 0.26 | 0.06 | 26.87 | 5.82 | 0.00 |

| Mean value: | 34.07 | 32.43 | 10.82 | 1.09 | 0.59 | 0.48 | 16.78 | 3.63 | 0.11 |

| Sigma: | 18.68 | 9.88 | 19.44 | 0.46 | 0.21 | 0.22 | 17.88 | 4.62 | 0.11 |

| Sigma means: | 7.06 | 3.73 | 7.35 | 0.17 | 0.08 | 0.08 | 6.76 | 1.74 | 0.04 |

| Mass Percent (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Spectrum | C | O | Na | Mg | K | Ca | Ti | Ni | Cu |

| 1 | 6.97 | 26.22 | 3.44 | 1.75 | 0.00 | 0.65 | 48.33 | 12.63 | 0.00 |

| 2 | 32.51 | 52.42 | 4.29 | 0.90 | 1.40 | 1.14 | 7.11 | 0.24 | 0.00 |

| 3 | 37.36 | 44.98 | 3.74 | 0.67 | 1.16 | 0.69 | 10.54 | 0.79 | 0.06 |

| 4 | 9.19 | 41.51 | 2.44 | 0.95 | 0.13 | 0.17 | 34.57 | 10.09 | 0.96 |

| 5 | 36.21 | 47.42 | 3.85 | 0.63 | 0.92 | 0.76 | 8.77 | 1.44 | 0.00 |

| 6 | 8.92 | 38.48 | 2.77 | 1.83 | 0.00 | 0.56 | 36.02 | 10.55 | 0.87 |

| 7 | 38.65 | 35.63 | 1.12 | 0.70 | 0.00 | 0.61 | 22.50 | 0.79 | 0.00 |

| Mean value: | 24.26 | 40.95 | 3.09 | 1.06 | 0.52 | 0.66 | 23.98 | 5.22 | 0.27 |

| Sigma: | 15.01 | 8.58 | 1.08 | 0.51 | 0.62 | 0.29 | 16.07 | 5.56 | 0.44 |

| Sigma means: | 5.67 | 3.24 | 0.41 | 0.19 | 0.23 | 0.11 | 6.07 | 2.10 | 0.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soltan, A.A.M.; Esen, İ.; Kara, S.A.; Ahlatçı, H. Examination of the Corrosion Behavior of Shape Memory NiTi Material for Biomedical Applications. Materials 2023, 16, 3951. https://doi.org/10.3390/ma16113951

Soltan AAM, Esen İ, Kara SA, Ahlatçı H. Examination of the Corrosion Behavior of Shape Memory NiTi Material for Biomedical Applications. Materials. 2023; 16(11):3951. https://doi.org/10.3390/ma16113951

Chicago/Turabian StyleSoltan, Aboujaila A. M., İsmail Esen, Seyit Ali Kara, and Hayrettin Ahlatçı. 2023. "Examination of the Corrosion Behavior of Shape Memory NiTi Material for Biomedical Applications" Materials 16, no. 11: 3951. https://doi.org/10.3390/ma16113951

APA StyleSoltan, A. A. M., Esen, İ., Kara, S. A., & Ahlatçı, H. (2023). Examination of the Corrosion Behavior of Shape Memory NiTi Material for Biomedical Applications. Materials, 16(11), 3951. https://doi.org/10.3390/ma16113951