Stress Corrosion Cracking of 316L Stainless Steel Additively Manufactured with Sinter-Based Material Extrusion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Analytical Characterization

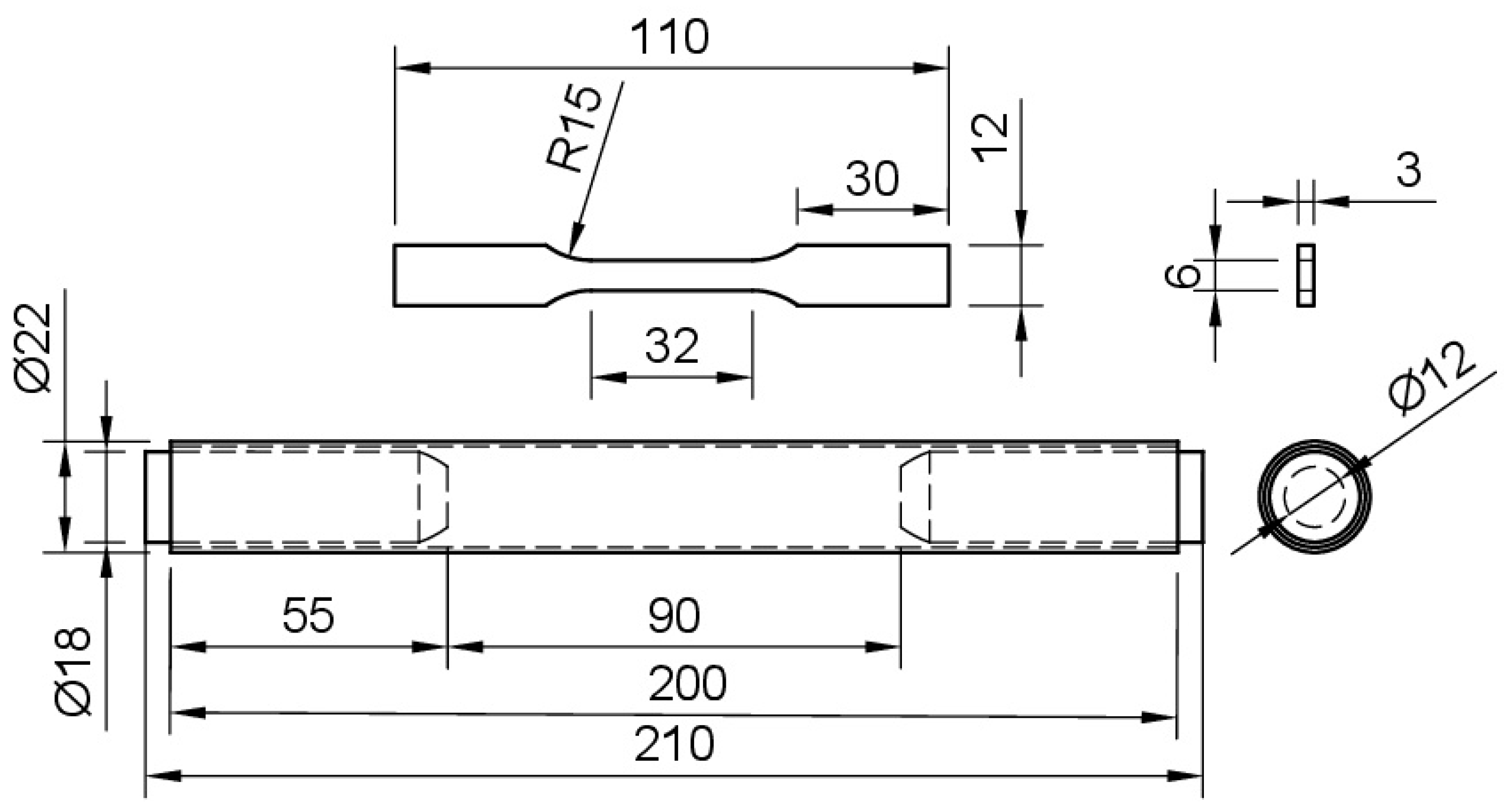

2.3. Mechanical Testing

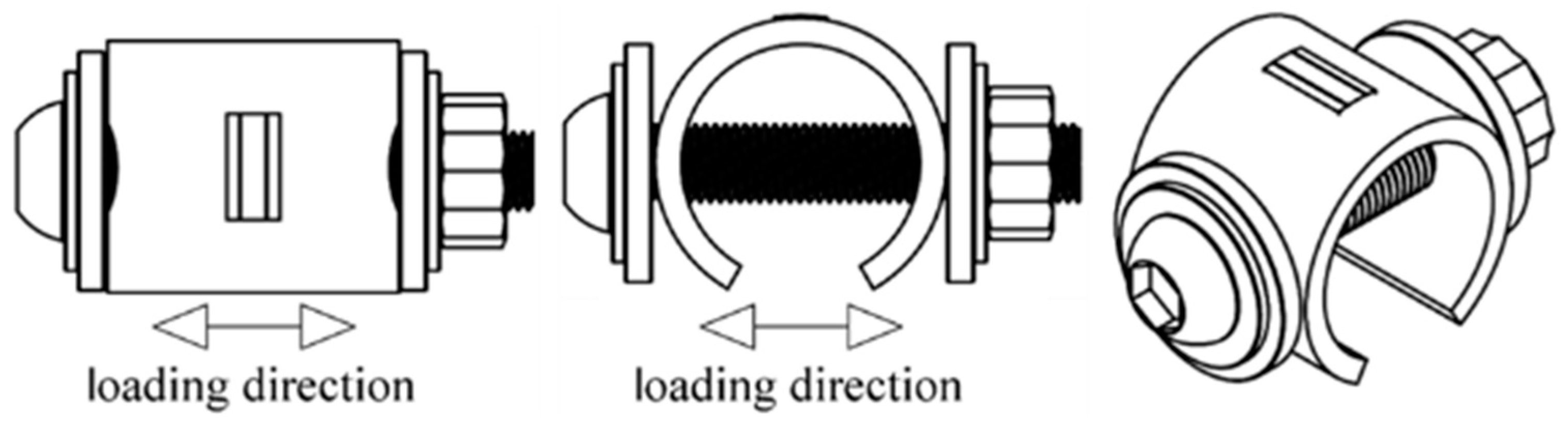

2.4. SCC Susceptibility and Crack-Branching

3. Results

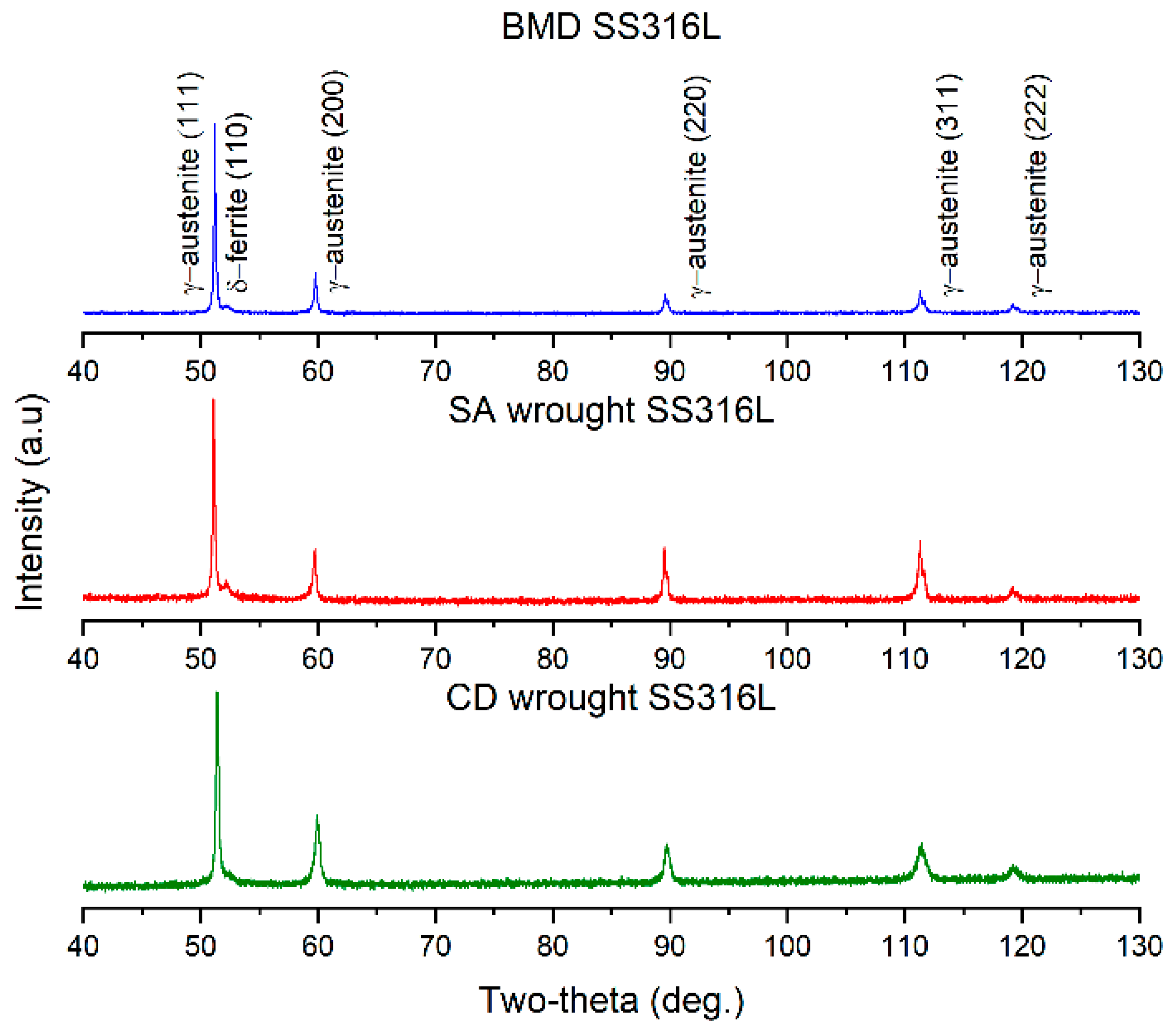

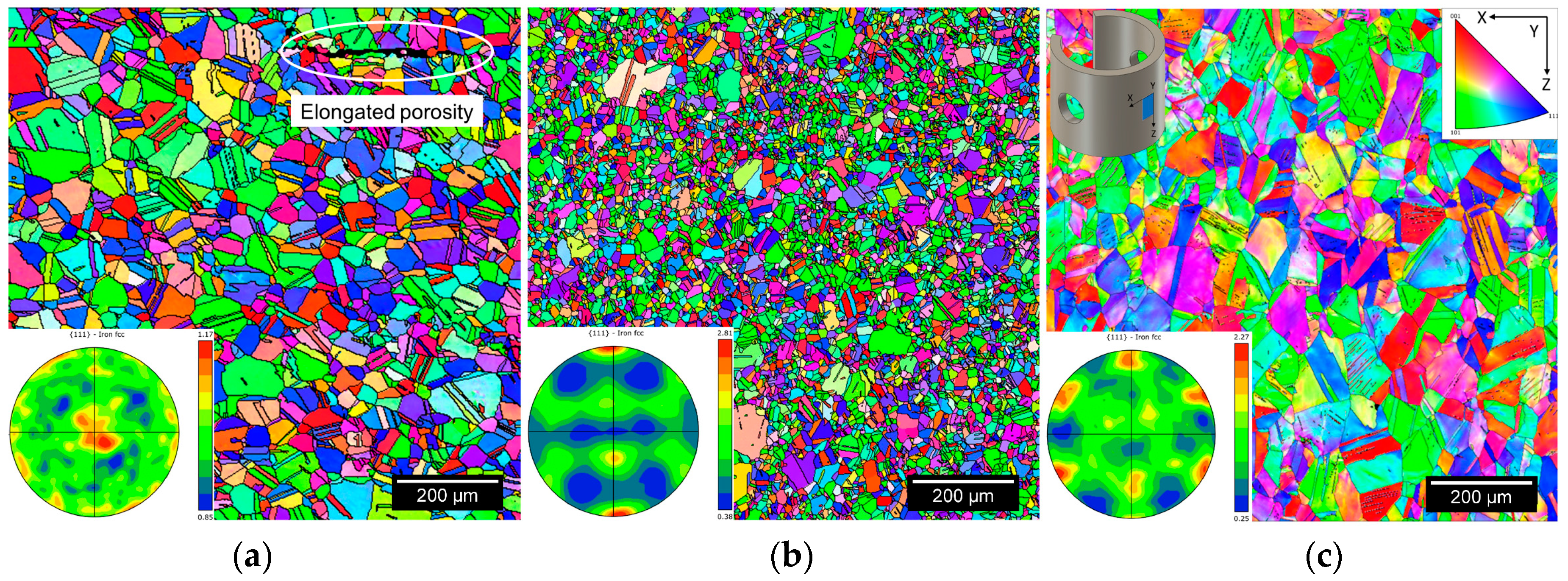

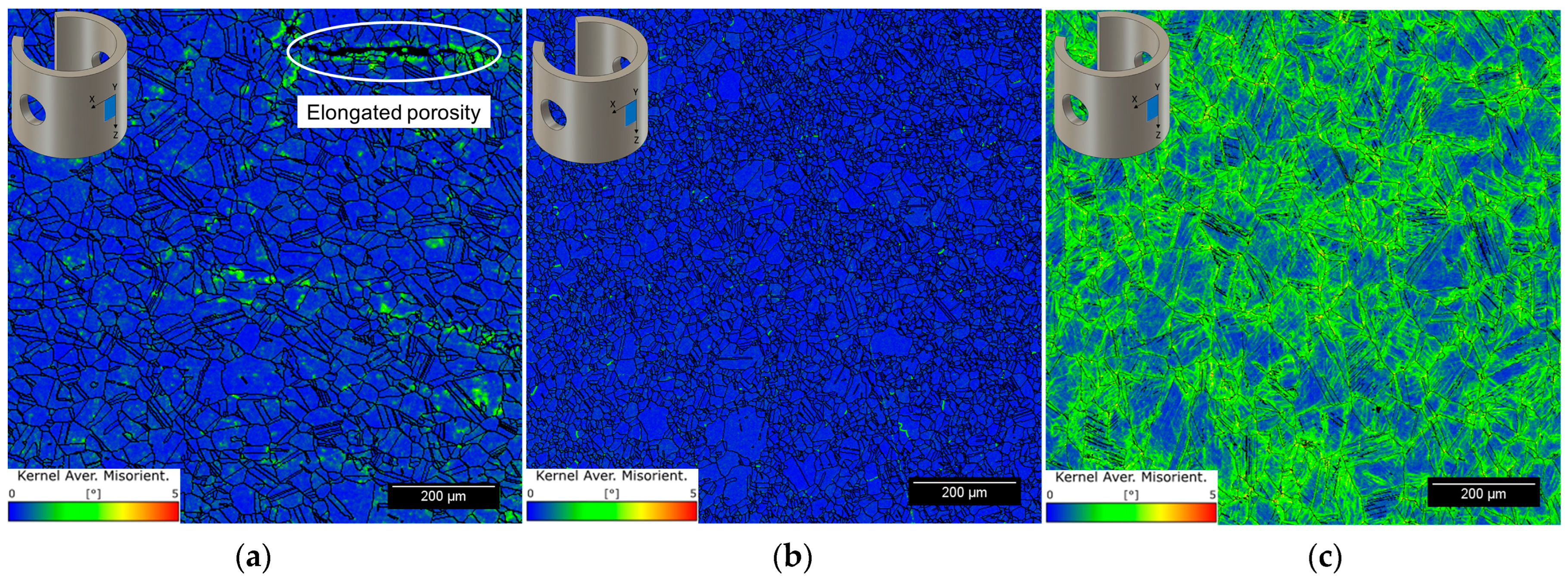

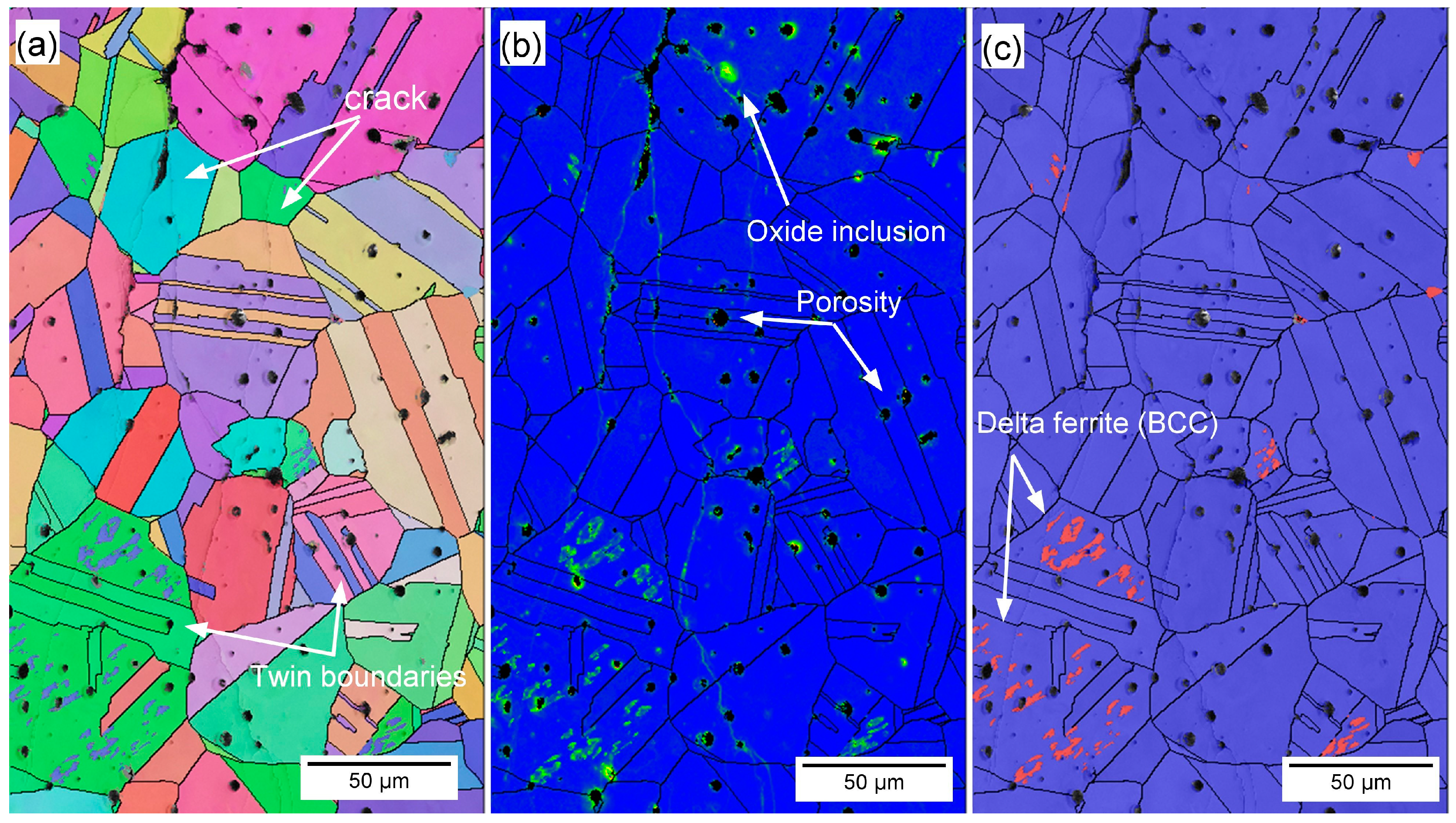

3.1. Analytical Characterization

3.2. Mechanical Testing

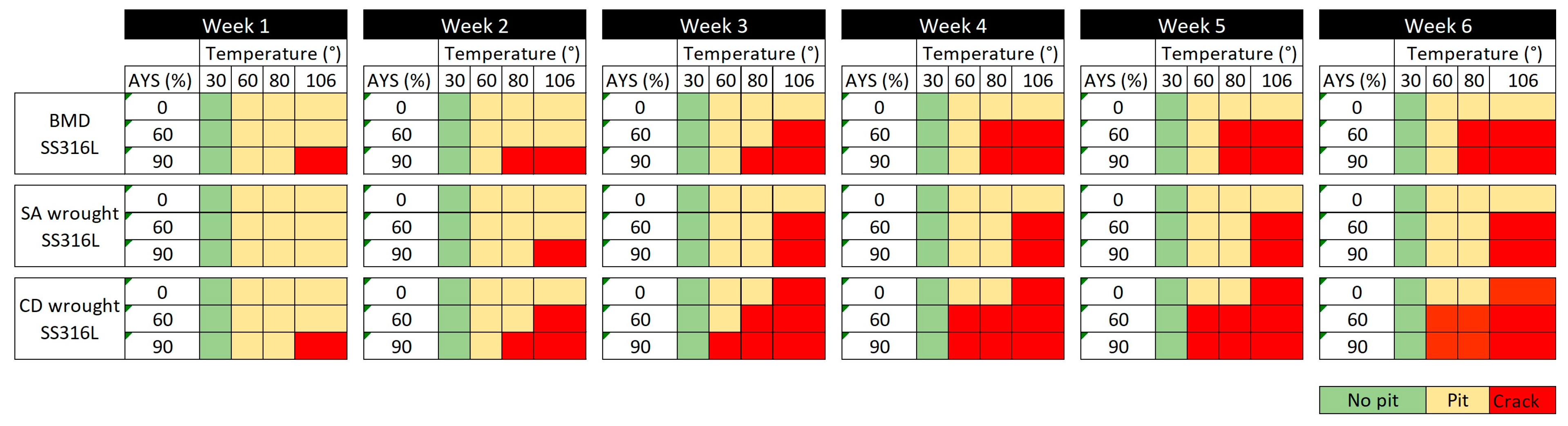

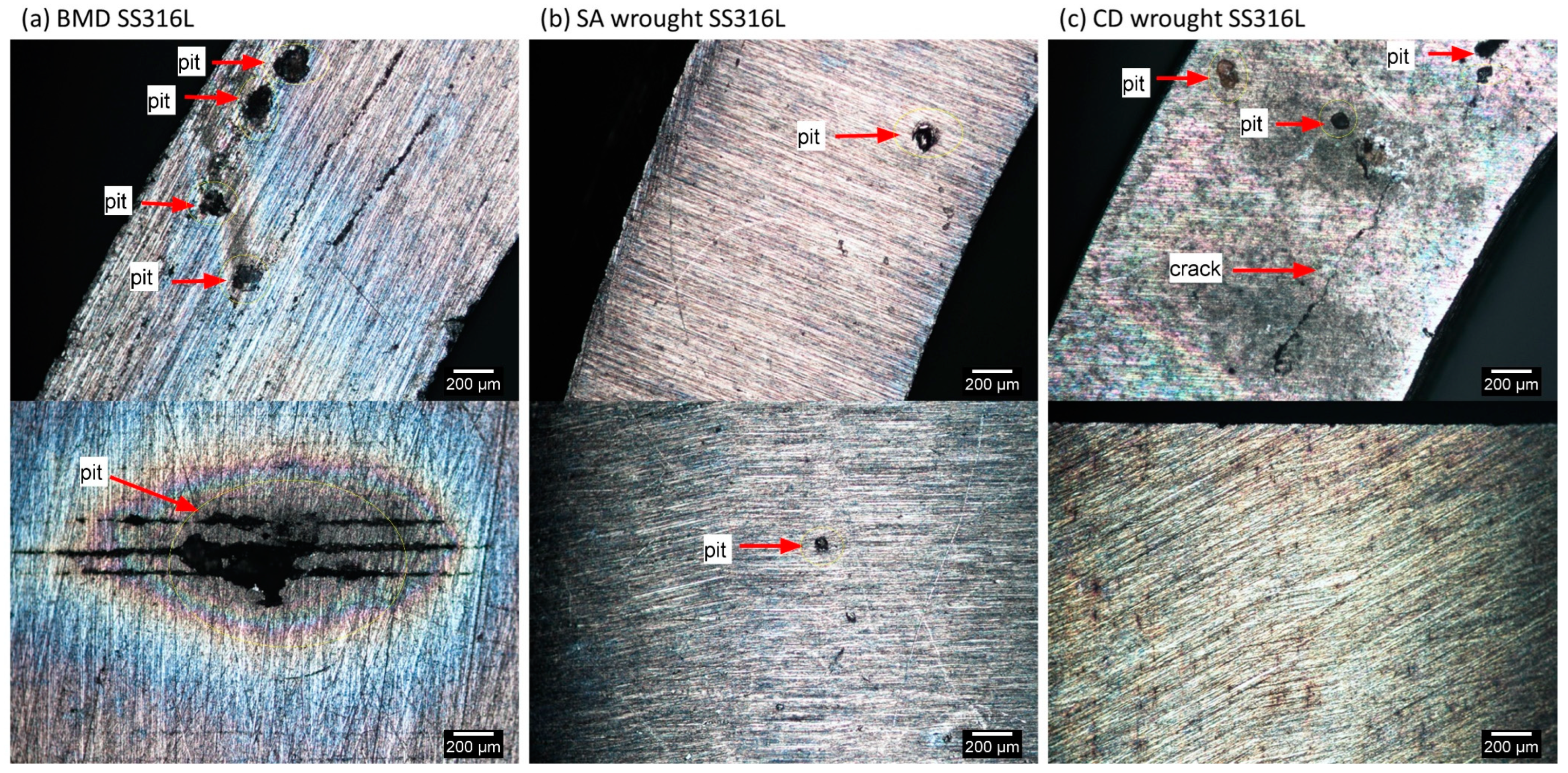

3.3. Pitting and Cracking Susceptibility

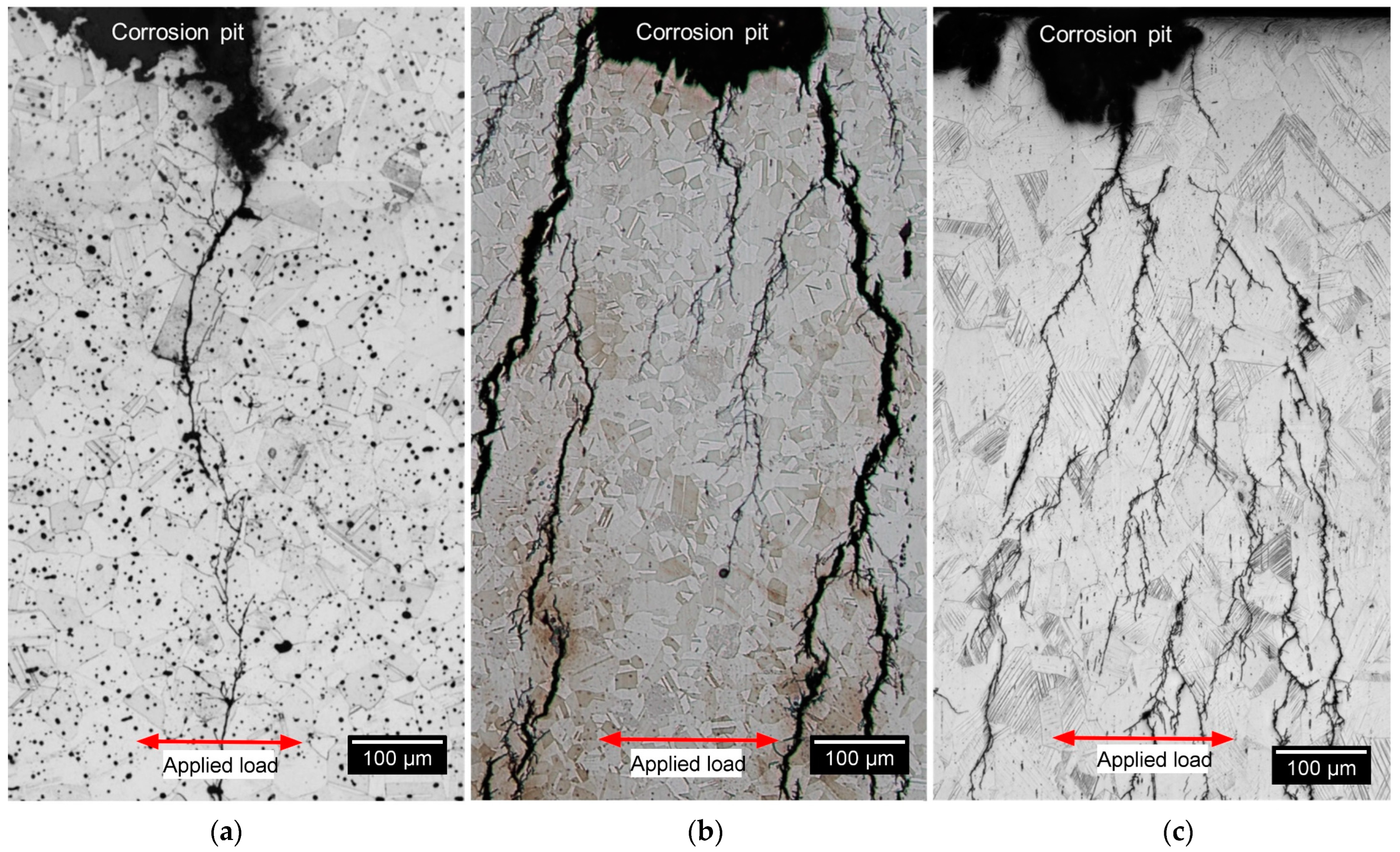

3.4. Crack-Branching Susceptibility

4. Discussion

4.1. Susceptibility to SCC Initiation: Pit-to-Crack Transition

4.2. Crack-Branching

5. Conclusions

- SCC resistance increased in the following order: SA wrought > BMD > CD wrought SS316L.

- The sinter-based manufacturing process used to produce BMD SS316L resulted in lower residual stresses and lower strength, contributing to a higher SCC initiation resistance than the highly stressed CD wrought condition.

- The large grain aggregates, equiaxed grain morphology, weak crystallographic texture, and a large content of twin boundaries decreased the SCC crack-branching of BMD SS316L when compared to SA and CD wrought SS316L.

- The porosity distribution of BMD SS316L had a mixed impact on its SCC resistance. While these defects facilitated the pit-to-crack transition, they also acted as crack arrestors by blunting the crack tips.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ISO/ASTM-52900; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. ISO: Geneva, Switzerland, 2015. [CrossRef]

- ISO-17296-2; Additive Manufacturing—General Principles—Part 2: Overview of Process Categories and Feedstock. ISO International: Geneva, Switzerland, 2015.

- Redwood, B.; Schöffer, F.; Garret, B. The 3D Printing Handbook: Technologies, Design and Applications; 3D Hubs B.V.: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Poszvek, G.; Stattler, G.; Markl, E.; Seemann, R.; Lackner, M. Fused Filament Fabrication of Metallic Components for Semi-professional and Home Use. In Digital Conversion on the Way to Industry 4.0; Durakbasa, N.M., Gençyılmaz, M.G., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 140–149. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Li, X.; Yan, Z. On hot isostatic pressing sintering of fused filament fabricated 316L stainless steel—Evaluation of microstructure, porosity, and tensile properties. Mater. Lett. 2021, 296, 129854. [Google Scholar] [CrossRef]

- Thompson, Y.; Gonzalez-Gutierrez, J.; Kukla, C.; Felfer, P. Fused filament fabrication, debinding and sintering as a low cost additive manufacturing method of 316L stainless steel. Addit. Manuf. 2019, 30, 100861. [Google Scholar] [CrossRef]

- Jiang, D.; Ning, F. Additive Manufacturing of 316L Stainless Steel by a Printing-Debinding-Sintering Method: Effects of Microstructure on Fatigue Property. J. Manuf. Sci. Eng. 2021, 143, 091007. [Google Scholar] [CrossRef]

- Caminero, M.Á.; Romero, A.; Chacón, J.M.; Núñez, P.J.; García-Plaza, E.; Rodríguez, G.P. Additive manufacturing of 316L stainless-steel structures using fused filament fabrication technology: Mechanical and geometric properties. Rapid Prototyp. J. 2021, 27, 583–591. [Google Scholar] [CrossRef]

- Santamaria, R.; Salasi, M.; Bakhtiari, S.; Leadbeater, G.; Iannuzzi, M.; Quadir, M.Z. Microstructure and mechanical behaviour of 316L stainless steel produced using sinter-based extrusion additive manufacturing. J. Mater. Sci. 2022, 57, 9646–9662. [Google Scholar] [CrossRef]

- Mendoza, M.Y.; Samimi, P.; Brice, D.A.; Martin, B.W.; Rolchigo, M.R.; LeSar, R.; Collins, P.C. Microstructures and grain refinement of additive-manufactured Ti-xW alloys. Metall. Mater. Trans. A 2017, 48, 3594–3605. [Google Scholar] [CrossRef]

- Ziętala, M.; Durejko, T.; Polański, M.; Kunce, I.; Płociński, T.; Zieliński, W.; Łazińska, M.; Stępniowski, W.; Czujko, T.; Kurzydłowski, K.J.; et al. The microstructure, mechanical properties and corrosion resistance of 316L stainless steel fabricated using laser engineered net shaping. Mater. Sci. Eng. A 2016, 677, 1–10. [Google Scholar] [CrossRef]

- Edwards, P.; O’Conner, A.; Ramulu, M. Electron Beam Additive Manufacturing of Titanium Components: Properties and Performance. J. Manuf. Sci. Eng. 2013, 135, 061016. [Google Scholar] [CrossRef]

- Wang, X.; Chou, K. EBSD study of beam speed effects on Ti-6Al-4V alloy by powder bed electron beam additive manufacturing. J. Alloys Compd. 2018, 748, 236–244. [Google Scholar] [CrossRef]

- Zaharia, S.M.; Lancea, C.; Chicos, L.A.; Pop, M.A.; Caputo, G.; Serra, E. Mechanical properties and corrosion behaviour of 316l stainless steel honeycomb cellular cores manufactured by selective laser melting. Trans. FAMENA 2017, 41, 11–24. [Google Scholar] [CrossRef]

- Guzmán-Nogales, R.; Estupiñán-López, F.; Gaona-Tiburcio, C.; Lopez-Botello, O.E.; Ramírez-Rodríguez, J.G.; Zambrano-Robledo, P.C. Corrosion Resistance Measurement of 316L Stainless Steel Manufactured by Selective Laser Melting. Materials 2021, 14, 4509. [Google Scholar] [CrossRef] [PubMed]

- Jones, D.A. Principles and Prevention of Corrosion, 2nd ed.; New international edition; Pearson: Essex, UK, 1996. [Google Scholar]

- Newman, R.C. Stress-Corrosion Cracking Mechanisms; Corrosion Technology: New York, NY, USA; Basel, Switzerland, 2002; Volume 17, pp. 399–450. [Google Scholar]

- McCafferty, E. Introduction to Corrosion Science; Springer Science & Business Media: Cham, Switzerland, 2010. [Google Scholar]

- Zhang, W.; Fang, K.; Hu, Y.; Wang, S.; Wang, X. Effect of machining-induced surface residual stress on initiation of stress corrosion cracking in 316 austenitic stainless steel. Corros. Sci. 2016, 108, 173–184. [Google Scholar] [CrossRef]

- Spencer, D.; Edwards, M.; Wenman, M.; Tsitsios, C.; Scatigno, G.; Chard-Tuckey, P. The initiation and propagation of chloride-induced transgranular stress-corrosion cracking (TGSCC) of 304L austenitic stainless steel under atmospheric conditions. Corros. Sci. 2014, 88, 76–88. [Google Scholar] [CrossRef]

- Bryan, C.R.; Dingreville, R.P.M.; Enos, D. Estimating Bounding Corrosion Pit Sizes on Stainless Steel SNF Interim Storage Canisters; Sandia National Lab. (SNL-NM): Albuquerque, NM, USA, 2016.

- Martin, U.; Bastidas, D.M. Stress corrosion cracking failure analysis of AISI 1018 carbon steel reinforcing bars in carbonated and chloride contaminated environment. Eng. Fail. Anal. 2023, 147, 107159. [Google Scholar] [CrossRef]

- Horner, D.A.; Connolly, B.J.; Zhou, S.; Crocker, L.; Turnbull, A. Novel images of the evolution of stress corrosion cracks from corrosion pits. Corros. Sci. 2011, 53, 3466–3485. [Google Scholar] [CrossRef]

- Katona, R.; Karasz, E.; Schaller, R. A Review of the Governing Factors in Pit-to-Crack Transitions of Metallic Structures. Corrosion 2023, 79, 72–96. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.-G.; Xu, J.-Q. 3D analysis for pit evolution and pit-to-crack transition during corrosion fatigue. J. Zhejiang Univ. Sci. A 2013, 14, 292–299. [Google Scholar] [CrossRef]

- Fang, B.Y.; Eadie, R.L.; Chen, W.X.; Elboujdaini, M. Pit to crack transition in X-52 pipeline steel in near neutral pH environment Part 1—Formation of blunt cracks from pits under cyclic loading. Corros. Eng. Sci. Technol. 2010, 45, 302–312. [Google Scholar] [CrossRef]

- Marcus, P. Corrosion Mechanisms in Theory and Practice; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Scatigno, G.G.; Ryan, M.P.; Giuliani, F.; Wenman, M.R. The effect of prior cold work on the chloride stress corrosion cracking of 304L austenitic stainless steel under atmospheric conditions. Mater. Sci. Eng. A 2016, 668, 20–29. [Google Scholar] [CrossRef]

- Russell, H.J. Stress Corrosion Cracking; The Materials Information Society, ASM International: Materials Park, OH, USA, 1992. [Google Scholar]

- Sedriks, A.J. Corrosion of Stainless Steels, 2nd ed.; John Wiley & Sons, Inc.: New York, NY, USA, 1996. [Google Scholar]

- Revie, R.W. Uhlig’s Corrosion Handbook, 3rd ed.; The Electrochemical Society Series; John Wiley & Sons: Pennington, NJ, USA, 2011. [Google Scholar]

- Raja, V.; Shoji, T. Stress Corrosion Cracking: Theory and Practice; Woodhead Publising Limited: Cambridge, UK, 2011. [Google Scholar]

- Jones, R.H. Stress-Corrosion Cracking: Materials Performance and Evaluation; ASM International: Materials Park, OH, USA, 2017. [Google Scholar] [CrossRef]

- Khatak, H.S.; Raj, B. Corrosion of Austenitic Stainless Steels: Mechanism, Mitigation and Monitoring; Woodhead Publishing: Cambridge, UK, 2002. [Google Scholar]

- McGuire, M.F. Stainless Steels for Design Engineers; ASM International: Materials Park, OH, USA, 2008. [Google Scholar]

- ASTM-A213; Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes. ASTM International: West Conshohocken, PA, USA, 2022. Available online: https://www.astm.org/a0213_a0213m-18.html (accessed on 25 May 2022).

- Newman, R.C. Stress-corrosion cracking mechanisms. In Corrosion Mechanisms in Theory and Practice; CRC Press: Boca Raton, FL, USA, 2011; pp. 511–556. [Google Scholar]

- Liverani, E.; Toschi, S.; Ceschini, L.; Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Mater. Process. Technol. 2017, 249, 255–263. [Google Scholar] [CrossRef]

- Woźniak, A.; Adamiak, M.; Chladek, G.; Kasperski, J. The Influence of the Process Parameters on the Microstructure and Properties SLM Processed 316L Stainless Steel. Arch. Metall. Mater. 2020, 65, 73–80. [Google Scholar] [CrossRef]

- Chao, Q.; Thomas, S.; Birbilis, N.; Cizek, P.; Hodgson, P.D.; Fabijanic, D. The effect of post-processing heat treatment on the microstructure, residual stress and mechanical properties of selective laser melted 316L stainless steel. Mater. Sci. Eng. A 2021, 821, 141611. [Google Scholar] [CrossRef]

- Kurzynowski, T.; Gruber, K.; Stopyra, W.; Kuźnicka, B.; Chlebus, E. Correlation between process parameters, microstructure and properties of 316 L stainless steel processed by selective laser melting. Mater. Sci. Eng. A 2018, 718, 64–73. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Ramamurty, U. Mechanical behavior of selective laser melted 316L stainless steel. Mater. Sci. Eng. A 2017, 696, 113–121. [Google Scholar] [CrossRef]

- Man, C.; Dong, C.; Liu, T.; Kong, D.; Wang, D.; Li, X. The enhancement of microstructure on the passive and pitting behaviors of selective laser melting 316L SS in simulated body fluid. Appl. Surf. Sci. 2019, 467–468, 193–205. [Google Scholar] [CrossRef]

- Shaeri Karimi, M.H.; Yeganeh, M.; Alavi Zaree, S.R.; Eskandari, M. Corrosion behavior of 316L stainless steel manufactured by laser powder bed fusion (L-PBF) in an alkaline solution. Opt. Laser Technol. 2021, 138, 106918. [Google Scholar] [CrossRef]

- Sander, G.; Thomas, S.; Cruz, V.; Jurg, M.; Birbilis, N.; Gao, X.; Brameld, M.; Hutchinson, C.R. On The Corrosion and Metastable Pitting Characteristics of 316L Stainless Steel Produced by Selective Laser Melting. J. Electrochem. Soc. 2017, 164, C250–C257. [Google Scholar] [CrossRef]

- Lodhi, M.J.K.; Deen, K.M.; Haider, W. Corrosion behavior of additively manufactured 316L stainless steel in acidic media. Materialia 2018, 2, 111–121. [Google Scholar] [CrossRef]

- Bian, L.; Shamsaei, N.; Usher, J.M. Laser-Based Additive Manufacturing of Metal Parts: Modeling, Optimization, and Control of Mechanical Properties; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Ma, M.; Wang, Z.; Zeng, X. A comparison on metallurgical behaviors of 316L stainless steel by selective laser melting and laser cladding deposition. Mater. Sci. Eng. A 2017, 685, 265–273. [Google Scholar] [CrossRef]

- Diaz Vallejo, N.; Lucas, C.; Ayers, N.; Graydon, K.; Hyer, H.; Sohn, Y. Process Optimization and Microstructure Analysis to Understand Laser Powder Bed Fusion of 316L Stainless Steel. Metals 2021, 11, 832. [Google Scholar] [CrossRef]

- Tsutsumi, Y.; Ishimoto, T.; Oishi, T.; Manaka, T.; Chen, P.; Ashida, M.; Doi, K.; Katayama, H.; Hanawa, T.; Nakano, T. Crystallographic texture- and grain boundary density-independent improvement of corrosion resistance in austenitic 316L stainless steel fabricated via laser powder bed fusion. Addit. Manuf. 2021, 45, 102066. [Google Scholar] [CrossRef]

- Dong, P.; Vecchiato, F.; Yang, Z.; Hooper, P.A.; Wenman, M.R. The effect of build direction and heat treatment on atmospheric stress corrosion cracking of laser powder bed fusion 316L austenitic stainless steel. Addit. Manuf. 2021, 40, 101902. [Google Scholar] [CrossRef]

- Bian, P.; Shi, J.; Liu, Y.; Xie, Y. Influence of laser power and scanning strategy on residual stress distribution in additively manufactured 316L steel. Opt. Laser Technol. 2020, 132, 106477. [Google Scholar] [CrossRef]

- Yazdanpanah, A.; Franceschi, M.; Bergamo, G.; Bonesso, M.; Dabalà, M. On the exceptional stress corrosion cracking susceptibility of selective laser melted 316L stainless steel under the individual effect of surface residual stresses. Eng. Fail. Anal. 2022, 136, 106192. [Google Scholar] [CrossRef]

- Yazdanpanah, A.; Lago, M.; Gennari, C.; Dabalà, M. Stress corrosion cracking probability of selective laser melted 316l austenitic stainless steel under the effect of grinding induced residual stresses. Metals 2021, 11, 327. [Google Scholar] [CrossRef]

- ASTM-E1245; Standard Practice for Determining the Inclusion or Second-Phase Constituent Content of Metals by Automatic Image Analysis. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- ASTM-E8; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- ASTM-E384; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM-B962; Standard Test Methods for Density of Compacted or Sintered Powder Metallurgy (PM) Products Using Archimedes’ Principle. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM-G15; Standard Terminology Relating to Corrosion and Corrosion Testing. ASTM International: West Conshohocken, PA, USA, 2010. [CrossRef]

- ASTM-G38; Standard Practice for Making and Using C-Ring Stress-Corrosion Test Specimens. ASTM International: West Conshohocken, PA, USA, 2013. Available online: https://www.astm.org/g0038-01r21.html (accessed on 27 October 2022).

- ASTM-G123; Standard Test Method for Evaluationg Stress-Corrosion Cracking of Stainless Steel Alloys with Different Nickel Content in Boiling Acidified Sodium Chloride Solution. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- Matsuda, F.; Nakagawa, H.; Kato, I.; Murata, Y. Effects of ferrite content and microsegregation on solidification crack susceptibility of duplex stainless steel weld metals. Weld. Int. 1988, 2, 529–535. [Google Scholar] [CrossRef]

- ASTM-G46; Standard Guide for Examination and Evaluation of Pitting Corrosion. ASTM International: West Conshohocken, PA, USA, 2018. [CrossRef]

- German, R.M. Powder Metallurgy of Iron and Steel; John Wiley & Sons, Inc.: New York, NY, USA, 1998; 496p. [Google Scholar]

- Heaney, D.F. Handbook of Metal Injection Molding; Woodhead Publishing: Philadelphia, PA, USA, 2012. [Google Scholar]

- Klar, E.; Samal, P.K. Powder Metallurgy Stainless Steels: Processing, Microstructures, and Properties; ASM International: Materials Park, OH, USA, 2007. [Google Scholar]

- Verhoeven, J.D. Steel Metallurgy for the Non-Metallurgist; ASM International: Materials Park, OH, USA, 2007. [Google Scholar]

- Hosford, W.F. Iron and Steel; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Yang, L.; Hsu, K.; Baughman, B.; Godfrey, D.; Medina, F.; Menon, M.; Wiener, S. Additive Manufacturing of Metals: The Technology, Materials, Design and Production; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Colón Quintana, J.L.; Redmann, A.; Mazzei Capote, G.A.; Pérez-Irizarry, A.; Bechara, A.; Osswald, T.A.; Lakes, R. Viscoelastic properties of fused filament fabrication parts. Addit. Manuf. 2019, 28, 704–710. [Google Scholar] [CrossRef]

- Ravi Kumar, B.; Mahato, B.; Singh, R. Influence of Cold-Worked Structure on Electrochemical Properties of Austenitic Stainless Steels. Metall. Mater. Trans. A 2007, 38, 2085–2094. [Google Scholar] [CrossRef]

- Damon, J.; Dietrich, S.; Gorantla, S.; Popp, U.; Okolo, B.; Schulze, V. Process porosity and mechanical performance of fused filament fabricated 316L stainless steel. Rapid Prototyp. J. 2019, 25, 1319–1327. [Google Scholar] [CrossRef]

- Liu, B.; Wang, Y.; Lin, Z.; Zhang, T. Creating metal parts by Fused Deposition Modeling and Sintering. Mater. Lett. 2020, 263, 127252. [Google Scholar] [CrossRef]

- Gong, H.; Snelling, D.; Kardel, K.; Carrano, A. Comparison of Stainless Steel 316L Parts Made by FDM- and SLM-Based Additive Manufacturing Processes. JOM 2019, 71, 880–885. [Google Scholar] [CrossRef]

- Ghosh, S.; Rana, V.P.S.; Kain, V.; Mittal, V.; Baveja, S.K. Role of residual stresses induced by industrial fabrication on stress corrosion cracking susceptibility of austenitic stainless steel. Mater. Des. 2011, 32, 3823–3831. [Google Scholar] [CrossRef]

- Acharyya, S.G.; Khandelwal, A.; Kain, V.; Kumar, A.; Samajdar, I. Surface working of 304L stainless steel: Impact on microstructure, electrochemical behavior and SCC resistance. Mater. Charact. 2012, 72, 68–76. [Google Scholar] [CrossRef]

- Turnbull, A.; Mingard, K.; Lord, J.D.; Roebuck, B.; Tice, D.R.; Mottershead, K.J.; Fairweather, N.D.; Bradbury, A.K. Sensitivity of stress corrosion cracking of stainless steel to surface machining and grinding procedure. Corros. Sci. 2011, 53, 3398–3415. [Google Scholar] [CrossRef]

- Wenman, M.R.; Trethewey, K.R.; Jarman, S.E.; Chard-Tuckey, P.R. A finite-element computational model of chloride-induced transgranular stress-corrosion cracking of austenitic stainless steel. Acta Mater. 2008, 56, 4125–4136. [Google Scholar] [CrossRef]

- Turnbull, A.; McCartney, L.N.; Zhou, S. A model to predict the evolution of pitting corrosion and the pit-to-crack transition incorporating statistically distributed input parameters. Corros. Sci. 2006, 48, 2084–2105. [Google Scholar] [CrossRef]

- Turnbull, A.; McCartney, L.N.; Zhou, S. Modelling of the evolution of stress corrosion cracks from corrosion pits. Scr. Mater. 2006, 54, 575–578. [Google Scholar] [CrossRef]

- Dieter, G.E.; Bacon, D.J. Mechanical Metallurgy; McGraw-Hill: New York, NY, USA, 1976; Volume 3. [Google Scholar]

- Callister, W.D.; Rethwisch, D.G.; Blicblau, A.; Bruggeman, K.; Cortie, M.; Long, J.; Hart, J.; Marceau, R.; Ryan, M.; Parvizi, R. Materials Science and Engineering: An Introduction; Wiley: Hoboken, NJ, USA, 2021. [Google Scholar]

- Galvele, J.; Duffó, G. Procesos de Corrosión; Cursos ECOMAR, Comisión Nacional de Energía Atómica: Buenos Aires, Argentina, 1975.

- Abbass, M.K.; Ajeel, S.A.; Wadullah, H.M. Biocompatibility, bioactivity and corrosion resistance of stainless steel 316L nanocoated with TiO2 and Al2O3 by atomic layer deposition method. J. Phys. Conf. Ser. 2018, 1, 012017. [Google Scholar] [CrossRef]

- Abdullah, Z.; Ismail, A.; Ahmad, S. The influence of porosity on corrosion attack of Austenitic stainless steel. J. Phys. Conf. Ser. 2017, 1, 012013. [Google Scholar] [CrossRef]

- García, C.; Martín, F.; de Tiedra, P.; Cambronero, L.G. Pitting corrosion behaviour of PM austenitic stainless steels sintered in nitrogen–hydrogen atmosphere. Corros. Sci. 2007, 49, 1718–1736. [Google Scholar] [CrossRef]

- Deng, P.; Karadge, M.; Rebak, R.B.; Gupta, V.K.; Prorok, B.C.; Lou, X. The origin and formation of oxygen inclusions in austenitic stainless steels manufactured by laser powder bed fusion. Addit. Manuf. 2020, 35, 101334. [Google Scholar] [CrossRef]

- Mao, Y.; Yuan, J.; Heng, Y.; Feng, K.; Cai, D.; Wei, Q. Effect of hot isostatic pressing treatment on porosity reduction and mechanical properties enhancement of 316L stainless steel fabricated by binder jetting. Virtual Phys. Prototyp. 2023, 18, e2174703. [Google Scholar] [CrossRef]

- Atkinson, H.; Davies, S. Fundamental aspects of hot isostatic pressing: An overview. Metall. Mater. Trans. A 2000, 31, 2981–3000. [Google Scholar] [CrossRef]

- Teng, Q.; Xie, Y.; Sun, S.; Xue, P.; Long, A.; Wu, T.; Cai, C.; Guo, J.; Wei, Q. Understanding on processing temperature-metallographic microstructure-tensile property relationships of third-generation nickel-based superalloy WZ-A3 prepared by hot isostatic pressing. J. Alloys Compd. 2022, 909, 164668. [Google Scholar] [CrossRef]

- Cai, C.; Gao, X.; Teng, Q.; Kiran, R.; Liu, J.; Wei, Q.; Shi, Y. Hot isostatic pressing of a near α-Ti alloy: Temperature optimization, microstructural evolution and mechanical performance evaluation. Mater. Sci. Eng. A 2021, 802, 140426. [Google Scholar] [CrossRef]

- Damon, J.; Dietrich, S.; Vollert, F.; Gibmeier, J.; Schulze, V. Process dependent porosity and the influence of shot peening on porosity morphology regarding selective laser melted AlSi10Mg parts. Addit. Manuf. 2018, 20, 77–89. [Google Scholar] [CrossRef]

- AlMangour, B.; Yang, J.-M. Improving the surface quality and mechanical properties by shot-peening of 17-4 stainless steel fabricated by additive manufacturing. Mater. Des. 2016, 110, 914–924. [Google Scholar] [CrossRef]

- Rautio, T.; Jaskari, M.; Gundgire, T.; Iso-Junno, T.; Vippola, M.; Järvenpää, A. The Effect of Severe Shot Peening on Fatigue Life of Laser Powder Bed Fusion Manufactured 316L Stainless Steel. Materials 2022, 15, 3517. [Google Scholar] [CrossRef]

- Jemaa, N.; Shu, J.; Kaliaguine, S.; Grandjean, B.P. Thin palladium film formation on shot peening modified porous stainless steel substrates. Ind. Eng. Chem. Res. 1996, 35, 973–977. [Google Scholar] [CrossRef]

- Lépinoux, J.; Magnin, T. Stress corrosion microcleavage in a ductile f.c.c. alloy. In Fundamental Aspects of Dislocation Interactions; Kostorz, G., Calderon, H.A., Martin, J.L., Eds.; Elsevier: Amsterdam, The Netherlands, 1993; pp. 266–269. [Google Scholar] [CrossRef]

- Qu, H. Effect of Crystallography on Stress Corrosion Cracking Growth in Austenitic Stainless Steels. Master’s Thesis, Purdue University Graduate School, West Lafayette, IN, USA, 2020. [Google Scholar]

- Hosford, W. Mechanical testing. In Mechanical Behavior of Materials; Pearson: London, UK, 2009; pp. 36–64. [Google Scholar]

- Haidemenopoulos, G.N. Physical Metallurgy: Principles and Design; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Qu, H.J.; Tao, F.; Gu, N.; Montoya, T.; Taylor, J.M.; Schaller, R.F.; Schindelholz, E.; Wharry, J.P. Crystallographic effects on transgranular chloride-induced stress corrosion crack propagation of arc welded austenitic stainless steel. npj Mater. Degrad. 2022, 6, 43. [Google Scholar] [CrossRef]

- Koyama, M.; Ogawa, T.; Yan, D.; Matsumoto, Y.; Tasan, C.C.; Takai, K.; Tsuzaki, K. Hydrogen desorption and cracking associated with martensitic transformation in Fe-Cr-Ni-Based austenitic steels with different carbon contents. Int. J. Hydrogen Energy 2017, 42, 26423–26435. [Google Scholar] [CrossRef]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Conway, K.M.; Kunka, C.; White, B.C.; Pataky, G.J.; Boyce, B.L. Increasing fracture toughness via architected porosity. Mater. Des. 2021, 205, 109696. [Google Scholar] [CrossRef]

- Kumar, P.; Jayaraj, R.; Suryawanshi, J.; Satwik, U.R.; McKinnell, J.; Ramamurty, U. Fatigue strength of additively manufactured 316L austenitic stainless steel. Acta Mater. 2020, 199, 225–239. [Google Scholar] [CrossRef]

- Vieille, B.; Keller, C.; Mokhtari, M.; Briatta, H.; Breteau, T.; Nguejio, J.; Barbe, F.; Ben Azzouna, M.; Baustert, E. Investigations on the fracture behavior of Inconel 718 superalloys obtained from cast and additive manufacturing processes. Mater. Sci. Eng. A 2020, 790, 139666. [Google Scholar] [CrossRef]

| Printing Parameters | Debinding Parameters | ||

|---|---|---|---|

| Extrude line width: | 0.5 mm | Debinding time: | 15 h |

| Deposited layer height: | 0.15 mm | Debinding temperature: | 50 °C |

| Contour shell thickness: | 1.50 mm | Debinding pressure: | Atmospheric |

| Extrusion nozzle size: | 0.40 mm | Sintering parameters | |

| Extrusion rate: | 30 mm/s | Heating rate: | ~1.0 °C/min |

| Extrusion temperature: | 175 °C | Thermal debinding temperature: | 550 °C |

| Build plate temperature: | 60 °C | Thermal debinding dwell time: | 2 h |

| Sintering scale factors: | X = Y = Z = 1.15 | Sintering temperature: | 1350 °C |

| Bulk volume raster pattern: | +45°/−45° each layer | Sintering atmosphere: | Ar > 99.997% vol. |

| Infill density: | 100% | Sintering dwell time: | 2 h |

| Print orientation: | Vertical (Z) | Cooling rate: | Furnace cooling |

| Alloy | Source | Fe | C | Cr | Ni | Mo | Si | Mn | P | S |

|---|---|---|---|---|---|---|---|---|---|---|

| BMD SS316L | ICP-AES | Bal. | 0.020 | 16.3 | 10.4 | 2.12 | 0.61 | 1.22 | 0.010 | 0.010 |

| SA SS316L | MTR | Bal. | 0.012 | 16.1 | 10.1 | 2.03 | 0.46 | 0.92 | 0.036 | 0.002 |

| CD SS316L | MTR | Bal | 0.019 | 16.7 | 10.1 | 2.03 | 0.41 | 1.72 | 0.024 | 0.025 |

| UNS S31603 | ASTM A213 [36] | Bal. | Max. 0.035 | 16.0 18.0 | 10.0 14.0 | 2.00 3.00 | Max. 1.00 | Max. 2.00 | Max. 0.045 | Max. 0.030 |

| Alloy | Non-Metallic Inclusions (%) | δ-Ferrite Phase (%) | Average Grain Size (µm) | Aspect Ratio | Twin Boundaries (%) | Schmid Factor {111}<110> |

|---|---|---|---|---|---|---|

| BMD SS316L | 3.23 | 6.09 | 40.8 ± 23.8 | 3.1 ± 2.4 | 53.2 | 0.69 |

| SA SS316L | 0.01 | 7.86 | 16.2 ± 8.5 | 2.2 ± 1.3 | 45.5 | 0.94 |

| CD SS316L | 0.39 | 0.95 | 43.5 ± 33.6 | 3.9 ± 3.6 | 39.4 | 0.96 |

| Alloy | AYS (MPa) | Microhardness (HV2) | Bulk Density (g/cm3) | Relative Bulk Porosity (%) |

|---|---|---|---|---|

| BMD SS316L | 167 ± 2 | 117.1 ± 3.2 | 7.564 ± 0.013 | 5.21 |

| SA SS316L | 293 ± 6 | 163.9 ± 2.5 | 7.935 ± 0.025 | 0.57 |

| CD SS316L | 646 ± 8 | 277.3 ± 3.2 | 7.953 ± 0.027 | 0.35 |

| Alloy | Unstressed C-Ring (0%AYS) in Boiling Solution after 1 Week | Stressed C-Ring (90%AYS) in Boiling Solution after Cracking | ||

|---|---|---|---|---|

| Pit Size (µm) in Flat Surface | Pit Size (µm) in Curved Surface | Pit Size (µm) | Pit Depth (µm) | |

| BMDSS3 16L | 112 ± 117 | 89 ± 154 | 406 ± 359 | 190 ± 135 |

| SA SS316L | 31 ± 27 | 28 ± 16 | 213 ± 178 | 58 ± 27 |

| CD SS316L | 88 ± 61 | 27 ± 11 | 205 ± 118 | 130 ± 84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santamaria, R.; Wang, K.; Salasi, M.; Iannuzzi, M.; Mendoza, M.Y.; Quadir, M.Z. Stress Corrosion Cracking of 316L Stainless Steel Additively Manufactured with Sinter-Based Material Extrusion. Materials 2023, 16, 4006. https://doi.org/10.3390/ma16114006

Santamaria R, Wang K, Salasi M, Iannuzzi M, Mendoza MY, Quadir MZ. Stress Corrosion Cracking of 316L Stainless Steel Additively Manufactured with Sinter-Based Material Extrusion. Materials. 2023; 16(11):4006. https://doi.org/10.3390/ma16114006

Chicago/Turabian StyleSantamaria, Ricardo, Ke Wang, Mobin Salasi, Mariano Iannuzzi, Michael Y. Mendoza, and Md Zakaria Quadir. 2023. "Stress Corrosion Cracking of 316L Stainless Steel Additively Manufactured with Sinter-Based Material Extrusion" Materials 16, no. 11: 4006. https://doi.org/10.3390/ma16114006

APA StyleSantamaria, R., Wang, K., Salasi, M., Iannuzzi, M., Mendoza, M. Y., & Quadir, M. Z. (2023). Stress Corrosion Cracking of 316L Stainless Steel Additively Manufactured with Sinter-Based Material Extrusion. Materials, 16(11), 4006. https://doi.org/10.3390/ma16114006