Structure and Phase Composition of WNb Alloy Formed by the Impact of Compression Plasma Flows

Abstract

1. Introduction

2. Materials and Methods

3. Results

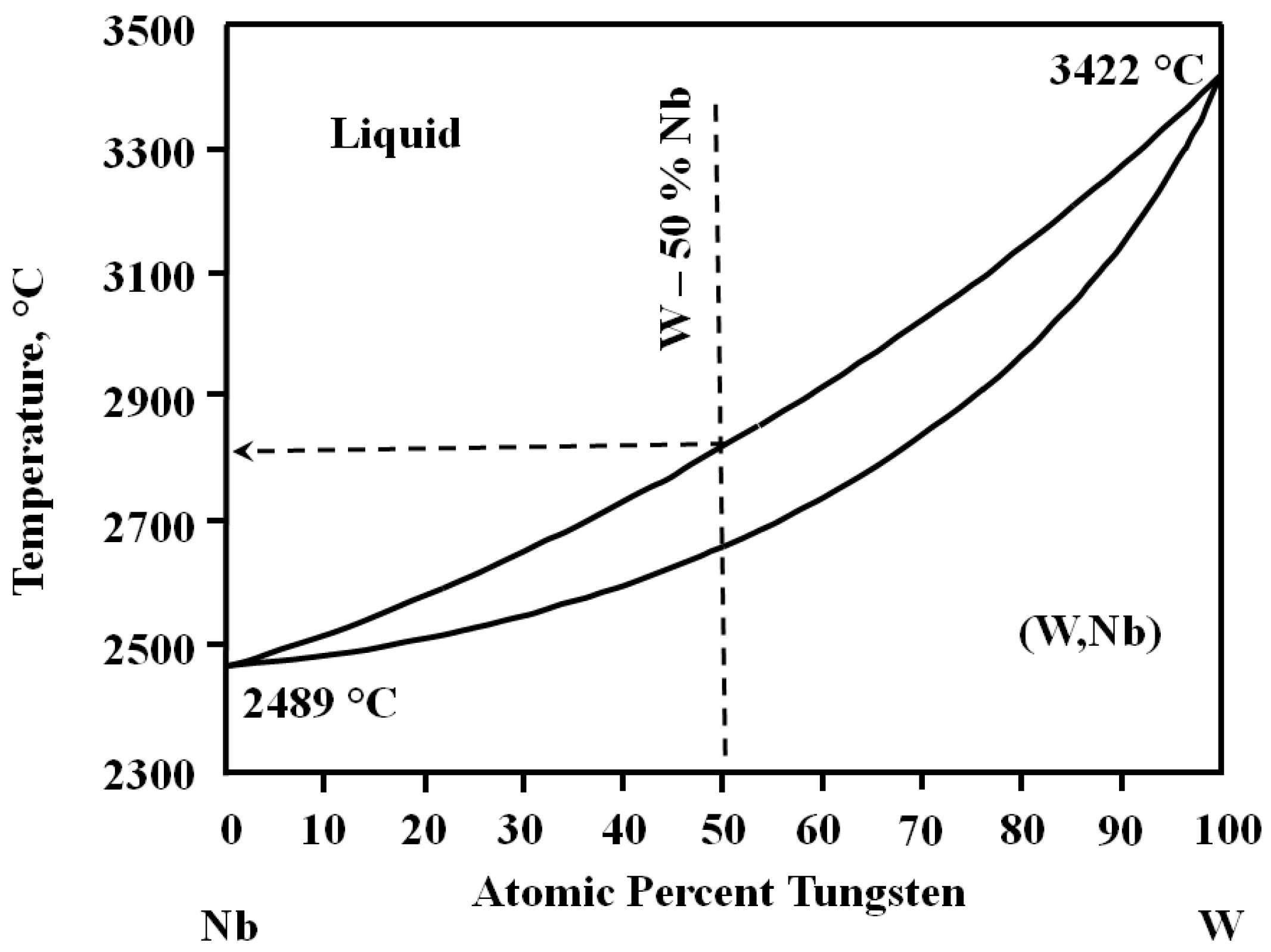

3.1. Temperature Transfer Analysis

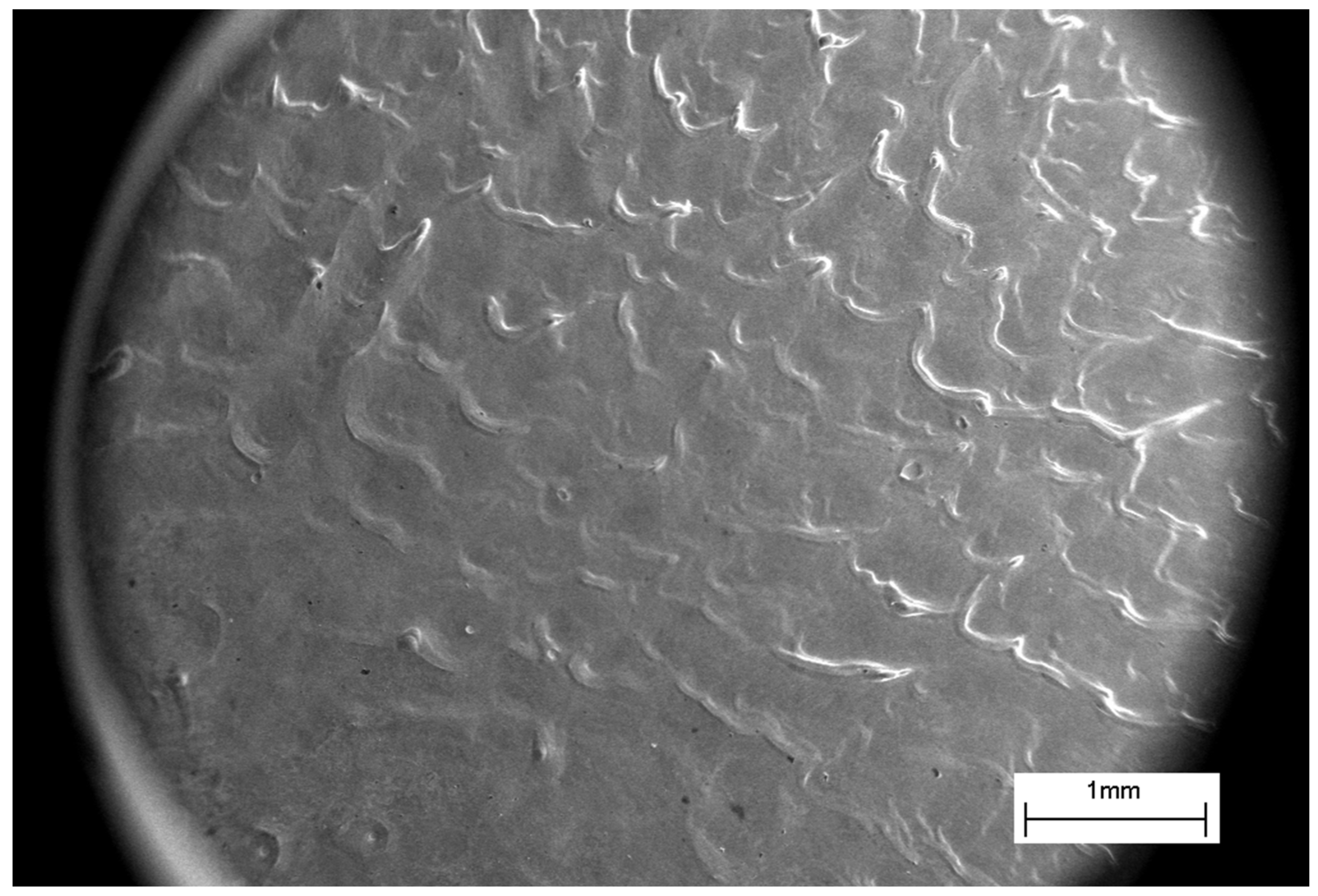

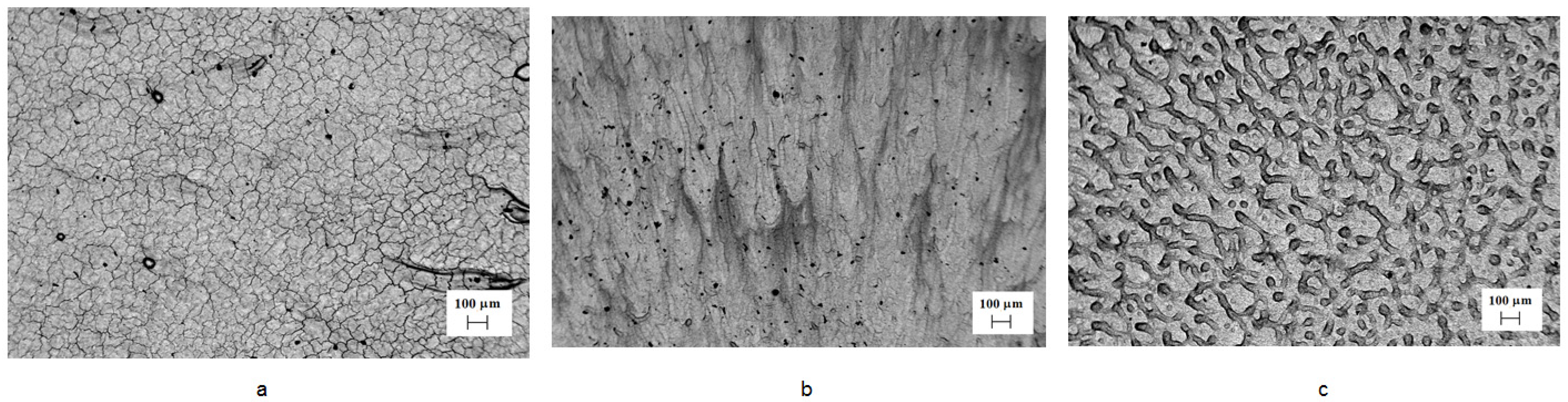

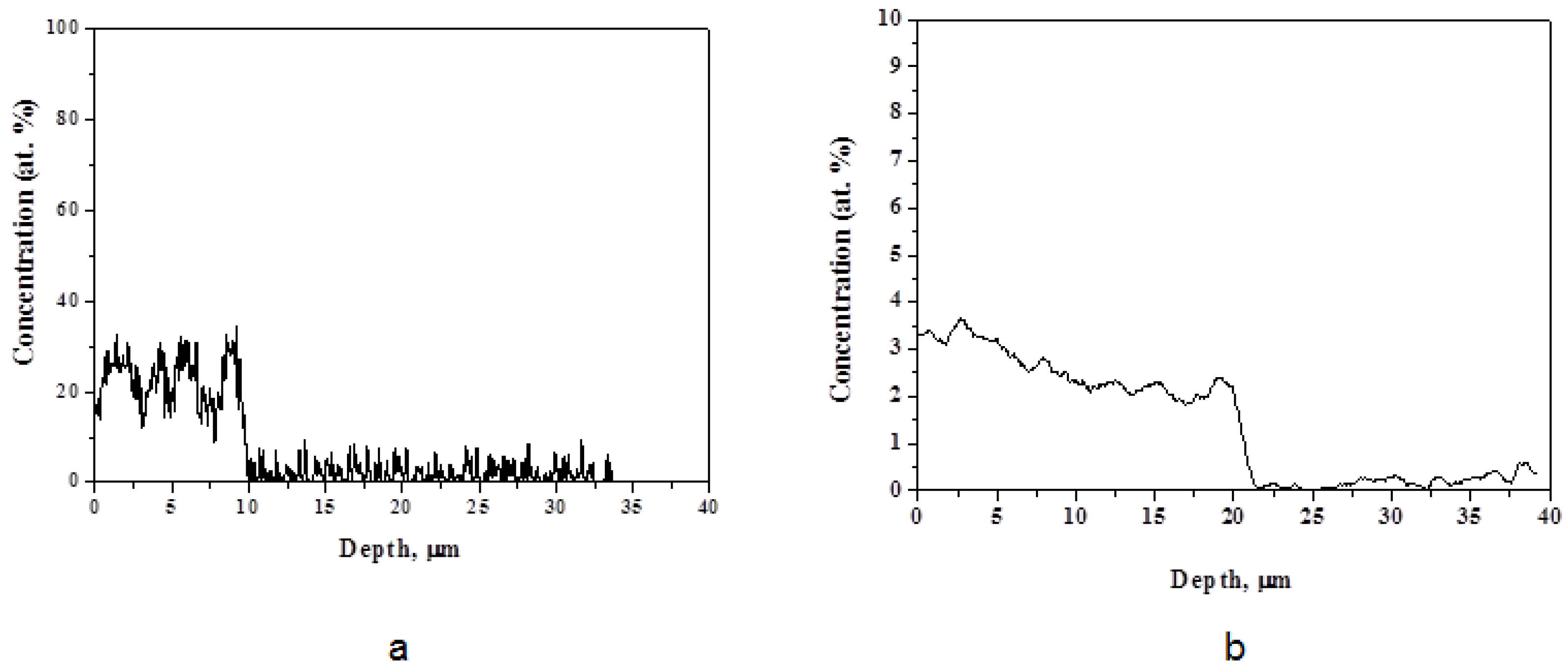

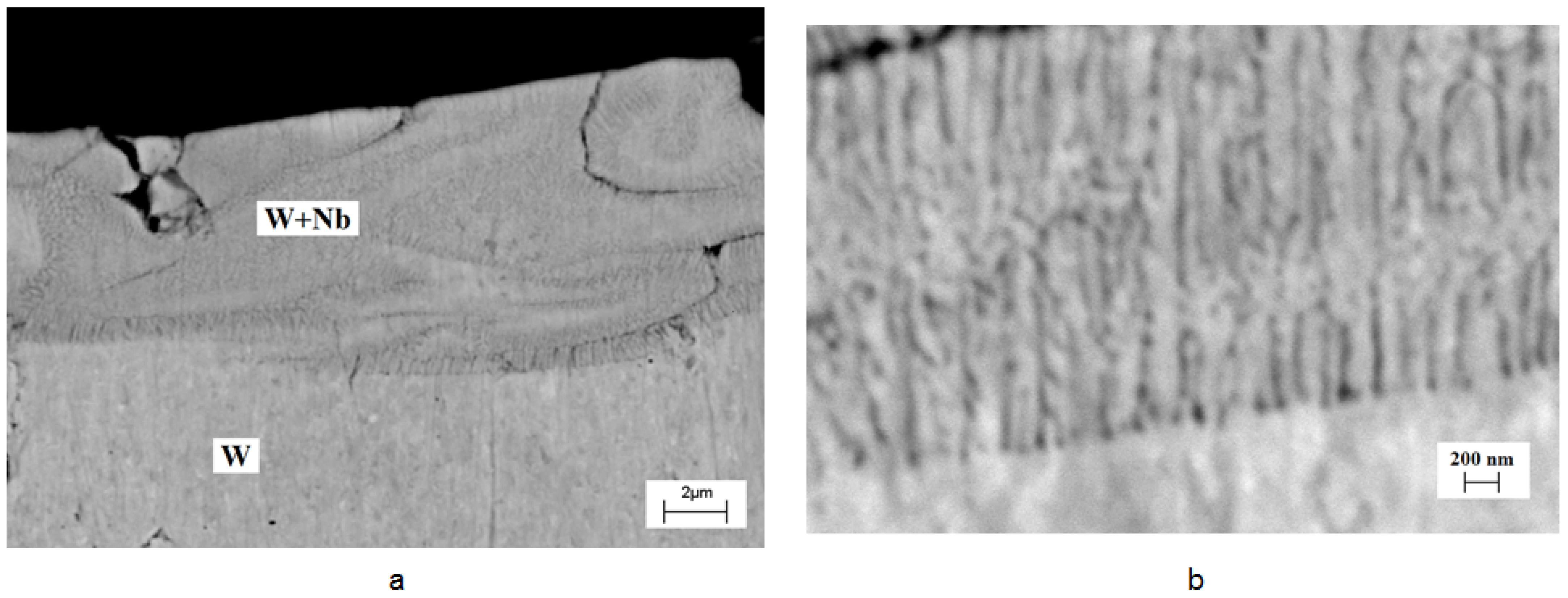

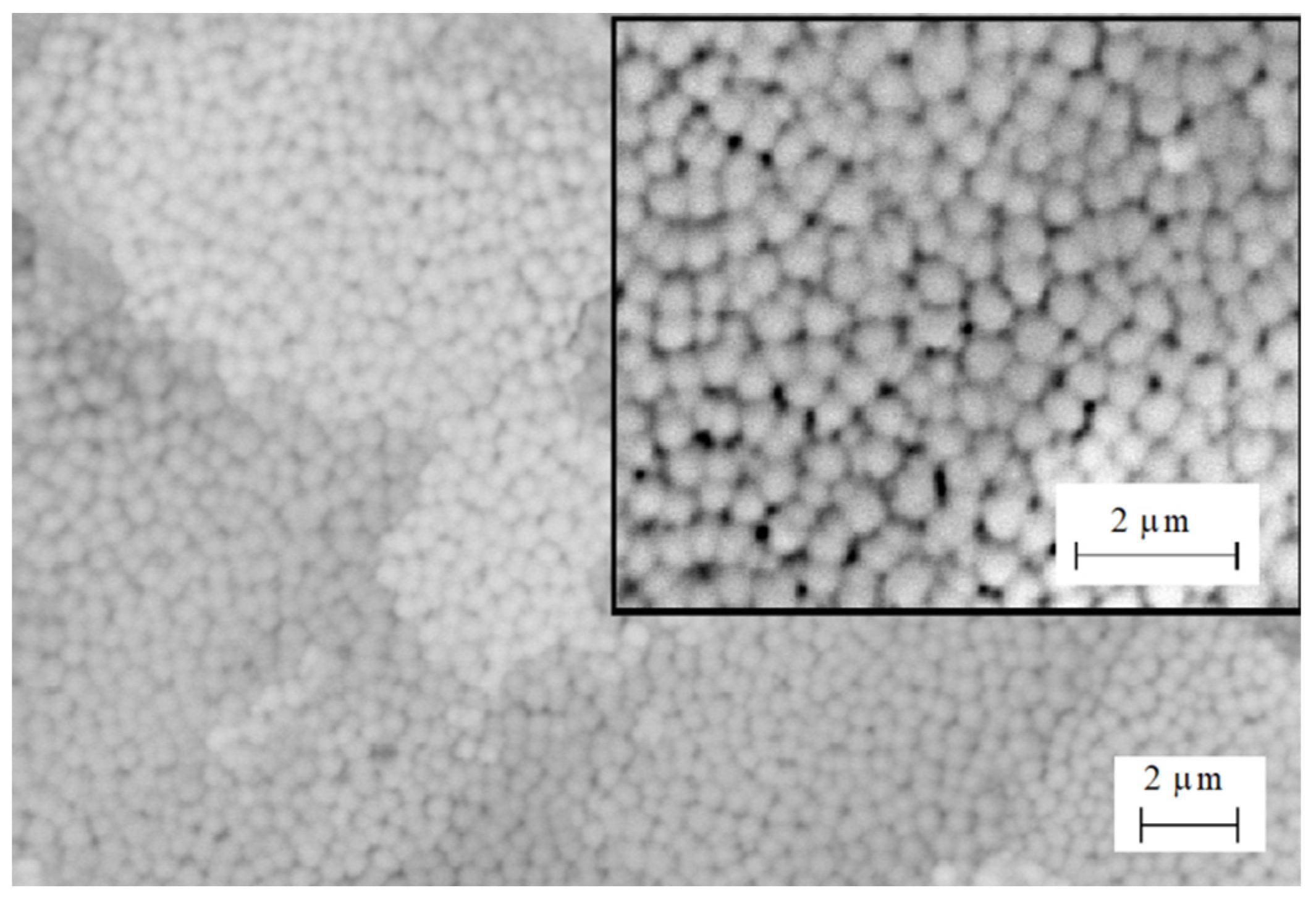

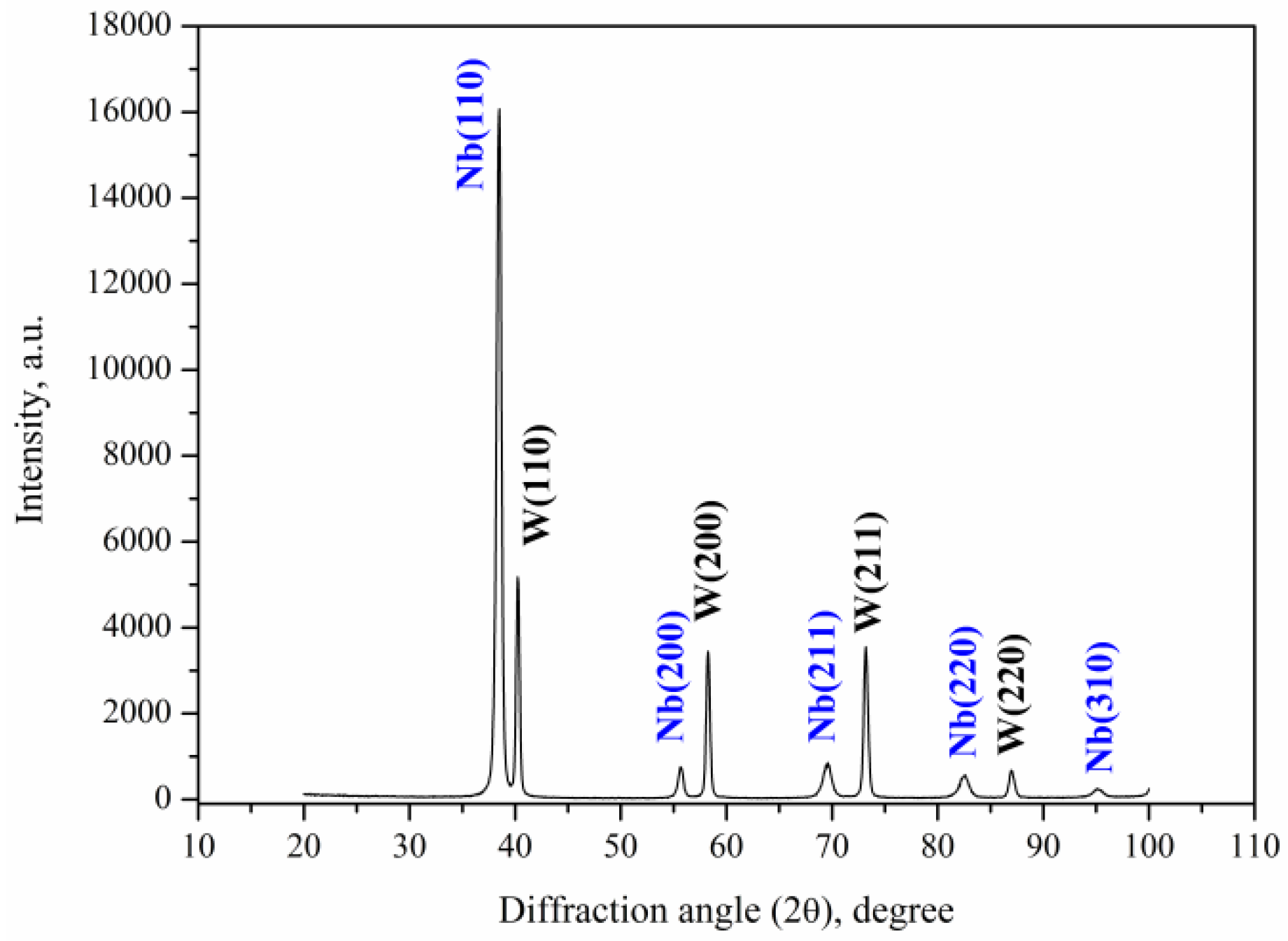

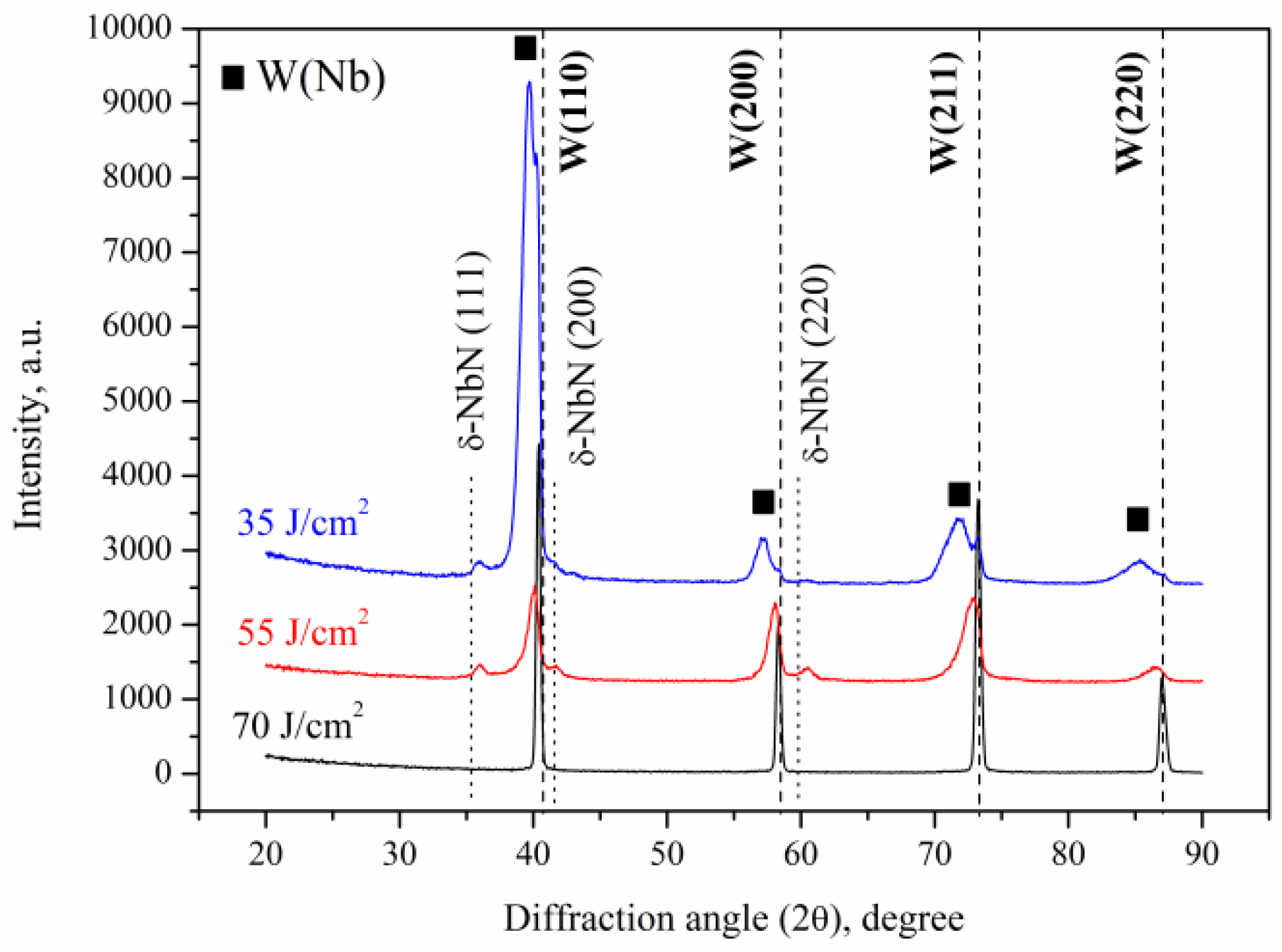

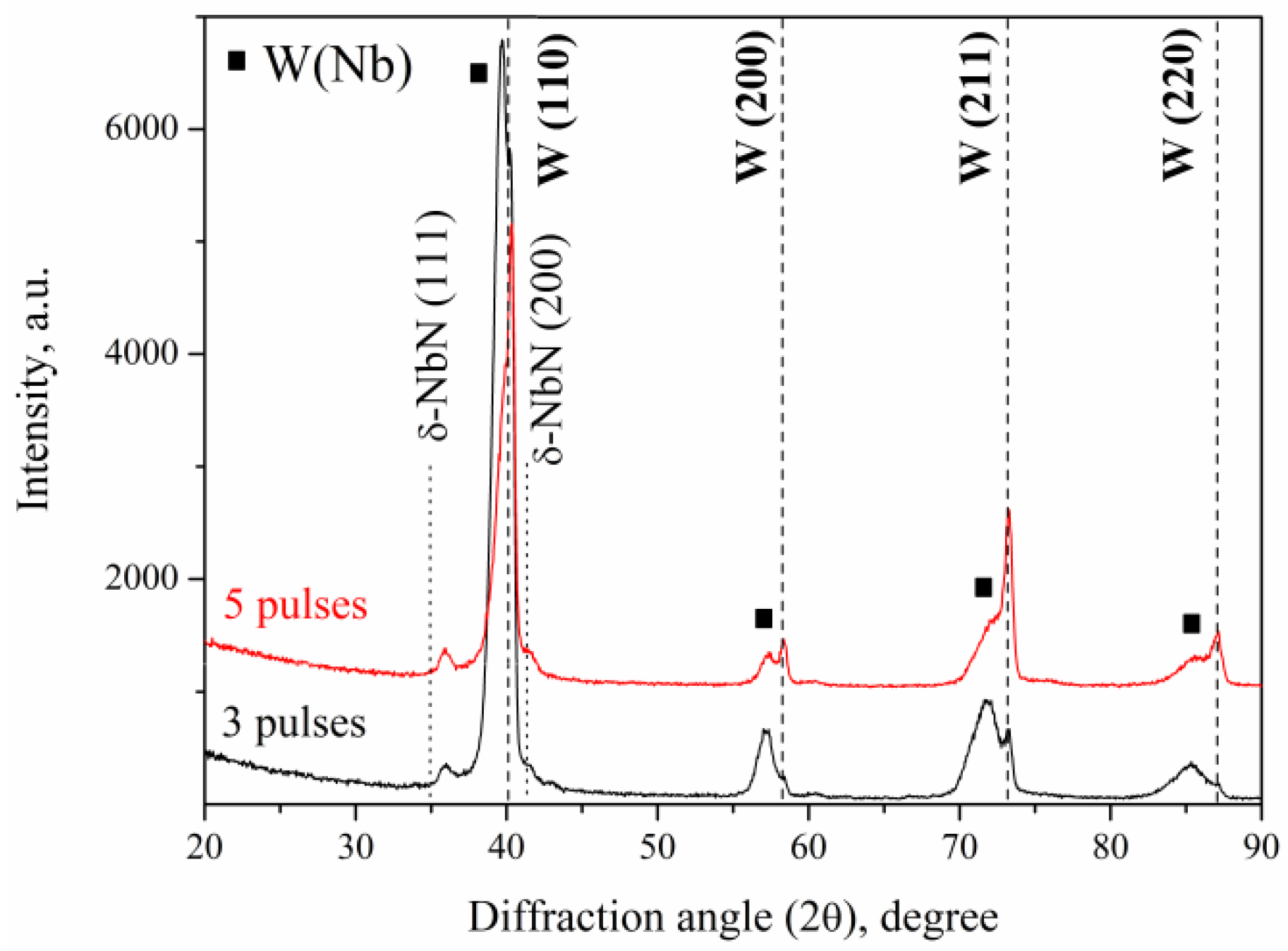

3.2. Structure and Phase Composition

4. Discussion

5. Conclusions

- The plasma treatment melted the niobium coating and a part of the tungsten substrate that made it possible to mix both liquid layers and produce a WNb alloy.

- The composition of the alloy was determined by the relation between the thicknesses of the melted layers and, as a result, by the absorbed energy density. The plasma flow with the absorbed energy density in the range of 35–55 J/cm2 predominantly melted the niobium coating and produced the solid solution W(Nb) in the areas in contact with the tungsten. The lattice parameter of the bcc solid solution W(Nb) depended on the niobium concentration.

- The thickness of the WNb alloy layer increased from 10 to 20 μm with the absorbed energy density rising from 55 to 70 J/cm2. The highest absorbed energy density of 70 J/cm2 provided a uniform niobium distribution in the modified layer with the niobium concentration of 4 at.%.

- The plasma treatment with the absorbed energy density from 55 to 70 J/cm2 can be effectively used for solid solution W(Nb) production in tungsten. This mode of the treatment provides melting of the top layer without the intense evaporation of niobium.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nogami, S.; Watanabe, S.; Reiser, J.; Rieth, M.; Sickinger, S.; Hasegawa, A. A Review of Impact Properties of Tungsten Materials. Fusion Eng. Des. 2018, 135, 196–203. [Google Scholar] [CrossRef]

- Fukuda, M.; Hasegawa, A.; Nogami, S. Thermal Properties of Pure Tungsten and Its Alloys for Fusion Applications. Fusion Eng. Des. 2018, 132, 1–6. [Google Scholar] [CrossRef]

- Coenen, J.W.; Mao, Y.; Almanstötter, J.; Calvo, A.; Sistla, S.; Gietl, H.; Jasper, B.; Riesch, J.; Rieth, M.; Pintsuk, G.; et al. Advanced Materials for a Damage Resilient Divertor Concept for DEMO: Powder-Metallurgical Tungsten-Fiber Reinforced Tungsten. Fusion Eng. Des. 2017, 124, 964–968. [Google Scholar] [CrossRef]

- Bhuyan, M.; Mohanty, S.R.; Rao, C.V.S.; Rayjada, P.A.; Raole, P.M. Plasma Focus Assisted Damage Studies on Tungsten. Appl. Surf. Sci. 2013, 264, 674–680. [Google Scholar] [CrossRef]

- Wang, K.; Bannister, M.E.; Meyer, F.W.; Parish, C.M. Effect of Starting Microstructure on Helium Plasma-Materials Interaction in Tungsten. Acta Mater. 2017, 124, 556–567. [Google Scholar] [CrossRef]

- Reiser, J.; Garrison, L.; Greuner, H.; Hoffmann, J.; Weingärtner, T.; Jäntsch, U.; Klimenkov, M.; Franke, P.; Bonk, S.; Bonnekoh, C.; et al. Ductilisation of Tungsten (W): Tungsten Laminated Composites. Int. J. Refract. Met. Hard Mater. 2017, 69, 66–109. [Google Scholar] [CrossRef]

- Ren, C.; Fang, Z.Z.; Koopman, M.; Butler, B.; Paramore, J.; Middlemas, S. Methods for Improving Ductility of Tungsten—A Review. Int. J. Refract. Met. Hard Mater. 2018, 75, 170–183. [Google Scholar] [CrossRef]

- Gong, X.; Fan, J.; Ding, F. Tensile Mechanical Properties and Fracture Behavior of Tungsten Heavy Alloys at 25–1100 °C. Mater. Sci. Eng. A 2015, 646, 315–321. [Google Scholar] [CrossRef]

- Daoush, W.M.; Yao, J.; Shamma, M.; Morsi, K. Ultra-Rapid Processing of High-Hardness Tungsten-Copper Nanocomposites. Scr. Mater. 2016, 113, 246–249. [Google Scholar] [CrossRef]

- Mazrouei, S.A.; Mohanta, A.; Shymanski, V.I.; Matras, G.; Kasmi, C. Chromium Doped Tungsten Alloy for Plasma-Facing Components of Fusion Reactors Formed by Compression Plasma Flows. J. Phys. Conf. Ser. 2022, 2368, 012025. [Google Scholar] [CrossRef]

- Shymanski, V.I.; Cherenda, N.N.; Uglov, V.V.; Astashynski, V.M.; Kuzmitski, A.M. Structure and Phase Composition of Nb/Ti System Subjected to Compression Plasma Flow Impact. Surf. Coat. Technol. 2015, 278, 183–189. [Google Scholar] [CrossRef]

- Shymanski, V.I.; Uglov, V.V.; Cherenda, N.N.; Pigasova, V.S.; Astashynski, V.M.; Kuzmitski, A.M.; Zhong, H.W.; Zhang, S.J.; Le, X.Y.; Remnev, G.E. Structure and Phase Composition of Tungsten Alloys Modified by Compression Plasma Flows and High-Intense Pulsed Ion Beam Impacts. Appl. Surf. Sci. 2019, 491, 43–52. [Google Scholar] [CrossRef]

- Chen, J.-B.; Luo, L.-M.; Zhao, M.-L.; Xu, Q.; Zan, X.; Wu, Y.-C. Investigation of Microstructure and Irradiation Behavior of W-Nb/Ti Composites Prepared by Spark Plasma Sintering. Fusion Eng. Des. 2016, 112, 349–354. [Google Scholar] [CrossRef]

- Xu, M.-Y.; Luo, L.-M.; Zhou, Y.-F.; Zan, X.; Xu, Y.; Xu, Q.; Tokunaga, K.; Zhu, X.-Y.; Wu, Y.-C. Helium Irradiation Behavior of Tungsten-Niobium Alloys under Different Ion Energies. Fusion Eng. Des. 2018, 132, 7–12. [Google Scholar] [CrossRef]

- Das, J.; Appa Rao, G.; Pabi, S.K.; Sankaranarayana, M.; Nandy, T.K. Oxidation studies on W-Nb alloy. Int. J. Refract. Met. Hard Mater. 2014, 47, 25–37. [Google Scholar] [CrossRef]

- Uglov, V.V.; Anishchik, V.M.; Astashynski, V.V.; Astashynski, V.M.; Ananin, S.I.; Askerko, V.V.; Kostyukevich, E.A.; Kuz’mitski, A.M.; Kvasov, N.T.; Danilyuk, A.L. The Effect of Dense Compression Plasma Flow on Silicon Surface Morphology. Surf. Coat. Technol. 2002, 158, 273–276. [Google Scholar] [CrossRef]

- Qin, Y.; Zou, J.; Dong, C.; Wang, X.; Wu, A.; Liu, Y.; Hao, S.; Guan, Q. Temperature-stress fields and related phenomena induced by a high current pulsed electron beam. Nucl. Instrum. Methods Phys. Res. B 2004, 225, 544–554. [Google Scholar] [CrossRef]

- Zhu, X.K.; Chao, Y.J. Numerical simulation of transient temperature and residual stresses in friction stir welding of 304L stainless steel. J. Mater. Process. Technol. 2004, 146, 263–272. [Google Scholar] [CrossRef]

- Kovalev, A.A.; Zhvavyi, S.P.; Zykov, G.L. Dynamics of laser-induced phase transition in cadmium telluride. Phys. Tech. Semicond. 2005, 39, 1345–1349. (In Russia) [Google Scholar] [CrossRef]

- Villars, P. Nb-W Binary Phase Diagram 0–100 at.% W. PAULING FILE in: Inorganic Solid Phases, Springer Materials. Available online: https://materials.springer.com/isp/phase-diagram/docs/c_0901730 (accessed on 20 March 2023).

- Brandes, E.A.; Brook, G.B. (Eds.) Smithells Metals Reference Book, 7th ed.; Elsevier Butterworth-Heinemann: Oxford, UK, 1992; ISBN 978-0-08-051730-8. [Google Scholar]

- Rotshtein, V.P.; Proskurovsky, D.I.; Ozur, G.E.; Ivanov, Y.F.; Markov, A.B. Surface Modification and Alloying of Metallic Materials with Low-Energy High-Current Electron Beams. Surf. Coat. Technol. 2004, 180, 377–381. [Google Scholar] [CrossRef]

- Yan, S.; Le, X.Y.; Zhao, W.J.; Shang, Y.J.; Wang, Y.; Xue, J. Study of Metal Film/Substrate Mixing by Intense Pulsed Ion Beam. Surf. Coat. Technol. 2007, 201, 4817–4821. [Google Scholar] [CrossRef]

- Tulenbergenov, T.; Skakov, M.; Kolodeshnikov, A.; Zuev, V.; Rakhadilov, B.; Sokolov, I.; Ganovichev, D.; Miniyazov, A.; Bukina, O. Interaction between Nitrogen Plasma and Tungsten. Nucl. Mater. Energy 2017, 13, 63–67. [Google Scholar] [CrossRef]

| Q, J/cm2 | Temperature Gradient Near the Surface (dT/dx), 107 K/m | Cooling Rate Near the SURFACE (dT/dt), 108 K/s |

|---|---|---|

| 35 | 2.1 | 1.2 |

| 55 | 3.2 | 2.0 |

| 70 | 4.2 | 2.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ryskulov, A.; Shymanski, V.; Uglov, V.; Ivanov, I.; Astashynski, V.; Amanzhulov, B.; Kuzmitski, A.; Kurakhmedov, A.; Filipp, A.; Ungarbayev, Y.; et al. Structure and Phase Composition of WNb Alloy Formed by the Impact of Compression Plasma Flows. Materials 2023, 16, 4445. https://doi.org/10.3390/ma16124445

Ryskulov A, Shymanski V, Uglov V, Ivanov I, Astashynski V, Amanzhulov B, Kuzmitski A, Kurakhmedov A, Filipp A, Ungarbayev Y, et al. Structure and Phase Composition of WNb Alloy Formed by the Impact of Compression Plasma Flows. Materials. 2023; 16(12):4445. https://doi.org/10.3390/ma16124445

Chicago/Turabian StyleRyskulov, Azamat, Vitaliy Shymanski, Vladimir Uglov, Igor Ivanov, Valiantsin Astashynski, Bauyrzhan Amanzhulov, Anton Kuzmitski, Alisher Kurakhmedov, Andrei Filipp, Yerulan Ungarbayev, and et al. 2023. "Structure and Phase Composition of WNb Alloy Formed by the Impact of Compression Plasma Flows" Materials 16, no. 12: 4445. https://doi.org/10.3390/ma16124445

APA StyleRyskulov, A., Shymanski, V., Uglov, V., Ivanov, I., Astashynski, V., Amanzhulov, B., Kuzmitski, A., Kurakhmedov, A., Filipp, A., Ungarbayev, Y., & Koloberdin, M. (2023). Structure and Phase Composition of WNb Alloy Formed by the Impact of Compression Plasma Flows. Materials, 16(12), 4445. https://doi.org/10.3390/ma16124445