Failure Mechanism Research on Bending Fretting Fatigue of 6061-T6 Aluminum Alloy by Experiment and Finite Element Method

Abstract

:1. Introduction

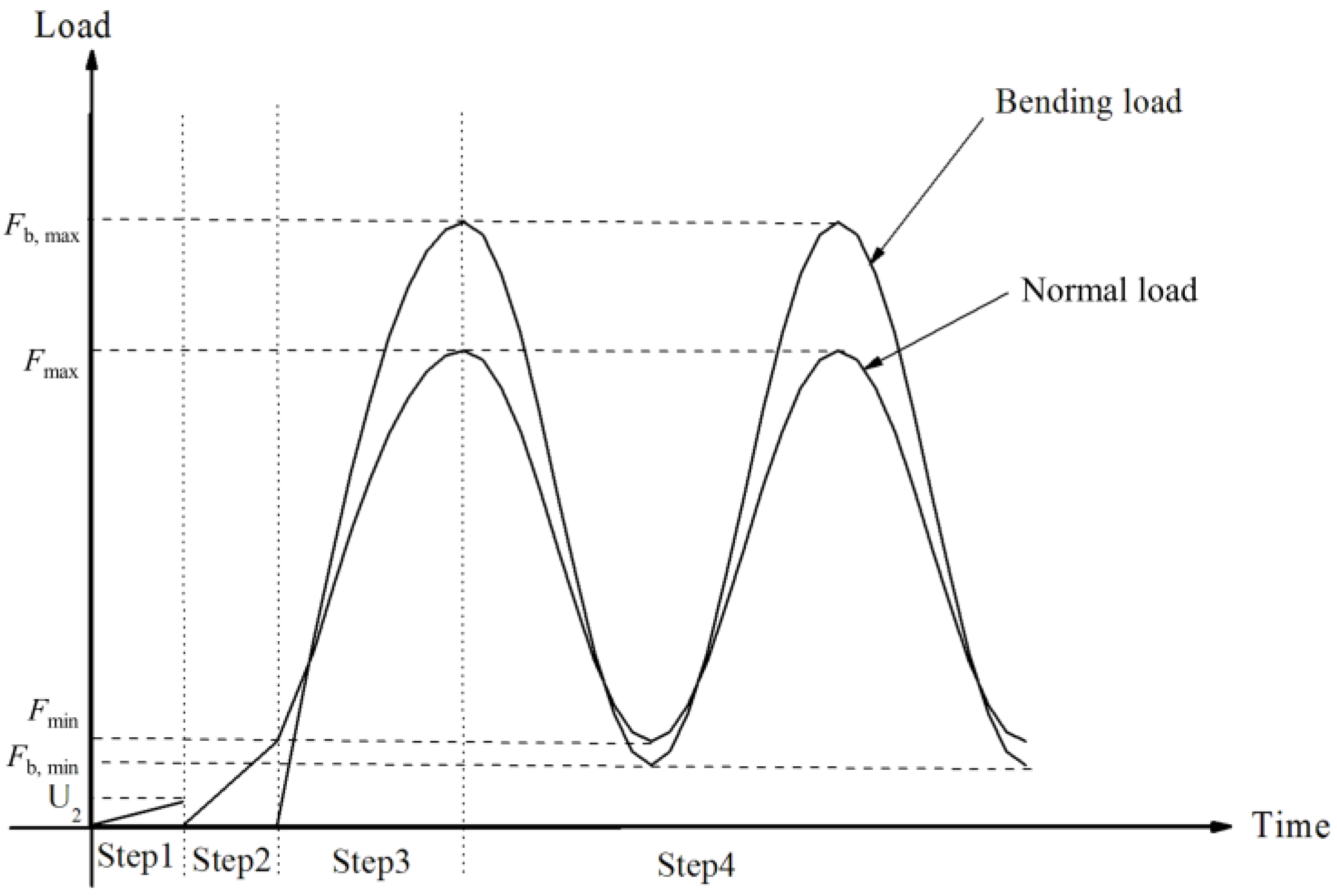

2. Bending Fretting Experiment

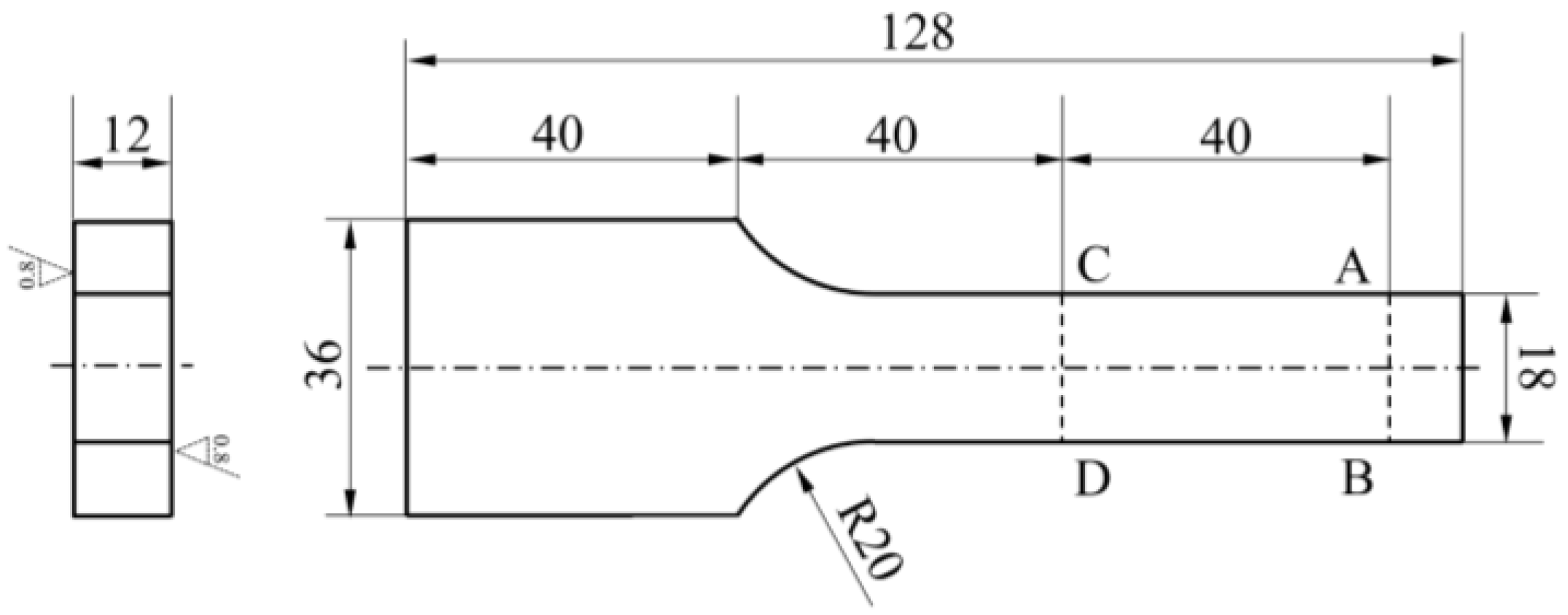

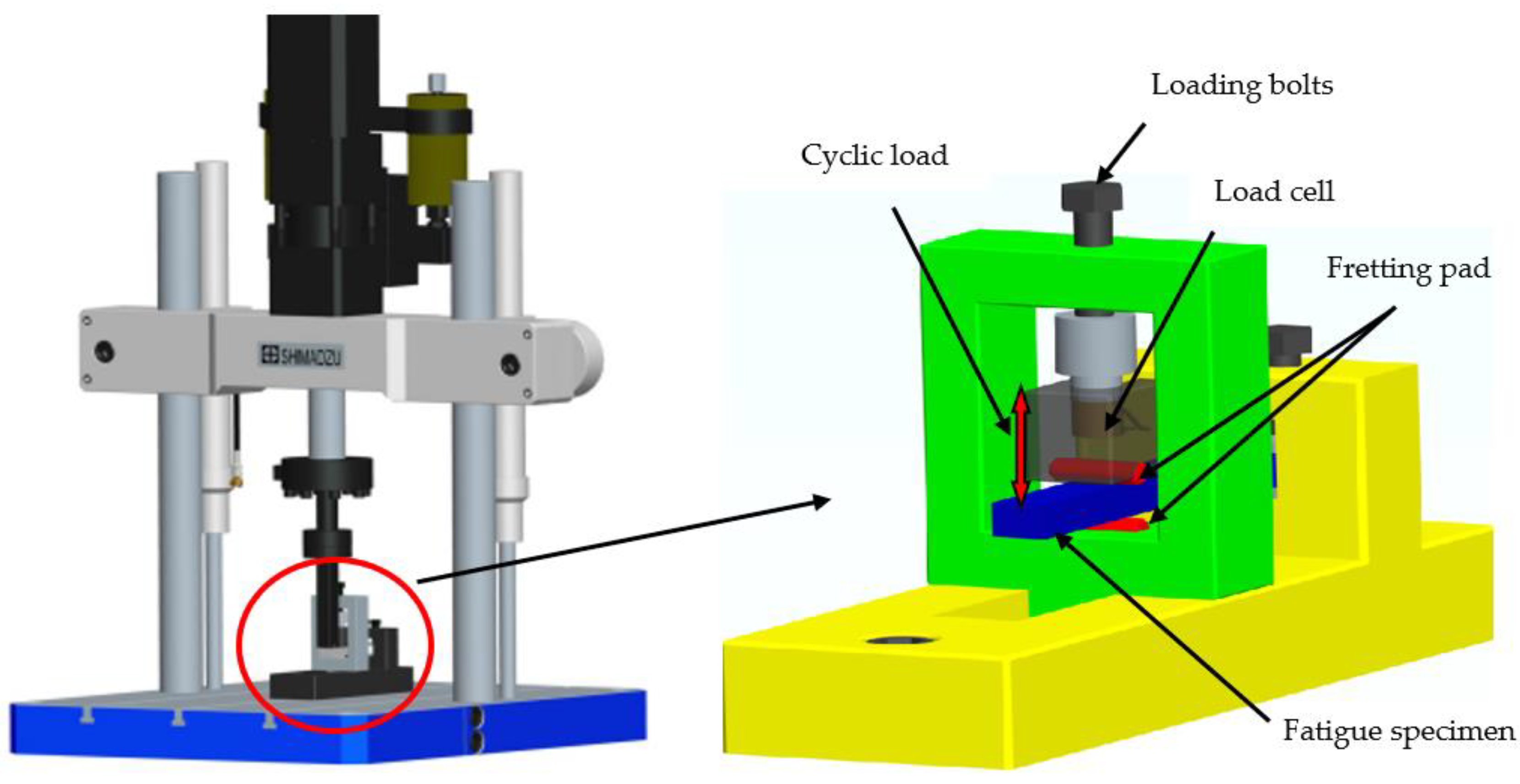

2.1. Materials and Test Method

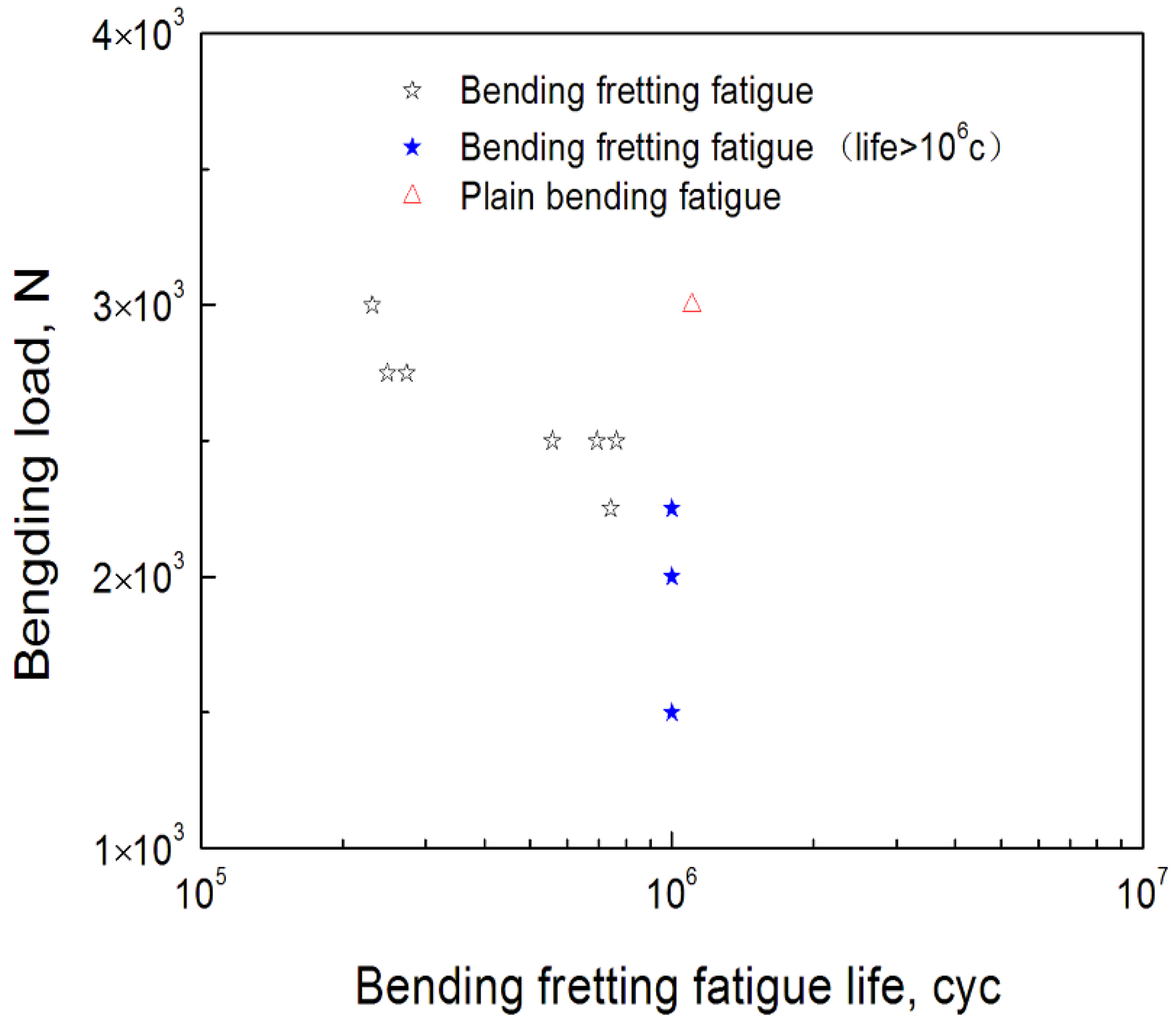

2.2. Relation of Cyclic Load and Fatigue Lives

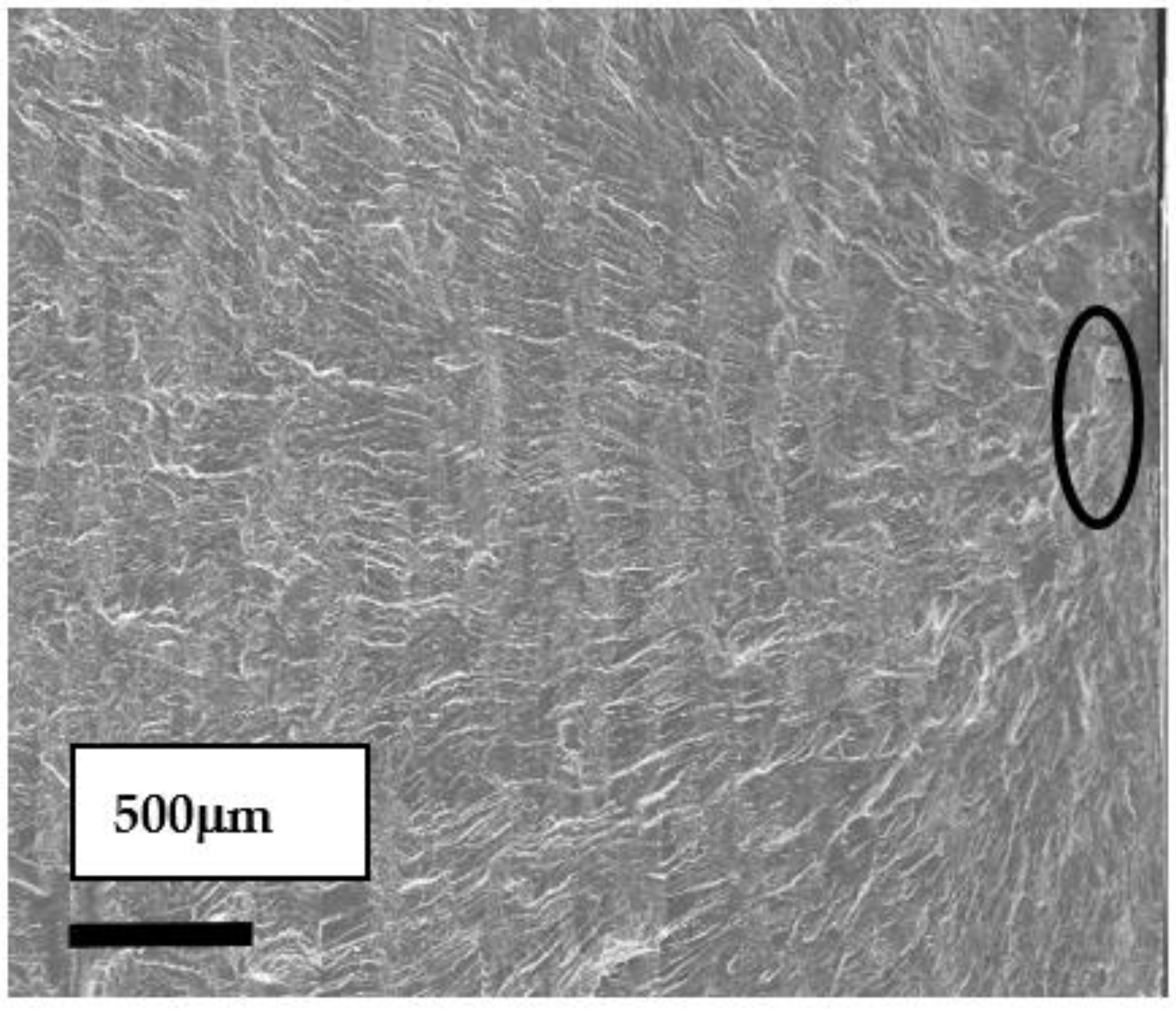

2.3. Fracture Analysis of Bending Fretting Fatigue

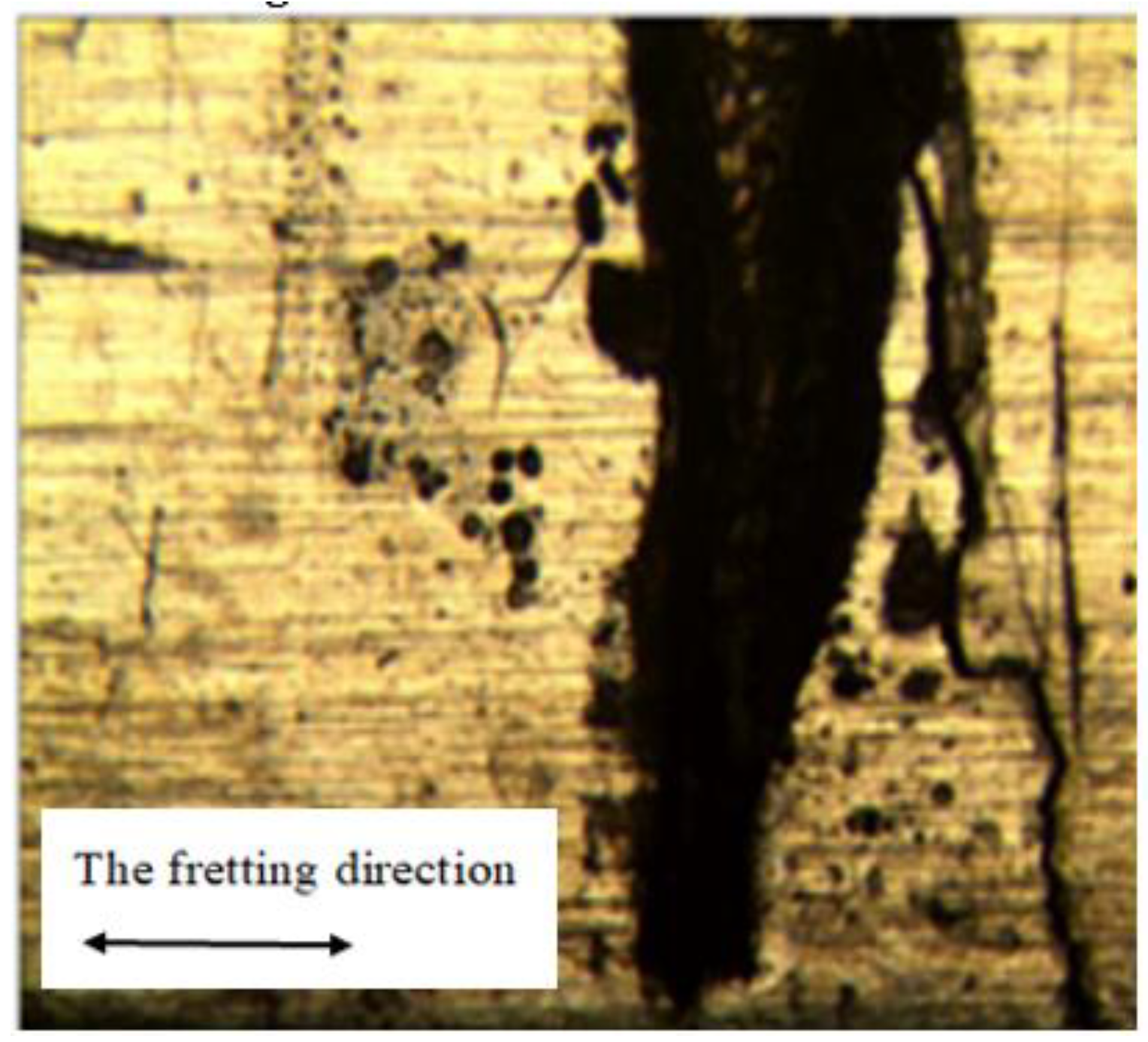

2.4. Evolution of Fretting Damage under Different Cycles

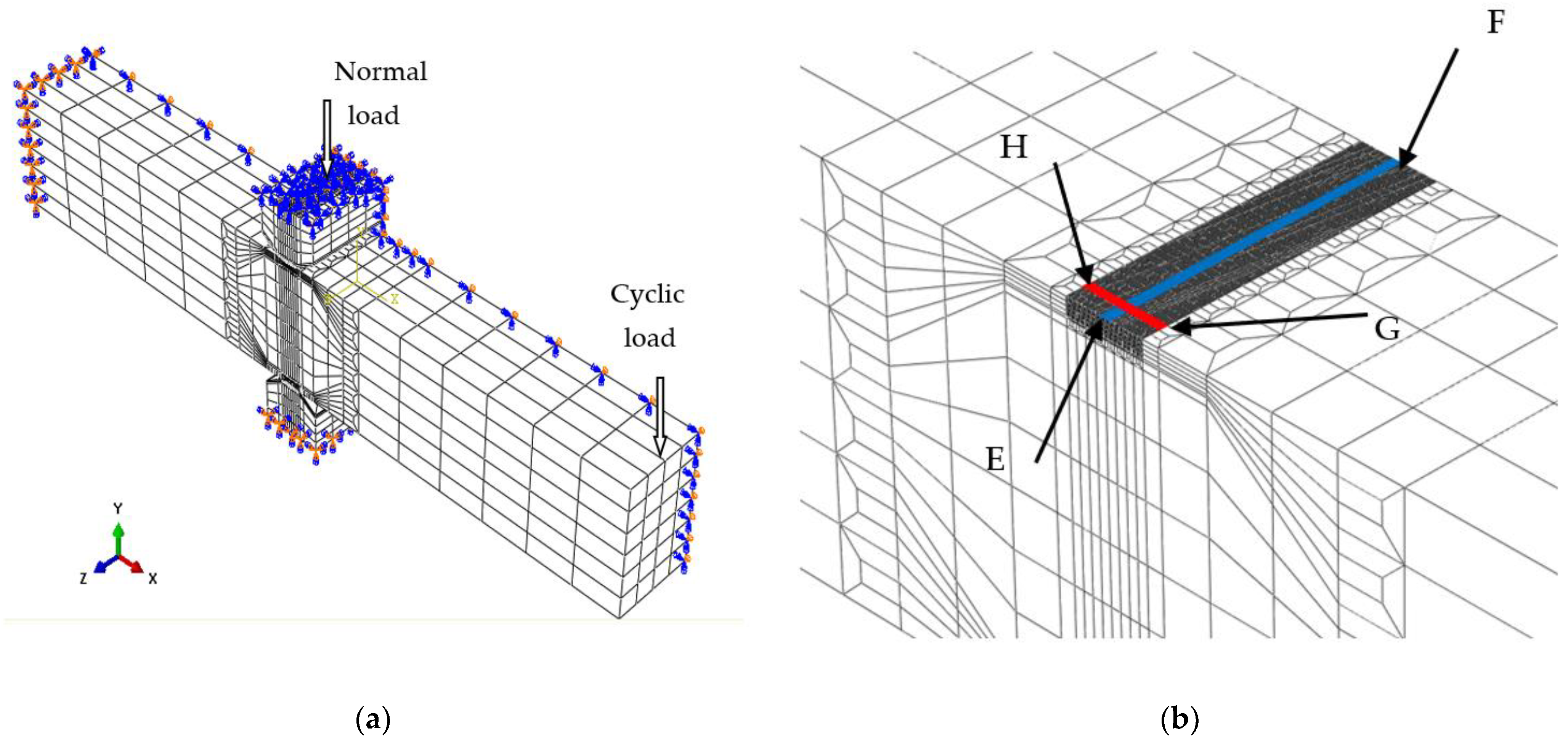

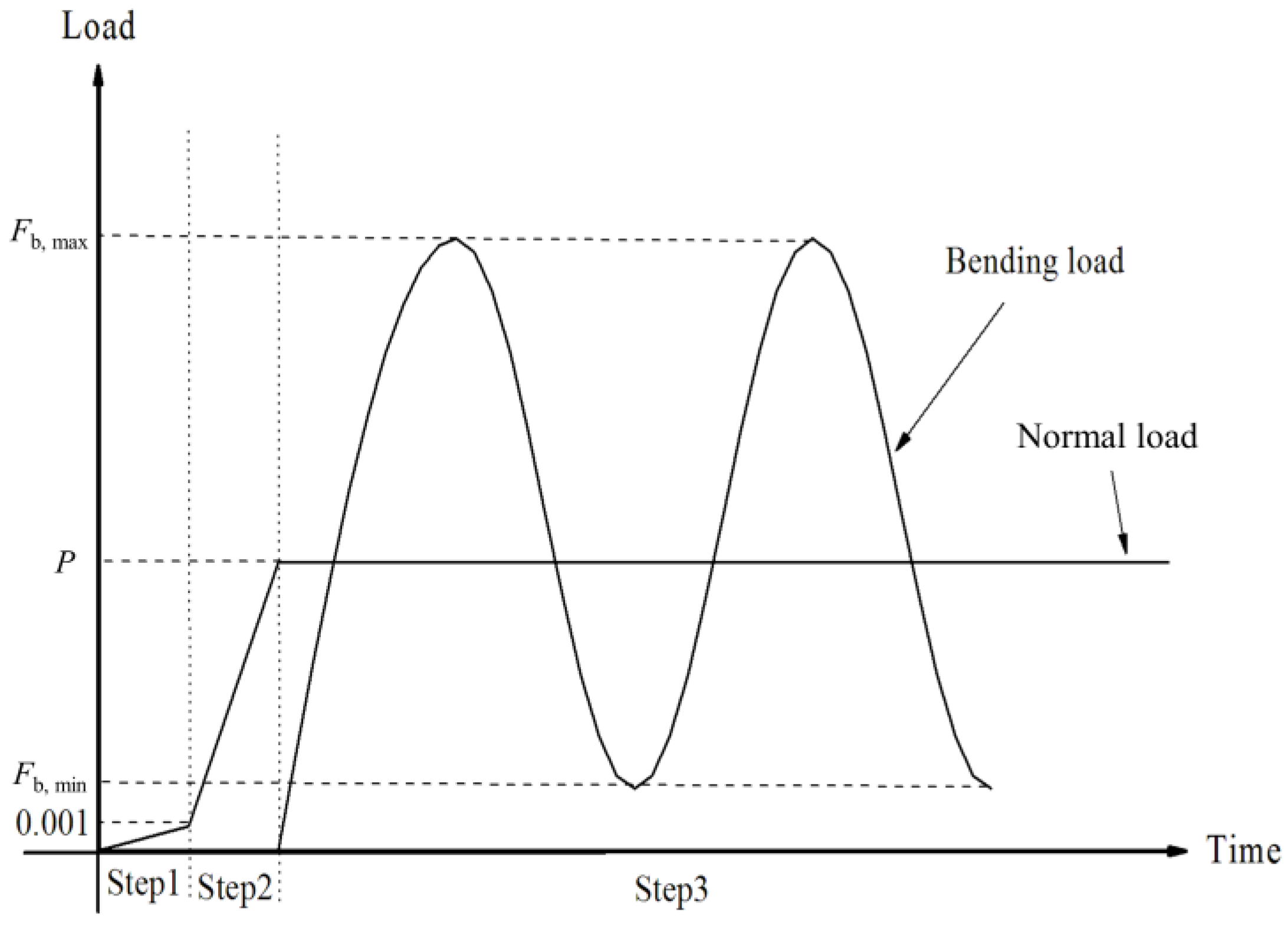

3. Finite Element Simulation

3.1. Cyclic Constitutive Equation

3.1.1. Main Equations

3.1.2. Nonlinear Kinematic Hardening Evolution

3.1.3. Isotropic Hardening Evolution

3.2. Verification of the Suggested Cyclic Constitutive Equation

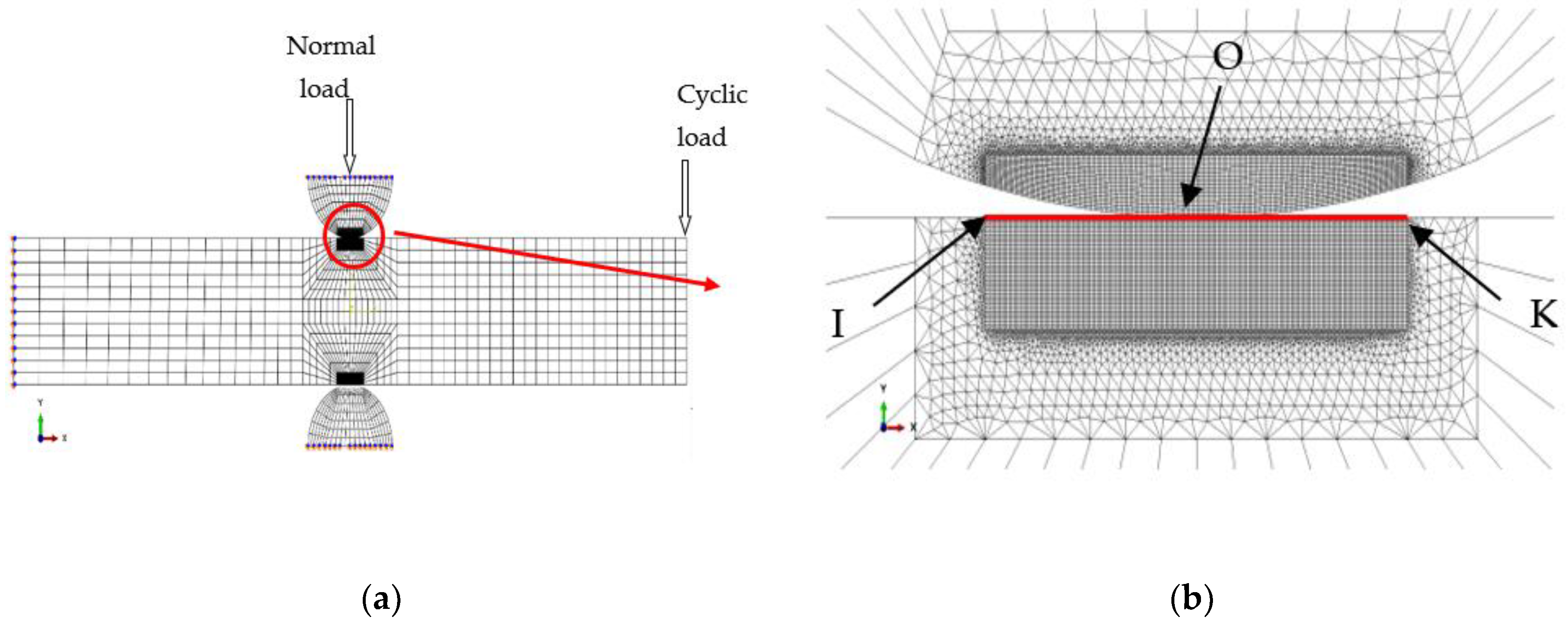

3.3. Two-Dimensional Finite Element Model

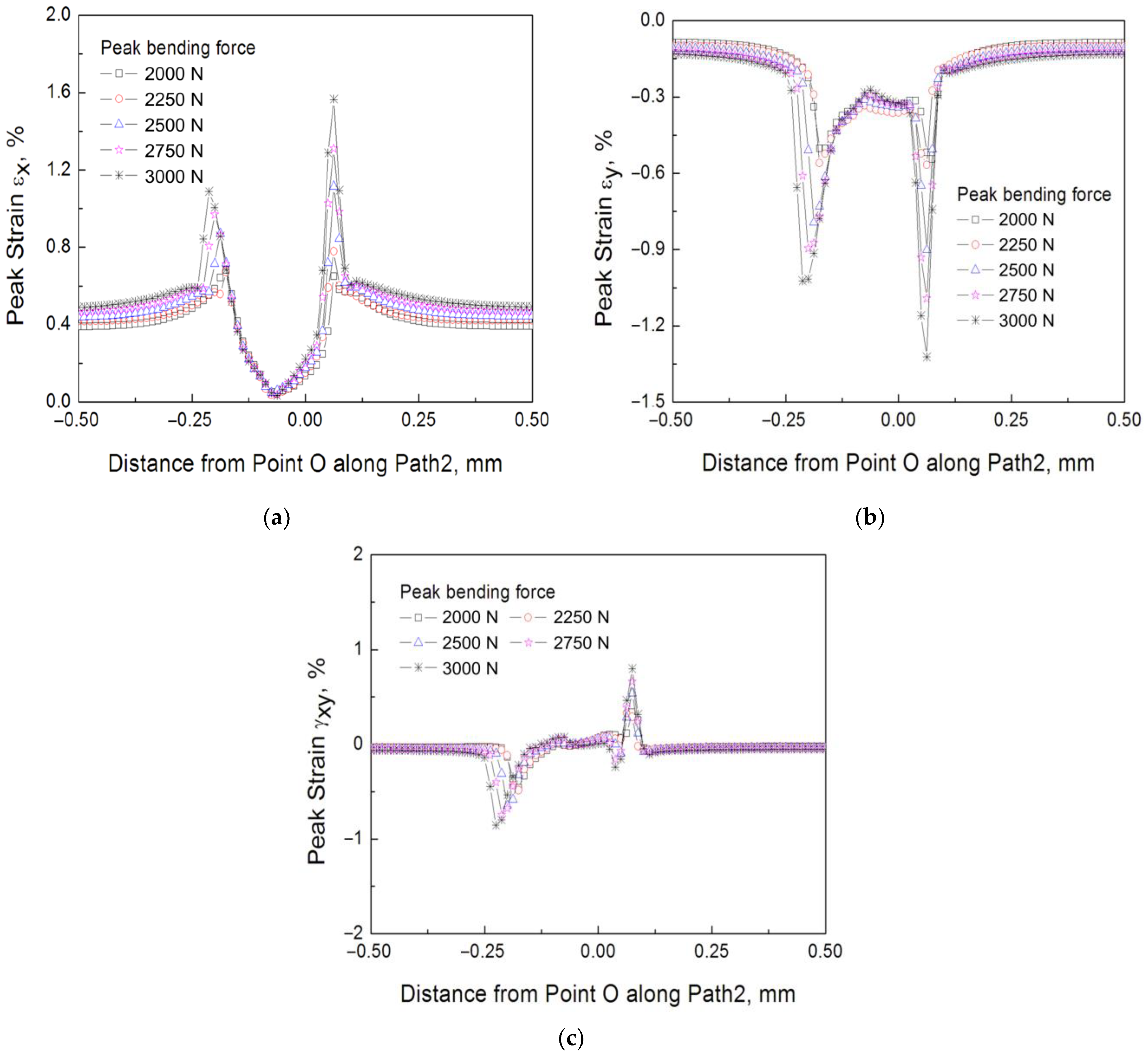

3.4. Simulation Results

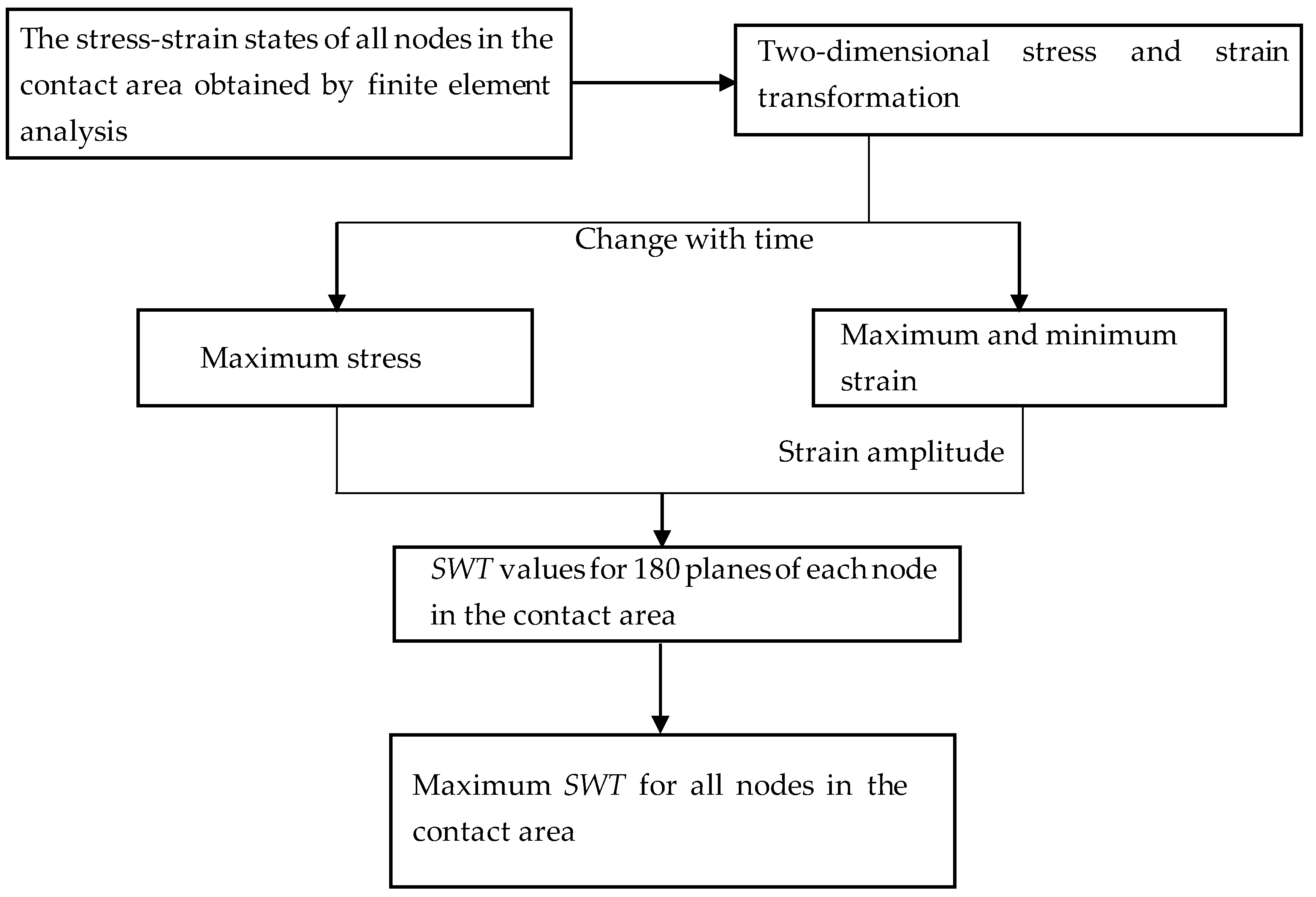

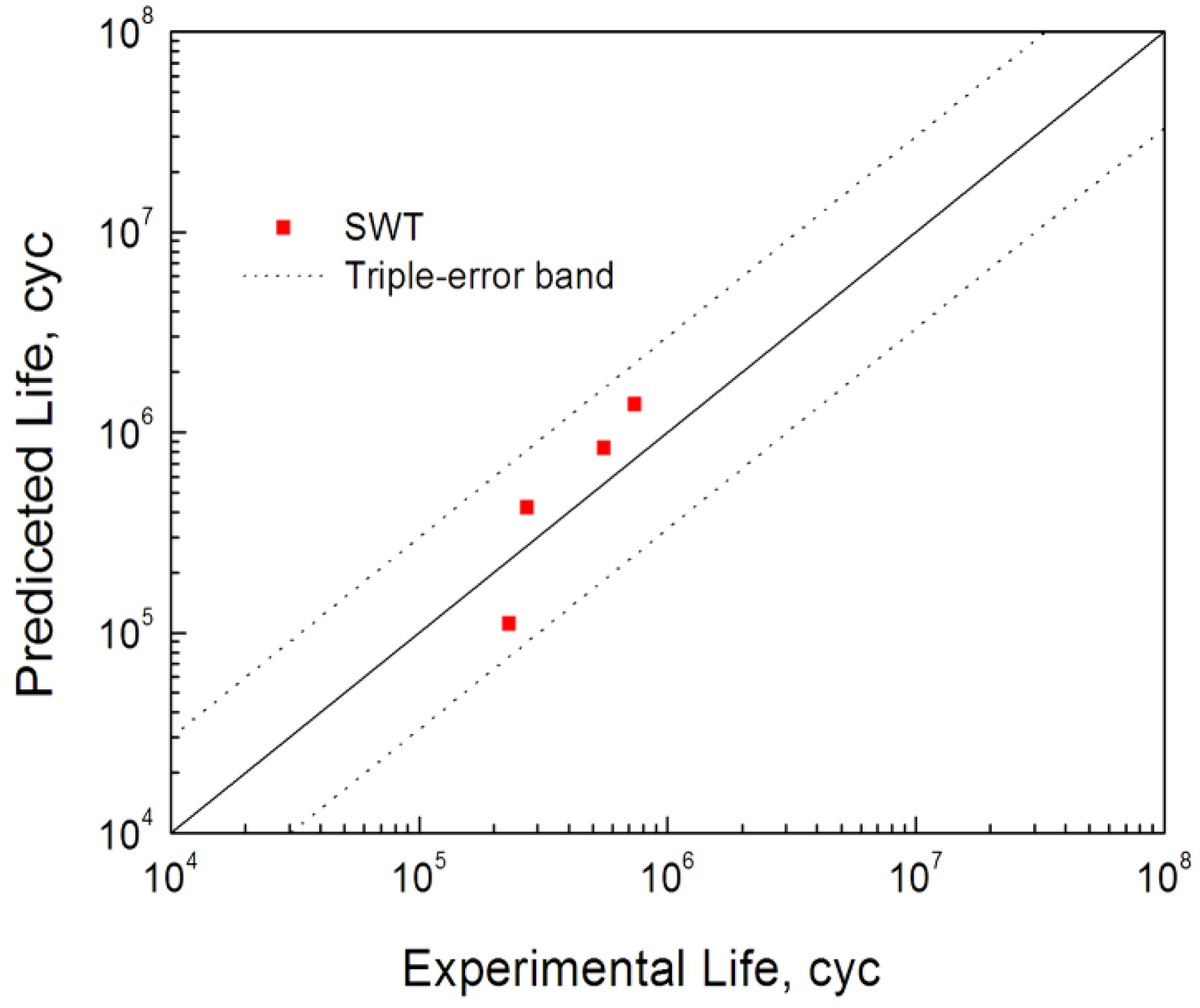

4. Prediction of Fatigue Life

5. Conclusions

- (1)

- The fatigue life of plain bending with zero normal load is clearly higher than that of bending fretting under the same cyclic bending load.

- (2)

- The bending fretting fatigue lifespan of 6061-T6 aluminum alloy decreases significantly with the increase in peak bending force under the same normal load. So, the bending load is an important factor that cannot be ignored in analyzing bending fretting fatigue failure.

- (3)

- Based on the calculated finite element results, the bending fretting fatigue lives and crack initiation positions can be assessed reasonably using the SWT critical plane approach referring to a critical averaging dimension method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| σ0.2 | yield stress |

| HV | hardness |

| total strain tensor | |

| elastic strain tensor | |

| stress tensor | |

| plastic strain rate tensor | |

| back stress tensor | |

| isotropic deformation resistance | |

| back stress component | |

| , | ratchetting parameter |

| accumulated inelastic strain | |

| critical surface | |

| v | Poisson’s ratio |

| equivalent normal force per unit length applied in the 2-D finite element model | |

| fatigue life | |

| strain range | |

| fatigue ductility exponent | |

| fatigue ductility coefficient | |

| lc | the length of cubic grain |

| σb | strength limit |

| elastic modulus | |

| plastic strain tensor | |

| Hooke’s elasticity tensor | |

| (:) | inner product of tensors |

| deviatoric stress tensor | |

| yield function | |

| , | material constants for kinematic hardening |

| direction tensor of i-th back stress | |

| Heaviside function | |

| resistance of saturated isotropic deformation | |

| material parameter that controls evolution rate | |

| εx, εy, γxy | peak strain components |

| maximum normal stress | |

| fatigue strength exponent | |

| fatigue strength coefficient | |

| Vc | critical volume |

References

- Nowell, D.; Dini, D.; Hills, D.A. Recent developments in the understanding of fretting fatigue. Eng. Fract. Mech. 2006, 73, 207–222. [Google Scholar] [CrossRef] [Green Version]

- Yang, M.S.; Chen, Y.L.; Yu, D.Z.; Hu, J.L. Several key problems in studying on fretting fatigue. Struct. Environ. Eng. 2008, 35, 45–54. (In Chinese) [Google Scholar]

- Wang, J.C.; Gao, Y.K. Numerical and experimental investigations on fretting fatigue properties of GH4169 superalloy at the elevated temperature. Int. J. Fatigue 2021, 149, 106274. [Google Scholar] [CrossRef]

- Abbasi, F.; Majzoobi, G.H. An investigation into the effect of elevated temperatures on fretting fatigue response under cyclic normal contact loading. Theor. Appl. Fract. Mech. 2018, 93, 144–154. [Google Scholar] [CrossRef]

- Cwiekala, N.; Hills, D.A. Asymptotic description of fretting wear and fretting fatigue for incomplete contacts. Eng. Fract. Mech. 2021, 256, 107986. [Google Scholar] [CrossRef]

- Winkler, J.; Georgakis, C.T.; Fischer, G. Fretting fatigue behavior of high-strength steel monostrands under bending load. Int. J. Fatigue 2015, 70, 13–23. [Google Scholar] [CrossRef]

- Bhatti, N.A.; Abdel Wahab, M. Fretting fatigue crack nucleation: A review. Tribol. Int. 2018, 121, 121–138. [Google Scholar] [CrossRef]

- Shen, M.X.; Peng, J.F.; Zheng, J.F.; Song, C.; Mo, J.L.; Zhu, M.H. Study and development of fretting fatigue. Mater. Eng. 2010, 55, 86–91. (In Chinese) [Google Scholar]

- Xu, Z.B.; Peng, J.F.; Liu, J.H.; Liu, X.Y.; Zhang, W.L.; Zhu, M.H. Study on tribo-chemical and fatigue behavior of 316L austenitic stainless steel in torsional fretting fatigue. J. Eng. Tribol. 2020, 234, 84–93. [Google Scholar] [CrossRef]

- Peng, J.F.; Wang, B.T.; Jin, X.; Xu, Z.B.; Liu, J.H.; Cai, Z.B.; Luo, Z.P.; Zhu, M.H. Effect of contact pressure on torsional fretting fatigue damage evolution of a 7075 aluminum alloy. Tribol. Int. 2019, 137, 1–10. [Google Scholar] [CrossRef]

- Peng, J.F.; Zhu, M.H.; Cai, Z.B.; Liu, J.H.; Zuo, K.C.; Song, C.; Wang, W.J. On the damage mechanisms of bending fretting fatigue. Tribol. Int. 2014, 76, 133–141. [Google Scholar] [CrossRef]

- Chowdhury, M.A.; Kowser, M.A.; Zobaer Shah, Q.M.; Das, S. Characteristics and damage mechanisms of bending fretting fatigue of materials. Int. J. Damage Mech. 2018, 27, 453–487. [Google Scholar] [CrossRef]

- Ebaraa, R.; Fujimurab, M. Fretting fatigue behaviour of Ti–6Al–4V alloy under plane bending stress and contact stress. Tribol. Int. 2006, 39, 1181–1186. [Google Scholar] [CrossRef]

- Kubotaa, M.; Noyamab, N.; Sakaea, C.; Kondoa, Y. Fretting fatigue in hydrogen gas. Tribol. Int. 2006, 39, 1241–1247. [Google Scholar] [CrossRef]

- Peng, J.F.; Song, C.; Shen, M.X.; Zheng, J.F.; Zhou, Z.R.; Zhu, M.H. An experimental study on bending fretting fatigue characteristics of 316L austenitic stainless steel. Tribol. Int. 2011, 44, 1417–1426. [Google Scholar] [CrossRef]

- Peng, J.F.; Liu, J.H.; Cai, Z.B.; Shen, M.X.; Song, C.; Zhu, M.H. Study on bending fretting fatigue damages of 7075 aluminum alloy. Tribol. Int. 2013, 59, 38–46. [Google Scholar] [CrossRef]

- Tian, L.; Chen, H.; Peng, J.F.; Cao, F.; Liu, J.H.; Song, C.; Zhu, M.H. Bending Fretting Fatigue Characteristics of 40CrNi2MoA Alloy Steel. Lubr. Eng. 2014, 39, 14–18. (In Chinese) [Google Scholar]

- Liu, D.W.; Peng, J.F.; Tian, L.; Song, C.; Liu, J.H.; Zhu, M.H. Bending fretting fatigue characteristics of 30CrNiMo alloy steel. Mater. Mech. Eng. 2014, 38, 48–52. (In Chinese) [Google Scholar]

- Jiang, C.S. A study on numerical simulation of bending fretting fatigue of 316L stainless steel. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2012. (In Chinese). [Google Scholar]

- Zhu, Y.L.; Kang, G.Z.; Ding, J.; Zhu, M.H. Study on bending fretting fatigue of LZ50 axle steel considering ratchetting by finite element method. Fatigue Fract. Eng. M. 2012, 36, 127–138. [Google Scholar] [CrossRef]

- Abdel-Karim, M.; Ohno, N. Kinematic hardening model suitable for ratchetting with steady-state. Int. J. Plast. 2000, 16, 225–240. [Google Scholar] [CrossRef]

- Ding, J.; Kang, G.Z.; Kan, Q.H.; Liu, Y.J. Constitutive model for uniaxial time-dependent ratcheting of 6061-T6 aluminum alloy. Comput. Mater. Sci. 2012, 57, 67–72. [Google Scholar] [CrossRef]

- Kobayashi, M.; Ohno, N. Implementation of cyclic plasticity models based on a general form of kinematic hardening. Int. J. Numer. Methods Eng. 2002, 53, 2217–2238. [Google Scholar] [CrossRef]

- Li, Z. Experimental and failure model study of low cycle fatigue considering ratchetting effect. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2007. (In Chinese). [Google Scholar]

- Araujo, J.A.; Nowell, D. The effect of rapidly varying contact stress fields on fretting fatigue. Int. J. Fatigue 2002, 24, 63–775. [Google Scholar] [CrossRef]

| Materials | Yield Stress σ0.2 (MPa) | Strength Limit σb (MPa) | Hardness HV | Elastic Modulus E (GPa) |

|---|---|---|---|---|

| 6061-T6 aluminum alloy | 295 | 324 | 95 | 76 |

| 52100 bearing steel | 1700 | 2000 | 890 | 210 |

| M = 8, μ = 0.01, γ = 4.0; E = 76 GPa, Q0 = 315.8 MPa, Qsa = 310.8 MPa, v = 0.33, ζ(1) = 10,000, ζ(2) = 2083, ζ(3) = 649, ζ(4) = 359.7, ζ(5) = 207, ζ(6) = 101, ζ(7) = 50.8, ζ(8) = 25; r(1) = 2.51, r(2) = 25.8, r(3) = 4.39, r(4) = 2.3, r(5) = 1.68, r(6) = 3.94, r(7) = 3.92, r(8) = 22.66 MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, J.; Yang, L.; Liu, W. Failure Mechanism Research on Bending Fretting Fatigue of 6061-T6 Aluminum Alloy by Experiment and Finite Element Method. Materials 2023, 16, 4161. https://doi.org/10.3390/ma16114161

Ding J, Yang L, Liu W. Failure Mechanism Research on Bending Fretting Fatigue of 6061-T6 Aluminum Alloy by Experiment and Finite Element Method. Materials. 2023; 16(11):4161. https://doi.org/10.3390/ma16114161

Chicago/Turabian StyleDing, Jun, Long Yang, and Wei Liu. 2023. "Failure Mechanism Research on Bending Fretting Fatigue of 6061-T6 Aluminum Alloy by Experiment and Finite Element Method" Materials 16, no. 11: 4161. https://doi.org/10.3390/ma16114161

APA StyleDing, J., Yang, L., & Liu, W. (2023). Failure Mechanism Research on Bending Fretting Fatigue of 6061-T6 Aluminum Alloy by Experiment and Finite Element Method. Materials, 16(11), 4161. https://doi.org/10.3390/ma16114161