Investigation of Crack Propagation Behaviour in Thin-Rim Gears: Experimental Tests and Numerical Simulations

Abstract

1. Introduction

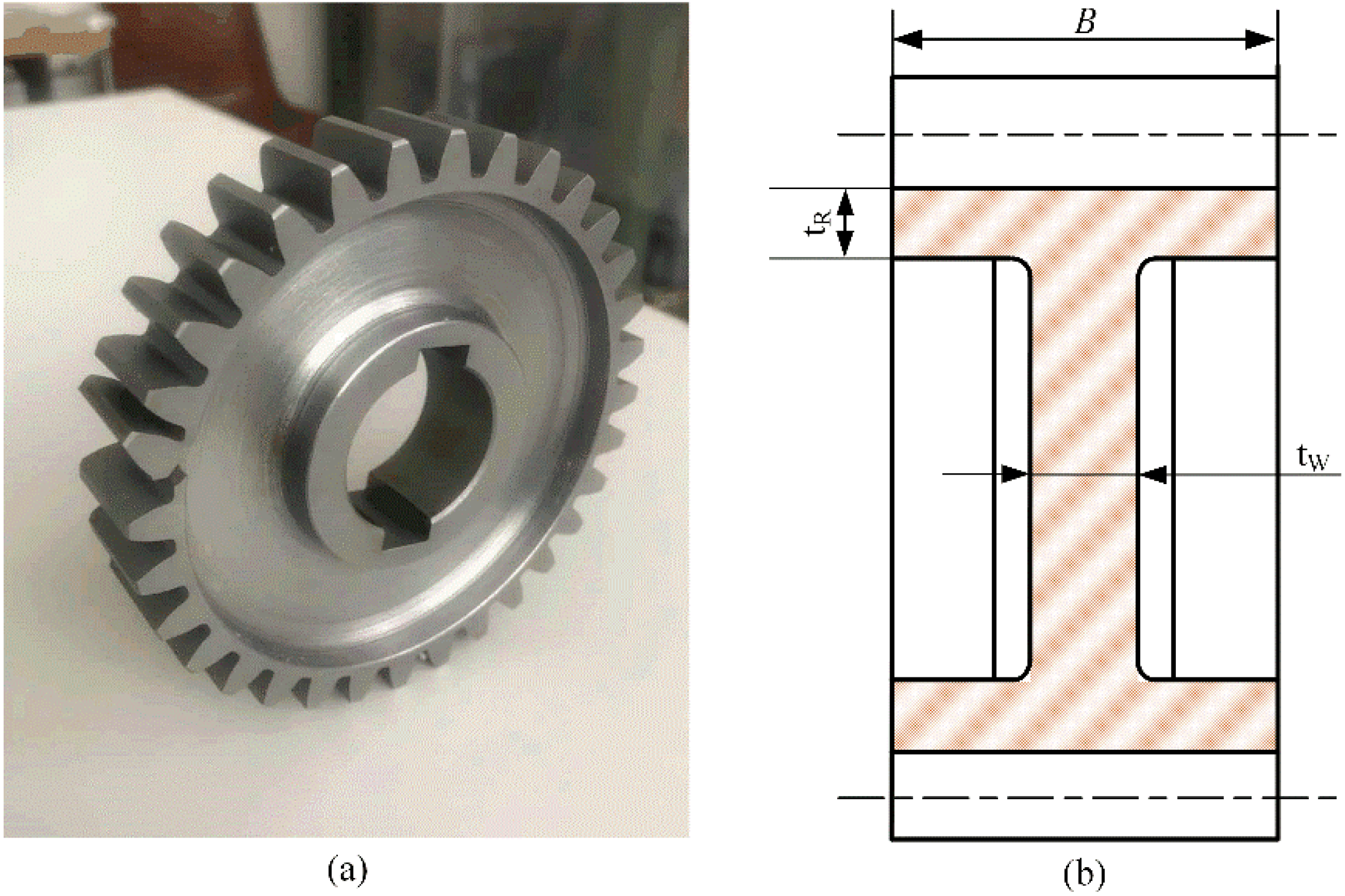

2. Experimental Setup

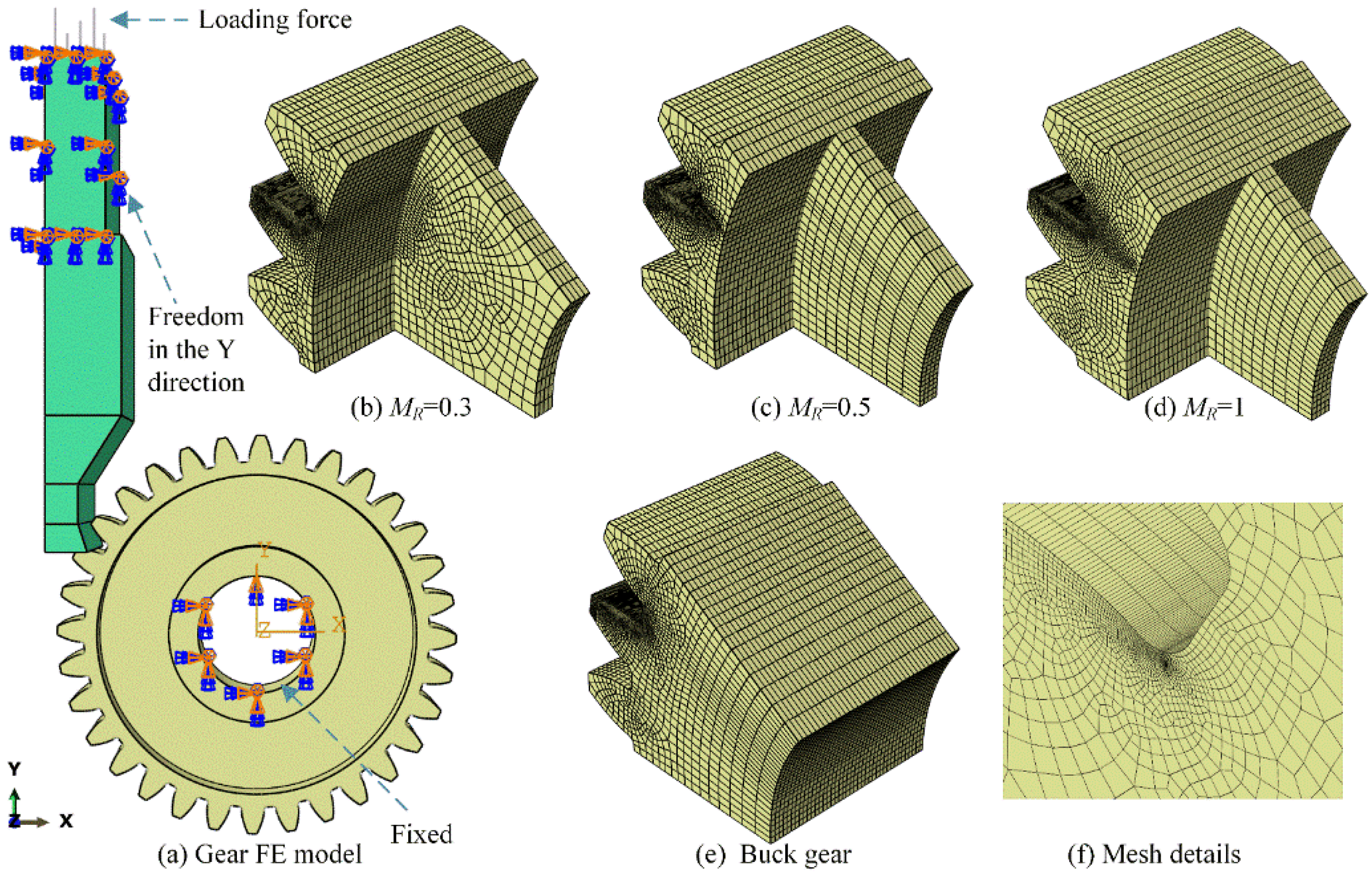

3. FE Simulations

4. Results and Discussion

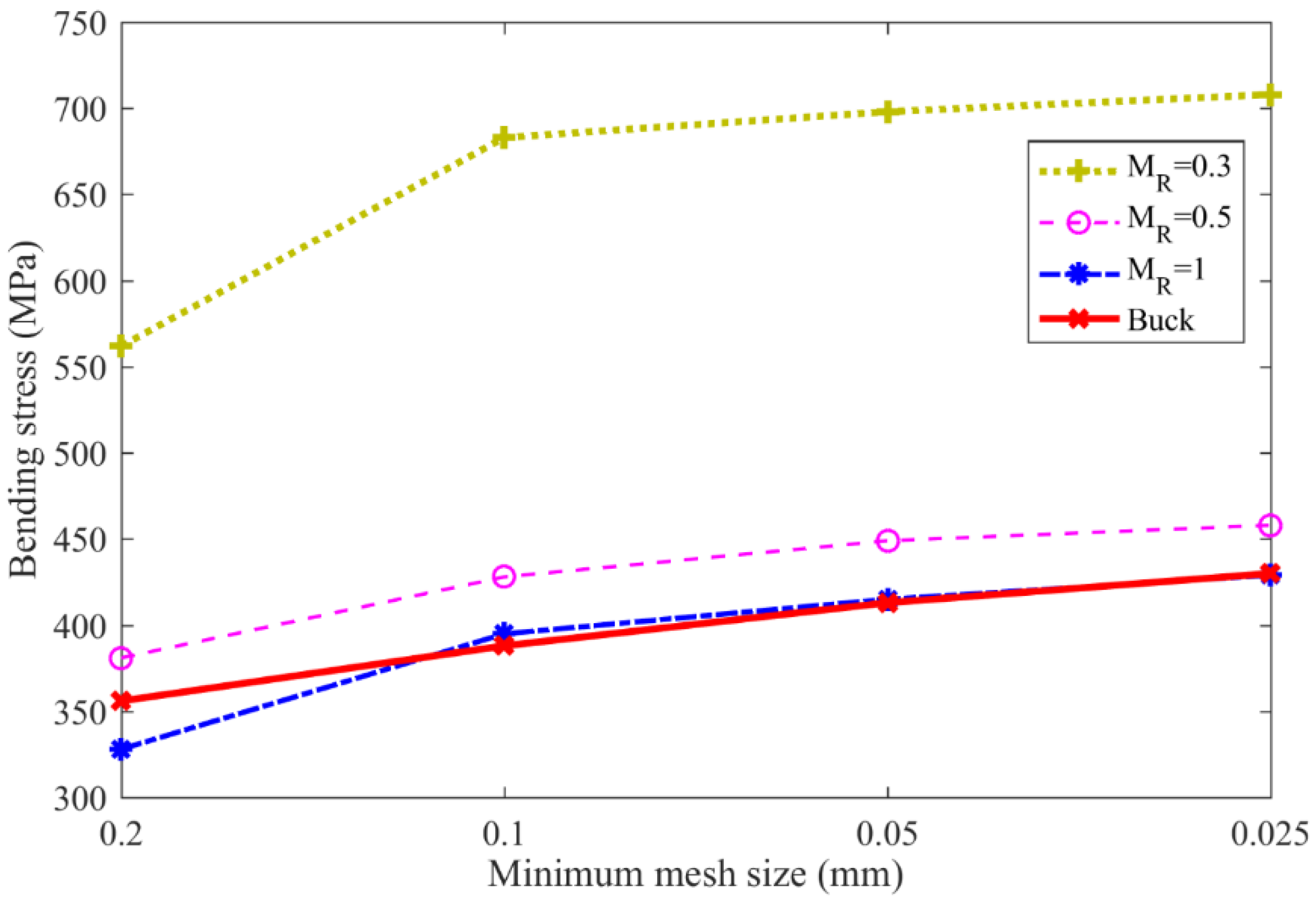

4.1. Gear Finite Element Model Stress Convergence Verification

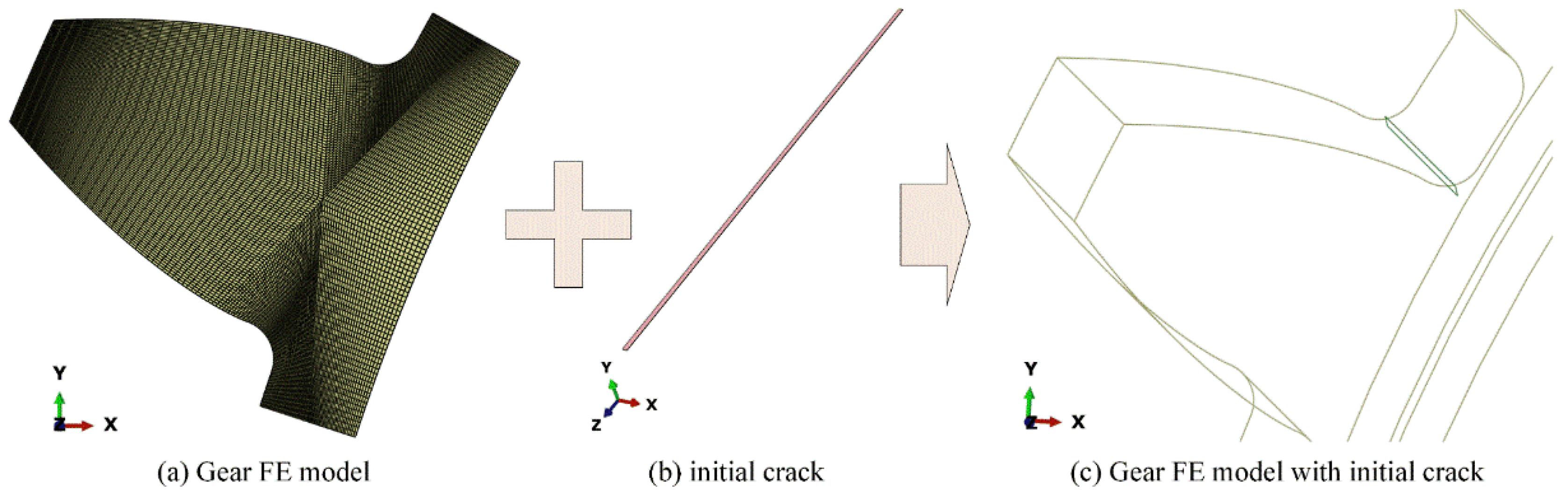

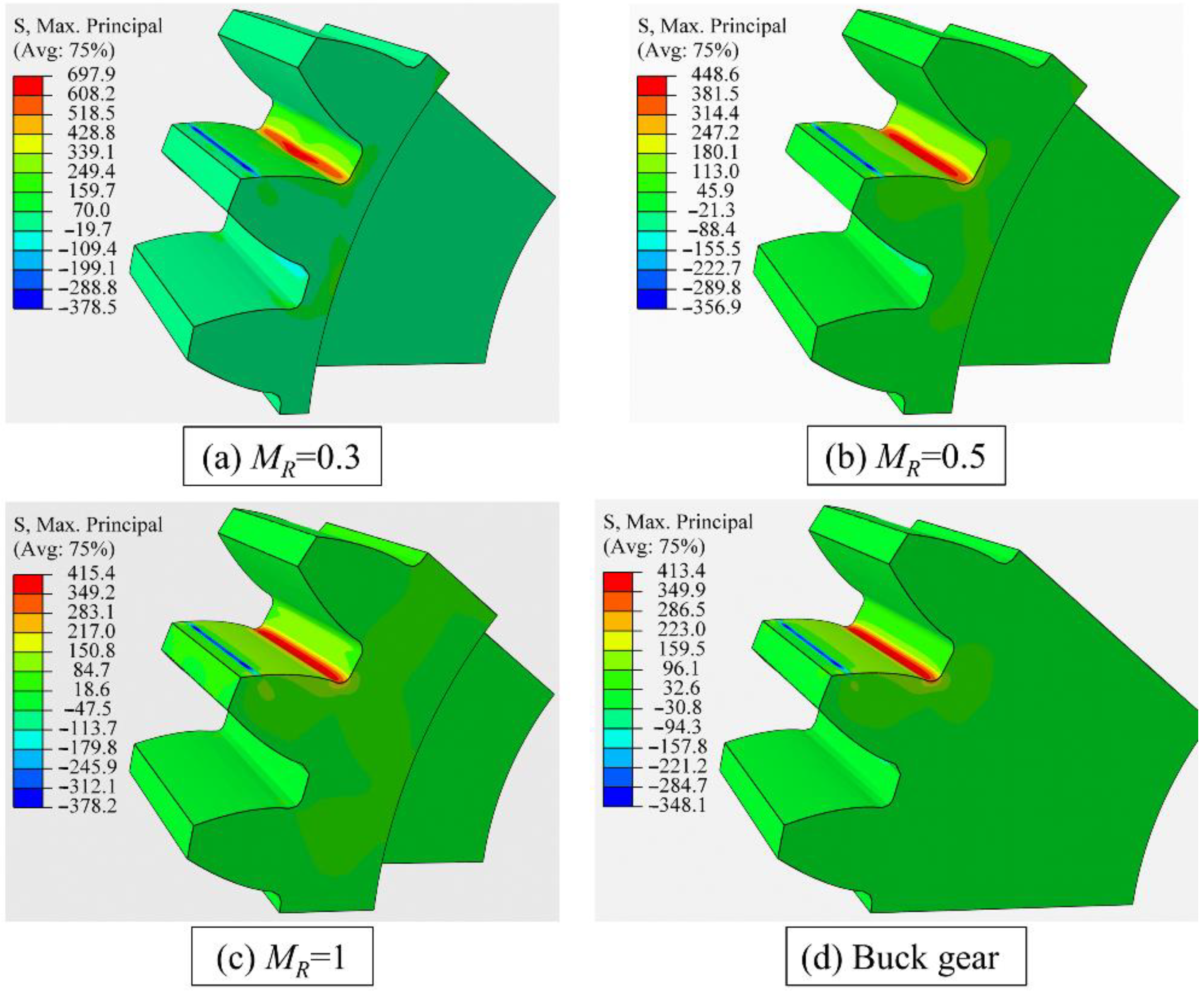

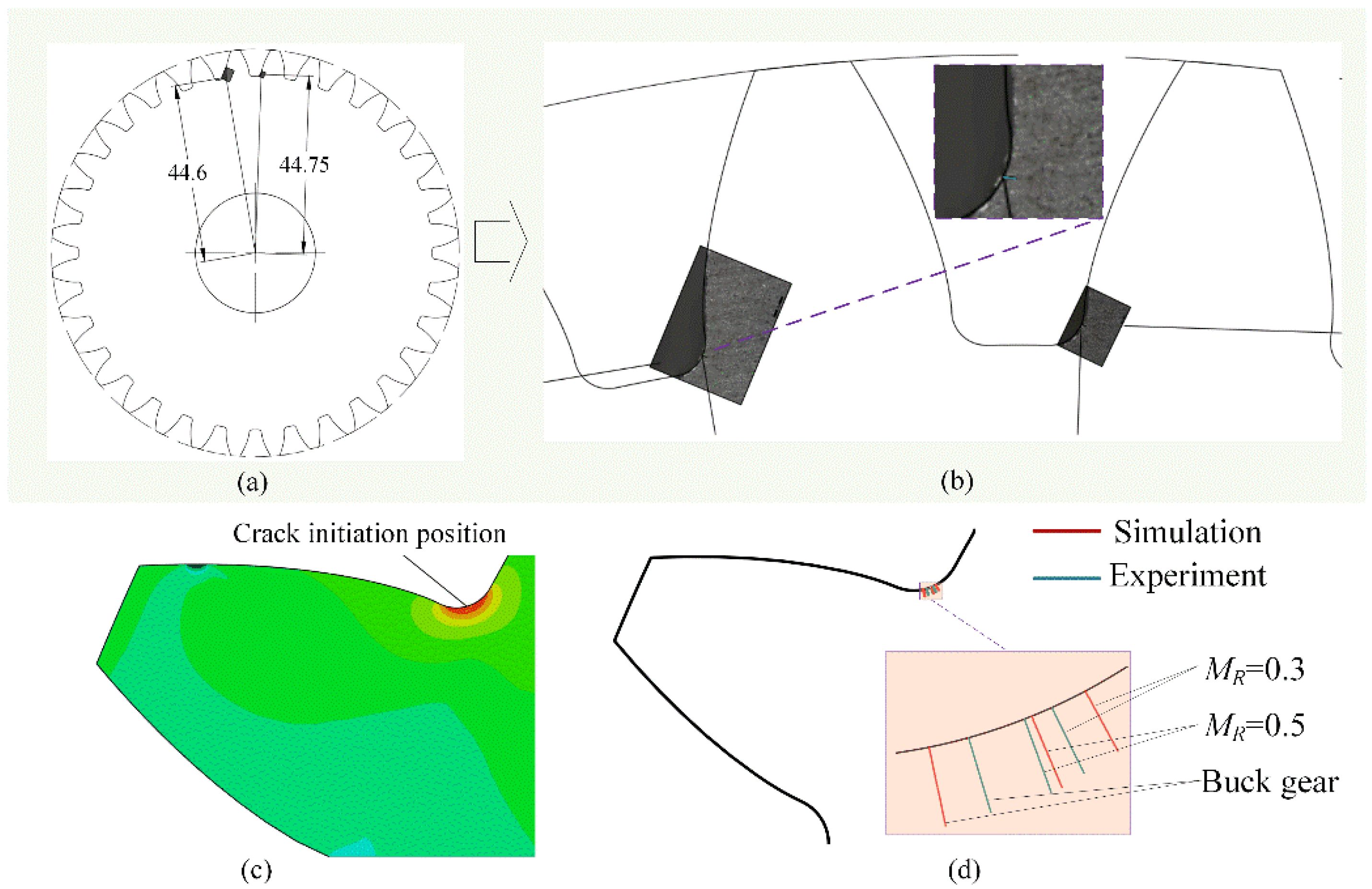

4.2. Crack Initiation Position

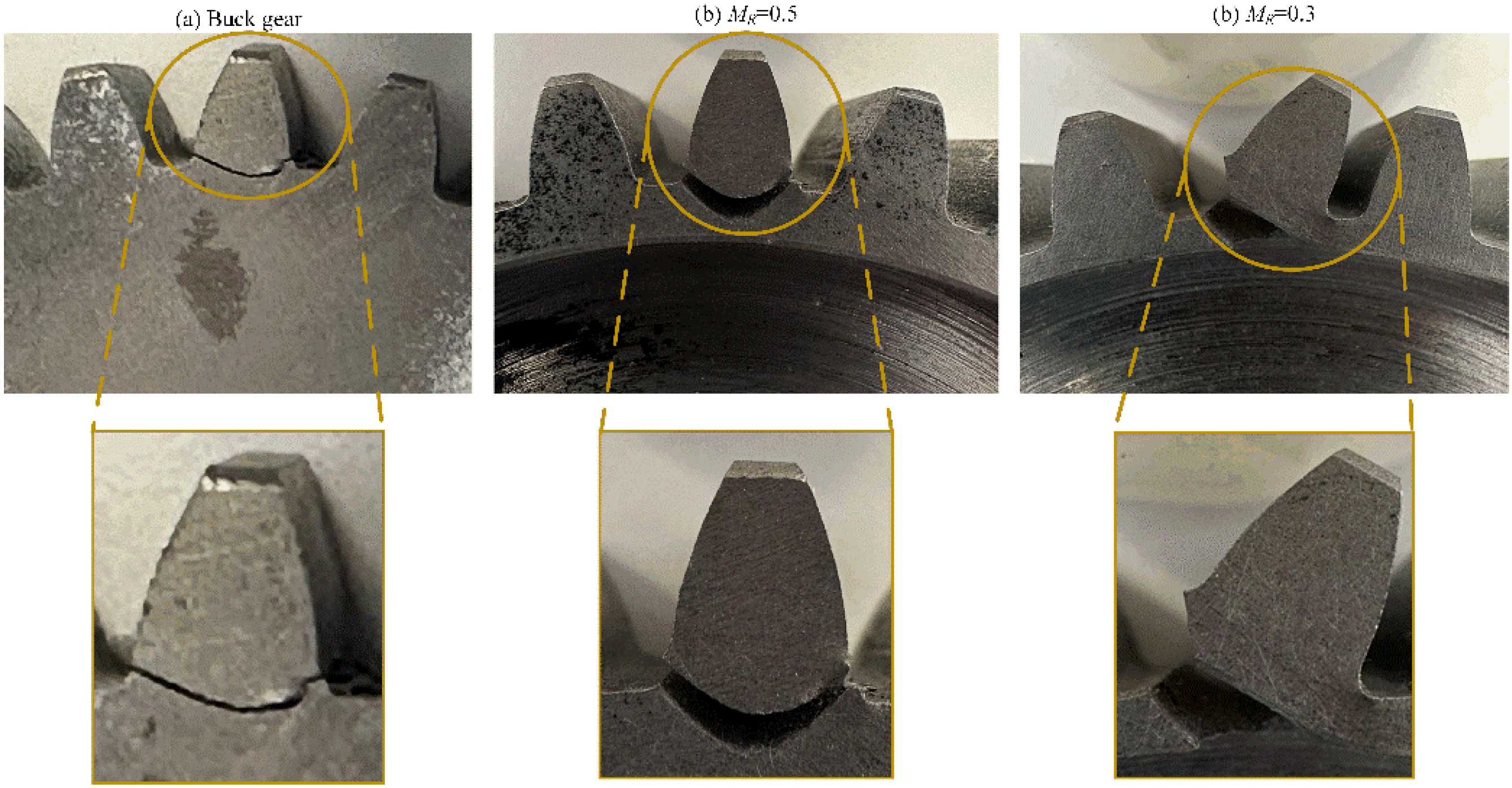

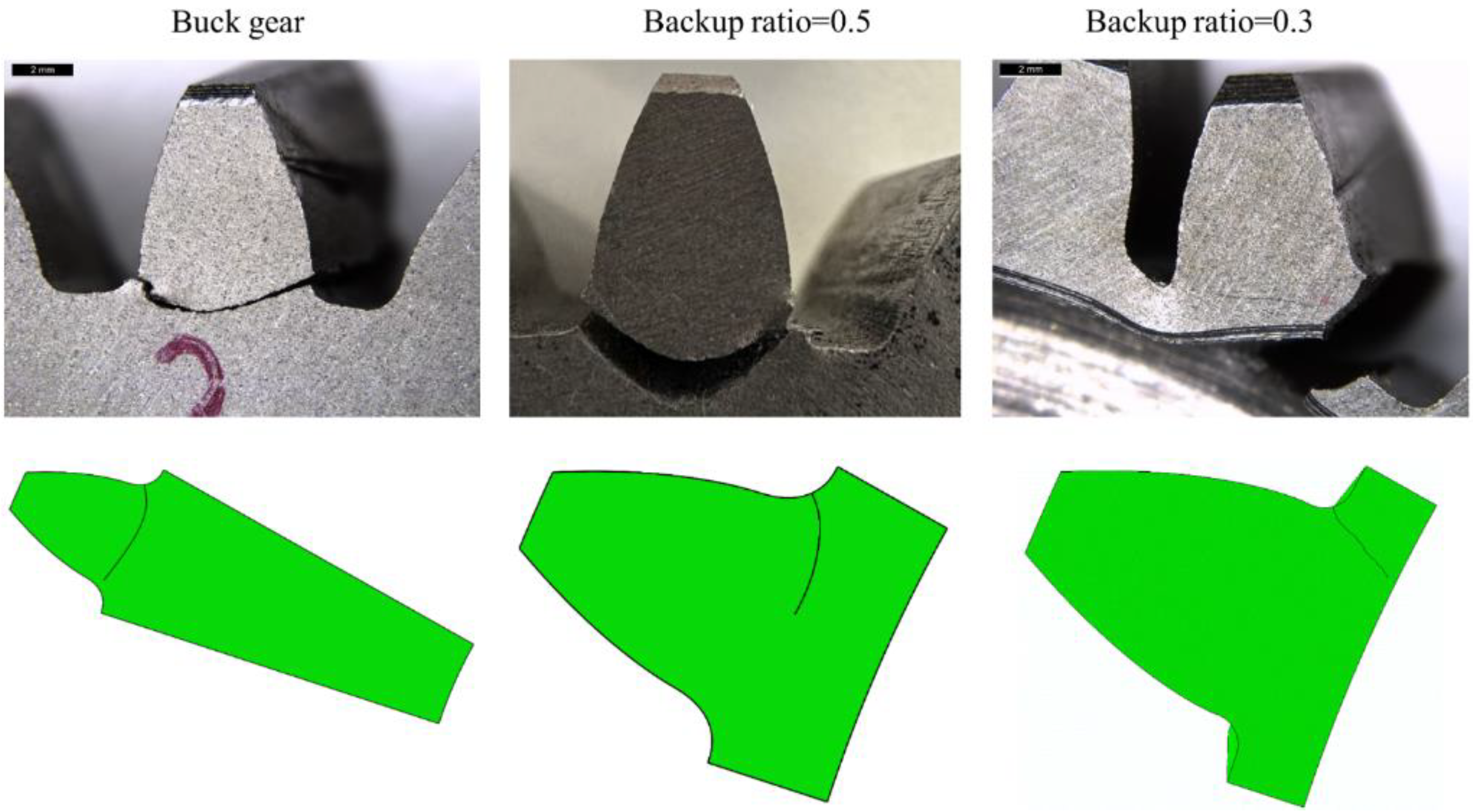

4.3. Crack Propagation Path

5. Conclusions

- (1)

- The gear bending stress increases dramatically as the rim thickness decreases. The effect of rim thickness on the gear bending stress needs to be considered when the back ratio is less than 0.5. The gear root crack initiation position is closer to the gear root centre as the rim thickness decreases. The distance between the gear root centre and the crack initiation position reduces from 1.50 mm through 1.40 mm to 1.35 mm when the backup ratio decreases from 1 through 0.5 to 0.3.

- (2)

- When the gear backup ratio is larger than 0.5, the root crack propagates through the tooth thickness; yet, the crack in the wheel with a backup ratio of 0.3 propagates through the rim thickness and finally results in catastrophic failure.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| the bending moment arm, mm | |

| the tooth root normal chord, mm | |

| the rim thickness, mm | |

| the web thickness, mm | |

| the shifting coefficient | |

| B | face width, mm |

| HPSTC | the highest point of single tooth contact |

| the gear backup ratio | |

| the gear web ratio | |

| the geometry factor | |

| the stress concentration factor | |

| the teeth number | |

| the normal loading force applied on the tooth at HPSTC, N | |

| the tangential loading force applied on the tooth at HPSTC, N | |

| the normal | |

| the load direction angle | |

| the radius of the root fillet, mm |

References

- Kahraman, A.; Kharazi, A.A.; Umrani, M. A deformable body dynamic analysis of planetary gears with thin rims. J. Sound Vib. 2003, 262, 752–768. [Google Scholar] [CrossRef]

- Lewicki, D.G. Crack Propagation Studies to Determine Benign or Catastrophic Failure Modes for Aerospace Thin-Rim Gears. Ph.D. Thesis, Case Western Reserve University, Cleveland, OH, USA, 1996. [Google Scholar]

- Lewicki, D.G.; Ballarini, R. Effect of rim thickness on gear crack propagation path. J. Mech. Des. 1997, 119, 88–95. [Google Scholar] [CrossRef]

- Lewicki, D.G.; Ballarini, R. Rim thickness effects on gear crack propagation life. Int. J. Fract. 1997, 87, 59–86. [Google Scholar] [CrossRef]

- Lewicki, D. Effect of Speed (Centrifugal Load) on Gear Crack Propagation; US Army Research Laboratory, Glenn Research Center: Cleveland, OH, USA, 2001.

- Lewicki, D.G. Gear crack propagation path studies-guidelines for ultra-safe design. J. Am. Helicopter Soc. 2002, 47, 64–72. [Google Scholar] [CrossRef]

- Moriwaki, I.; Fukushima, T.; Ueda, A.; Nakamura, M. Effect of rim thickness on tatigue breakage in plastic-gear teeth. J. Jpn. Soc. Precis. Eng. 2010, 76, 201–206. [Google Scholar] [CrossRef]

- Oda, S.; Miyachika, K. Effects of key on bending fatigue breakage of thin-rimmed spur gear. Bull. JSME 1984, 27, 2279–2286. [Google Scholar] [CrossRef]

- Kahraman, A.; Ligata, H.; Singh, A. Influence of ring gear rim thickness on planetary gear set behavior. J. Mech. Des. 2010, 132, 021002. [Google Scholar] [CrossRef]

- Xu, X.; Yu, Z.; Gao, Y.; Wang, T. Crack failure of gears used in generating electricity equipment by wind power. Eng. Fail. Anal. 2008, 15, 938–945. [Google Scholar] [CrossRef]

- Yan, H.; Wei, P.; Zhou, P.; Chen, L.; Liu, H.; Zhu, C. Experimental investigation of crack growth behaviors and mechanical properties degradation during gear bending fatigue. J. Mech. Sci. Technol. 2022, 36, 1233–1242. [Google Scholar] [CrossRef]

- Zouari, S.; Maatar, M.; Fakhfakh, T.; Haddar, M. Following spur gear crack propagation in the tooth foot by finite element method. J. Fail. Anal. Prev. 2010, 10, 531–539. [Google Scholar] [CrossRef]

- Cura, F.; Mura, A.; Rosso, C. Effect of rim and web interaction on crack propagation paths in gears by means of XFEM technique. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 1237–1245. [Google Scholar] [CrossRef]

- Cura, F.; Mura, A.; Rosso, C. Effect of centrifugal load on crack path in thin-rimmed and webbed gears. Frat. Ed Integrità Strutt. 2015, 9, 447–455. [Google Scholar]

- Cura, F.; Mura, A.; Rosso, C. Crack propagation behavior in planet gears. Procedia Struct. Integr. 2016, 2, 3610–3616. [Google Scholar] [CrossRef]

- Cura, F.; Mura, A.; Rosso, C. Influence of high speed on crack propagation path in thin rim gears. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 120–129. [Google Scholar] [CrossRef]

- Oguz, D.; Celalettin, Y.; Fatih, K. Effects of rim thickness and drive side pressure angle on gear tooth root stress and fatigue crack propagation life. Eng. Fail. Anal. 2021, 122, 105260. [Google Scholar]

- Namboothiri, N.V.; Marimuthu, P.; Kumar, S.S. Analysis of fracture characteristics of thin and thick rim asymmetric spur gear based on strain energy release rate. Theor. Appl. Fract. Mech. 2022, 121, 103496. [Google Scholar] [CrossRef]

- Kramberger, J.; Sraml, M.; Potrc, I.; Flasker, J. Numerical calculation of bending fatigue life of thin-rim spur gears. Eng. Fract. Mech. 2004, 71, 647–656. [Google Scholar] [CrossRef]

- Kramberger, J.; Flašker, J. Numerical simulation of 3-D crack growth in thin-rim gears. In Proceedings of the International Conference on CRACK PATHS, Parma, Italy, 14–16 September 2006. [Google Scholar]

- Lalonde, S.; Guilbault, R. Prediction of thin-rimmed gear crack propagation from a factorial design approach. Fatigue Fract. Eng. Mater. Struct. 2011, 34, 470–486. [Google Scholar] [CrossRef]

- Gueye, B.; Shao, Y.; Chen, Z. Prediction of gear tooth crack propagation path based on pseudo evolutionary structural optimization. Int. J. COMADEM 2017, 20, 29–34. [Google Scholar]

- Podrug, S.; Jelaska, D.; GlodeŽ, S. Influence of different load models on gear crack path shapes and fatigue lives. Fatigue Fract. Eng. Mater. Struct. 2008, 31, 327–339. [Google Scholar] [CrossRef]

- Miyachika, K.; Oda, S.; Koide, T.; Fujiwara, S. Bending Strength Estimation of Thin-Rimmed Spur Gears. Trans. Jpn. Soc. Mech. Eng. Ser. C 1995, 61, 386–391. [Google Scholar] [CrossRef]

- Li, S. Deformation and bending stress analysis of a three-dimensional, thin-rimmed gear. J. Mech. Des. 2002, 124, 129–135. [Google Scholar] [CrossRef]

- Opalic, M.; Vuckovic, K.; Zezelj, D. Effect of rotational speed on thin-rim gear bending fatigue crack initiation life. In Advances in Fracture and Damage Mechanics X; Tonkovic, Z., Aliabadi, M.H., Eds.; Trans Tech Publications Ltd.: Stafa, Germany, 2012; pp. 456–459. [Google Scholar]

- Chen, Z.G.; Shao, Y.M. Mesh stiffness of an internal spur gear pair with ring gear rim deformation. Mech. Mach. Theory 2013, 69, 1–12. [Google Scholar] [CrossRef]

- Karpat, F.; Engin, B.; Dogan, O.; Yuce, C.; Yilmaz, T.G. Asme, Effects of rim thickness on tooth root stress and mesh stiffness of internal gears. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2015; pp. 1–7. [Google Scholar]

- Lin, Y.; Liu, S.; Zhao, X.; Mao, E.; Cao, C.; Suh, C.S. Fatigue life prediction of engaging spur gears using power density. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 232, 4332–4341. [Google Scholar] [CrossRef]

- He, H.; Liu, H.; Mura, A.; Zhu, C. Gear bending fatigue life prediction based on continuum damage mechanics and linear elastic fracture mechanics. Meccanica 2023, 58, 119–135. [Google Scholar] [CrossRef]

- He, H.; Zhou, Y.; Liu, H.; Zhu, C.; Xiao, B.; Zhang, T. Study on gear bending fatigue considering gradient characteristics: Numerical analysis and experiments. Eng. Fract. Mech. 2023, 277, 108983. [Google Scholar] [CrossRef]

- Vuckovic, K.; Galic, I.; Bozic, Z.; Glodez, S. Effect of friction in a single-tooth fatigue test. Int. J. Fatigue 2018, 114, 148–158. [Google Scholar] [CrossRef]

- ISO 6336–3; Calculation and Load Capacity of Spur and Helical Gears—Part 3: Calculation of Tooth Bending Strength. International Organization for Standardization: Geneva, Switzerland, 2019.

| Teeth Number | Z = 32 | Pressure Angle | |

|---|---|---|---|

| Module | mn = 3 mm | Gear tooth width | B = 20 mm |

| Shifting coefficient | xn = 0 | Tooth addendum coefficients | 1 |

| Material | C45E |

| C | Si | Mn | S | P | Cr | Ni | Mo | Al |

|---|---|---|---|---|---|---|---|---|

| 0.44 | 0.22 | 0.63 | 0.004 | 0.01 | 0.31 | 0.03 | 0.04 | 0.022 |

| Backup Ratios | ISO | Finite Element Simulation (Minimum Mesh Size) | |||

|---|---|---|---|---|---|

| 0.2 mm | 0.1 mm | 0.05 mm | 0.025 mm | ||

| 0.3 | 365 | 562 | 683 | 698 | 708 |

| 0.5 | 381 | 428 | 449 | 458 | |

| 1 | 328 | 395 | 415 | 429 | |

| Buck | 356 | 388 | 413 | 430 | |

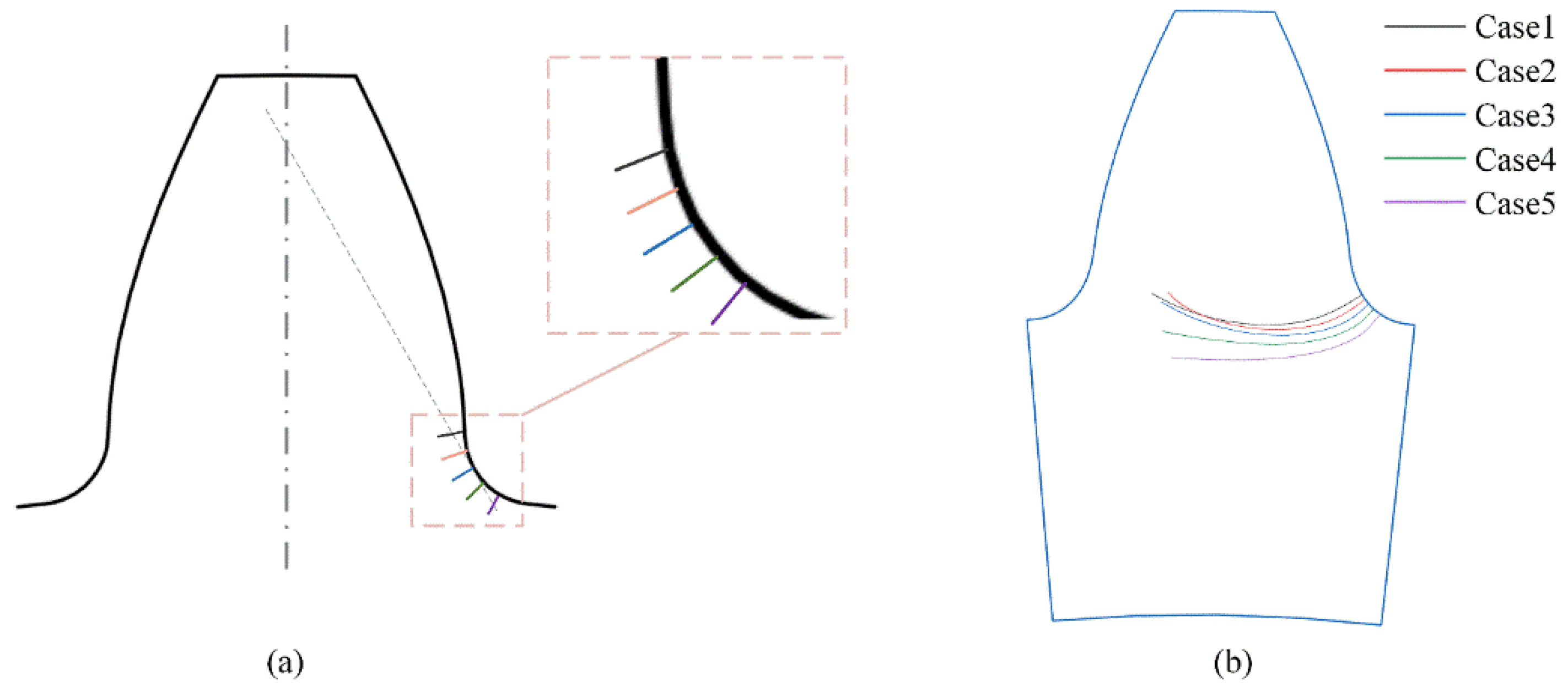

| Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | |

|---|---|---|---|---|---|

| Radius of crack initiation position (mm) | 44.80 | 44.70 | 44.60 | 44.50 | 44.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, H.; Mura, A.; Zhang, T.; Liu, H.; Xu, W. Investigation of Crack Propagation Behaviour in Thin-Rim Gears: Experimental Tests and Numerical Simulations. Materials 2023, 16, 4095. https://doi.org/10.3390/ma16114095

He H, Mura A, Zhang T, Liu H, Xu W. Investigation of Crack Propagation Behaviour in Thin-Rim Gears: Experimental Tests and Numerical Simulations. Materials. 2023; 16(11):4095. https://doi.org/10.3390/ma16114095

Chicago/Turabian StyleHe, Haifeng, Andrea Mura, Taihua Zhang, Heli Liu, and Weiping Xu. 2023. "Investigation of Crack Propagation Behaviour in Thin-Rim Gears: Experimental Tests and Numerical Simulations" Materials 16, no. 11: 4095. https://doi.org/10.3390/ma16114095

APA StyleHe, H., Mura, A., Zhang, T., Liu, H., & Xu, W. (2023). Investigation of Crack Propagation Behaviour in Thin-Rim Gears: Experimental Tests and Numerical Simulations. Materials, 16(11), 4095. https://doi.org/10.3390/ma16114095