Evolution and Influencing Mechanisms of the Yili Loess Mechanical Properties under Combined Wetting-Drying and Freeze-Thaw Cycling

Abstract

:1. Introduction

2. Experimental Setups

2.1. Sample Preparation

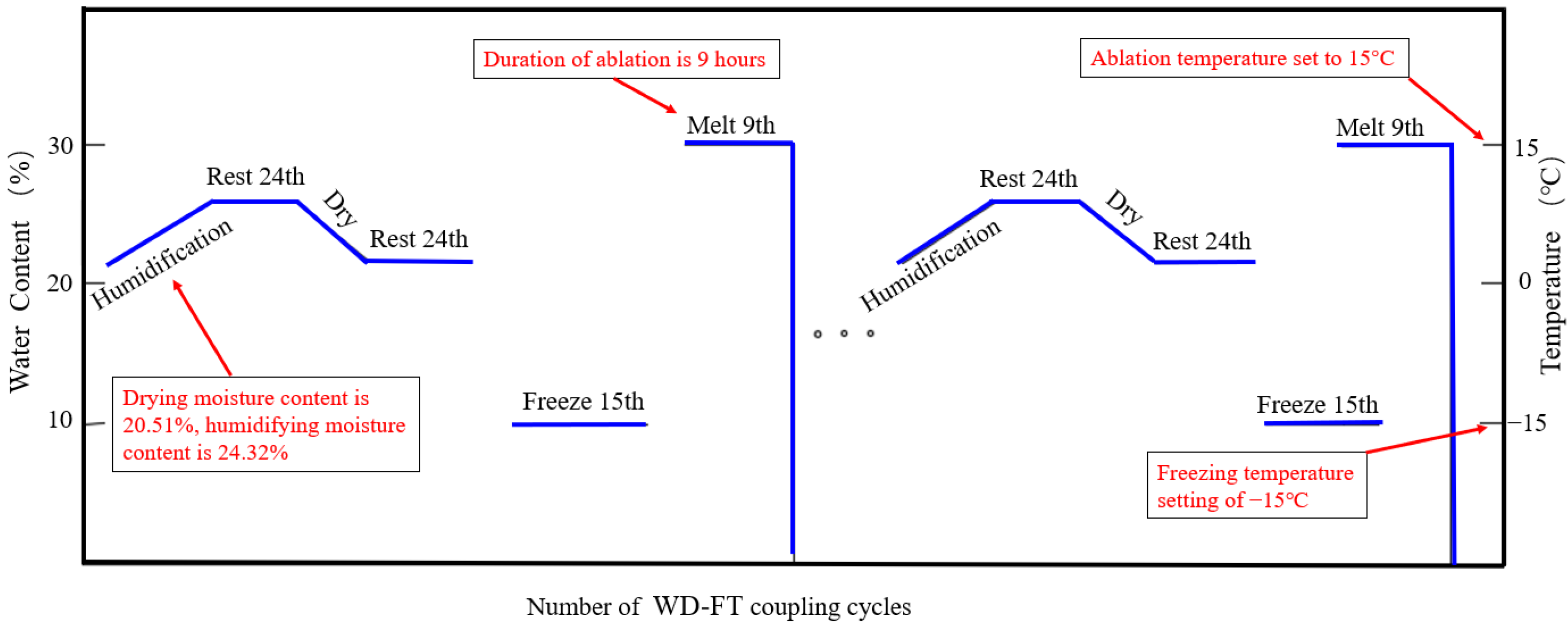

2.2. Coupled WD-FT Cyclic Tests

2.3. Triaxial Shear Test

2.4. Scanning Electron Microscopy Examination

2.5. Gray Correlation Analysis

3. Experimental Results and Analysis

3.1. Analysis of the Triaxial Shear Test Results

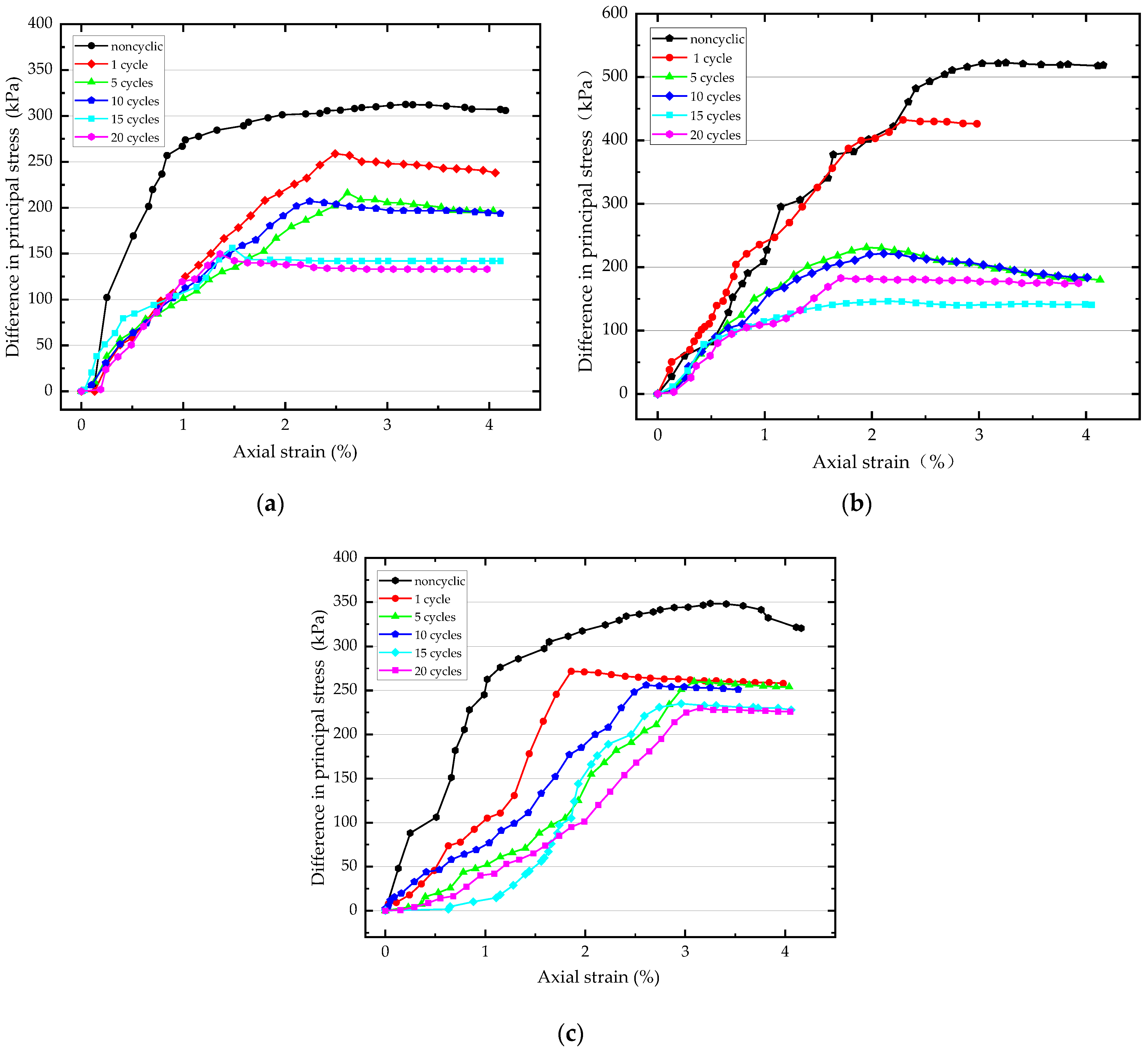

3.2. Stress-Strain Curves

3.3. Shear Strength Inde

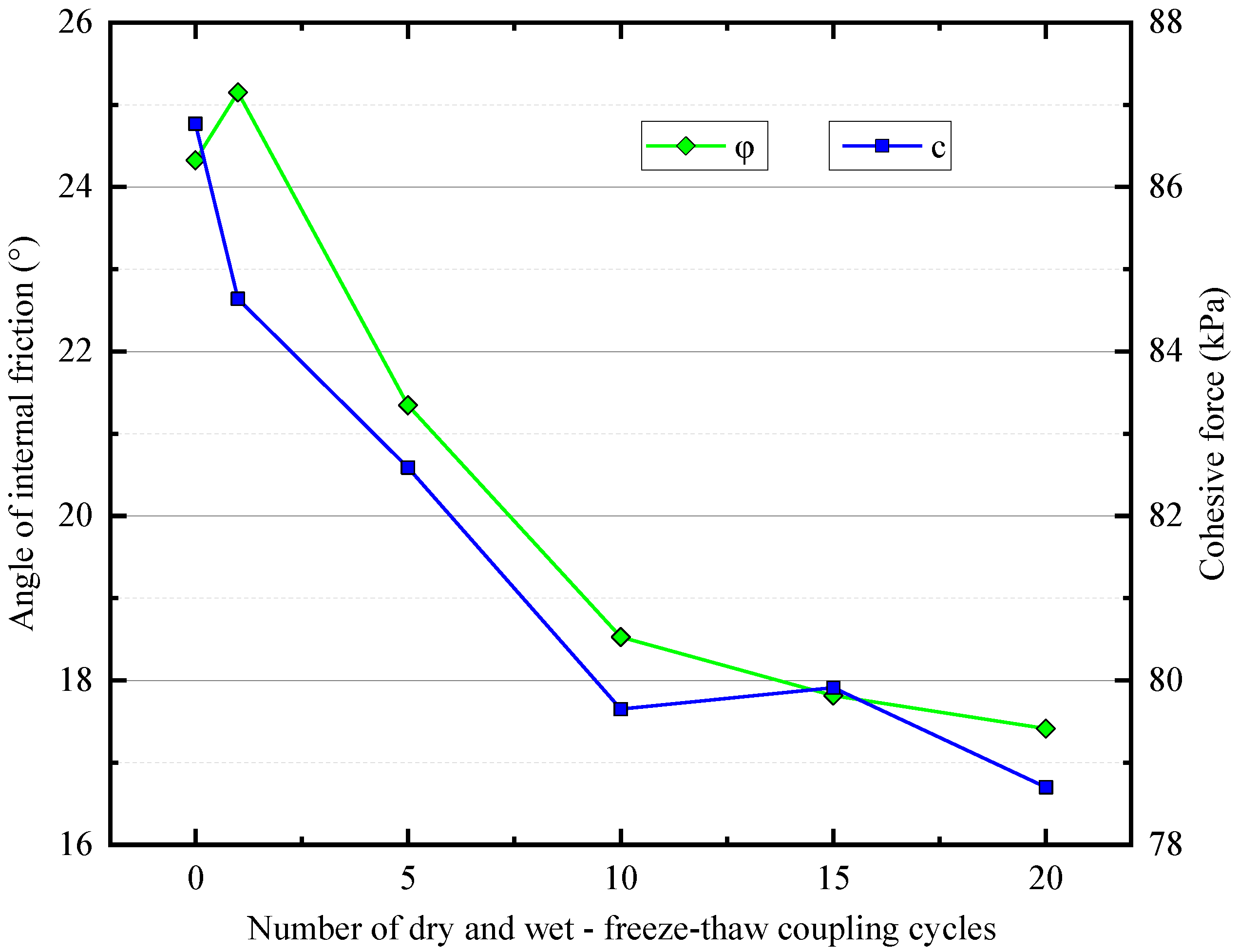

3.4. Shear Strength

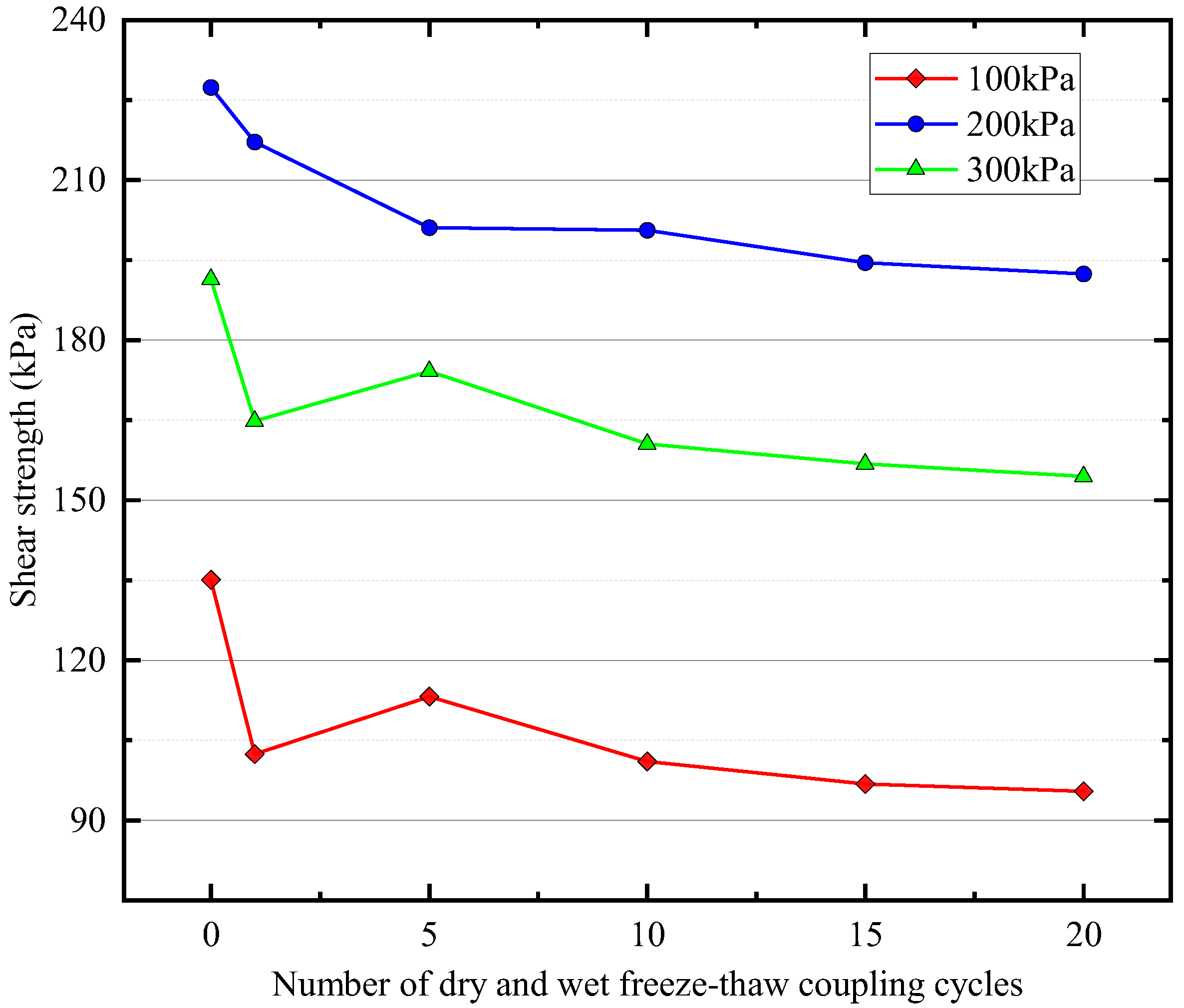

3.5. Changes in Microscopic Particle Structure of Loess

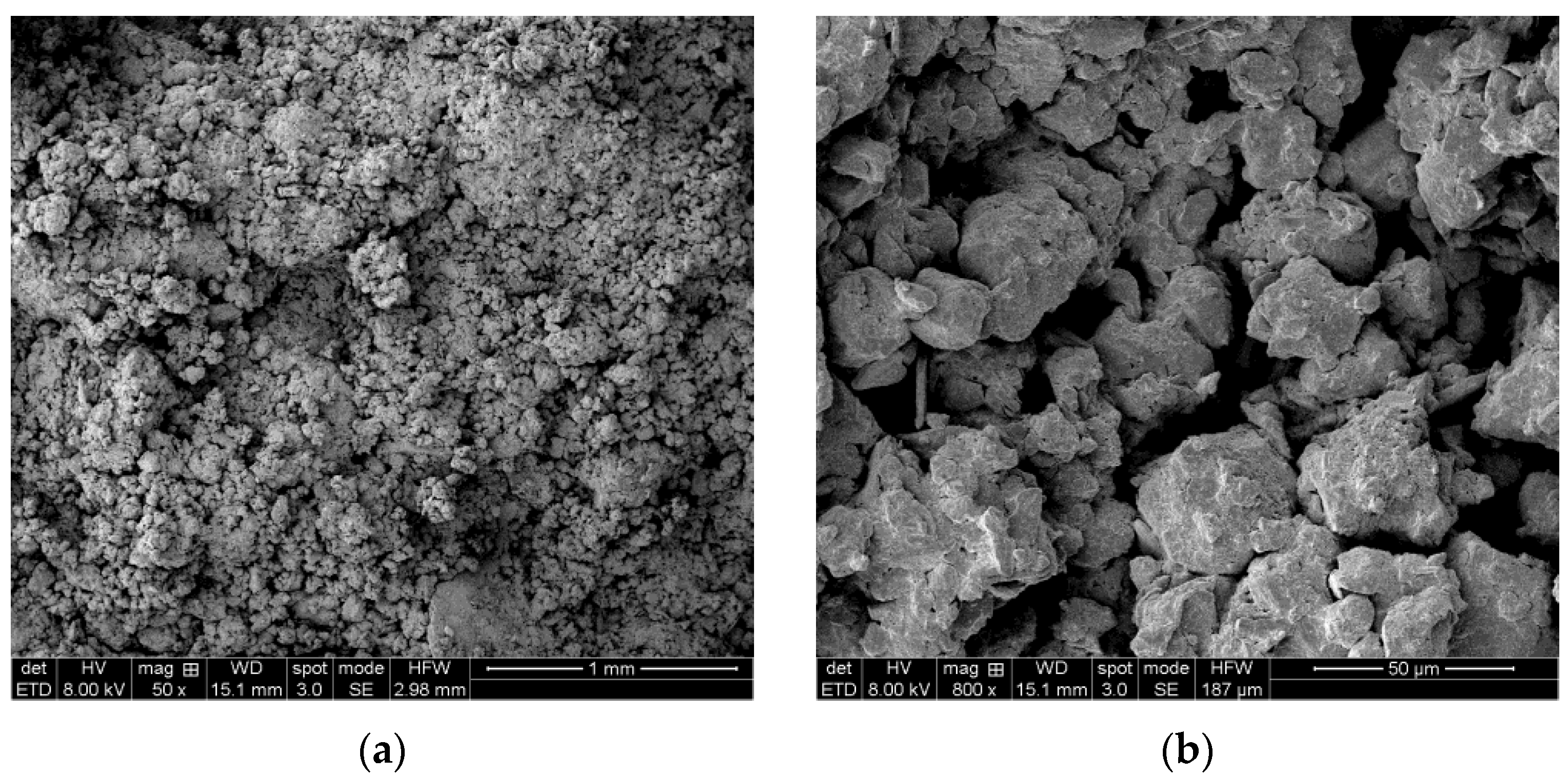

3.5.1. Acquiring Microscopic Images

3.5.2. Microscopic Image Processing

3.6. Microscopic Experimental Results and Analysis

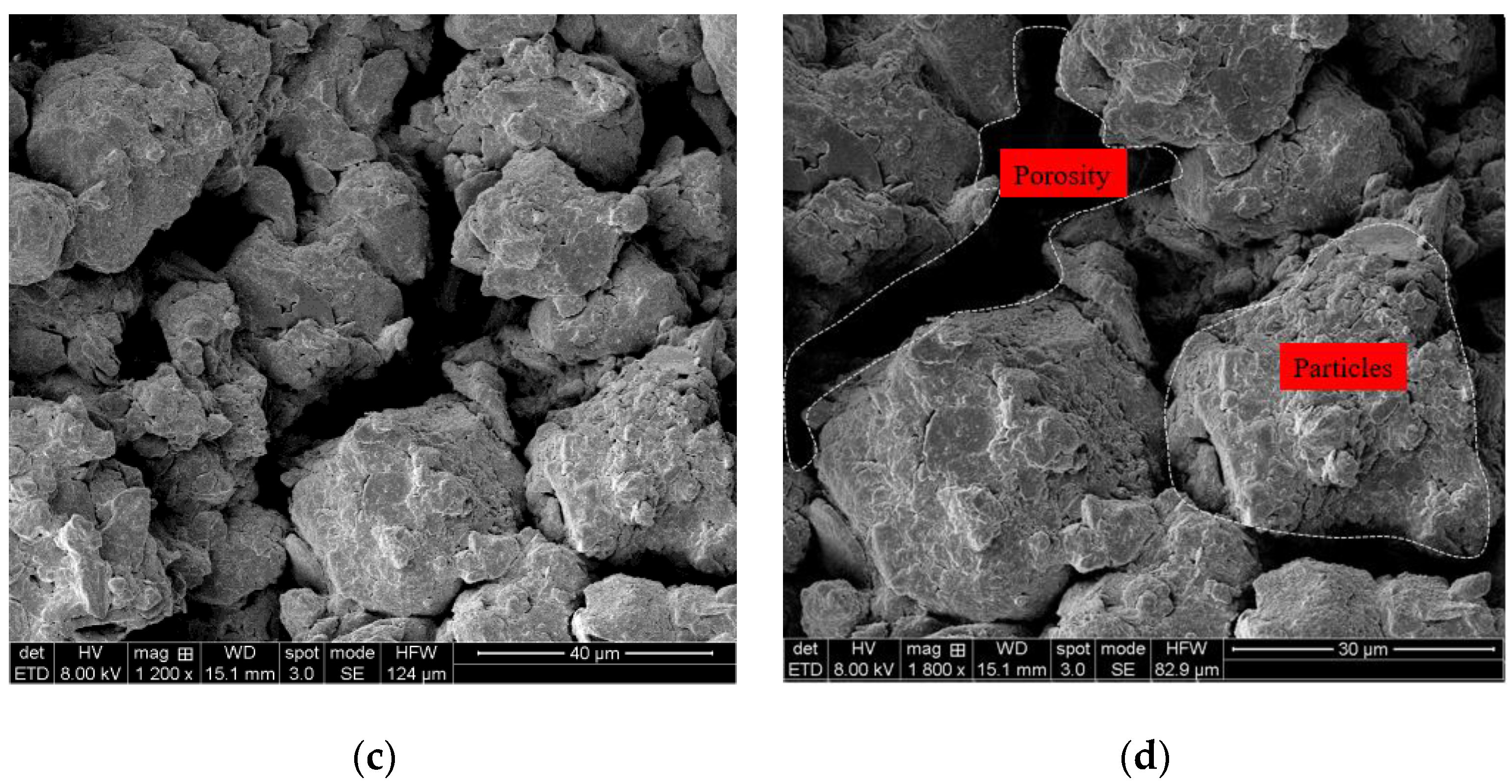

3.6.1. Qualitative Analysis

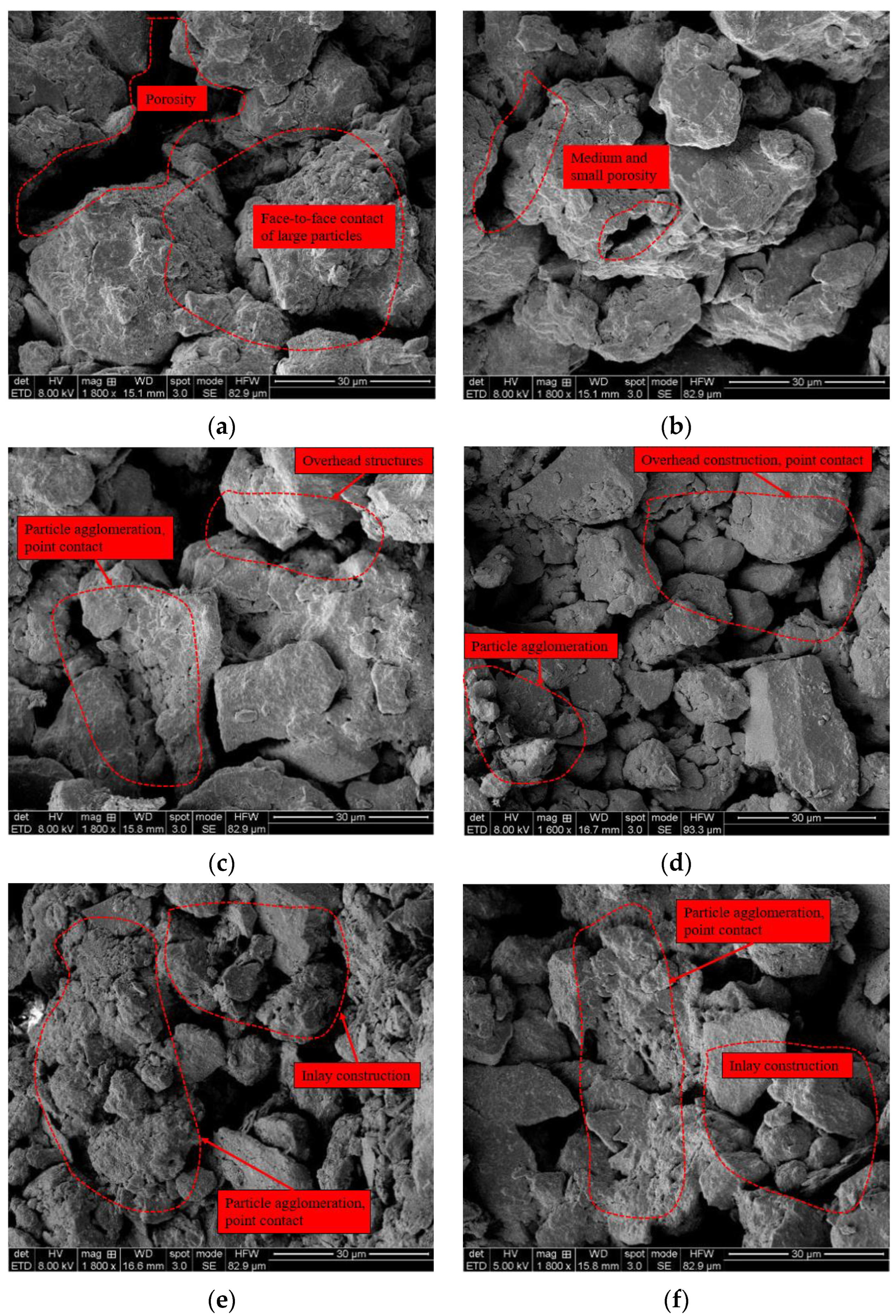

3.6.2. Quantitative Analysis

3.6.3. Image Information Extraction

3.7. Grey Correlation Results and Analysis

3.7.1. Determination of the Analysis Sequence

3.7.2. Dimensionless Processing of Variables [31]

3.7.3. Calculating the Correlation Coefficient

3.7.4. Correlation Assessment

4. Conclusions

- After undergoing WD-FT coupled cycling, the internal friction angle and cohesive force decreased to varying degrees. Both indices underwent the most drastic drop during the first WD-FT cycle; then, the degree of change gradually slowed, tending to stabilize with an increased number of cycles, eventually reaching a new stable state.

- Under the unconsolidated undrained (UU) conditions, compared with the initial state of the sample, the shear strength of the sample subjected to WD-FT coupled cycling first dropped and then stabilized. The initial effect of WD-FT coupled cycling on the shear strength of the soil was the most significant. With the increased number of cycles, it stabilized below the initial one.

- The SEM image analysis after WD-FT coupled cycling revealed numerous cracks generated in the soil/loess samples due to the cumulative effect of WD-FT cycles. Besides, large particles were broken, and the interparticle bonding was weakened, resulting in a gradual decrease in soil cohesion with increased cycles. The distribution of fine particles in the soil after WD-FT coupled cycling affected the internal friction angle, as soil particles broke and the generated fine particles easily became embedded into large pores, resulting in a “lubrication effect” on particle sliding and causing a certain degree of decrease in the internal friction angle of the soil.

- The gray correlation analysis revealed that the grain size dimension closely correlated with the macroscopic internal friction angle during the coupled WD-FT cycling, while the correlation significance between the pore area ratio, particle roundness, average abundance, directional probability entropy, average diameter, and macroscopic internal friction angle decreased sequentially. The pore area ratio closely correlates with the macroscopic cohesion force during coupled WD-FT cycling. The correlation significance between grain size dimension, average diameter, directional probability entropy, particle roundness, average abundance, and macroscopic cohesion force decreased sequentially.

- The wetting-drying cycle effect on soil strength was weaker than that of the freeze-thaw cycle. The first WD, FT, and WD-FT cycles produced the strongest effects on the soil’s mechanical and microstructural properties. From the standpoints of the internal friction angle, cohesion, and shear strength attenuation, the coupled WD-FT cycling effect had neither superposition nor synergetic pattern: it exceeded the effects of single (FT or WD) factors but was less than their sum. The follow-up study envisages a more detailed study of the FT and WD loading history effect in soil samples’ coupled FT and WD cycling.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cui, K.; Wang, P.; Chen, W.; Wu, G. Study on Deterioration of Soil Properties on Mountain Road Slopes under Different Wet and Dry Effects. J. Eng. Geol. 2019, 27, 230–238. [Google Scholar]

- Zhang, Y.; Shi, Y.; Wang, J.; Jie, X.; Shi, L. Research on InSAR Identification and Development Characteristics of Landslide Hidden Hazards in Yili Area, Xinjiang. Remote Sens. Technol. Appl. 2023, 38, 496–507. [Google Scholar]

- Yanli, Q.; Bai, M.Z.; Zhou, H.; Shi, H.; Li, P.; He, B. Study on the mechanical properties of red clay under drying-wetting cycles. Adv. Mater. Sci. Eng. 2021, 2021, 8665167. [Google Scholar]

- Wu, Z.; Xu, J.; Chen, H.; Shao, L.; Zhou, X.; Wang, S. Shear strength and mesoscopic characteristics of basalt fiber–reinforced loess after dry–wet cycles. J. Mater. Civ. Eng. 2022, 34, 04022083. [Google Scholar] [CrossRef]

- Chamberlain, E.J.; Iskandar, I.; Hunsicker, S.E. Effect of freeze-thaw cycles on the permeability and macrostructure of soils. Cold Reg. Res. Eng. Lab. 1990, 90, 145–155. [Google Scholar]

- Yan, C.; An, N.; Wang, Y.; Sun, W. Effect of dry-wet cycles and freeze-thaw cycles on the antierosion ability of fiber-reinforced loess. Adv. Mater. Sci. Eng. 2021, 2021, 8834598. [Google Scholar] [CrossRef]

- Viklander, P. Permeability and volume changes in till due to cyclic freeze/thaw. Can. Geotech. J. 1998, 35, 471–477. [Google Scholar] [CrossRef]

- Xiao, D.H.; Feng, W.J.; Zhang, Z.; Ming, J.; Wang, Q. Research on the Lanzhou loess’s permeabilities changing with freezing-thawing cycles. J. Glaciol. Geocryol. 2014, 36, 1192–1198. [Google Scholar]

- Lian, J.B.; Zhang, A.J.; Guo, M.X.; Dong, X.H. Influence of iterative freezing-thawing on void ratio and permeability coefficient of loess. Yangtze River 2010, 41, 55–58. [Google Scholar]

- Xu, J.; Wang, Z.-Q.; Ren, J.-W.; Wang, S.-H.; Jin, L. Mechanism of slope failure in loess terrains during spring thawing. J. Mt. Sci. 2018, 15, 845–858. [Google Scholar] [CrossRef]

- Chamberlain, E.J.; Gow, A.J. Effect of freezing and thawing on the permeability and structure of soils. Dev. Geotech. Eng. 1979, 26, 73–92. [Google Scholar]

- Ni, W.K.; Shi, H.Q. Influence of freezing-thawing cycles on micro-structure and shear strength of loess. J. Glaciol. Geocryol. 2014, 36, 922–927. [Google Scholar]

- Ye, W.; Li, C. The consequences of changes in the structure of loess as a result of cyclic freezing and thawing. Bull. Eng. Geol. Environ. 2019, 78, 2125–2138. [Google Scholar] [CrossRef]

- Zhao, X.F. Summary of Grey System Theory. J. Educ. Inst. Jilin Prov. 2011, 27, 152–154. [Google Scholar]

- Zhao, Y.; Liu, G.; Mao, J.; Chen, L.; Wei, M. Sensitivity analysis for the stability of loess slope based on grey correlation degree. J. Yangtze River Sci. Res. Inst. 2015, 32, 94. [Google Scholar]

- Bai, Z.; Li, D.; Zhao, D.; Lu, W.; Liu, J. Experimental Research on Collapsibility of Xi’an Loess Improved by Calcium Lignosulfonate. Coatings 2023, 13, 157. [Google Scholar] [CrossRef]

- Miao, F.; Wu, Y.; Li, L.; Tang, H.; Xiong, F. Weakening laws of slip zone soils during wetting–drying cycles based on fractal theory: A case study in the Three Gorges Reservoir (China). Acta Geotech. 2020, 15, 1909–1923. [Google Scholar] [CrossRef]

- Li, Y.; Xu, J.; Wang, Z.; Wang, B. Experimental Study on Microstructure and Hydraulic Performance of Bentonite Modified Loess. KSCE J. Civ. Eng. 2023, 27, 2778–2791. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, H.; Chen, W.; Niu, F.; Niu, Z. Strength deterioration model of remolded loess contaminated with acid and alkali solution under freeze-thaw cycles. Bull. Eng. Geol. Environ. 2020, 79, 3007–3018. [Google Scholar] [CrossRef]

- Liu, L.N.; Li, S.; Jiang, Y.; Bai, Y.H.; Luo, Y. Failure mechanism of loess landslides due to saturated-unsaturated seepage-case study of Gallente landslide in Ili, Xinjiang. J. Eng. Geol. 2017, 25, 1230–1237. [Google Scholar]

- GB/T 50123—1999; Standard for Soil Test Method. Nanjing Institute of Water Resources Science: Nanjing, China, 1999.

- Zhu, S.; Yin, Y.; Wang, W.; Wei, Y.; Shao, H.; Huang, Z.; Zhuang, M.; Shi, A. Mechanism of freeze-thaw loess landslide in Yili River Valley, Xinjiang. Acta Geosci. Sin. 2019, 2, 339–349. [Google Scholar]

- Li, Z.; Yang, G.; Liu, H. The influence of regional freeze–thaw cycles on loess landslides: Analysis of strength deterioration of loess with changes in pore structure. Water 2020, 12, 3047. [Google Scholar] [CrossRef]

- Lian, B.; Wang, X.; Zhan, H.; Wang, J.; Peng, J.; Gu, T.; Zhu, R. Creep mechanical and microstructural insights into the failure mechanism of loess landslides induced by dry-wet cycles in the Heifangtai platform, China. Eng. Geol. 2022, 300, 106589. [Google Scholar] [CrossRef]

- Wu, W.; Jing, G.; Wei, J. The application of the grey relevancy analysing method in ventilation system scheme (in the near future) optimisation of Pingdingshan Coal Mine No. 6. Mei T’an Hsueh Pao (J. China Coal Soc.) 2001, 26, 290–293. [Google Scholar]

- Heymann, J. Coulomb’s Memoir on Statics; Cambridge University Press: Cambridge, UK, 1972. [Google Scholar]

- Zhang, W. Experimental Study on Compressive Deformation and Microscopic Properties of Remolded Loess under Coupling Effect of Dry-Wet and Freezing-Thawi. Master’s Thesis, Chang’an University, Xi’an, China, 2018. [Google Scholar]

- Qi, J.; Vermeer, P.A.; Cheng, G. A review of the influence of freeze-thaw cycles on soil geotechnical properties. Permafr. Periglac. Process. 2006, 17, 245–252. [Google Scholar] [CrossRef]

- Fang, Y.G.; Wu, Y.H.; Gu, R.G. Triaxial Drainage Shear Tests and Analysis of the Influence of Particle Size on Soil Deformation and Strength. Adhesion 2021, 48, 172–177. [Google Scholar]

- Lei, X.Y. Size of loess pores in relationto collapsibility. Hydrogeol. Eng. Geol. 1987, 14, 15–18. [Google Scholar]

- Yang, G.; Gui, Q.; Chen, Y.; Luo, Y.; Yang, Y. Spatial and Temporal Evolution Characteristics of Ecological Security in Three Gorges Reservoir Area during 2015–2019 Based on Grey Relational Theory. Bull. Soil Water Conserv. 2021, 41, 348–356. [Google Scholar]

| Natural Density | Natural Water Content | Maximum Dry Density | Saturated Water Content | Optimum Moisture Content |

|---|---|---|---|---|

| 1.95 g/cm3 | 20.51% | 1.86 g/cm3 | 24.32% | 17.4% |

| Parameters | Calculation Method | Remarks |

|---|---|---|

| Average diameter of soil particles as well as internal pores | D = | None |

| Abundance (ratio of short axis to long axis) | C = | Abundance is defined as the ratio of the short axis B to the long axis L. |

| Particle size fractal dimension | Dps = − | Where: r is the particle size, N(r) is the number of particles exceeding the selected size. |

| Directional probability entropy | Hm = | Where: Fi (α) is the orientation frequency; Hm takes the value of 0~1. |

| Particle roundness | R = | None |

| Pore area ratio | PAR = | Where: PAR denotes pore area ratio (%), A1 denotes pore area, A2 denotes total image area. |

| Number of WD-FT Coupling Cycles | Average Particle and Pore Diameter | Abundance | Particle Size Dimensioning | Directional Probability Entropy | Roundness of Particles | Pore Area Ratio |

|---|---|---|---|---|---|---|

| 0 | 2.58 | 0.59 | 0.98 | 0.91 | 1.14 | 21.2 |

| 1 | 2.40 | 0.55 | 0.97 | 0.88 | 1.25 | 23.5 |

| 5 | 2.34 | 0.57 | 0.96 | 0.9 | 1.12 | 24.2 |

| 10 | 2.19 | 0.51 | 0.95 | 0.87 | 1.26 | 24.4 |

| 15 | 1.96 | 0.47 | 0.93 | 0.85 | 1.35 | 24.7 |

| 20 | 1.95 | 0.46 | 0.93 | 0.84 | 1.35 | 24.9 |

| Number of WD-FT Coupling Cycles | 0 | 1 | 5 | 10 | 15 | 20 | |

|---|---|---|---|---|---|---|---|

| Reference Department | Angle of internal friction | 23.52 | 23.11 | 23.61 | 23.01 | 22.18 | 22.15 |

| Cohesive force | 80.45 | 78.21 | 81.94 | 78.66 | 74.31 | 73.11 | |

| Comparative Department | Average diameter | 2.58 | 2.40 | 2.34 | 2.19 | 1.96 | 1.95 |

| Average abundance | 0.59 | 0.55 | 0.57 | 0.51 | 0.47 | 0.46 | |

| Particle size fractional dimension | 0.98 | 0.97 | 0.96 | 0.95 | 0.93 | 0.93 | |

| directional probability entropy | 0.91 | 0.88 | 0.9 | 0.87 | 0.85 | 0.84 | |

| Average diameter | 2.58 | 2.40 | 2.34 | 2.19 | 1.96 | 1.95 | |

| Average Abundance | 0.59 | 0.55 | 0.57 | 0.51 | 0.47 | 0.46 | |

| ζ1 | ζ2 | ζ3 | ζ4 | ζ5 | ζ6 |

|---|---|---|---|---|---|

| 0.56 | 0.34 | 0.78 | 0.47 | 0.87 | 0.41 |

| 0.39 | 0.69 | 0.39 | 0.33 | 0.25 | 0.26 |

| 0.85 | 0.36 | 0.85 | 0.55 | 0.40 | 0.34 |

| 0.60 | 0.43 | 0.56 | 0.41 | 0.62 | 0.42 |

| 0.43 | 0.44 | 0.38 | 0.47 | 0.52 | 0.45 |

| 0.54 | 0.75 | 0.48 | 0.66 | 0.79 | 0.52 |

| ε1 | ε2 | ε3 | ε4 | ε5 | ε6 |

|---|---|---|---|---|---|

| 0.46 | 0.38 | 0.71 | 0.42 | 0.53 | 0.47 |

| 0.41 | 0.51 | 0.42 | 0.38 | 0.35 | 0.31 |

| 0.75 | 0.42 | 0.87 | 0.60 | 0.51 | 0.42 |

| 0.64 | 0.52 | 0.62 | 0.46 | 0.76 | 0.50 |

| 0.51 | 0.35 | 0.55 | 0.58 | 0.64 | 0.39 |

| 0.43 | 0.81 | 0.48 | 0.71 | 0.81 | 0.53 |

| Compare Series | Gray Correlation | |

|---|---|---|

| Angle of Internal Friction | Cohesive Force | |

| Average diameter | 0.43 | 0.73 |

| Average abundance | 0.59 | 0.61 |

| Directional probability entropy | 0.56 | 0.65 |

| Particle roundness | 0.61 | 0.64 |

| Pore area ratio | 0.64 | 0.66 |

| Particle size fractional dimension | 0.69 | 0.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhang, Z.; Hu, W.; Zhang, Y. Evolution and Influencing Mechanisms of the Yili Loess Mechanical Properties under Combined Wetting-Drying and Freeze-Thaw Cycling. Materials 2023, 16, 4727. https://doi.org/10.3390/ma16134727

Zhang Y, Zhang Z, Hu W, Zhang Y. Evolution and Influencing Mechanisms of the Yili Loess Mechanical Properties under Combined Wetting-Drying and Freeze-Thaw Cycling. Materials. 2023; 16(13):4727. https://doi.org/10.3390/ma16134727

Chicago/Turabian StyleZhang, Yongliang, Zizhao Zhang, Wanhong Hu, and Yanyang Zhang. 2023. "Evolution and Influencing Mechanisms of the Yili Loess Mechanical Properties under Combined Wetting-Drying and Freeze-Thaw Cycling" Materials 16, no. 13: 4727. https://doi.org/10.3390/ma16134727