Development and Promotion of Concrete Strength at Initial 24 Hours

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Concrete Mixture and Sample Preparation

2.3. Test Methods

3. Results and Discussion

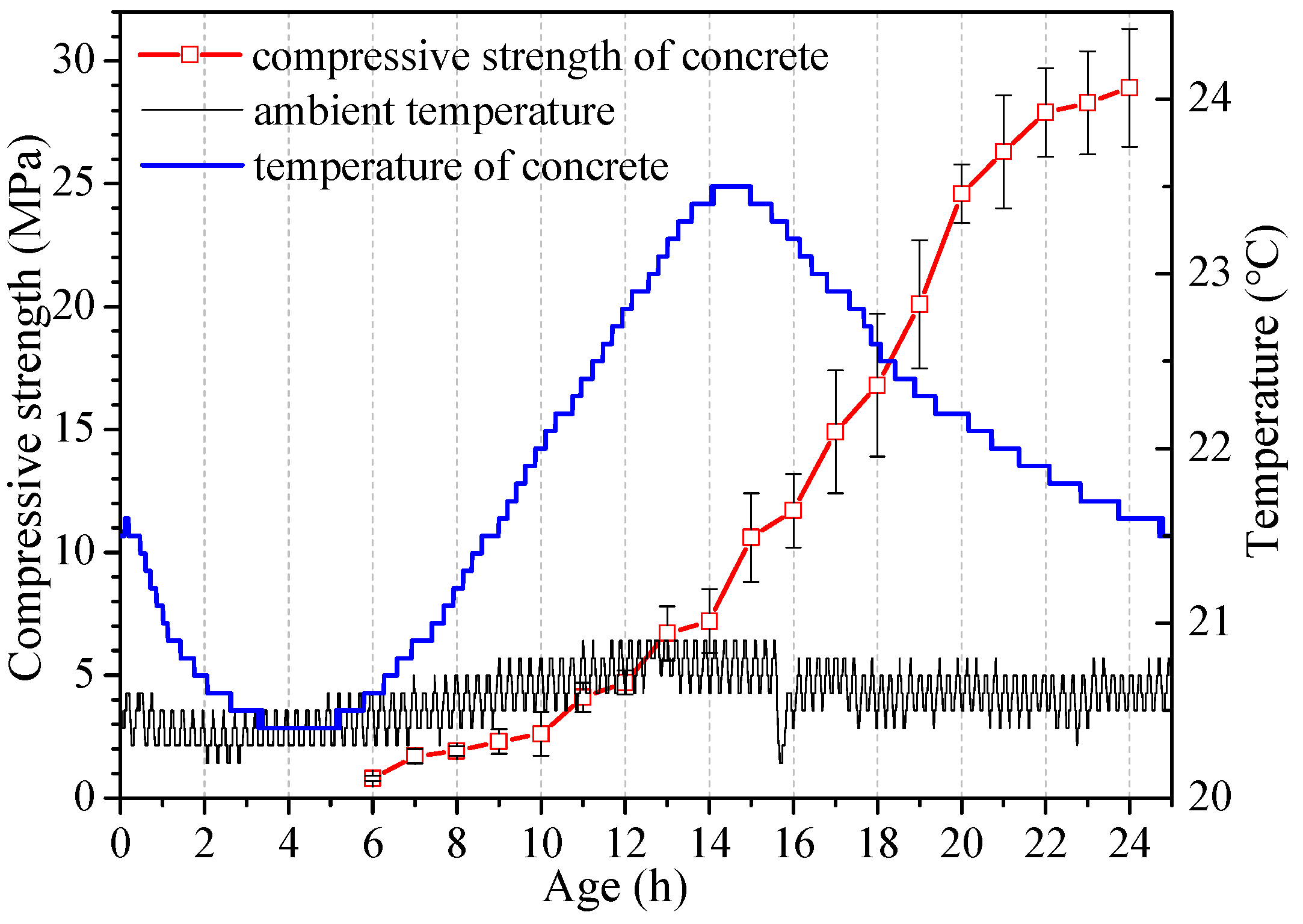

3.1. Strength Development and Temperature Variation of Concrete within 1 d

3.2. Effect of Factors on Strength Development

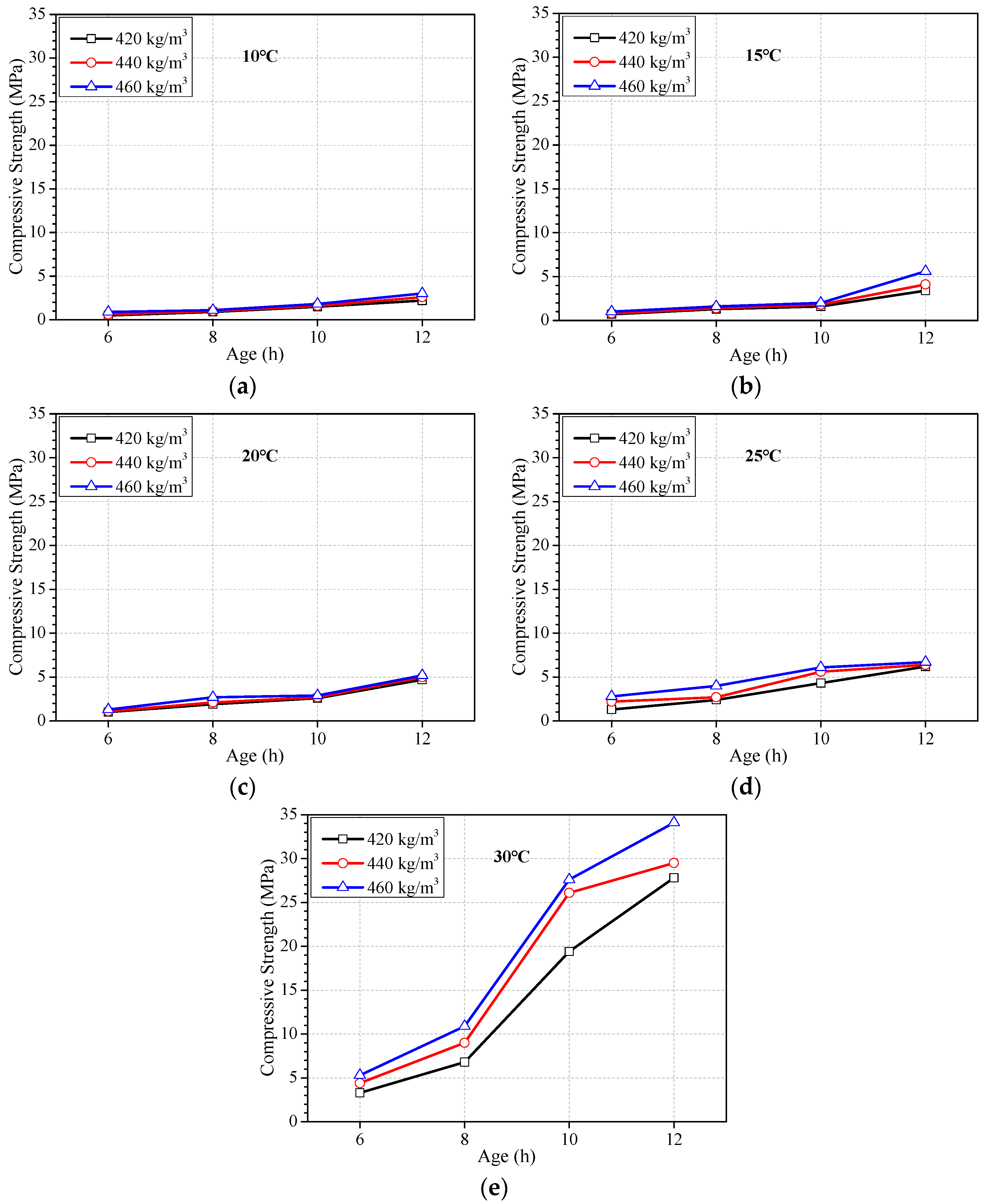

- (1)

- Increasing content of Portland cement

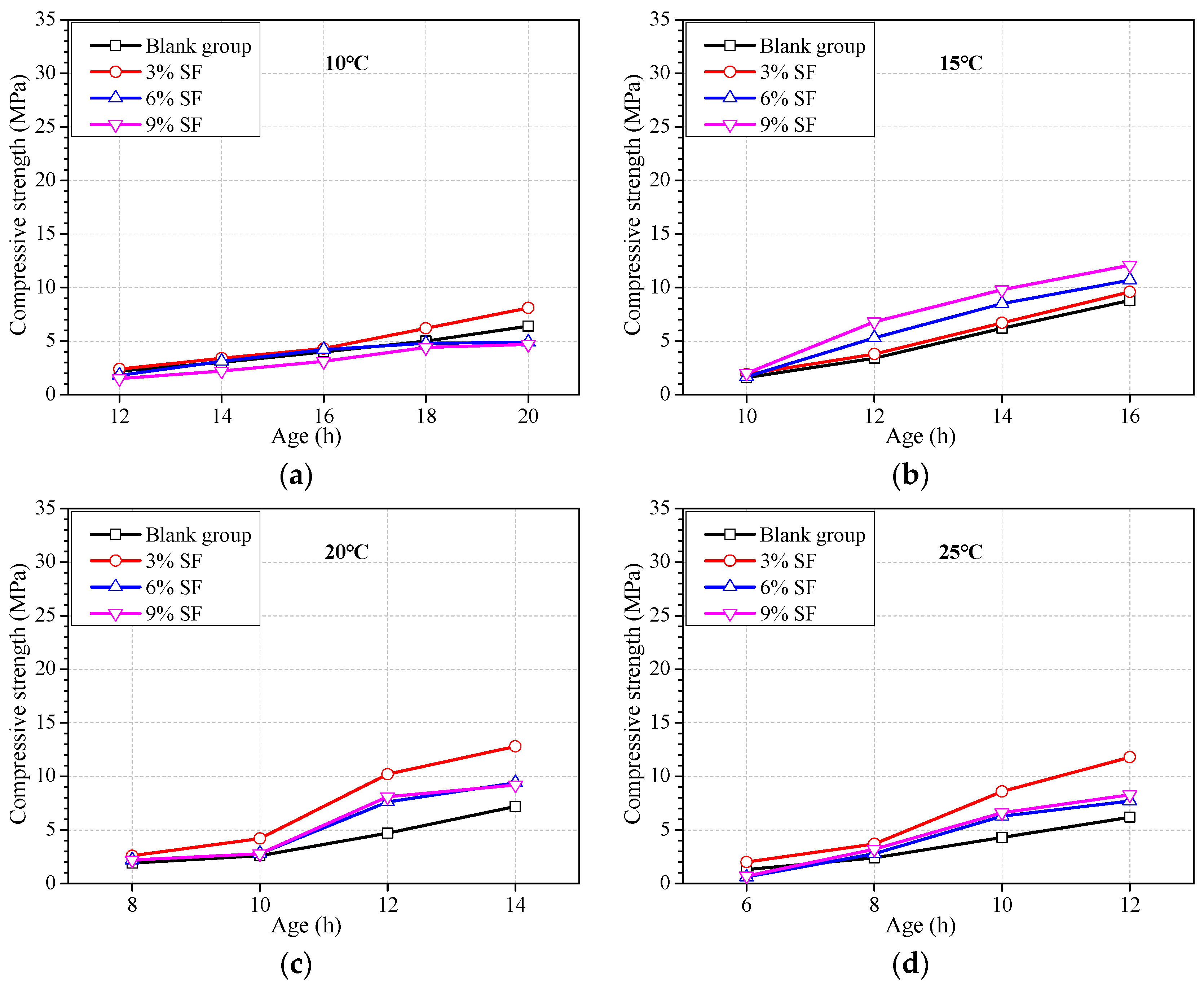

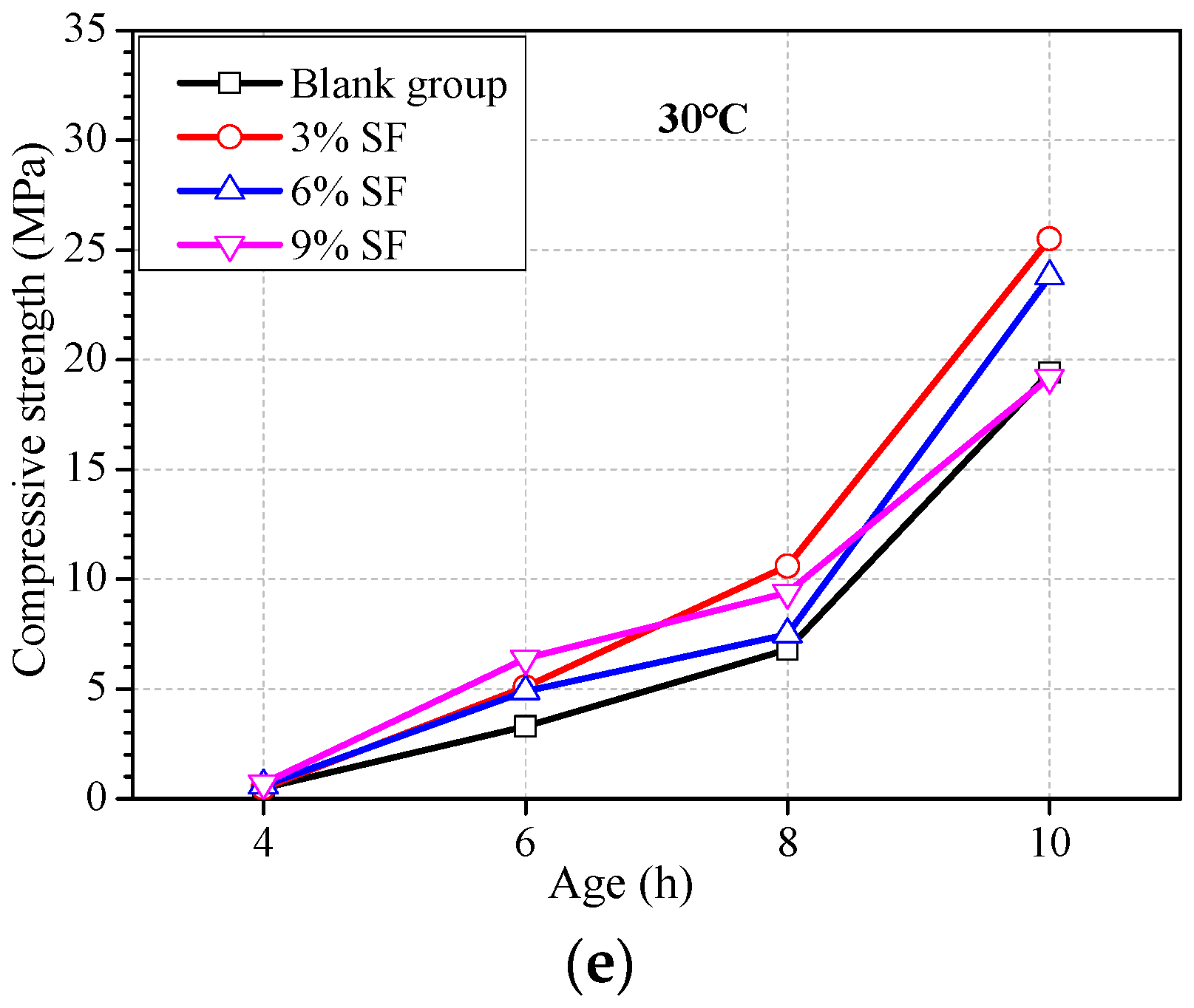

- (2)

- Addition of SF

- (3)

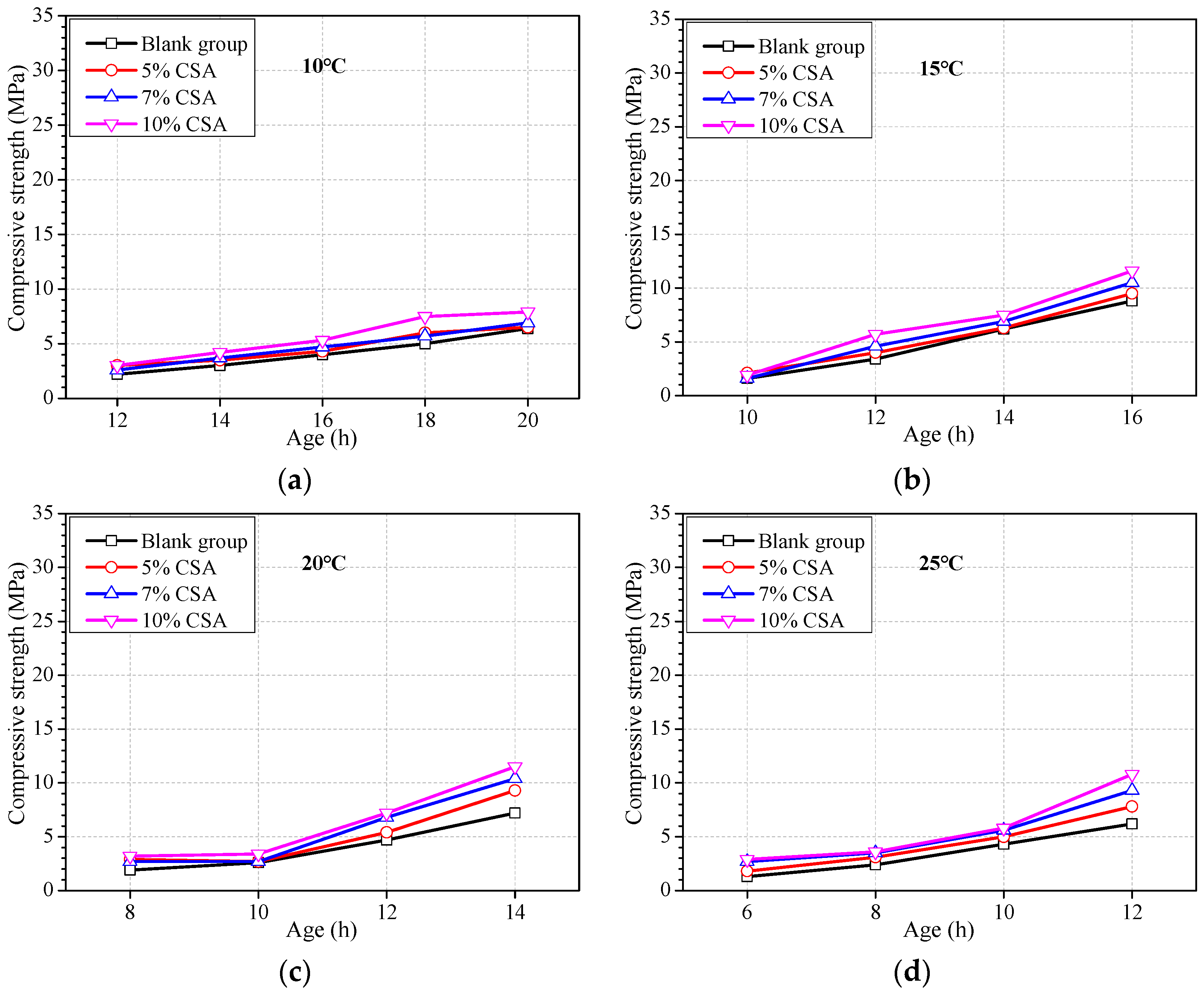

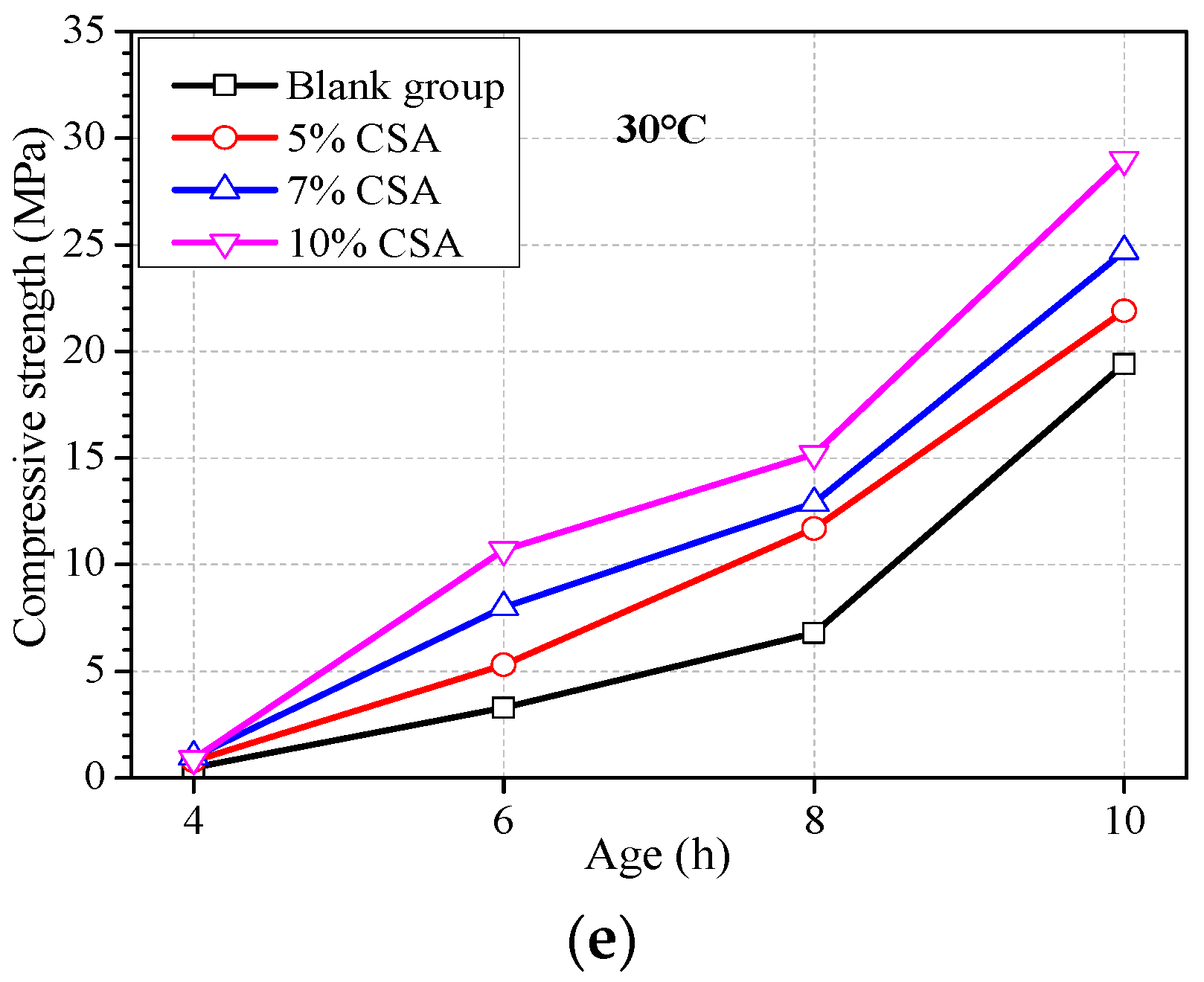

- Addition of calcium sulfoaluminate cement (CSA)

- (4)

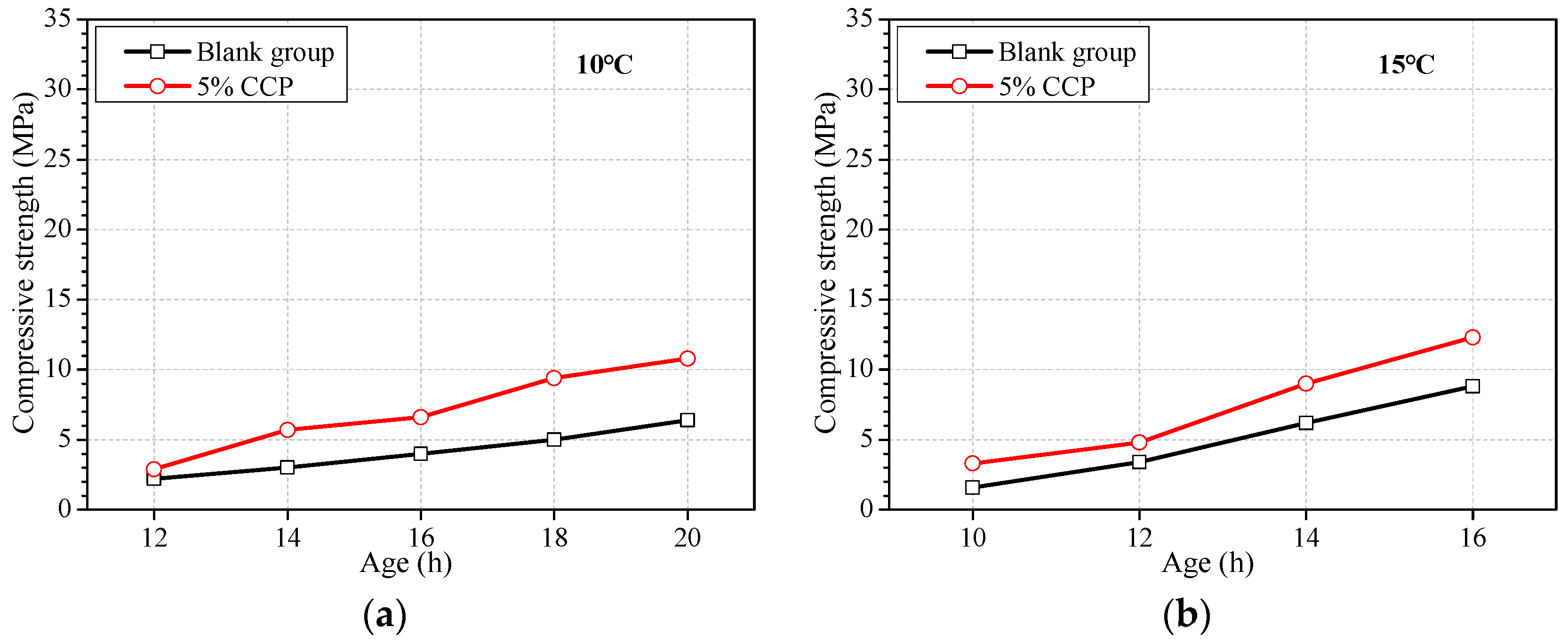

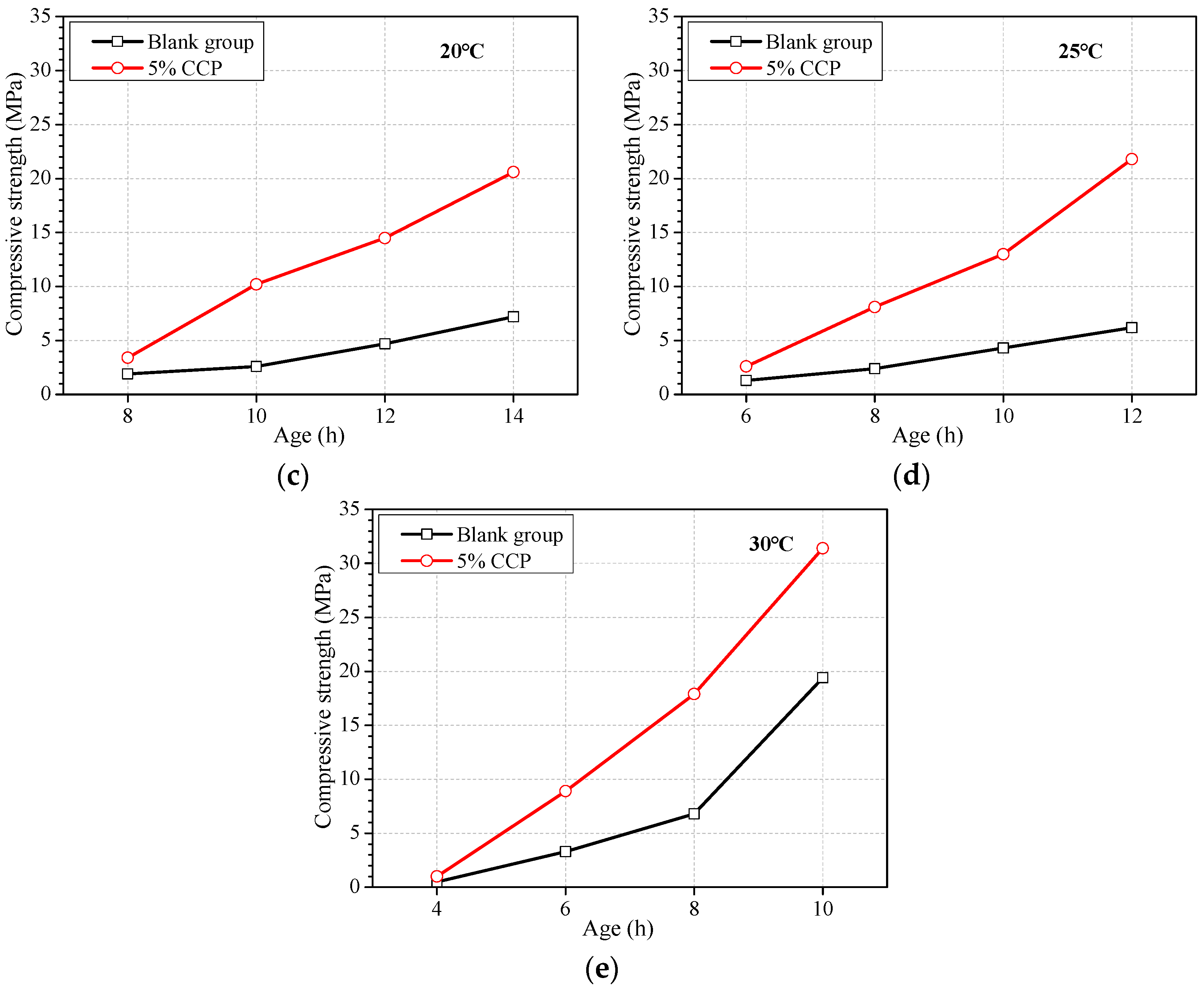

- Addition of early strength agent

- (5)

- Discussion

3.3. Microanalysis

- (1)

- XRD

- (2)

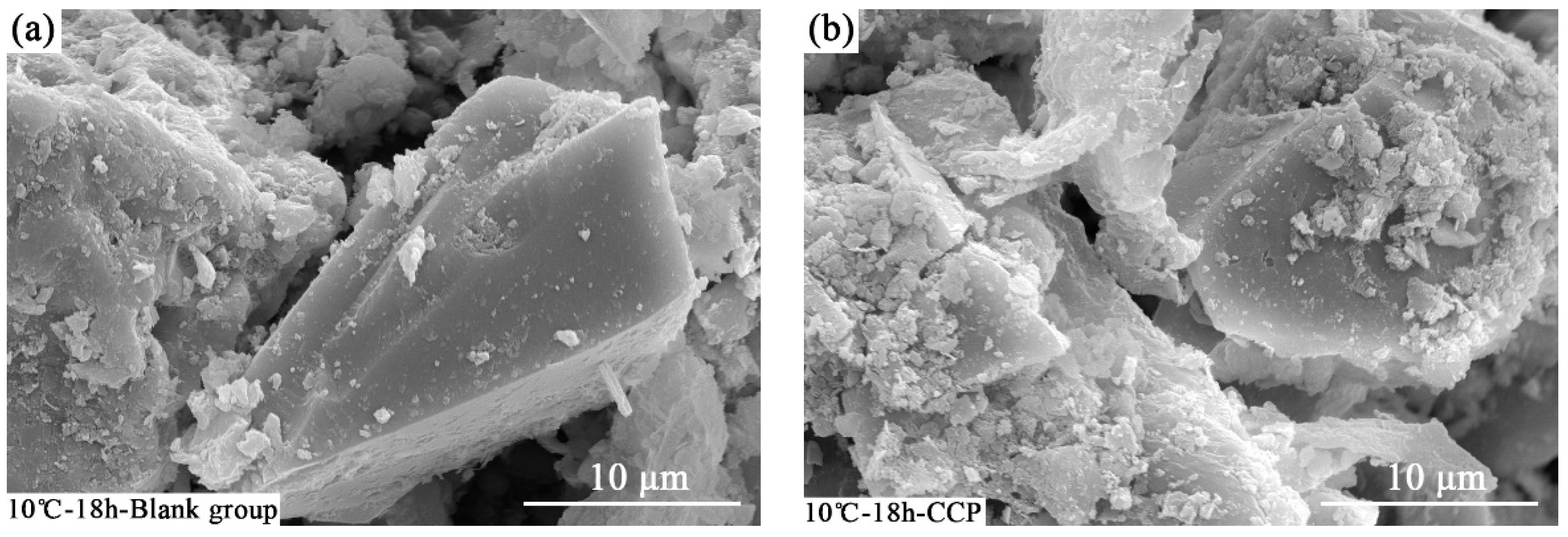

- SEM

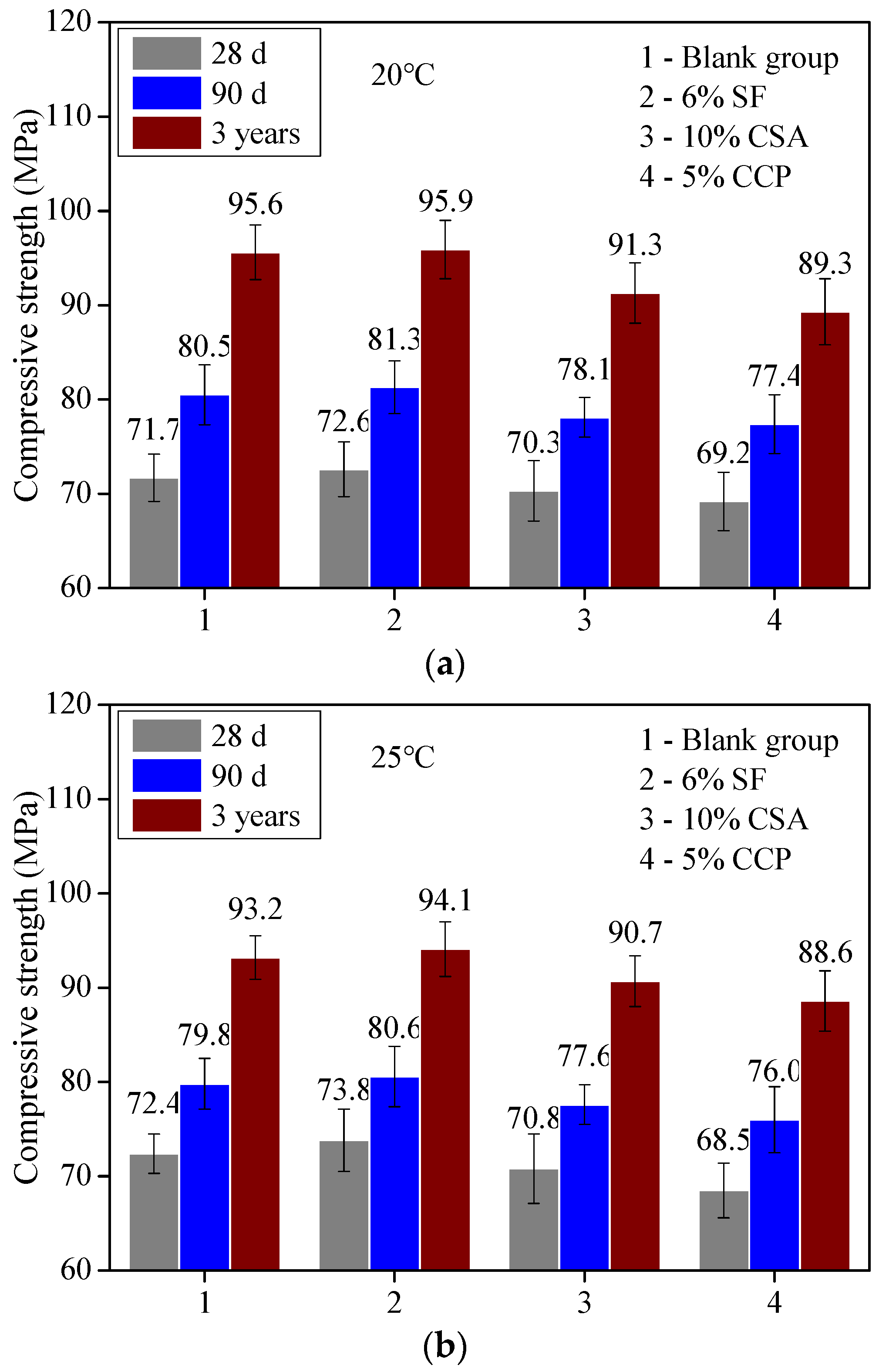

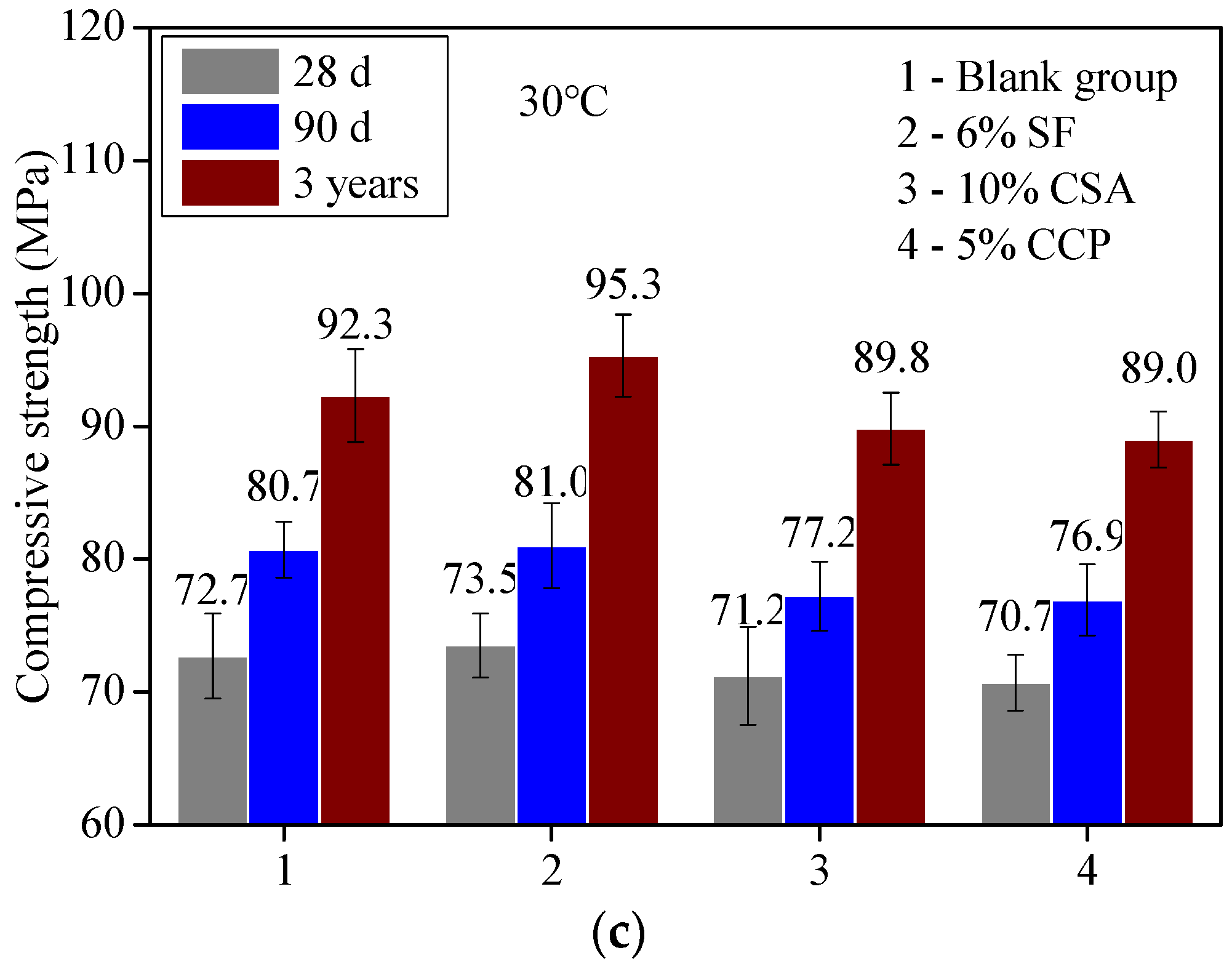

3.4. Long-Term Properties

- (1)

- Effect of measures for promoting earlier strength on the long-term strength of concrete

- (2)

- Effect of measures for promoting earlier strength on chloride migration coefficient

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aitcin, P. Cements of yesterday and today concrete of tomorrow. Cem. Concr. Res. 2000, 30, 1349–1359. [Google Scholar] [CrossRef]

- Damme, H. Concrete material science: Past, present, and future innovations. Cem. Concr. Res. 2018, 112, 5–24. [Google Scholar] [CrossRef]

- Xu, D.; Cui, Y.; Li, H.; Yang, K.; Xu, W.; Chen, Y. On the future of Chinese cement industry. Cem. Concr. Res. 2015, 78, 2–13. [Google Scholar] [CrossRef]

- Juenger, M.; Siddique, R. Recent advances in understanding the role of supplementary cementitious materials in concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Wembe, J.; Ngueyep, L.; Moukete, E.; Eslammi, J.; Pliya, P.; Ndjaka, J.; Noumowe, A. Physical, mechanical properties and microstructure of concretes made with natural and crushed aggregates: Application in building construction. Clean. Mater. 2023, 7, 100173. [Google Scholar] [CrossRef]

- Cheung, J.; Roberts, L.; Liu, J. Admixtures and sustainability. Cem. Concr. Res. 2018, 114, 79–89. [Google Scholar] [CrossRef]

- Liu, J.; Yu, C.; Shu, X.; Ran, Q.; Yang, Y. Recent advance of chemical admixtures in concrete. Cem. Concr. Res. 2019, 124, 105834. [Google Scholar] [CrossRef]

- Scrivener, K.; Kirkpatrick, R. Innovation in use and research on cementitious material. Cem. Concr. Res. 2008, 38, 128–136. [Google Scholar] [CrossRef]

- Dushimimana, A.; Niyonsenga, A.; Nzamurambaho, F. A review on strength development of high performance concrete. Constr. Build. Mater. 2021, 307, 124865. [Google Scholar] [CrossRef]

- Nunez, I.; Marani, A.; Flah, M.; Nehdi, M. Estimating compressive strength of modern concrete mixtures using computational intelligence: A systematic review. Constr. Build. Mater. 2021, 310, 125279. [Google Scholar] [CrossRef]

- Abasi, A.; Sadhu, A.; Dunphy, K.; Banting, B. Evaluation of tensile properties of early-age concrete-block masonry assemblages. Constr. Build. Mater. 2023, 369, 130542. [Google Scholar] [CrossRef]

- Esfeh, S.; Rong, H.; Dong, W.; Zhang, B. Experimental investigation on bond behaviours of deformed steel bars embedded in early age concrete under biaxial lateral pressures at low curing temperatures. Constr. Build. Mater. 2021, 303, 124419. [Google Scholar] [CrossRef]

- Orozco, C.; Babel, S.; Tangtermsirikul, S.; Sugiyama, T. Understanding the environmental, economic, and social impact of fly ash utilization on early-age high-strength mass concrete using life cycle analysis. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Kosmatka, S.; Wilson, M. Design and Control of Concrete Mixtures; Portland Cement Association: Skokie, IL, USA, 2016; Volume 18. [Google Scholar]

- Mehta, P.; Monteiro, P. Concrete Microstructure, Properties, and Materials, 3rd ed.; The McGraw-Hill Companies: New York, NY, USA, 2006. [Google Scholar]

- Dorn, T.; Blask, O.; Stephan, D. Acceleration of cement hydration—A review of the working mechanisms, effects on setting time, and compressive strength development of accelerating admixtures. Constr. Build. Mater. 2022, 323, 126554. [Google Scholar] [CrossRef]

- Li, D.; Shen, J.; Chen, L.; Wu, X. The influence of fast-setting/early-strength agent on high phosphorous slag content cement. Cem. Concr. Res. 2001, 31, 19–24. [Google Scholar]

- Su, Y.; Wu, L.; He, X.; Zheng, Z.; Tan, H.; Yang, J.; Ma, Q.; Ding, J.; Bao, M. A novel early strength agent prepared by wet-grinding concrete waste slurry and its effect on early hydration and mechanical properties of cement based materials. Constr. Build. Mater. 2023, 362, 129673. [Google Scholar] [CrossRef]

- Zou, F.; Hu, C.; Wang, F.; Ruan, Y.; Hu, S. Enhancement of early-age strength of the high content fly ash blended cement paste by sodium sulfate and C-S-H seeds towards a greener binder. J. Clean. Prod. 2020, 244, 118566. [Google Scholar] [CrossRef]

- Zhang, F.; Bai, Y.; Cai, Y.; Chen, B.; Ning, F. Early Hydration and Microstructure of Cement Pastes Mixed with Low-Temperature Early Strength Accelerator at 5 °C. J. Chin. Ceram. Soc. 2020, 48, 211–221. [Google Scholar]

- Zhang, J.; Ye, C.; Tan, H.; Liu, X. Potential application of Portland cement—sulfoaluminate cement system in precast concrete cured under ambient temperature. Constr. Build. Mater. 2020, 251, 118869. [Google Scholar] [CrossRef]

- Tan, H.; Li, M.; Ren, J.; Deng, X.; Zhang, X.; Nie, K.; Zhang, J.; Yu, Z. Effect of aluminum sulfate on the hydration of tricalcium silicate. Constr. Build Mater. 2019, 205, 414–424. [Google Scholar] [CrossRef]

- Pelletier, L.; Winnefeld, F.; Lothenbach, B. The ternary system Portland cement—calcium sulphoaluminate clinker—anhydrite: Hydration mechanism and mortar properties. Cem. Concr. Compos. 2010, 32, 497–507. [Google Scholar] [CrossRef]

- Pelletier-Chaignat, L.; Winnefeld, F.; Lothenbach, B.; Saout, G.; Müller, C.; Famy, C. Influence of the calcium sulphate source on the hydration mechanism of Portland cement—calcium sulphoaluminate clinke—calcium sulphate binders. Cem. Concr. Compos. 2011, 33, 551–561. [Google Scholar] [CrossRef]

- Prasittisopin, L.; Sereewatthanawut, I. Dissolution, nucleation, and crystal growth mechanism of calcium aluminate cement. J. Sustain. Cen.-Based Mater. 2019, 8, 180–197. [Google Scholar] [CrossRef]

- Bideci, Ö.; Yılmaz, H.; Gencel, O.; Bideci, A.; Çomak, B.; Nodehi, M.; Ozbakkaloglu, T. Fiber-Reinforced lightweight calcium aluminate cement-based concrete: Effect of exposure to elevated temperatures. Sustainability 2013, 15, 4722. [Google Scholar] [CrossRef]

- Kanchanason, V.; Plank, J. Effectiveness of a calcium silicate hydrate—polycarboxylate ether (C-S-H-PCE) nanocomposite on early strength development of fly ash cement. Constr. Build. Mater. 2018, 169, 20–27. [Google Scholar] [CrossRef]

- Grrit, L.; Dietmar, S. Controlling cement hydration with nanoparticles. Cem. Concr. Compos. 2015, 57, 64–67. [Google Scholar]

- Norhasri, M.; Hamidah, M.; Fadzil, A. Applications of using nano material in concrete: A review. Constr. Build. Mater. 2017, 133, 91–97. [Google Scholar] [CrossRef]

- Abhilash, P.; Nayak, D.; Sangoju, B.; Kumar, R.; Kumar, V. Effect of nano-silica in concrete; a review. Constr. Build. Mater. 2021, 278, 122347. [Google Scholar]

- John, E.; Matschei, T.; Stephan, D. Nucleation seeding with calcium silicate hydrate—A review. Cement Concr. Res. 2018, 113, 74–85. [Google Scholar] [CrossRef]

- Land, G.; Stephan, D. The effect of synthesis conditions on the efficiency of C-S-H seeds to accelerate cement hydration. Cement Concr. Compos. 2018, 87, 73–78. [Google Scholar] [CrossRef]

- Ouyang, X.; Koleva, D.; Ye, G.; Breugel, K. Insights into the mechanisms of nucleation and growth of C-S-H on fillers. Mater. Struct. 2017, 50, 213. [Google Scholar] [CrossRef] [Green Version]

- Hubler, M.; Thomas, J.; Jennings, H. Influence of nucleation seeding on the hydration kinetics and compressive strength of alkali activated slag paste. Cement Concr. Res. 2011, 41, 842–846. [Google Scholar] [CrossRef]

- Jing, G.; Wu, J.; Lei, T.; Wang, S.; Strokova, V.; Nelyubova, V.; Wang, M.; Ye, Z. From graphene oxide to reduced graphene oxide: Enhanced hydration and compressive strength of cement composites. Constr. Build. Mater. 2020, 248, 118699. [Google Scholar] [CrossRef]

- Chintalapudi, K.; Pannem, R. An intense review on the performance of graphene oxide and reduced graphene oxide in an admixed cement system. Constr. Build. Mater. 2020, 259, 120598. [Google Scholar] [CrossRef]

- Zhu, X.; Kang, X. Effect of graphene oxide (GO) on the hydration and dissolution of alite in a synthetic cement system. J. Mater. Sci. 2019, 55, 3419–3433. [Google Scholar] [CrossRef]

- Kang, X.; Zhu, X.; Liu, J.; Shu, X.; Qian, J.; Huang, Y. Hydration of C3A/gypsum composites in the presence of graphene oxide. Mater. Today Commun. 2020, 23, 100889. [Google Scholar] [CrossRef]

- Liu, Y.; Fu, S.; Gao, J.; Yang, Y. Prediction for temperature evolution and compressive strength of non-mass concrete with thermal insulation curing in cold weather. J. Build. Eng. 2020, 32, 101737. [Google Scholar] [CrossRef]

- Zeyad, A.; Tayeh, B.; Adesina, A.; Azevedo, A.; Amin, M.; Hadzima-Nyarko, M.; Agwa, I. Review on effect of steam curing on behavior of concrete. Clean. Mater. 2022, 3, 100042. [Google Scholar] [CrossRef]

- Gallucci, E.; Zhang, X.; Scrivener, K. Effect of temperature on the microstructure of calcium silicate hydrate (CSH). Cem. Concr. Res. 2013, 53, 185–195. [Google Scholar] [CrossRef]

- Hanif, A.; Kim, Y.; Lu, Z.; Park, C. Early-age behavior of recycled aggregate concrete under steam curing regime. J. Clean. Prod. 2017, 152, 103–114. [Google Scholar] [CrossRef]

- Cassagnabère, F.; Escadeillas, G.; Mouret, M. Study of the reactivity of cement/metakaolin binders at early age for specific use in steam cured precast concrete. Constr. Build. Mater. 2009, 23, 775–784. [Google Scholar] [CrossRef]

- Liao, X.; Yan, Q.; Zhang, H.; Zhang, Y.; Zhang, C. Integrating PZT-enabled active sensing with deep learning techniques for automatic monitoring and assessment of early-age concrete strength. Measurement 2023, 211, 112657. [Google Scholar] [CrossRef]

- Gagg, C. Cement and concrete as an engineering material: An historic appraisal and case study analysis. Eng. Fail. Anal. 2014, 40, 114–140. [Google Scholar] [CrossRef]

- Tang, Z.; Lim, Y.; Smith, S.; Mostafa, A.; Lam, A.; Soh, C. Monitoring the curing process of in-situ concrete with piezoelectric-based techniques—A practical application. Struct. Health Monit. 2023, 22, 518–539. [Google Scholar] [CrossRef]

- Wang, F.; Kong, X.; Wang, D.; Wang, Q. The effects of nano-C-S-H with different polymer stabilizers on early cement hydration. J. Am. Ceram. Soc. 2019, 102, 5103–5116. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Standards Press of China: Beijing, China, 2019.

- GB/T 50082-2009; Standard for Test Method of Long-Term Performance and Durability of Ordinary Concrete. Standards Press of China: Beijing, China, 2009.

- Taylor, H. Cement Chemistry, 2nd ed.; Thomas Telford: Telford, UK, 1997; p. 212. [Google Scholar]

- Yan, P.; Zhang, B. Mechanical properties of high strength concrete prepared with different densities of silica fume. J. Chin. Ceram. Soc. 2016, 44, 196–201. [Google Scholar]

- Li, M.; Lan, M.; Chen, Z.; Wang, J.; Cui, S.; Wang, Y. Research on the hydration properties of C4A3-CH2 cement system at different temperatures. Materials 2020, 13, 4000. [Google Scholar]

- Zou, D.; Wnag, K.; Li, H.; Guan, X. Effect of LiAl-layered double hydroxides on hydration of calcium sulfoaluminate cement at low temperature. Constr. Build. Mater. 2019, 223, 910–917. [Google Scholar] [CrossRef]

- Trauchessec, R.; Mechling, J.; Lecomte, A.; Roux, A.; Rolland, B. Hydration of ordinary Portland cement and calcium sulfoaluminate cement blends. Cem. Concr. Compos. 2015, 56, 106–114. [Google Scholar] [CrossRef]

- Pe´ra, J.; Ambroise, J. New applications of calcium sulfoaluminate cement. Cem. Concr. Res. 2004, 34, 671–676. [Google Scholar] [CrossRef]

- Sereewatthanawut, I.; Pansuk, W.; Pheinsusom, P.; Prasittisopin, L. Chloride-induced corrosion of a galvanized steel-embedded calcium sulfoaluminate stucco system. J. Build. Eng. 2021, 44, 103376. [Google Scholar] [CrossRef]

- Bentz, D.; Barrett, T.; Varga, I.; Weiss, J. Relating compressive strength to heat release in mortars. Adv. Civ. Eng. Mater. 2012, 1, 14. [Google Scholar] [CrossRef] [Green Version]

| Sample | CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | MgO | Others |

|---|---|---|---|---|---|---|---|

| OPC | 54.79 | 26.16 | 6.93 | 3.36 | 2.92 | 2.91 | 2.93 |

| SF | 0.13 | 97.87 | 0.06 | 0.08 | 0.61 | 0.66 | 0.59 |

| CSA | 51.17 | 7.63 | 21.76 | 1.93 | 14.72 | 1.61 | 1.18 |

| OPC | Sand | Fine Gravel | Coarse Gravel | Water | PCA |

|---|---|---|---|---|---|

| 426 | 734 | 459 | 689 | 128 | 2.56 |

| OPC | Sand | Fine Gravel | Coarse Gravel | Water | PCA |

|---|---|---|---|---|---|

| 420 | 739 | 462 | 693 | 126 | 2.52 |

| 440 | 729 | 456 | 684 | 132 | 2.64 |

| 460 | 718 | 449 | 674 | 138 | 2.76 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, C.; Qian, J.; Sun, H.; Fan, Y. Development and Promotion of Concrete Strength at Initial 24 Hours. Materials 2023, 16, 4452. https://doi.org/10.3390/ma16124452

Fan C, Qian J, Sun H, Fan Y. Development and Promotion of Concrete Strength at Initial 24 Hours. Materials. 2023; 16(12):4452. https://doi.org/10.3390/ma16124452

Chicago/Turabian StyleFan, Chuanhe, Jueshi Qian, Huaqiang Sun, and Yingru Fan. 2023. "Development and Promotion of Concrete Strength at Initial 24 Hours" Materials 16, no. 12: 4452. https://doi.org/10.3390/ma16124452