Fracture Toughness and Fatigue Crack Growth Analyses on a Biomedical Ti-27Nb Alloy under Constant Amplitude Loading Using Extended Finite Element Modelling

Abstract

:1. Introduction

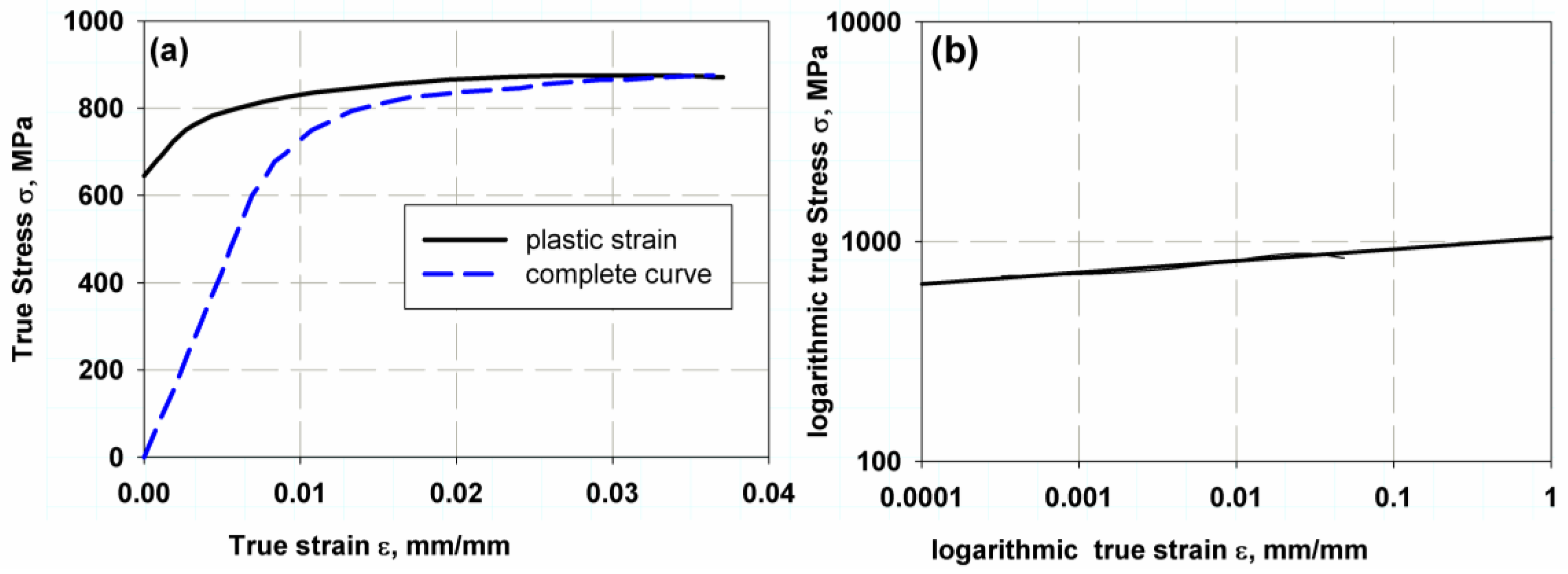

2. Material (Ti-27Nb Alloy)

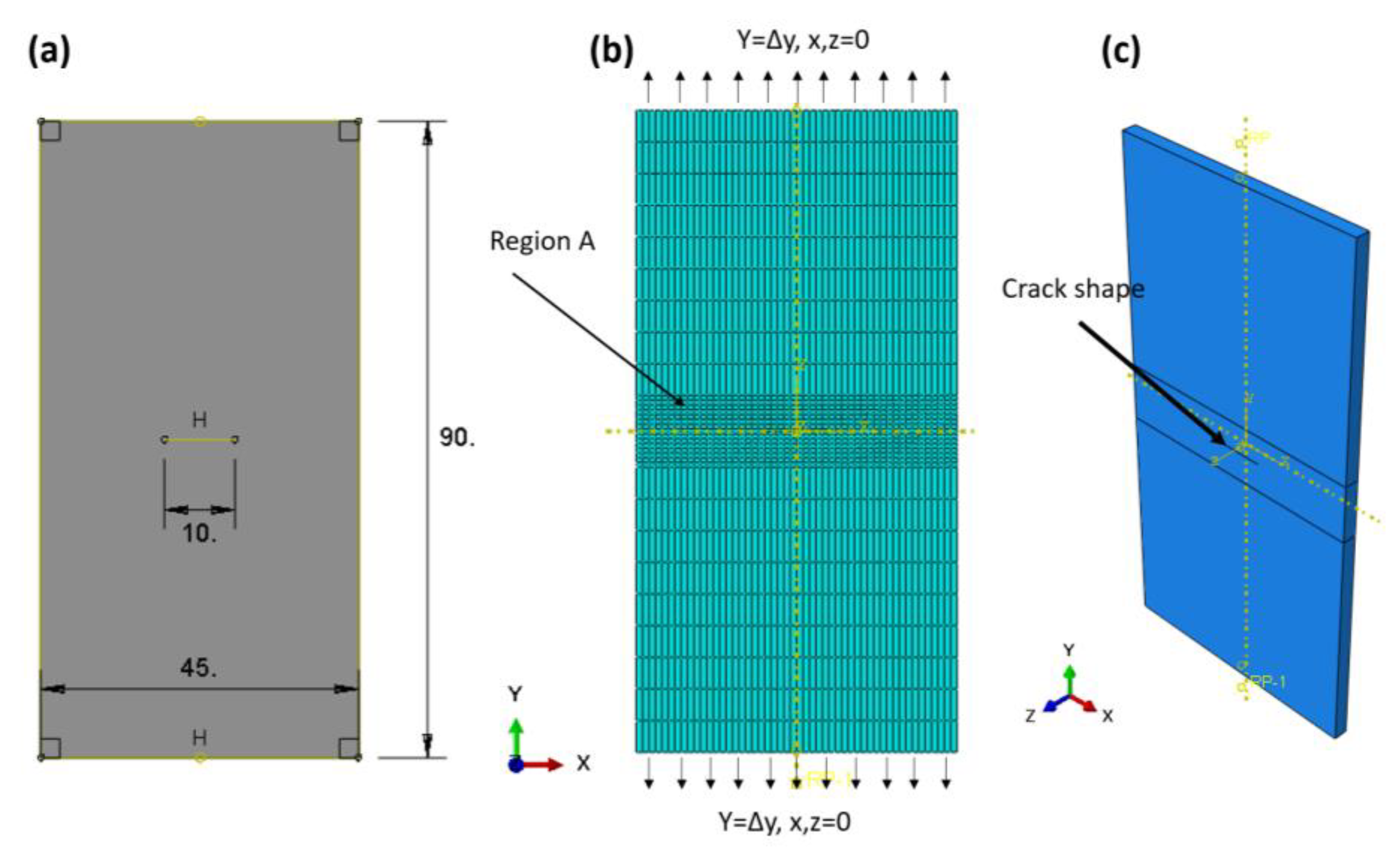

3. Extended Finite Element Method XFEM

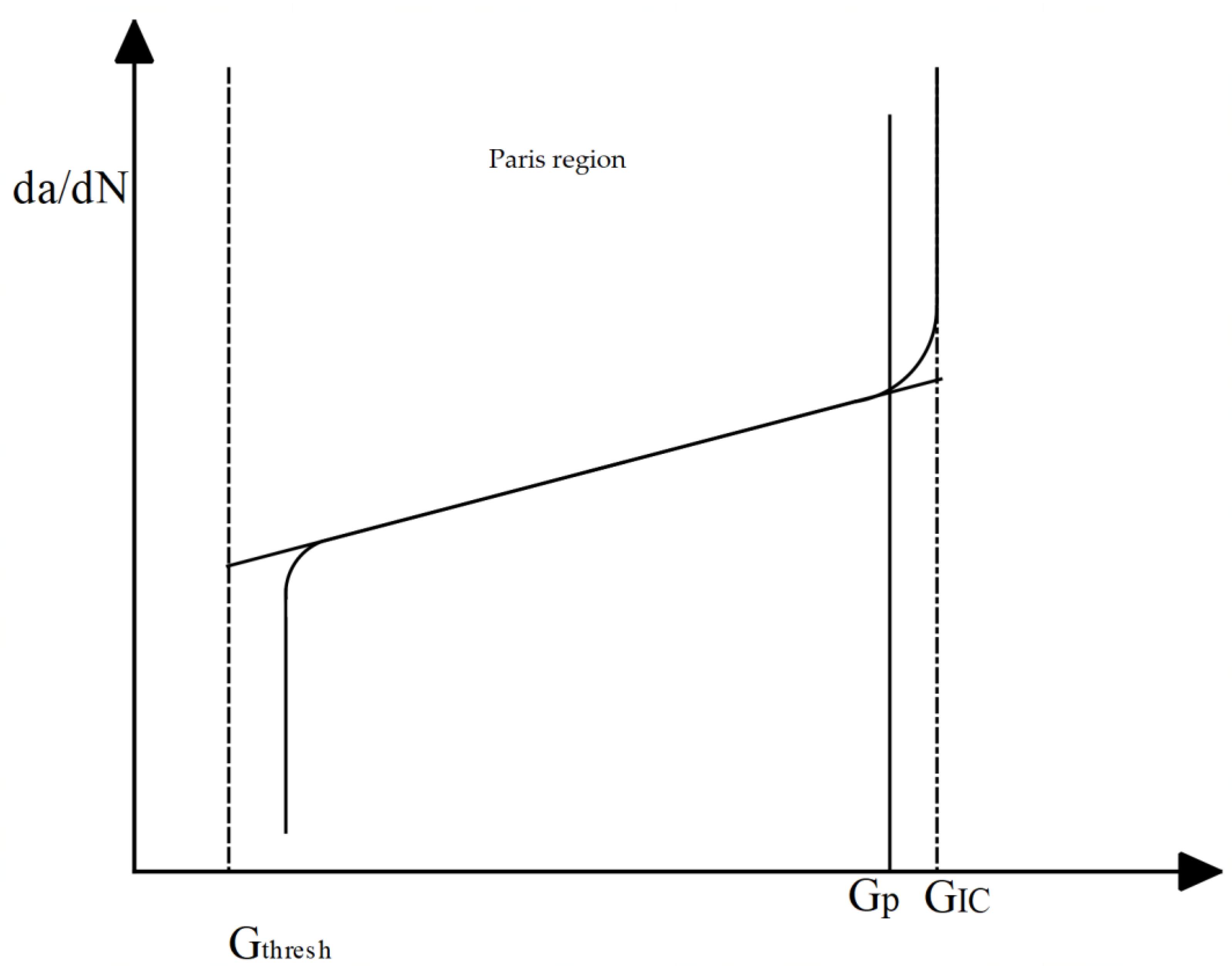

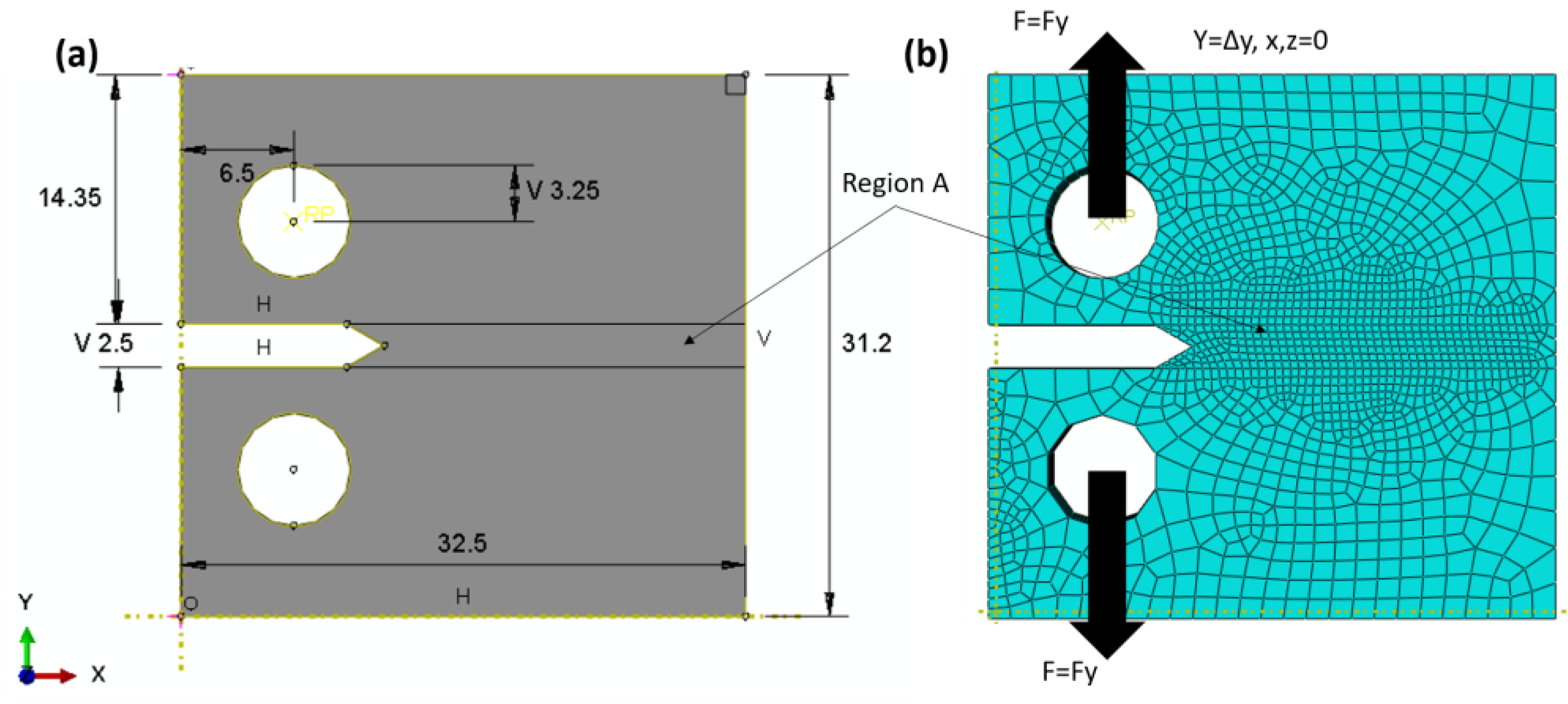

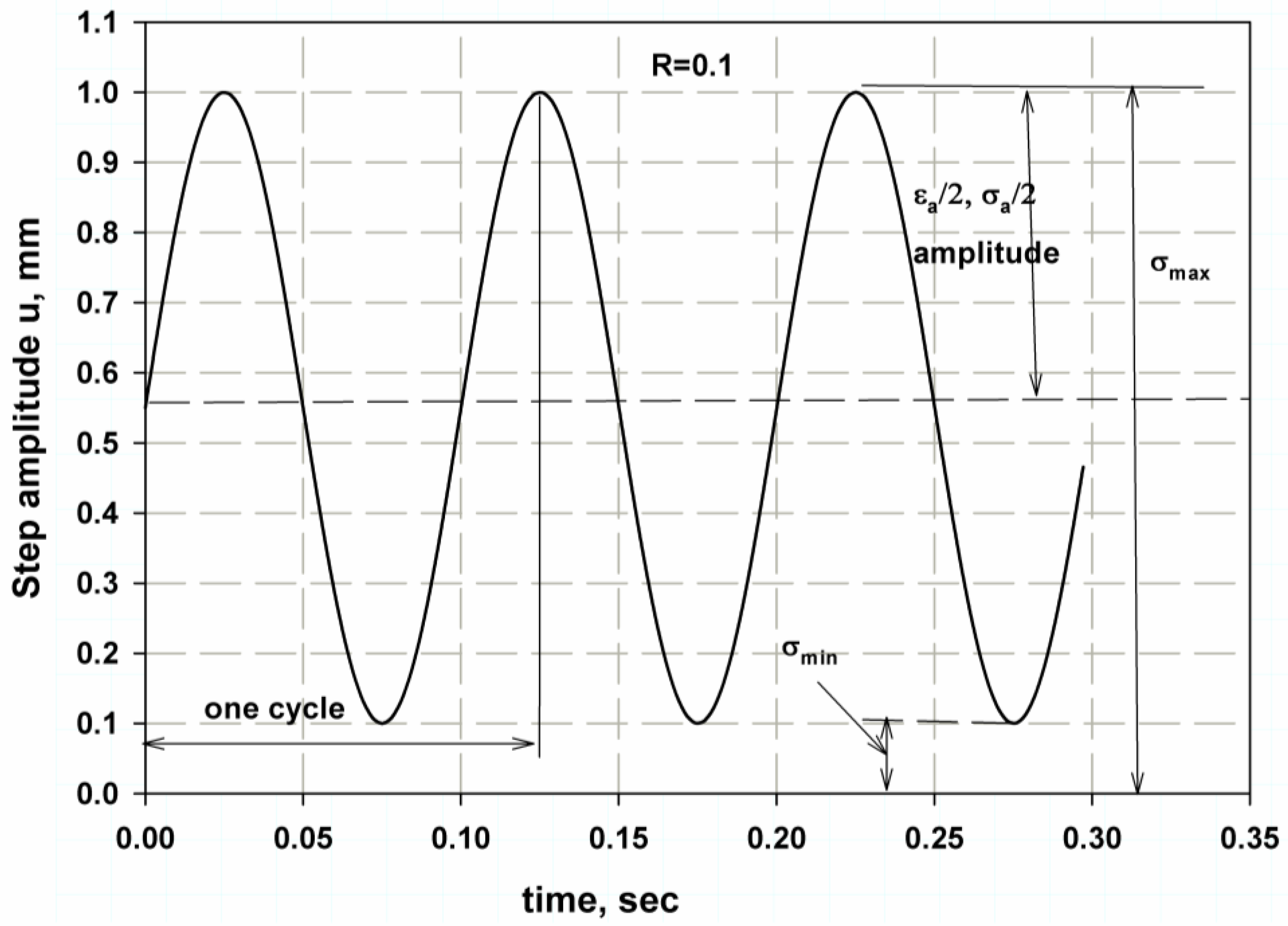

4. Direct Cycle Fatigue

Mesh Convergence and Mesh Refinement

5. Results and Discussion

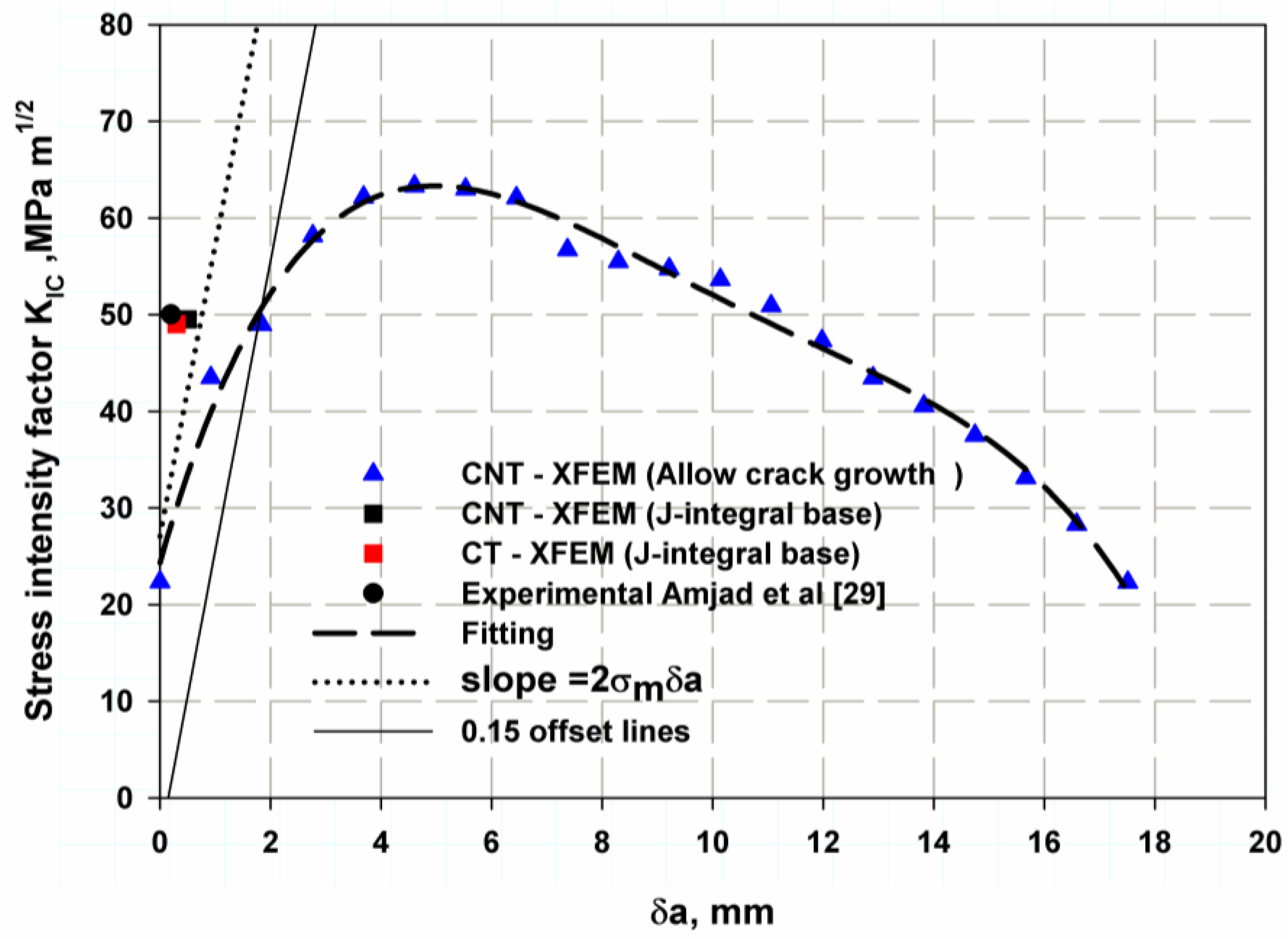

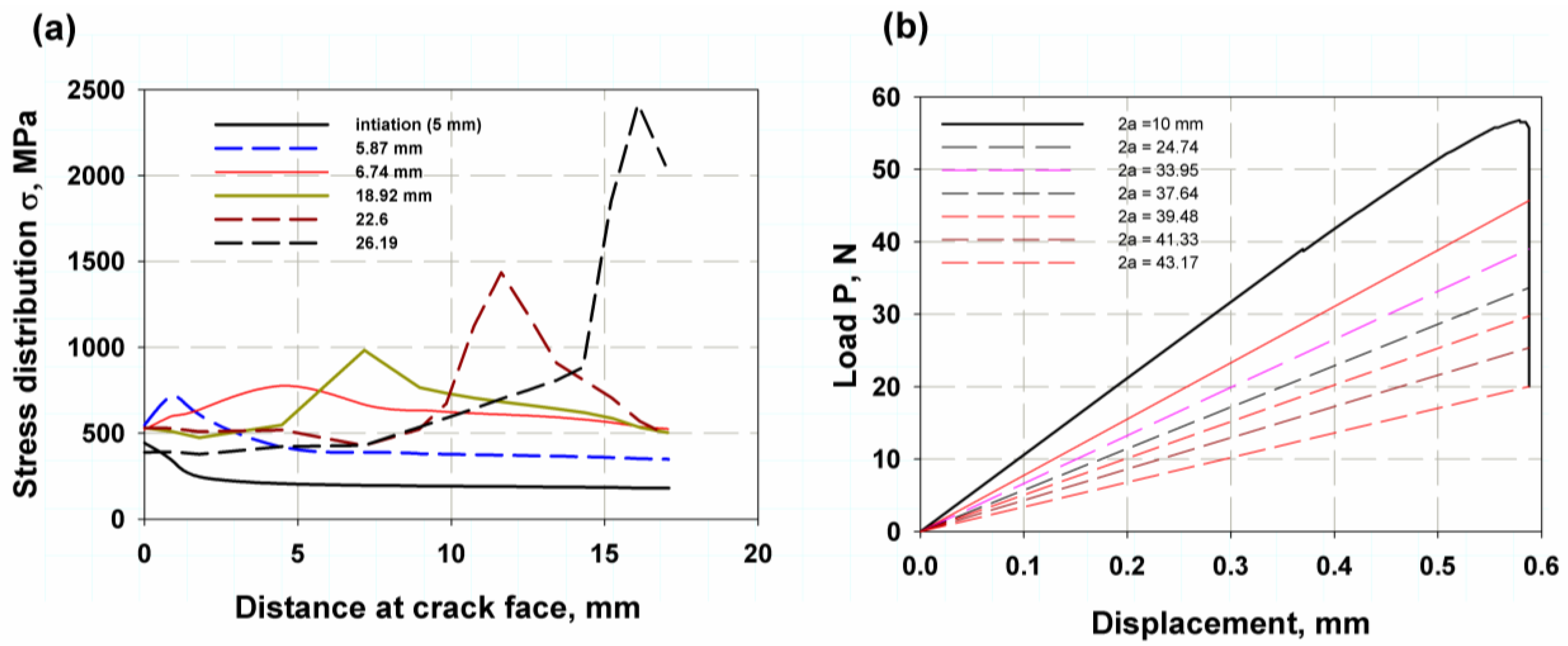

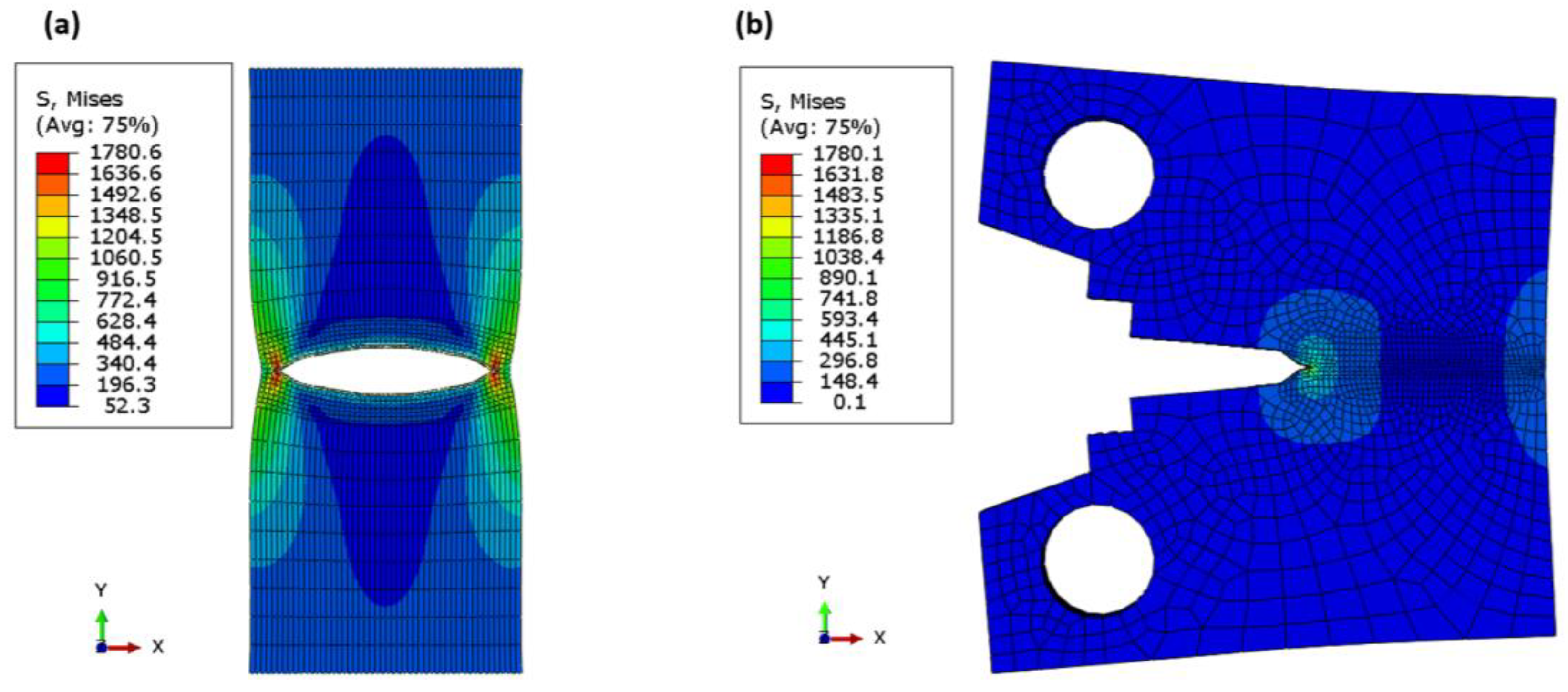

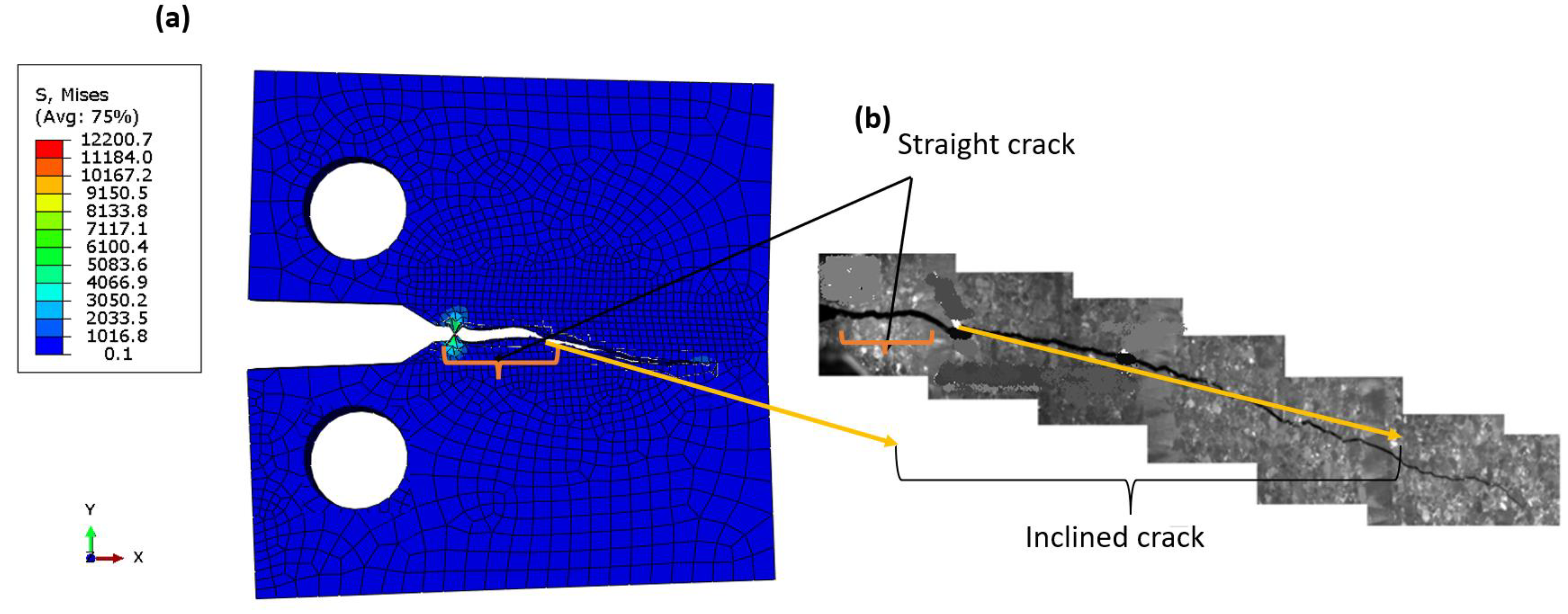

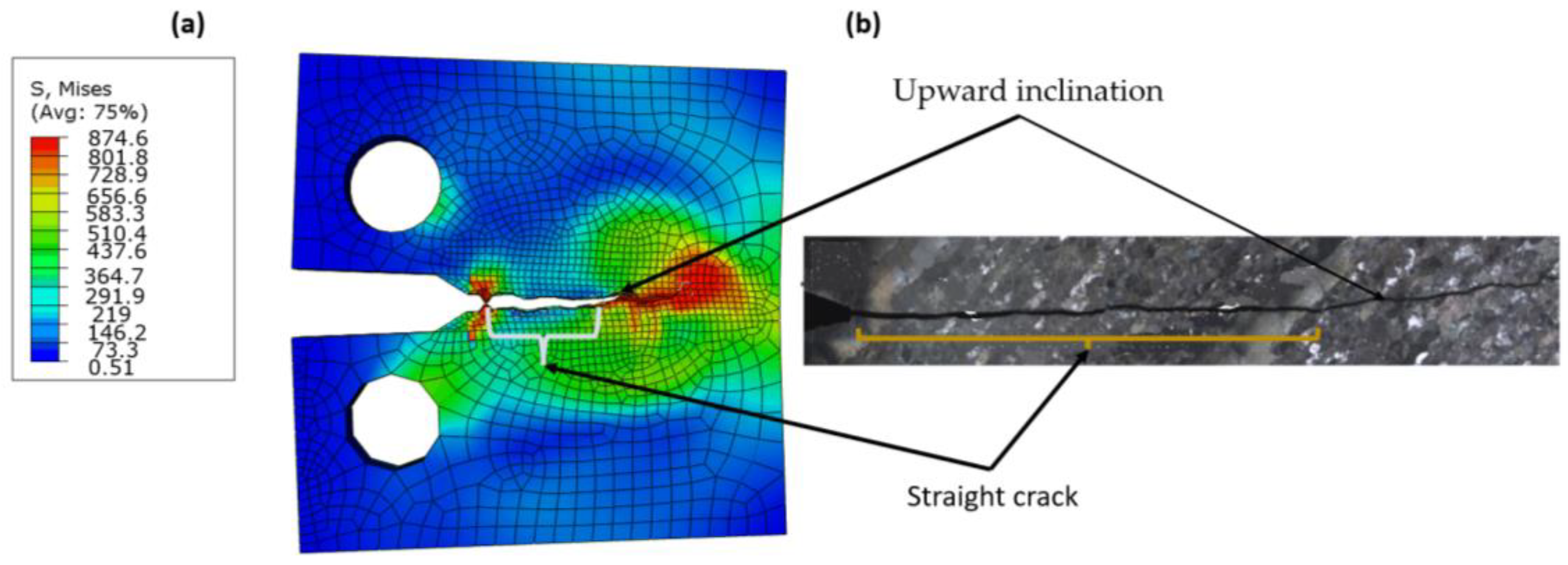

5.1. Facture Toughness

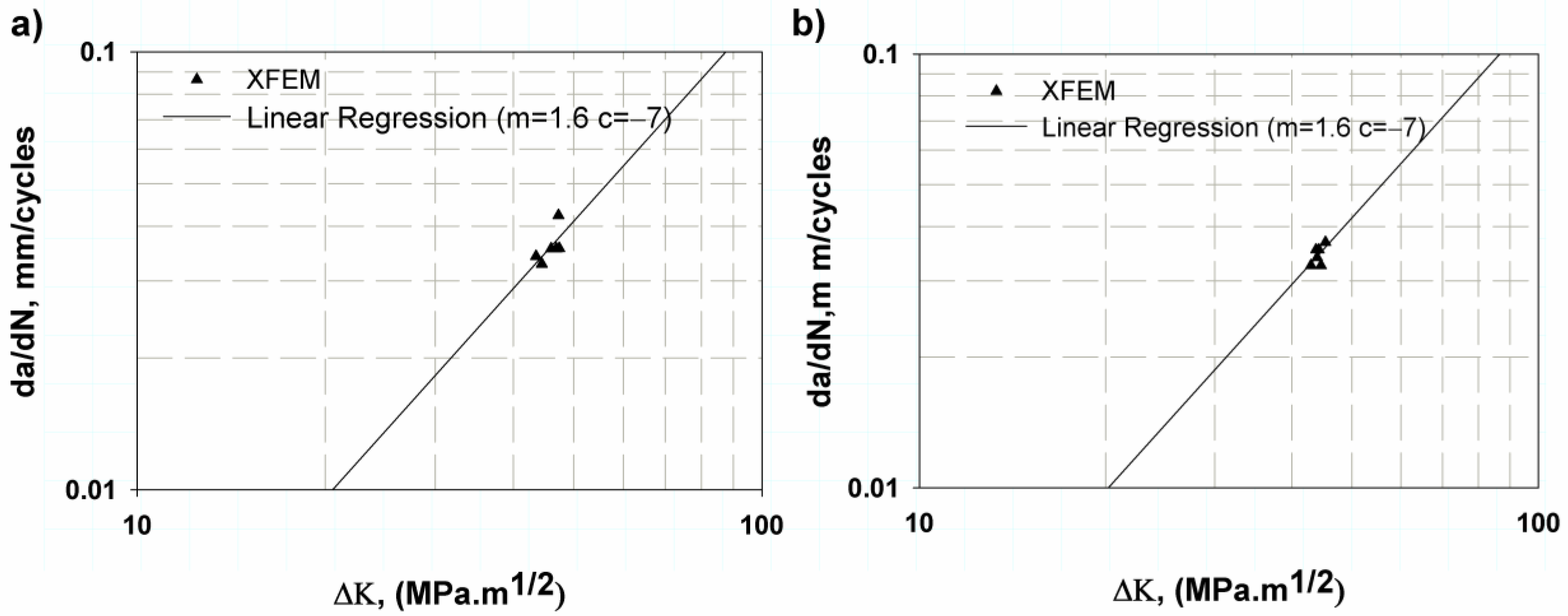

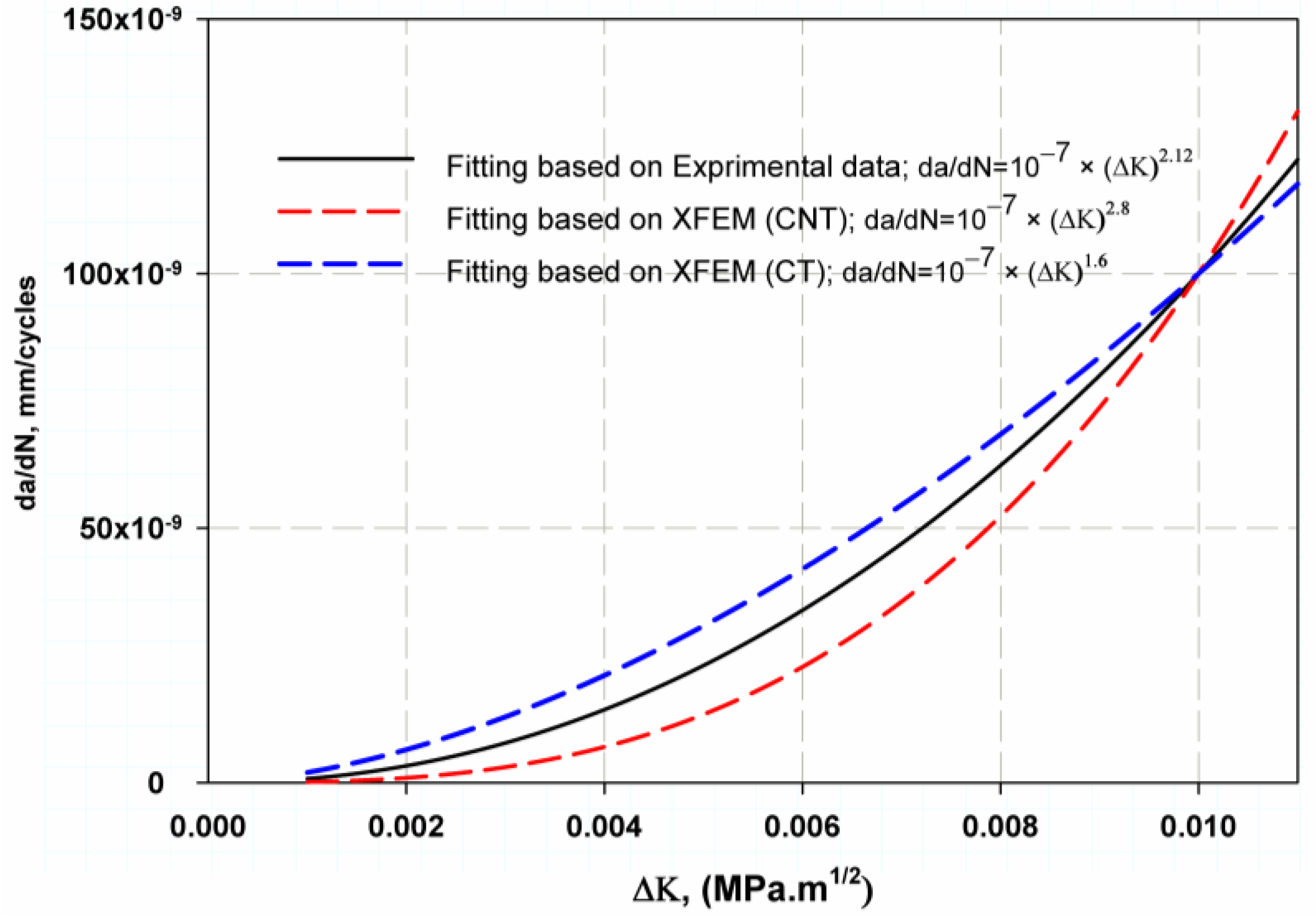

5.2. Direct Cycle Fatigue

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kayabasi, O.; Erzincanli, F. Finite element modelling and analysis of a new cemented hip prosthesis. Adv. Eng. Softw. 2006, 37, 477–483. [Google Scholar] [CrossRef]

- Zhang, L.C.; Chen, L.Y. A review on biomedical titanium alloys: Recent progress and prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef] [Green Version]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Long, M.; Rack, H. Titanium alloys in total joint replacement—A materials science perspective. Biomaterials 1998, 19, 1621–1639. [Google Scholar] [CrossRef] [PubMed]

- Gepreel, M.A.-H.; Niinomi, M. Biocompatibility of Ti-alloys for long-term implantation. J. Mech. Behav. Biomed. Mater. 2013, 20, 407–415. [Google Scholar] [CrossRef]

- Niinomi, M. Recent metallic materials for biomedical applications. Metall. Mater. Trans. A 2002, 33, 477–486. [Google Scholar] [CrossRef]

- Medvedev, A.E.; Molotnikov, A.; Lapovok, R.; Zeller, R.; Berner, S.; Habersetzer, P.; Dalla Torre, F. Microstructure and mechanical properties of Ti–15Zr alloy used as dental implant material. J. Mech. Behav. Biomed. Mater. 2016, 62, 384–398. [Google Scholar] [CrossRef]

- Janeček, M.; Nový, F.; Harcuba, P.; Stráský, J.; Trško, L.; Mhaede, M.; Wagner, L. The Very High Cycle Fatigue Behaviour of Ti-6Al-4V Alloy. Acta Phys. Pol. A 2015, 128, 497–502. [Google Scholar] [CrossRef]

- Rozumek, D.; Hepner, M. Influence of oxygenation time on crack growth in titanium alloy under cyclic bending. Mater. Sci. 2011, 47, 89–94. [Google Scholar] [CrossRef] [Green Version]

- Ribesse, A.; Ismail, K.; Croonenborghs, M.; Irda, N.; Miladi, L.; Jacques, P.J.; Mousny, M.; Pardoen, T. Fracture mechanisms in Ti and Co–Cr growing rods and impact on clinical practice. J. Mech. Behav. Biomed. Mater. 2021, 121, 104620. [Google Scholar] [CrossRef]

- Bédouin, Y.; Gordin, D.M.; Pellen-Mussi, P.; Pérez, F.; Tricot-Doleux, S.; Vasilescu, C.; Drob, S.I.; Chauvel-Lebret, D.; Gloriant, T. Enhancement of the biocompatibility by surface nitriding of a low-modulus titanium alloy for dental implant applications. J. Biomed. Mater. Res. Part B Appl. Biomater. 2019, 107, 1483–1490. [Google Scholar] [CrossRef]

- Nalla, R.; Campbell, J.; Ritchie, R. Mixed-mode, high-cycle fatigue-crack growth thresholds in Ti-6Al-4V: Role of small cracks. Int. J. Fatigue 2002, 24, 1047–1062. [Google Scholar] [CrossRef]

- Nalla, R.; Ritchie, R.; Boyce, B.; Campbell, J.; Peters, J. Influence of microstructure on high-cycle fatigue of Ti-6Al-4V: Bimodal vs. lamellar structures. Metall. Mater. Trans. A 2002, 33, 899–918. [Google Scholar] [CrossRef]

- Wang, Q.; Ren, J.; Zhang, B.; Xin, C.; Wu, Y.; Ye, M. Influence of microstructure on the fatigue crack growth behavior of a near-alpha TWIP Ti alloy. Mater. Charact. 2021, 178, 111208. [Google Scholar] [CrossRef]

- Campanelli, L.C.; Bortolan, C.C.; da Silva, P.S.C.P.; Bolfarini, C.; Oliveira, N.T.C. Effect of an amorphous titania nanotubes coating on the fatigue and corrosion behaviors of the biomedical Ti-6Al-4V and Ti-6Al-7Nb alloys. J. Mech. Behav. Biomed. Mater. 2017, 65, 542–551. [Google Scholar] [CrossRef] [PubMed]

- Niinomi, M. Mechanical biocompatibilities of titanium alloys for biomedical applications. J. Mech. Behav. Biomed. Mater. 2008, 1, 30–42. [Google Scholar] [CrossRef]

- Hirth, J.; Froes, F. Interrelations between fracture toughness and other mechanical properties in titanium alloys. Metall. Trans. A 1977, 8, 1165–1176. [Google Scholar] [CrossRef]

- Wang, K.; Wang, F.; Cui, W.; Hayat, T.; Ahmad, B. Prediction of short fatigue crack growth of Ti-6Al-4V. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 1075–1086. [Google Scholar] [CrossRef]

- Prasad, K.; Abhaya, S.; Amarendra, G.; Kumar, V.; Rajulapati, K.; Rao, K.B.S. Fatigue crack growth behaviour of a near α titanium alloy Timetal 834 at 450 °C and 600 °C. Eng. Fract. Mech. 2013, 102, 194–206. [Google Scholar] [CrossRef]

- Wang, L.; Lin, Z.; Wang, X.; Shi, Q.; Yin, W.; Zhang, D.; Liu, Z.; Lu, W. Effect of aging treatment on microstructure and mechanical properties of Ti27Nb2Ta3Zr β titanium alloy for implant applications. Mater. Trans. 2014, 55, 141–146. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Duan, H.; Li, H. Microstructure and mechanical properties of biomedical Ti-27Nb-8Zr alloy with low elastic modulus. Rare Met. Mater. Eng. 2010, 39, 1707–1710. [Google Scholar] [CrossRef]

- Neto, D.; Borges, M.; Antunes, F.; Jesus, J. Mechanisms of fatigue crack growth in Ti-6Al-4V alloy subjected to single overloads. Theor. Appl. Fract. Mech. 2021, 114, 103024. [Google Scholar] [CrossRef]

- Verma, R.; Kumar, P.; Jayaganthan, R.; Pathak, H. Extended finite element simulation on Tensile, fracture toughness and fatigue crack growth behaviour of additively manufactured Ti6Al4V alloy. Theor. Appl. Fract. Mech. 2022, 117, 103163. [Google Scholar] [CrossRef]

- Da Silva, R.S.; Ribeiro, A.A. Characterization of Ti-35Nb alloy surface modified by controlled chemical oxidation for surgical implant applications. Matér. (Rio Jan.) 2019, 24. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, Y.; Zhang, E.; Cheng, Y.; Xiong, X.; Zheng, Y.; Wei, S. Alkali-heat treatment of a low modulus biomedical Ti–27Nb alloy. Biomed. Mater. 2009, 4, 044108. [Google Scholar] [CrossRef] [PubMed]

- Froes, F. Titanium, Encyclopedia of Materials Science and Engineering; Elsevier: Oxford, UK, 2000. [Google Scholar]

- Poondla, N.; Srivatsan, T.S.; Patnaik, A.; Petraroli, M. A study of the microstructure and hardness of two titanium alloys: Commercially pure and Ti-6Al-4V. J. Alloys Compd. 2009, 486, 162–167. [Google Scholar] [CrossRef]

- Lütjering, G. Influence of processing on microstructure and mechanical properties of (α + β) titanium alloys. Mater. Sci. Eng. A 1998, 243, 32–45. [Google Scholar] [CrossRef]

- Amjad, M.; Badshah, S.; Rafique, A.F.; Adil Khattak, M.; Khan, R.U.; Abdullah Harasani, W.I. Mechanism of Fatigue Crack Growth in Biomedical Alloy Ti-27Nb. Materials 2020, 13, 2299. [Google Scholar] [CrossRef]

- Amjad, M.; Badshah, S.; Khattak, M.A.; Khan, R.U.; Mujahid, M. Characterization of Nickle Free Titanium Alloy TI-27Nb for Biomedical Applications. J. Eng. Appl. Sci. (JEAS) 2017, 36, 9–15. [Google Scholar]

- Amjad, M.; Rafai, A.; Badshah, S.; Khan, R.U.; Ahmad, S. Finite element analysis of the real life loadings on the Ti-27nb hip bone implant. J. Eng. Appl. Sci. (JEAS) 2018, 37, 15–20. [Google Scholar]

- Belytschko, T.; Black, T. Elastic crack growth in finite elements with minimal remeshing. Int. J. Numer. Methods Eng. 1999, 45, 601–620. [Google Scholar] [CrossRef]

- Melenk, J.M.; Babuška, I. The partition of unity finite element method: Basic theory and applications. Comput. Methods Appl. Mech. Eng. 1996, 139, 289–314. [Google Scholar] [CrossRef] [Green Version]

- Datta, D. Introduction to extended finite element (XFEM) method. arXiv 2013, arXiv:1308.5208. [Google Scholar]

- Abdellah, M.Y.; Alsoufi, M.S.; Hassan, M.K.; Ghulman, H.A.; Mohamed, A.F. Extended finite element numerical analysis of scale effect in notched glass fiber reinforced epoxy composite. Arch. Mech. Eng. 2015, 62, 217–236. [Google Scholar] [CrossRef] [Green Version]

- Yvonnet, J.; Quang, H.L.; He, Q.-C. An XFEM/level set approach to modelling surface/interface effects and to computing the size-dependent effective properties of nanocomposites. Comput. Mech. 2008, 42, 119–131. [Google Scholar] [CrossRef] [Green Version]

- Zaid, M.; Mishra, S.; Rao, K. Finite element analysis of static loading on urban tunnels. In Geotechnical Characterization and Modelling: Proceedings of IGC 2018; Springer: Singapore, 2020; pp. 807–823. [Google Scholar]

- Wen, L.; Tian, R. Improved XFEM: Accurate and robust dynamic crack growth simulation. Comput. Methods Appl. Mech. Eng. 2016, 308, 256–285. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y. Extended Finite Element Methods for Brittle and Cohesive Fracture; Columbia University: New York, NY, USA, 2017. [Google Scholar]

- Yang, Z.; Lei, Y.; Li, G. Experimental and Finite Element Analysis of Shear Behavior of Prestressed High-Strength Concrete Piles. Int. J. Civ. Eng. 2023, 21, 219–233. [Google Scholar] [CrossRef]

- ASTM E399-90; Standard Test Method for Plane-Strain Fracture Toughness of Metallic Materials. ASTM: West Conshohocken, PA, USA, 1997.

- ASTM E647; Standard Test Method for Measurement of Fatigue Crack Growth Rates. ASTM: West Conshohocken, PA, USA, 2011.

- Newman, J., Jr.; Haines, M.J. Verification of stress-intensity factors for various middle-crack tension test specimens. Eng. Fract. Mech. 2005, 72, 1113–1118. [Google Scholar] [CrossRef]

- Feddersen, C. Discussion to plane strain crack toughness testing. ASTM STP 1966, 410, 77. [Google Scholar]

- Hahn, G.T.; Rosenfield, A.R. Local yielding and extension of a crack under plane stress. Acta Metall. 1965, 13, 293–306. [Google Scholar] [CrossRef]

- Perez, N. Crack Tip Plasticity. In Fracture Mechanics; Springer: Berlin/Heidelberg, Germany, 2017; pp. 187–225. [Google Scholar]

- Hossain, M.; Ziehl, P. Modelling of Fatigue Crack Growth with Abaqus; University of South Carolina: Colombia, SC, USA, 2012. [Google Scholar]

- Hibbitt, D.; Karlsson, B.; Sorensen, P. Abaqus 6.11 Documentation; Dassault Systèmes: Vélizy-Villacoublay, France, 2011. [Google Scholar]

- London, T.; De Bono, D.; Sun, X. An evaluation of the low cycle fatigue analysis procedure in abaqus for crack propagation: Numerical benchmarks and experimental validation. In Proceedings of the SIMULIA UK Regional Users Meeting, Manchester, UK, 3–4 November 2015. [Google Scholar]

- O’Brien, T.K.; Johnston, W.M.; Toland, G.J. Mode II Interlaminar Fracture Toughness and Fatigue Characterization of a Graphite Epoxy Composite Material; Report No. NF1676L-10105; NASA: Washington, DC, USA, 2010. [Google Scholar]

- Murri, G.B. Evaluation of delamination growth characterization methods under mode I fatigue loading. In Proceedings of the 15th US-Japan Conference on Composite Materials, Arlington, VA, USA, 1 October 2012. [Google Scholar]

- Newman, J., Jr.; Anagnostou, E.; Rusk, D. Fatigue and crack-growth analyses on 7075-T651 aluminum alloy coupons under constant-and variable-amplitude loading. Int. J. Fatigue 2014, 62, 133–143. [Google Scholar] [CrossRef]

- Crack Growth Equation. Available online: https://en.wikipedia.org/wiki/Crack_growth_equation#cite_note-14 (accessed on 13 June 2023).

- Morin, P.; Nochetto, R.H.; Siebert, K.G. Convergence of adaptive finite element methods. SIAM Rev. 2002, 44, 631–658. [Google Scholar] [CrossRef] [Green Version]

- Finite Element Analysis Convergence and Mesh. Available online: https://www.xceed-eng.com/ (accessed on 13 June 2023).

- Li, H.; Li, J.; Yuan, H. A review of the extended finite element method on macrocrack and microcrack growth simulations. Theor. Appl. Fract. Mech. 2018, 97, 236–249. [Google Scholar] [CrossRef]

- Zhuang, Z.; Liu, Z.; Cheng, B.; Liao, J. Overview of Extended Finite Element Method. In Extended Finite Element Method; Academic Press: Cambridge, MA, USA, 2014; pp. 1–12. [Google Scholar]

- How to Perform a Mesh Convergence Study. Available online: https://www.autodesk.com/support/technical/article/caas/sfdcarticles/sfdcarticles/How-to-Perform-a-Mesh-Convergence-Study.html?us_oa=dotcom-us&us_si=80d830ee-9e07-4ae9-ac56-a896a9ebc8ee&us_st=How%20to%20Perform%20a%20Mesh%20Convergence%20Study (accessed on 13 June 2023).

- Agathos, K.; Chatzi, E.; Bordas, S.P. Multiple crack detection in 3D using a stable XFEM and global optimization. Comput. Mech. 2018, 62, 835–852. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Elruby, A.; Nakhla, S.; Hussein, A. Automating XFEM modeling process for optimal failure predictions. Math. Probl. Eng. 2018, 2018, 1654751. [Google Scholar] [CrossRef]

- Hillerborg, A.; Modéer, M.; Petersson, P.-E. Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem. Concr. Res. 1976, 6, 773–781. [Google Scholar] [CrossRef]

- Abdellah, M.Y. Ductile Fracture and S–N Curve Simulation of a 7075-T6 Aluminum Alloy under Static and Constant Low-Cycle Fatigue. J. Fail. Anal. Prev. 2021, 21, 1476–1488. [Google Scholar] [CrossRef]

- Abdellah, M.Y.; Alfattani, R.; Alnaser, I.A.; Abdel-Jaber, G. Stress Distribution and Fracture Toughness of Underground Reinforced Plastic Pipe Composite. Polymers 2021, 13, 2194. [Google Scholar] [CrossRef]

- Manual, A.S.U. Abaqus 6.11. 2012. Available online: http://160.36.100.126:2080/v6.11/pdf_books/SCRIPT_USER.pdf (accessed on 13 June 2023).

- Version, A. 6.11 Documentation; Dassault Systemes Simulia Corp.: Providence, RI, USA, 2011. [Google Scholar]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Kobayashi, T. Strength and Toughness of Materials; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Kobayashi, T.; Yamada, S. Evaluation of static and dynamic fracture toughness in ductile cast iron. Metall. Mater. Trans. A 1994, 25, 2427–2436. [Google Scholar] [CrossRef]

- Khashaba, U.; Seif, M. Effect of different loading conditions on the mechanical behavior of [0/±45/90] s woven composites. Compos. Struct. 2006, 74, 440–448. [Google Scholar] [CrossRef]

- Wang, K.; Bao, R.; Jiang, B.; Wu, Y.; Liu, D.; Yan, C. Effect of primary α phase on the fatigue crack path of laser melting deposited Ti–5Al–5Mo–5V–1Cr–1Fe near β titanium alloy. Int. J. Fatigue 2018, 116, 535–542. [Google Scholar] [CrossRef]

| Properties | Value |

|---|---|

| Density (Kg/m3) | 4520 |

| Young’s modulus (GPa) | 87.45 |

| Yield strength (MPa) | 600.5 |

| Ultimate strength (MPa) | 874.63 |

| Fracture strain | 0.0264571 |

| Strain rate, (mm/mm)/s | 0.166 |

| Poisson’s ratio, µ | 0.33 |

| N, strain hardening | 0.7 |

| K, (MPa) | 1148 |

| Models | Experimental [29] | XFEM | %Error | J-Integral (Fixed-Crack XFEM) | |||

|---|---|---|---|---|---|---|---|

| CNT | %Error | CT | %Error | ||||

| Fracture toughness KIC, MPam1/2 | 50 | 48.9 | 2.2 | 49.5 | 1 | 49 | 2 |

| Release energy GIC, kJ/m2 | 26.3 | 24.8 | 5.2 | 25.5 | 3 | 25 | 4.5 |

| FEM Model | Fatigue Constants | %Average Difference | |

|---|---|---|---|

| m | c | ||

| Experimental data [29] | 2.12 | ||

| CNT–non-direct cycle XFEM–elastic model | 2.9 | 13.8 | |

| CNT–direct cycle XFEM–elastic model | 2.8 | 12 | |

| CT-elastic XFEM | 1.6 | 9.2 | |

| CT–elastic–plastic (nonlinear behaviour) XFEM | 1.6 | 9.2 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdellah, M.Y.; Alharthi, H. Fracture Toughness and Fatigue Crack Growth Analyses on a Biomedical Ti-27Nb Alloy under Constant Amplitude Loading Using Extended Finite Element Modelling. Materials 2023, 16, 4467. https://doi.org/10.3390/ma16124467

Abdellah MY, Alharthi H. Fracture Toughness and Fatigue Crack Growth Analyses on a Biomedical Ti-27Nb Alloy under Constant Amplitude Loading Using Extended Finite Element Modelling. Materials. 2023; 16(12):4467. https://doi.org/10.3390/ma16124467

Chicago/Turabian StyleAbdellah, Mohammed Y., and Hamzah Alharthi. 2023. "Fracture Toughness and Fatigue Crack Growth Analyses on a Biomedical Ti-27Nb Alloy under Constant Amplitude Loading Using Extended Finite Element Modelling" Materials 16, no. 12: 4467. https://doi.org/10.3390/ma16124467

APA StyleAbdellah, M. Y., & Alharthi, H. (2023). Fracture Toughness and Fatigue Crack Growth Analyses on a Biomedical Ti-27Nb Alloy under Constant Amplitude Loading Using Extended Finite Element Modelling. Materials, 16(12), 4467. https://doi.org/10.3390/ma16124467