Efficient, Fine-Grained Fly Ash Concrete Based on Metal and Basalt Fibers

Abstract

:1. Introduction

2. Materials and Methods

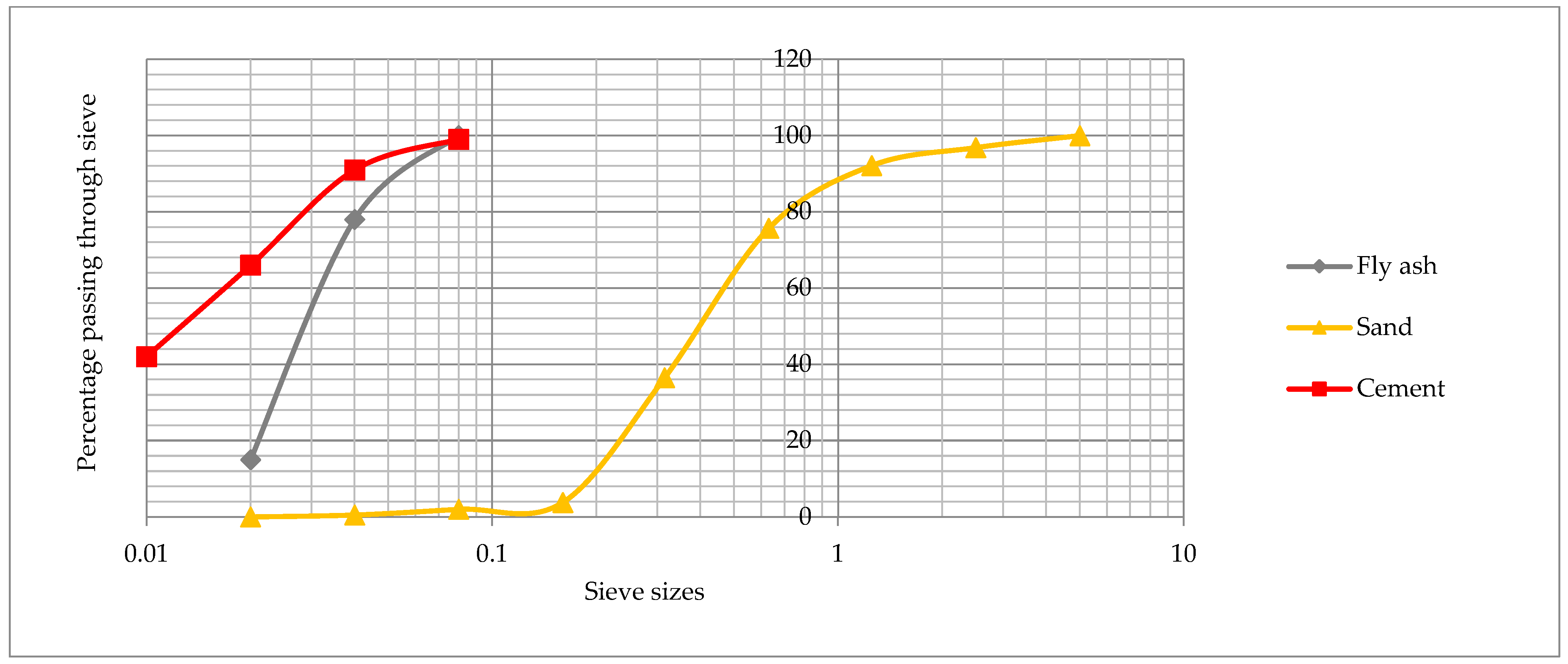

- Portland cement CEM I 42.5R from the “Dyckerhoff” Wiesbaden, Germany, cement plant in Ukraine. Mineralogical composition of clinker: C3S—57.10%; C2S—21.27%; C3A—6.87%; C4AF—12.19% (EN 196-2). The specific surface area of Portland cement SCem = 300–320 m2/kg (EN 196-6). The chemical composition of Portland cement (determined chemically according to EN 196-2) is shown in Table 1; particle size distribution of Portland cement is shown in Figure 1;

- Fly ash from “Burshtyn” TPP (Ivano-Frankivsk Oblast, Ukraine), which is a type II category B ash with a 45 μm sieve particle size of no more than 25% (class 2) (EN 450-1:2012). The specific surface area of the fly ash SA = 250–280 m2/kg (EN 196-6). The chemical composition of the fly ash is shown in Table 1; particle size distribution of fly ash is shown in Figure 1;

- Quartz sand with a fineness modulus FM = 2.05. Dust and clay particle content up to 1.5% (EN 12620+A1); particle size distribution of sand is shown in Figure 1;

- Granite aggregate of a 2–5.6 mm fraction. Dust and clay particle content up to 0.5% (EN 12620+A1);

- Polycarboxylate superplasticizer with 30% water reduction effect (EN 934-2);

- Steel fiber (StF) with a wavy shape. The standard tensile strength is 1350 MPa (EN 14889-1). Fiber dimensions: length—60.0 ± 5.0 mm; thickness—1.0 ± 0.1 mm, wave width—6.0 ± 0.1 mm. A photo of the steel fiber is shown in Figure 2a;

- Basalt fiber (BF). Fiber dimensions: length—24 mm, diameter—16 µm. Tensile strength 2800 MPa and elastic modulus 85 GPa. A photo of the basalt fiber is shown in Figure 2b.

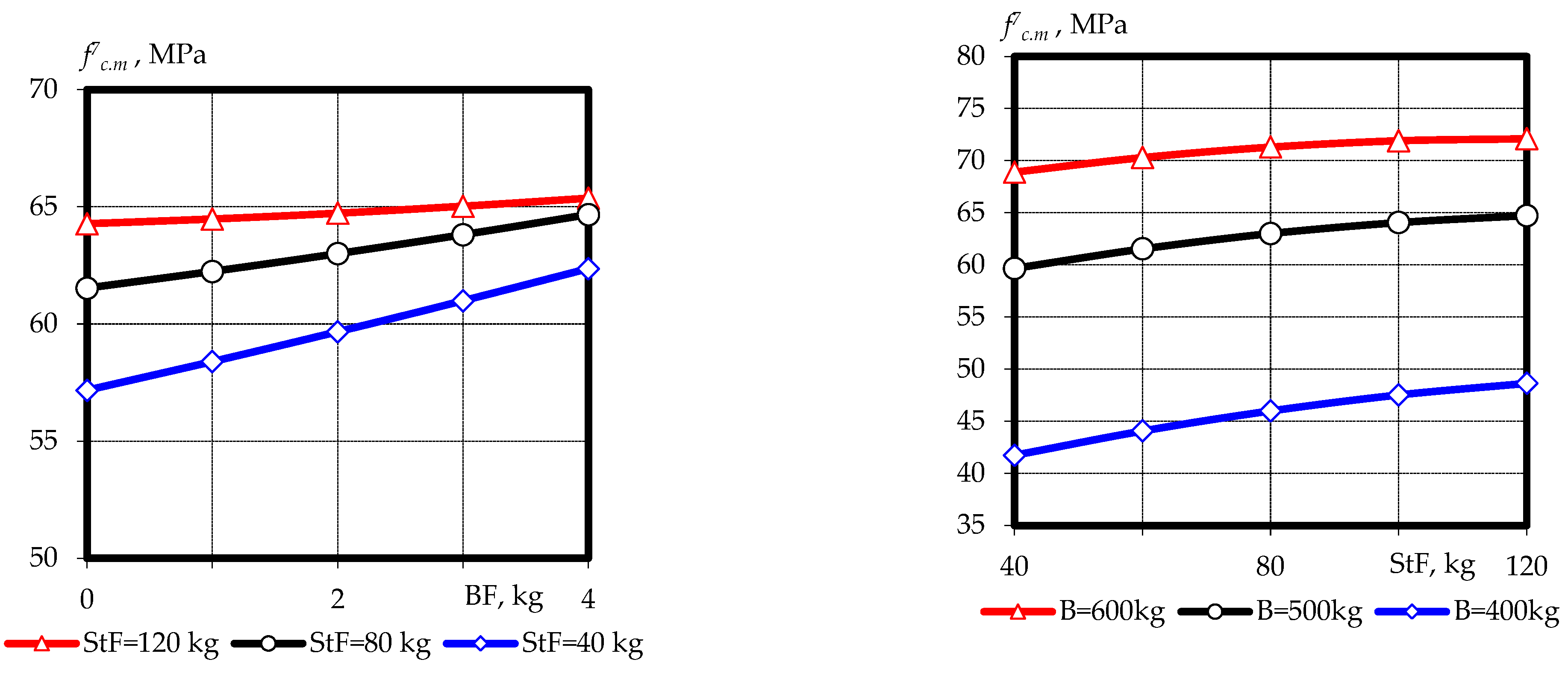

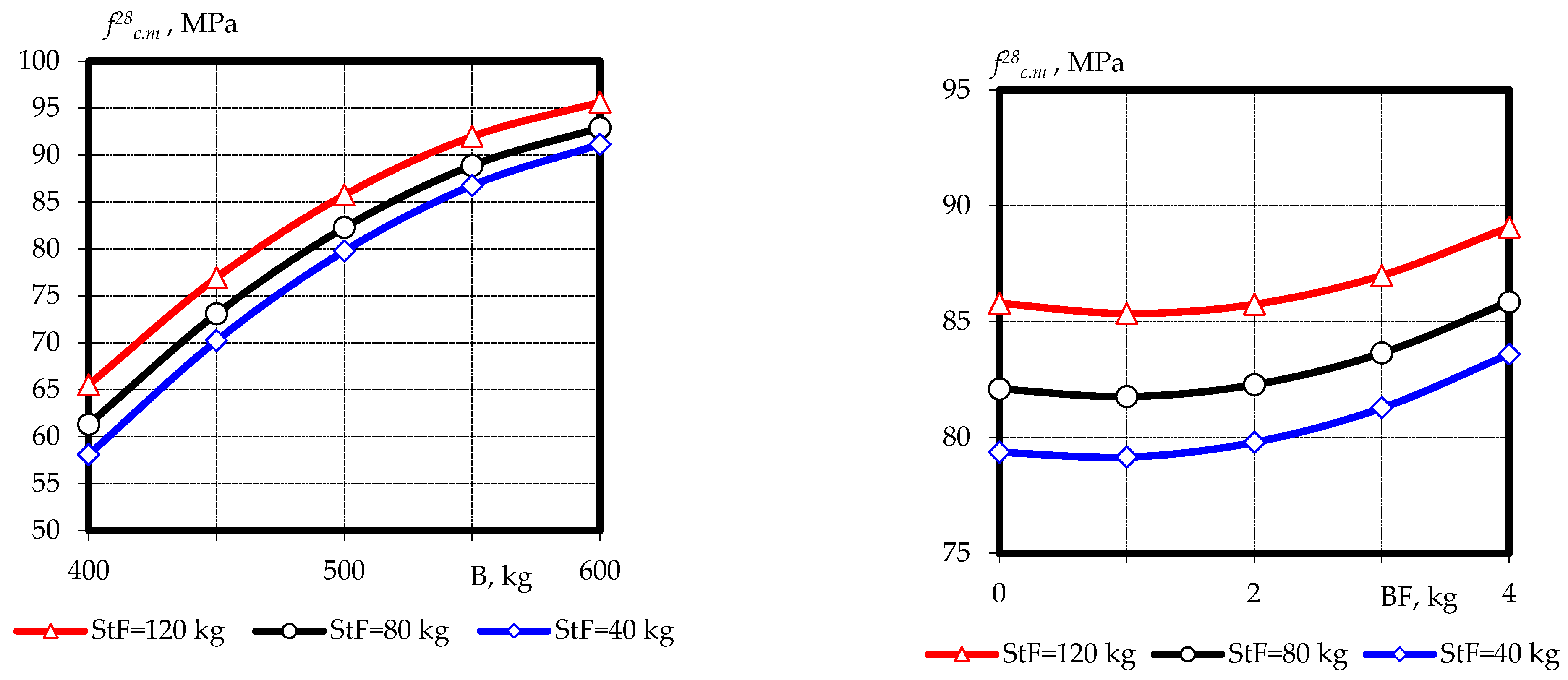

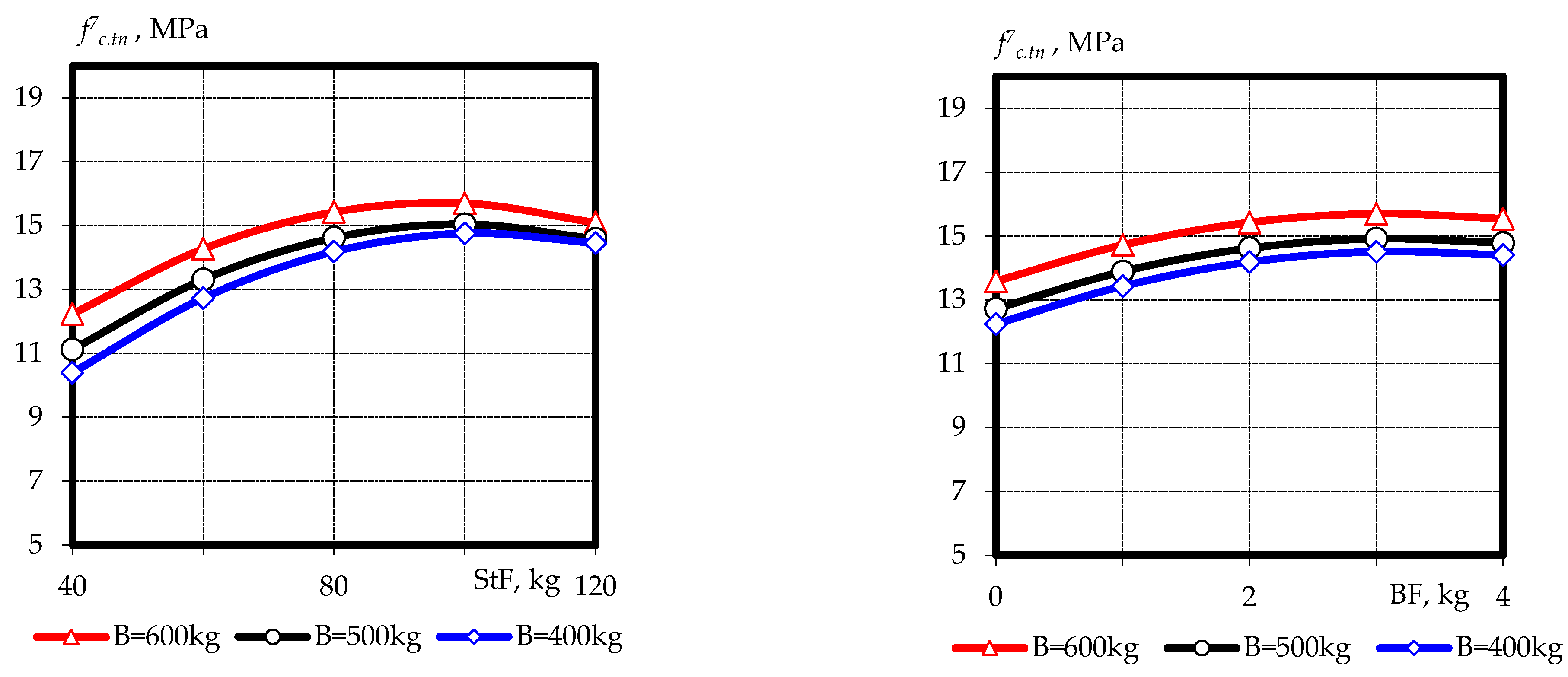

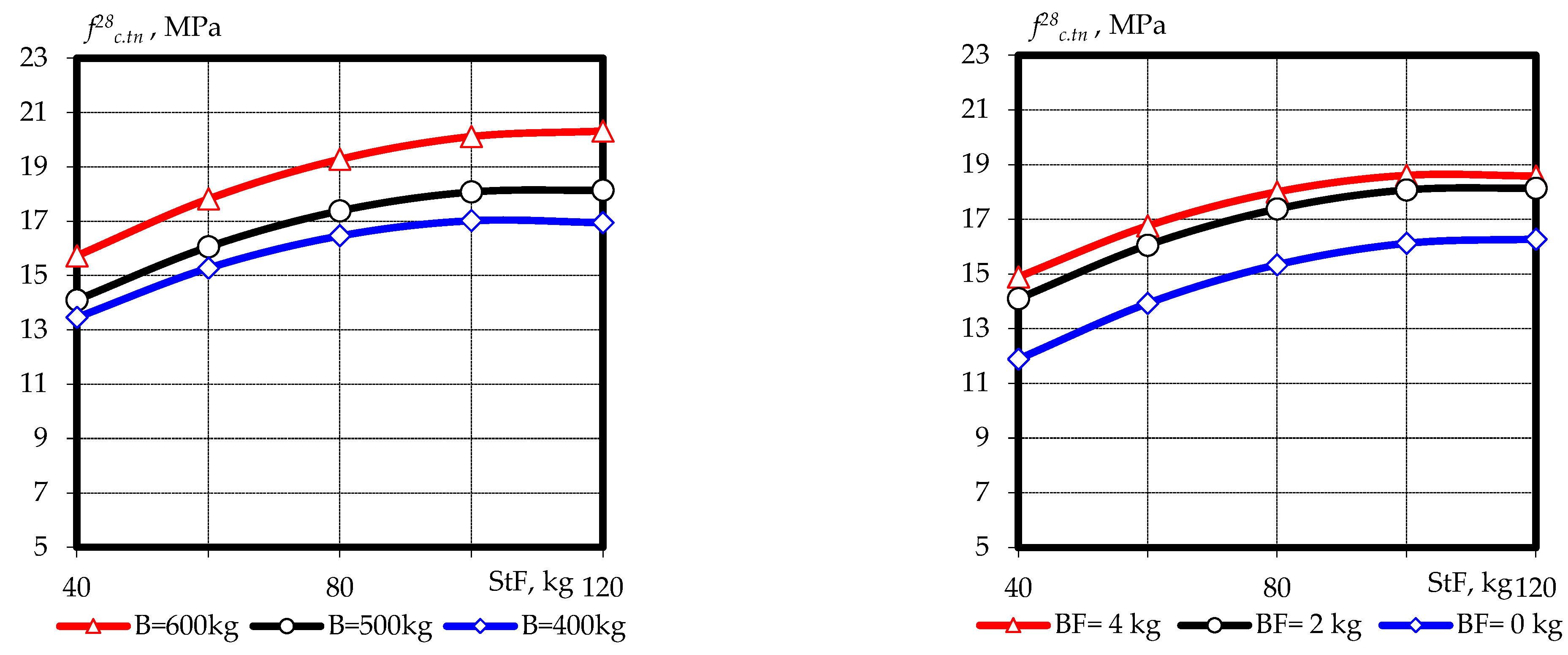

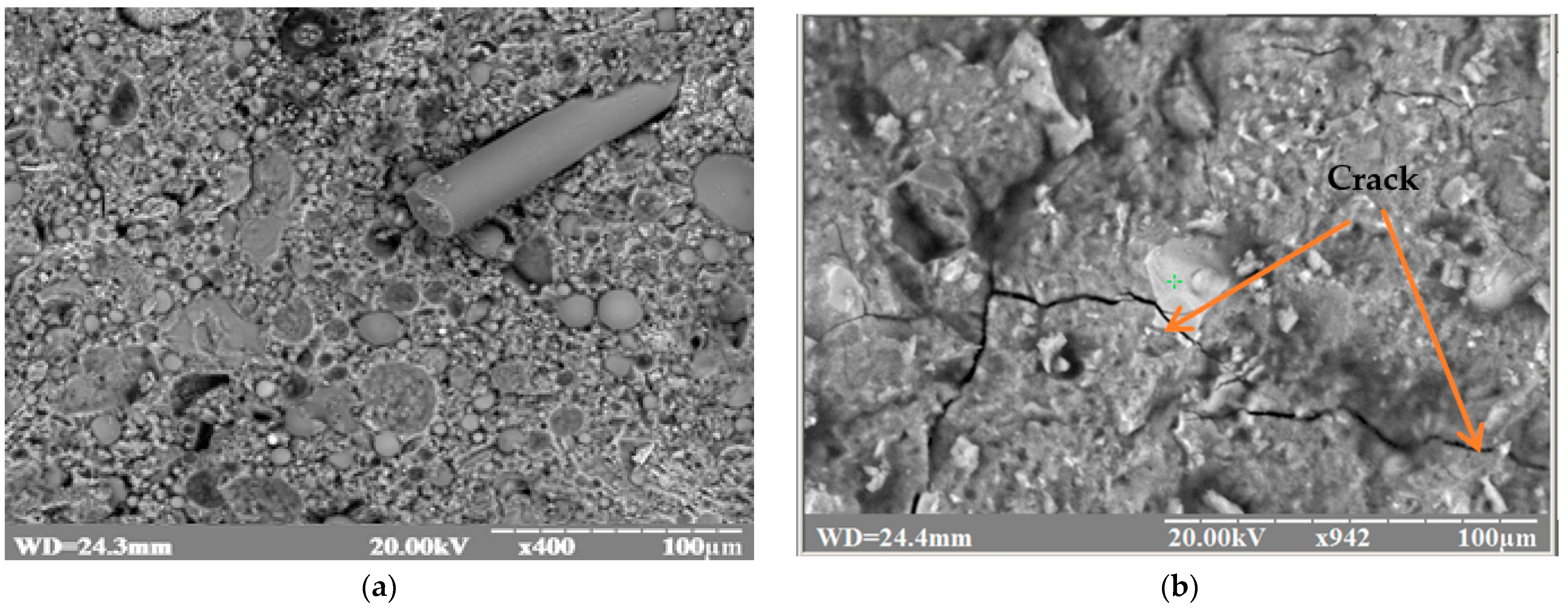

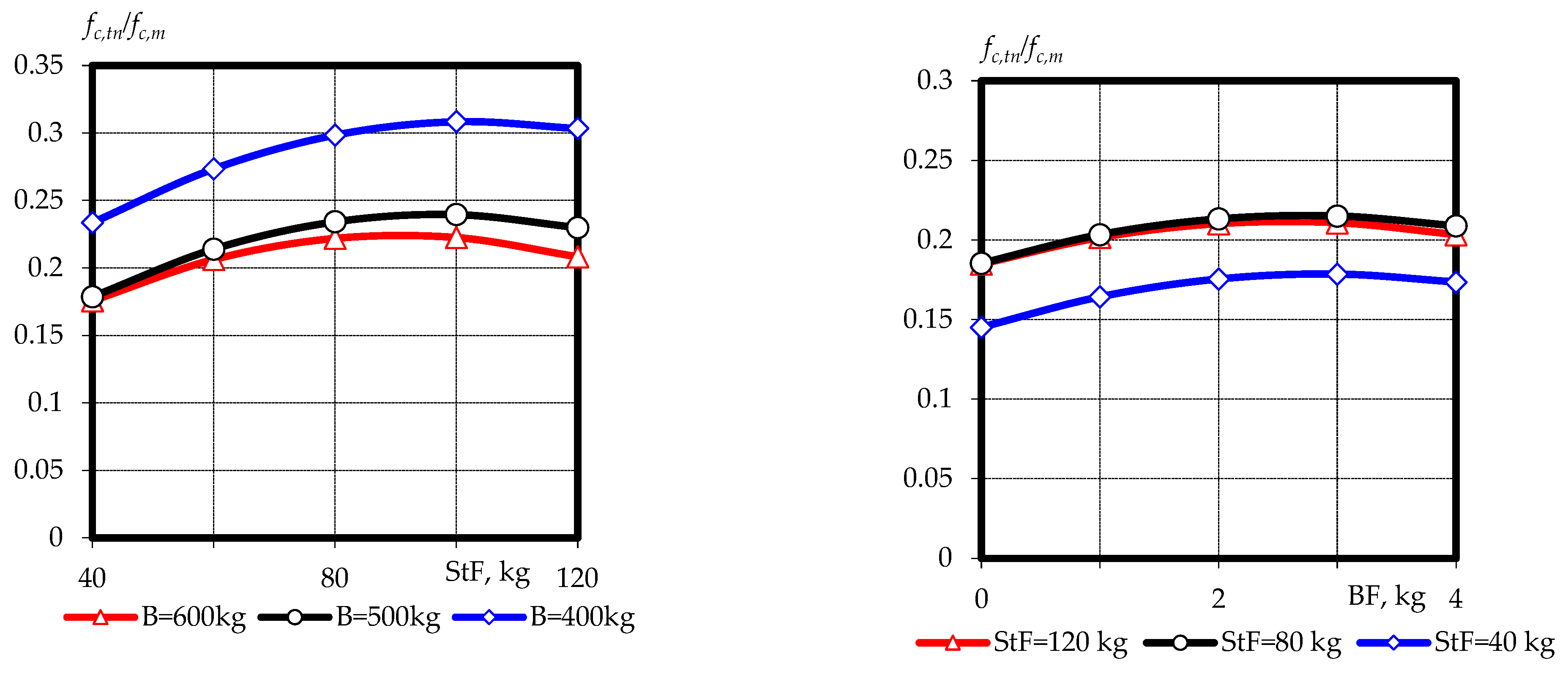

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dvorkin, L.I.; Dvorkin, O.L. Special Concretes; Infra-Injeneriya: Moscow, Russia, 2012; p. 368. [Google Scholar]

- Guerini, V.; Conforti, A.; Plizzari, G.; Kawashima, S. Influence of Steel and Macro-Synthetic Fibers on Concrete Properties. Fibers 2018, 6, 47. [Google Scholar] [CrossRef]

- Lau, C.K.; Chegenizadeh, A.; Htut, T.N.S.; Nikraz, H. Performance of the Steel Fibre Reinforced Rigid Concrete Pavement in Fatigue. Buildings 2020, 10, 186. [Google Scholar] [CrossRef]

- Khan, I.U.; Gul, A.; Khan, K.; Akbar, S.; Irfanullah. Mechanical Properties of Steel-Fiber-Reinforced Concrete. Eng. Proc. 2022, 22, 6. [Google Scholar]

- Choi, S.-W.; Choi, J.; Lee, S.-C. Probabilistic Analysis for Strain-Hardening Behavior of High-Performance Fiber-Reinforced Concrete. Materials 2019, 12, 2399. [Google Scholar] [CrossRef]

- Haido, J.H.; Abdul-Razzak, A.A.; Al-Tayeb, M.M.; Bakar, B.H.; Yousif, S.T.; Tayeh, B.A. Dynamic response of reinforced concrete members incorporating steel fibers with different aspect ratios. Adv. Concr. Constr. 2021, 11, 89–98. [Google Scholar]

- Wang, C.; Xue, G.; Zhao, X. Influence of Fiber Shape and Volume Content on the Performance of Reactive Powder Concrete (RPC). Buildings 2021, 11, 286. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. High-performance fiber-reinforced concrete: A review. J. Mater. Sci. 2016, 51, 6517–6551. [Google Scholar] [CrossRef]

- Wang, L.; Zeng, X.; Li, Y.; Yang, H.; Tang, S. Influences of MgO and PVA Fiber on the Abrasion and Cracking Resistance, Pore Structure and Fractal Features of Hydraulic Concrete. Fractal Fract. 2022, 6, 674. [Google Scholar] [CrossRef]

- Wang, L.; Guo, F.; Yang, H.; Wang, Y.; Tang, S. Comparison of Fly Ash, PVA Fiber, MgO and Shrinkage-reducing Admixture on the Frost Resistance of Face Slab Concrete via Pore Structural and Fractal Analysis. Fractals 2021, 29, 2140002. [Google Scholar] [CrossRef]

- Jiao, D.; Shi, C.; Yuan, Y.; Zhu, D.; De Shutter, G. Effects of rotational shearing on rheological behavior of fresh mortar with short glass fiber. Constr. Build. Mater. 2019, 203, 314–321. [Google Scholar] [CrossRef]

- Amin, M.N.; Ahmad, W.; Khan, K.; Ahmad, A. Steel Fiber-Reinforced Concrete: A Systematic Review of the Research Progress and Knowledge Mapping. Materials 2022, 15, 6155. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.; Ali, M. Use of glass and nylon fibers in concrete for controlling early age micro cracking in bridge decks. Constr. Build. Mater. 2016, 125, 800–808. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, J.; Wang, J.; Wu, B. Effect of Hybrid Steel-Basalt Fiber on Behaviors of Manufactured Sand RPC and Fiber Content Optimization Using Center Composite Design. Adv. Civ. Eng. 2020, 2020, 1–17. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Kim, S.; Park, G.-J.; Park, J.-J.; Kim, S.-W. Effects of fiber shape, aspect ratio, and volume fraction on flexural behavior of ultra-high-performance fiber-reinforced cement composites. Compos. Struct. 2017, 174, 375–388. [Google Scholar] [CrossRef]

- Al-Baghdadi, H.M.; Al-Merib, F.H.; Ibrahim, A.A.; Hassan, R.F.; Hussein, H.H. Effects of Coarse Aggregate Maximum Size on Synthetic/Steel Fiber Reinforced Concrete Performance with Different Fiber Parameters. Buildings 2021, 11, 158. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, J.; Fan, C.; Wang, Z. Effect of Surface Shape and Content of Steel Fiber on Mechanical Properties of Concrete. Adv. Civ. Eng. 2020, 2020, 8834507. [Google Scholar] [CrossRef]

- Abbas, S.; Soliman, A.M.; Nehdi, M.L. Exploring mechanical and durability properties of ultra-high performance concrete incorporating various steel fiber lengths and dosages. Constr. Build. Mater. 2015, 75, 429–441. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of steel fiber content and shape on mechanical properties of ultra-high performance concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Zhou, R.; Jin, Y. Study on Mechanical Properties of Concrete with Different Steel Fiber Content. Int. J. Multiphysics 2021, 15, 87–99. [Google Scholar]

- Larsen, I.L.; Thorstensen, R.T. The influence of steel fibers on compressive and tensile strength of ultra-high performance concrete: A review. Construct. Build. Mater. 2020, 256, 119459. [Google Scholar] [CrossRef]

- Ortiz-Navas, F.; Navarro-Gregori, J.; Leiva-Herdocia, G.E.; Serna, P.; Cuenca, E. An experimental study on the shear behaviour of reinforced concrete beams with macro-synthetic fibres. Constr. Build. Mater. 2018, 169, 888–899. [Google Scholar] [CrossRef]

- Teng, L.; Meng, W.; Khayat, K.H. Rheology control of ultra-high-performance concrete made with different fiber contents. Cem. Concr. Res. 2020, 138, 106222. [Google Scholar] [CrossRef]

- Wang, R.; Gao, X. Relationship between Flowability, Entrapped Air Content and Strength of UHPC Mixtures Containing Different Dosage of Steel Fiber. Appl. Sci. 2016, 6, 216. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H. Investigation of mechanical properties and shrinkage of ultra-high performance concrete: Influence of steel fiber content and shape. Compos. Part B Eng. 2019, 174, 107021. [Google Scholar] [CrossRef]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.S.D. Experimental Investigation on the Effect of Corrosion on the Bond Between Reinforcing Steel Bars and Fibre Reinforced Geopolymer Concrete. Structures 2018, 14, 251–261. [Google Scholar] [CrossRef]

- Wu, K.; Lin, S.; Xu, C.; Chen, C.; Chen, F. Energy dissipation and debonding mechanism of steel and steel fibre reinforced concrete composite beams. Eng. Struct. 2021, 226, 111353. [Google Scholar] [CrossRef]

- Frazão, C.; Barros, J.A.O.; Bogas, J.A. Durability of Recycled Steel Fiber Reinforced Concrete in Chloride Environment. Fibers 2019, 7, 111. [Google Scholar] [CrossRef]

- Cai, Z.; Ren, J.; Shen, G.; Jin, C.; Gu, X.; Cheng, W.; Wang, H. The Influence of Assembly Unit of Fibers on the Mechanical and Long-Term Properties of Reactive Powder Concrete. Coatings 2023, 13, 412. [Google Scholar] [CrossRef]

- Shoaib, S.; El-Maaddawy, T.; El-Hassan, H.; El-Ariss, B.; Alsalami, M. Fresh and Hardened Properties of Concrete Reinforced with Basalt Macro-Fibers. Buildings 2022, 12, 1136. [Google Scholar] [CrossRef]

- Granju, J.-L.; Ullah Balouch, S. Corrosion of Steel Fibre Reinforced Concrete from the Cracks. Cem. Concr. Res. 2005, 35, 572–577. [Google Scholar] [CrossRef]

- Balouch, S.U.; Forth, J.P.; Granju, J.-L. Surface Corrosion of Steel Fibre Reinforced Concrete. Cem. Concr. Res. 2010, 40, 410–414. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A.; Raza, A.; Nawaz, M.A.; Rehman, S.U.; Rashid, M.U. Influence of Glass Fibers on Mechanical Properties of Concrete with Recycled Coarse Aggregates. Civ. Eng. J. 2019, 5, 1007–1019. [Google Scholar] [CrossRef]

- Arslan, M.E. Effects of Basalt and Glass Chopped Fibers Addition on Fracture Energy and Mechanical Properties of Ordinary Concrete: CMOD Measurement. Constr. Build. Mater. 2016, 114, 383–391. [Google Scholar] [CrossRef]

- AL-Kharabsheh, B.N.; Arbili, M.M.; Majdi, A.; Alogla, S.M.; Hakamy, A.; Ahmad, J.; Deifalla, A.F. Basalt Fibers Reinforced Concrete: Strength and Failure Modes. Materials 2022, 15, 7350. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Dai, W.; Zhong, C.; Yang, X. Study on Mechanical Properties and Microstructure of Basalt Fiber Reactive Powder Concrete. Buildings 2022, 12, 1734. [Google Scholar] [CrossRef]

- Wang, Y.; Hughes, P.; Niu, H.; Fan, Y. A New Method to Improve the Properties of Recycled Aggregate Concrete: Composite Addition of Basalt Fiber and Nano-Silica. J. Clean. Prod. 2019, 236, 117602. [Google Scholar] [CrossRef]

- Katkhuda, H.; Shatarat, N. Improving the Mechanical Properties of Recycled Concrete Aggregate Using Chopped Basalt Fibers and Acid Treatment. Constr. Build. Mater. 2017, 140, 328–335. [Google Scholar] [CrossRef]

- Li, Y.; Li, X.; Tan, Y. Effect of aging on fatigue performance of cement emulsified asphalt repair material. Constr. Build. Mater. 2021, 292, 123417. [Google Scholar] [CrossRef]

- Wu, H.; Qin, X.; Huang, X.; Kaewunruen, S. Engineering, Mechanical and Dynamic Properties of Basalt Fiber Reinforced Concrete. Materials 2023, 16, 623. [Google Scholar] [CrossRef]

- Dvorkin, L.; Bordiuzhenko, O.; Tekle, B.H.; Ribakov, Y. A Method for the Design of Concrete with Combined Steel and Basalt Fiber. Appl. Sci. 2021, 11, 8850. [Google Scholar] [CrossRef]

- Sanytsky, M.; Sobol, H.; Markiv, M. Modified Cement Composites; NULP: Lviv, Ukraine, 2010; p. 132. [Google Scholar]

- Wang, L.; Huang, Y.; Zhao, F.; Huo, T.; Chen, E.; Tang, S. Comparison between the Influence of Finely Ground Phosphorous Slag and Fly Ash on Frost Resistance and Fractal Reatures of Hydraulic Concrete. Fractal Fract. 2022, 6, 598. [Google Scholar] [CrossRef]

- Jiao, D.; De Schryver, R.; Shi, C.; De Schutter, G. Trixotropic structural build-up of cement-based materials: A state-of-the-art review. Cem. Concr. Compos. 2021, 122, 104152. [Google Scholar] [CrossRef]

- Du, Y.; Wang, S.; Hao, W.; Shi, F.; Wang, H.; Xu, F.; Du, T. Investigations of the Mechanical Properties and Durability of Reactive Powder Concrete Containing Waste Fly Ash. Buildings 2022, 12, 560. [Google Scholar] [CrossRef]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.S.D. Engineering properties of ambient cured alkali-activated fly ash-slag concrete reinforced with different types of steel fiber. J. Mater. Civ. Eng. 2018, 30, 04018142. [Google Scholar] [CrossRef]

- Dvorkin, L.; Zhitkovsky, V.; Sonebi, M.; Marchuk, V.; Stepasiuk, Y. Improving Concrete and Mortar Using Modified Ash and Slag Cements; Boca Raton CRC Press: London, UK, 2020; p. 184. [Google Scholar]

- Sanytsky, M.; Marushchak, U.; Olevych, Y.; Novytskyi, Y. Nano–Modified Ultra–rapid Hardening Portland Cement Compositions for High Strength Concrete. In Proceedings of the CEE 2019; Lecture Notes in Civil Engineering. Researchgate: Berlin, Germany, 2008; Volume 47, pp. 392–399. [Google Scholar]

- Lingvay, I.; Velciu, G.; Lingvay, D.; Bors, A.M.; Moanta, A. Increasing Shielding Capabilities of Cement Mortars by Fly Ash Addition. Rev. Chim. 2019, 70, 2742–2746. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Xie, C.; Ali, M. Effectiveness of hybrid steel-basalt fiber reinforced concrete under compression. Case Stud. Constr. Mater. 2022, 16, e00941. [Google Scholar] [CrossRef]

- Wang, Q.; Yi, Y.; Ma, G.; Luo, H. Hybrid effects of steel fibers, basalt fibers and calcium sulfate on mechanical performance of PVA-ECC containing high-volume fly ash. Cem. Concr. Compos. 2019, 97, 357–368. [Google Scholar] [CrossRef]

- Dvorkin, L.; Dvorkin, O.; Ribakov, Y. Multi-Parametric Concrete Compositions Design; Nova Science Publishers: New York, NY, USA, 2013; p. 223. [Google Scholar]

| Material Name | L.O.I. | Oxide Content, % | |||||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O | ||

| Clinker | – | 21.80 | 5.32 | 4.11 | 66.80 | 0.95 | 0.63 | 0.54 | 0.42 |

| Fly ash | 5.1 | 46.1 | 18.1 | 22.1 | 2.1 | 2.0 | 2.3 | 1.2 | |

| Technological Factors | Levels of Variation | Variation Interval | |||

|---|---|---|---|---|---|

| Natural View | Coded View | −1 | 0 | +1 | |

| Cement–ash binder content (B), kg/m3 | X1 | 400 | 500 | 600 | 100 |

| Steel fiber content, (StF), kg/m3 | X2 | 40 | 80 | 120 | 40 |

| Basalt fiber content, (BF), kg/m3 | X3 | 0 | 2 | 4 | 2 |

| No. | Coded View | Natural View | The Composition of the Concrete Mixture, kg/m3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X1 | X2 | X3 | Binder | Steel Fiber | Basalt Fiber | Cement 1 | Fly ash 1 | Coarse Aggregate | Sand | Water | SP | |

| 1 | +1 | +1 | +1 | 600 | 120 | 4 | 450 | 150 | 1030 | 580 | 144 | 4.2 |

| 2 | +1 | +1 | −1 | 600 | 120 | 0 | 450 | 150 | 1030 | 610 | 132 | 4.2 |

| 3 | +1 | −1 | +1 | 600 | 40 | 4 | 450 | 150 | 1030 | 680 | 138 | 4.2 |

| 4 | +1 | −1 | −1 | 600 | 40 | 0 | 450 | 150 | 1030 | 700 | 126 | 4.2 |

| 5 | −1 | +1 | +1 | 400 | 120 | 4 | 300 | 100 | 1080 | 720 | 160 | 2.8 |

| 6 | −1 | +1 | −1 | 400 | 120 | 0 | 300 | 100 | 1080 | 730 | 156 | 2.8 |

| 7 | −1 | −1 | +1 | 400 | 40 | 4 | 300 | 100 | 1080 | 780 | 152 | 2.8 |

| 8 | −1 | −1 | −1 | 400 | 40 | 0 | 300 | 100 | 1080 | 810 | 144 | 2.8 |

| 9 | +1 | 0 | 0 | 600 | 80 | 2 | 450 | 150 | 1030 | 630 | 138 | 4.2 |

| 10 | −1 | 0 | 0 | 400 | 80 | 2 | 300 | 100 | 1080 | 750 | 160 | 2.8 |

| 11 | 0 | +1 | 0 | 500 | 120 | 2 | 375 | 125 | 1055 | 675 | 135 | 3.5 |

| 12 | 0 | −1 | 0 | 500 | 40 | 2 | 375 | 125 | 1055 | 750 | 125 | 3.5 |

| 13 | 0 | 0 | +1 | 500 | 80 | 4 | 375 | 125 | 1055 | 700 | 135 | 3.5 |

| 14 | 0 | 0 | −1 | 500 | 80 | 0 | 375 | 125 | 1055 | 710 | 125 | 3.5 |

| 15 | 0 | 0 | 0 | 500 | 80 | 2 | 375 | 125 | 1055 | 710 | 130 | 3.5 |

| 16 | 0 | 0 | 0 | 500 | 80 | 2 | 375 | 125 | 1055 | 710 | 130 | 3.5 |

| 17 | 0 | 0 | 0 | 500 | 80 | 2 | 375 | 125 | 1055 | 710 | 130 | 3.5 |

| No. | W/C | Strength, MPa | Crack Resistance 1 fc,tn/fc,m | |||

|---|---|---|---|---|---|---|

| Tensile Splitting, fc,tn, at Age | Compressive, fc,m, at Age | |||||

| 7 Days | 28 Days | 7 Days | 28 Days | 28 Days | ||

| 1 | 0.24 | 15.3 | 21.0 | 73.0 | 98.4 | 0.21 |

| 2 | 0.22 | 13.1 | 18.8 | 75.0 | 96.1 | 0.20 |

| 3 | 0.23 | 12.2 | 16.8 | 71.0 | 95.4 | 0.18 |

| 4 | 0.21 | 11.1 | 14.0 | 75.5 | 92.1 | 0.15 |

| 5 | 0.40 | 13.8 | 16.8 | 46.4 | 68.8 | 0.24 |

| 6 | 0.39 | 12.8 | 15.0 | 47.5 | 64.7 | 0.23 |

| 7 | 0.38 | 10.9 | 13.8 | 45.2 | 62.8 | 0.22 |

| 8 | 0.36 | 8.2 | 11.2 | 44.1 | 57.8 | 0.19 |

| 9 | 0.23 | 14.9 | 17.9 | 69.0 | 91.1 | 0.20 |

| 10 | 0.40 | 14.7 | 17.6 | 47.8 | 61.1 | 0.29 |

| 11 | 0.27 | 15.2 | 18.2 | 65.7 | 86.7 | 0.21 |

| 12 | 0.25 | 10.5 | 13.8 | 58.2 | 76.8 | 0.18 |

| 13 | 0.27 | 15.4 | 18.5 | 64.4 | 85.0 | 0.22 |

| 14 | 0.25 | 12.1 | 14.6 | 61.3 | 80.9 | 0.18 |

| 15 | 0.26 | 14.7 | 17.6 | 64.0 | 82.8 | 0.21 |

| 16 | 0.26 | 14.4 | 17.3 | 62.7 | 84.5 | 0.20 |

| 17 | 0.26 | 14.6 | 17.5 | 62.5 | 82.5 | 0.21 |

| Parameter | Experimental and Statistical Models | |

|---|---|---|

| Compressive strength at the age of 7 days | f7c,m = 63.0 + 12.66∙X1 + 2.53∙X2 + 1.57∙X3 − 0.93∙X1X2 − 0.43∙X1X3 − 1.03∙X2X3 − + 4.35∙X12 − 0.8∙X22 + 0.1∙X32; R2 = 0.974 | (3) |

| Compressive strength at the age of 28 days | f28c,m = 82.28 + 15.79∙X1 + 2.98∙X2 + 1.88∙X3 − 0.73∙X1X2 − 0.44∙X1X3 − 0.24∙X2X3 − + 5.16∙X12 + 0.49∙X22 + 1.69∙X32; R2 = 0.992 | (4) |

| Tensile splitting strength at the age of 7 days | f7c,tn = 14.62 + 0.62∙X1 + 1.73∙X2 + 1.03∙X3 − 0.3∙X1X2 − 0.05∙X1X3 − 0.08∙X2X3 + + 0.19∙X12 − 1.76∙X22 − 0.86∙X32; R2 = 0.947 | (5) |

| Tensile splitting strength at the age of 28 days | f28c,tn = 17.38 + 1.41∙X1 + 2.02∙X2 + 1.33∙X3 + 0.38∙X1X2 + 0.08∙X1X3 − 0.18∙X2X3 + + 0.49∙X12 − 1.26∙X22 − 0.71∙X32; R2 = 0.945 | (6) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dvorkin, L.; Konkol, J.; Marchuk, V.; Huts, A. Efficient, Fine-Grained Fly Ash Concrete Based on Metal and Basalt Fibers. Materials 2023, 16, 3969. https://doi.org/10.3390/ma16113969

Dvorkin L, Konkol J, Marchuk V, Huts A. Efficient, Fine-Grained Fly Ash Concrete Based on Metal and Basalt Fibers. Materials. 2023; 16(11):3969. https://doi.org/10.3390/ma16113969

Chicago/Turabian StyleDvorkin, Leonid, Janusz Konkol, Vitaliy Marchuk, and Andriy Huts. 2023. "Efficient, Fine-Grained Fly Ash Concrete Based on Metal and Basalt Fibers" Materials 16, no. 11: 3969. https://doi.org/10.3390/ma16113969

APA StyleDvorkin, L., Konkol, J., Marchuk, V., & Huts, A. (2023). Efficient, Fine-Grained Fly Ash Concrete Based on Metal and Basalt Fibers. Materials, 16(11), 3969. https://doi.org/10.3390/ma16113969