Toughening Mechanism of Directional Fabric Woven Net and/or Non-Directional Short-Cut Fiber-Reinforced Sprayed Cement Mortar Thin-Plates

Abstract

1. Introduction

2. Experimental Program

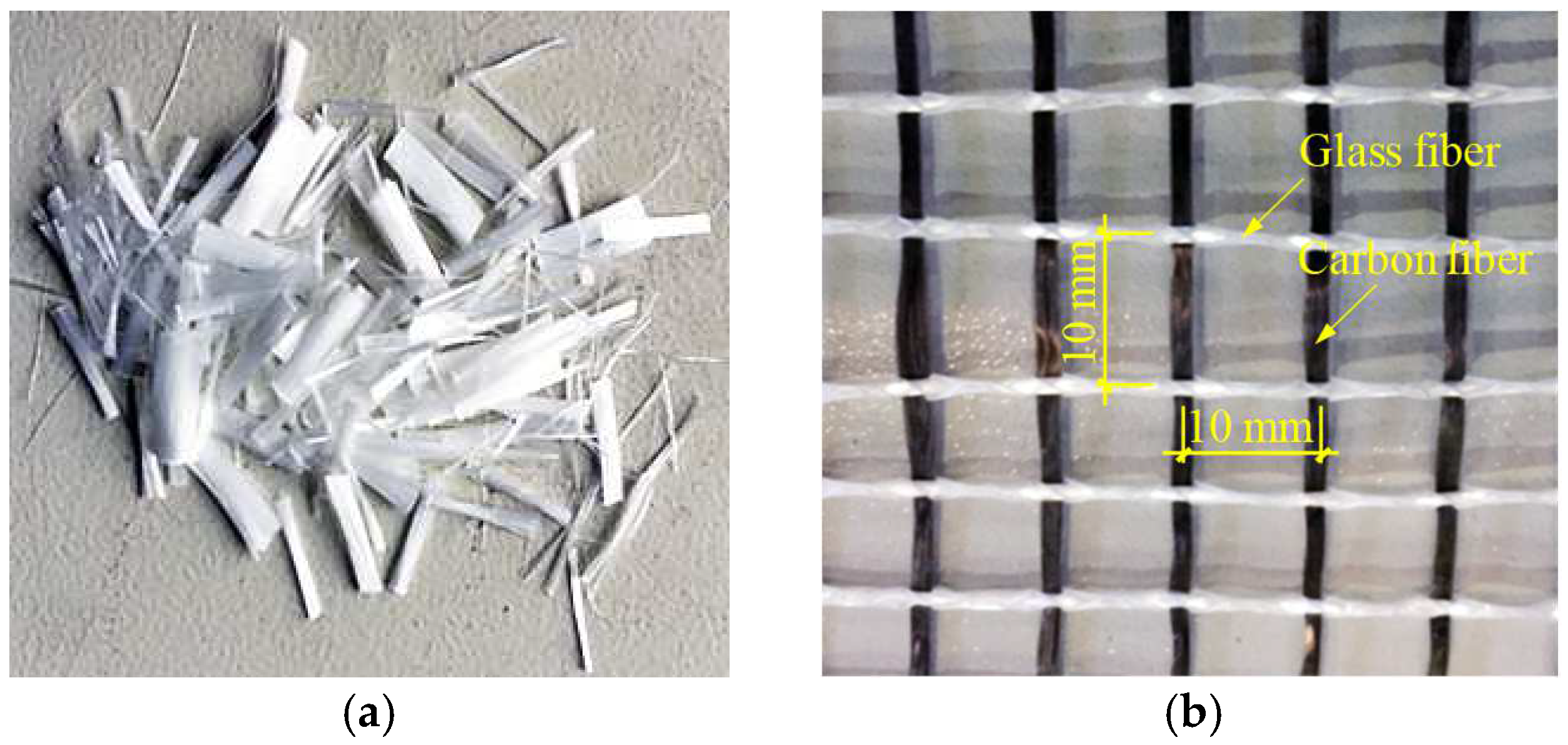

2.1. Raw Materials and Mixed Proportion

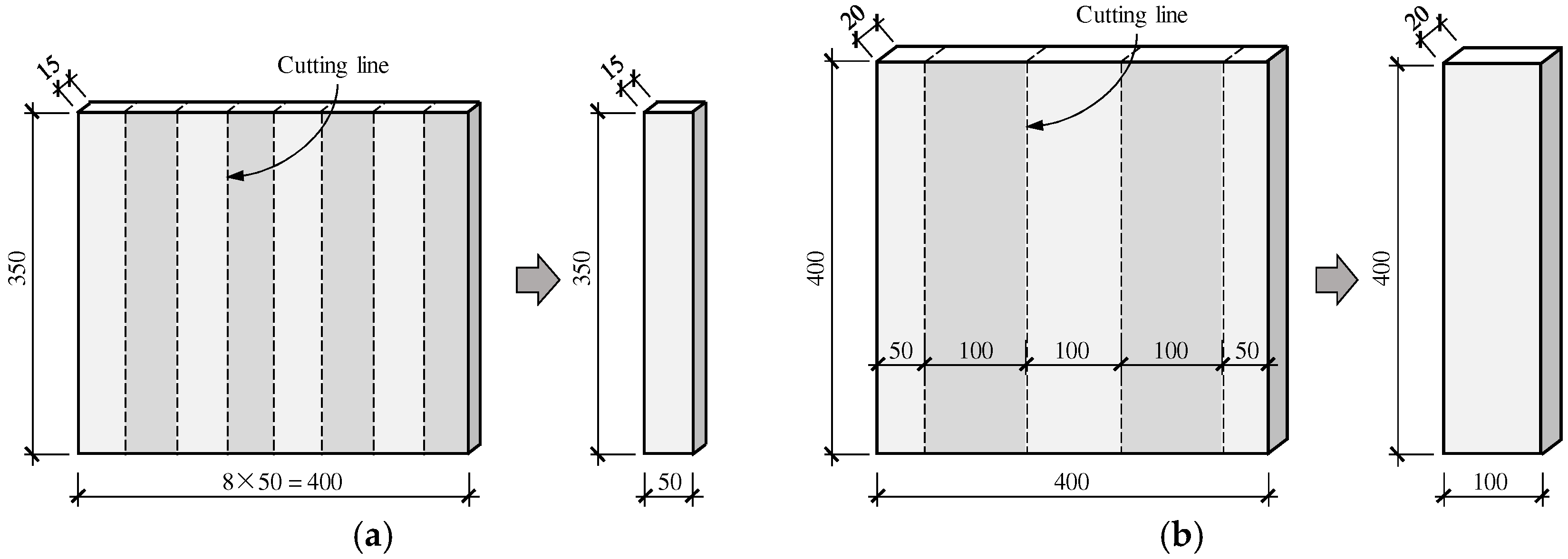

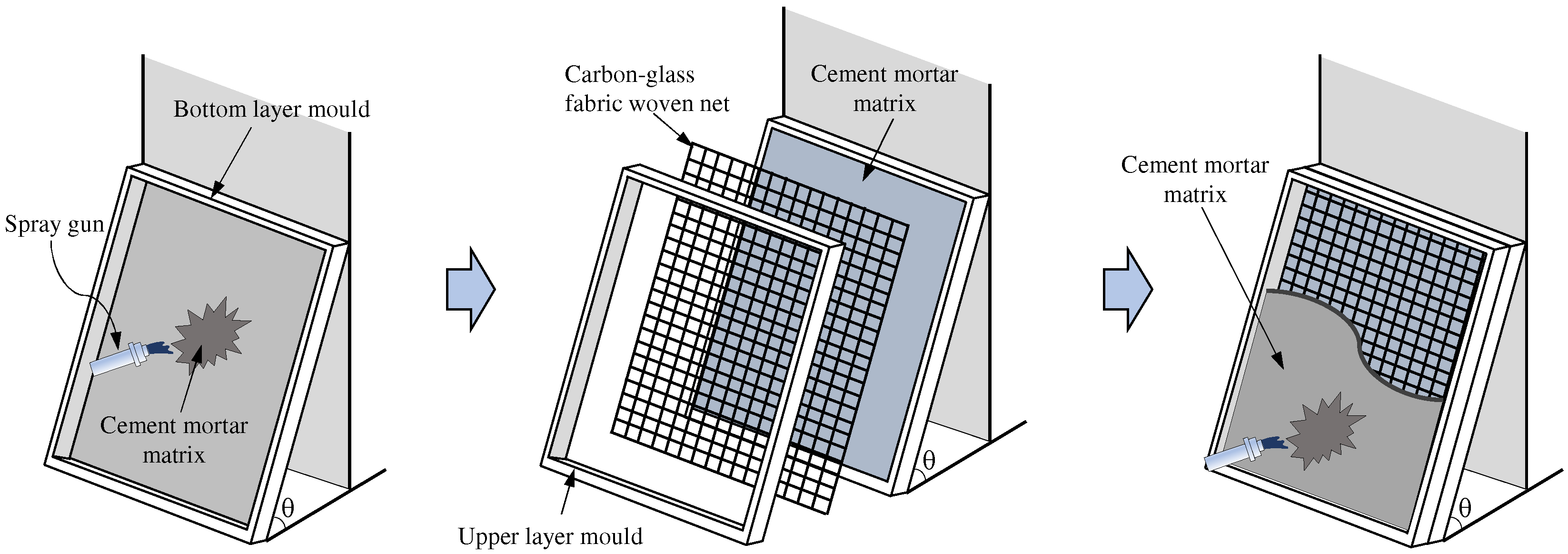

2.2. Specimens and Preparation

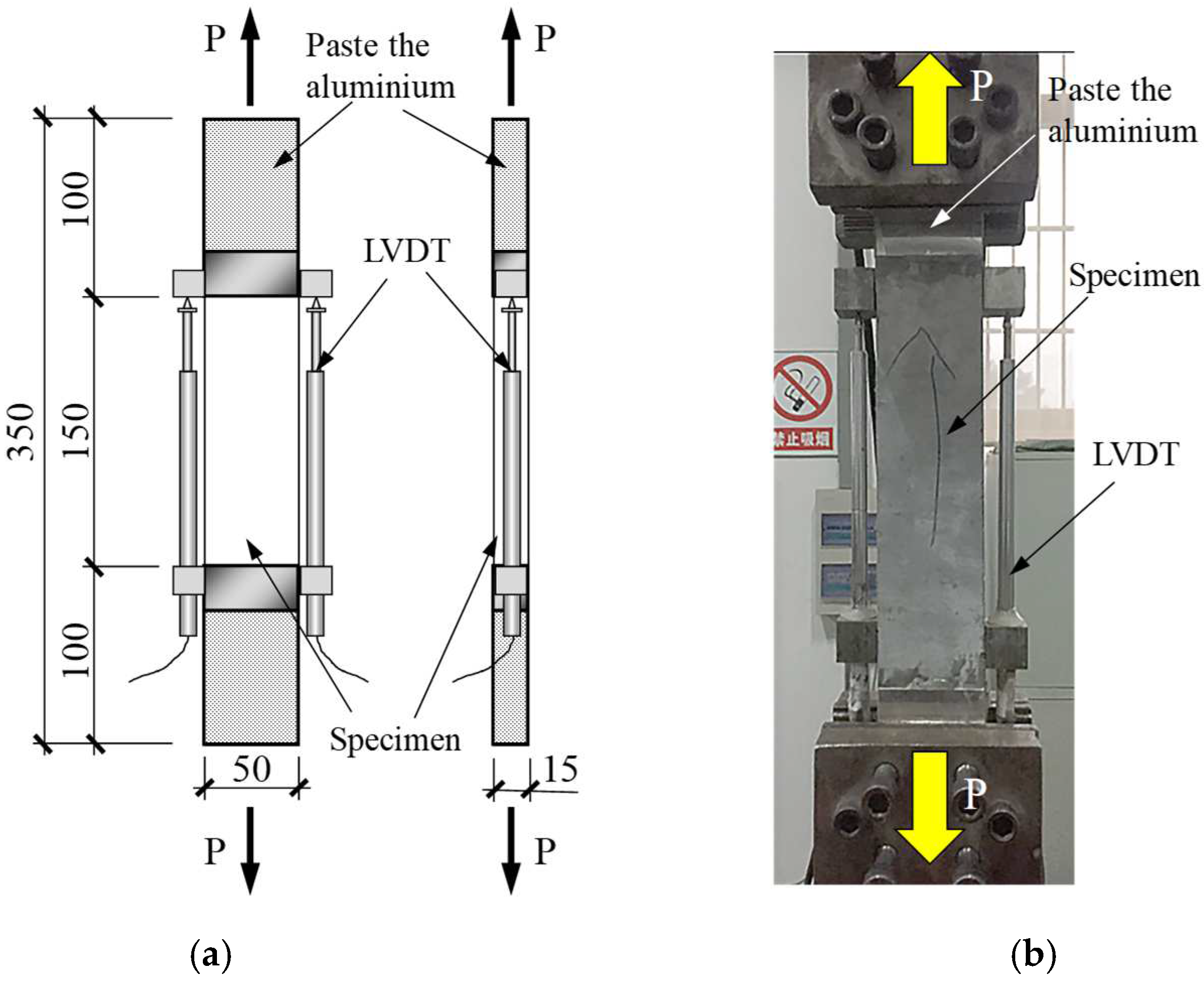

2.3. Testing Method

3. Experimental Results and Discussion

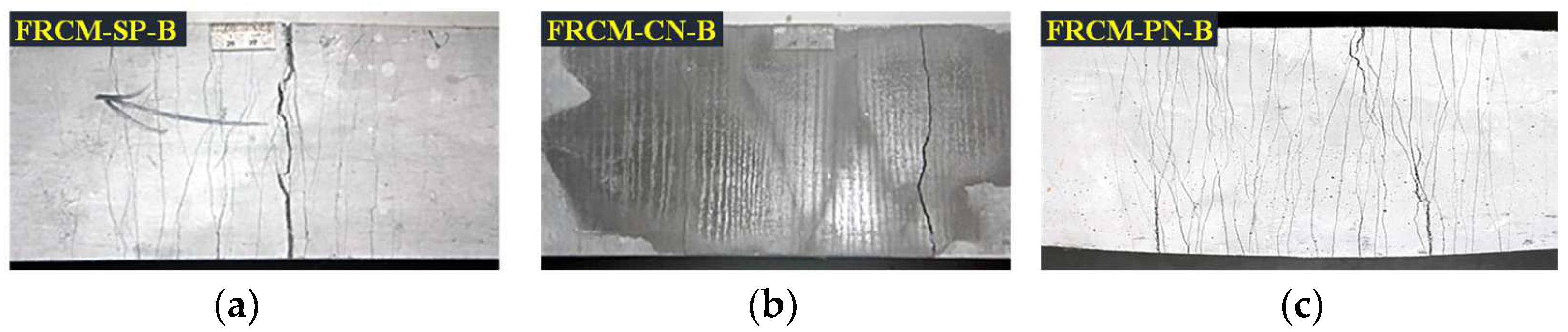

3.1. Crack Propagation Analysis and Failure Mode

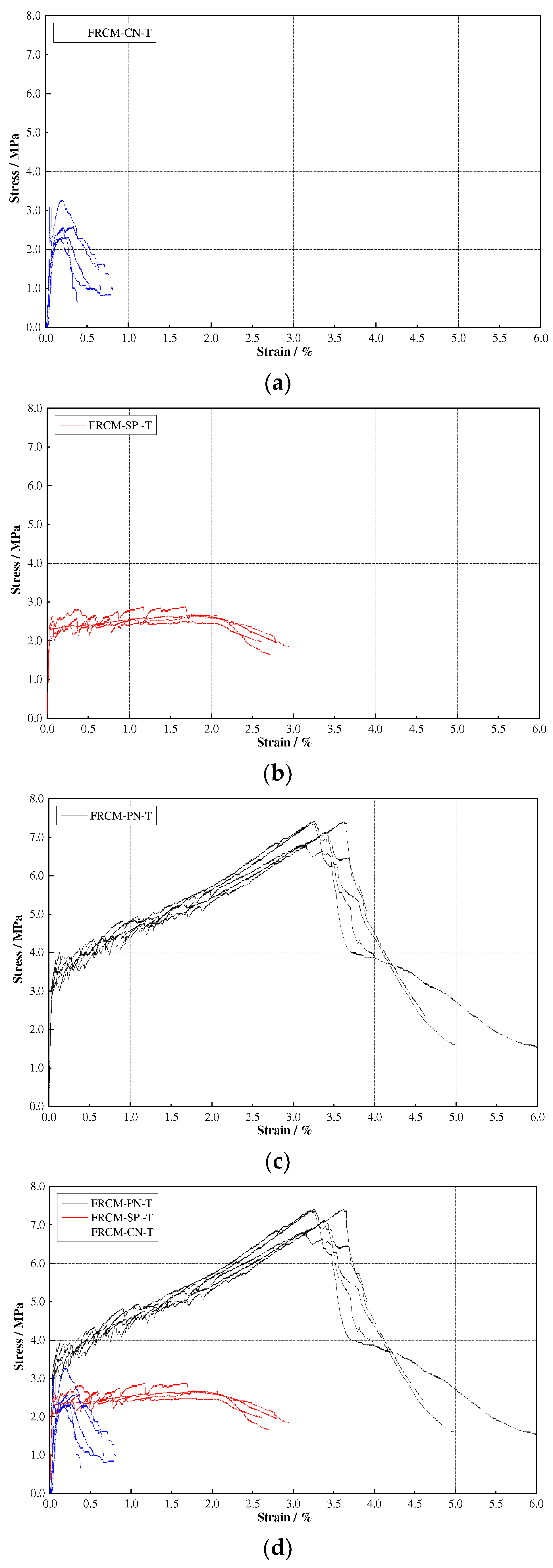

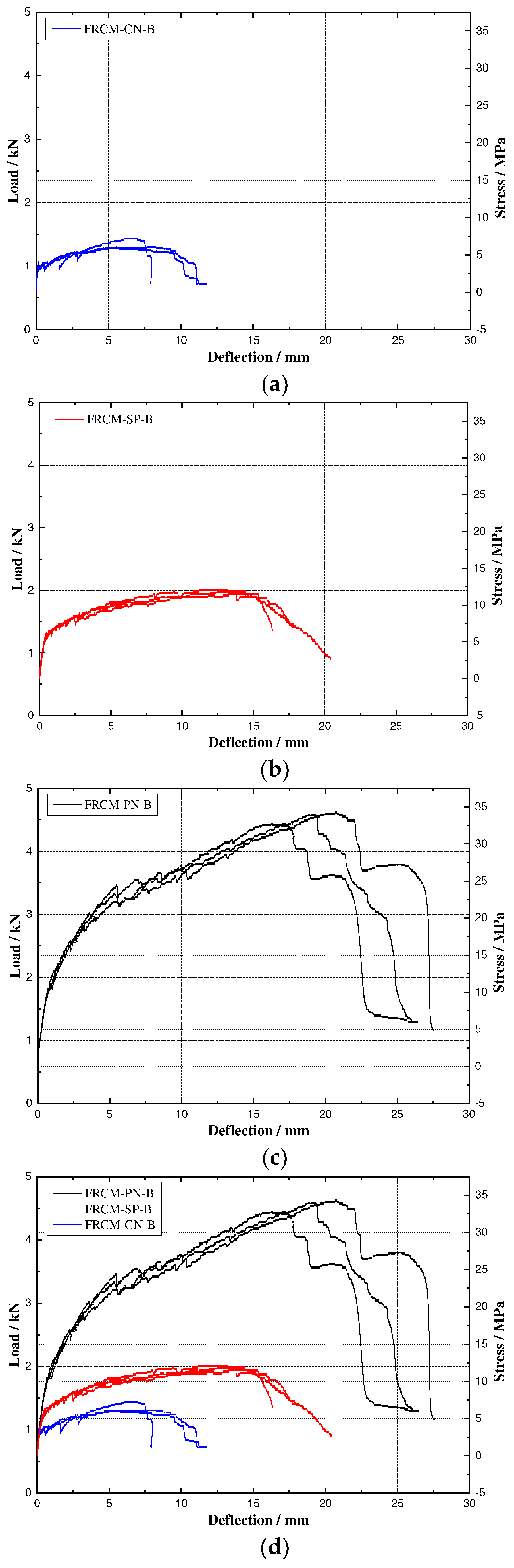

3.2. Tensile and Flexural Experiment Results

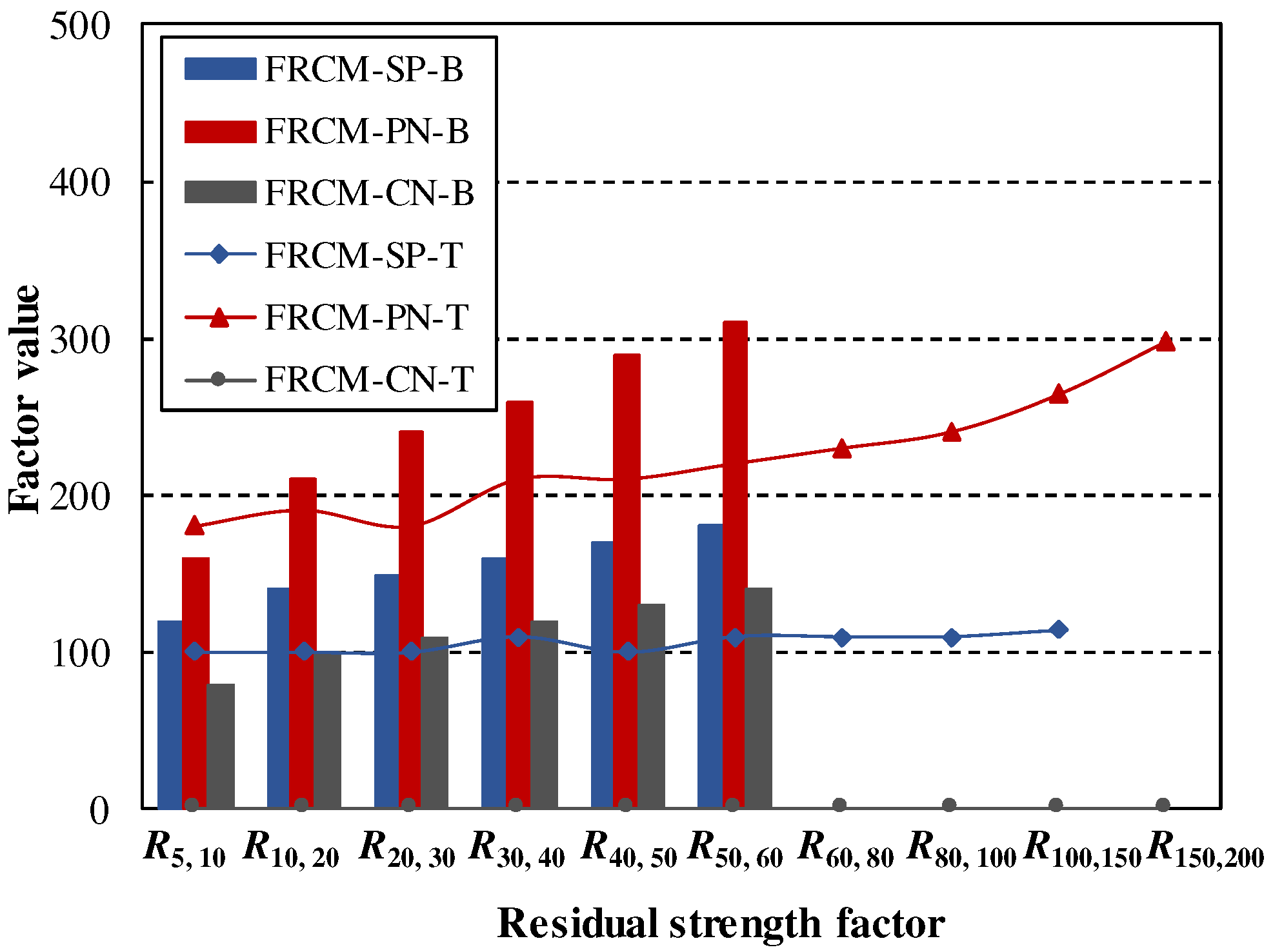

3.3. Tensile and Flexural Toughness

4. Conclusions

- (1)

- In the uniaxial tensile test of FRCM-CN series thin plates, specimens show brittle and single-crack failure behavior, which indicates that the fiber woven net and cement mortar matrix do not show good bonding or a cooperative working effect, resulting in the tensile properties of the fiber woven net not being effectively utilized. However, in the four-point bending tests, the specimens show good flexural toughness, which indicates that the fiber woven net and the cement mortar matrix have a good cooperative working effect under the composite tensile, shear, and compressive stress of the section. Therefore, only considering uniaxial tensile mechanical indexes to evaluate the mechanical properties of such materials in structural design may be conservative, but relatively safe.

- (2)

- The toughness indexes of FRCM-SP and FRCM-PN were greater than the corresponding subscripts, and the residual strength factors were greater than 100, indicating that both of them are strain-hardening materials. Moreover, the toughness index and residual strength factor of FRCM-PN are greater than that of FRCM-SP. The above phenomenon indicates that a certain amount of PVA short-cut fiber makes the cement mortar matrix form strain-hardening material, which further improves the strength and toughness under the co-action with the fabric woven net.

- (3)

- In the failure stage, the cracks observed in FRCM-PN are finer and denser than those observed in FRCM-SP and FRCM-CN, which proves that adding short-cut fibers into the sprayed cement mortar matrix can effectively enhance the cooperative working performance of the mortar matrix and the fiber yarn and improve the crack control ability of FRCM-CN.

- (4)

- In this study, there are limitations in the selection of test parameters and the constraint of direct tensile tests, and the interfacial bonding mechanism between the matrix and fiber bundles is not investigated in more depth. Therefore, in the future, we will conduct more in-depth studies on the multilayer fabric woven net reinforced cement mortar, the constraint treatment of the tests, the interfacial bonding mechanism between matrix and fabric bundles, and its relationship with the macroscopic mechanical properties, and will provide basic data for the engineering application and promotion of FRCM.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Evans, A.G.; Zok, F.W.; Davis, J. The role of interfaces in fiber reinforced brittle matrix composites. Compos. Sci. Technol. 1991, 42, 3–24. [Google Scholar] [CrossRef]

- Häußler-Combe, U.; Hartig, J. Bond and failure mechanisms of textile reinforced concrete (TRC) under uniaxial tensile loading. Cem. Concr. Compos. 2007, 29, 279–289. [Google Scholar] [CrossRef]

- Hegger, J.; Will, N.; Bruckermann, O.; Voss, S. Load-bearing behaviour and simulation of textile reinforced concrete. Mater. Struct. 2006, 39, 765–776. [Google Scholar] [CrossRef]

- Xu, S.; Krüger, M.; Reinhardt, H.W.; Ožbolt, J. Bond characteristics of carbon, alkali resistant glass, and aramid textiles in mortar. J. Mater. Civ. Eng. 2004, 16, 356–364. [Google Scholar] [CrossRef]

- Hegger, J.; Will, N.; Rüberg, K. Textile reinforced concrete—A new composite material. In Advanced in Construction Materials 2007; Grosse, C.U., Ed.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 147–155. [Google Scholar]

- Orlowsky, J.; Raupach, M. Textile reinforced concrete from research to application. Cem. Wapno Beton 2011, 16, 323–331. [Google Scholar]

- Marcari, G.; Basili, M.; Vestroni, F. Experimental investigation of tuff masonry panels reinforced with surface bonded basalt textile-reinforced mortar. Compos. Part B Eng. 2017, 108, 131–142. [Google Scholar] [CrossRef]

- Yin, S.P.; Xu, S.L.; Wang, F. Investigation on the flexural behavior of concrete members reinforced with epoxy resin-impregnated textiles. Mater. Struct. 2015, 48, 153–166. [Google Scholar] [CrossRef]

- Donnini, J.; Basalo, F.D.C.; Corinaldesi, V.; Lancioni, G.; Nanni, A. Fabric-reinforced cementitious matrix behavior at high-temperature: Experimental and numerical results. Compos. Part B Eng. 2017, 108, 108–121. [Google Scholar] [CrossRef]

- Reinhardt, H.W.; Krüger, M.; Große, C.U. Concrete Prestressed with Textile Fabric. Adv. Concr. Technol. 2003, 1, 231–239. [Google Scholar] [CrossRef]

- Zhu, D.J.; Gencoglu, M.; Mobasher, B. Low velocity flexural impact behavior of AR glass fabric reinforced cement composites. Cem. Concr. Compos. 2009, 31, 379–387. [Google Scholar] [CrossRef]

- Du, Y.X.; Zhang, X.Y.; Zhou, F.; Zhu, D.J.; Zhang, M.M.; Pan, W. Flexural behavior of basalt textile-reinforced concrete. Constr. Build. Mater. 2018, 183, 7–21. [Google Scholar] [CrossRef]

- Hinzen, M.; Rrameshuber, W. Improvement of serviceability and strength of textile-reinforced concrete elements with short fiber mixes. In Design and Application of Textile-Reinforced Concrete; Aldea, C.M., Ed.; SP-251; American Concrete Institute: Farmington Hills, MI, USA, 2008; pp. 7–18. [Google Scholar]

- Barhum, R.; Mechtcherine, V. Effect of short, dispersed glass and carbon fibers on the behavior of textile reinforced concrete under tensile loading. Eng. Fract. Mech. 2012, 92, 56–71. [Google Scholar] [CrossRef]

- Yin, S.P.; Xu, S.L. Improved mechanical properties of textile reinforced concrete thin plate. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2013, 28, 92–98. [Google Scholar] [CrossRef]

- Li, V.C.; Leung, C.K. Steady state and multiple cracking of short random fiber composites. J. Eng. Mech. 1992, 188, 2246–2264. [Google Scholar] [CrossRef]

- Li, V.C. On Engineered Cementitious Composites (ECC): A Review of the Material and Its Applications. J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Yu, J.; Li, H.; Leung, C.K.; Lin, X.; Lam, J.Y.; Sham, I.M.; Shih, K. Matrix design for waterproof engineered cementitious composites (ECCs). Constr. Build. Mater. 2017, 139, 438–446. [Google Scholar] [CrossRef]

- Yu, K.Q.; Yu, J.T.; Dai, J.G.; Lu, Z.D.; Shah, S.P. Development of ultra-high performance engineered cementitious composites using polyethylene (PE) fibers. Constr. Build. Mater. 2018, 158, 217–227. [Google Scholar] [CrossRef]

- Lepech, M.D.; Li, V.C. Water permeability of engineered cementitious composites. J. Cem. Concr. Compos. 2009, 31, 744–753. [Google Scholar] [CrossRef]

- Li, V.C.; Hashida, T. Engineering ductile fracture in brittle-matrix composites. J. Mater. Sci. Lett. 1993, 12, 898–901. [Google Scholar] [CrossRef]

- Yu, J.; Yao, J.; Lin, X.; Li, H.; Lam, J.Y.; Leung, C.K.; Sham, I.M.L.; Shih, K. Tensile performance of sustainable Strain-Hardening Cementitious Composites with hybrid PVA and recycled PET fibers. Cem. Concr. Res. 2018, 107, 110–123. [Google Scholar] [CrossRef]

- Lin, X.; Yu, J.; Li, H.; Lam, J.Y.; Shih, K.; Sham, I.M.; Leung, C.K. Recycling polyethylene terephthalate wastes as short fibers in strain-hardening cementitious composites (SHCC). J. Hazard. Mater. 2018, 357, 40–52. [Google Scholar] [CrossRef] [PubMed]

- Hou, L.J.; Luan, Z.Y.; Chen, D. Experimental study of the shear properties of reinforced ultra-high toughness cementitious composite beams. J. Zhejiang Univ. Sci. A 2015, 16, 251–264. [Google Scholar] [CrossRef]

- Li, Q.H.; Zhao, X.; Xu, S.L. Influence of steel fiber on dynamic compressive behavior of hybrid fiber ultra high toughness cementitious composites at different strain rates. Constr. Build. Mater. 2016, 125, 490–500. [Google Scholar] [CrossRef]

- Huang, B.T.; Li, Q.H.; Xu, S.L. Fatigue deformation model of plain and fiber-reinforced concrete based on the Weibull function. J. Struct. Eng. 2018, 145, 04018234. [Google Scholar] [CrossRef]

- Wu, M.; Johannesson, B.; Geiker, M. A review: Self-healing in cementitious materials and engineered cementitious composite as a self-healing material. Constr. Build. Mater. 2012, 28, 571–583. [Google Scholar] [CrossRef]

- Ma, H.; Shun, Z.Q.; Zhang, Z.G. Effect of self-healing on water permeability and mechanical propertyof Medium-Early-Strength Engineered Cementitious Composites. Constr. Build. Mater. 2014, 68, 92–101. [Google Scholar] [CrossRef]

- Huang, B.T.; Li, Q.H.; Xu, S.L.; Liu, W.; Wang, H.T. Fatigue deformation behavior and fiber failure mechanism of ultra-high toughness cementitious composites in compression. Mater. Des. 2018, 157, 457–468. [Google Scholar] [CrossRef]

- Huang, B.T.; Li, Q.H.; Xu, S.L.; Zhou, B.M. Tensile fatigue behavior of fiber-reinforced cementitious material with high ductility: Experimental study and novel P-S-N model. Constr. Build. Mater. 2018, 178, 349–359. [Google Scholar] [CrossRef]

- Huang, B.T.; Li, Q.H.; Xu, S.L.; Li, C.F. Development of reinforced ultra-high toughness cementitious composite permanent formwork: Experimental study and Digital Image Correlation analysis. Compos. Struct. 2017, 180, 892–903. [Google Scholar] [CrossRef]

- Li, V.C.; Horii, H.; Kabele, P.; Kanda, T.; Lim, Y.M. Repair and retrofit with engineered cementitious composites. Eng. Fract. Mech. 2000, 65, 317–334. [Google Scholar] [CrossRef]

- Leung, C.K.Y.; Cao, Q. Development of pseudo-ductile permanent formwork for durable concrete structures. Mater. Struct. 2010, 43, 993–1007. [Google Scholar] [CrossRef]

- Yu, K.; Li, L.; Yu, J.; Xiao, J.; Ye, J.; Wang, Y. Feasibility of using ultra-high ductility cementitious composites for concrete structures without steel rebar. Eng. Struct. 2018, 170, 11–20. [Google Scholar] [CrossRef]

- Ding, Y.; Yu, K.Q.; Yu, J.T.; Xu, S.L. Structural behaviors of ultra-high performance engineered cementitious composites (UHP-ECC) beams subjected to bending-experimental study. Constr. Build. Mater. 2018, 177, 102–115. [Google Scholar] [CrossRef]

- Pang, S.S.; Pandian, A.; Bradshaw, R.D. Modified Tsai-Wu failure criterion for fiber-reinforced composite laminates. Polym. Compos. 1992, 13, 273–277. [Google Scholar] [CrossRef]

- Kabir, H.; Aghdam, M.M. A robust Bézier based solution for nonlinear vibration and post-buckling of random checkerboard graphene nano-platelets reinforced composite beams. Compos. Struct. 2019, 212, 184–198. [Google Scholar] [CrossRef]

- Li, H.D.; Xu, S.L.; Leung, C.K. Tensile and flexural properties of ultra-high toughness cementitious composite. J. Wuhan Univ. Technol. 2009, 24, 677–683. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Kong, H.J.; Li, V.C. Design of engineered cementitious composite suitable for wet-mixture shotcreting. ACI Mater. J. 2003, 100, 511–518. [Google Scholar]

- Kim, Y.Y.; Fischer, G.; Lim, Y.M.; Li, V.C. Mechanical performance of sprayed engineered cementitious composite using wet-mix shotcreting process for repair applications. ACI Mater. J. 2004, 101, 42–49. [Google Scholar]

- Kim, Y.Y. Repair performance of engineered cementitious composites (ECC) treated with wet-mix spraying process. Int. J. Concr. Struct. Mater. 2006, 18, 207–211. [Google Scholar]

- Xu, S.L.; Zhou, B.; Li, Q.H.; Wu, Y.X. Mechanical performance of sprayable Ultra High Toughness Cementitious Composites. J. Hydraul. Eng. 2015, 46, 619–625. (In Chinese) [Google Scholar]

- Xu, S.L.; Mu, F.J.; Wang, J.Y.; Li, W.P. Experimental study on interfacial bonding behaviors between sprayed UHTCC and concrete substrate. Constr. Build. Mater. 2019, 195, 638–649. [Google Scholar] [CrossRef]

- Shen, L.H.; Wang, J.Y.; Xu, S.L.; Zhao, X.; Peng, Y. Flexural behavior of TRC contained chopped fibers subjected to high temperature. Constr. Build. Mater. 2020, 262, 120561. [Google Scholar] [CrossRef]

- ASTM C 1018; Standard Test Method for Flexural Toughness and First-Crack Strength of Fiber Reinforced Concrete—Standards for Concrete and Mineral Aggregates. American Society for Testing Materials, ASTM: West Conshohocken, PA, USA, 1997.

- Said, S.H.; Razak, H.A.; Othman, I. Flexural behavior of engineered cementitious composite (ECC) slabs with polyvinyl alcohol fibers. Constr. Build. Mater. 2015, 75, 176–188. [Google Scholar] [CrossRef]

- Li, V.C.; Wu, C.; Wang, S.; Ogawa, A.; Saito, T. Interface tailoring for strain-hardening polyvinyl alcohol-engineered cementitious composite (PVA-ECC). ACI Mater. J. 2002, 99, 463–472. [Google Scholar]

- Matsumoto, T.; Mihashi, H. JCI-DFRCC summary report on DFRCC terminologies and application concepts. In Proceedings of the JCI International Workshop on Ductile Fiber Reinforced Cementitious Composites-Application and Evaluation, Takayama, Japan, 21–22 October 2002; pp. 1–8. [Google Scholar]

- Shen, L.H.; Xu, S.L.; Wang, J.Y. Mechanical behavior of TRC thin-plates exposed to high temperature: Experimental study. Mag. Concr. Res. 2015, 67, 1135–1149. [Google Scholar] [CrossRef]

| Cement | Fly Ash | Silica Fume | Fine Sand | Metakaolin | Thixotropic Agent | Superplasticizer |

|---|---|---|---|---|---|---|

| 452 | 198 | 45 | 1400 | 50 | 1.0 | 3.5 |

| Tensile Strength (MPa) | Diameter (μm) | Fiber Length (mm) | Young’s Modulus (GPa) | Elongation (%) |

|---|---|---|---|---|

| 1600 | 39 | 8 | 40 | 6 |

| Tensile Strength (MPa) | Tex (g/km) | Density (g/cm3) | Theoretical Area (mm2) | Young’s Modulus (GPa) | Elongation (%) |

|---|---|---|---|---|---|

| 4900 | 800 | 1.82 | 0.44 | 230 | 1.35 |

| Specimen | Test Method | Dimension (mm) | Number | Fiber Type |

|---|---|---|---|---|

| FRCM-SP-T | Tensile | 15 × 50 × 350 | 6 | Short-cut PVA |

| FRCM-SP-B | Bending | 20 × 100 × 400 | 3 | Short-cut PVA |

| FRCM-CN-T | Tensile | 15 × 50 × 350 | 6 | Glass-carbon woven net |

| FRCM-CN-B | Bending | 20 × 100 × 400 | 3 | Glass-carbon woven net |

| FRCM-PN-T | Tensile | 15 × 50 × 350 | 6 | PVA + woven net |

| FRCM-PN-B | Bending | 20 × 100 × 400 | 3 | PVA + woven net |

| Specimens | FRCM-SP | FRCM-PN | FRCM-CT |

|---|---|---|---|

| w-1% | 50~80 μm | 20~30 μm | failure |

| w-2% | 70~100 μm | 40~60 μm | failure |

| Crack number | 31 ± 3 | 59 ± 3 | 1 |

| Crack spacing | 4~9 mm | 2~5 mm | - |

| Failure mode | ductile mode | ductile mode | brittle mode |

| Specimens | FRCM-SP | FRCM-PN | FRCM-CT |

|---|---|---|---|

| w-5 | 40~60 μm | 20~30 μm | >0.5 mm |

| w-10 | 60~80 μm | 40~50 μm | >1.0 mm |

| w-15 | 80~100 μm | 50~70 μm | >2.0 mm |

| Crack number | 48 ± 3 | 81 ± 3 | 3~5 |

| Crack spacing | 3~8 mm | 2~5 mm | >10 mm |

| Failure mode | ductile mode | ductile mode | brittle mode |

| Specimen | Tensile Stiffness (GPa) | Initial Cracking Strength (MPa) | Initial Cracking Strain (%) | Ultimate Strength (MPa) | Ultimate Strain (%) |

|---|---|---|---|---|---|

| FRCM-SP-T | 7.85 | 2.24 (0.059) | 0.026 | 2.62 (0.33) | 2.02 |

| FRCM-CN-T | 5.92 | 3.14 (0.216) | 0.053 | 3.42 (0.151) | 0.24 |

| FRCM-PN-T | 14.5 | 3.76 (0.109) | 0.026 | 7.22 (0.208) | 3.34 |

| Specimen | Bending Stiffness (GPa) | Initial Cracking Strength (MPa) | Initial Cracking Strain (%) | Ultimate Strength (MPa) | Ultimate Deflection (mm) |

| FRCM-SP-B | 15.86 | 6.98 (0.238) | 0.044 | 11.92 (0.132) | 15.82 |

| FRCM-CN-B | 23.93 | 3.83 (0.124) | 0.016 | 6.48 (0.17) | 8.36 |

| FRCM-PN-B | 16.08 | 9.49 (0.134) | 0.059 | 33.67 (0.391) | 19.18 |

| Flexural | I5 | I10 | I20 | I30 | I40 | I50 | I60 | I80 | I100 | I150 | I200 | IU |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FRCM-SP | 5 | 11 | 25 | 40 | 56 | 73 | 91 | - | - | - | - | 94 |

| FRCM-PN | 6 | 14 | 35 | 59 | 85 | 114 | 145 | - | - | - | - | 139 |

| FRCM-CN | 4 | 8 | 18 | 29 | 41 | 54 | 68 | - | - | - | - | 131 |

| Tensile | I5 | I10 | I20 | I30 | I40 | I50 | I60 | I80 | I100 | I150 | I200 | IU |

| FRCM-SP | 5 | 10 | 20 | 30 | 41 | 51 | 62 | 84 | 106 | 163 | - | 166 |

| FRCM-PN | 7 | 16 | 35 | 53 | 74 | 95 | 117 | 163 | 211 | 343 | 492 | 656 |

| FRCM-CN | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Flexural | R5,10 | R10,20 | R20,30 | R30,40 | R40,50 | R50,60 | R60,80 | R80,100 | R100,150 | R150,200 |

|---|---|---|---|---|---|---|---|---|---|---|

| FRCM-SP | 120 | 140 | 150 | 160 | 170 | 180 | - | - | - | - |

| FRCM-PN | 160 | 210 | 240 | 260 | 290 | 310 | - | - | - | - |

| FRCM-CN | 80 | 100 | 110 | 120 | 130 | 140 | - | - | - | - |

| Tensile | R5,10 | R10,20 | R20,30 | R30,40 | R40,50 | R50,60 | R60,80 | R80,100 | R100,150 | R150,200 |

| FRCM-SP | 100 | 100 | 100 | 110 | 100 | 110 | 110 | 110 | 114 | - |

| FRCM-PN | 180 | 190 | 180 | 210 | 210 | 220 | 230 | 240 | 264 | 298 |

| FRCM-CN | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Yu, D.; Mu, F.; Ji, X.; Peng, Y. Toughening Mechanism of Directional Fabric Woven Net and/or Non-Directional Short-Cut Fiber-Reinforced Sprayed Cement Mortar Thin-Plates. Materials 2023, 16, 4418. https://doi.org/10.3390/ma16124418

Wang J, Yu D, Mu F, Ji X, Peng Y. Toughening Mechanism of Directional Fabric Woven Net and/or Non-Directional Short-Cut Fiber-Reinforced Sprayed Cement Mortar Thin-Plates. Materials. 2023; 16(12):4418. https://doi.org/10.3390/ma16124418

Chicago/Turabian StyleWang, Jiyang, Dan Yu, Fujiang Mu, Xiaohua Ji, and Yu Peng. 2023. "Toughening Mechanism of Directional Fabric Woven Net and/or Non-Directional Short-Cut Fiber-Reinforced Sprayed Cement Mortar Thin-Plates" Materials 16, no. 12: 4418. https://doi.org/10.3390/ma16124418

APA StyleWang, J., Yu, D., Mu, F., Ji, X., & Peng, Y. (2023). Toughening Mechanism of Directional Fabric Woven Net and/or Non-Directional Short-Cut Fiber-Reinforced Sprayed Cement Mortar Thin-Plates. Materials, 16(12), 4418. https://doi.org/10.3390/ma16124418