Effect of Micro-Nano Bubble Water and Silica Fume on Properties of C60 Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Mixing Water

2.1.1. Materials

2.1.2. WNBW Preparation

2.2. Mix Proportion

2.3. Testing Method

2.3.1. Concrete Workability Test

2.3.2. Compressive Strength of Concrete

2.3.3. Concrete Impermeability Test

2.3.4. Concrete Carbonation Resistance Test

2.3.5. Concrete Frost-Resistance Test

2.3.6. Analysis Test of Freeze–Thaw Concrete Pore Structure

2.3.7. V-Funnel through Time

3. Results and Discussion

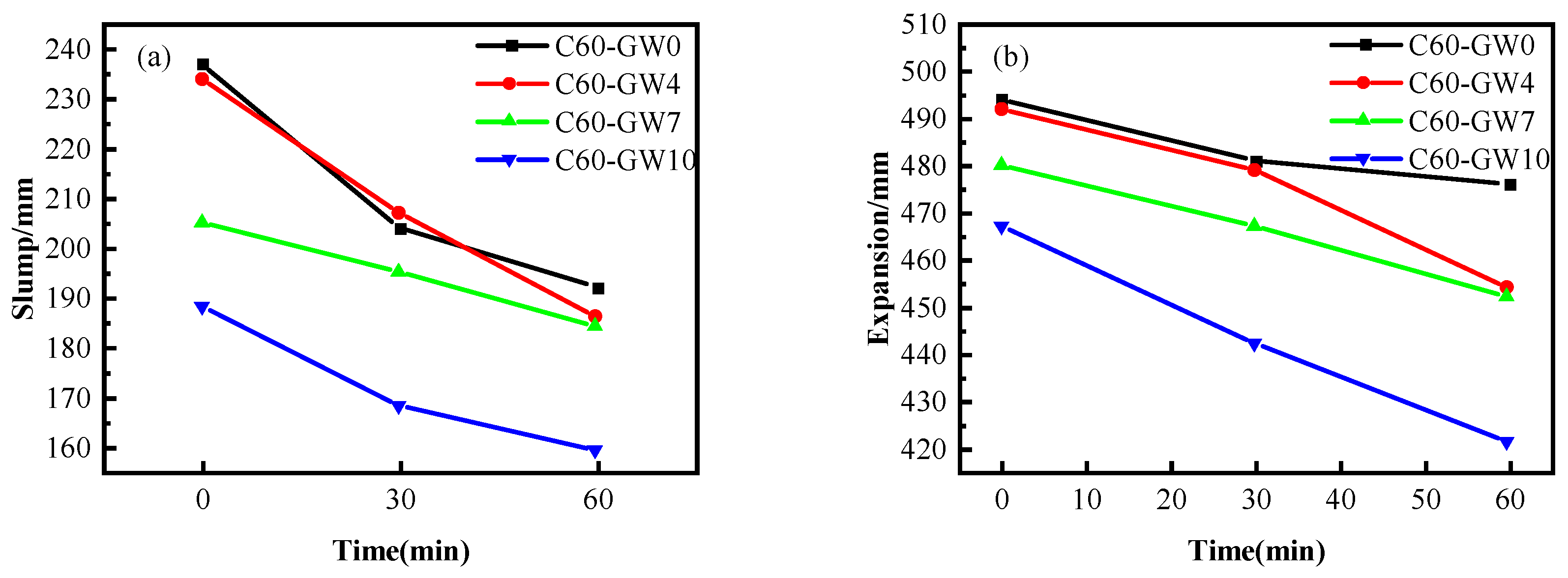

3.1. Working Performance

3.2. V-Funnel through Time

3.3. Compressive Strength

3.4. Impermeability of Concrete

3.5. Carbonation Resistance of Concrete

3.6. Frost Resistance of Concrete

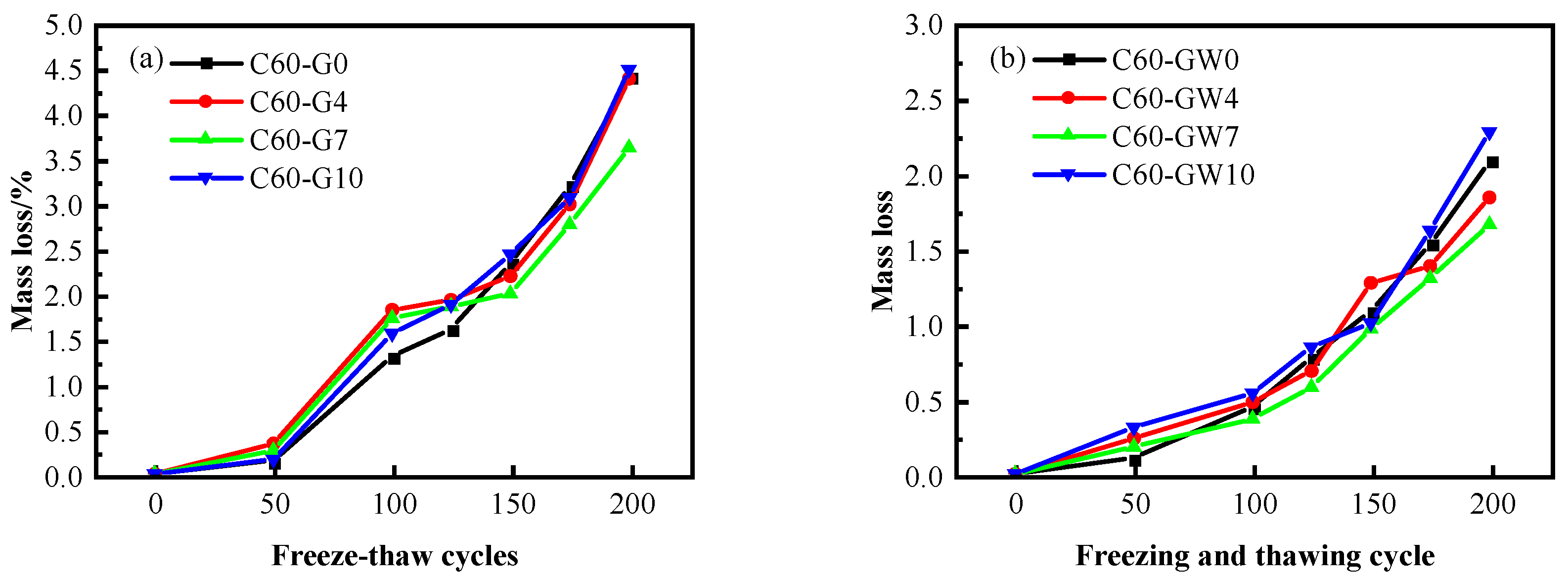

3.6.1. Mass Loss

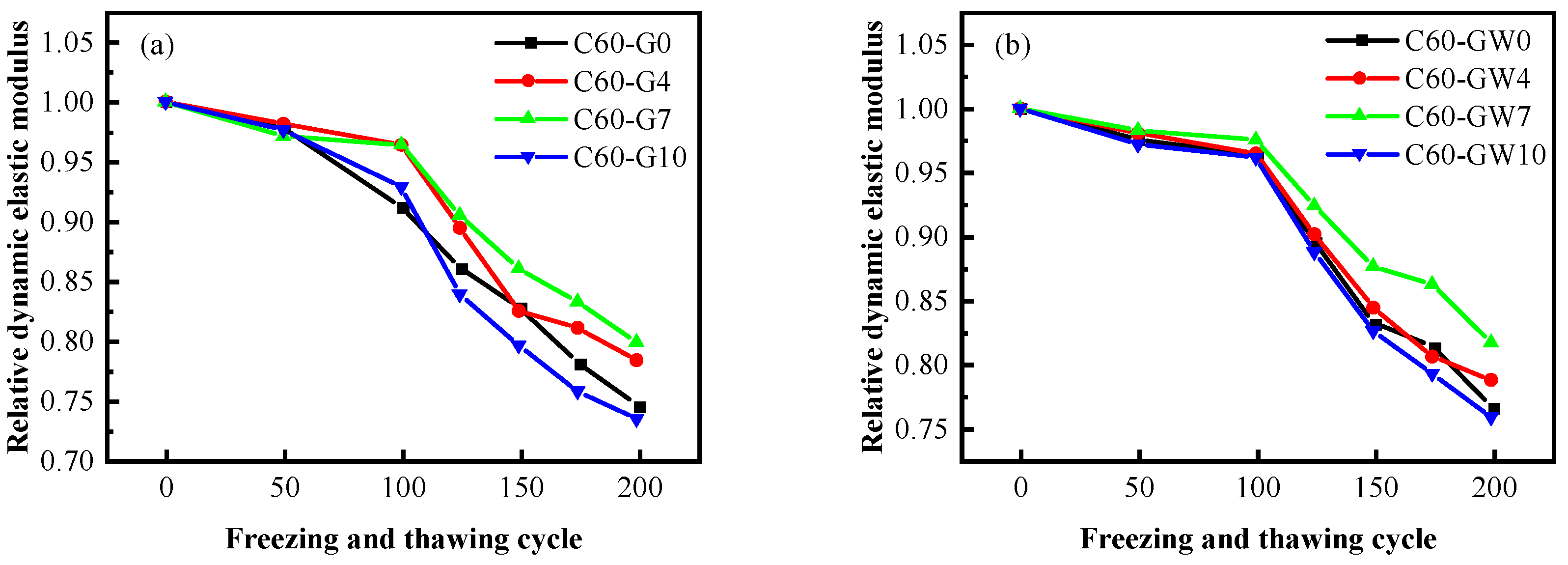

3.6.2. Relative Dynamic Elastic Modulus

3.6.3. Characteristic Parameters of Pore Structure

3.6.4. Pore Size Distribution

4. Conclusions

- (1)

- The introduction of micro-nano bubble water and silica fume as additives in the C60 concrete mixture resulted in a reduction in slump and expansion. The observed decrease, although present, does not significantly impact the utility of fresh concrete. The results of the V-shaped funnel test revealed that micro-nano bubble water has a significant impact on the viscosity of C60 concrete, resulting in a 40% reduction. As per the aforementioned study, it can be inferred that the incorporation of micro-nano bubble water and silica fume in C60 concrete results in the reduced viscosity of high-strength concrete, thereby facilitating the transportation and construction of real-world projects. The reason for this phenomenon is attributed to the introduction of a significant quantity of micro-nano bubbles into the concrete mixture. This is beneficial, as these bubbles act as ball bearings, effectively reducing the inter-component friction within the concrete.

- (2)

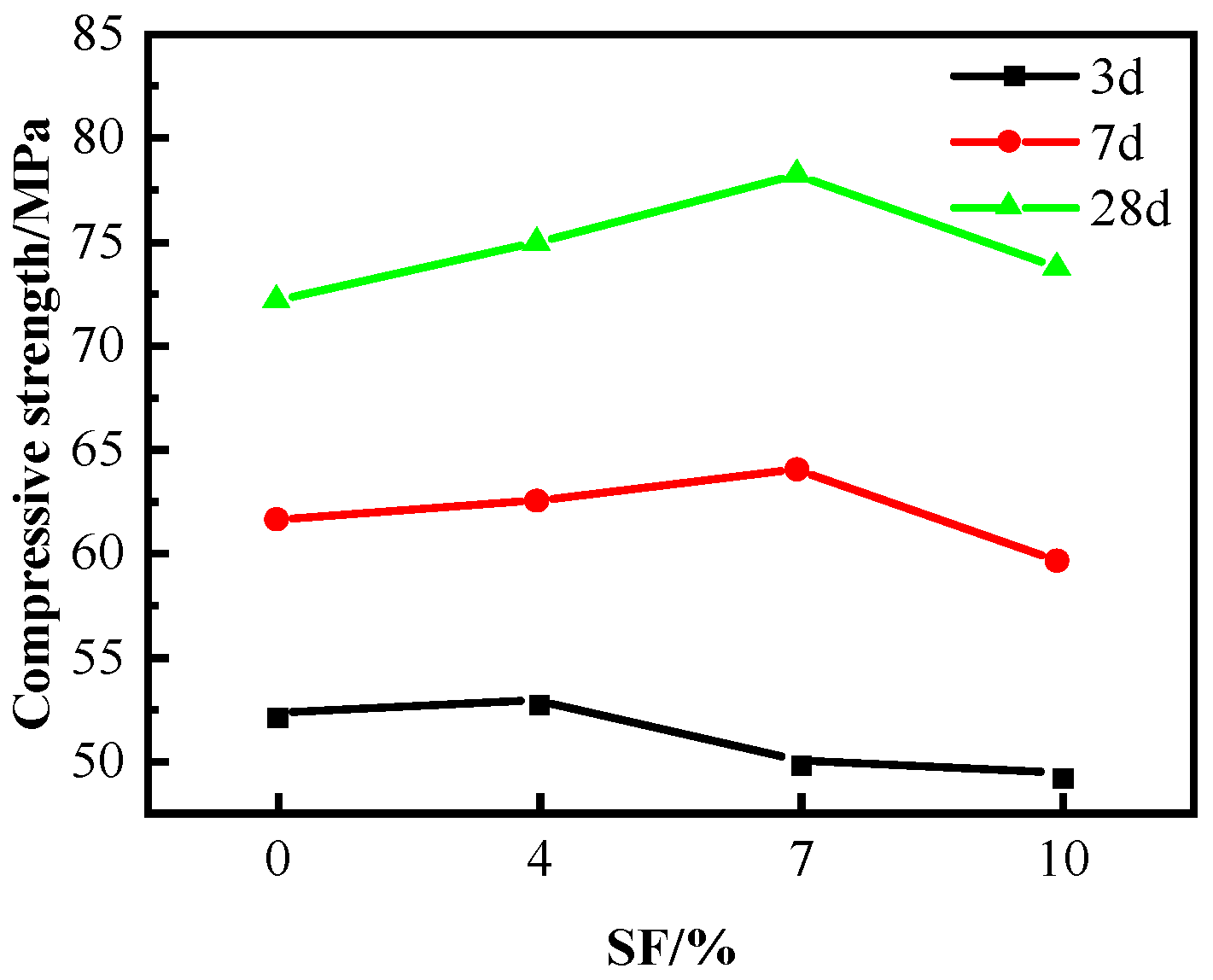

- Incorporating SF into concrete can reduce the cement content and subsequently lower the 3 d compressive strength of C60 concrete. SF functions as a filling agent within the concrete material during the early stages. The compressive strength of C60 concrete, as characterised by its 7-day and 28-day compressive strength, exhibited an initial increase followed by a decrease with the escalating content of SF. To achieve optimal results, a 7% SF volume fraction is recommended for C60 concrete. According to the findings, the compressive strength of concrete produced using WNBW exhibits superior performance compared to concrete produced with ordinary water over 3, 7, and 28 d. By using micro-nano bubble water as the mixing water for concrete, there is an enhancement in the powder’s dispersion. This results in an increased probability of the powder colliding with the mixing water, leading to a higher reaction speed and degree of hydration reaction.

- (3)

- The electric flux test results revealed that the C60 concrete, blended with 100% WNBW and 7% silica fume, exhibits the lowest electric flux reading of 321.32 C, indicating optimal impermeability. The obtained mechanism aligns with that derived from the strength test. Concrete blended with micro-nano bubble water and silica fume exhibits a compact structure.

- (4)

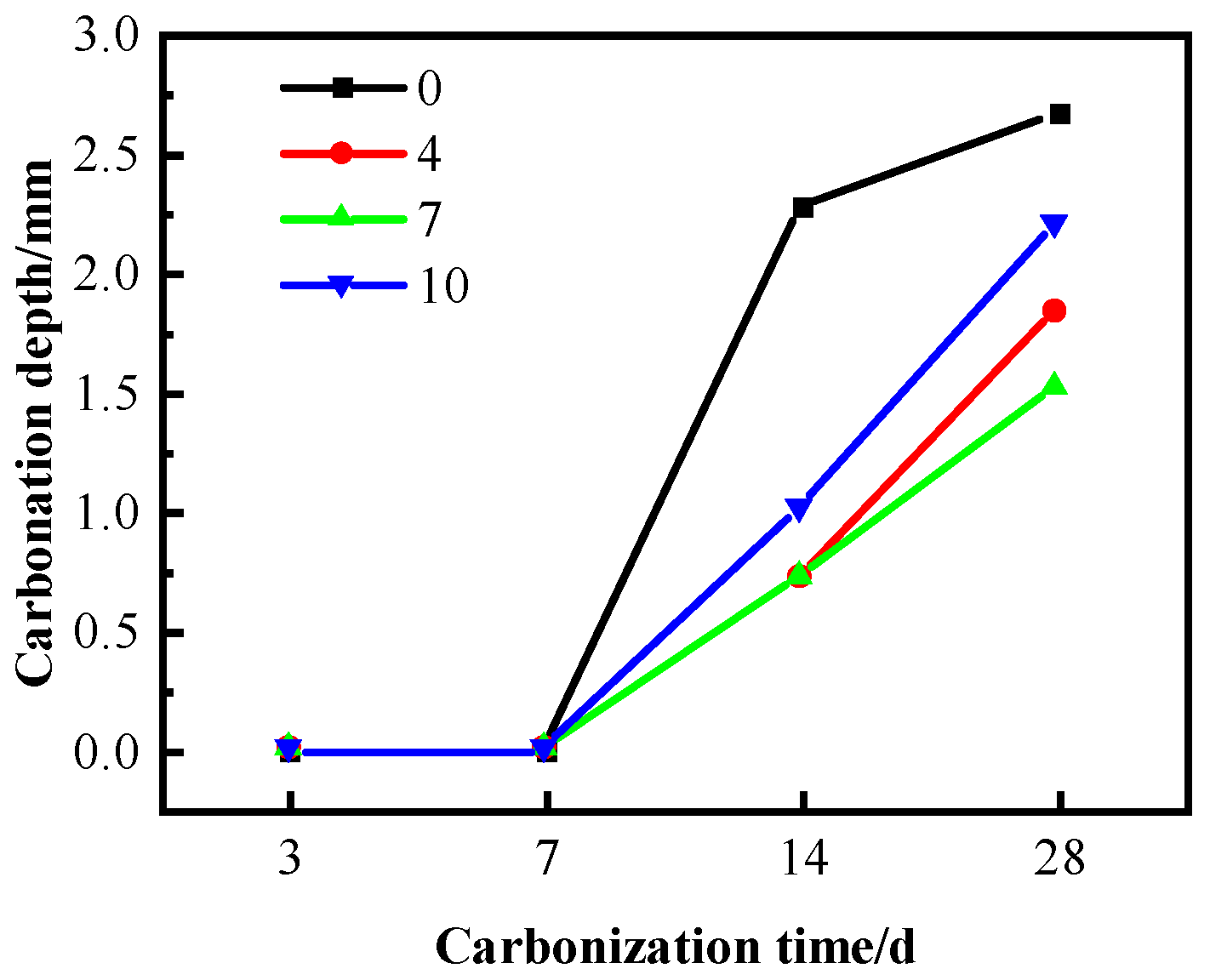

- Based on the results of the study, the incorporation of 100% WNBW into the concrete mix, which comprises 7% SF, has been determined to provide the most effective protection against carbonation for C60 concrete. It has been suggested that this success may be attributed to the favourable distribution of the pore structure within the resulting hardened concrete. The subsequent course of investigation entails a thorough examination and evaluation of the impact of WNBW and silica fume on the enduring carbonation performance of concrete.

- (5)

- The frost resistance of concrete can be optimised using ordinary water with 7% SF content. The concrete with 4% and 7% SF exhibited a lower porosity and macropore content when compared to the blank group. However, a 10% SF content can decrease frost resistance in C60 concrete. On the other hand, when mixed with WNBW, the frost resistance of C60 concrete was observed to improve. The pore analysis diagram of the concrete reveals that the utilisation of micro-nano bubble water can effectively refine the pore structure of concrete, preserving a significant number of closed micro-pores and minimising the occurrence of macropores. This phenomenon serves to support the rationale behind the enhancement of concrete strength and durability, showcasing the potential benefits of incorporating such water into concrete production.

- (6)

- The synergistic utilisation of WNBW and SF yields advantageous outcomes towards the transport and construction of C60 concrete, while simultaneously enhancing its compressive strength and durability. This paper offers theoretical substantiation for using the aforementioned approach in real-world engineering scenarios.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Lin, E. Emerging energy-efficiency and CO2 emission-reduction technologies for cement and concrete production: A technical review. Renew. Sustain. Energy Rev. 2012, 16, 6220–6238. [Google Scholar] [CrossRef] [Green Version]

- Kanamarlapudi, L.; Jonalagadda, K.B.; Jagarapu, D.C.K.; Eluru, A. Different mineral admixtures in concrete: A review. SN Appl. Sci. 2020, 2, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Kanagaraj, B.; Kiran, T.; Al Jabri, K. Development and strength assessment of eco-friendly geopolymer concrete made with natural and recycled aggregates. Constr. Innov. 2023, 23, 524–545. [Google Scholar] [CrossRef]

- Elchalakani, M. High strength rubberized concrete containing silica fume for the construction of sustainable road side barriers. Structures 2015, 1, 20–38. [Google Scholar] [CrossRef]

- Shuraim, A.B.; Aslam, F.; Rizwan Hussain, R.; Alhozaimy, A.M. Coupled Effect of Coarse Aggregate Type and Silica Fume on Creep Coefficients of High-Strength Concrete. J. Mater. Civ. Eng. 2016, 28, 899–1561. [Google Scholar] [CrossRef]

- Reddy, T.C.S.; Elumalai, J.K. Study of macro mechanical properties of ultra high strength concrete using quartz sand and silica fume. Int. J. Res. Eng. Technol. 2014, 3, 391–396. [Google Scholar]

- Shi, C.; Wang, D.; Wu, L.; Wu, Z. The hydration and microstructure of ultra high-strength concrete with cement–silica fume–slag binder. Cem. Concr. Compos. 2015, 61, 0958–9465. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, X.; Wei, D. Influence of Silica Fume Content on Performance of High-Performance Concrete. E3S Web Conf. EDP Sci. 2021, 237, 3039. [Google Scholar] [CrossRef]

- Wang, X.; Huang, J.; Dai, S.; Ma, B.; Tan, H.; Jiang, Q. Effect of silica fume particle dispersion and distribution on the performance of cementitious materials: A theoretical analysis of optimal sonication treatment time. Constr. Build. Mater. 2019, 212, 549–560. [Google Scholar] [CrossRef]

- Tsardaka, E.C.; Stefanidou, M. Application of an alternative way for silica fume dispersion in cement pastes without ultrasonication. Cem. Concr. Res. 2019, 115, 59–69. [Google Scholar] [CrossRef]

- Kiski, S.S.; Ponomarev, A.N.; Ageev, I.V.; Cun, C. Modification of the fine-aggregate concrete by high disperse silica fume and carbon nanoparticles containing modifiers. Adv. Mater. Res. Trans. Tech. Publ. 2014, 941–944, 430–435. [Google Scholar] [CrossRef]

- Han, D.; Han, M. Effect of pre-mixed cement on the dispersion of silica fume in ternary blended cementitious paste. Mater. Res. Innov. 2015, 19, S5-700–S5-707. [Google Scholar] [CrossRef]

- Singh, B.; Shukla, N.; Cho, C.; Kim, B.S.; Park, M.; Kim, K. Effect and application of micro-and nanobubbles in water purification. Toxicol. Environ. Health Sci. 2021, 13, 9–16. [Google Scholar] [CrossRef]

- Ebrahimi, H.; Karamoozian, M.; Saghravani, S.F. Interaction of applying stable micro-nano bubbles and ultrasonic irradiation in coal flotation. Int. J. Coal Prep. Util. 2022, 42, 1548–1562. [Google Scholar] [CrossRef]

- Klammler, H.; Mohamed, M.M.; Hatfield, K.; Achar, J.; Jung, J. Modeling micro-and nano-bubble stability and treatment mechanisms in batch reactors. J. Environ. Eng. 2020, 146, 04020079. [Google Scholar] [CrossRef]

- Qiu, J.; Zou, Z.; Wang, S.; Wang, X.; Wang, L.; Dong, Y.; Zhao, H.; Zhang, L.; Hu, J. Formation and stability of bulk nanobubbles generated by ethanol–water exchange. Chemphyschem 2017, 18, 1345–1350. [Google Scholar] [CrossRef]

- Bai, M.; Liu, Z.; Zhang, J.; Lu, L. Prediction and experimental study of mass transfer properties of micronanobubbles. Ind. Eng. Chem. Res. 2021, 60, 8291–8300. [Google Scholar] [CrossRef]

- Zhou, W.; Liu, K.; Wang, L.; Zhou, B.; Niu, J.; Ou, L. The role of bulk micro-nanobubbles in reagent desorption and potential implication in flotation separation of highly hydrophobized minerals. Ultrason. Sonochem. 2020, 64, 104996. [Google Scholar] [CrossRef]

- Maruyama, T.; Takahashi, N.; Hashimoto, S.; Date, S. Effect on the flow properties of the mortar using micro-nano bubbles. Adv. Mater. Res. 2015, 1110, 249–252. [Google Scholar] [CrossRef]

- Sheikh Hassani, M.; Torki, A.; Asadollahfardi, G.; Saghravani, S.F.; Shafaei, J. The effect of water to cement ratio and age on the mechanical properties of cement mortar and concrete made of micro-nano bubbles without adding any admixtures. Struct. Concr. 2021, 22, E756–E768. [Google Scholar] [CrossRef]

- Grzegorczyk-Frańczak, M.; Barnat-Hunek, D.; Andrzejuk, W.; Zaburko, J.; Zalewska, M.; Łagód, G. Physical Properties and Durability of Lime-Cement Mortars Prepared with Water Containing Micro-Nano Bubbles of Various Gases. Materials 2021, 14, 1902. [Google Scholar] [CrossRef] [PubMed]

- Arefi, A.; Saghravani, S.F.; Mozaffari Naeeni, R. Mechanical behavior of concrete, made with micro-nano air bubbles. Civ. Eng. Infrastruct. J. 2016, 49, 139–147. [Google Scholar]

- Zhenmin, W.; Tingshu, H.; Ning, C.; Shuang, H.; Zhenhao, S.; Xiaodong, M.; Renhe, Y. Study on frost resistance of shotcrete by micro-nano bubble water and admixture. Ceram. Int. 2023, 49, 11123–11139. [Google Scholar]

- GB 175-2007; National Standard of The People’s Republic of China, Common Portland Cement. Standardization Administration of People’s Republic of China: Beijing, China, 2007.

- Zhang, M.; Qiu, L.; Liu, G. Basic characteristics and application of micro-nano bubbles in water treatment. In Proceedings of the IOP Conference Series: Earth and Environmental Science: IOP Publishing, Changsha, China, 18–20 September 2020; p. 42050. [Google Scholar]

- Khoshroo, M.; Javid, A.A.S.; Katebi, A. Effects of micro-nano bubble water and binary mineral admixtures on the mechanical and durability properties of concrete. Constr. Build. Mater. 2018, 164, 371–385. [Google Scholar] [CrossRef]

- GB/T50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. Ministry of Housing and Urban-Ural Construction of the People’s Republic of China: China, 2016.

- GB/T50081-2019; Chinese Code for Test Methods of Concrete Physical and Mechanical Properties. Chinese Ministry of Housing and Urban-Rural: China, 2019.

- GBT50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. China Architecture& Building Press: Beijing, China, 2009.

- Zhou, M.; Li, G.-N.; Zhao, H.-M.; Xu, M. Effects of Rubber Particle Content and Fineness on the Impermeability and Frost-Salt Resistance of Road Cement Concrete. J. Highw. Transp. Res. Dev. (Engl. Ed.) 2015, 9, 41–47. [Google Scholar] [CrossRef]

- Huang, C.; Tang, S.M.; Zhu, P.L.; Niu, M.W.; Zhang, J.J. Influence of Concrete Synergist on Performance of Stone Chip Concrete. Key Eng. Mater. 2017, 727, 1054–1061. [Google Scholar] [CrossRef]

- Adil, G.; Kevern, J.T.; Mann, D. Influence of silica fume on mechanical and durability of pervious concrete. Constr. Build. Mater. 2020, 247, 118453. [Google Scholar] [CrossRef]

- Yahyaei, B.; Asadollahfardi, G.; Salehi, A.M. Study of using micro-nano bubble to improve workability and durability of self-compact concrete. Struct. Concr. 2022, 23, 579–592. [Google Scholar] [CrossRef]

- Çelik, Z.; Bingöl, A.F.; Ağsu, A.S. Fresh, mechanical, sorptivity and rapid chloride permeability properties of self-compacting concrete with silica fume and fly ash. Iran. J. Sci. Technol. Trans. Civ. Eng. 2022, 46, 789–799. [Google Scholar] [CrossRef]

- Chand, V.S.; Rao, B.K.; Rao, C.H. Investigation on chloride penetration in concrete mixes of different cement replacement percentages with fly ash and silica fume. Mater. Today Proc. 2020, 33, 820–827. [Google Scholar] [CrossRef]

- Chaudhary, S.K.; Sinha, A.K. Effect of silica fume on permeability and microstructure of high strength concrete. Civ. Eng. J. 2020, 6, 1697–1703. [Google Scholar] [CrossRef]

- Mohsen Zadeh, P.; Saghravani, S.F.; Asadollahfardi, G. Mechanical and durability properties of concrete containing zeolite mixed with meta-kaolin and micro-nano bubbles of water. Struct. Concr. 2019, 20, 786–797. [Google Scholar] [CrossRef]

- Khalil, E.A.B.; Anwar, M. Carbonation of ternary cementitious concrete systems containing fly ash and silica fume. Water Sci. 2015, 29, 36–44. [Google Scholar] [CrossRef] [Green Version]

- Kim, B.-J.; Lee, G.-W.; Choi, Y.-C. Hydration and Mechanical Properties of High-Volume Fly Ash Concrete with Nano-Silica and Silica Fume. Materials 2022, 15, 6599. [Google Scholar] [CrossRef] [PubMed]

- Mehta, P.K.; Monteiro, P.J. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Duan, P.; Shui, Z.; Chen, W.; Shen, C. Effects of metakaolin, silica fume and slag on pore structure, interfacial transition zone and compressive strength of concrete. Constr. Build. Mater. 2013, 44, 1–6. [Google Scholar] [CrossRef]

| Chemical Composition | Cement | FA | SF | GGBS |

|---|---|---|---|---|

| SiO2 | 21.14 | 53.97 | 89.24 | 36.23 |

| Al2O3 | 5.38 | 31.15 | 2.30 | 14.64 |

| Fe2O3 | 3.22 | 4.16 | 0.74 | 2.54 |

| CaO | 63.24 | 4.01 | 0.21 | 35.48 |

| MgO | 1.19 | 1.01 | 0.15 | 6.91 |

| Na2O | 0.28 | 0.89 | 1.03 | 0.06 |

| K2O | 0.54 | 2.04 | 1.07 | 0.97 |

| SO3 | 2.34 | 0.73 | 1.90 | 2.15 |

| Clay/% | Mud/% | Compacted Bulk Density/kg/m3 | Loose Bulk Density /kg/m3 | Apparent Density /kg/m3 | Fineness Modulus |

|---|---|---|---|---|---|

| 1.4 | 0.3 | 1680 | 1640 | 2760 | 2.6 |

| Clay/% | Mud/% | Crush Index/% | Loose Bulk Density /kg/m3 | Apparent Density /kg/m3 | Needle-Like/% |

|---|---|---|---|---|---|

| 0.3 | 0.1 | 7 | 1630 | 2620 | 6 |

| Number | Cement | FA | GGBS | SF | River Sand | Stone | Water | WNBW |

|---|---|---|---|---|---|---|---|---|

| C60-G0 | 340 | 105 | 105 | 0 | 746 | 989 | 153 | 0 |

| C60-G4 | 326 | 105 | 105 | 14 | 746 | 989 | 153 | 0 |

| C60-G7 | 316 | 105 | 105 | 24 | 746 | 989 | 153 | 0 |

| C60-G10 | 306 | 105 | 105 | 34 | 746 | 989 | 153 | 0 |

| C60-GW0 | 340 | 105 | 105 | 0 | 746 | 989 | 0 | 153 |

| C60-GW4 | 326 | 105 | 105 | 14 | 746 | 989 | 0 | 153 |

| C60-GW7 | 316 | 105 | 105 | 24 | 746 | 989 | 0 | 153 |

| C60-GW10 | 306 | 105 | 105 | 34 | 746 | 989 | 0 | 153 |

| Mixing Water Types | Tap Water | WNBW | ||||||

|---|---|---|---|---|---|---|---|---|

| SF/% | 0 | 4 | 7 | 10 | 0 | 4 | 7 | 10 |

| V-funnel through time/s | 107.5 | 114.7 | 121.4 | 146.2 | 64.5 | 69.9 | 69.3 | 72.4 |

| SF/% | Tap Water/C | WNBW/C |

|---|---|---|

| 0 | 711.12 | 459.03 |

| 4 | 363.56 | 321.32 |

| 7 | 403.08 | 405.68 |

| 10 | 422.64 | 489.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, S.; He, T.; Wan, Z.; Zhao, Q. Effect of Micro-Nano Bubble Water and Silica Fume on Properties of C60 Concrete. Materials 2023, 16, 4684. https://doi.org/10.3390/ma16134684

He S, He T, Wan Z, Zhao Q. Effect of Micro-Nano Bubble Water and Silica Fume on Properties of C60 Concrete. Materials. 2023; 16(13):4684. https://doi.org/10.3390/ma16134684

Chicago/Turabian StyleHe, Shuang, Tingshu He, Zhenmin Wan, and Qing Zhao. 2023. "Effect of Micro-Nano Bubble Water and Silica Fume on Properties of C60 Concrete" Materials 16, no. 13: 4684. https://doi.org/10.3390/ma16134684

APA StyleHe, S., He, T., Wan, Z., & Zhao, Q. (2023). Effect of Micro-Nano Bubble Water and Silica Fume on Properties of C60 Concrete. Materials, 16(13), 4684. https://doi.org/10.3390/ma16134684