Analysis of Pore Structure in Cement Pastes with Micronized Natural Zeolite

Abstract

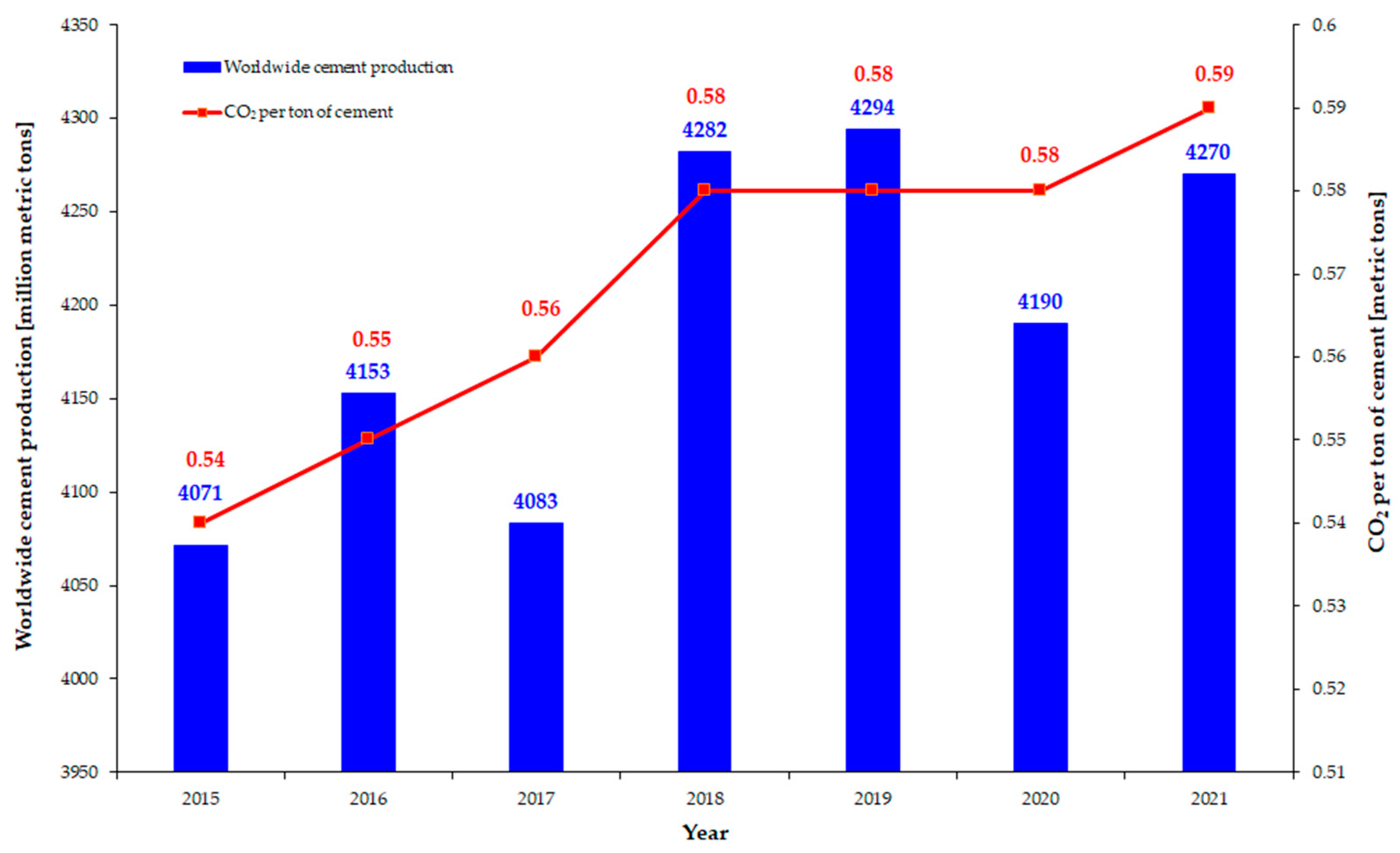

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results

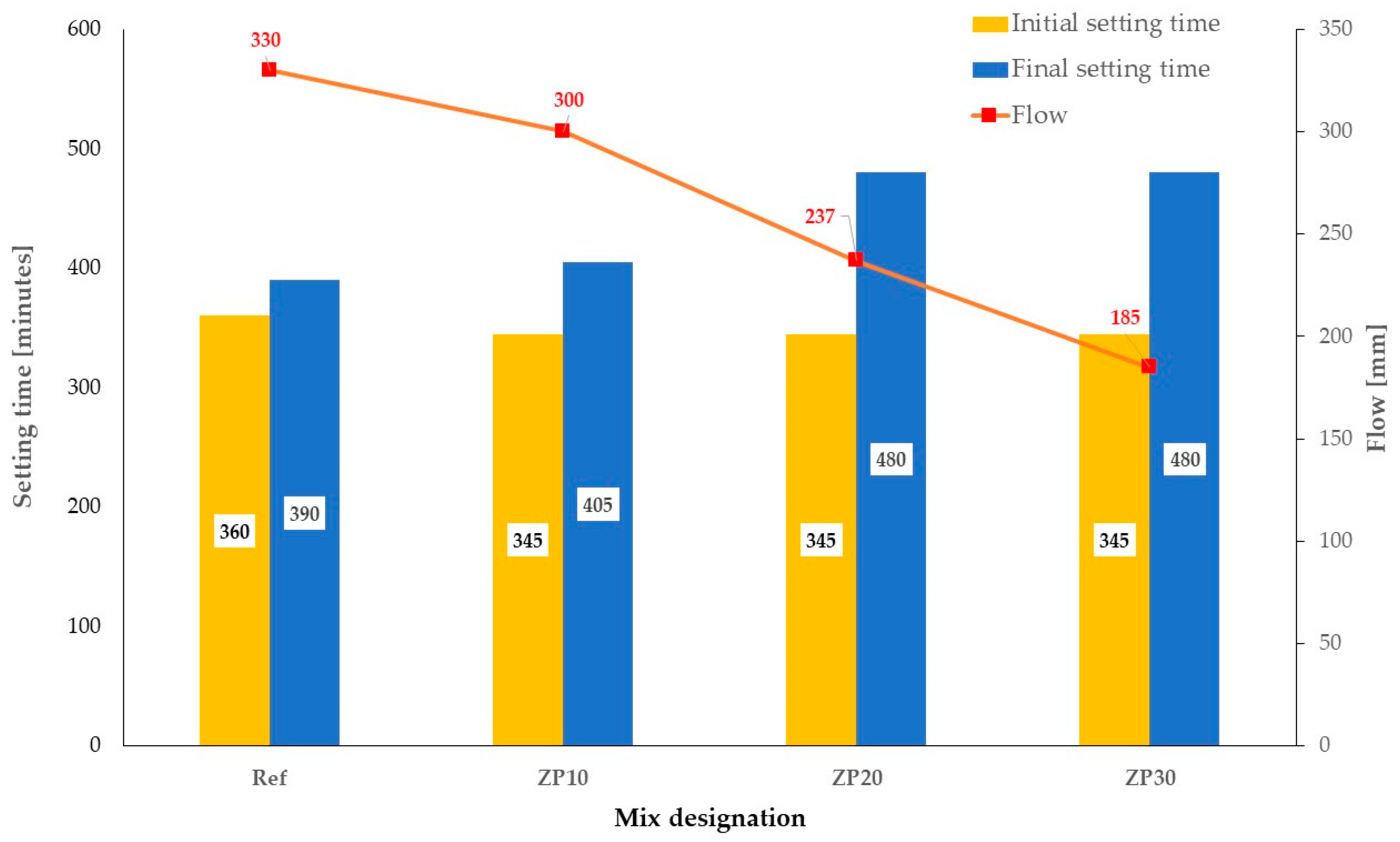

3.1. Flowability and Setting Time

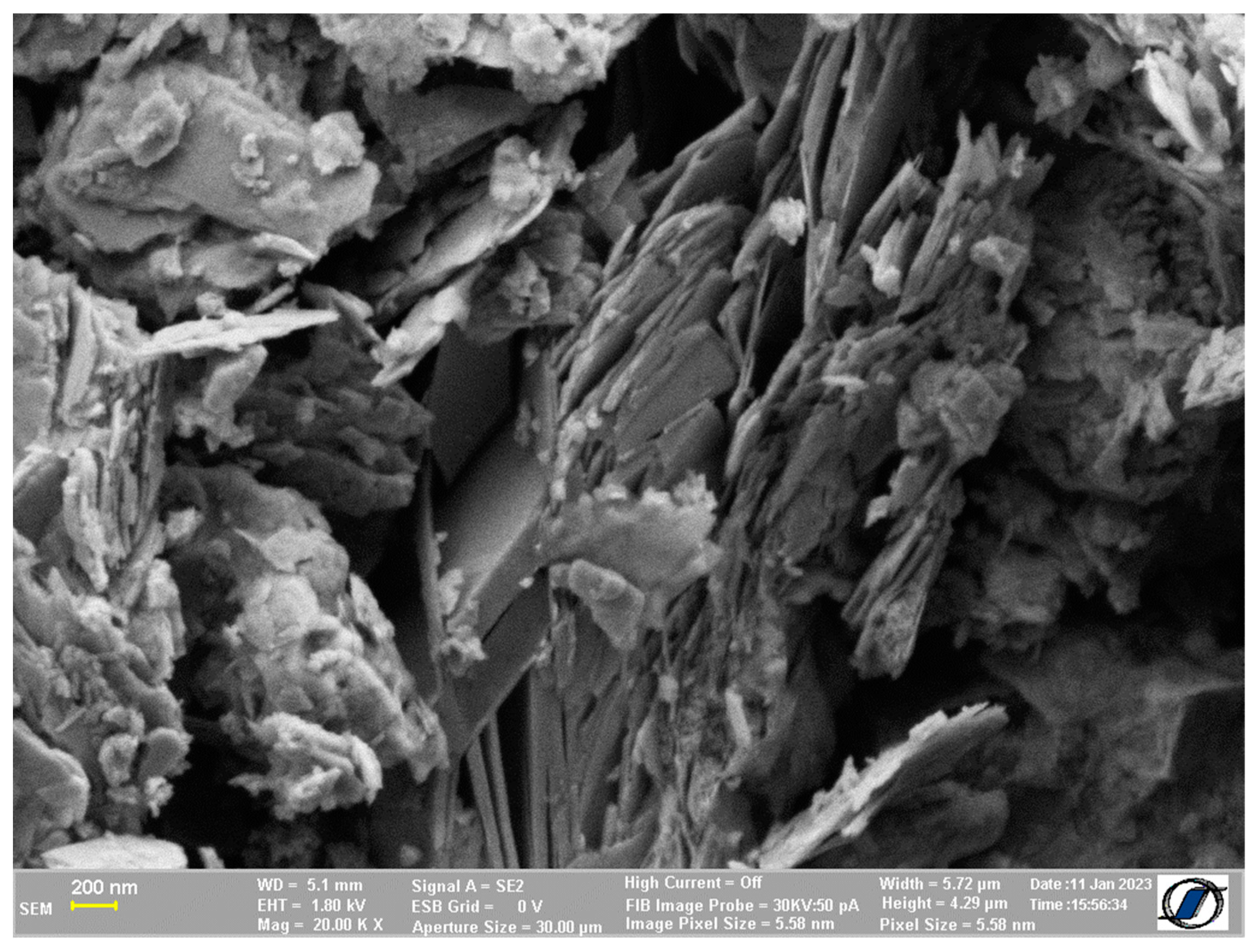

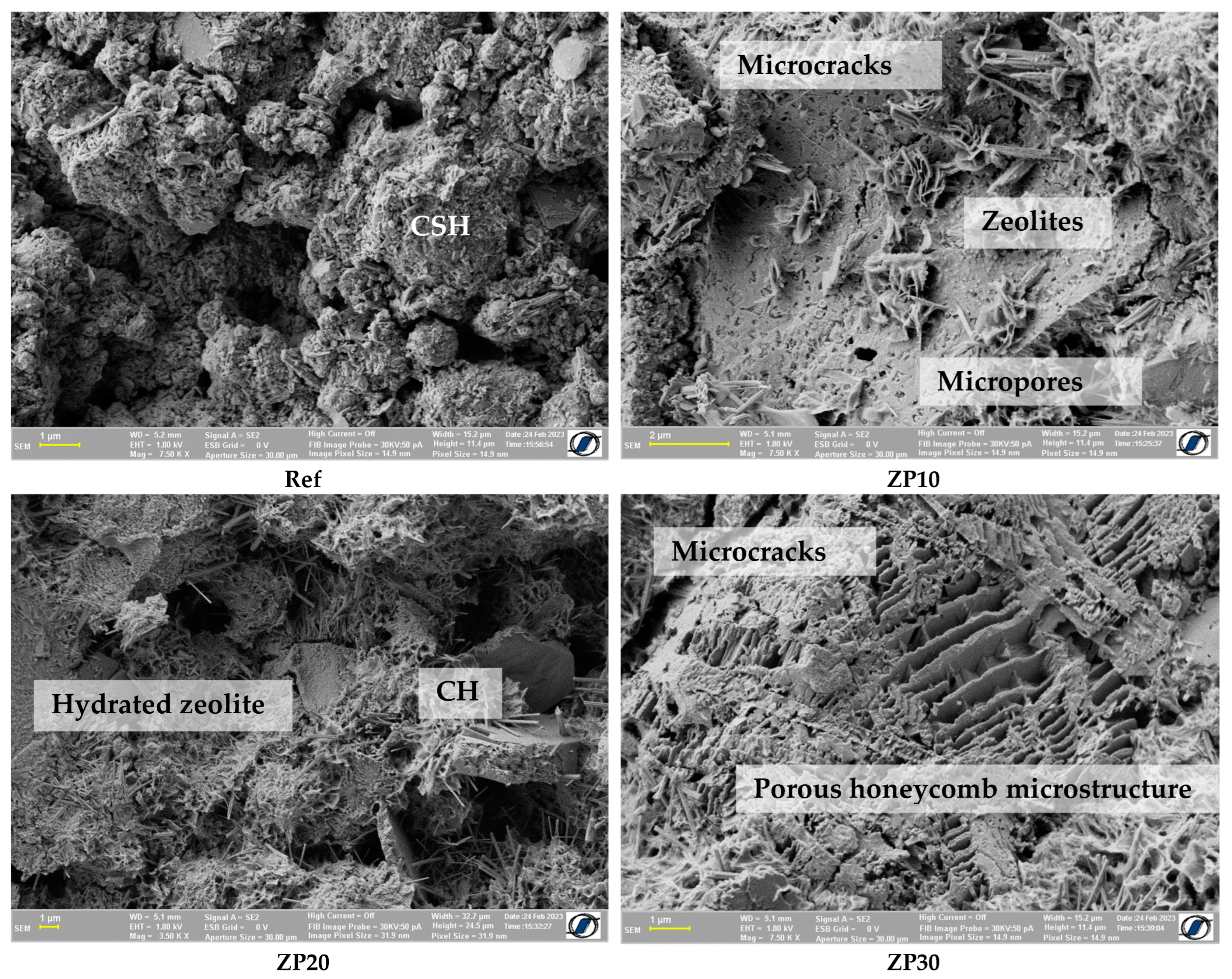

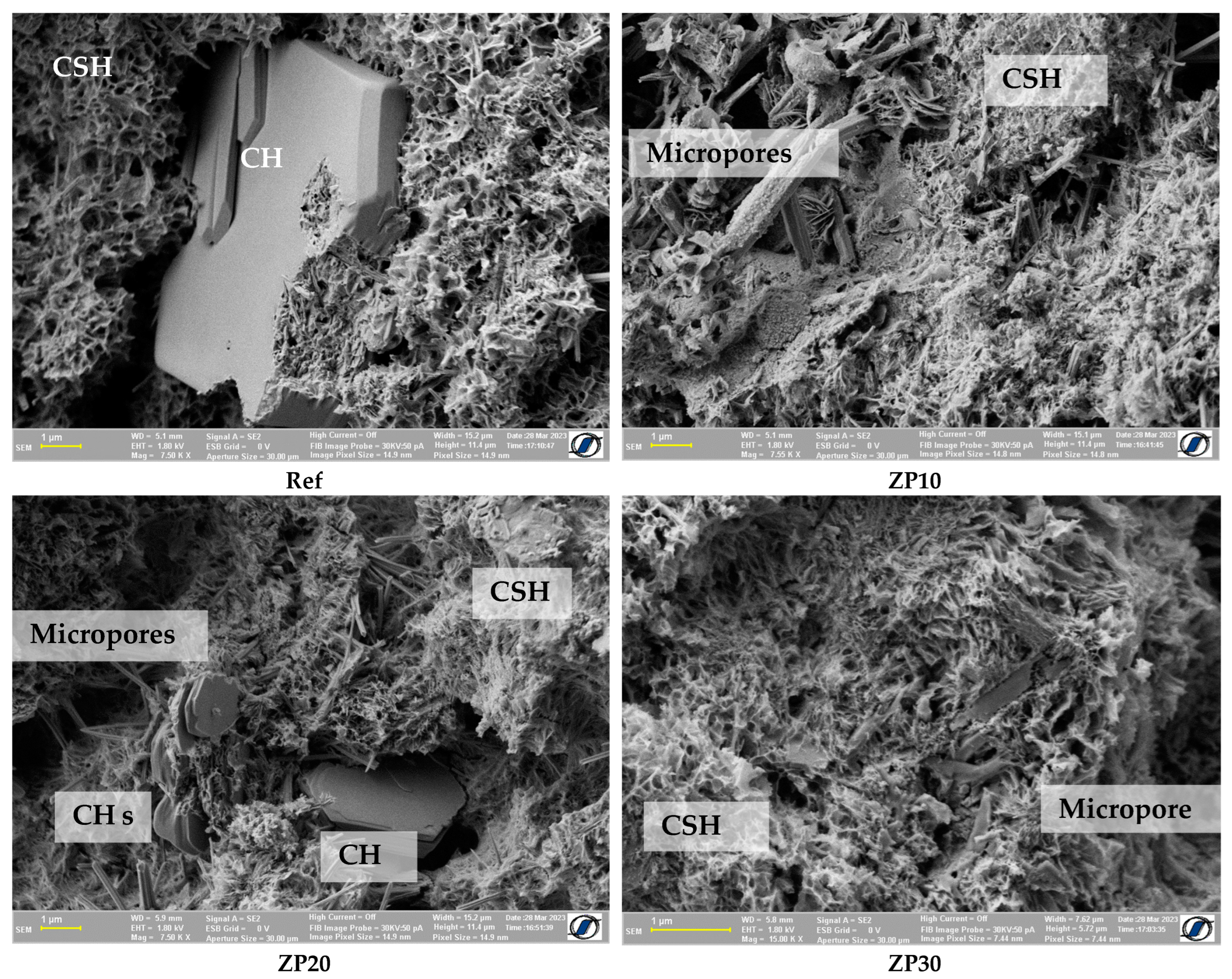

3.2. SEM Analyses

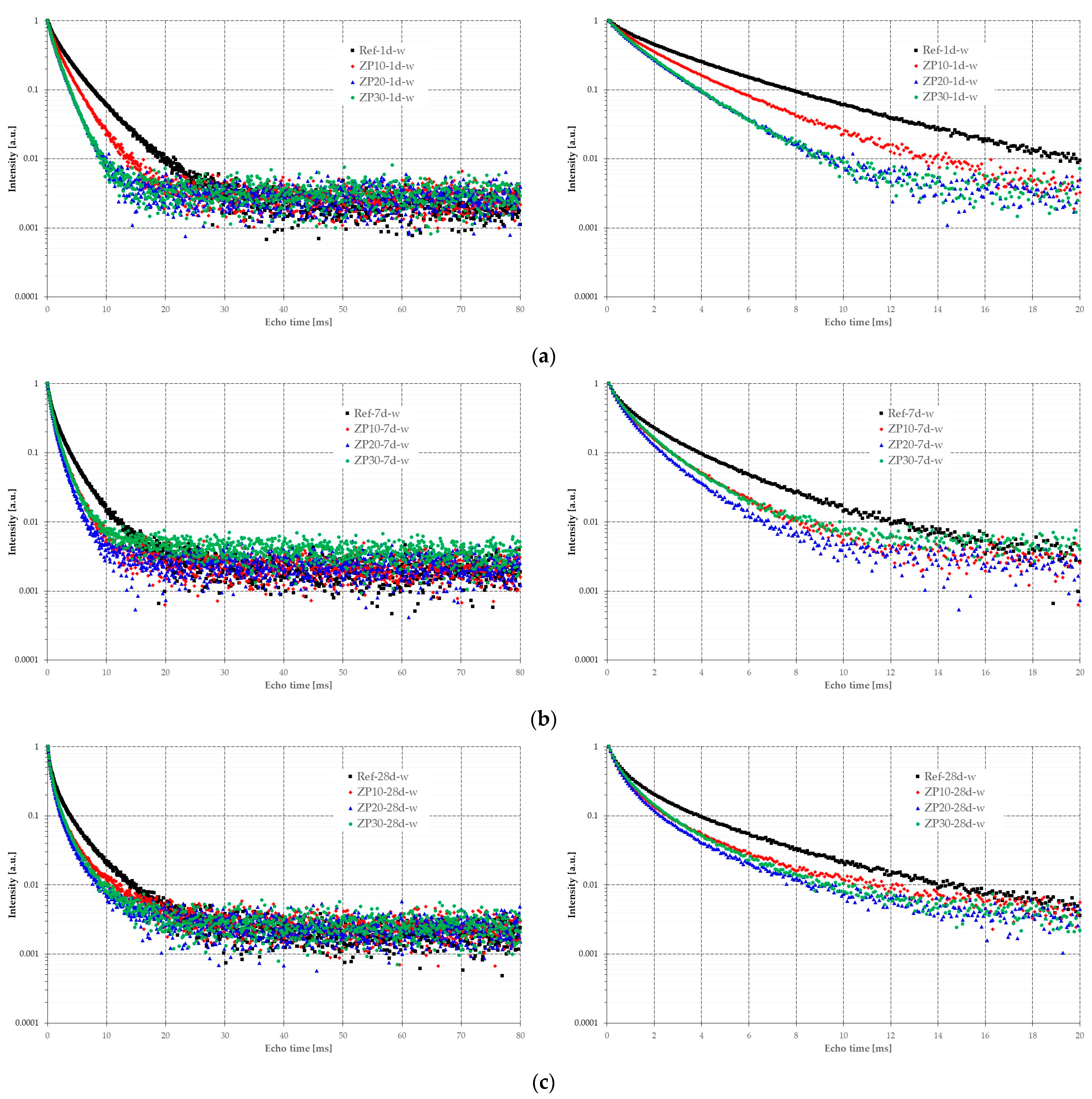

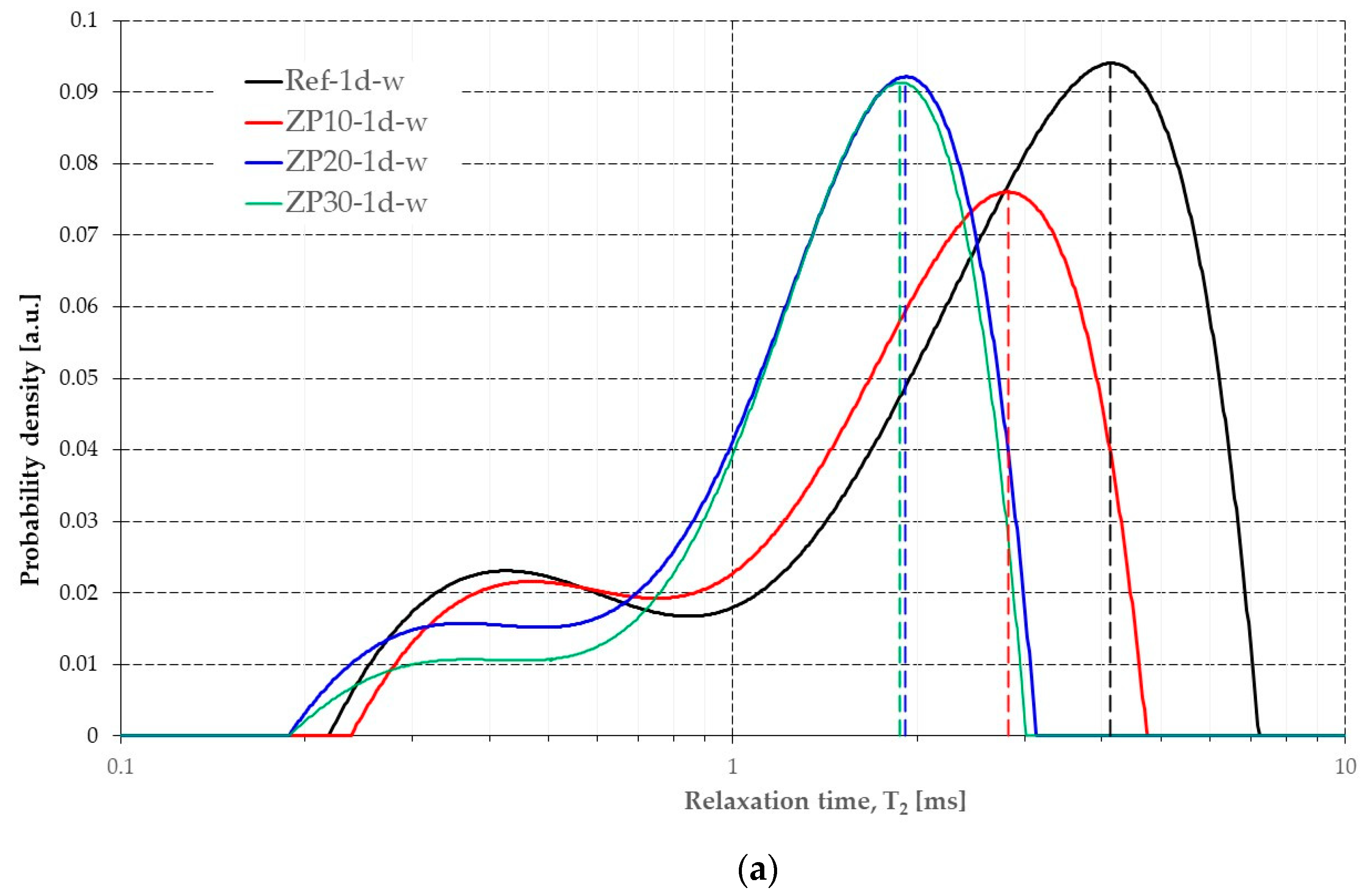

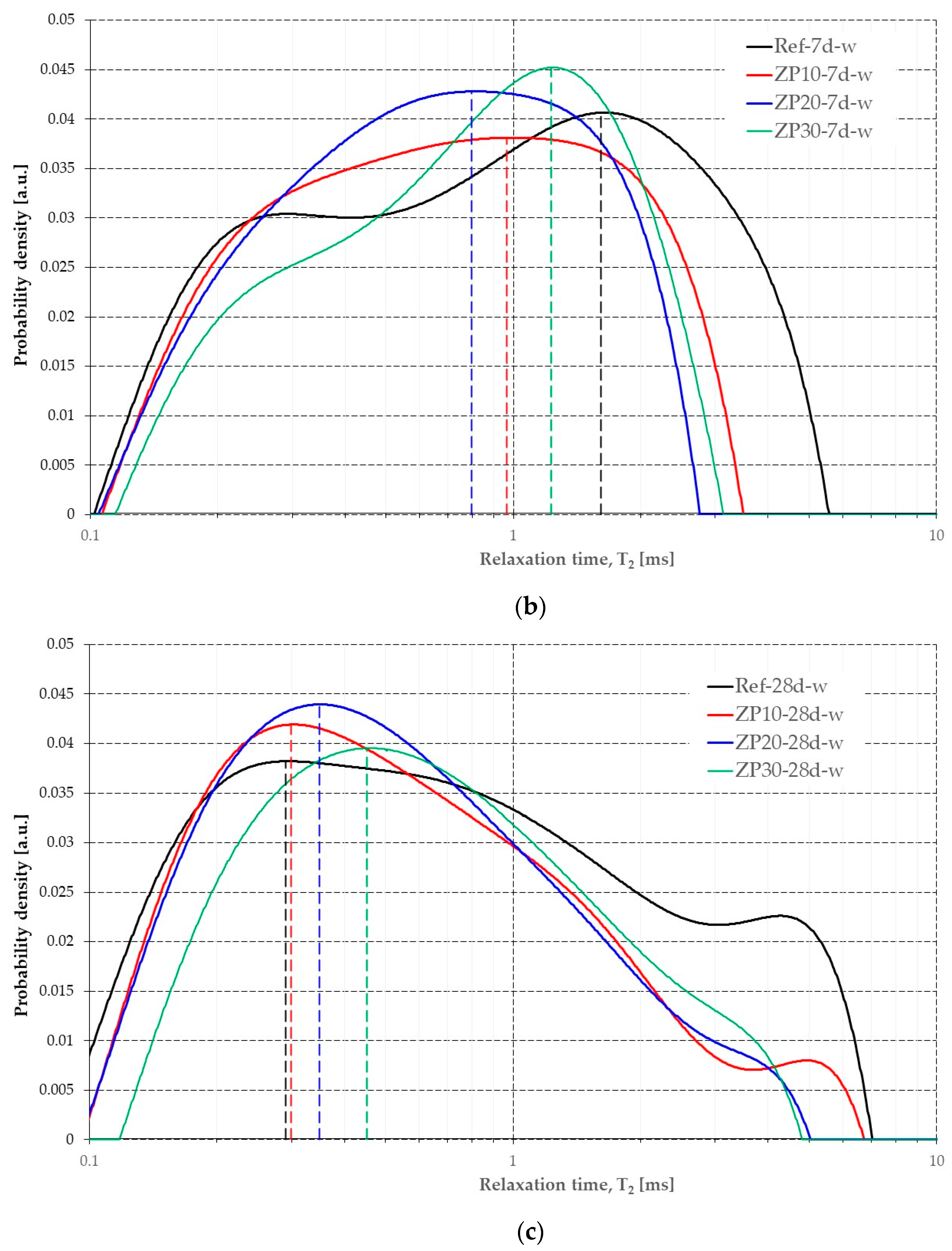

3.3. NMR Relaxometry

4. Discussion

5. Conclusions

- The gradual generation of CSH gels with curing age is rendered evident by means of SEM analyses. Moreover, CSH formations due to the pozzolanic reaction of micronized zeolite are also identified. The microstructure of cement pastes becomes more compact and denser with curing age. At the same time, fewer micropores can be identified. A replacement of OPC by natural zeolites in the range of 10–20% by mass of cement is also reported in the scientific literature as leading to the highest improvements in terms of durability properties and long-term strength values of cement-based materials. The microstructure analyses confirm the fact that smaller pores are obtained in cement pastes with a 10% and 20% replacement of OPC by natural zeolite. Increasing the replacement percentage to 30% results in larger pores due to a higher amount of water being absorbed and stored in the porous structure of zeolites.

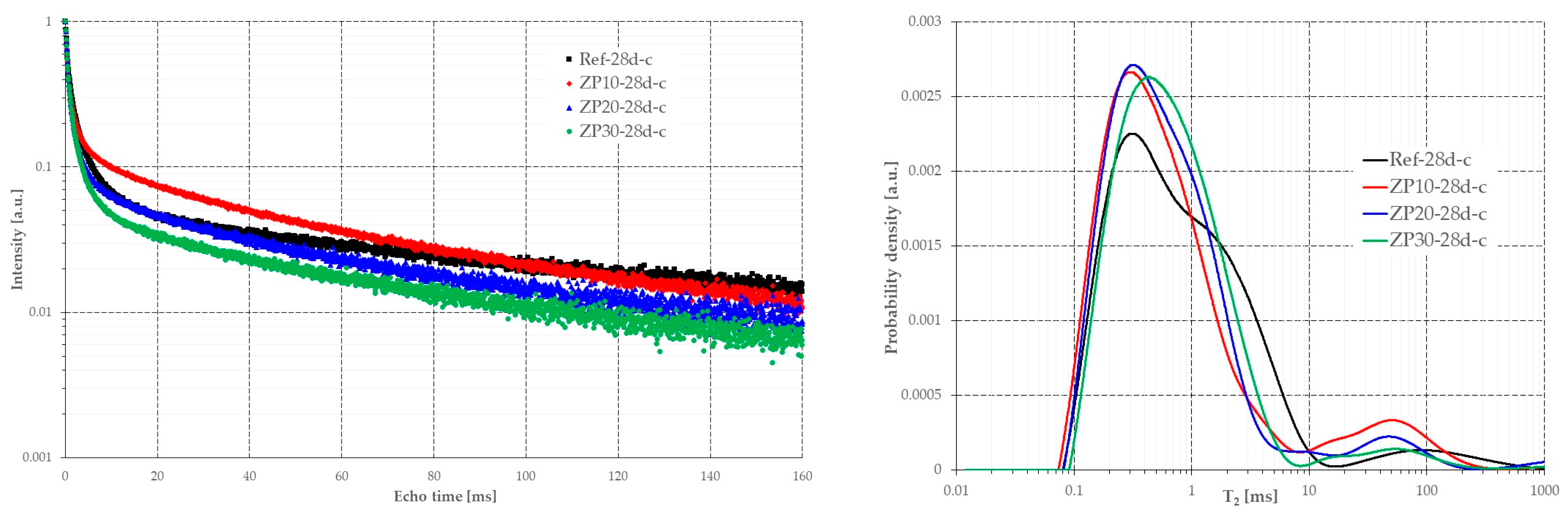

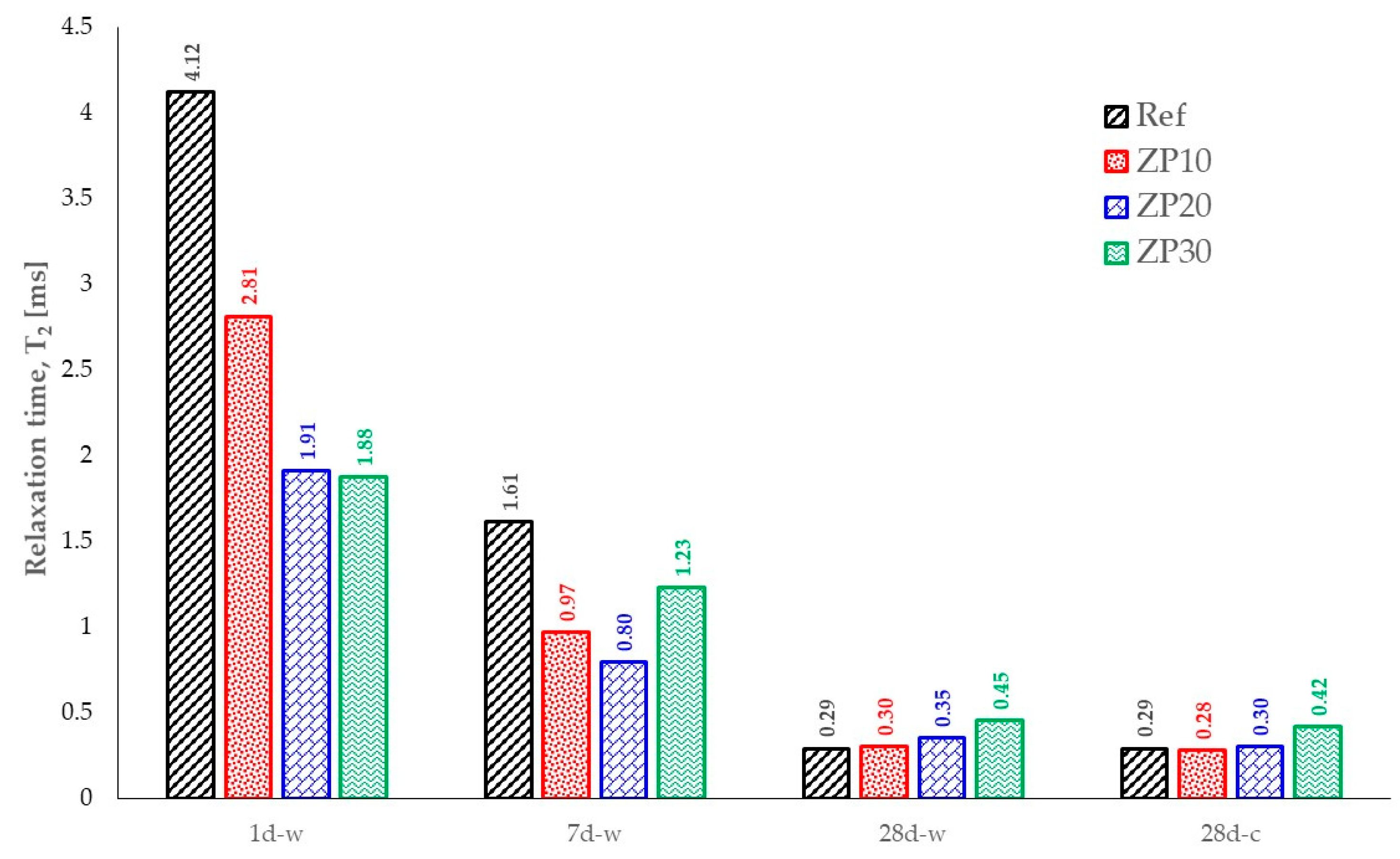

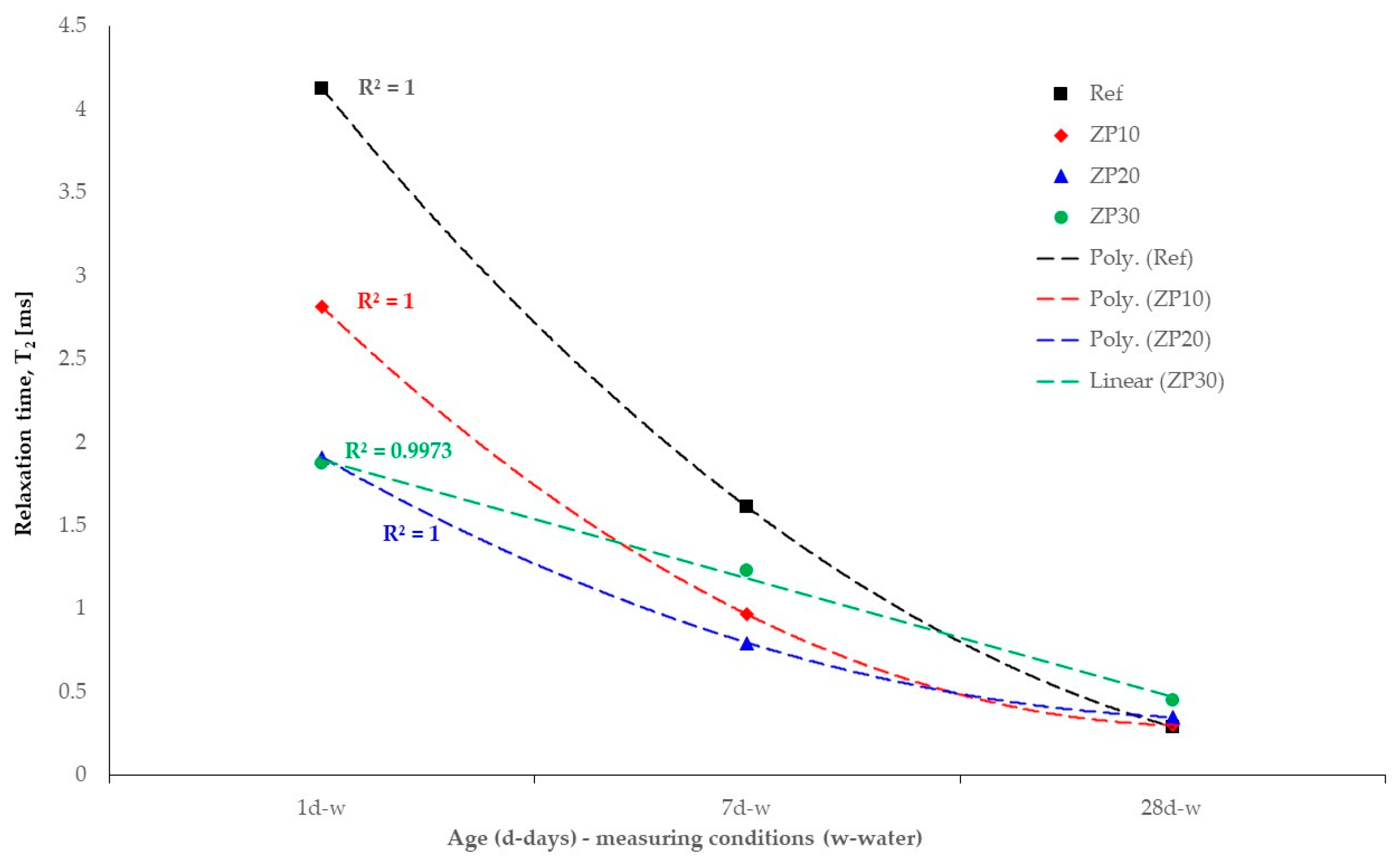

- The NMR relaxometry technique is used to qualitatively assess the pore structure of the cement pastes. At an early age, e.g., 1 day, there is a clear distinction between the inter- and intra-CSH pores. The presence of water molecules in the former pores results in larger relaxation time values, whereas the latter yield lower values of the relaxation time. The replacement of OPC by micronized natural zeolites results in a shift towards lower values of relaxation time, which means smaller pores in the cementitious matrix. While at early ages the ZP20 and ZP30 pastes have similar pore structures, as a result of the very close values of relaxation time corresponding to the mixes, at the ages of 7 days and 28 days the values of T2 corresponding to the ZP20 mix are closer to the ones corresponding to the ZP10 mix. This could indicate that there might be a threshold of cement replacement by micronized zeolite above which the effect might be detrimental in terms of pore structure.

- At the age of 28 days, the pore structures of the Ref, ZP10, and ZP20 mixes are similar. The T2 values of the ZP10 and ZP20 mixes are slightly larger than the one of Ref mix by 3.4% and 3.5%, respectively. The ZP30, however, registers a 43.7% increase in the value of relaxation time, indicating the presence of larger-diameter pores. Similar results are obtained when saturating the samples with cyclohexane. The pozzolanic nature of zeolite, coupled with the use of blended cement, leads to slower development of hydration products, e.g., CSH, as demonstrated in the scientific literature. Higher percentages of zeolite result in lower amounts of available CH, leading to decreased formation of CSH gels due to secondary pozzolanic reactions. As a result, the decreased availability of CH results in a lower amount of water needed for chemical reactions, and, therefore, the water absorbed by zeolite during the early stages of hydration remains trapped in the pores. This can have detrimental effects on the durability and strength development of cement-based construction materials in the long run.

- Although the pore structure of cement pastes containing zeolites as a replacement for OPC in different percentages can be assessed by means of NMR relaxometry, a more in-depth analysis is required to determine the relaxivity constant. The results obtained by NMR should be confirmed by other assessment techniques such as computer tomography (CT).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Miller, S.A.; Habert, G.; Myers, R.J.; Harvey, J.T. Achieving net zero greenhouse gas emissions in the cement industry via value chain mitigation strategies. One Earth 2021, 4, 1398–1411. [Google Scholar] [CrossRef]

- The European Cement Association (CEMBUREAU). Cementing the European Green Deal; CEMBUREAU: Bruxelles, Belgium, 2023. [Google Scholar]

- International Energy Agency (IEA). Cement. 2022. Available online: https://www.iea.org/reports/cement (accessed on 27 April 2023).

- Salamanova, M.; Murtazaev, S.-A.; Saidumov, M.; Alaskhanov, A.; Murtazaeva, T.; Fediuk, R. Recycling of Cement Industry Waste for Alkali-Activated Materials Production. Materials 2022, 15, 6660. [Google Scholar] [CrossRef] [PubMed]

- Torréns-Martín, D.; Fernández-Carrasco, L.J.; Blanco-Varela, M.T. Up to 100% Replacement of Natural Materials from Residues: Recycling Blast Furnace Slag and Fly Ash as Self-Leveling Cementitious Building Materials. Materials 2023, 16, 3350. [Google Scholar] [CrossRef]

- da Silva, S.R.; de Oliveira Andrade, J.J. Investigation of mechanical properties and carbonation of concretes with construction and demolition waste and fly ash. Constr. Build. Mater. 2017, 153, 704–715. [Google Scholar] [CrossRef]

- Park, B.; Choi, Y.C. Effects of fineness and chemical activators on the hydration and physical properties of high-volume fly-ash cement pastes. J. Build. Eng. 2022, 51, 104274. [Google Scholar] [CrossRef]

- Fu, J.X.; Wang, K.; Wang, J. Internal pore evolution and early hydration characterization of fly ash cement backfill. J. Build. Eng. 2023, 72, 106716. [Google Scholar] [CrossRef]

- Luan, C.; Yuan, L.; Wang, J.; Zhou, Z. Uncovering the Mechanism of the Role of Fly Ash in the Self-Healing Ability of Mortar with Different Curing Ages. Materials 2023, 16, 3453. [Google Scholar] [CrossRef]

- Nicula, L.M.; Manea, D.L.; Simedru, D.; Cadar, O.; Becze, A.; Dragomir, M.L. The Influence of Blast Furnace Slag on Cement Concrete Road by Microstructure Characterization and Assessment of Physical-Mechanical Resistances at 150/480 Days. Materials 2023, 16, 3332. [Google Scholar] [CrossRef]

- Liu, Z.; Takasu, K.; Suyama, H.; Koyamada, H.; Liu, S.; Hao, Q. The Effect of Cementitious Materials on the Engineering Properties and Pore Structure of Concrete with Recycled Fine Aggregate. Materials 2022, 16, 305. [Google Scholar] [CrossRef]

- Ghostine, R.; Bur, N.; Feugeas, F.; Hoteit, I. Curing Effect on Durability of Cement Mortar with GGBS: Experimental and Numerical Study. Materials 2022, 15, 4394. [Google Scholar] [CrossRef] [PubMed]

- Toma, I.-O.; Covatariu, D.; Toma, A.-M.; Taranu, G.; Budescu, M. Strength and elastic properties of mortars with various percentages of environmentally sustainable mineral binder. Constr. Build. Mater. 2013, 43, 348–361. [Google Scholar] [CrossRef]

- Li, P.; Zhang, X.; Zhong, M.; Fan, Z.; Xiong, J.; Zhang, Z. Phosphogypsum-Based Ultra-Low Basicity Cementing Material. Materials 2022, 15, 6601. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Xiang, Z.; Liu, T.; Deng, C.; Zhang, H. Study on the Mechanical Properties of Cast-In-Situ Phosphogypsum as Building Material for Structural Walls. Materials 2023, 16, 1481. [Google Scholar] [CrossRef]

- Barbieri, L.; Altimari, F.; Andreola, F.; Maggi, B.; Lancellotti, I. Characterization of Volcano-Sedimentary Rocks and Related Scraps for Design of Sustainable Materials. Materials 2023, 16, 3408. [Google Scholar] [CrossRef]

- Aissa, Y.H.; Goual, I.; Benabed, B. Mix-design and properties of self-compacting concrete made with calcareous tuff. J. Build. Eng. 2020, 27, 100997. [Google Scholar] [CrossRef]

- Ma, B.; Fernandez-Martinez, A.; Mancini, A.; Lothenbach, B. Spectroscopic investigations on structural incorporation pathways of FeIII into zeolite frameworks in cement-relevant environments. Cem. Concr. Res. 2021, 140, 106304. [Google Scholar] [CrossRef]

- Kazemian, M.; Shafei, B. Internal curing capabilities of natural zeolite to improve the hydration of ultra-high performance concrete. Constr. Build. Mater. 2022, 340, 127452. [Google Scholar] [CrossRef]

- Stocker, K.; Ellersdorfer, M.; Lehner, M.; Raith, J.G. Characterization and Utilization of Natural Zeolites in Technical Applications. BHM Berg- Und Hüttenmännische Mon. 2017, 162, 142–147. [Google Scholar] [CrossRef]

- Wang, Q.; Xiong, Z.; He, J.; Lai, M.; Ho, J. Effective solution for improving rheological properties of cement paste containing zeolite. Constr. Build. Mater. 2022, 351, 128780. [Google Scholar] [CrossRef]

- Kriptavičius, D.; Girskas, G.; Skripkiūnas, G. Use of Natural Zeolite and Glass Powder Mixture as Partial Replacement of Portland Cement: The Effect on Hydration, Properties and Porosity. Materials 2022, 15, 4219. [Google Scholar] [CrossRef] [PubMed]

- Gong, J.; Mao, Z.; Cao, Z.; Huang, X.; Deng, M. Effect of Different Fineness of Cement on the Autogenous Shrinkage of Mass Concrete under Variable Temperature Conditions. Materials 2023, 16, 2367. [Google Scholar] [CrossRef] [PubMed]

- Ding, Z.; Chen, J.; Zheng, S.; Hu, Y.; Fang, Y. Influence of Anhydrite on the Properties and Microstructure of Aluminophosphate Cement. Materials 2022, 15, 7005. [Google Scholar] [CrossRef] [PubMed]

- Morales-Cantero, A.; Cuesta, A.; De la Torre, A.G.; Mazanec, O.; Borralleras, P.; Weldert, K.S.; Gastaldi, D.; Canonico, F.; Aranda, M.A.G. Portland and Belite Cement Hydration Acceleration by C-S-H Seeds with Variable w/c Ratios. Materials 2022, 15, 3553. [Google Scholar] [CrossRef]

- Li, Y.; Luo, Y.; Du, H.; Liu, W.; Tang, L.; Xing, F. Evolution of Microstructural Characteristics of Carbonated Cement Pastes Subjected to High Temperatures Evaluated by MIP and SEM. Materials 2022, 15, 6037. [Google Scholar] [CrossRef]

- Pinheiro, D.G.L.; Sousa, M.I.C.; Pelisser, F.; da Silva Rêgo, J.H.; Moragues Terrades, A.; Frías Rojas, M. Physical and Chemical Effects in Blended Cement Pastes Elaborated with Calcined Clay and Nanosilica. Materials 2023, 16, 1837. [Google Scholar] [CrossRef]

- Beaudoin, J.J. Porosity measurement of some hydrated cementitious systems by high pressure mercury intrusion-microstructural limitations. Cem. Concr. Res. 1979, 9, 771–781. [Google Scholar] [CrossRef]

- Hidalgo, A.; Petit, S.; García Calvo, J.L.; Alonso, C.; Andrade, C. Microstructure of the system calcium aluminate cement-silica fume: Application in waste immobilization. Stud. Surf. Sci. Catal. 2007, 170, 1617–1628. [Google Scholar] [CrossRef]

- Hasanuzzaman, M.; Harunur Rashid, A.R.M.; Olabi, A.-G. Characterization of Porous Glass and Ceramics by Mercury Intrusion Porosimetry. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Yao, Y.; Liu, D. Comparison of low-field NMR and mercury intrusion porosimetry in characterizing pore size distributions of coals. Fuel 2012, 95, 152–158. [Google Scholar] [CrossRef]

- Ardelean, I. The Effect of an Accelerator on Cement Paste Capillary Pores: NMR Relaxometry Investigations. Molecules 2021, 26, 5328. [Google Scholar] [CrossRef] [PubMed]

- Pop, A.; Ardelean, I. Monitoring the size evolution of capillary pores in cement paste during the early hydration via diffusion in internal gradients. Cem. Concr. Res. 2015, 77, 76–81. [Google Scholar] [CrossRef]

- Xu, J.; Zhan, P.; Zhou, W.; Zuo, J.; Shah, S.P.; He, Z. Design and assessment of eco-friendly ultra-high performance concrete with steel slag powder and recycled glass powder. Powder Technol. 2023, 419, 118356. [Google Scholar] [CrossRef]

- Rusu, M.M.; Vulpoi, A.; Vilau, C.; Dudescu, C.M.; Păşcuţă, P.; Ardelean, I. Analyzing the Effects of Calcium Nitrate over White Portland Cement: A Multi-Scale Approach. Materials 2022, 16, 371. [Google Scholar] [CrossRef]

- Rusu, M.M.; Vilau, C.; Dudescu, C.; Pascuta, P.; Popa, F.; Ardelean, I. Characterization of the Influence of an Accelerator upon the Porosity and Strength of Cement Paste by Nuclear Magnetic Resonance (NMR) Relaxometry. Anal. Lett. 2023, 56, 303–311. [Google Scholar] [CrossRef]

- SR EN 197-1; Cement. Part I: Composition, Specifications and Conformity Criteria for Normal Use Cements. ASRO (Romanian Standards Association): Bucharest, Romania, 2011.

- Favier, A.; De Wolf, C.; Scrivener, K.; Habert, G. A Sustainable Future for the European Cement and Concrete Industry; ETH: Zurich, Switzerland, 2018. [Google Scholar]

- ASTM C 618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2022.

- Sáez, P.; Rodríguez, A.; Gómez, J.M.; Paramio, C.; Fraile, C.; Díez, E. H-Clinoptilolite as an Efficient and Low-Cost Adsorbent for Batch and Continuous Gallium Removal from Aqueous Solutions. J. Sustain. Metall. 2021, 7, 1699–1716. [Google Scholar] [CrossRef]

- Carr, H.Y.; Purcell, E.M. Effects of Diffusion on Free Precession in Nuclear Magnetic Resonance Experiments. Phys. Rev. 1954, 94, 630–638. [Google Scholar] [CrossRef]

- Meiboom, S.; Gill, D. Modified Spin-Echo Method for Measuring Nuclear Relaxation Times. Rev. Sci. Instrum. 1958, 29, 688–691. [Google Scholar] [CrossRef] [Green Version]

- Provencher, S.W. CONTIN: A general purpose constrained regularization program for inverting noisy linear algebraic and integral equations. Comput. Phys. Commun. 1982, 27, 229–242. [Google Scholar] [CrossRef]

- Bede, A.; Scurtu, A.; Ardelean, I. NMR relaxation of molecules confined inside the cement paste pores under partially saturated conditions. Cem. Concr. Res. 2016, 89, 56–62. [Google Scholar] [CrossRef]

- Cadar, C.; Cotet, C.; Baia, L.; Barbu-Tudoran, L.; Ardelean, I. Probing into the mesoporous structure of carbon xerogels via the low-field NMR relaxometry of water and cyclohexane molecules. Microporous Mesoporous Mater. 2017, 251, 19–25. [Google Scholar] [CrossRef]

- Dilbas, H. Effect of Cement Type and Water-to-Cement Ratio on Fresh Properties of Superabsorbent Polymer-Modified Cement Paste. Materials 2023, 16, 2614. [Google Scholar] [CrossRef] [PubMed]

- SR EN 196-3:2017; Methods of Testing Cement. Determination of Setting Times and Soundness. ASRO (Romanian Standards Association): Bucharest, Romania, 2017.

- Chen, J.J.; Li, L.G.; Ng, P.L.; Kwan, A.K.H. Effects of superfine zeolite on strength, flowability and cohesiveness of cementitious paste. Cem. Concr. Compos. 2017, 83, 101–110. [Google Scholar] [CrossRef]

- Kocak, Y.; Tascı, E.; Kaya, U. The effect of using natural zeolite on the properties and hydration characteristics of blended cements. Constr. Build. Mater. 2013, 47, 720–727. [Google Scholar] [CrossRef]

- Liguori, B.; Aprea, P.; Gennaro, B.d.; Iucolano, F.; Colella, A.; Caputo, D. Pozzolanic Activity of Zeolites: The Role of Si/Al Ratio. Materials 2019, 12, 4231. [Google Scholar] [CrossRef] [Green Version]

- Ramezanianpour, A.A.; Mousavi, R.; Kalhori, M.; Sobhani, J.; Najimi, M. Micro and macro level properties of natural zeolite contained concretes. Constr. Build. Mater. 2015, 101, 347–358. [Google Scholar] [CrossRef]

- Kang, Y.; Swain, B.; Im, B.; Yoon, J.-H.; Park, K.H.; Lee, C.G.; Kim, D.G. Synthesis of Zeolite Using Aluminum Dross and Waste LCD Glass Powder: A Waste to Waste Integration Valorization Process. Metals 2019, 9, 1240. [Google Scholar] [CrossRef] [Green Version]

- Cornejo, M.H.; Elsen, J.; Baykara, H.; Paredes, C. Hydration process of zeolite-rich tuffs and siltstone-blended cement pastes at low W/B ratio, under wet curing condition. Eur. J. Environ. Civ. Eng. 2014, 18, 629–651. [Google Scholar] [CrossRef] [Green Version]

- Caputo, D.; Liguori, B.; Colella, C. Some advances in understanding the pozzolanic activity of zeolites: The effect of zeolite structure. Cem. Concr. Compos. 2008, 30, 455–462. [Google Scholar] [CrossRef]

- Rudžionis, Ž.; Adhikary, S.K.; Manhanga, F.C.; Ashish, D.K.; Ivanauskas, R.; Stelmokaitis, G.; Navickas, A.A. Natural zeolite powder in cementitious composites and its application as heavy metal absorbents. J. Build. Eng. 2021, 43, 103085. [Google Scholar] [CrossRef]

- Florez, C.; Restrepo-Baena, O.; Tobon, J.I. Effects of calcination and milling pre-treatments on natural zeolites as a supplementary cementitious material. Constr. Build. Mater. 2021, 310, 125220. [Google Scholar] [CrossRef]

- Chen, X.; Wu, S. Influence of water-to-cement ratio and curing period on pore structure of cement mortar. Constr. Build. Mater. 2013, 38, 804–812. [Google Scholar] [CrossRef]

- He, Z.; Cai, R.; Chen, E.; Tang, S. The investigation of early hydration and pore structure for limestone powder wastes blended cement pastes. Constr. Build. Mater. 2019, 229, 116923. [Google Scholar] [CrossRef]

- Shahbazpanahi, S.; Tajara, M.K.; Faraj, R.H.; Mosavi, A. Studying the C–H Crystals and Mechanical Properties of Sustainable Concrete Containing Recycled Coarse Aggregate with Used Nano-Silica. Crystals 2021, 11, 122. [Google Scholar] [CrossRef]

- Toma, I.-O.; Alexa-Stratulat, S.-M.; Mihai, P.; Toma, A.-M.; Venghiac, V.-M. Influence of elevated temperature on the early age properties of cement mortar with zeolite powder. In Proceedings of the 22nd International Multidisciplinary Scientific GeoConference SGEM 2022, Vienna, Austria, 6–8 December 2022; pp. 429–436. [Google Scholar]

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | Na2O | K2O | Cl | |

|---|---|---|---|---|---|---|---|---|---|

| CEM II | 58.49 | 16.32 | 4.83 | 2.24 | 1.39 | 2.85 | 0.34 | 0.46 | 0.035 |

| Zeolite | 2.86–5.2 | 68.75–71.30 | 11.35–13.10 | 1.90–2.10 | 1.18–1.20 | - | 0.82–1.30 | 3.17–3.40 | - |

| Mix | Binder | Water/Binder | |

|---|---|---|---|

| CEM II | Micronized Zeolite | ||

| [%] | [%] | [%] | |

| Ref | 100 | - | 0.6 |

| ZP10 | 90 | 10 | |

| ZP20 | 80 | 20 | |

| ZP30 | 70 | 30 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toma, I.-O.; Stoian, G.; Rusu, M.-M.; Ardelean, I.; Cimpoeşu, N.; Alexa-Stratulat, S.-M. Analysis of Pore Structure in Cement Pastes with Micronized Natural Zeolite. Materials 2023, 16, 4500. https://doi.org/10.3390/ma16134500

Toma I-O, Stoian G, Rusu M-M, Ardelean I, Cimpoeşu N, Alexa-Stratulat S-M. Analysis of Pore Structure in Cement Pastes with Micronized Natural Zeolite. Materials. 2023; 16(13):4500. https://doi.org/10.3390/ma16134500

Chicago/Turabian StyleToma, Ionut-Ovidiu, George Stoian, Mihai-Marius Rusu, Ioan Ardelean, Nicanor Cimpoeşu, and Sergiu-Mihai Alexa-Stratulat. 2023. "Analysis of Pore Structure in Cement Pastes with Micronized Natural Zeolite" Materials 16, no. 13: 4500. https://doi.org/10.3390/ma16134500