Carbon Monoxide Production during Bio-Waste Composting under Different Temperature and Aeration Regimes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

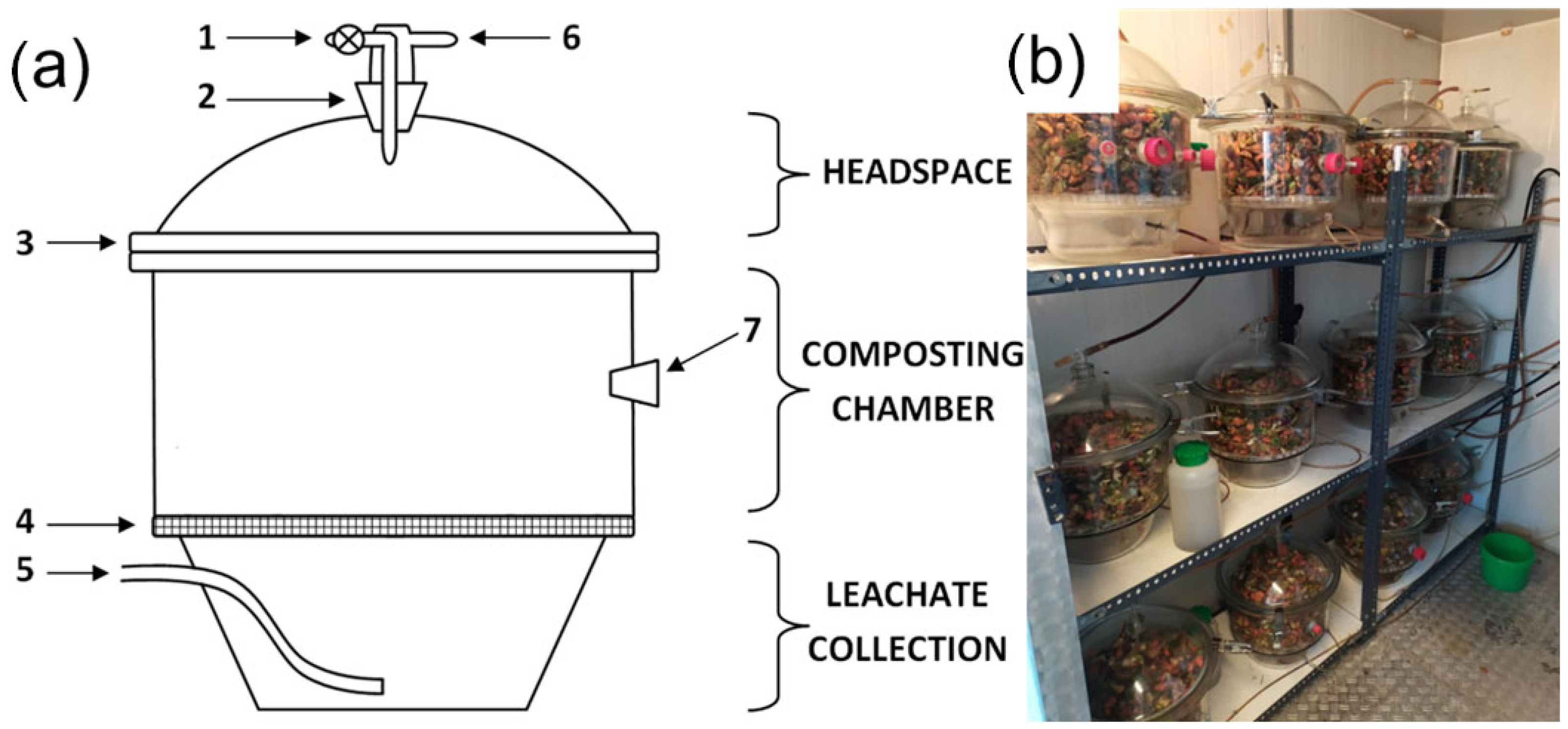

2.2. Bio-Waste Composting

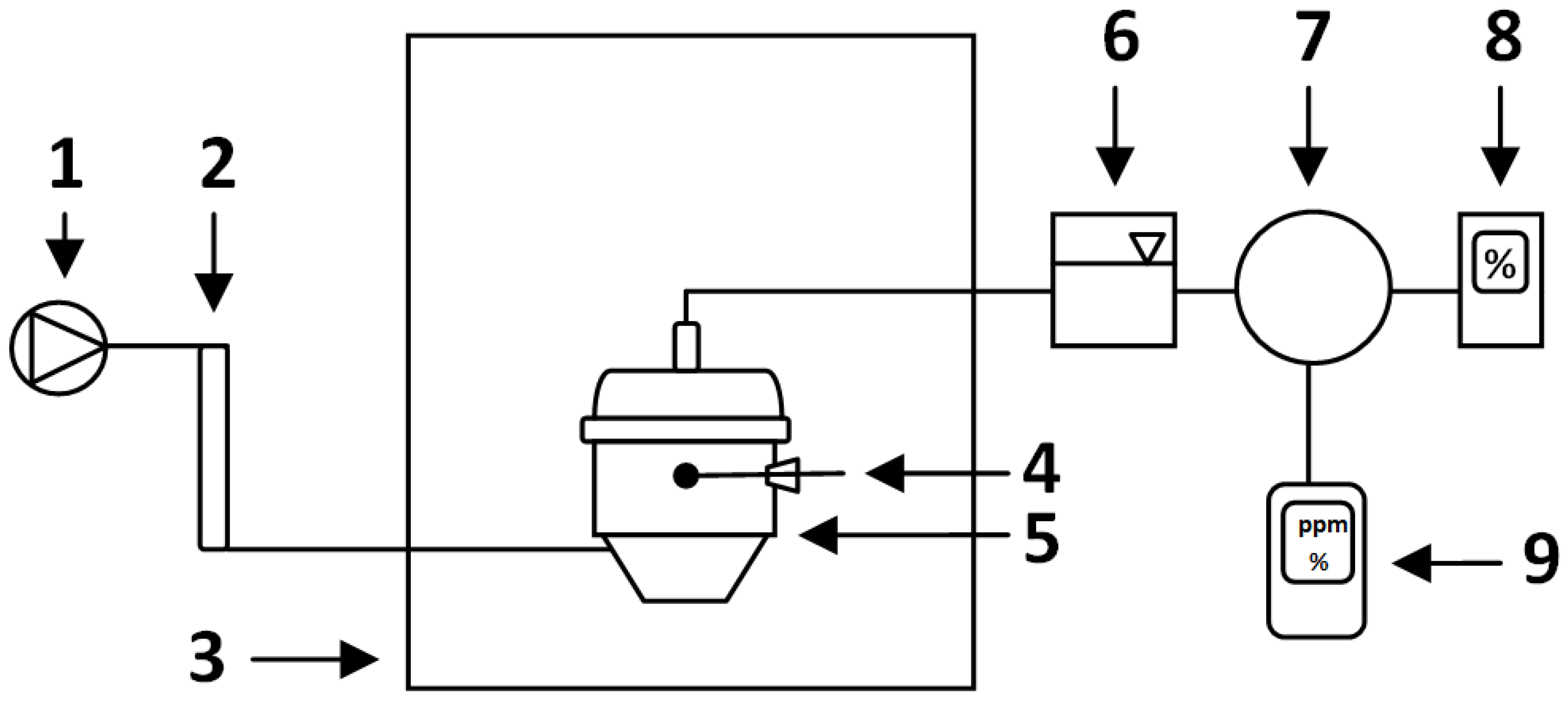

2.3. Measurements of Process Gases Concentration and Temperature

2.4. Bio-Waste Samples Collection

2.5. Bio-Waste and Compost Characterization

2.6. Calculations

2.7. Statistical Analyses

3. Results

3.1. Bio-Waste Initial Properties

3.2. Composts Properties

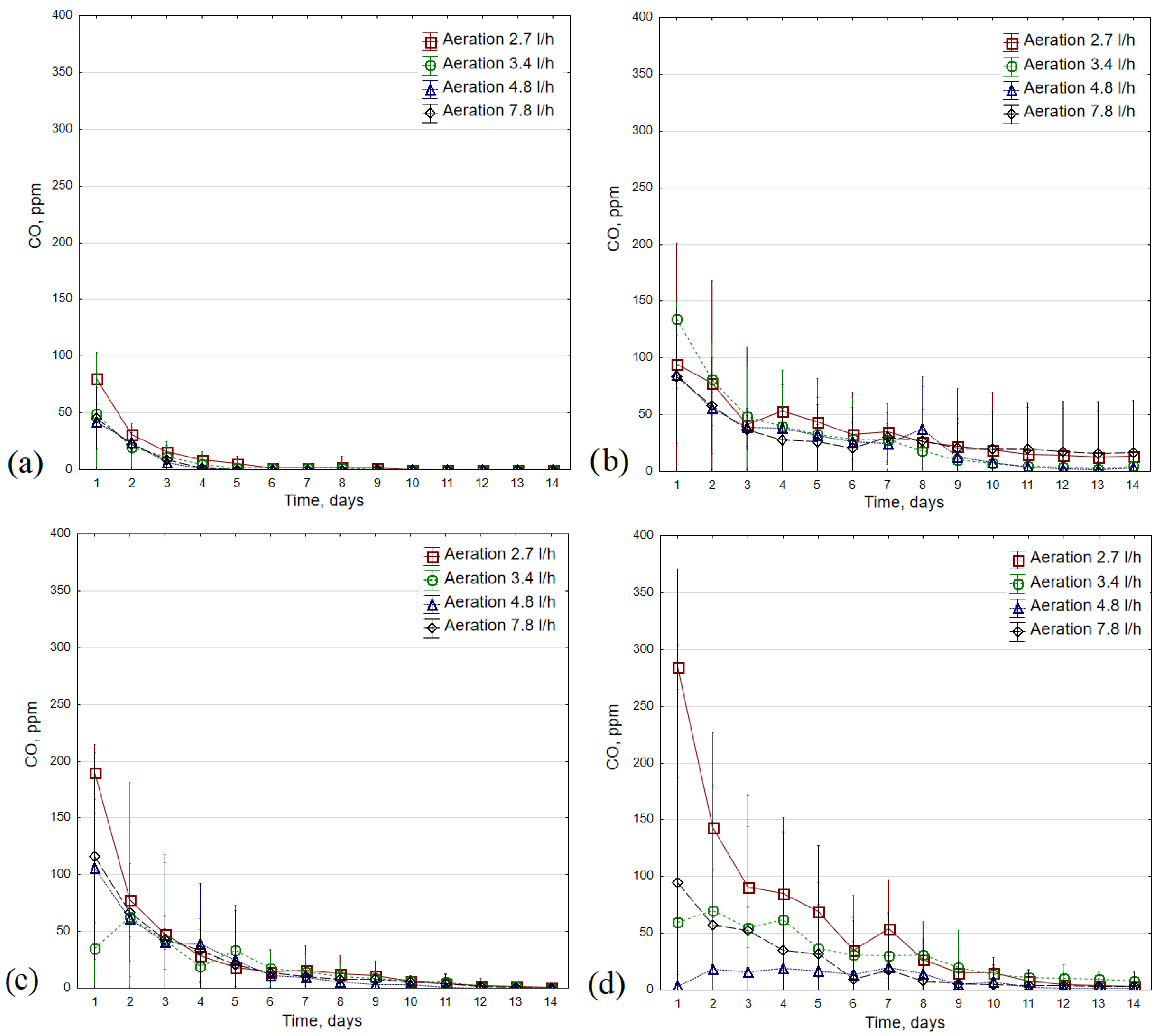

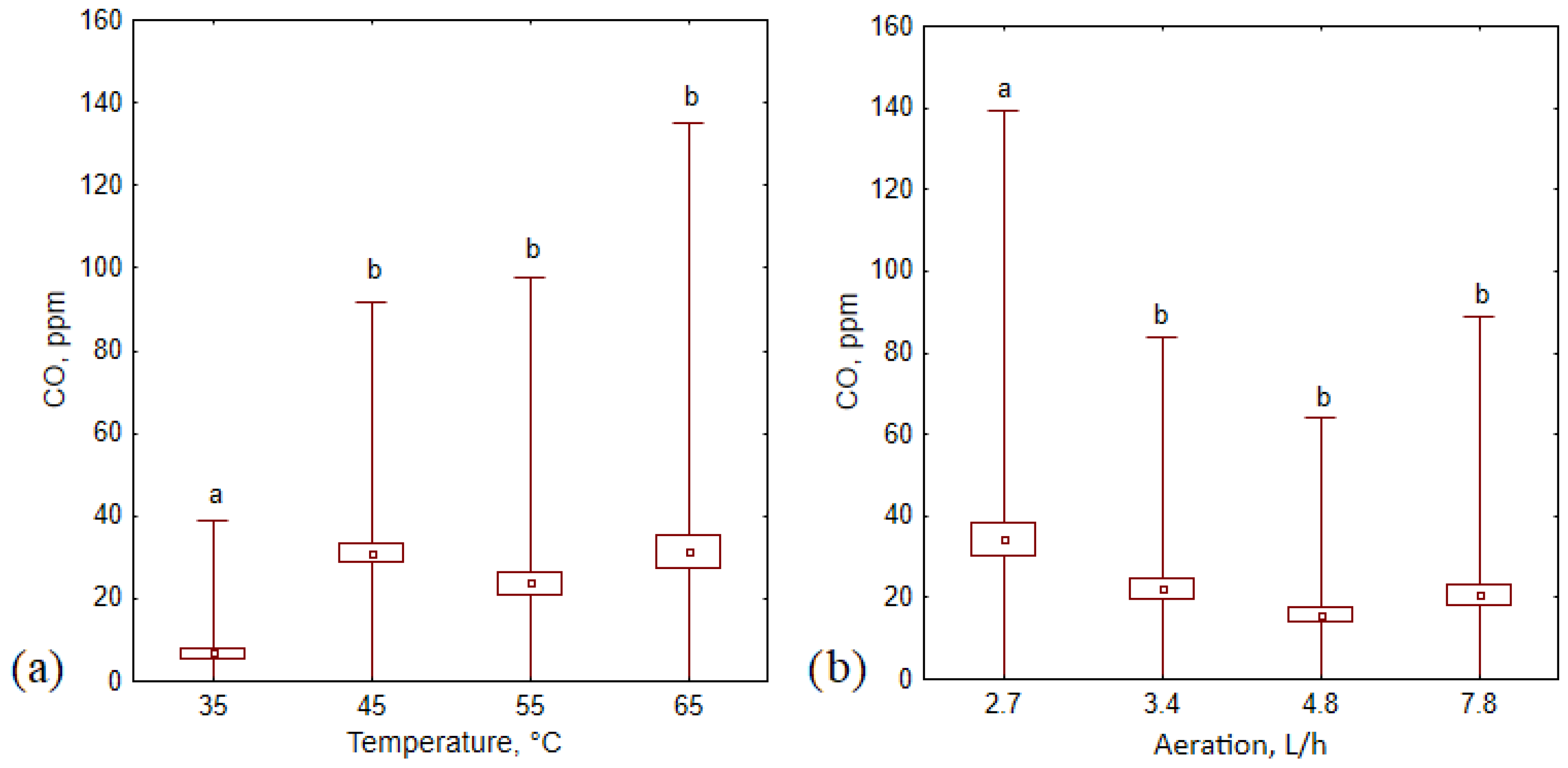

3.3. CO Concentrations

3.4. CO Production Kinetics

4. Discussion

5. Conclusions and Future Research Recommendations

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| EC | electrical conductivity |

| TOC | total organic carbon |

| TN | total nitrogen |

| LOI | loss on ignition |

| AT4 | respiratory activity |

| NH4-N | ammonium nitrogen content |

| NO3-N | nitrate nitrogen content |

References

- Awasthi, M.K.; Sindhu, R.; Sirohi, R.; Kumar, V.; Ahluwalia, V.; Binod, P.; Juneja, A.; Kumar, D.; Yan, B.; Sarsaiya, S.; et al. Agricultural waste biorefinery development towards circular bioeconomy. Renew. Sustain. Energy Rev. 2022, 158, 112122. [Google Scholar] [CrossRef]

- Sobieraj, K.; Stegenta-Dąbrowska, S.; Luo, G.; Koziel, J.A.; Białowiec, A. Biological treatment of biowaste as an innovative source of CO—The role of composting process. Front. Bioeng. Biotechnol. 2023, 11, 1126737. [Google Scholar] [CrossRef] [PubMed]

- Stegenta, S.; Sobieraj, K.; Pilarski, G.; Koziel, J.A.; Białowiec, A. Analysis of the Spatial and Temporal Distribution of Process Gases within Municipal Biowaste Compost. Sustainability 2019, 11, 2340. [Google Scholar] [CrossRef] [Green Version]

- Stegenta, S.; Dębowski, M.; Bukowski, P.; Randerson, P.F.; Białowiec, A. The influence of perforation of foil reactors on greenhouse gas emission rates during aerobic biostabilization of the undersize fraction of municipal wastes. J. Environ. Manag. 2018, 207, 355–365. [Google Scholar] [CrossRef] [PubMed]

- Stegenta-Dąbrowska, S.; Randerson, P.F.; Christofides, S.R.; Białowiec, A. Carbon Monoxide Formation during Aerobic Biostabilization of the Organic Fraction of Municipal Solid Waste: The Influence of Technical Parameters in a Full-Scale Treatment System. Energies 2020, 13, 5624. [Google Scholar] [CrossRef]

- Phillip, E.A.; Clark, O.G.; Londry, K.; Yu, S.; Leonard, J. Emission of Carbon Monoxide During Composting of Municipal Solid Waste. Compost Sci. Util. 2011, 19, 170–177. [Google Scholar] [CrossRef]

- Hellebrand, H.J.; Kalk, W.-D. Emission of carbon monoxide during composting of dung and green waste. Nutr. Cycl. Agroecosystems 2001, 60, 79–82. [Google Scholar] [CrossRef]

- Haarstad, K.; Bergersen, O.; Sorheim, R. Occurrence of carbon monoxide during organic waste degradation. J. Air Waste Manag. Assoc. 2006, 56, 575–581. [Google Scholar] [CrossRef] [Green Version]

- Ma, X.; Albertsma, J.; Gabriels, D.; Horst, R.; Polat, S.; Snoeks, C.; Kapteijn, F.; Burak Eral, H.; Vermaas, D.A.; Mei, B.; et al. Carbon monoxide separation: Past, present and future. Chem. Soc. Rev. 2023, 52, 3741–3777. [Google Scholar] [CrossRef]

- Abubackar, H.N.; Veiga, M.C.; Kennes, C. Biological conversion of carbon monoxide: Rich syngas or waste gases to bioethanol. Biofuels Bioprod. Biorefining 2011, 5, 93–114. [Google Scholar] [CrossRef] [Green Version]

- Cha, S.; Lim, H.G.; Kwon, S.; Kim, D.; Kang, C.W.; Jung, G.Y. Design of mutualistic microbial consortia for stable conversion of carbon monoxide to value-added chemicals. Metab. Eng. 2021, 64, 146–153. [Google Scholar] [CrossRef]

- Du, C.; Lu, P.; Tsubaki, N. Efficient and New Production Methods of Chemicals and Liquid Fuels by Carbon Monoxide Hydrogenation. ACS Omega 2020, 5, 49–56. [Google Scholar] [CrossRef] [PubMed]

- Watson, J.; Zhang, Y.; Si, B.; Chen, W.-T.; de Souza, R. Gasification of biowaste: A critical review and outlooks. Renew. Sustain. Energy Rev. 2018, 83, 1–17. [Google Scholar] [CrossRef]

- Hellebrand, H.J. Emission of Nitrous Oxide and other Trace Gases during Composting of Grass and Green Waste. J. Agric. Eng. Res. 1998, 69, 365–375. [Google Scholar] [CrossRef] [Green Version]

- Hellebrand, H. Carbon Monoxide from Composting due to Thermal Oxidation of Biomass: An Additional Pathway for CO in Agricultural and Forest Ecosystems. In Proceedings of the Workshop on Agricultural Air Quality: State of the Science, Potomac, MA, USA, 4 June 2006. [Google Scholar]

- Hellebrand, H.; Schade, G. Carbon Monoxide from Composting due to Thermal Oxidation of Biomass. J. Environ. Qual. 2008, 37, 592–598. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stegenta-Dąbrowska, S.; Drabczyński, G.; Sobieraj, K.; Koziel, J.A.; Białowiec, A. The Biotic and Abiotic Carbon Monoxide Formation During Aerobic Co-digestion of Dairy Cattle Manure With Green Waste and Sawdust. Front. Bioeng. Biotechnol. 2019, 7, 283. [Google Scholar] [CrossRef]

- Stegenta-Dąbrowska, S.; Sobieraj, K.; Koziel, J.A.; Bieniek, J.; Białowiec, A. Kinetics of Biotic and Abiotic CO Production during the Initial Phase of Biowaste Composting. Energies 2020, 13, 5451. [Google Scholar] [CrossRef]

- King, G.M. Attributes of atmospheric carbon monoxide oxidation by Maine forest soils.—Abstract—Europe PMC. Appl. Environ. Microbiol. 1999, 65, 5257–5264. [Google Scholar] [CrossRef] [Green Version]

- Rich, J.J.; King, G.M. Carbon monoxide consumption and production by wetland peats. FEMS Microbiol. Ecol. 1999, 28, 215–224. [Google Scholar] [CrossRef]

- Grassinger, D. Einfluß von Temperatur und Sauerstoffgehalt auf Die Humifizierung und Die Mineralisierung bei der Verrottung von Bioabfall; Universität für Bodenkultur Wien: Vienna, Austria, 1998. [Google Scholar]

- Świechowski, K.; Rasaq, W.A.; Stegenta-Dąbrowska, S.; Białowiec, A. Characterization of Engineered Biochar: Proximate Analyses, Ultimate Analyses, Physicochemical Analyses, Surface Analyses, and Molecular Analyses. In Engineered Biochar: Fundamentals, Preparation, Characterization and Applications; Ramola, S., Mohan, D., Masek, O., Méndez, A., Tsubota, T., Eds.; Springer Nature: Singapore, 2022; pp. 127–148. ISBN 978-981-19248-8-0. [Google Scholar]

- Binner, E.; Böhm, K.; Lechner, P. Large scale study on measurement of respiration activity (AT(4)) by Sapromat and OxiTop. Waste Manag. 2012, 32, 1752–1759. [Google Scholar] [CrossRef]

- Sobieraj, K.; Derkacz, D.; Krasowska, A.; Białowiec, A. Isolation and identification of CO-producing microorganisms from compost. Environ. Microbiol. Rep. 2023. (under review). [Google Scholar]

- Sáez, J.A.; Clemente, R.; Bustamante, M.Á.; Yañez, D.; Bernal, M.P. Evaluation of the slurry management strategy and the integration of the composting technology in a pig farm—Agronomical and environmental implications. J. Environ. Manag. 2017, 192, 57–67. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Hu, Z.; Zhang, J.; Xie, H.; Guimbaud, C.; Fang, Y. Effects of pH on nitrogen transformations in media-based aquaponics. Bioresour. Technol. 2016, 210, 81–87. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Environment of Republic of Poland. Regulation of the Minister of the Environment of September 11, 2012 on the mechanical and biological treatment of unsorted municipal waste. J. Laws 2012, 2012, 1052. [Google Scholar]

- García-Sánchez, M.; Taušnerová, H.; Hanč, A.; Tlustoš, P. Stabilization of different starting materials through vermicomposting in a continuous-feeding system: Changes in chemical and biological parameters. Waste Manag. 2017, 62, 33–42. [Google Scholar] [CrossRef]

- Sharma, D.; Varma, V.S.; Yadav, K.D.; Kalamdhad, A.S. Evolution of chemical and biological characterization during agitated pile composting of flower waste. Int. J. Recycl. Org. Waste Agric. 2017, 6, 89–98. [Google Scholar] [CrossRef] [Green Version]

- Soobhany, N.; Gunasee, S.; Rago, Y.P.; Joyram, H.; Raghoo, P.; Mohee, R.; Garg, V.K. Spectroscopic, thermogravimetric and structural characterization analyses for comparing Municipal Solid Waste composts and vermicomposts stability and maturity. Bioresour. Technol. 2017, 236, 11–19. [Google Scholar] [CrossRef]

- Esmaeili, A.; Khoram, M.R.; Gholami, M.; Eslami, H. Pistachio waste management using combined composting-vermicomposting technique: Physico-chemical changes and worm growth analysis. J. Clean. Prod. 2020, 242, 118523. [Google Scholar] [CrossRef]

- Aydın Temel, F. Evaluation of the influence of rice husk amendment on compost quality in the composting of sewage sludge. Bioresour. Technol. 2023, 373, 128748. [Google Scholar] [CrossRef]

- Biester, A.; Dementin, S.; Drennan, C.L. Visualizing the gas channel of a monofunctional carbon monoxide dehydrogenase. J. Inorg. Biochem. 2022, 230, 111774. [Google Scholar] [CrossRef]

- Wittenborn, E.C.; Guendon, C.; Merrouch, M.; Benvenuti, M.; Fourmond, V.; Léger, C.; Drennan, C.L.; Dementin, S. The Solvent-Exposed Fe–S D-Cluster Contributes to Oxygen-Resistance in Desulfovibrio vulgaris Ni–Fe Carbon Monoxide Dehydrogenase. ACS Catal. 2020, 10, 7328–7335. [Google Scholar] [CrossRef] [PubMed]

- Merrouch, M.; Hadj-Saïd, J.; Domnik, L.; Dobbek, H.; Léger, C.; Dementin, S.; Fourmond, V. O2 Inhibition of Ni-Containing CO Dehydrogenase Is Partly Reversible. Chem.-Eur. J. 2015, 21, 18934–18938. [Google Scholar] [CrossRef] [PubMed]

- Alfano, M.; Cavazza, C. The biologically mediated water–gas shift reaction: Structure, function and biosynthesis of monofunctional [NiFe]-carbon monoxide dehydrogenases. Sustain. Energy Fuels 2018, 2, 1653–1670. [Google Scholar] [CrossRef]

- Andreides, D.; Fliegerova, K.O.; Pokorna, D.; Zabranska, J. Biological conversion of carbon monoxide and hydrogen by anaerobic culture: Prospect of anaerobic digestion and thermochemical processes combination. Biotechnol. Adv. 2022, 58, 107886. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Can, M.; Ragsdale, S.W.; Armstrong, F.A. Fast and Selective Photoreduction of CO2 to CO Catalyzed by a Complex of Carbon Monoxide Dehydrogenase, TiO2, and Ag Nanoclusters. ACS Catal. 2018, 8, 2789–2795. [Google Scholar] [CrossRef]

- Robb, F.T.; Techtmann, S.M. Life on the fringe: Microbial adaptation to growth on carbon monoxide. F1000Research 2018, 7, 1981. [Google Scholar] [CrossRef] [Green Version]

- Sokolova, T.G.; Henstra, A.-M.; Sipma, J.; Parshina, S.N.; Stams, A.J.M.; Lebedinsky, A.V. Diversity and ecophysiological features of thermophilic carboxydotrophic anaerobes. FEMS Microbiol. Ecol. 2009, 68, 131–141. [Google Scholar] [CrossRef] [Green Version]

- Insam, H.; de Bertoldi, M. Chapter 3 Microbiology of the composting process. In Waste Management Series; Diaz, L.F., de Bertoldi, M., Bidlingmaier, W., Stentiford, E., Eds.; Compost Science and Technology; Elsevier: Amsterdam, The Netherlands, 2007; Volume 8, pp. 25–48. [Google Scholar]

- Swaidan, R.; Ghanem, B.; Litwiller, E.; Pinnau, I. Physical Aging, Plasticization and Their Effects on Gas Permeation in “Rigid” Polymers of Intrinsic Microporosity. Macromolecules 2015, 48, 6553–6561. [Google Scholar] [CrossRef] [Green Version]

- Gilbert, J.; Siebert, S. ECN Data Report 2022. Compost and Digestate for a Circular Bioeconomy. Overview of Bio-Waste Collection, Treatment & Markets Across Europe; European Compost Network ECN e.V: Bochum, Germany, 2022. [Google Scholar]

| Composting Series # | Compost Substrates | Duration of the Process, Days | Temperature, °C | Aeration Rate, L·h−1 |

|---|---|---|---|---|

| 1 | Bio-waste (green waste and vegetables) mixed with chopped branches | 14 | 35 | 2.7 |

| 3.4 | ||||

| 4.8 | ||||

| 7.8 | ||||

| 2 | 45 | 2.7 | ||

| 3.4 | ||||

| 4.8 | ||||

| 7.8 | ||||

| 3 | 55 | 2.7 | ||

| 3.4 | ||||

| 4.8 | ||||

| 7.8 | ||||

| 4 | 65 | 2.7 | ||

| 3.4 | ||||

| 4.8 | ||||

| 7.8 |

| Substrates for the Composting Process | ||||

|---|---|---|---|---|

| Properties ± std. dev. | 35 °C | 45 °C | 55 °C | 65 °C |

| pH | 7.48 ± 0.07 | 5.60 ± 0.01 | 6.51 ± 0.11 | 6.75 ± 0.09 |

| EC, mS·cm−1 | 3.53 ± 0.03 | 4.06 ± 0.05 | 3.09 ± 0.06 | 3.51 ± 0.04 |

| TOC, % d.m. | 35.66 ± 0.07 | 33.81 ± 0.47 | 33.03 ± 0.12 | 36.94 ± 0.83 |

| TN, % d.m. | 1.26 ± 0.02 | 1.50 ± 0.01 | 1.44 ± 0.03 | 1.62 ± 0.03 |

| C/N | 28 | 24 | 23 | 23 |

| Water content, % | 54.40 ± 0.30 | 55.70 ± 0.89 | 54.28 ± 0.32 | 61.00 ± 0.23 |

| LOI, % d.m. | 69.19 ± 0.26 | 67.48 ± 0.44 | 64.15 ± 0.30 | 71.01 ± 0.37 |

| AT4, mg O2·g d.m.−1 | 37.6 ± 0.2 | 64.0 ± 2.8 | 61.7 ± 1.2 | 71.1 ± 10.0 |

| NH4-N, mg·kg d.m.−1 | 140.46 ± 3.02 | 850.40 ± 13.76 | 689.28 ± 44.56 | 248.08 ± 1.63 |

| NO3-N, mg·kg d.m.−1 | 58.22 ± 6.10 | 82.90 ± 6.36 | 30.42 ± 12.69 | 169.62 ± 26.65 |

| Process Temperature, °C | Aeration Rate, L·h−1 | pH | EC | AT4 | TOC | TN | C/N | Water Content | LOI | NH4-N | NO3-N |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 35 | 2.7 | 12.47 | −24.54 | −65.38 | −6.17 | 38.93 | −32.14 | 3.27 | −8.21 | −90.94 | −51.23 |

| 3.4 | 12.47 | −25.25 | −65.65 | −6.87 | 43.77 | −35.71 | 1.65 | −8.89 | −89.95 | −33.10 | |

| 4.8 | 13.87 | −24.54 | −65.65 | −8.56 | 39.05 | −32.14 | −5.27 | −9.83 | −92.11 | −55.96 | |

| 7.2 | 15.08 | −23.40 | −66.18 | −8.70 | 46.42 | −35.71 | −0.73 | −11.70 | −93.21 | −66.07 | |

| 45 | 2.7 | −6.59 | 21.20 | −78.99 | −6.02 | 9.92 | −16.67 | 1.01 | −6.37 | 74.25 | −12.06 |

| 3.4 | 31.17 | 11.64 | −51.58 | −4.22 | 17.24 | −20.83 | 0.59 | −7.68 | −2.08 | −32.01 | |

| 4.8 | 32.06 | −0.49 | −27.23 | −9.66 | 22.50 | −29.17 | −7.49 | −10.22 | −22.49 | −4.45 | |

| 7.2 | 32.50 | −13.60 | −32.91 | −8.29 | 18.12 | −25.00 | −10.23 | −9.39 | −45.47 | −44.19 | |

| 55 | 2.7 | 27.59 | −19.68 | −46.19 | −3.02 | 19.07 | −17.39 | −12.36 | −5.15 | −43.29 | −7.94 |

| 3.4 | 27.44 | −22.90 | −76.23 | −4.06 | 28.45 | −26.09 | −23.68 | −8.93 | −80.02 | 184.66 | |

| 4.8 | 26.83 | −26.45 | −85.02 | −5.16 | 20.02 | −21.74 | −28.44 | −6.15 | −79.62 | −21.03 | |

| 7.2 | 27.36 | −22.90 | −80.00 | −8.54 | 29.52 | −30.43 | −28.84 | −7.18 | −89.53 | −30.12 | |

| 65 | 2.7 | 11.64 | −18.97 | −63.33 | −2.55 | 20.23 | −17.39 | −9.44 | −5.87 | 6.97 | −94.06 |

| 3.4 | 11.56 | −17.83 | −69.03 | −2.71 | 25.04 | −21.74 | −8.80 | −4.67 | −21.63 | −98.09 | |

| 4.8 | 14.68 | −26.96 | −75.93 | −3.06 | 15.45 | −17.39 | −15.98 | −4.84 | −61.60 | −85.16 | |

| 7.2 | 15.72 | −27.25 | −52.55 | −4.80 | 24.82 | −26.09 | −16.96 | −6.18 | −53.74 | −89.25 |

| Aeration Rate, L·h−1 | Weight Loss, % | 35 °C | 45 °C | 55 °C | 65 °C |

|---|---|---|---|---|---|

| 2.7 | Total | 11.44 ± 1.05 | 4.90 ± 2.50 | 7.48 ± 0.82 | 9.94 ± 0.96 |

| As leachate | 5.95 ± 1.03 | 0.99 ± 1.71 | 16.47 ± 1.65 | 9.20 ± 2.98 | |

| 3.4 | Total | 11.66 ± 1.16 | 8.09 ± 3.87 | 12.51 ± 0.85 | 12.04 ± 2.02 |

| As leachate | 6.18 ± 0.35 | 2.88 ± 2.50 | 18.84 ± 2.47 | 5.41 ± 4.69 | |

| 4.8 | Total | 13.64 ± 0.41 | 15.83 ± 9.10 | 16.15 ± 0.09 | 16.20 ± 0.37 |

| As leachate | 5.32 ± 0.83 | 7.43 ± 7.21 | 20.03 ± 0.82 | 12.31 ± 1.18 | |

| 7.8 | Total | 13.59 ± 0.76 | 12.88 ± 8.07 | 13.26 ± 1.27 | 16.14 ± 2.94 |

| As leachate | 5.80 ± 1.86 | 4.71 ± 4.93 | 20.10 ± 2.88 | 14.61 ± 4.09 |

| The Composting Variant, °C | Ambient Temperature, °C | Compost Temperature, °C | CO2, % | O2, % | |

|---|---|---|---|---|---|

| CO, ppm | 35 | 0.22 * | 0.59 * | 0.40 * | −0.47 * |

| 45 | −0.03 | −0.24 * | −0.03 | 0.09 | |

| 55 | −0.11 | −0.56 * | −0.53 * | 0.55 * | |

| 65 | 0.31 * | 0.16 | 0.22 * | −0.11 |

| Process T, °C | Aeration, L·h−1 | Reaction Order | CCO max, ppm | k, d−1 | a = k·CCO max, ppm·d−1 |

|---|---|---|---|---|---|

| 35 | 2.7 | 1st-order | 185.3 ± 21.4 | 0.846 ± 0.025 | 156.5 ± 15.6 |

| 3.4 | 1st-order | 109.5 ± 52.5 | 0.822 ± 0.185 | 90.4 ± 43.1 | |

| 4.8 | 1st-order | 101.0 ± 19.0 | 0.834 ± 0.160 | 86.2 ± 32.5 | |

| 7.8 | 1st-order | 120.1 ± 77.7 | 0.850 ± 0.335 | 119.4 ± 120.5 | |

| 45 | 2.7 | 1st-order | 103.1 ± 44.0 | 0.185 ± 0.053 | 18.5 ± 8.8 |

| 3.4 | 1st-order | 214.6 ± 84.7 | 0.453 ± 0.301 | 114.2 ± 116.2 | |

| 4.8 | 1st-order | 95.6 ± 12.4 | 0.218 ± 0.041 | 21.1 ± 6.5 | |

| 7.8 | 1st-order | 80.2 ± 18.2 | 0.179 ± 0.092 | 14.9 ± 10.2 | |

| 55 | 2.7 | 1st-order | 471.9 ± 283.4 | 0.816 ± 0.496 | 478.8 ± 530.0 |

| 3.4 | 1st-order | 168.8 ± 84.4 | 0.338 ± 0.088 | 61.9 ± 46.1 | |

| 4.8 | 1st-order | 153.0 ± 19.3 | 0.410 ± 0.051 | 62.2 ± 5.0 | |

| 7.8 | 1st-order | 183.9 ± 87.3 | 0.434 ± 0.157 | 89.0 ± 61.6 | |

| 65 | 2.7 | 1st-order | 403.6 ± 43.1 | 0.422 ± 0.090 | 172.8 ± 56.2 |

| 3.4 | 1st-order | 127.5 ± 89.1 | 0.183 ± 0.111 | 29.9 ± 27.6 | |

| 4.8 | 0th-order | – | – | 0.09 ± 0.1 | |

| 7.8 | 1st-order | 161.9 ± 152.2 | 0.670 ± 0.620 | 92.0 ± 73.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sobieraj, K.; Stegenta-Dąbrowska, S.; Zafiu, C.; Binner, E.; Białowiec, A. Carbon Monoxide Production during Bio-Waste Composting under Different Temperature and Aeration Regimes. Materials 2023, 16, 4551. https://doi.org/10.3390/ma16134551

Sobieraj K, Stegenta-Dąbrowska S, Zafiu C, Binner E, Białowiec A. Carbon Monoxide Production during Bio-Waste Composting under Different Temperature and Aeration Regimes. Materials. 2023; 16(13):4551. https://doi.org/10.3390/ma16134551

Chicago/Turabian StyleSobieraj, Karolina, Sylwia Stegenta-Dąbrowska, Christian Zafiu, Erwin Binner, and Andrzej Białowiec. 2023. "Carbon Monoxide Production during Bio-Waste Composting under Different Temperature and Aeration Regimes" Materials 16, no. 13: 4551. https://doi.org/10.3390/ma16134551

APA StyleSobieraj, K., Stegenta-Dąbrowska, S., Zafiu, C., Binner, E., & Białowiec, A. (2023). Carbon Monoxide Production during Bio-Waste Composting under Different Temperature and Aeration Regimes. Materials, 16(13), 4551. https://doi.org/10.3390/ma16134551