Effect of Plastic Deformation on the Structure and Mechanical Properties of the Zn-4Ag-1Cu Zinc Alloy

Abstract

1. Introduction

2. Experimental Section

2.1. Processing

2.2. Simulation

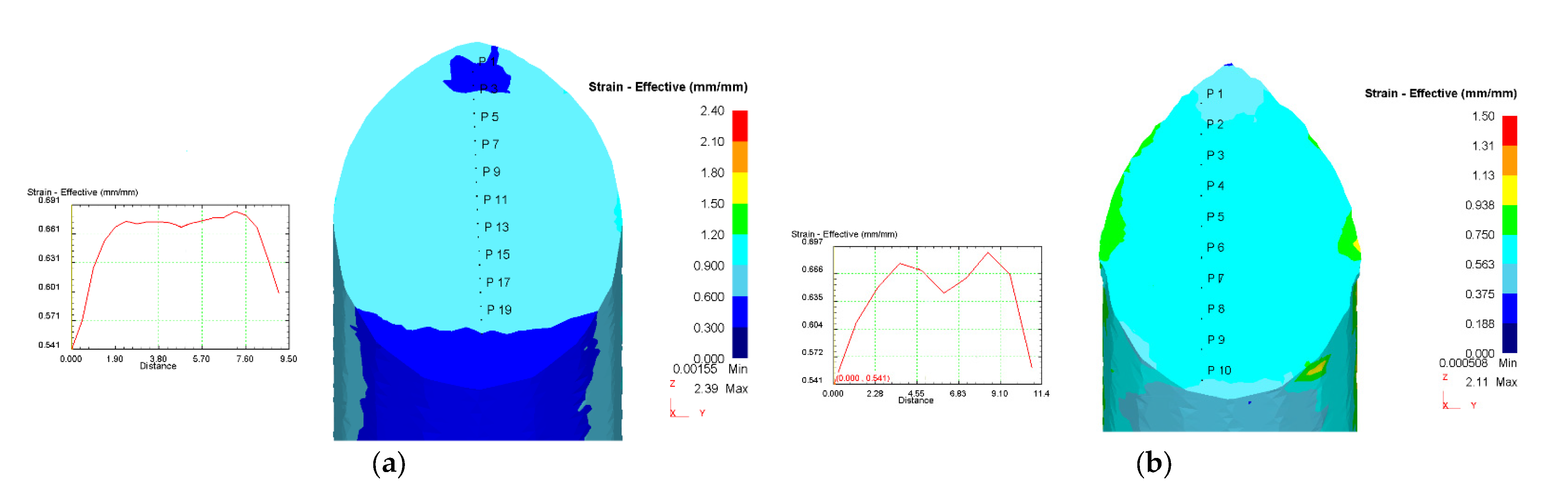

- -

- Increased values of tensile stresses in the ECAP-treated specimens lead to the initiation of cracks;

- -

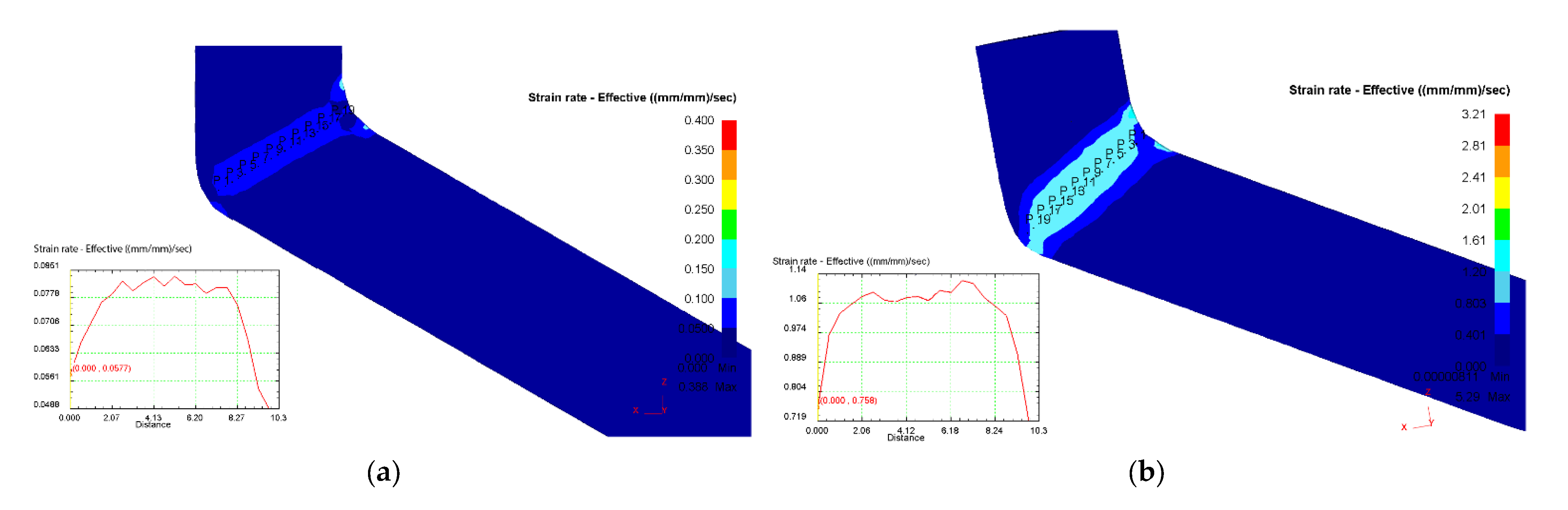

- Due to internal friction, deformation heating increases, and with an increase in speed, the process of grain refinement is intensified due to an increase in the density of dislocations and formation of low- and high-angle grain boundaries. Accordingly, the increased non-uniformity of the strain rate distribution affects the uniformity of the structure and mechanical properties of the workpieces;

- -

- The maximum values of force parameters are the main condition for choosing tooling and tool material.

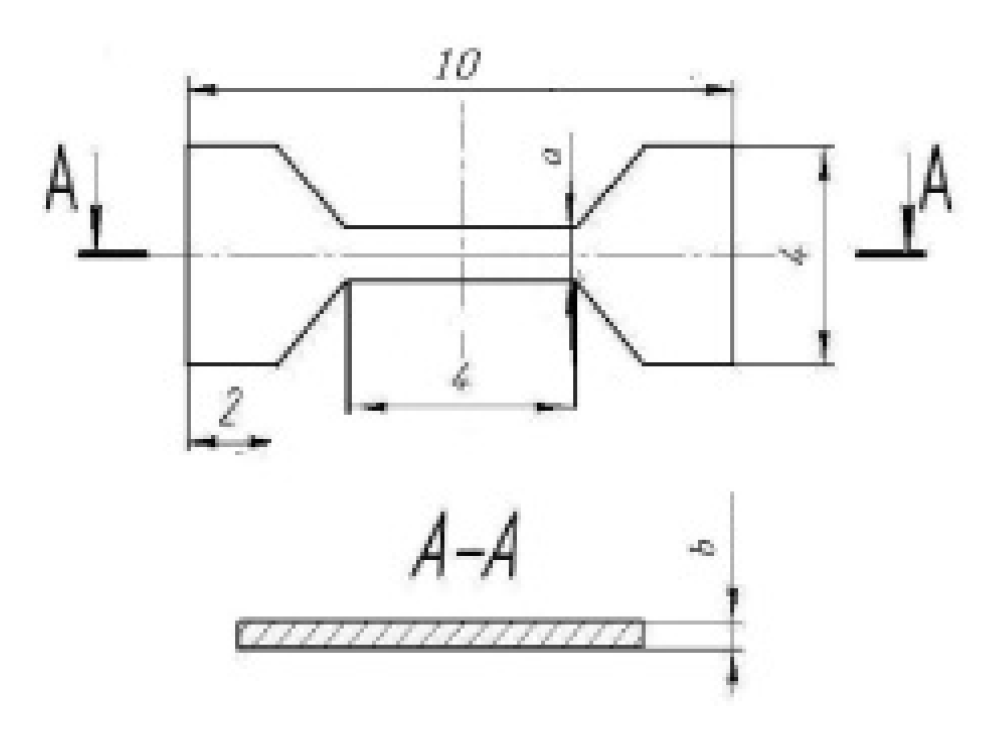

- Material of the initial billet—zinc alloy Zn-Ag-Cu;

- Dimensions of the original workpiece d = 10 mm, length 60 mm;

- Number of finite elements 64,000–78,500, element size 0.54 mm;

- Conditions for compensating the volume of the workpiece model are included;

- Deformation temperature 150, 200 °C;

- Friction coefficient is equal to µ = 0.3;

- Number of simulation steps 100–250 with a step of 0.5 s;

- Deformation speed v = 0.4, v = 7.8 mm/s.

2.3. Microstructural Characterization

2.4. Mechanical Performance

3. Results

3.1. Simulation

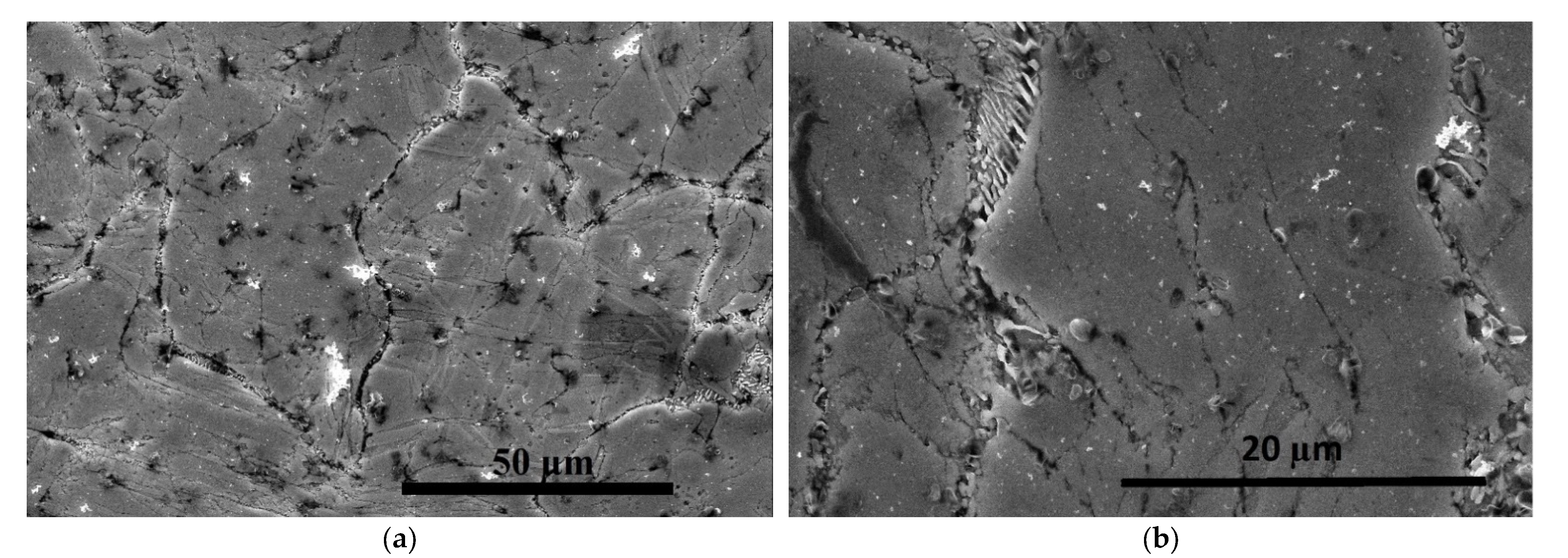

3.2. Microstructure

3.3. Mechanical Properties

4. Discussion

5. Conclusions

- 1.

- According to results of computer simulation, it is recommended to carry out ECAP of the Zn-4Ag-1Cu alloy with a low deformation speed of 0.4 mm/s and temperatures of 150 °C and 200 °C.

- 2.

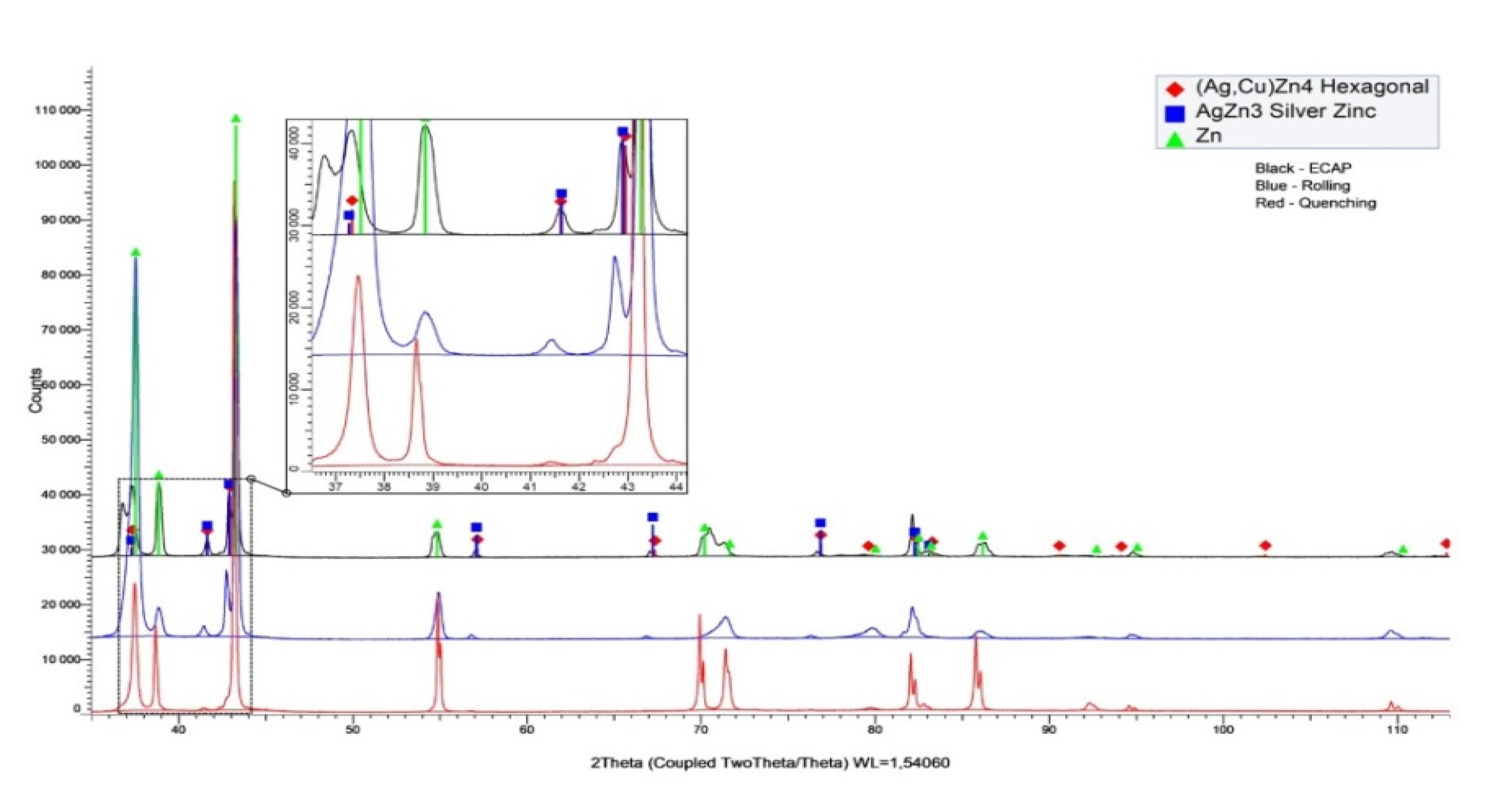

- The grain refinement and additional precipitation of (AgCu)Zn4 and AgZn3 in the ECAP samples leads to enhanced ultimate tensile strength of 348 MPa at a ductility of 27%. For comparison, 195 MPa and 13%, respectively, were observed in the initial coarse-grained samples. Yield stress of both ECAP samples is ensured by grain boundaries and additionally by precipitates and dislocations.

- 3.

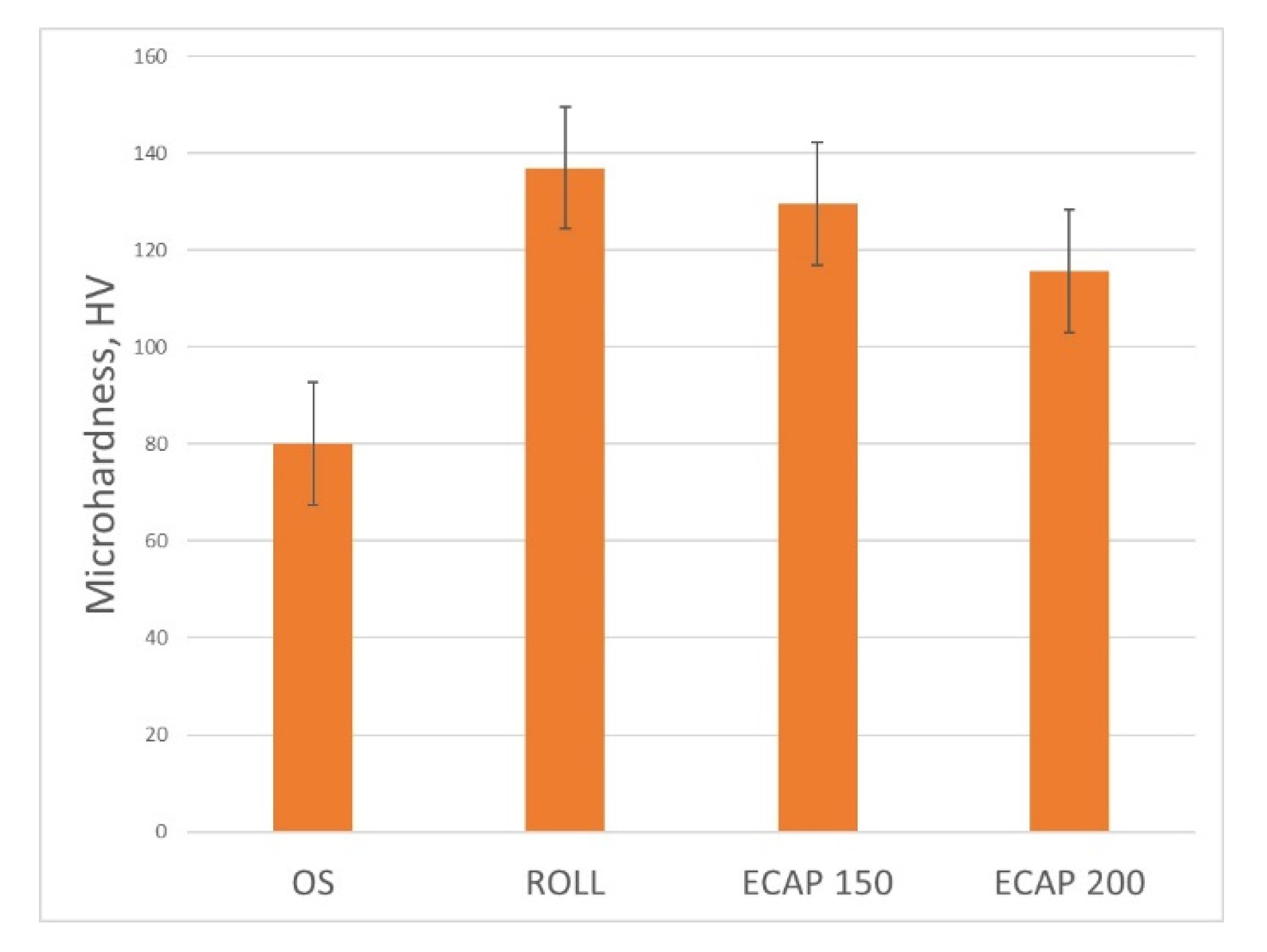

- The microhardness of the ECAP samples remains stable after heating to temperature of 350 °C, although the grain size increases to 30 μm. This may indicate a violation of the correlation between microhardness and a grain size during heating of ECAP samples as a result of increasing fraction of precipitates.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng, Y.; Xu, X.; Xu, Z.; Wang, J.; Cai, H. Metallic Biomaterials. New Directions and Technologies; Wiley-VCH Verlag GmbH & Co. KGaA: Hoboken, NJ, USA, 2017; Volume 307. [Google Scholar] [CrossRef]

- Zhuo, X.; Wu, Y.; Ju, J.; Liu, H.; Jiang, J.; Hu, Z.; Bai, J.; Xue, F. Recent progress of novel biodegradable zinc alloys: From the perspective of strengthening and toughening. J. Mater. Res. Technol. 2022, 17, 244–269. [Google Scholar] [CrossRef]

- Li, G.; Yang, H.; Zhen, Y.; Chen, X.-H.; Yang, J.-A.; Zhu, D.; Ruan, L.; Takashima, K. Challenges in the use of zinc and its alloys as biodegradable metals: Perspective from biomechanical compatibility. Acta Biom. 2019, 97, 23–45. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Jia, B.; Zhang, Z.; Qu, X.; Li, G.; Lin, W.; Zhu, D.; Dai, K.; Zheng, Y. Alloying design of biodegradable zinc as promising bone implants for load-bearing applications. Nat. Commun. 2020, 11, 401. [Google Scholar] [CrossRef] [PubMed]

- Bowen, P.K.; Drelich, J.; Goldman, J. Zinc exhibits ideal physiological corrosion behavior for bioabsorbable stents. Adv. Mater. 2013, 25, 2577–2582. [Google Scholar] [CrossRef] [PubMed]

- Drelich, A.J.; Zhao, S.; Guillory, R.J.; Drelich, J.W.; Goldman, J. Long-term surveillance of zinc implant in murine artery: Surprisingly steady biocorrosion rate. Acta Biom. 2017, 58, 539–549. [Google Scholar] [CrossRef] [PubMed]

- Mostaed, E.; Sikora-Jasinska, M.; Drelich, J.W.; Vedani, M. Zinc-based alloys for degradable vascular stent applications. Acta Biom. 2018, 71, 1–23. [Google Scholar] [CrossRef]

- Levy, G.K.; Goldman, J.; Aghion, E. The Prospects of Zinc as a Structural Material for Biodegradable Implants; A Review Paper. Metals 2017, 7, 402. [Google Scholar] [CrossRef]

- Mostaed, E.; Sikora-Jasinska, M.; Mostaed, A.; Loffredo, S.; Demir, A.G.; Previtali, B.; Mantovani, D.; Beanland, R.; Vedani, M. Novel Zn-based alloys for biodegradable stent applications: Design, development and in vitro degradation. J. Mech. Behav. Biomed. Mater. 2016, 60, 581–602. [Google Scholar] [CrossRef]

- Kubasek, J.; Pospíšilová, I.; Vojtěch, D.; Jablonská, E.; Ruml, T. Structural, mechanical and cytotoxicity characterization of as-cast biodegradable Zn–xMg (x = 0.8–8.3 wt.%) alloys. Mater. Technol. 2014, 48, 623–629. [Google Scholar]

- Tang, Z.; Niu, J.; Huang, H.; Zhang, H.; Pei, J.; Ou, J.; Yuan, G. Potential biodegradable Zn-Cu binary alloys developed for cardiovascular implant applications. J. Mech. Behav. Biomed. Mater. 2017, 72, 182–191. [Google Scholar] [CrossRef]

- Ren, L.; Nan, L.; Yang, K. Study of copper precipitation behavior in a Cu-bearing austenitic antibacterial stainless steel. Mater. Des. 2011, 32, 2374–2379. [Google Scholar] [CrossRef]

- Edalati, K.; Bachmaier, A.; Beloshenko, V.; Beygelzimer, Y.; Blank, V.; Botta, W.; Bryɫa, K.; Čižek, J.; Divinski, S.; Enikev, N.; et al. Nanomaterials by severe plastic deformation: Review of historical developments and recent advances. Mater. Res. Lett. 2022, 10, 163–256. [Google Scholar] [CrossRef]

- Valiev, R.; Zhilyaev, A.; Langdon, T. Bulk Nanostructured Materials: Fundamentals and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; Volume 470, ISBN 978-1-118-09540-9. [Google Scholar]

- Valiev, R.; Estrin, Y.; Horita, Z.; Langdon, T.; Zehetbauer, M.; Zhu, Y. Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 2016, 68, 1216–1226. [Google Scholar] [CrossRef]

- Xiao, C.; Wang, L.; Ren, Y.; Sun, S.; Zhang, E.; Yan, C.; Liu, Q.; Sun, X.; Shou, F.; Duan, J.; et al. Indirectly extruded biodegradable Zn-0.05wt%Mg alloy with improved strength and ductility: In vitro and in vivo studies. J. Mater. Sci. Technol. 2018, 34, 1618–1627. [Google Scholar] [CrossRef]

- Liu, S.; Kent, D.; Doan, N.; Dargusch, M.; Wang, G. Effects of deformation twinning on the mechanical properties of biodegradable Zn-Mg alloys. Bioact. Mater. 2019, 4, 8–16. [Google Scholar] [CrossRef]

- Polenok, M.V.; Khafizova, E.D.; Islamgaliev, R.K. The influence of severe plastic deformation on mechanical properties of pure zinc. Front. Mater. Technol. 2022, 3, 25–31. [Google Scholar] [CrossRef]

- Martynenko, N.S.; Rybalchenko, O.V.; Temralieva, D.R.; Prosvirnin, D.V.; Dobatkin, S.V. Study of mechanical properties and corrosion resistance of pure Zn after high pressure torsion. Mater. Technol. Des. 2022, 4, 3. [Google Scholar]

- Bednarczyk, W.; Kawałko, J.; Wątroba, M.; Gao, N.; Starink, M.J.; Bała, P.; Langdon, T.G. Microstructure and mechanical properties of a Zn-0.5Cu alloy processed by high-pressure torsion. Mat. Sci. Eng. A. 2022, 776, 139047. [Google Scholar] [CrossRef]

- Bednarczyk, W.; Kawałko, J.; Rutkowski, B.; Wątroba, M.; Gao, N.; Starink, M.J.; Bała, P.; Langdon, T.G. Abnormal grain growth in a Zn-0.8Ag alloy after processing by high-pressure torsion. Acta Mater. 2021, 207, 116667. [Google Scholar] [CrossRef]

- Ye, L.; Liu, H.; Sun, C.; Zhuo, X.; Ju, J.; Xue, F.; Bai, J.; Jiang, J.; Xin, Y. Achieving high strength, excellent ductility, and suitable biodegradability in a Zn-0.1Mg alloy using room-temperature ECAP. J. Alloys Compd. 2022, 926, 166906. [Google Scholar] [CrossRef]

- Dambatta, M.S.; Izman, S.; Kurniawan, D.; Hermawan, H. Processing of Zn-3Mg alloy by equal channel angular pressing for biodegradable metal implants. J. King. Saud. Univ. Sci. 2017, 29, 455–461. [Google Scholar] [CrossRef]

- Sikora-Jasinska, M.; Mostaed, E.; Mostaed, A.; Beanland, R.; Mantovani, D.; Vedani, M. Fabrication, mechanical properties and in vitro degradation behavior of newly developed Zn-Ag alloys for degradable implant applications. Mat. Sci. Eng. C. 2017, 77, 1170–1181. [Google Scholar] [CrossRef] [PubMed]

- Bednarczyk, W.; Wątroba, M.; Kawałko, J.; Bała, P. Can zinc alloys be strengthened by grain refinement? A critical evaluation of the processing of low-alloyed binary zinc alloys using ECAP. Mater. Sci. Eng. A. 2019, 748, 357–366. [Google Scholar] [CrossRef]

- Pal, H.; Pradhan, S.K.; De, M. Microstructural characterisation of hexagonal (Ag, Cu)Zn4 alloys in the deformed and as-cast state. Jpn. J. Appl. Phys. 1994, 33, 1443–1449. [Google Scholar] [CrossRef]

- Alawad, M.O.; Alateyah, A.I.; El-Garaihy, W.H.; BaQais, A.; Elkatatny, S.; Kouta, H.; Kamel, M.; El-Sanabary, S. Optimizing the ECAP parameters of biodegradable Mg-Zn-Zr alloy based on experimental, mathematical empirical, and response surface methodology. Materials 2022, 15, 7719. [Google Scholar] [CrossRef] [PubMed]

- Pérez, C.J.L.; Irigoyen, R.L.; Arbizu, I.P.; Pérez, D.S.; Iriarte, J.L.; Bonel, J.P.F. Analysis of tribological properties in disks of AA-5754 and AA-5083 Aluminium Alloys Previously Processed by Equal Channel Angular Pressing and Isothermally Forged. Metals 2020, 10, 938. [Google Scholar] [CrossRef]

- Ehsan, M.; Ardakani, M.S.; Malgorzata, S.J.; Jaroslaw, W.D. Precipitation induced room temperature superplasticity in Zn-Cu alloys. J. Mater. Lett. 2019, 244, 203–206. [Google Scholar]

- Meyers, M.A.; Chawla, K.K. Mechanical Behavior of Materials; Cambridge University Press: Cambridge, UK, 2008; Volume 882. [Google Scholar] [CrossRef]

- Liu, Z.; Qiu, D.; Wawg, F.; Tailor, J.A.; Zhang, M. Effect of grain refinement on tensile properties of cast zinc alloys. Metal. Mater. Trans. A 2016, 47, 830–841. [Google Scholar] [CrossRef]

- Bailey, J.E.; Hirsch, P.B. The dislocation distribution, flow stress, and stored energy in cold-worked polycrystalline silver. Philos. Mag. 1960, 5, 485–497. [Google Scholar] [CrossRef]

- Islamgaliev, R.K.; Nikitina, M.A.; Ganeev, A.V.; Sitdikov, V.D. Strengthening mechanisms in ultrafine-grained martensitic steel. Mat. Sci. Eng. A 2019, 744, 163–170. [Google Scholar] [CrossRef]

- Gladman, T. Precipitation hardening in metals. Mater. Sci. Technol. 1999, 15, 30–36. [Google Scholar] [CrossRef]

| Zn | Ag | Cu | Mg |

|---|---|---|---|

| 93.86 ± 0.1 | 3.89 ± 0.02 | 1.02 ± 0.08 | 0.44 ± 0.02 |

| Temperature, °C | Strain Rate, s−1 | σ0.2, MPa | σUTS, MPa | True Strain |

|---|---|---|---|---|

| 20 | 0.1 | 83.16 | 163.06 | 0.05 |

| 0.5 | 140.67 | 198.24 | 0.12 | |

| 1.0 | 105.16 | 138.50 | 0.05 | |

| 150 | 0.1 | 126.51 | 186.03 | 0.14 |

| 0.5 | 81.20 | 181.05 | 0.10 | |

| 1.0 | 182.63 | 126.33 | 0.16 | |

| 200 | 0.1 | 115.43 | 161.27 | 0.15 |

| 0.5 | 88.79 | 164.79 | 0.12 | |

| 1.0 | 99.12 | 173.17 | 0.16 | |

| 250 | 0.1 | 102.34 | 129.03 | 0.12 |

| 0.5 | 118.85 | 148.61 | 0.16 | |

| 1.0 | 48.48 | 138.89 | 0.12 |

| Parameters | T = 150 °C, v = 0.4 mm/s | T = 150 °C, v = 7.8 mm/s | T = 200 °C v = 0.4 mm/s | T = 200 °C, v = 7.8 mm/s |

|---|---|---|---|---|

| Maximum load, kN | 26 | 28 | 26 | 27.2 |

| Maximum heating temperature, °C | 157 | 195 | 208 | 231 |

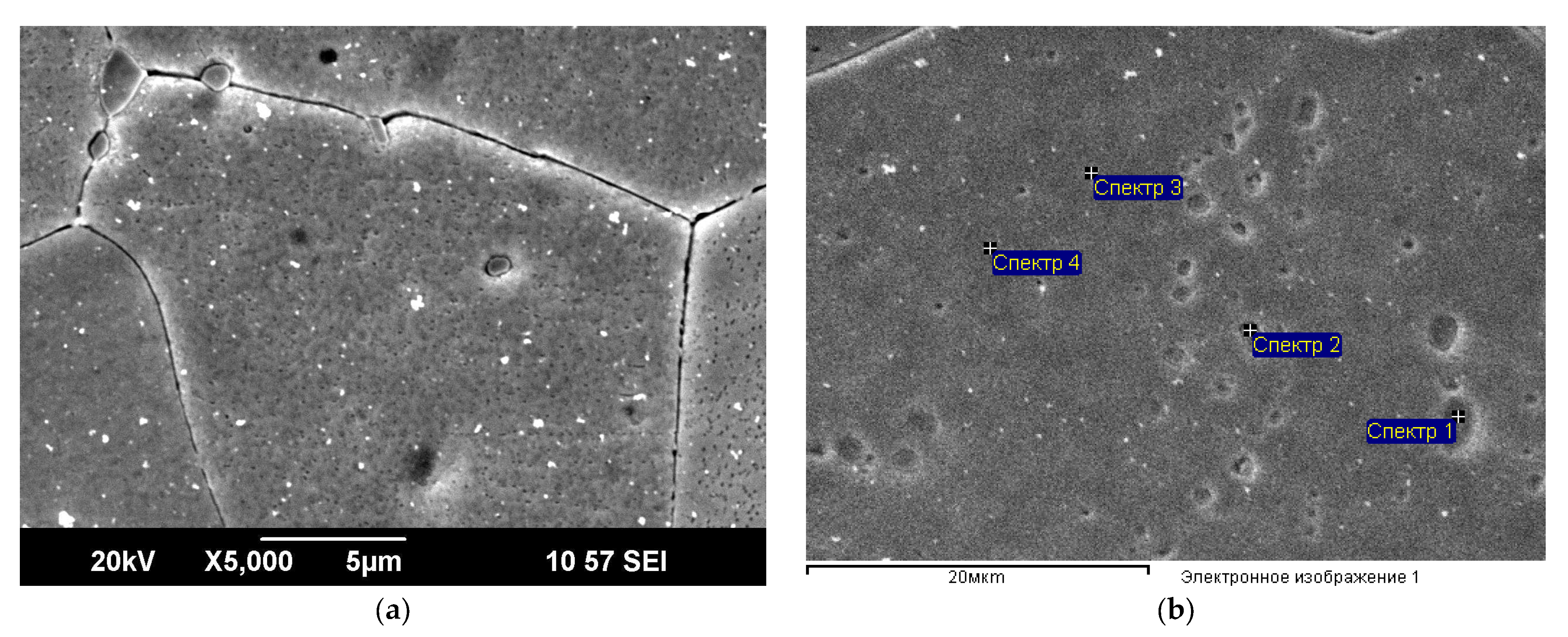

| Cu | Zn | Ag | |

|---|---|---|---|

| Point 1 | 2.55 | 96.30 | 1.15 |

| Point 2 | 1.48 | 95.80 | 2.72 |

| Point 3 | 0.73 | 92.03 | 7.24 |

| Point 4 | 0.82 | 95.42 | 3.75 |

| Processing | (AgCu)Zn4 | AgZn3 | Density of Dislocations, m−2 | ||

|---|---|---|---|---|---|

| Fraction, % | Size, nm | Fraction, % | Size, nm | ||

| Rolling | 2.22 ± 0.2 | - | - | - | 3.78 × 1013 |

| ECAP 150 °C | 15.34 ± 0.5 | 690 | 0.26 ± 0.06 | 90 | 11.74 × 1013 |

| ECAP 200 °C | 19.06 ± 0.7 | 720 | 0.78 ± 0.04 | 110 | 4.06 × 1013 |

| 20 °C | 200 °C | 250 °C | 300 °C | 350 °C | |

|---|---|---|---|---|---|

| Initial | 110 ± 20 | 99.7 ± 19.5 | 106 ± 12 | 106 ± 10 | 105 ± 21 |

| ECAP Ø10 mm 150 °C | 129 ± 9 | 116.8 ± 6 | 109 ± 10 | 124.8 ± 13 | 108 ± 15 |

| ECAP Ø10 mm 200°C | 111 ± 14 | 117 ± 7 | 115 ± 7 | 122 ± 11 | 116 ± 13 |

| Treatment | Calculated Data, MPa | Experimental Data, MPa | ||||||

|---|---|---|---|---|---|---|---|---|

| UTS | YS | |||||||

| ECAP 150 °C | 11 | 193 | 66 | 16 | 21 | 307 | 348 | 276 |

| ECAP 200 °C | 11 | 142 | 39 | 16 | 78 | 286 | 335 | 272 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khafizova, E.; Fakhretdinova, E.; Islamgaliev, R.; Polenok, M.; Sitdikov, V.; Yilmazer, H. Effect of Plastic Deformation on the Structure and Mechanical Properties of the Zn-4Ag-1Cu Zinc Alloy. Materials 2023, 16, 4646. https://doi.org/10.3390/ma16134646

Khafizova E, Fakhretdinova E, Islamgaliev R, Polenok M, Sitdikov V, Yilmazer H. Effect of Plastic Deformation on the Structure and Mechanical Properties of the Zn-4Ag-1Cu Zinc Alloy. Materials. 2023; 16(13):4646. https://doi.org/10.3390/ma16134646

Chicago/Turabian StyleKhafizova, Elvira, Elvira Fakhretdinova, Rinat Islamgaliev, Milena Polenok, Vil Sitdikov, and Hakan Yilmazer. 2023. "Effect of Plastic Deformation on the Structure and Mechanical Properties of the Zn-4Ag-1Cu Zinc Alloy" Materials 16, no. 13: 4646. https://doi.org/10.3390/ma16134646

APA StyleKhafizova, E., Fakhretdinova, E., Islamgaliev, R., Polenok, M., Sitdikov, V., & Yilmazer, H. (2023). Effect of Plastic Deformation on the Structure and Mechanical Properties of the Zn-4Ag-1Cu Zinc Alloy. Materials, 16(13), 4646. https://doi.org/10.3390/ma16134646