New Numerical Method Based on Linear Damage Evolution Law for Predicting Mechanical Properties of TiB2/6061Al

Abstract

1. Introduction

2. Finite Element Model

2.1. Material Constitutive and Fracture Behavior

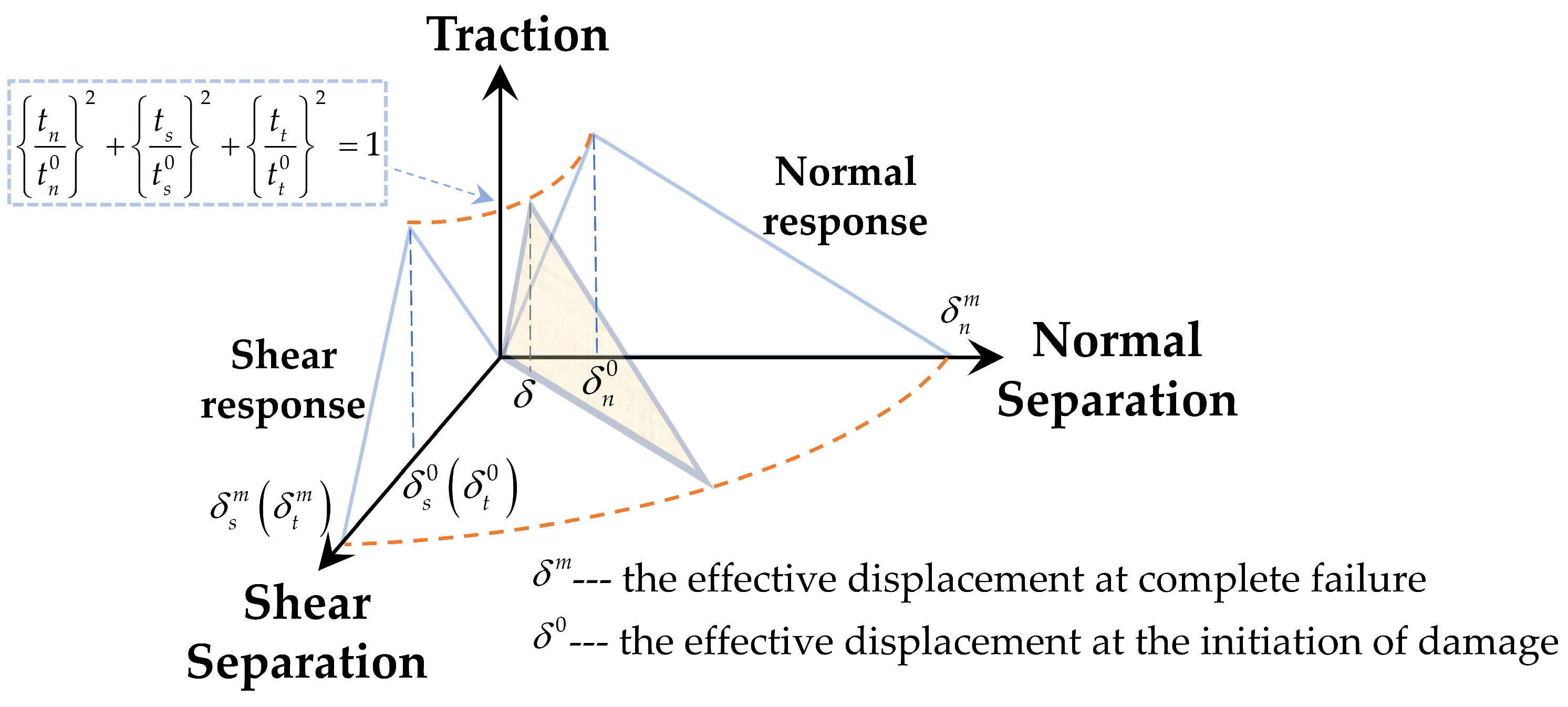

2.2. Quantitative Characterization of Damage Behavior

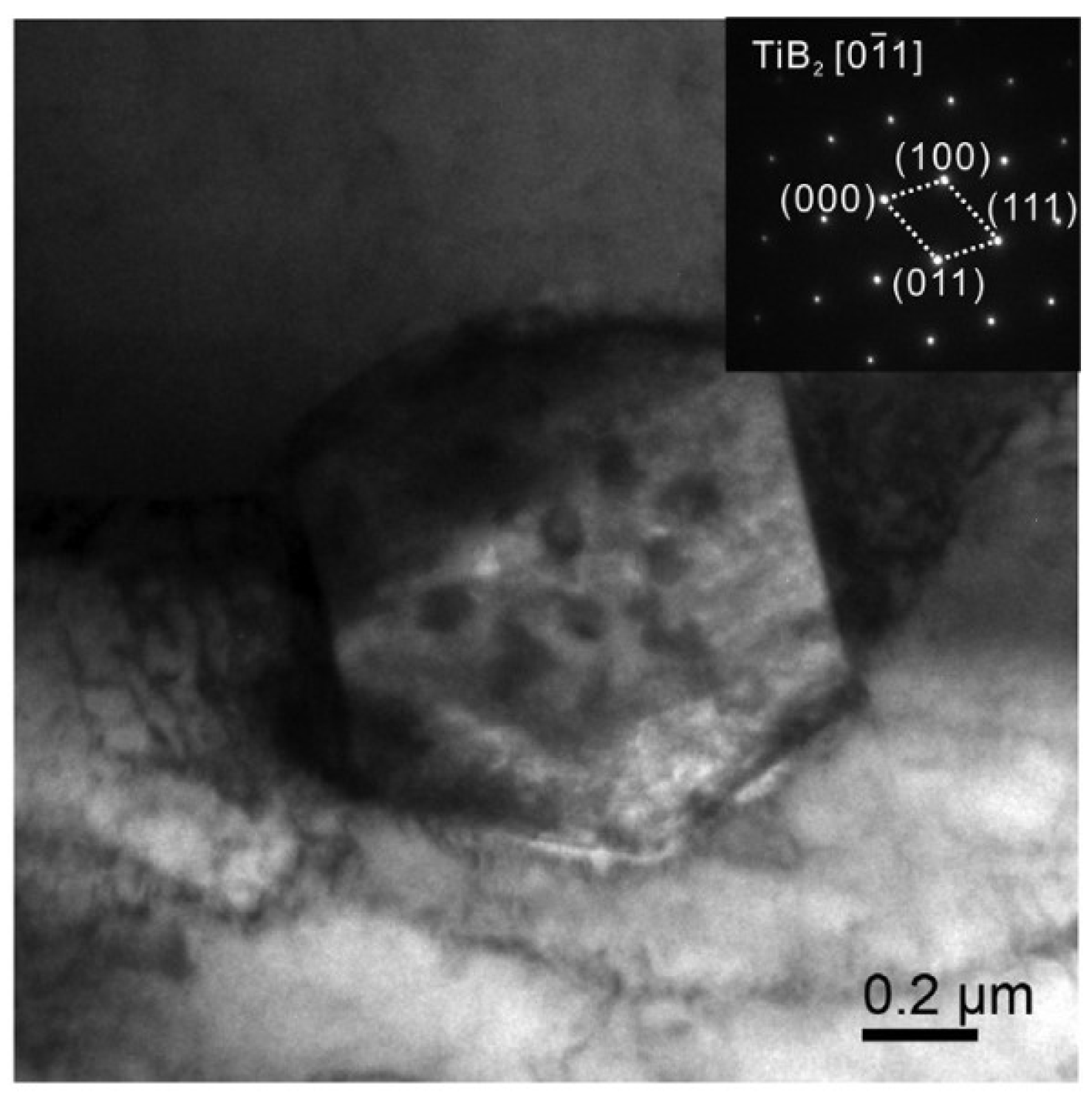

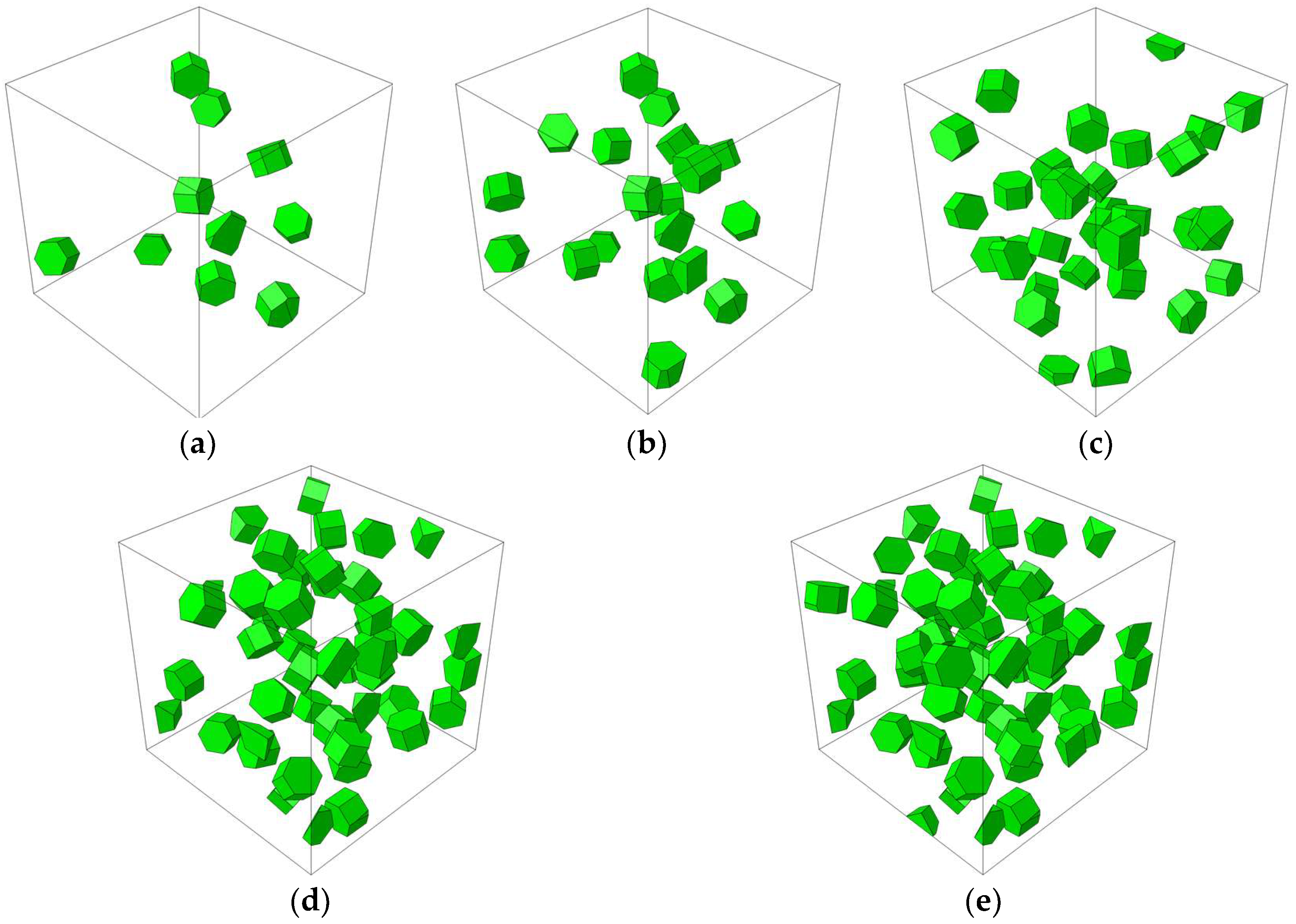

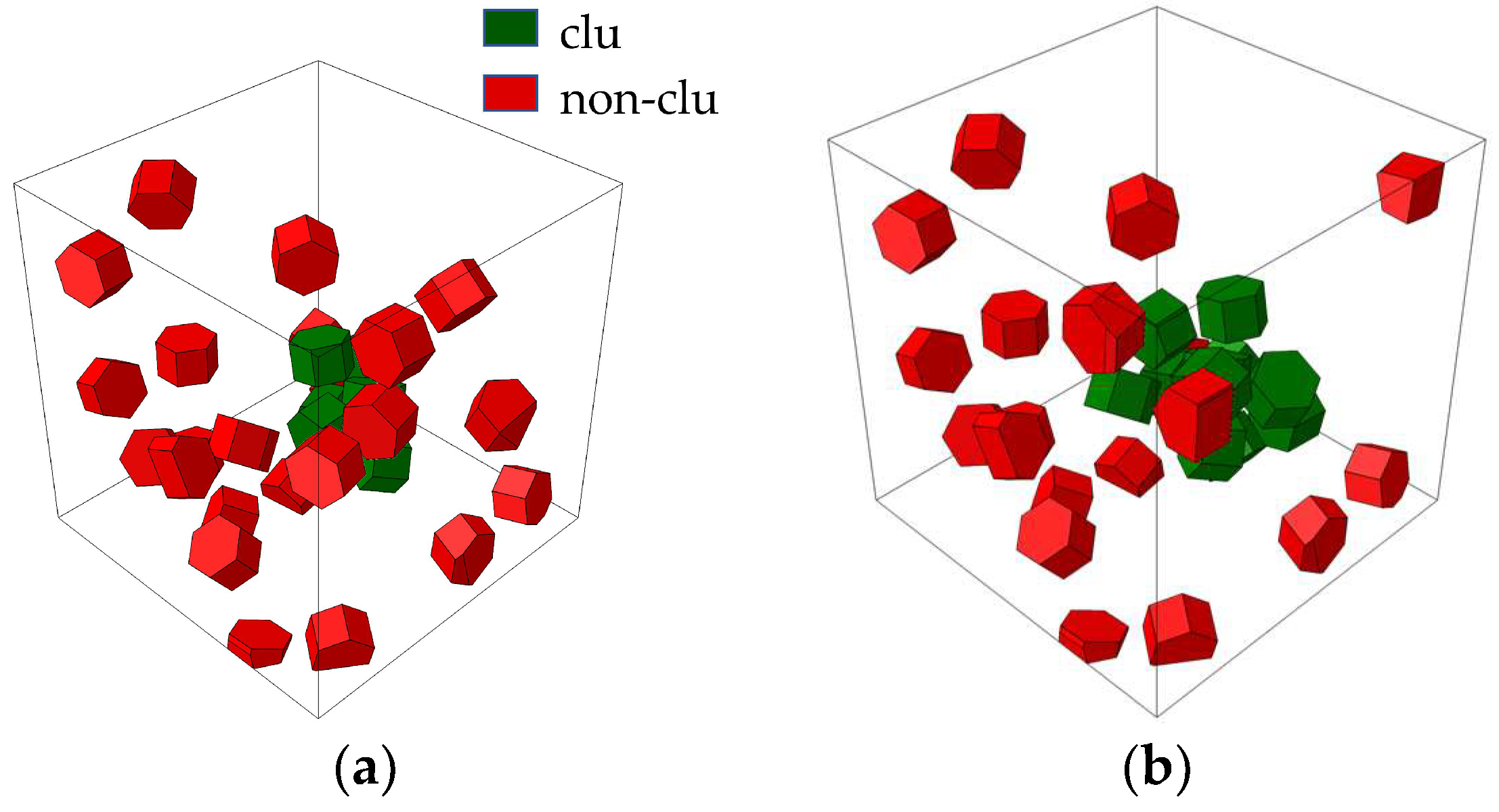

2.3. Establish the RVE Model

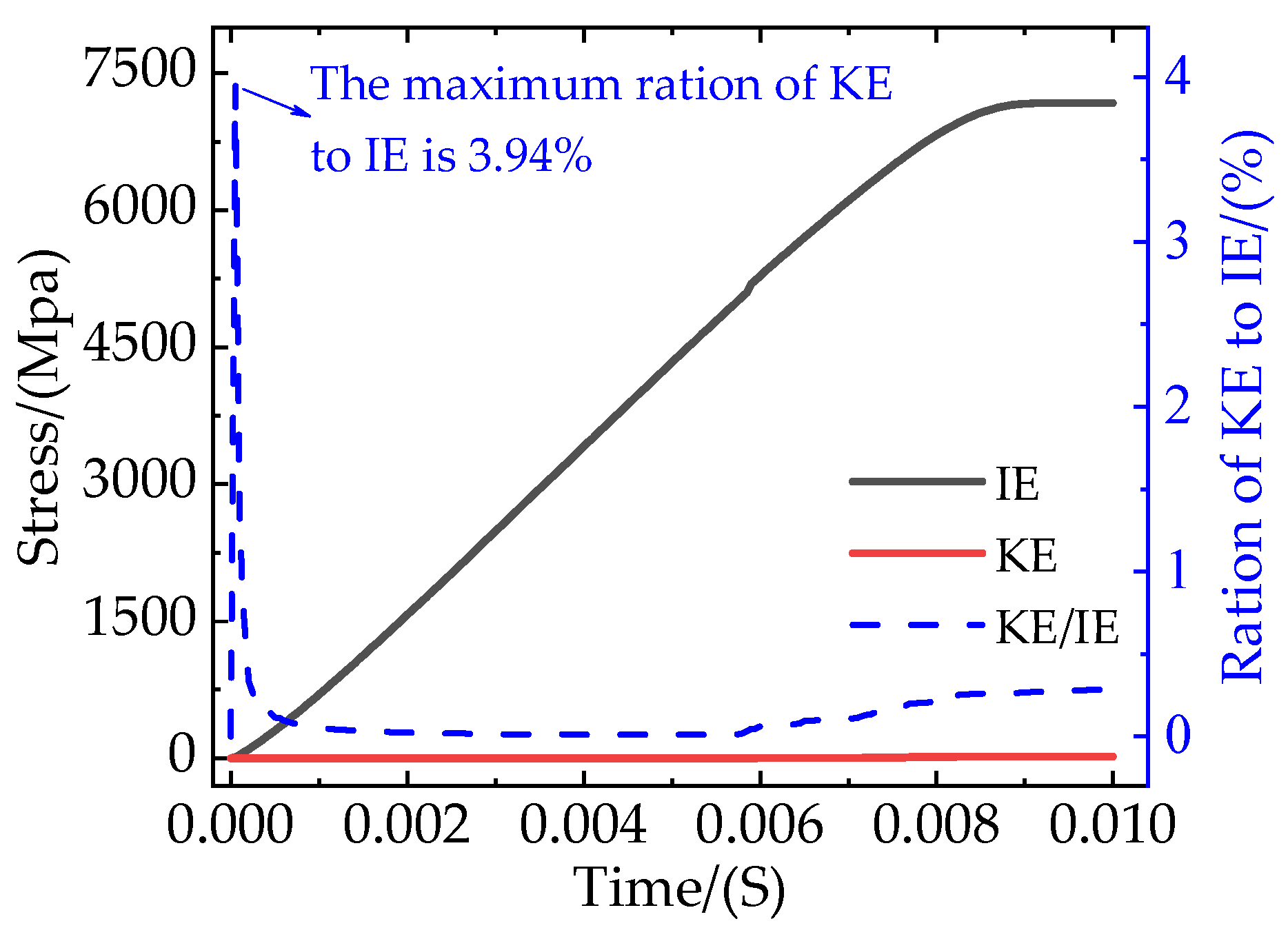

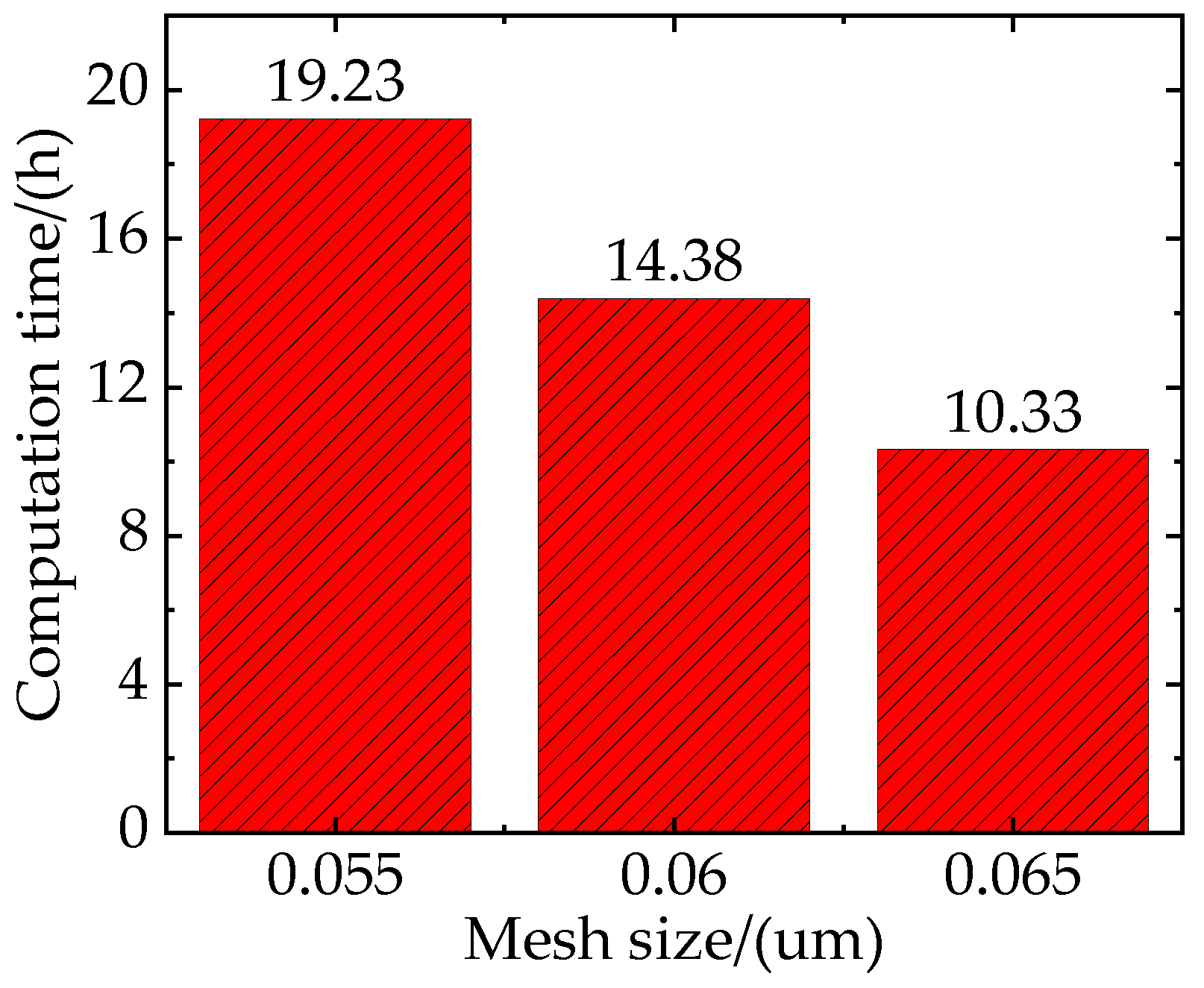

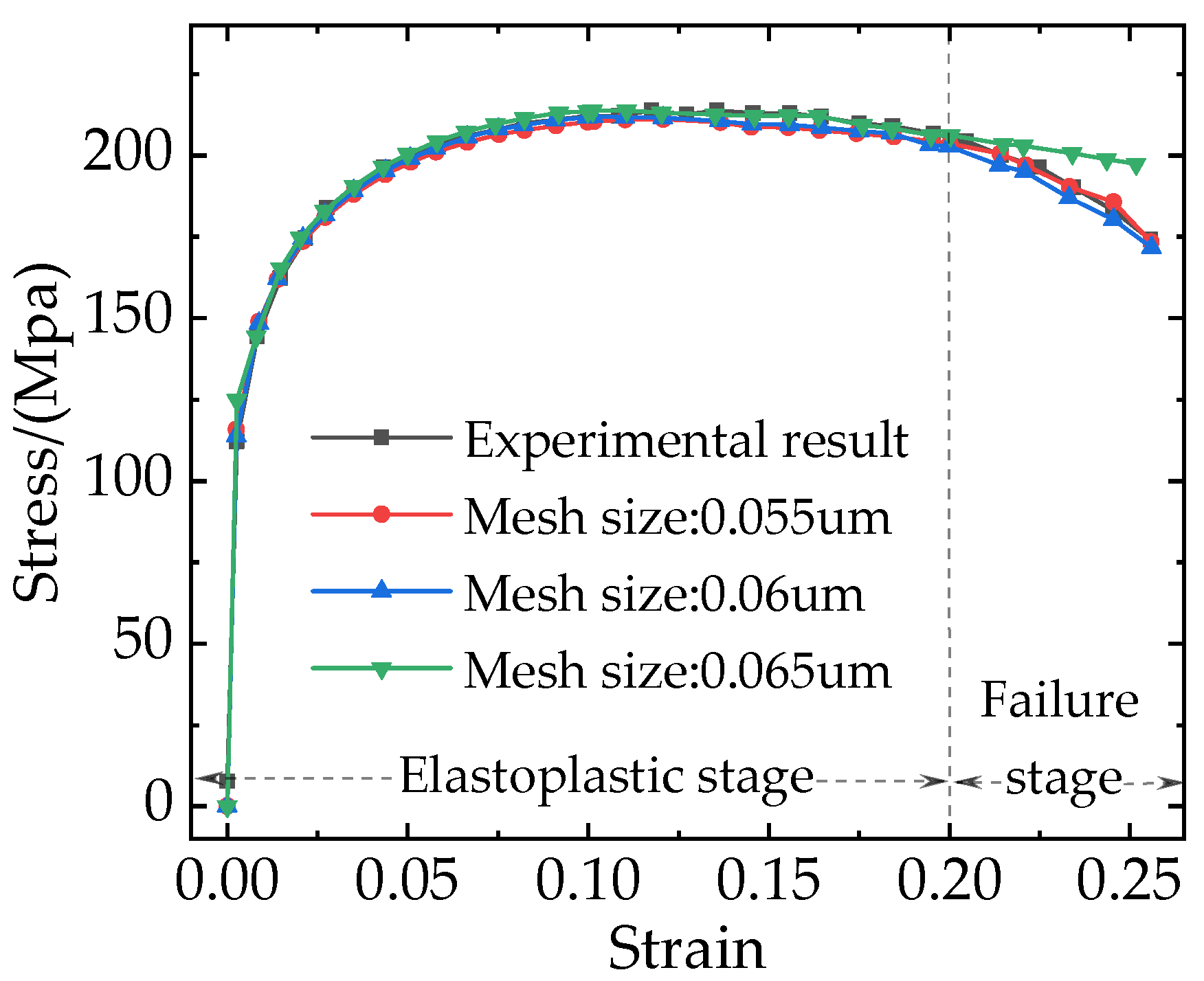

2.4. Model Verification

3. Results and Discussion

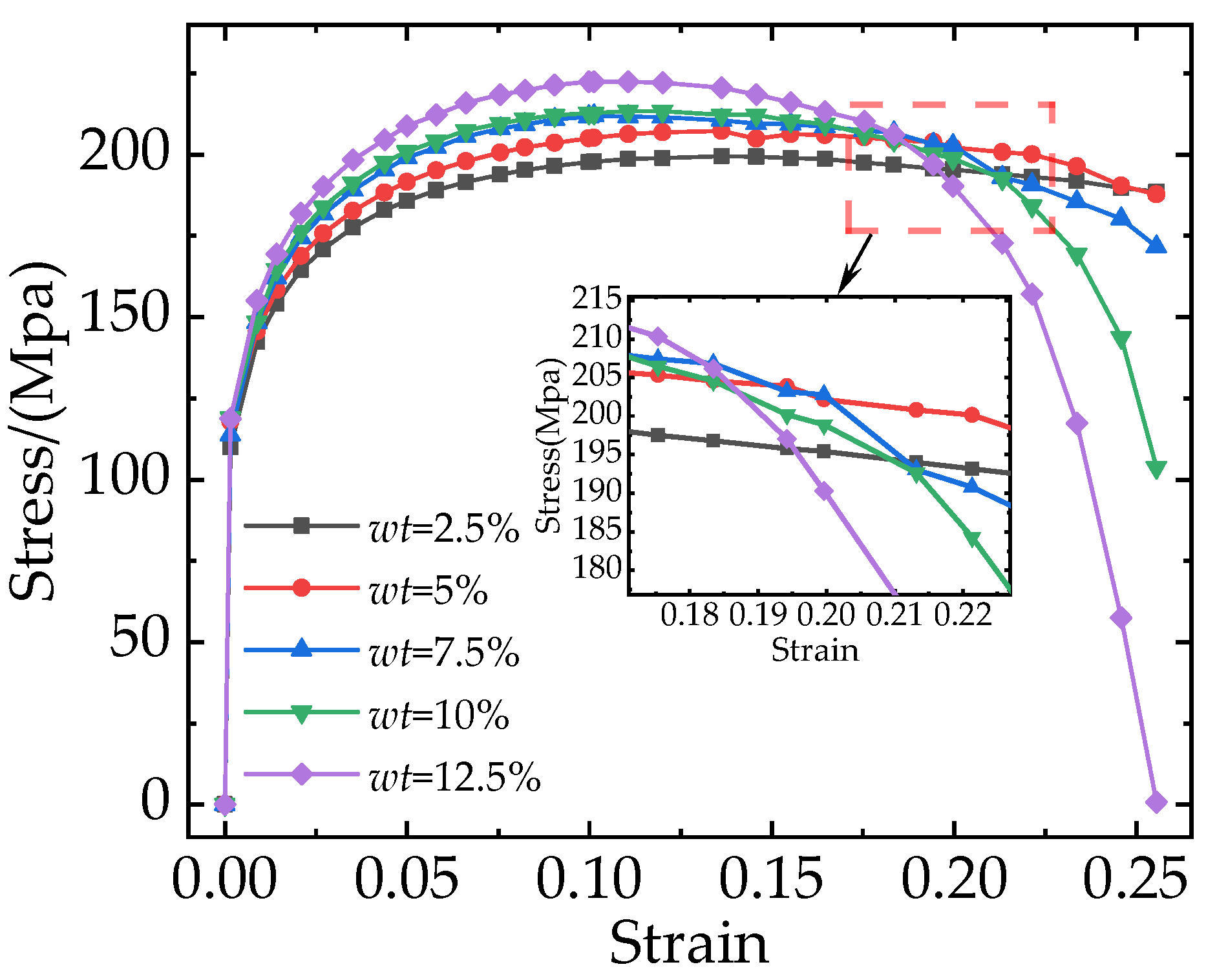

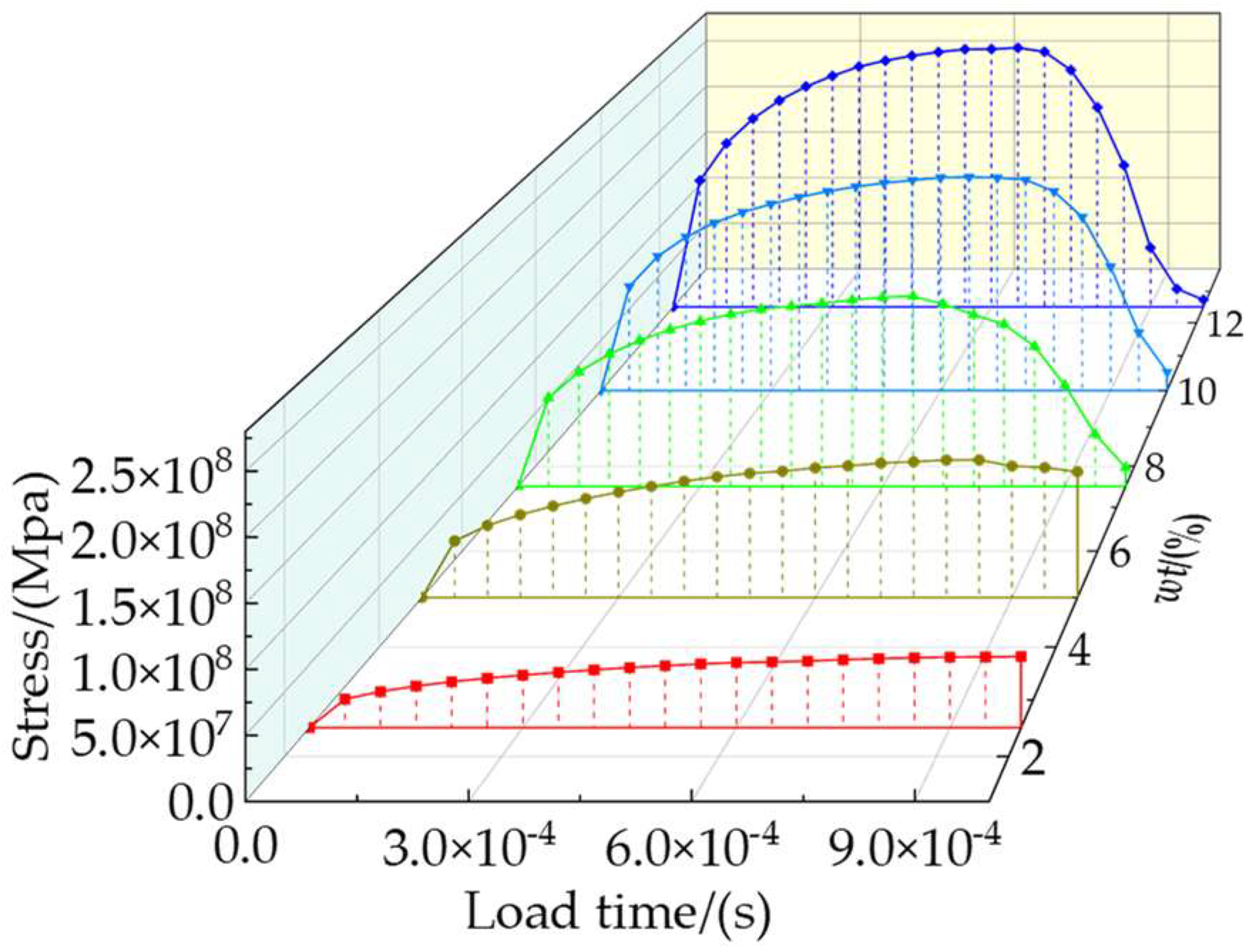

3.1. Effects of Different Particle Weight Fractions on TiB2/6061Al Composites

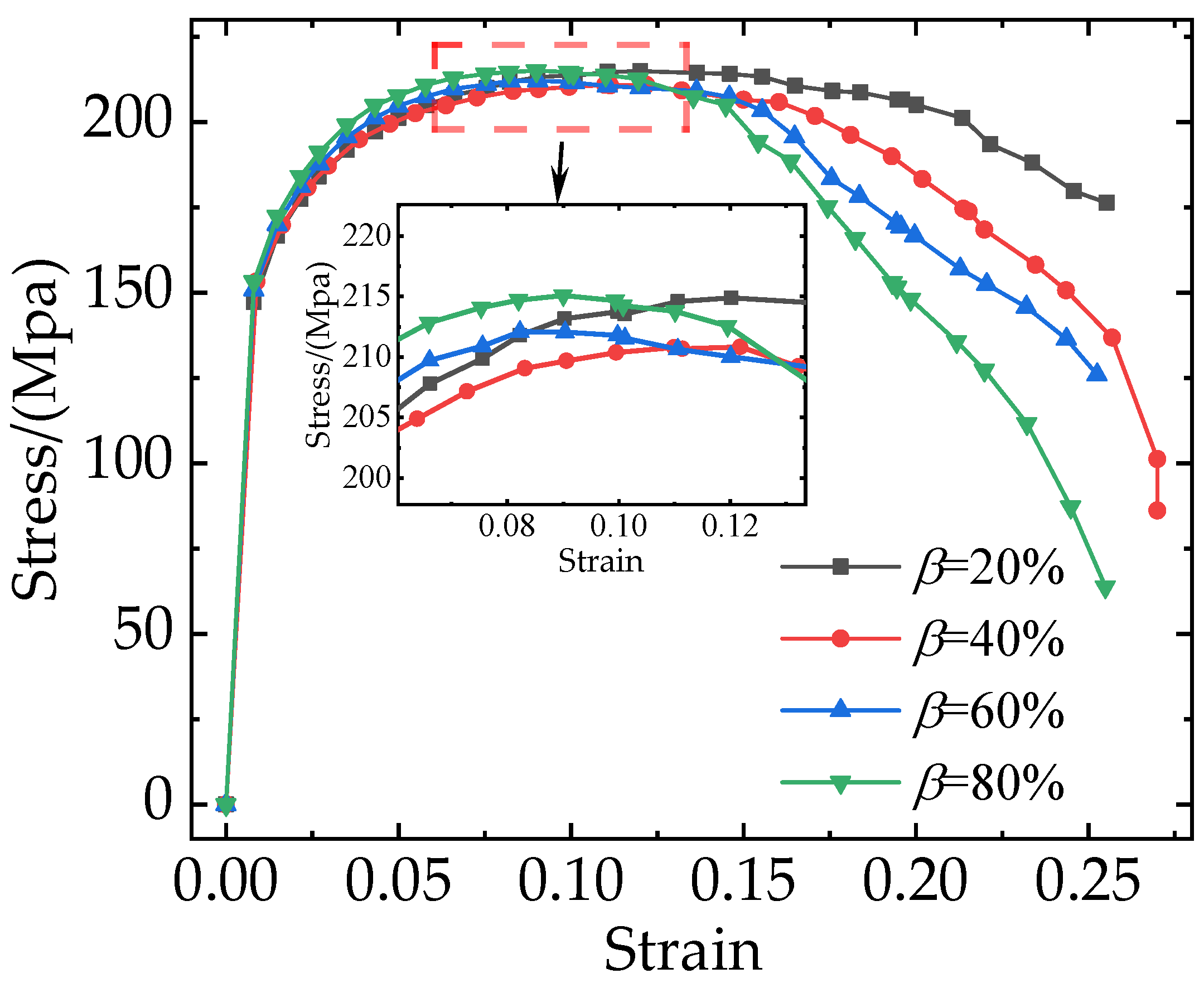

3.2. Effect of Different Clustering Rates on TiB2/6061Al Composites

4. Conclusions

- (1).

- The RVE model comprehensively considers the ductile fracture of the matrix and the traction separation behavior of the interface. It also introduces the linear damage evolution law to characterize the stiffness degradation of the element. It was successfully applied to predict the mechanical properties of composites.

- (2).

- For TiB2/6061Al composites, increasing the particle weight fraction improves strength but reduces toughness. With an increase in the weight fraction of TiB2 from 2.5% to 12.5%, the elastic modulus, yield strength, and tensile strength increased by 8%, 10.37%, and 11.55%, respectively, whereas elongation decreased by 10%.

- (3).

- Clustered particles also have an important effect on the internal stress field of composites. The results show that the clustering rate of particles has a great effect on toughness. With an increase in the clustering rate from 20% to 80%, the rate of decrease in stress increases constantly, and the elongation of composites decreases by 8%. However, it has little effect on yield strength, tensile strength, or elastic modulus.

- (4).

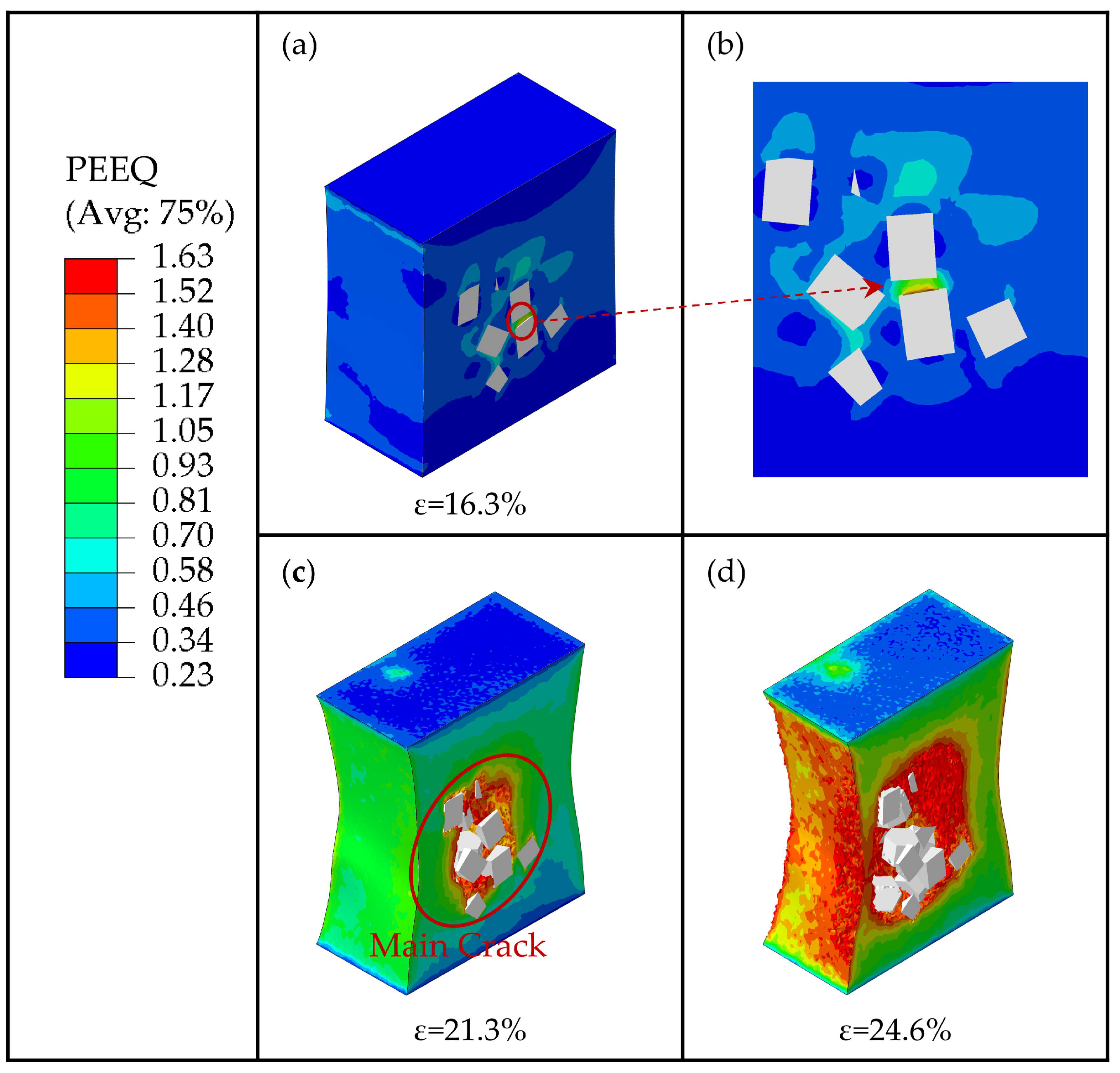

- The mechanism of crack generation and propagation was also studied. A fine crack is first generated around the particles. Then, this fine crack merges with other fine cracks nearby, forming a main crack and eventually leading to the fracture of the composites.

- (5).

- The high-strain region in the matrix provides a fast expansion path for crack propagation. The reduction in particle spacing causes the stress on the particles to increase and the damage to occur earlier.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bi, S.; Xiao, B.L.; Ji, Z.H.; Liu, B.S.; Liu, Z.Y.; Ma, Z.Y. Dispersion and Damage of Carbon Nanotubes in Carbon Nanotube/7055Al Composites During High-Energy Ball Milling Process. Acta Metall. Sin. 2021, 34, 196–204. [Google Scholar] [CrossRef]

- Liu, R.; Wang, W.; Chen, H. Synthesis of Nano- to Micrometer-Sized B4C Particle-Reinforced Aluminum Matrix Composites via Powder Metallurgy and Subsequent Heat Treatment. J. Cent. South Univ. 2021, 28, 2295–2306. [Google Scholar] [CrossRef]

- Li, Z.; Chen, L.; Zhang, X.; Que, B.; Zhao, G.; Zhang, C. Effects of TiB2 Particle and Local Aspect Ratio on Microstructure and Mechanical Properties of an I-Shaped TiB2/6061Al Composite Profile. Mater. Sci. Eng. A 2022, 846, 143284. [Google Scholar] [CrossRef]

- Xie, K.; Nie, J.; Hu, K.; Ma, X.; Liu, X. Improvement of High-Temperature Strength of 6061 Al Matrix Composite Reinforced by Dual-Phased Nano-AlN and Submicron-Al2O3 Particles. Trans. Nonferrous Met. Soc. China 2022, 32, 3197–3211. [Google Scholar] [CrossRef]

- Liang, S.; Li, W.; Jiang, Y.; Cao, F.; Dong, G.; Xiao, P. Microstructures and Properties of Hybrid Copper Matrix Composites Reinforced by TiB Whiskers and TiB2 Particles. J. Alloys Compd. 2019, 797, 589–594. [Google Scholar] [CrossRef]

- Shi, Z.; Wang, K.; Xie, H.; Dai, L.; Zhao, G. Precipitation of Ceramic Particles in Fe-TiB2 and Fe-Ni-TiB2 Cast Steels during the Sub-Rapid Solidification Process. J. Alloys Compd. 2023, 943, 169148. [Google Scholar] [CrossRef]

- Lv, Z.; Sha, J.; Lin, G.; Wang, J.; Guo, Y.; Dong, S. Mechanical and Thermal Expansion Behavior of Hybrid Aluminum Matrix Composites Reinforced with SiC Particles and Short Carbon Fibers. J. Alloys Compd. 2023, 947, 169550. [Google Scholar] [CrossRef]

- Yang, R.; Zhang, Z.; Zhao, Y.; Chen, G.; Liu, M.; Jiao, L.; Chen, L. Microstructure-Property Analysis of ZrB 2 /6061Al Hierarchical Nanocomposites Fabricated by Direct Melt Reaction. Mater. Charact. 2016, 112, 51–59. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, S.; Li, Z.; Zhao, G.; Zhang, C.; Lin, J. Investigation on Peripheral Coarse Grains and Precipitation Behavior of In-Situ TiB2/Al–Cu–Mg Composites with Various Mg Contents. Mater. Sci. Eng. A 2021, 826, 142000. [Google Scholar] [CrossRef]

- Huang, L.J.; Wang, S.; Dong, Y.S.; Zhang, Y.Z.; Pan, F.; Geng, L.; Peng, H.X. Tailoring a Novel Network Reinforcement Architecture Exploiting Superior Tensile Properties of in Situ TiBw/Ti Composites. Mater. Sci. Eng. A 2012, 545, 187–193. [Google Scholar] [CrossRef]

- Kumar, M.S.; Yang, C.-H.; Ishfaq, K.; Jeyaprakash, N.; Rehman, M. Evaluating the Effects of Vortex Generation and the Settling Time of Reinforcing Particles on the Mechanical Characteristics of the PRMMC: A Real-Time Simulation and Experimental Study. J. Manuf. Process. 2023, 98, 80–94. [Google Scholar] [CrossRef]

- Ma, S.; Wang, X. Mechanical Properties and Fracture of In-Situ Al3Ti Particulate Reinforced A356 Composites. Mater. Sci. Eng. A 2019, 754, 46–56. [Google Scholar] [CrossRef]

- Law, E.; Pang, S.D.; Quek, S.T. Effects of Particle Arrangement and Particle Damage on the Mechanical Response of Metal Matrix Nanocomposites: A Numerical Analysis. Acta Mater. 2012, 60, 8–21. [Google Scholar] [CrossRef]

- Weng, G.J. Some Elastic Properties of Reinforced Solids, with Special Reference to Isotropic Ones Containing Spherical Inclusions. Int. J. Eng. Sci. 1984, 22, 845–856. [Google Scholar] [CrossRef]

- Farkash, A.; Mittelman, B.; Hayun, S.; Priel, E. Aluminum Matrix Composites with Weak Particle Matrix Interfaces: Effective Elastic Properties Investigated Using Micromechanical Modeling. Materials 2021, 14, 6083. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, W.; He, X.; Lan, X.; Sha, A.; Hao, W. Effects of Strength and Distribution of SiC on the Mechanical Properties of SiCp/Al Composites. Materials 2022, 15, 1288. [Google Scholar] [CrossRef]

- Cai, C.; Wang, B.; Yin, W.; Xu, Z.; Wang, R.; He, X. A New Algorithm to Generate Non-Uniformly Dispersed Representative Volume Elements of Composite Materials with High Volume Fractions. Mater. Des. 2022, 219, 110750. [Google Scholar] [CrossRef]

- Gad, S.I.; Attia, M.A.; Hassan, M.A.; El-Shafei, A.G. Predictive Computational Model for Damage Behavior of Metal-Matrix Composites Emphasizing the Effect of Particle Size and Volume Fraction. Materials 2021, 14, 2143. [Google Scholar] [CrossRef]

- Sun, Q.; Asqardoust, S.; Sarmah, A.; Jain, M.K. Elastoplastic Analysis of AA7075-O Aluminum Sheet by Hybrid Micro-Scale Representative Volume Element Modeling with Really-Distributed Particles and in-Situ SEM Experimental Testing. J. Mater. Sci. Technol. 2022, 123, 201–221. [Google Scholar] [CrossRef]

- Sun, Q.; Zhou, G.; Tang, H.; Chen, Z.; Fenner, J.; Meng, Z.; Jain, M.; Su, X. A Combined Experimental and Computational Analysis of Failure Mechanisms in Open-Hole Cross-Ply Laminates under Flexural Loading. Compos. Part B Eng. 2021, 215, 108803. [Google Scholar] [CrossRef]

- Sun, Q.; Zhou, G.; Meng, Z.; Jain, M.; Su, X. An Integrated Computational Materials Engineering Framework to Analyze the Failure Behaviors of Carbon Fiber Reinforced Polymer Composites for Lightweight Vehicle Applications. Compos. Sci. Technol. 2021, 202, 108560. [Google Scholar] [CrossRef]

- Sun, Q.; Zhou, G.; Guo, H.; Meng, Z.; Chen, Z.; Liu, H.; Kang, H.; Su, X. Failure Mechanisms of Cross-Ply Carbon Fiber Reinforced Polymer Laminates under Longitudinal Compression with Experimental and Computational Analyses. Compos. Part B Eng. 2019, 167, 147–160. [Google Scholar] [CrossRef]

- Sun, Q.; Zhou, G.; Meng, Z.; Guo, H.; Chen, Z.; Liu, H.; Kang, H.; Keten, S.; Su, X. Failure Criteria of Unidirectional Carbon Fiber Reinforced Polymer Composites Informed by a Computational Micromechanics Model. Compos. Sci. Technol. 2019, 172, 81–95. [Google Scholar] [CrossRef]

- Suo, Y.; Wang, B.; Jia, P.; Gong, Y. Numerical Analysis of Mechanical Properties and Particle Cracking Probability of Metal Matrix Composites. Mater. Today Commun. 2020, 24, 101082. [Google Scholar] [CrossRef]

- Zhang, J.F.; Andrä, H.; Zhang, X.X.; Wang, Q.Z.; Xiao, B.L.; Ma, Z.Y. An Enhanced Finite Element Model Considering Multi Strengthening and Damage Mechanisms in Particle Reinforced Metal Matrix Composites. Compos. Struct. 2019, 226, 111281. [Google Scholar] [CrossRef]

- Nan, L.; Qian, L.; Yihui, J.; Yishi, S.; Wenting, T.; Shuhua, L. Composite Structural Modeling and Mechanical Behavior of Whisker Reinforced Cu Matrix Composites. Comput. Mater. Sci. 2021, 195, 110492. [Google Scholar] [CrossRef]

- Ma, S.; Zhuang, X.; Wang, X. 3D Micromechanical Simulation of the Mechanical Behavior of an In-Situ Al3Ti/A356 Composite. Compos. Part B Eng. 2019, 176, 107115. [Google Scholar] [CrossRef]

- Dao, M.; Chollacoop, N.; Van Vliet, K.J.; Venkatesh, T.A.; Suresh, S. Computational Modeling of the Forward and Reverse Problems in Instrumented Sharp Indentation. Acta Mater. 2001, 49, 3899–3918. [Google Scholar] [CrossRef]

- Liu, N.; Zhang, Q.; Zhang, H.; Cao, F.; Feng, P.; Zuo, Y.; Jiang, Y.; Tang, W.; Liang, S. Experimental Verification and Numerical Analysis on Plastic Deformation and Mechanical Properties of the In-Situ TiB2 Homogeneous Composites and TiB2/Cu Network Composites Prepared by Powder Metallurgy. J. Alloys Compd. 2022, 920, 165897. [Google Scholar] [CrossRef]

- Liu, N.; Zhang, X.; Zhang, Q.; Jiang, Y.; Su, Y.; Li, Q.; Feng, P.; Tang, W.; Liang, S. Numerical Evaluation and Experimental Verification of Mechanical Properties and Fracture Behavior for TiB2/Cu Composites Prepared by in-Situ Mixing Casting. J. Alloys Compd. 2022, 895, 162475. [Google Scholar] [CrossRef]

- Rice, J.R.; Tracey, D.M. On the Ductile Enlargement of Voids in Triaxial Stress Fields∗. J. Mech. Phys. Solids 1969, 17, 201–217. [Google Scholar] [CrossRef]

- Tursun, G.; Weber, U.; Soppa, E.; Schmauder, S. The Influence of Transition Phases on the Damage Behaviour of an Al/10vol.%SiC Composite. Comput. Mater. Sci. 2006, 37, 119–133. [Google Scholar] [CrossRef]

- Qing, H. Automatic Generation of 2D Micromechanical Finite Element Model of Silicon–Carbide/Aluminum Metal Matrix Composites: Effects of the Boundary Conditions. Mater. Des. 2013, 44, 446–453. [Google Scholar] [CrossRef]

- Elices, M.; Guinea, G.V.; Gómez, J.; Planas, J. The Cohesive Zone Model: Advantages, Limitations and Challenges. Eng. Fract. Mech. 2002, 69, 137–163. [Google Scholar] [CrossRef]

- Zhang, J.; Ouyang, Q.; Guo, Q.; Li, Z.; Fan, G.; Su, Y.; Jiang, L.; Lavernia, E.J.; Schoenung, J.M.; Zhang, D. 3D Microstructure-Based Finite Element Modeling of Deformation and Fracture of SiCp/Al Composites. Compos. Sci. Technol. 2016, 123, 1–9. [Google Scholar] [CrossRef]

- Liu, N.; Zhang, Q.; Feng, P.; Zuo, Y.; Han, F.; Xu, Y.; Jiang, Y.; Tang, W.; Liang, S. Effects of Configuration Parameters on the Deformation and Fracture Behaviors of TiB2/Cu Composites with Network Structure: A Numerical Approach Using an Enhanced Finite Element Model. Comput. Mater. Sci. 2022, 205, 111212. [Google Scholar] [CrossRef]

- Hou, Y.; Xu, J.; Zhou, C.; Chen, X. Microstructural Simulations of Debonding, Nucleation, and Crack Propagation in an HMX-MDB Propellant. Mater. Des. 2021, 207, 109854. [Google Scholar] [CrossRef]

- Zhou, Q.-C.; Chen, X.; Niu, R.-M.; Zhou, C.-S. Extraction of Rate-Dependent Fracture Properties of Adhesive Interface Involving Large-Scale Yielding. J. Adhes. Sci. Technol. 2015, 29, 1118–1135. [Google Scholar] [CrossRef]

- Rintoul, M.D.; Torquato, S. Reconstruction of the Structure of Dispersions. J. Colloid Interface Sci. 1997, 186, 467–476. [Google Scholar] [CrossRef]

- Nafar Dastgerdi, J.; Anbarlooie, B.; Miettinen, A.; Hosseini-Toudeshky, H.; Remes, H. Effects of Particle Clustering on the Plastic Deformation and Damage Initiation of Particulate Reinforced Composite Utilizing X-Ray CT Data and Finite Element Modeling. Compos. Part B Eng. 2018, 153, 57–69. [Google Scholar] [CrossRef]

- Sahu, S.K.; Rama Sreekanth, P.S. Multiscale RVE Modeling for Assessing Effective Elastic Modulus of HDPE Based Polymer Matrix Nanocomposite Reinforced with Nanodiamond. Int. J. Interact Des. Manuf. 2022. [Google Scholar] [CrossRef]

- Cho, Y.J.; Lee, W.J.; Park, Y.H. Effect of Boundary Conditions on the Numerical Solutions of Representative Volume Element Problems for Random Heterogeneous Composite Microstructures. Met. Mater. Int. 2014, 20, 1085–1093. [Google Scholar] [CrossRef]

- Williams, J.J.; Flom, Z.; Amell, A.A.; Chawla, N.; Xiao, X.; De Carlo, F. Damage Evolution in SiC Particle Reinforced Al Alloy Matrix Composites by X-Ray Synchrotron Tomography. Acta Mater. 2010, 58, 6194–6205. [Google Scholar] [CrossRef]

- Ayyar, A.; Crawford, G.A.; Williams, J.J.; Chawla, N. Numerical Simulation of the Effect of Particle Spatial Distribution and Strength on Tensile Behavior of Particle Reinforced Composites. Comput. Mater. Sci. 2008, 44, 496–506. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, W.; Ma, J.; Liao, Z.; Xiong, H.; Fu, Y.; Wang, B. New Numerical Method Based on Linear Damage Evolution Law for Predicting Mechanical Properties of TiB2/6061Al. Materials 2023, 16, 4786. https://doi.org/10.3390/ma16134786

Fu W, Ma J, Liao Z, Xiong H, Fu Y, Wang B. New Numerical Method Based on Linear Damage Evolution Law for Predicting Mechanical Properties of TiB2/6061Al. Materials. 2023; 16(13):4786. https://doi.org/10.3390/ma16134786

Chicago/Turabian StyleFu, Weigang, Junchi Ma, Zhe Liao, Huanjie Xiong, Yaoming Fu, and Bin Wang. 2023. "New Numerical Method Based on Linear Damage Evolution Law for Predicting Mechanical Properties of TiB2/6061Al" Materials 16, no. 13: 4786. https://doi.org/10.3390/ma16134786

APA StyleFu, W., Ma, J., Liao, Z., Xiong, H., Fu, Y., & Wang, B. (2023). New Numerical Method Based on Linear Damage Evolution Law for Predicting Mechanical Properties of TiB2/6061Al. Materials, 16(13), 4786. https://doi.org/10.3390/ma16134786