Approaching Self-Bonded Medium Density Fiberboards Made by Mixing Steam Exploded Arundo donax L. and Wood Fibers: A Comparison with pMDI-Bonded Fiberboards on the Primary Properties of the Boards

Abstract

1. Introduction

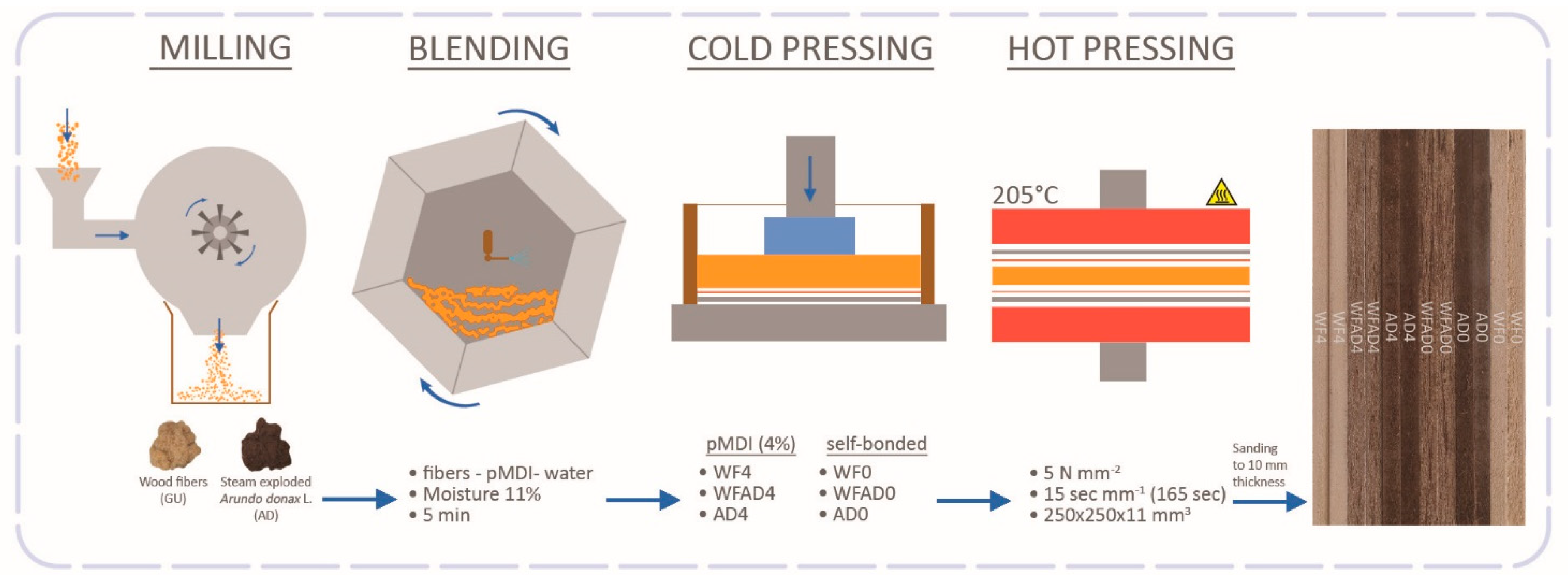

2. Materials and Methods

2.1. Preparation of the Materials

2.2. Medium Density Fiberboards Manufacturing

2.3. Physico-Mechanical Characterization

2.4. Statistical Analysis

3. Results and Discussion

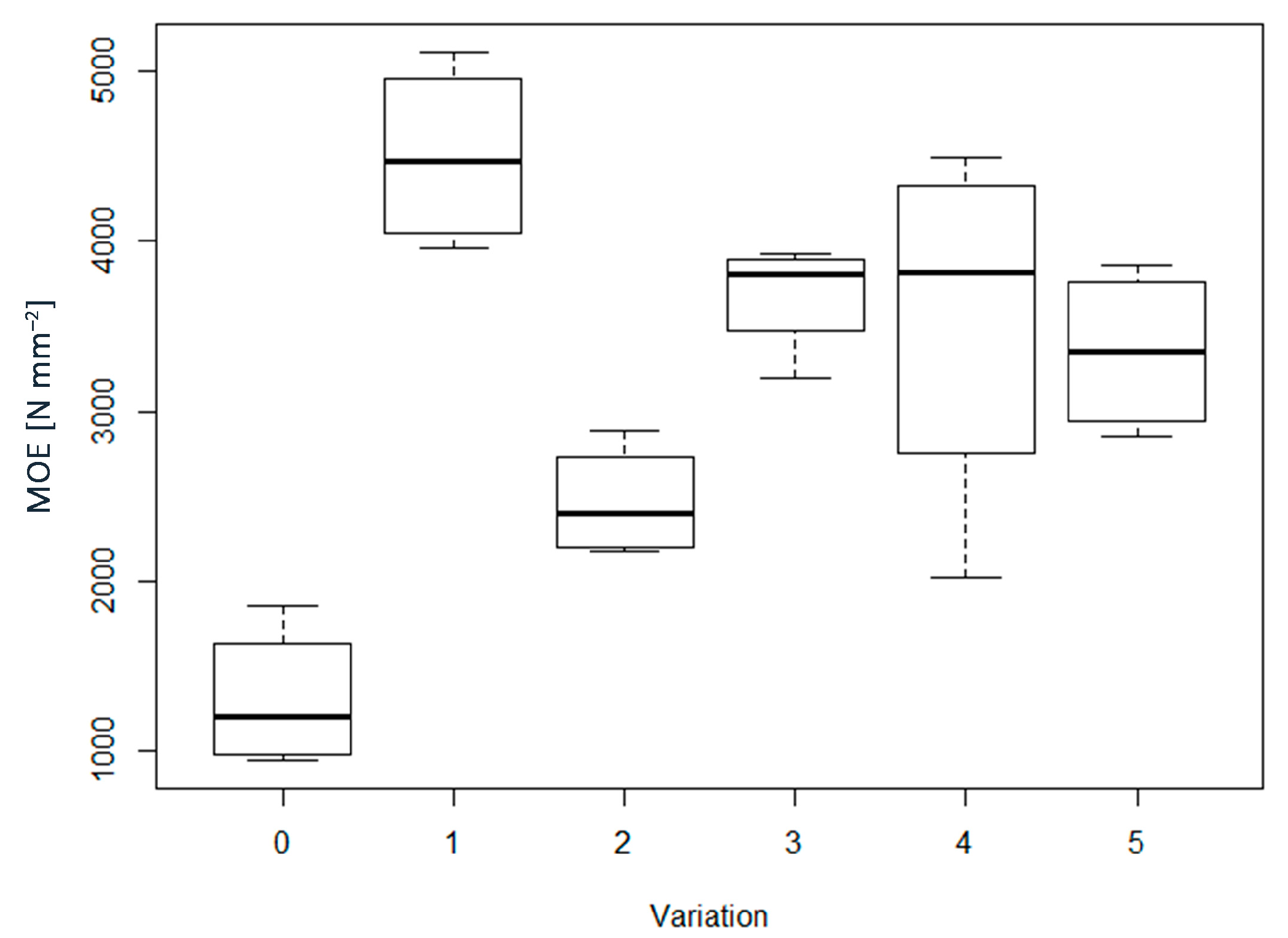

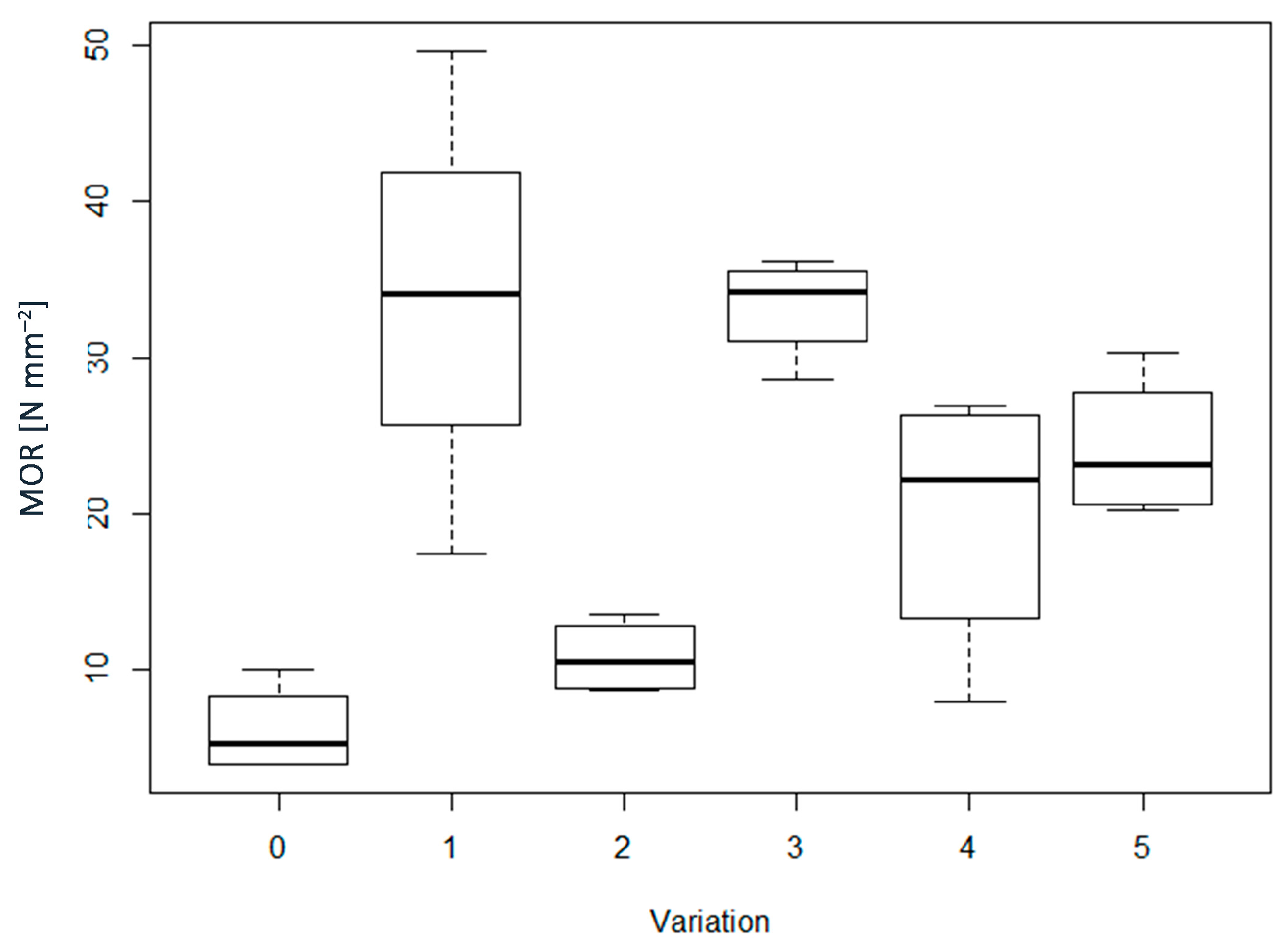

3.1. Density and Mechanical Properties

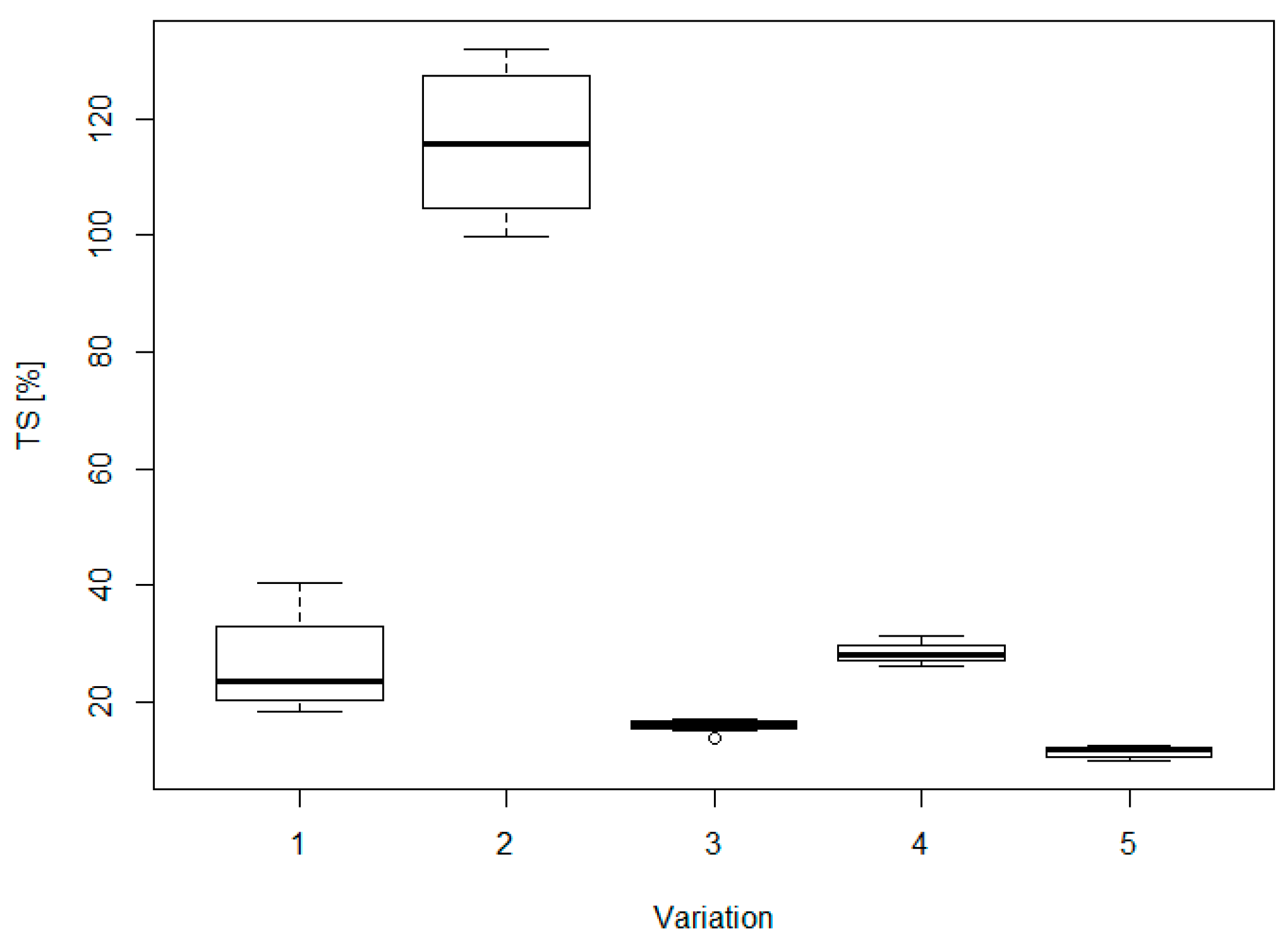

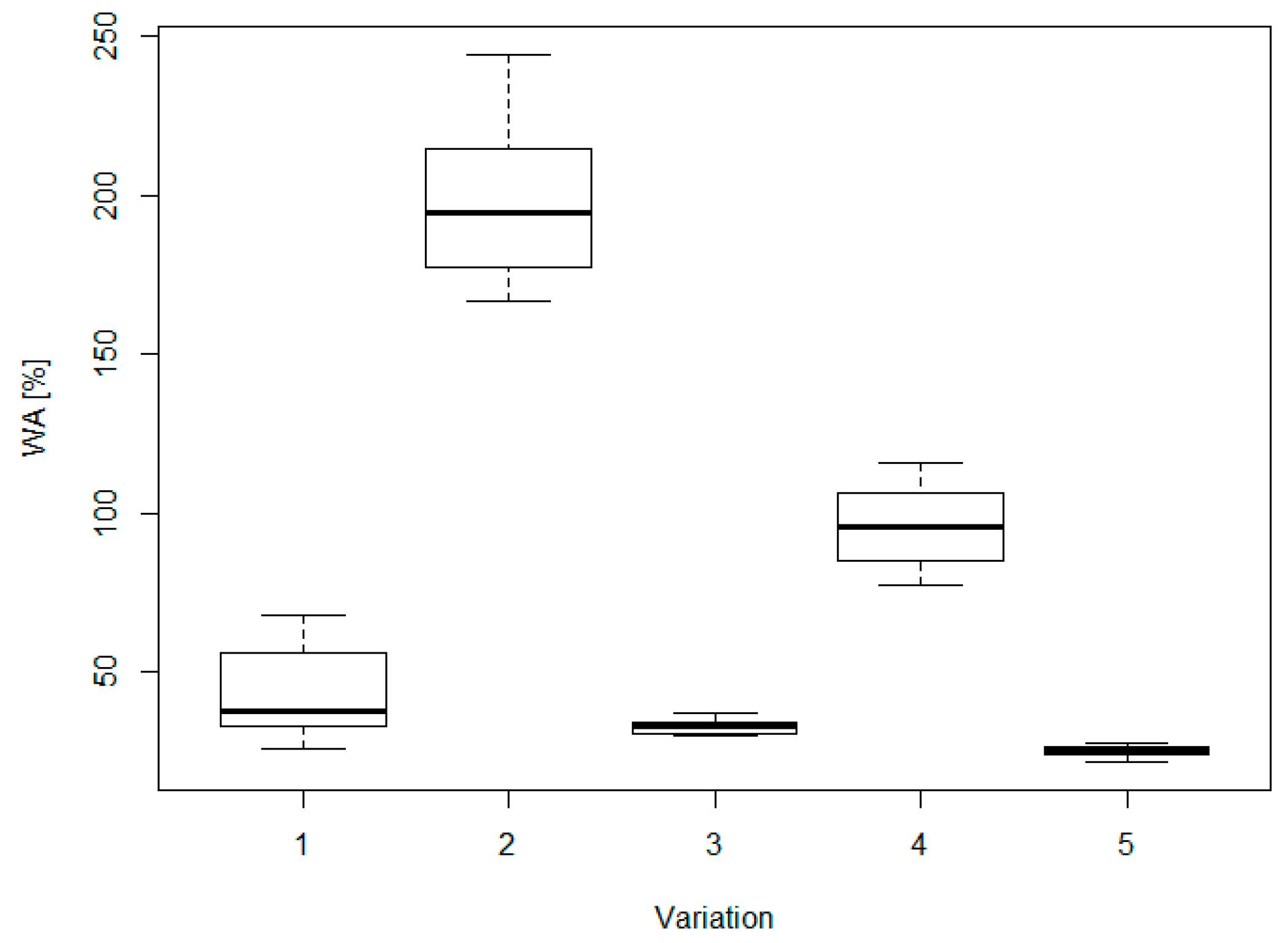

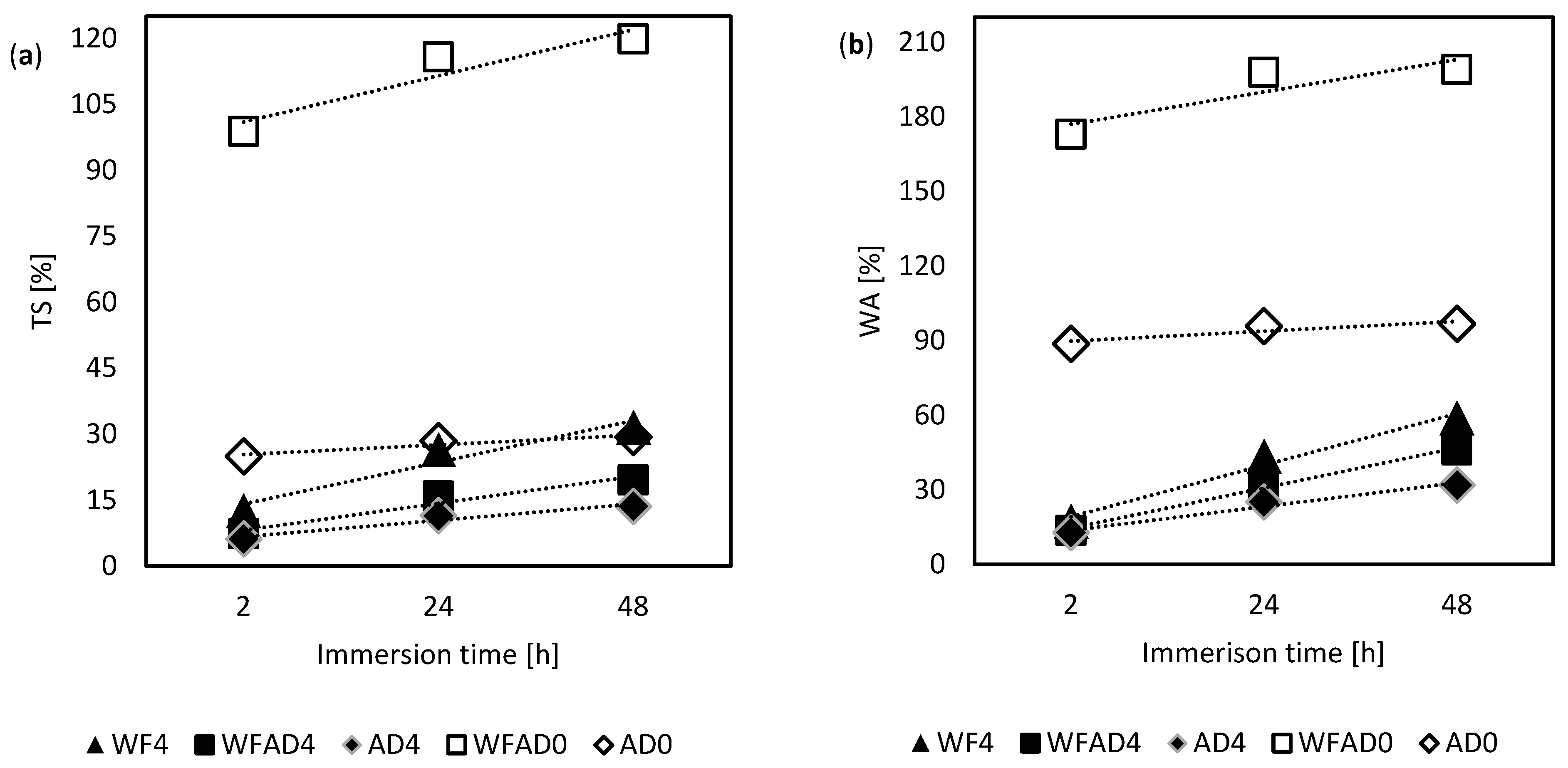

3.2. Dimensional Stability

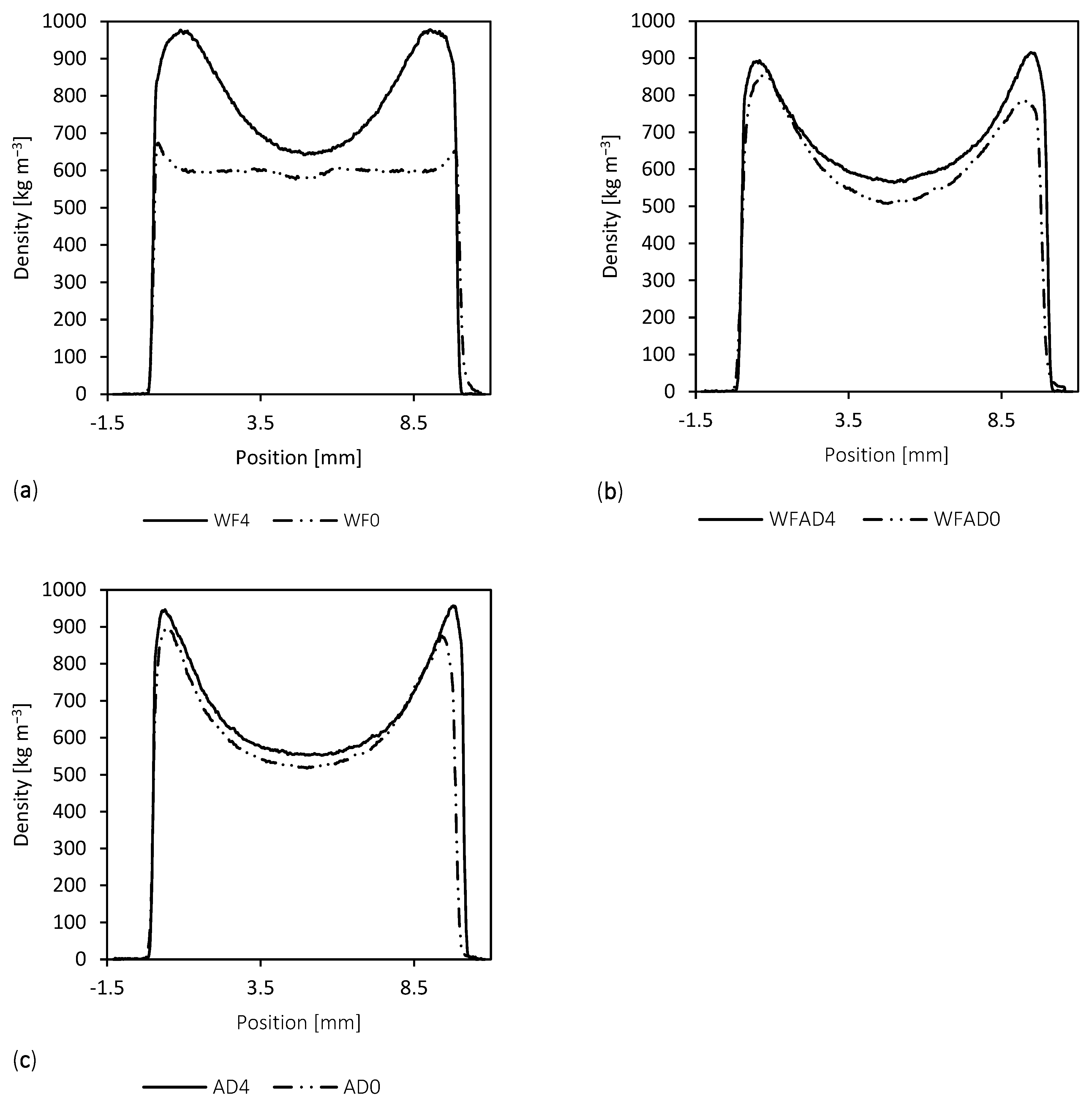

3.3. Vertical Density Profiles

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Balea, G.; Lunguleasa, A.; Zeleniuc, O.; Coşereanu, C. Three Adhesive Recipes Based on Magnesium Lignosulfonate, Used to Manufacture Particleboards with Low Formaldehyde Emissions and Good Mechanical Properties. Forests 2022, 13, 737. [Google Scholar] [CrossRef]

- Commission Regulation (EU) (2014) No 605/2014 of 5 June 2014. Available online: http://data.europa.eu/eli/reg/2014/605/oj (accessed on 7 June 2023).

- Ghani, A.; Ashaari, Z.; Bawon, P.; Lee, S.H. Reducing Formaldehyde Emission of Urea Formaldehyde-Bonded Particleboard by Addition of Amines as Formaldehyde Scavenger. Build. Environ. 2018, 142, 188–194. [Google Scholar] [CrossRef]

- Costa, N.A.; Pereira, J.; Ferra, J.; Cruz, P.; Martins, J.; Magalhães, F.D.; Mendes, A.; Carvalho, L.H. Scavengers for Achieving Zero Formaldehyde Emission of Wood-Based Panels. Wood Sci. Technol. 2013, 47, 1261–1272. [Google Scholar] [CrossRef]

- Marsal, A.; Cuadros, S.; Ollé, L.; Bacardit, A.; Manich, A.M.; Font, J. Formaldehyde Scavengers for Cleaner Production: A Case Study Focused on the Leather Industry. J. Clean. Prod. 2018, 186, 45–56. [Google Scholar] [CrossRef]

- Antov, P.; Savov, V.; Neykov, N. Reduction of Formaldehyde Emission from Engineered Wood Panels by Formaldehyde Scavengers—A Review. In Proceedings of the 13th International Scientific Conference Wood EMA 2020 and 31st International Scientific Conference ICWST, Vinkovci, Croatia, 28–30 September 2020; pp. 289–294. [Google Scholar]

- Gouveia, S.; Otero, L.A.; Fernández-Costas, C.; Filgueira, D.; Sanromán, Á.; Moldes, D. Green Binder Based on Enzymatically Polymerized Eucalypt Kraft Lignin for Fiberboard Manufacturing: A Preliminary Study. Polymers 2018, 10, 642. [Google Scholar] [CrossRef]

- Chen, H.; Yan, N. Application of Western Red Cedar (Thuja Plicata) Tree Bark as a Functional Filler in PMDI Wood Adhesives. Ind. Crops Prod. 2018, 113, 1–9. [Google Scholar] [CrossRef]

- Solt, P.; Konnerth, J.; Gindl-Altmutter, W.; Kantner, W.; Moser, J.; Mitter, R.; van Herwijnen, H.W.G. Technological Performance of Formaldehyde-Free Adhesive Alternatives for Particleboard Industry. Int. J. Adhes. Adhes. 2019, 94, 99–131. [Google Scholar] [CrossRef]

- Hemmilä, V.; Adamopoulos, S.; Hosseinpourpia, R.; Ahmed, S.A. Ammonium Lignosulfonate Adhesives for Particleboards with PMDI and Furfuryl Alcohol as Crosslinkers. Polymers 2019, 11, 1633. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, G.; Pizzi, A.; Lei, H.; Xi, X.; Du, G. A Green Resin Wood Adhesive from Synthetic Polyamide Crosslinking with Glyoxal. Polymers 2022, 14, 2819. [Google Scholar] [CrossRef]

- Ballerini, A.; Despres, A.; Pizzi, A. Non-Toxic, Zero Emission Tannin-Glyoxal Adhesives for Wood Panels. Holz Roh Werkst. 2005, 63, 477–478. [Google Scholar] [CrossRef]

- Kordkheili, H.Y.; Pizzi, A. Improving Properties of Phenol- Lignin- Glyoxal Resin as a Wood Adhesive by an Epoxy Resin. Eur. J. Wood Wood Prod. 2021, 79, 199–205. [Google Scholar] [CrossRef]

- Kan, Y.; Sun, B.; Kan, H.; Bai, Y.; Gao, Z. Preparation and Characterization of a Melamine-Urea-Glyoxal Resin and Its Modified Soybean Adhesive. Int. J. Adhes. Adhes. 2021, 111, 102986. [Google Scholar] [CrossRef]

- Li, X.; Cai, Z.; Winandy, J.E.; Basta, A.H. Selected Properties of Particleboard Panels Manufactured from Rice Straws of Different Geometries. Bioresour. Technol. 2010, 101, 4662–4666. [Google Scholar] [CrossRef]

- Pędzik, M.; Janiszewska, D.; Rogoziński, R. Alternative Lignocellulosic Raw Materials in Particleboard Production: A Review. Ind. Crops Prod. 2021, 174, 114162. [Google Scholar] [CrossRef]

- Das, S.; Malmberg, M.J.; Frazier, C.E. Cure Chemistry of Wood/Polymeric Isocyanate (PMDI) Bonds: Effect of Wood Species. Int. J. Adhes. Adhes. 2007, 27, 250–257. [Google Scholar] [CrossRef]

- Luo, P.; Yang, C.; Li, M.; Wang, Y. Manufacture of Thin Rice Straw Particleboards Bonded with Various Polymeric Methane Diphenyl Diisocyanate/Urea Fromaldehyde Resin Mixtures. Bioresources 2020, 15, 935–944. [Google Scholar] [CrossRef]

- Tupciauskas, R.; Rizhikovs, J.; Brazdausks, P.; Fridrihsone, V.; Andzs, M. Influence of Steam Explosion Pre-Treatment Conditions on Binder-Less Boards from Hemp Shives and Wheat Straw. Ind. Crops Prod. 2021, 170, 113717. [Google Scholar] [CrossRef]

- Asafu-Adjaye, O.; Via, B.; Banerjee, S. Soy Flour Substitution in Polymeric Methylene Diphenyl Diisocyanate Resin for Composite Panel Applications. For. Prod. J. 2020, 70, 350–355. [Google Scholar] [CrossRef]

- Pan, Z.; Cathcart, A.; Wang, D. Properties of Particleboard Bond with Rice Bran and Polymeric Methylene Diphenyl Diisocyanate Adhesives. Ind. Crops Prod. 2006, 23, 40–45. [Google Scholar] [CrossRef]

- Hidayat, W.; Aprilliana, N.; Asmara, S.; Bakri, S.; Hidayati, S.; Banuwa, I.S.; Lubis, M.A.R.; Iswanto, A.H. Performance of Eco-Friendly Particleboard from Agro-Industrial Residues Bonded with Formaldehyde-Free Natural Rubber Latex Adhesive for Interior Applications. Polym. Compos. 2022, 43, 2222–2233. [Google Scholar] [CrossRef]

- Ostendorf, K.; Ahrens, C.; Beulshausen, A.; Tayo, J.L.T.; Euring, M. On the Feasibility of a Pmdi-Reduced Production of Wood Fiber Insulation Boards by Means of Kraft Lignin and Ligneous Canola Hulls. Polymers 2021, 13, 1088. [Google Scholar] [CrossRef]

- Bekhta, P.; Niemz, P. Effect of High Temperature on the Change in Color, Dimensional Stability and Mechanical Properties of Spruce Wood. Holzforschung 2003, 57, 539–546. [Google Scholar] [CrossRef]

- Mansouri, E.; Pizzi, A.; Salvadó, J.; El Mansouri, N.-E.; Salvadó, J.; Pizzi, A. Lignin-Based Wood Panel Adhesives without Formaldehyde Nour-Eddine. Holz Roh Werkst. 2007, 65, 65–70. [Google Scholar] [CrossRef]

- Gendron, J.; Stambouli, I.; Bruel, C.; Boumghar, Y.; Montplaisir, D. Characterization of Different Types of Lignin and Their Potential Use in Green Adhesives. Ind. Crops Prod. 2022, 182, 114893. [Google Scholar] [CrossRef]

- Karthäuser, J.; Biziks, V.; Mai, C.; Militz, H.; Charrier, B.; Kowaluk, G. Lignin and Lignin-Derived Compounds for Wood Applications-A Review. Molecules 2021, 26, 2533. [Google Scholar] [CrossRef]

- Antov, P.; Savov, V.; Krišt’ák, L.; Réh, R.; Mantanis, G.I. Eco-Friendly, High-Density Fiberboards Bonded with Urea-Formaldehyde and Ammonium Lignosulfonate. Polymers 2021, 13, 220. [Google Scholar] [CrossRef]

- Bekhta, P.; Noshchenko, G.; Réh, R.; Kristak, L.; Sedliačik, J.; Antov, P.; Mirski, R.; Savov, V. Properties of Eco-Friendly Particleboards Bonded with Lignosulfonate-Urea-Formaldehyde Adhesives and PMDI as a Crosslinker. Materials 2021, 14, 4875. [Google Scholar] [CrossRef]

- Vitrone, F.; Ramos, D.; Ferrando, F.; Salvadó, J. Binderless Fiberboards for Sustainable Construction. Materials, Production Methods and Applications. J. Build. Eng. 2021, 44, 102625. [Google Scholar] [CrossRef]

- Mancera, C.; El Mansouri, N.-E.; Vilaseca, F.; Ferrando, F.; Salvado, J. The Effect of Lignin as a Natural Adhesive on the Physico-Mechanical Properties of Vitis Vinifera Fiberboards. Bioresources 2011, 6, 2851–2860. [Google Scholar]

- van Dam, J.E.G.; van den Oever, M.J.A.; Teunissen, W.; Keijsers, E.R.P.; Peralta, A.G. Process for Production of High Density/High Performance Binderless Boards from Whole Coconut Husk Part 1: Lignin as Intrinsic Thermosetting Binder Resin. Ind. Crops Prod. 2004, 19, 207–216. [Google Scholar] [CrossRef]

- Pereira Marques, F.; Mara, L.; Silva, A.; Lomonaco, D.; de Freitas Rosa, M.; Leitão, R.C. Steam Explosion Pretreatment to Obtain Eco-Friendly Building Blocks from Oil Palm Mesocarp Fiber. Ind. Crops Prod. 2019, 143, 11907. [Google Scholar] [CrossRef]

- Wu, J.; Chen, C.; Zhang, H.; Xia, L.; Huang, Y.; Huang, H.; Wang, Y.; Qian, D.; Wang, J.; Wang, X.; et al. Eco-Friendly Fiberboard Production without Binder Using Poplar Wood Shavings Bio-Pretreated by White Rot Fungi Coriolus Versicolor. Constr. Build. Mater. 2019, 236, 117620. [Google Scholar] [CrossRef]

- Luo, H.; Zhang, H.; Lu, X. Manufacture of Binderless Fiberboard Made from Bamboo Processing Residues by Steam Explosion Pretreatment. Wood Res. 2014, 59, 861–870. [Google Scholar]

- Anglés, M.N.; Ferrando, F.; Farriol, X.; Salvadó, J. Suitability of Steam Exploded Residual Softwood for the Production of Binderless Panels. Effect of the Pre-Treatment Severity and Lignin Addition. Biomass Bioenergy 2001, 21, 211–224. [Google Scholar] [CrossRef]

- Tupciauskas, R.; Irbe, I.; Janberga, A.; Buksans, E. Moisture and Decay Resistance and Reaction to Fire Properties of Self-Binding Fibreboard Made from Steam-Exploded Grey Alder Wood. Wood Mater. Sci. Eng. 2017, 12, 63–71. [Google Scholar] [CrossRef]

- Quintana, G.; Veí Asquez, J.; Betancourt, S.; Gañán, P. Binderless Fiberboard from Steam Exploded Banana Bunch. Ind. Crops Prod. 2008, 29, 60–66. [Google Scholar] [CrossRef]

- Shu, B.; Ren, Q.; He, Q.; Ju, Z.; Zhan, T.; Chen, Z.; Lu, X. Study on Mixed Biomass Binderless Composite Based on Simulated Wood. Wood Res. 2019, 64, 1023–1034. [Google Scholar]

- Tupciauskas, R.; Rizhikovs, J.; Andzs, M. Aproach of Binder-Less Fibreboard Production from Steam-Exploded Hemp Shives and Wheat Straw. In Proceedings of the 29th European Biomass Conference and Exhibition, Marseille, France, 26–29 April 2021; pp. 906–910. [Google Scholar]

- Kurokochi, Y.; Sato, M. Steam Treatment to Enhance Rice Straw Binderless Board Focusing Hemicellulose and Cellulose Decomposition Products. J. Wood Sci. 2020, 66, 7. [Google Scholar] [CrossRef]

- Ramos, D.; Salvadó, J.; Ferrando, F. High Mechanical Performance Boards Made from Fibers of Arundo donax without Added Adhesives. Bioresources 2017, 12, 5383–5394. [Google Scholar] [CrossRef]

- Ramos, D.; Ferrando, F.; Farriol, X.; Salvadó, J. Optimization of the Production Factors of Boards Obtained from Arundo donax L. Fibers without Added Adhesives. Molecules 2020, 25, 1660. [Google Scholar] [CrossRef]

- Vitrone, F.; Ramos, D.; Vitagliano, V.; Ferrando, F.; Salvadó, J. All-Lignocellulosic Fiberboards from Giant Reed (Arundo donax L.): Effect of Steam Explosion Pre-Treatment on Physical and Mechanical Properties. Constr Build. Mater. 2022, 319, 126064. [Google Scholar] [CrossRef]

- Ramos, D.; El Mansouri, N.E.; Ferrando, F.; Salvadó, J. All-Lignocellulosic Fiberboard from Steam Exploded Arundo donax L. Molecules 2018, 23, 2088. [Google Scholar] [CrossRef] [PubMed]

- Aidawati, W.N.; Nadhari, W.; Danish, M.; Syafiq, M.; Mohd Nasir, R.; Geng, J. Mechanical Properties and Dimensional Stability of Particleboard Fabricated from Steam Pre-Treated Banana Trunk Waste Particles. J. Build. Eng. 2019, 26, 100848. [Google Scholar] [CrossRef]

- He, Q.; Hou, Q.; Hong, L.; Lu, X.; Ziegler-Devin, I.; Chrusciel, L.; Besserer, A.; Brosse, N. Effect of Highly Efficient Steam Explosion Treatment on Beech, Poplar and Spruce Solid Wood Physicochemical and Permeable Performances. Ind. Crops Prod. 2022, 182, 114901. [Google Scholar] [CrossRef]

- Vitrone, F.; Ramos, D.; Ferrando, F.; Salvadó, J. The Influence of Thickness and Final Heat Treatment on Mechanical Properties and Dimensional Stability of Binderless Fiberboards from Steam Exploded Arundo donax L. Mater. Today Proc. 2022, 58, 999–1004. [Google Scholar] [CrossRef]

- Corno, L.; Pilu, R.; Adani, F.; Ricicla, G. Arundo donax L.: A Non-Food Crop for Bioenergy and Bio-Compound Production. Biotechnol. Adv. 2014, 32, 1535–1549. [Google Scholar] [CrossRef] [PubMed]

- e Silva, C.F.L.; Schirmer, M.A.; Maeda, R.N.; Barcelos, C.A.; Pereira, N. Potential of Giant Reed (Arundo donax L.) for Second Generation Ethanol Production. Electron. J. Biotechnol. 2015, 18, 10–15. [Google Scholar] [CrossRef]

- Ferrandez-García, M.T.; Ferrandez-Garcia, A.; Garcia-Ortuño, T.; Ferrandez-Garcia, C.E.; Ferrandez-Villena, M. Assessment of the Physical, Mechanical and Acoustic Properties of Arundo donax L. Biomass in Low Pressure and Temperature Particleboards. Polymers 2020, 12, 1361. [Google Scholar] [CrossRef]

- Velásquez, J.A.; Ferrando, F.; Salvadó, J. Binderless Fiberboard from Steam Exploded Miscanthus Sinensis: The Effect of a Grinding Process. Holz Roh Werkst. 2002, 60, 297–302. [Google Scholar] [CrossRef]

- Winter, A.; Gindl-Altmutter, W.; Mandlez, D.; Bauer, W.; Eckhart, R.; Leitner, J.; Veigel, S. Reinforcement Effect of Pulp Fines and Microfibrillated Cellulose in Highly Densified Binderless Paperboards. J. Clean. Prod. 2021, 281, 125258. [Google Scholar] [CrossRef]

- EN 323:1993; Wood-Based Panles—Determination of Density. European Standard: Plzen, Czech Republic, 1993.

- EN 310:1994; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strenght. European Standard: Plzen, Czech Republic, 1994.

- EN 319:1994; Particleboards and Fiberboards—Determination of Tensile Strenght Perpendicular to the Plane of the Board. European Standard: Plzen, Czech Republic, 1994.

- EN 317:1994; Particleboards and Fibreboards—Determination of Swelling in Thickness after Immersion in Water. European Standard: Plzen, Czech Republic, 1994.

- EN 622-5:2010; Fibreboards—Specifications—Part 5: Requirements for Dry Process Boards (MDF). European Standard: Plzen, Czech Republic, 2010.

- Troncoso-Ortega, E.; Castillo, R.D.P.; Reyes-Contreras, P.; Castaño-Rivera, P.; Teixeira Mendonça, R.; Schiappacasse, N.; Parra, C. Effects on Lignin Redistribution in Eucalyptus Globulus Fibres Pre-Treated by Steam Explosion: A Microscale Study to Cellulose Accessibility. Biomolecules 2021, 11, 507. [Google Scholar] [CrossRef] [PubMed]

- Domínguez-Robles, J.; Tarrés, Q.; Alcalà, M.; el Mansouri, N.-E.; Rodríguez, A.; Mutjé, P.; Delgado-Aguilar, M. Development of High-Performance Binderless Fiberboards from Wheat Straw Residue. Constr. Build. Mater. 2020, 232, 117247. [Google Scholar] [CrossRef]

- Buschmann, B.; Henke, K.; Talke, D.; Saile, B.; Asshoff, C.; Bunzel, F. Additive Manufacturing of Wood Composite Panels for Individual Layer Fabrication (Ilf). Polymers 2021, 13, 3423. [Google Scholar] [CrossRef] [PubMed]

- Pham Van, T.; Schöpper, C.; Klüppel, A.; Mai, C. Effect of Wood and Panel Density on the Properties of Lightweight Strand Boards. Wood Mater. Sci. Eng. 2021, 16, 237–245. [Google Scholar] [CrossRef]

- Medved, S.; Grudnik, J. Influence of Resin Content on the Surface Covered with Adhesive. Int. J. Adhes. Adhes. 2021, 104, 102698. [Google Scholar] [CrossRef]

- Fiorelli, J.; Bonilla Bueno, S.; Cabral, R. Assessment of Multilayer Particleboards Produced with Green Coconut and Sugarcane Bagasse Fibers. Constr. Build. Mater. 2019, 205, 1–9. [Google Scholar] [CrossRef]

- Okuda, N.; Sato, M. Manufacture and Mechanical Properties of Binderless Boards from Kenaf Core. J. Wood Sci. 2004, 50, 53–61. [Google Scholar] [CrossRef]

- Velásquez, J.A.; Ferrando, F.; Salvadó, J. Effects of Kraft Lignin Addition in the Production of Binderless Fiberboard from Steam Exploded Miscanthus Sinensis. Ind. Crops Prod. 2003, 18, 17–23. [Google Scholar] [CrossRef]

- Wistara, N.J.; Starini, W.; Febrianto, F.; Pari, G.; Kehutanan, J.I. Binderless MDF from Hydroxymethylated Kenaf Pulp MDF Tanpa Perekat Dari Pulp Kenaf Terhidroksimetilasi. J. For. Sci. 2018, 12, 3–13. [Google Scholar]

- Syafiqaz, N.; Arman, N.; Chen, S.; Ahmad, S. Review of State-of-the-Art Studies on the Water Absorption Capacity of Agricultural Fiber-Reinforced Polymer Composites for Sustainable Construction. Constr Build. Mater. 2021, 302, 124174. [Google Scholar] [CrossRef]

- Antov, P.; Krišt’ák, L.; Réh, R.; Savov, V.; Papadopoulos, A.N. Eco-Friendly Fiberboard Panels from Recycled Fibers Bonded with Calcium Lignosulfonate. Polymers 2021, 13, 639. [Google Scholar] [CrossRef] [PubMed]

- Kang, X.; Kirui, A.; Dickwella Widanage, M.C.; Mentink-Vigier, F.; Cosgrove, D.J.; Wang, T. Lignin-Polysaccharide Interactions in Plant Secondary Cell Walls Revealed by Solid-State NMR. Nat. Commun. 2019, 10, 347. [Google Scholar] [CrossRef] [PubMed]

- Halvarsson, S.; Edlund, H.; Norgren, M. Manufacture of Non-Resin Wheat Straw Fibreboards. Ind. Crops Prod. 2008, 29, 437–445. [Google Scholar] [CrossRef]

- Martins, R.S.F.; Gonçalves, F.G.; de Alcântara Segundinho, P.G.; Lelis, R.C.C.; Paes, J.B.; Lopez, Y.M.; Chaves, I.L.S.; de Oliveira, R.G.E. Investigation of Agro-Industrial Lignocellulosic Wastes in Fabrication of Particleboard for Construction Use. J. Build. Eng. 2021, 43, 102903. [Google Scholar] [CrossRef]

- Mahieu, A.; Alix, S.; Leblanc, N. Properties of Particleboards Made of Agricultural By-Products with a Classical Binder or Self-Bound. Ind. Crops Prod. 2019, 130, 371–379. [Google Scholar] [CrossRef]

| Variations | WF | AD | pMDI |

|---|---|---|---|

| wt% | wt% | wt% | |

| WF0 | 100 | 0 | 0 |

| WF4 | 96 | 0 | 4 |

| WFAD0 | 50 | 50 | 0 |

| WFAD4 | 48 | 48 | 4 |

| AD0 | 0 | 100 | 0 |

| AD4 | 0 | 96 | 4 |

| Multiple Comparison Pairs | ρ | MOE | MOR | IB |

|---|---|---|---|---|

| [kg m−3] | [N mm−2] | [N mm−2] | [N mm−2] | |

| ANOVA p-Value | ANOVA p-Value | ANOVA p-Value | ANOVA p-Value | |

| 1.56 × 10−9 | 1.18 × 10−5 | 0.0002 | 2.80 × 10−8 | |

| WF4-WF0 | <0.0001 | <0.0001 | 0.0013 | <0.0001 |

| WFAD4-WFAD0 | 0.7153 | 0.0876 | 0.0044 | <0.0001 |

| AD4-AD0 | 0.1397 | 0.9975 | 0.9525 | 0.0334 |

| WFAD0-WF0 | 0.0002 | 0.1119 | 0.9393 | 0.9999 |

| AD0-WF0 | <0.0001 | 0.0006 | 0.1325 | 0.8362 |

| AD0-WFAD0 | 0.9897 | 0.1622 | 0.5107 | 0.7568 |

| WFAD4-WF4 | 0.0011 | 0.4070 | 0.9999 | 0.9994 |

| AD4-WF4 | 0.0002 | 0.1172 | 0.5347 | 0.2782 |

| AD4-WFAD4 | 0.9977 | 0.9671 | 0.4998 | 0.5272 |

| Multiple Comparison Pairs | TS | WA |

|---|---|---|

| [%] | [%] | |

| ANOVA p-Value | ANOVA p-Value | |

| <2 × 10−16 | <2 × 10−16 | |

| WFAD4-WFAD0 | <0.0001 | <0.0001 |

| AD4-AD0 | 0.0002 | <0.0001 |

| AD0-WFAD0 | <0.0001 | <0.0001 |

| WFAD4-WF4 | 0.0307 | 0.61 |

| AD4-WF4 | 0.0009 | 0.1284 |

| AD4-WFAD4 | 0.6967 | 0.851 |

| Series Name | Peak Density (Left) | Peak Density (Right) | Core Density | Average Density |

|---|---|---|---|---|

| kg m−3 | kg m−3 | kg m−3 | kg m−3 | |

| WF0 | 666 | 652 | 582 | 662 |

| WF4 | 975 | 971 | 648 | 806 |

| WFAD0 | 846 | 784 | 510 | 739 |

| WFAD4 | 892 | 909 | 567 | 705 |

| AD0 | 887 | 862 | 520 | 682 |

| AD4 | 945 | 950 | 567 | 710 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vitrone, F.; Brinker, S.; Ramos, D.; Ferrando, F.; Salvadó, J.; Mai, C. Approaching Self-Bonded Medium Density Fiberboards Made by Mixing Steam Exploded Arundo donax L. and Wood Fibers: A Comparison with pMDI-Bonded Fiberboards on the Primary Properties of the Boards. Materials 2023, 16, 4343. https://doi.org/10.3390/ma16124343

Vitrone F, Brinker S, Ramos D, Ferrando F, Salvadó J, Mai C. Approaching Self-Bonded Medium Density Fiberboards Made by Mixing Steam Exploded Arundo donax L. and Wood Fibers: A Comparison with pMDI-Bonded Fiberboards on the Primary Properties of the Boards. Materials. 2023; 16(12):4343. https://doi.org/10.3390/ma16124343

Chicago/Turabian StyleVitrone, Federica, Sascha Brinker, Diego Ramos, Francesc Ferrando, Joan Salvadó, and Carsten Mai. 2023. "Approaching Self-Bonded Medium Density Fiberboards Made by Mixing Steam Exploded Arundo donax L. and Wood Fibers: A Comparison with pMDI-Bonded Fiberboards on the Primary Properties of the Boards" Materials 16, no. 12: 4343. https://doi.org/10.3390/ma16124343

APA StyleVitrone, F., Brinker, S., Ramos, D., Ferrando, F., Salvadó, J., & Mai, C. (2023). Approaching Self-Bonded Medium Density Fiberboards Made by Mixing Steam Exploded Arundo donax L. and Wood Fibers: A Comparison with pMDI-Bonded Fiberboards on the Primary Properties of the Boards. Materials, 16(12), 4343. https://doi.org/10.3390/ma16124343