Study on the Up-Conversion Luminescence and Conductivity Behavior of p-Type NiO:Yb,Er Thin Films

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

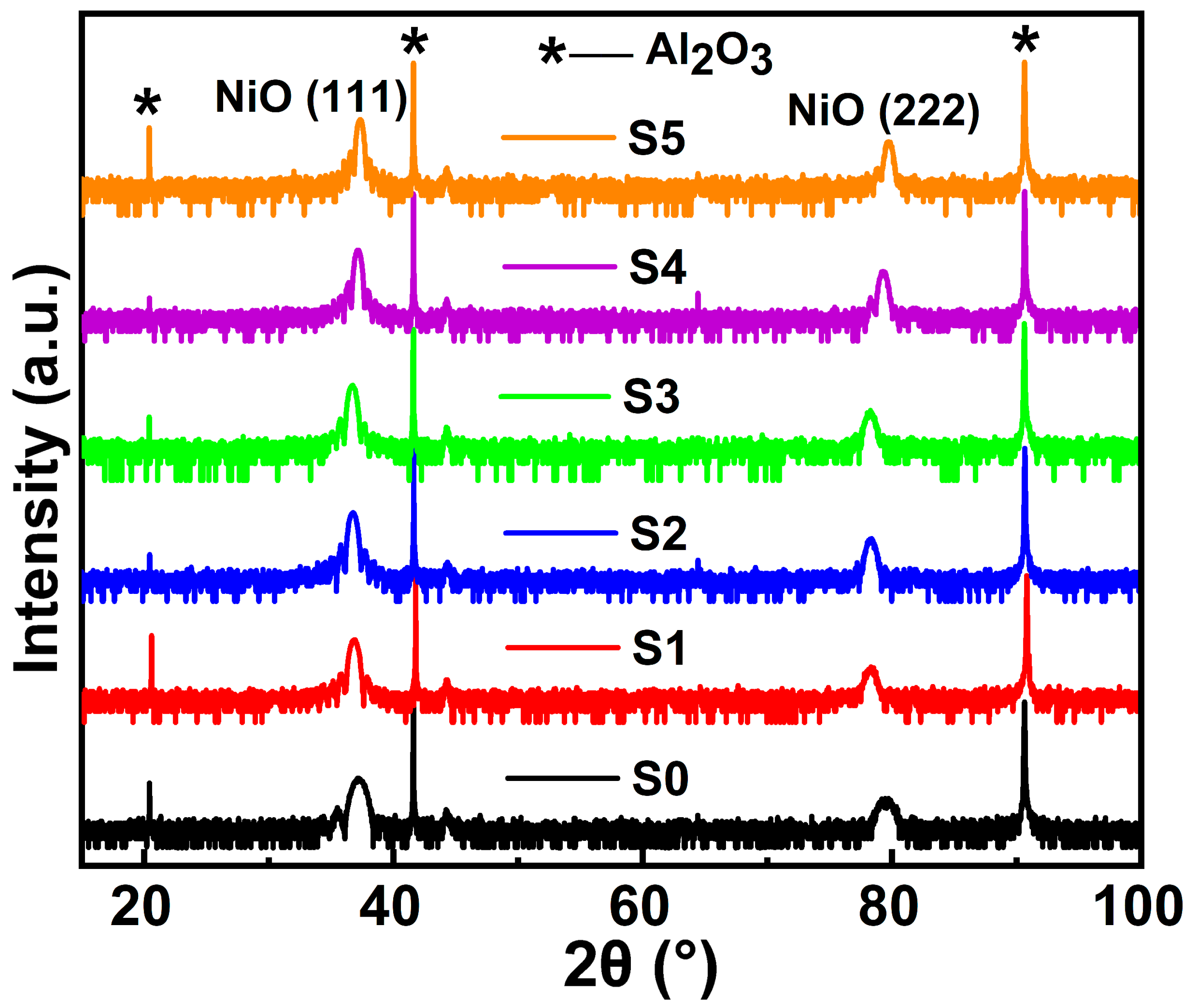

3.1. Crystalline Structure and Surface Morphology

3.2. Transmittance and UC Luminescence

3.3. Conductance Mechanism and Doping-Related Sheet Resistivity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, X.L.; Skripka, A.; Lai, Y.M.; Jiang, C.; Liu, J.D.; Vetrone, F.; Liang, J.Y. Fast wide-field upconversion luminescence lifetime thermometry enabled by single-shot compressed ultrahigh-speed imaging. Nat. Commun. 2021, 12, 6401. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Liu, Q.; Feng, W.; Sun, Y.; Li, F.Y. Upconversion Luminescent Materials: Advances and Applications. Chem. Rev. 2015, 115, 395–465. [Google Scholar] [CrossRef] [PubMed]

- Jones, C.M.S.; Biner, D.; Misopoulos, S.; Kramer, K.W.; Marques-Hueso, J. Optimized photoluminescence quantum yield in upconversion composites considering the scattering, inner-filter effects, thickness, self-absorption, and temperature. Sci. Rep. 2021, 11, 13910. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Kankala, R.K.; Liu, C.G.; Wang, S.B.; Chen, A.Z.; Zhang, Y. Lanthanides-doped near-infrared active upconversion nanocrystals: Upconversion mechanisms and synthesis. Coordin. Chem. Rev. 2021, 438, 213870. [Google Scholar] [CrossRef]

- Khare, A. A critical review on the efficiency improvement of upconversion assisted solar cells. J. Alloys Compd. 2020, 821, 153214. [Google Scholar] [CrossRef]

- Wang, N.L.; He, J.F. Color-tunable infrared-to-visible upconversion luminescence and intensified 1.54 μm near-infrared emission in Y2O3:Yb3+, Er3+, Eu3+ phosphors prepared by sol-gel method. J. Lumin. 2023, 257, 119718. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, H.; Xia, H.P.; Song, H.W.; Chen, X.; Hu, J.X.; Chen, B.J. Efficient up-conversion Yb3+, Er3+ co-doped Na2Lu9F32 single crystal for photovoltaic application under solar cell spectrum excitation. Chin. Chem. Lett. 2019, 17, 091601. [Google Scholar]

- Wang, J.; Deng, R.R.; MacDonald, M.A.; Chen, B.; Yuan, J.K.; Wang, F.; Chi, D.Z.; Hor, T.S.A.; Zhang, P.; Liu, P.K.; et al. Enhancing multiphoton upconversion through energy clustering at sublattice level. Nat. Mater. 2014, 13, 157–162. [Google Scholar] [CrossRef]

- Li, Z.; Lu, S.; Li, X.J.; Chen, Z.; Chen, X.Y. Lanthanide upconversion nanoplatforms for advanced bacteria-targeted detection and therapy. Adv. Opt. Mater. 2023, 11, 2202386. [Google Scholar] [CrossRef]

- Liao, J.Y.; Zhou, J.J.; Song, Y.L.; Liu, B.L.; Chen, Y.H.; Wang, F.; Chen, C.H.; Lin, J.; Chen, X.Y.; Lu, J.; et al. Preselectable optical fingerprints of heterogeneous upconversion nanoparticles. Nano Lett. 2021, 21, 7659–7668. [Google Scholar] [CrossRef]

- Tian, G.; Gu, Z.; Zhou, L.; Yin, W.; Liu, X.; Yan, L.; Jin, S.; Ren, W.; Xing, G.; Li, S.; et al. Mn2+ dopant-controlled synthesis of NaYF4:Yb/Er upconversion nanoparticles for in vivo imaging and drug delivery. Adv. Mater. 2012, 24, 1226–1231. [Google Scholar] [CrossRef]

- Han, S.Y.; Yi, Z.G.; Zhang, J.B.; Gu, Q.F.; Liang, L.L.; Qin, X.; Xu, J.H.; Wu, Y.M.; Xu, H.; Rao, A.; et al. Photon upconversion through triplet exciton-mediated energy relay. Nat. Commun. 2021, 12, 3704. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.Z.; Liang, L.L.; Liu, X.G. Lanthanide-doped nanoparticles in photovoltaics—More than just upconversion. J. Mater. Chem. C 2021, 9, 16110–16131. [Google Scholar] [CrossRef]

- Xu, F.; Sun, Y.; Gao, H.P.; Jin, S.Y.; Zhang, Z.L.; Zhang, H.F.; Pan, G.C.; Kang, M.; Ma, X.Q.; Mao, Y.L. Photovoltaic memristors based on photoelectric synaptic plasticity of a bulk photovoltaic effect device. ACS Appl. Mater. Interfaces 2021, 12, 2674–2684. [Google Scholar] [CrossRef] [PubMed]

- Cho, H.E.; Lee, N.K.; Song, Y.J.; Hong, J.; Kang, H.; Lim, S.Y.; Lee, J.; Kim, H.M.; Lee, N.; Cho, S.H.; et al. Strategically manipulated polymer solar cells to incorporate plasmonically enhanced spectral upconversion backplane. Adv. Opt. Mater. 2020, 8, 2000466. [Google Scholar] [CrossRef]

- Wang, M.; Wu, Y.Q.; Juan, F.Y.; Li, Y.J.; Shi, B.B.; Xu, F.; Jia, J.B.; Wei, H.M.; Cao, B.Q. Enhanced photocurrent of perovskite solar cells by dual-sensitized β-NaYF4:Nd3+/Yb3+/Er3+ up-conversion nanoparticles. Chem. Phys. Lett. 2021, 763, 138253. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Liu, J.J.; Ji, Y.; Li, D.K.; Xu, J.; Xu, L.; Chen, K.J. Enhanced up-conversion red light emission from rare earth titanium oxide nanocrystals with pyrochlore phase. Opt. Mater. Express 2018, 8, 2643–2653. [Google Scholar] [CrossRef]

- Jung, K.Y. Aerosol synthesis of TiO2:Er3+/Yb3+ submicron-sized spherical particles and upconversion optimization for application as anti-counterfeiting materials. RSC Adv. 2020, 10, 16323–16329. [Google Scholar] [CrossRef] [Green Version]

- Dong, J.; Li, Y.M.; Zheng, W.; Wang, R.; Xu, Y.L. Lower power dependent upconversion multicolor tunable properties in TiO2:Yb3+/Er3+/(Tm3+). Ceram. Int. 2019, 45, 432–438. [Google Scholar] [CrossRef]

- Wei, H.M.; Chen, X.; Wu, Y.Q.; Zhang, Y.Y.; Xu, J.; Cao, B.Q. Enhanced upconversion red light emission of TiO2:Yb,Er thin film via Mn doping. Opt. Express 2021, 29, 23159. [Google Scholar] [CrossRef]

- Wang, L.; Chen, K.C.; Tong, H.; Wang, K.; Tao, L.; Zhang, Y.X.; Zhou, X.F. Inverted pyramid Er3+ and Yb3+ co-doped TiO2 nanorod arrays based perovskite solar cell: Infrared response and improved current density. Ceram. Int. 2020, 46, 12073–12079. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Q.S.; Lv, Y.Q.; Yang, C.; Chen, H.H.; Zhou, X.F. Upconversion Er-doped TiO2 nanorod arrays for perovskite solar cells and the performance improvement. Mater. Res. Bull. 2018, 106, 346–352. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Z.L.; Qin, J.Q.; Shi, W.J.; Liu, Y.F.; Gao, H.P.; Mao, Y.L. Enhanced Photovoltaic Performance of Perovskite Solar Cells Based on Er-Yb Co-doped TiO2 Nanorod Arrays. Electrochim. Acta 2017, 245, 839–845. [Google Scholar] [CrossRef]

- Valadi, K.; Gharibi, S.; Taheri-Ledari, R.; Akin, S.; Maleki, A.; Shalan, A.E. Metal oxide electron transport materials for perovskite solar cells: A review. Environ. Chem. Lett. 2021, 19, 2185–2207. [Google Scholar] [CrossRef]

- Qiu, Z.W.; Gong, H.B.; Zheng, G.H.J.; Yuan, S.; Zhang, H.L.; Zhu, X.M.; Zhou, H.P.; Cao, Q.Q. Enhanced physical properties of pulsed laser deposited NiO films via annealing and lithium doping for improving perovskite solar cell efficiency. J. Mater. Chem. C 2017, 5, 7084–7094. [Google Scholar] [CrossRef]

- Park, J.H.; Seo, J.; Park, S.; Shin, S.S.; Kim, Y.C.; Jeon, N.J.; Shin, H.W.; Ahn, T.K.; Noh, J.H.; Yoon, S.C.; et al. Efficient CH3NH3PbI3 perovskite solar cells employing nanostructured p-type NiO electrode formed by a pulsed laser deposition. Adv. Mater. 2015, 27, 4013–4019. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.X.; Wei, H.M.; Wu, Y.Q.; Yang, C.; Han, P.G.; Juan, F.Y.; Chen, Y.; Xu, F.; Cao, B.Q. Highly transparent and conductive γ-CuI films grown by simply dipping copper films into iodine solution. Phys. B 2020, 384, 126831. [Google Scholar] [CrossRef]

- Yang, C.; Souchay, D.; Kneiβ, M.; Bogner, M.; Wei, H.M.; Lorenz, M.; Oeckler, O.; Benstetter, G.; Fu, Y.Q.; Grundmann, M. Transparent flexible thermoelectric material based on non-toxic earth-abundant p-type copper iodide thin film. Nat. Commun. 2017, 8, 16076. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.Q.; Liu, S.B.; Liu, J.J.; Ji, Y.; Xu, J.; Xu, L.; Chen, K.J. Efficient up-conversion red emission from TiO2:Yb,Er nanocrystals. Opt. Express 2017, 25, 22648–22657. [Google Scholar] [CrossRef]

- Wu, Y.Q.; Ji, Y.; Xu, X.; Liu, J.J.; Lin, Z.W.; Zhao, Y.L.; Sun, Y.; Xu, L.; Chen, K.J. Crystalline phase and morphology controlling to enhance the up-conversion emission from NaYF4:Yb,Er nanocrystals. Acta Mater. 2017, 131, 373–379. [Google Scholar] [CrossRef]

- Wu, Y.Q.; Zhang, Z.; Chen, X.; Wei, H.M.; Cao, B.Q. Enhancement of up-conversion luminescence through doping Ce3+ ions in YbxEr2− xTi2O7 thin films. Chem. Phys. Lett. 2022, 795, 139498. [Google Scholar] [CrossRef]

- Cao, B.S.; Wu, J.L.; Wang, X.H.; Feng, Z.Q.; Dong, B. Upconversion luminescence properties of Er3+ doped Yb2Ti2O7 nanophosphors by Gd3+ Codoping. J. Nanosci. Nanotechnol. 2016, 16, 3690–3694. [Google Scholar] [CrossRef] [PubMed]

- Nichols, J.; Korneta, O.B.; Terzic, J.; Long, L.E.D.; Cao, G.; Brill, J.W.; Seo, S.S.A. Anisotropic electronic properties of a-axis-oriented Sr2IrO4 epitaxial thin-films. Appl. Phys. Lett. 2013, 103, 131910. [Google Scholar] [CrossRef] [Green Version]

- Sta, I.; Jlassi, M.; Kandyla, M.; Hajji, M.; Koralli, P.; Allagui, R.; Kompitsas, M.; Ezzaouia, H. Hydrogen sensing by sol-gel grown NiO and NiO:Li thin films. J. Alloys Compd. 2015, 626, 87–92. [Google Scholar] [CrossRef] [Green Version]

- Wu, P.; Ligatchev, V.; Yu, Z.G.; Zheng, J.W.; Sullivan, M.B.; Zeng, Y.Z. Defects in codoped NiO with gigantic dielectric response. Phys. Rev. B 2009, 79, 235122. [Google Scholar] [CrossRef]

| Sample No. | Host Materials | Concentration of Li+ (%) | Sheet Resistivity (Ω/□) | Carriers Concentration (1/cm3) |

|---|---|---|---|---|

| S0 | NiO | 0 | 7.6 × 1010 | 6.1 × 1012 |

| S1 | NiO:Yb,Er | 0 | 6.9 × 1010 | 4.5 × 1011 |

| S2 | NiO:Yb,Er | 1% | 5.5 × 1010 | 4.1 × 1011 |

| S3 | NiO:Yb,Er | 2% | 2.8 × 109 | 5.1 × 1012 |

| S4 | NiO:Yb,Er | 5% | 3.1 × 106 | 1.1 × 1019 |

| S5 | NiO:Yb,Er | 10% | 3.8 × 105 | 4.5 × 1019 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, H.; Wu, Y. Study on the Up-Conversion Luminescence and Conductivity Behavior of p-Type NiO:Yb,Er Thin Films. Materials 2023, 16, 4637. https://doi.org/10.3390/ma16134637

Wei H, Wu Y. Study on the Up-Conversion Luminescence and Conductivity Behavior of p-Type NiO:Yb,Er Thin Films. Materials. 2023; 16(13):4637. https://doi.org/10.3390/ma16134637

Chicago/Turabian StyleWei, Haoming, and Yangqing Wu. 2023. "Study on the Up-Conversion Luminescence and Conductivity Behavior of p-Type NiO:Yb,Er Thin Films" Materials 16, no. 13: 4637. https://doi.org/10.3390/ma16134637