Optimising Two-Stage Vacuum Heat Treatment for a High-Strength Micro-Alloyed Steel in Railway Spring Clip Application: Impact on Microstructure and Mechanical Performance

Abstract

:1. Introduction

2. Materials and Methods

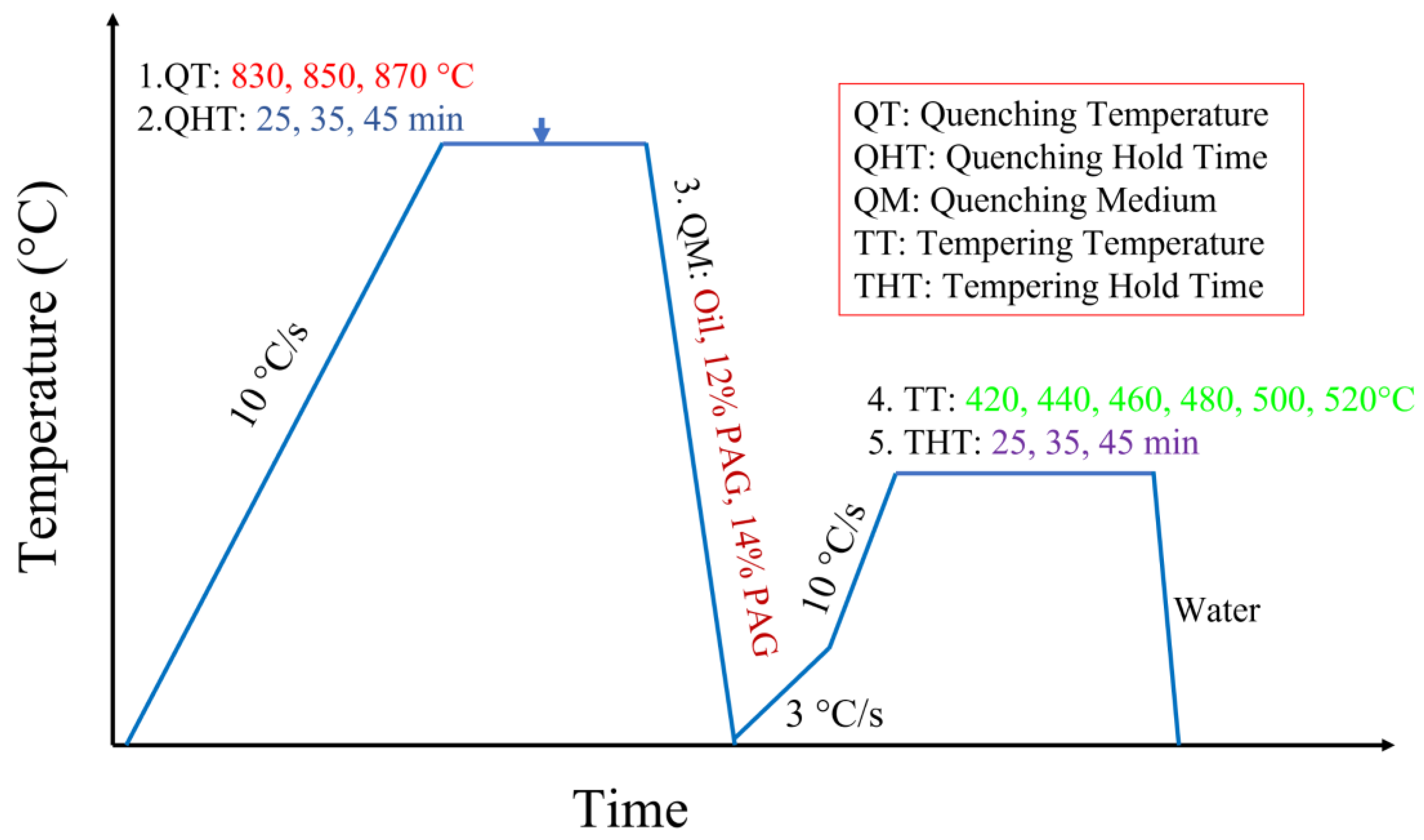

2.1. Heat Treatment Process

2.2. Material Characterisation Techniques

3. Results and Discussion

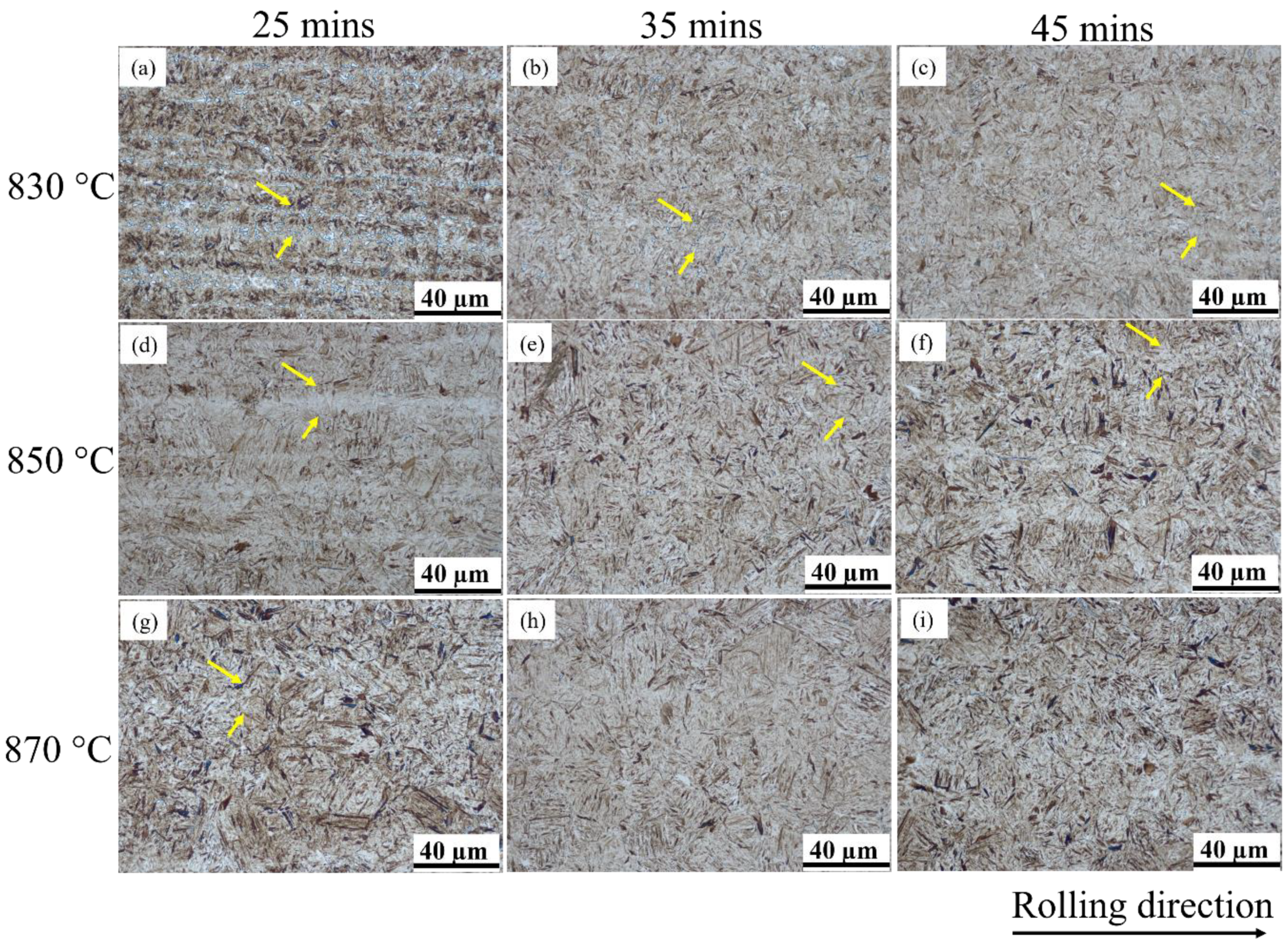

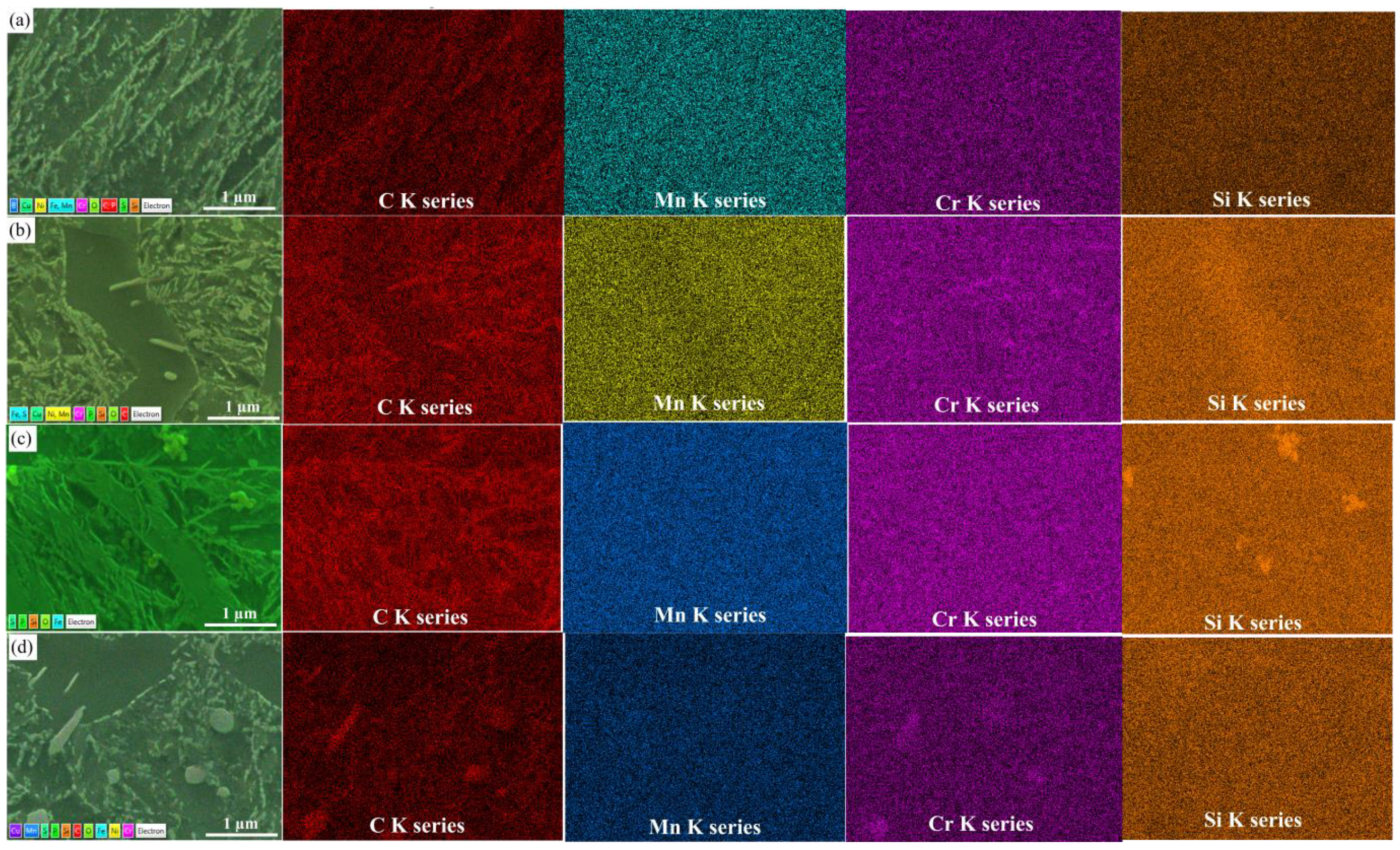

3.1. Microstructural Analysis of the Heat-Treated Status

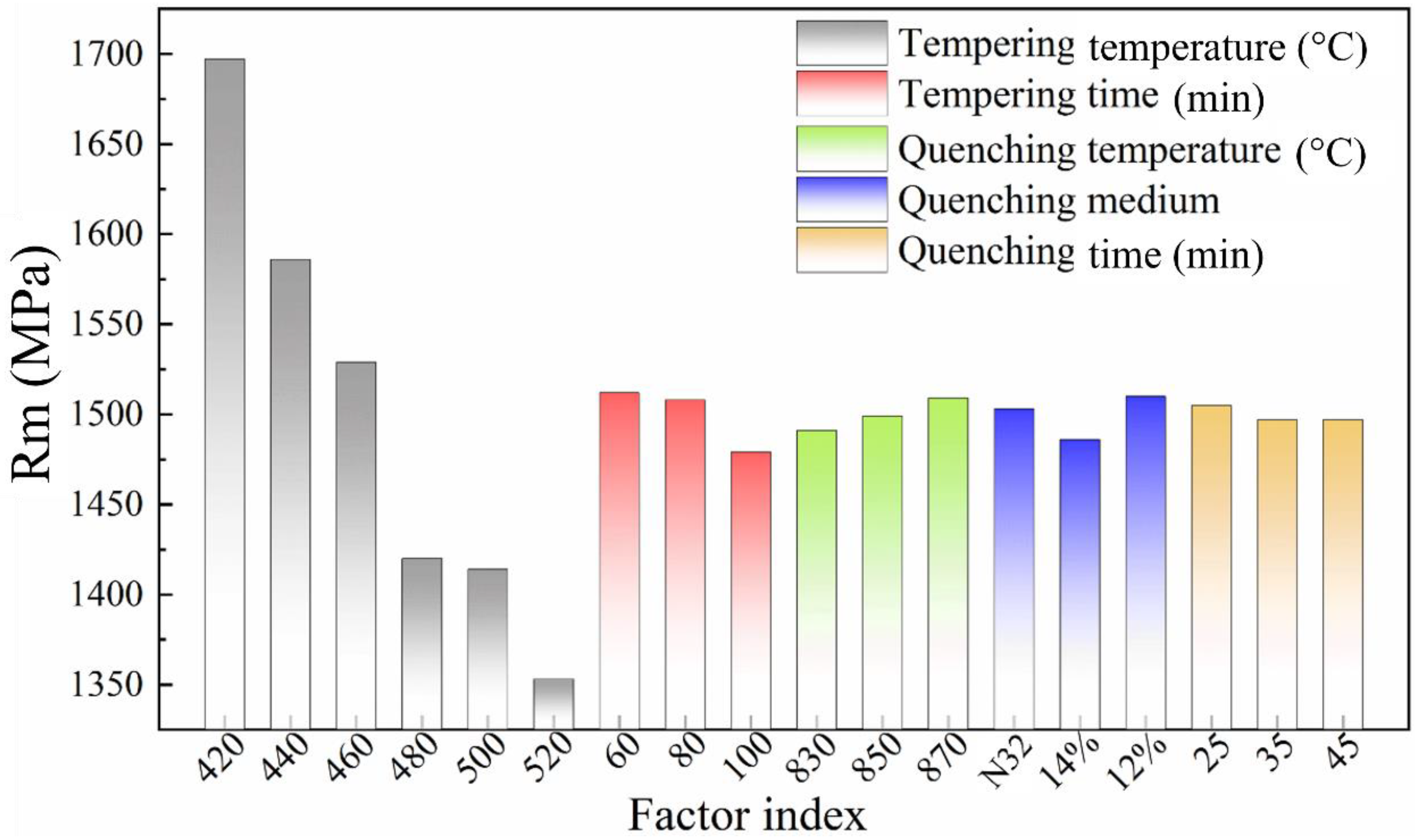

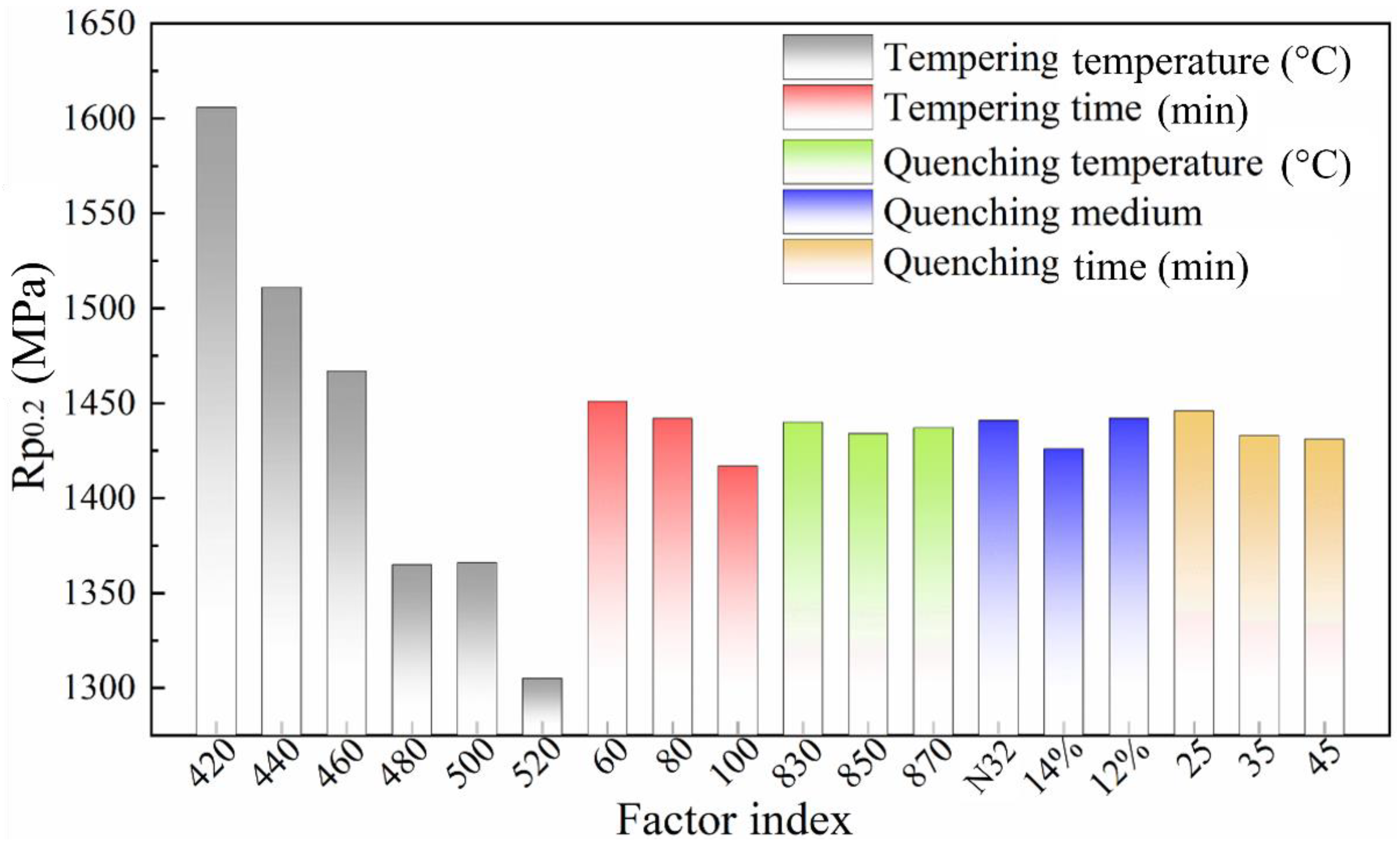

3.2. Mechanical Evolution of Specimens after Heat Treatment

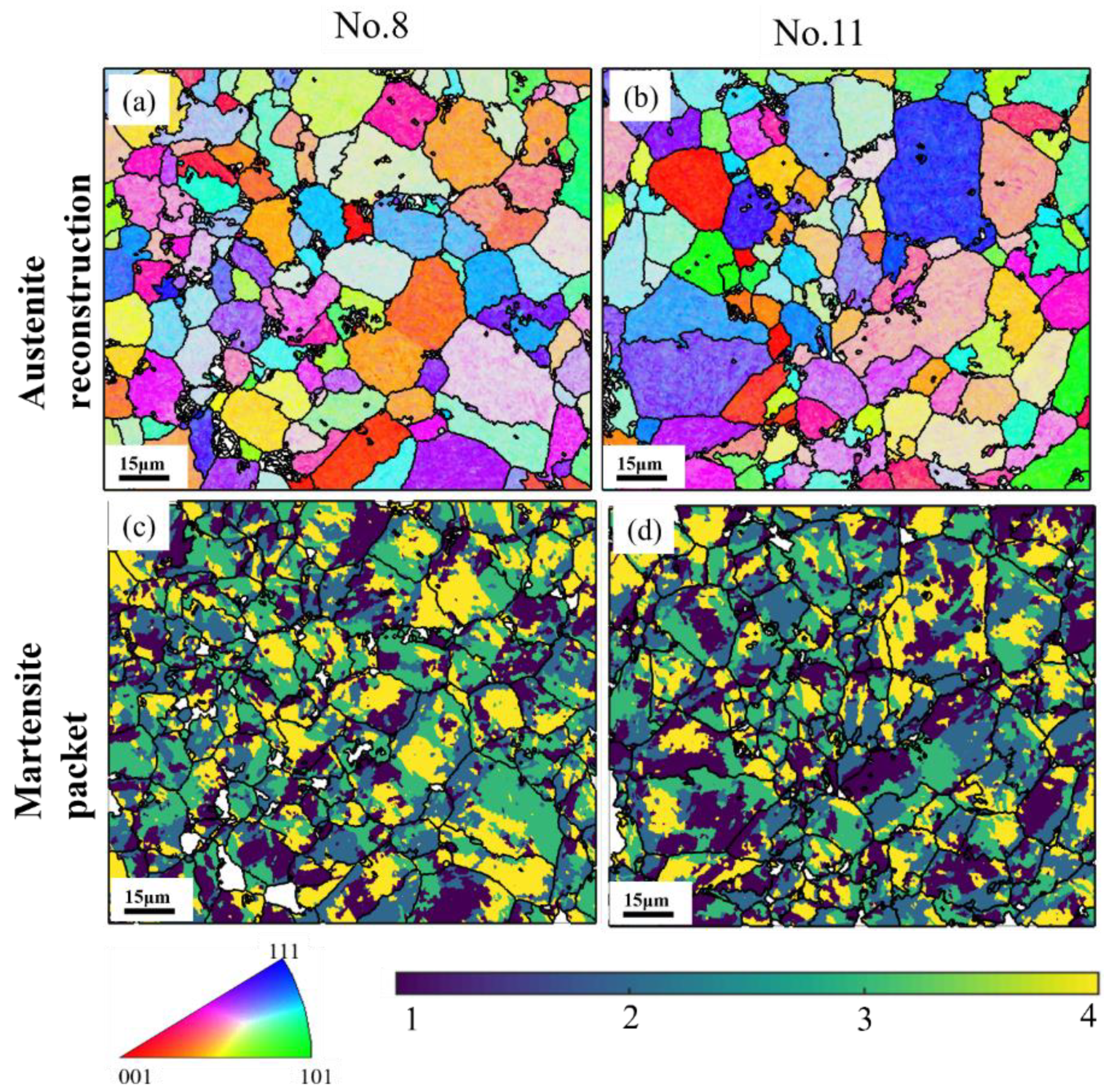

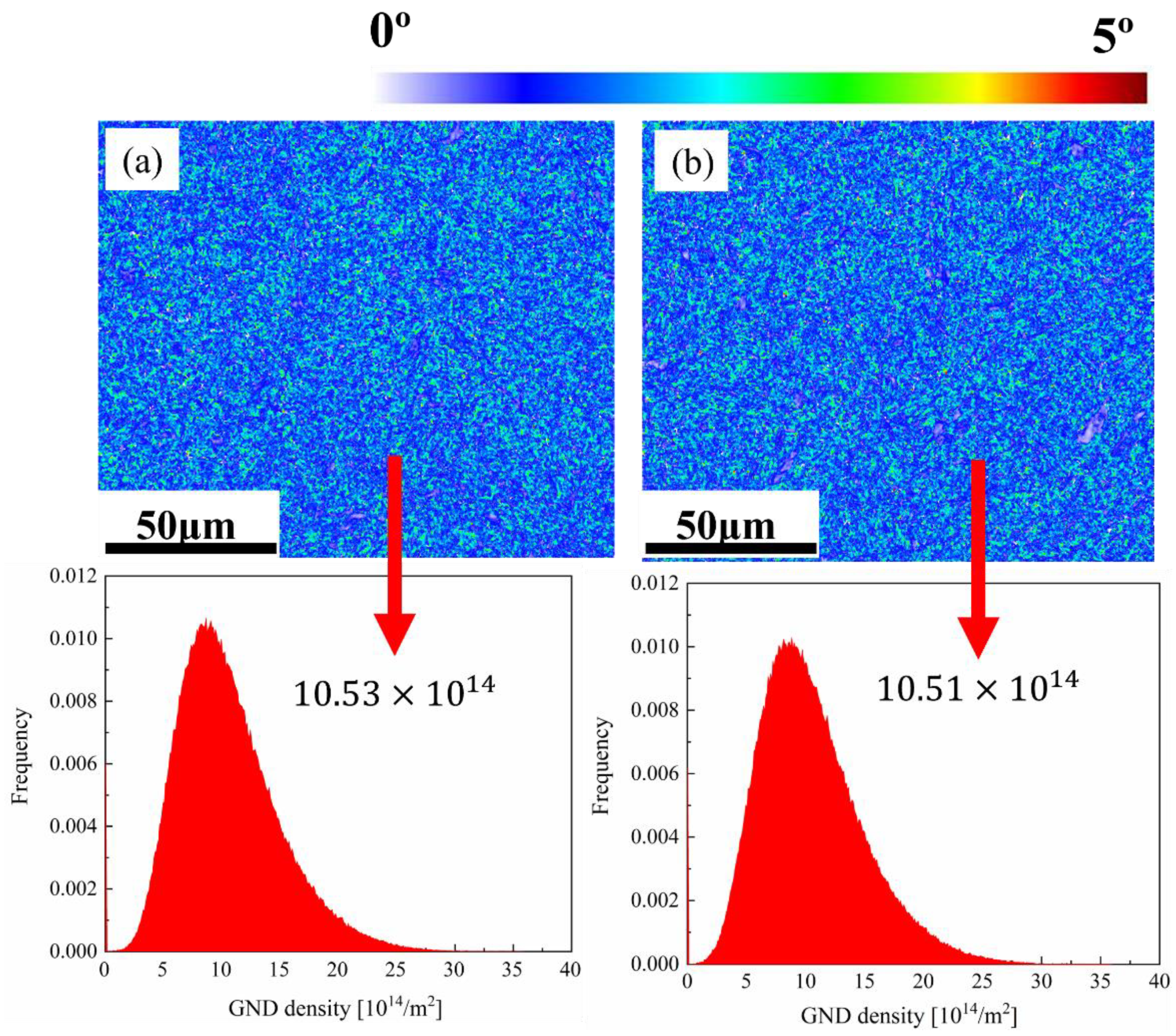

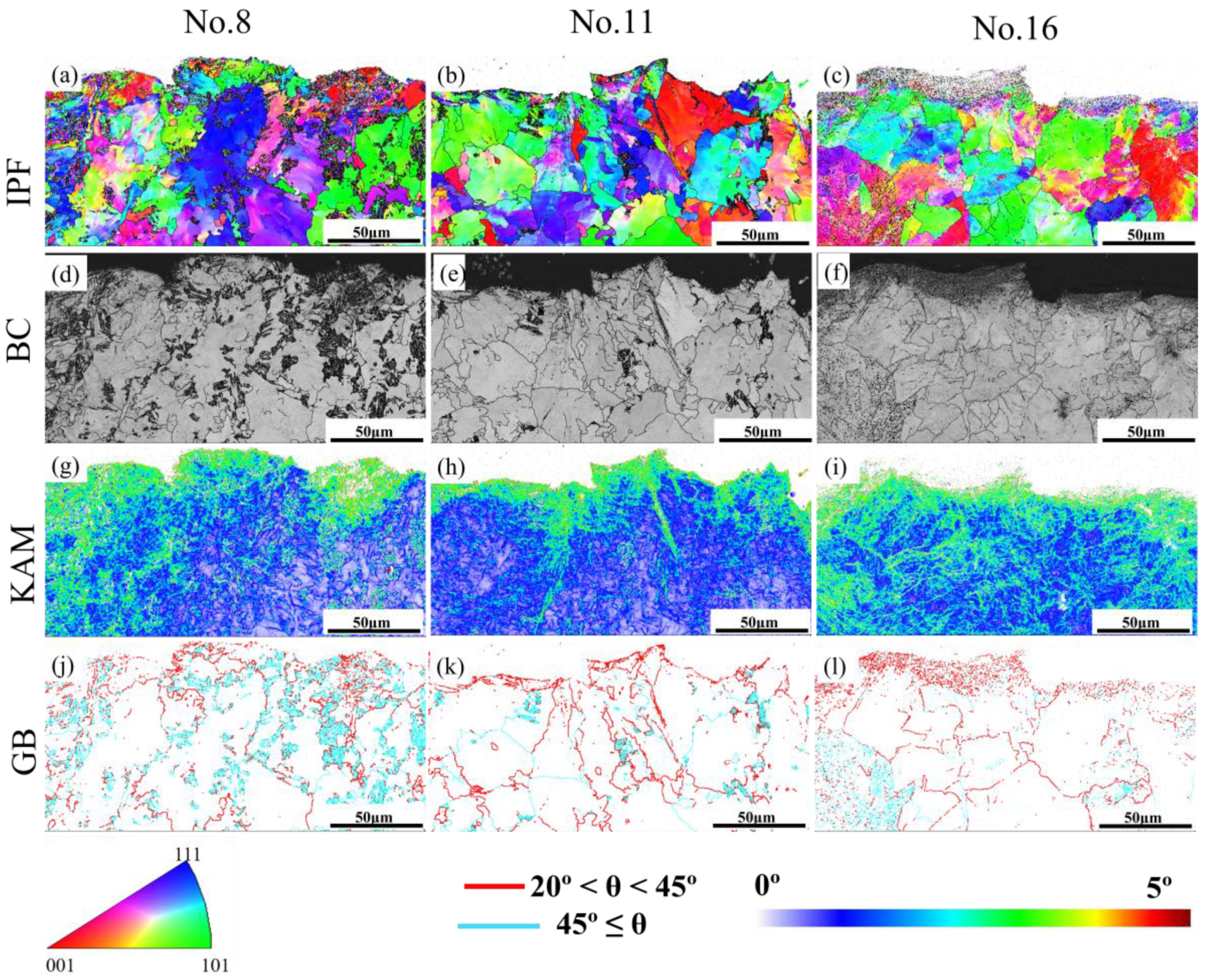

3.3. Crystallographic Features at the Tempered Status

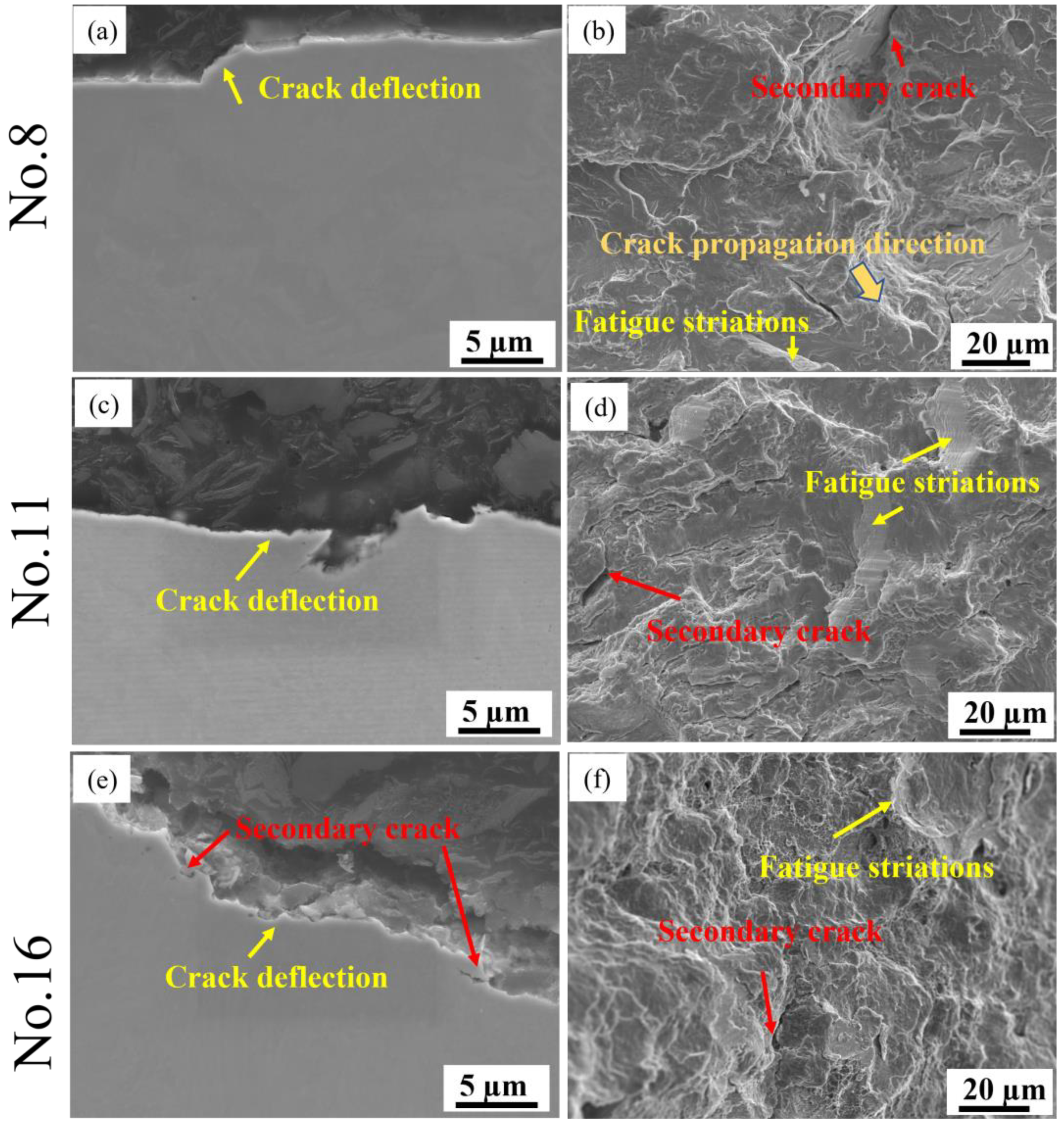

3.4. Fatigue Performance Comparison

4. Conclusions

- (1)

- The influence of main process parameters on the microstructure and mechanical properties of the investigated spring steel during quenching and subsequent tempering was systematically studied, and an optimal heat treatment process was determined (quenching temperature of 850 °C, quenching holding time of 35 min, quenching medium of 12% PAG aqueous solution, tempering temperature of 460 °C, tempering holding time of 60 min).

- (2)

- The tempering temperature has a more significant influence on the microstructures and mechanical properties of the experimental steel during the heat treatment process. The granular carbides grow with the increase in tempering temperatures, which leads to a decrease in dislocation density.

- (3)

- According to the fatigue testing results, it is obvious that the specimen with a high fatigue limit has a flat and ragged fracture surface, and the microstructure after fatigue testing is more uniform. The high ratio of martensite to ferrite improves fatigue performance significantly.

- (4)

- The research conducted in this study has a certain guiding effect on the thermal processing technology of high-speed railway spring fasteners.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, Y.; Xie, H.; Wang, J.; Jia, F.; Li, Z.; Lin, F.; Pan, D.; Han, J.; Jiang, Z. Simulation, microstructure and austenite reconstruction of a medium carbon micro-alloyed steel subjected to an austenitising bending process. Mater. Lett. 2021, 305, 130772. [Google Scholar] [CrossRef]

- Yuan, Z.; Zhu, S.; Yuan, X.; Zhai, W. Vibration-based damage detection of rail fastener clip using convolutional neural network: Experiment and simulation. Eng. Fail. Anal. 2021, 119, 104906. [Google Scholar] [CrossRef]

- Ke, J.; Wu, Z.-y.; Chen, X.-y.; Ying, Z.-p. A review on material selection, design method and performance investigation of composite leaf springs. Compos. Struct. 2019, 226, 111277. [Google Scholar] [CrossRef]

- Ferreño, D.; Casado, J.A.; Carrascal, I.A.; Diego, S.; Ruiz, E.; Saiz, M.; Sainz-Aja, J.A.; Cimentada, A.I. Experimental and finite element fatigue assessment of the spring clip of the SKL-1 railway fastening system. Eng. Struct. 2019, 188, 553–563. [Google Scholar] [CrossRef]

- Pashangeh, S.; Somani, M.; Banadkouki, S.S.G. Microstructural evolution in a high-silicon medium carbon steel following quenching and isothermal holding above and below the Ms temperature. J. Mater. Res. Technol. 2020, 9, 3438–3446. [Google Scholar] [CrossRef]

- Chen, K.; Jiang, Z.; Liu, F.; Yu, J.; Li, Y.; Gong, W.; Chen, C. Effect of quenching and tempering temperature on microstructure and tensile properties of microalloyed ultra-high strength suspension spring steel. Mater. Sci. Eng. A 2019, 766, 138272. [Google Scholar] [CrossRef]

- Zurnadzhy, V.I.; Efremenko, V.G.; Wu, K.M.; Azarkhov, A.Y.; Chabak, Y.G.; Greshta, V.L.; Isayev, O.B.; Pomazkov, M.V. Effects of stress relief tempering on microstructure and tensile/impact behavior of quenched and partitioned commercial spring steel. Mater. Sci. Eng. A 2019, 745, 307–318. [Google Scholar] [CrossRef]

- Lan, L.; Yu, M.; Qiu, C. On the local mechanical properties of isothermally transformed bainite in low carbon steel. Mater. Sci. Eng. A 2019, 742, 442–450. [Google Scholar] [CrossRef]

- Navarro-López, A.; Hidalgo, J.; Sietsma, J.; Santofimia, M.J. Characterization of bainitic/martensitic structures formed in isothermal treatments below the Ms temperature. Mater. Charact. 2017, 128, 248–256. [Google Scholar] [CrossRef]

- Hidalgo, J.; Santofimia, M.J. Effect of Prior Austenite Grain Size Refinement by Thermal Cycling on the Microstructural Features of As-Quenched Lath Martensite. Metall. Mater. Trans. A 2016, 47, 5288–5301. [Google Scholar] [CrossRef] [Green Version]

- Goulas, C.; Kumar, A.; Mecozzi, M.-G.; Castro-Cerda, F.M.; Herbig, M.; Petrov, R.H.; Sietsma, J. Atomic-scale investigations of isothermally formed bainite microstructures in 51CrV4 spring steel. Mater. Charact. 2019, 152, 67–75. [Google Scholar] [CrossRef]

- Wang, X.L.; Wu, K.M.; Hu, F.; Yu, L.; Wan, X.L. Multi-step isothermal bainitic transformation in medium-carbon steel. Scr. Mater. 2014, 74, 56–59. [Google Scholar] [CrossRef]

- Díaz-Fuentes, M.; Gutiérrez, I. Analysis of different acicular ferrite microstructures generated in a medium-carbon molybdenum steel. Mater. Sci. Eng. A 2003, 363, 316–324. [Google Scholar] [CrossRef]

- Cui, J.; Liu, Y.-z.; Pan, H.; Gao, L.-f. Reheating Austenitizing Temperature of Spring Steel 60Si2MnA for Railway. J. Iron Steel Res. Int. 2008, 15, 62–67. [Google Scholar] [CrossRef]

- Zhang, L.; Gong, D.; Li, Y.; Wang, X.; Ren, X.; Wang, E. Effect of Quenching Conditions on the Microstructure and Mechanical Properties of 51CrV4 Spring Steel. Metals 2018, 8, 1056. [Google Scholar] [CrossRef] [Green Version]

- Ravi Kumar, B.; Bhattacharya, D.K.; Das, S.K.; Ghosh Chowdhury, S. Premature fatigue failure of a spring due to quench cracks. Eng. Fail. Anal. 2000, 7, 377–384. [Google Scholar] [CrossRef]

- Mukhopadhyay, N.K.; Das, S.K.; Ravikumar, B.; Ranganath, V.R.; Ghosh Chowdhury, S. Premature failure of a leaf spring due to improper materials processing. Eng. Fail. Anal. 1997, 4, 161–170. [Google Scholar] [CrossRef]

- Baggerly, R.G. Quench cracks in truck spring “U” bolts and the implications for spring failure. Eng. Fail. Anal. 1994, 1, 135–141. [Google Scholar] [CrossRef]

- Dey, I.; Ghosh, S.K.; Saha, R. Effects of cooling rate and strain rate on phase transformation, microstructure and mechanical behaviour of thermomechanically processed pearlitic steel. J. Mater. Res. Technol. 2019, 8, 2685–2698. [Google Scholar] [CrossRef]

- Ardehali Barani, A.; Ponge, D.; Raabe, D. Refinement of grain boundary carbides in a Si–Cr spring steel by thermomechanical treatment. Mater. Sci. Eng. A 2006, 426, 194–201. [Google Scholar] [CrossRef]

- Matjeke, V.; Mukwevho, G.; Maleka, A.; Van Der Merwe, J. Effect of heat treatment on strength and ductility of 52CrMoV4 spring steel. IOP Conf. Ser. Mater. Sci. Eng. 2018, 430, 012044. [Google Scholar] [CrossRef]

- Sudiyanto, A.; Pujiyulianto, E. In The effect of varying quenching media on cooling time and microstructures of leaf spring steel AISI 5160. AIP Conf. Proc. 2021, 2363, 030024. [Google Scholar]

- Lee, C.S.; Lee, K.A.; Li, D.M.; Yoo, S.J.; Nam, W.J. Microstructural influence on fatigue properties of a high-strength spring steel. Mater. Sci. Eng. A 1998, 241, 30–37. [Google Scholar] [CrossRef]

- Lu, Y.; Xie, H.; Wang, J.; Jia, F.; Li, Z.; Kamali, H.; Xu, J.; Han, J.; Jiang, Z. Design of a novel austenitising bending process in forming characteristics of high-strength quenched and micro-alloyed steel: Experiment and simulation. Mater. Des. 2022, 215, 110458. [Google Scholar] [CrossRef]

- Lu, Y.; Xie, H.; Wang, J.; Li, Z.; Jia, F.; Wu, H.; Han, J.; Jiang, Z. Influence of hot compressive parameters on flow behaviour and microstructure evolution in a commercial medium carbon micro-alloyed spring steel. J. Manuf. Process. 2020, 58, 1171–1181. [Google Scholar] [CrossRef]

- Srivastava, K.; Sinha, A.A.; Sahani, R. Effect of heat treatment on hardness and toughness of EN8 steel. Mater. Today Proc. 2021, 42, 1297–1303. [Google Scholar] [CrossRef]

- Wang, Z.-M.; Chang, K.-H.; Muzaffer, S.; Hirohata, M. Fatigue Life and Crack Initiation in Monopile Foundation by Fatigue FE Analysis. Processes 2023, 11, 1317. [Google Scholar] [CrossRef]

- Peng, C.; Zhu, W.; Chen, L.; Zhu, X.; Chen, Z. Fracture Analysis of the Chain Pin Shaft of an Escalator Ladder. IOP Conf. Ser. Mater. Sci. Eng. 2020, 730, 012020. [Google Scholar] [CrossRef]

- Yan, X.; Hu, J.; Yu, H.; Wang, C.; Xu, W. Unraveling the significant role of retained austenite on the dry sliding wear behavior of medium manganese steel. Wear 2021, 476, 203745. [Google Scholar] [CrossRef]

- Lu, Y.; Xie, H.; Wang, J.; Jia, F.; Lin, F.; Zhou, C.; Xu, J.; Han, J.; Jiang, Z. Ex situ analysis of high-strength quenched and micro-alloyed steel during austenitising bending process: Numerical simulation and experimental investigation. Int. J. Adv. Manuf. Technol. 2022, 120, 8293–8309. [Google Scholar] [CrossRef]

- Li, Z.; Xie, H.; Jia, F.; Lu, Y.; Yuan, X.; Jiao, S.; Jiang, Z. Study on Deformation Characteristics and Microstructure Evolution of 2205/AH36 Bimetal Composite in a Novel Hot Forming Process. Metals 2020, 10, 1375. [Google Scholar] [CrossRef]

- Miyamoto, G.; Takayama, N.; Furuhara, T. Accurate measurement of the orientation relationship of lath martensite and bainite by electron backscatter diffraction analysis. Scr. Mater. 2009, 60, 1113–1116. [Google Scholar] [CrossRef]

- Flower, H.M.; Lindley, T.C. Electron backscattering diffraction study of acicular ferrite, bainite, and martensite steel microstructures. Mater. Sci. Technol. 2000, 16, 26–40. [Google Scholar]

- Uchimali, M.; Rao, B.C.; Vedantam, S. Modeling size and orientation effects on the morphology of microstructure formed in martensitic phase transformations using a novel discrete particle model. Acta Mater. 2021, 205, 116528. [Google Scholar] [CrossRef]

- Zhu, J.; Lin, G.T.; Zhang, Z.H.; Xie, J.X. The martensitic crystallography and strengthening mechanisms of ultra-high strength rare earth H13 steel. Mater. Sci. Eng. A 2020, 797, 140139. [Google Scholar] [CrossRef]

- Su, Y.; Wang, J.X.; Yu, X.F.; Wang, S.J.; Xia, Y.Z.; Liu, L.; Liu, J.L. Effect of deep tempering on microstructure and hardness of carburized M50NiL steel. J. Mater. Res. Technol. 2021, 14, 1080–1088. [Google Scholar] [CrossRef]

- Wilson, D.V. Effects of plastic deformation on carbide precipitation in steel. Acta Metall. 1957, 5, 293–302. [Google Scholar] [CrossRef]

- Shin, J.-C.; Lee, S.; Hwa Ryu, J. Correlation of microstructure and fatigue properties of two high-strength spring steels. Int. J. Fatigue 1999, 21, 571–579. [Google Scholar] [CrossRef]

- Niessen, F.; Nyyssönen, T.; Gazder, A.A.; Hielscher, R. Parent grain reconstruction from partially or fully transformed microstructures in MTEX. J. Appl. Crystallogr. 2022, 55, 180–194. [Google Scholar] [CrossRef]

- Javaheri, V.; Kolli, S.; Grande, B.; Porter, D. Insight into the induction hardening behavior of a new 0.40% C microalloyed steel: Effects of initial microstructure and thermal cycles. Mater. Charact. 2019, 149, 165–183. [Google Scholar] [CrossRef] [Green Version]

- Kitahara, H.; Ueji, R.; Tsuji, N.; Minamino, Y. Crystallographic features of lath martensite in low-carbon steel. Acta Mater. 2006, 54, 1279–1288. [Google Scholar] [CrossRef]

- Sun, L.; Muszka, K.; Wynne, B.P.; Palmiere, E.J. Effect of strain path on dynamic strain-induced transformation in a microalloyed steel. Acta Mater. 2014, 66, 132–149. [Google Scholar] [CrossRef]

- Lu, Y.; Xie, H.; Wang, J.; Li, Z.; Lin, F.; Han, J.; Han, J.; Jiang, Z. Characteristic flow behaviour prediction and microstructure analysis of a commercial Si–Cr micro-alloyed spring steel under isothermal compression. Vacuum 2021, 186, 110066. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, J.; Jia, F.; Lu, Y.; Liang, X.; Yuan, X.; Jiao, S.; Zhou, C.; Jiang, Z. Hot deformation behaviour and interfacial characteristics of bimetal composite at elevated temperatures. Intermetallics 2020, 125, 106893. [Google Scholar] [CrossRef]

- Ma, X.; Huang, C.; Moering, J.; Ruppert, M.; Höppel, H.W.; Göken, M.; Narayan, J.; Zhu, Y. Mechanical properties of copper/bronze laminates: Role of interfaces. Acta Mater. 2016, 116, 43–52. [Google Scholar] [CrossRef] [Green Version]

| C | Si | Mn | Cr | Ni | Cu | S | P |

|---|---|---|---|---|---|---|---|

| 0.55% | 1.4% | 0.65% | 0.65% | 0.11% | 0.12% | 0.012% | 0.018% |

| Factor | Tempering Temperature (°C) | Tempering Time (min) | Quenching Temperature (°C) | Quenching Medium | Quenching Hold Time (min) |

|---|---|---|---|---|---|

| 1 | 440 | 60 | 830 | 12% PAG | 25 |

| 2 | 480 | 100 | 870 | Mechanical oil | 35 |

| 3 | 420 | 80 | 850 | 14% PAG | 45 |

| 4 | 500 | ||||

| 5 | 520 | ||||

| 6 | 460 |

| No. | Tempering Tem. | Tempering Time | Quenching Tem. | Quenching Medium | Quenching Hold Time |

|---|---|---|---|---|---|

| 1 | 1 (440 °C) | 1 (60 min) | 3 (850 °C) | 2 (Mechanical oil) | 2 (35 min) |

| 2 | 1 | 2 (100 min) | 1 (830 °C) | 1 (12% PAG) | 1 (25 min) |

| 3 | 1 | 3 (80 min) | 2 (870 °C) | 3 (14% PAG) | 3 (45 min) |

| 4 | 2 (480 °C) | 1 | 2 | 1 | 2 |

| 5 | 2 | 2 | 3 | 3 | 1 |

| 6 | 2 | 3 | 1 | 2 | 3 |

| 7 | 3 (420 °C) | 1 | 1 | 3 | 1 |

| 8 | 3 | 2 | 2 | 2 | 3 |

| 9 | 3 | 3 | 3 | 1 | 2 |

| 10 | 4 (500 °C) | 1 | 1 | 1 | 3 |

| 11 | 4 | 2 | 2 | 3 | 2 |

| 12 | 4 | 3 | 3 | 2 | 1 |

| 13 | 5 (520 °C) | 1 | 3 | 3 | 3 |

| 14 | 5 | 2 | 1 | 2 | 2 |

| 15 | 5 | 3 | 2 | 1 | 1 |

| 16 | 6 (460 °C) | 1 | 2 | 2 | 1 |

| 17 | 6 | 2 | 3 | 1 | 3 |

| 18 | 6 | 3 | 1 | 3 | 2 |

| Cases | Rm (MPa) | Rp0.2 (MPa) | ak (J/cm2) | EL (%) | Tempered Hardness (HV) | Quenched Hardness (HV) |

|---|---|---|---|---|---|---|

| 1 | 1602 ± 12 | 1532 ± 15 | 13.75 ± 1.23 | 8.90 ± 0.65 | 468 ± 12 | 726 ± 23 |

| 2 | 1562 ± 8 | 1502 ± 10 | 17.50 ± 1.12 | 10.25 ± 0.77 | 468 ± 8 | 714 ± 14 |

| 3 | 1594 ± 13 | 1498 ± 13 | 13.75 ± 0.85 | 9.25 ± 0.58 | 450 ± 11 | 748 ± 21 |

| 4 | 1428 ± 9 | 1362 ± 9 | 20.00 ± 0.60 | 10.90 ± 0.69 | 445 ± 13 | 777 ± 15 |

| 5 | 1406 ± 22 | 1352 ± 20 | 22.50 ± 1.43 | 10.50 ± 1.02 | 413 ± 7 | 729 ± 11 |

| 6 | 1425 ± 18 | 1382 ± 12 | 21.88 ± 0.95 | 10.60 ± 1.13 | 440 ± 12 | 696 ± 9 |

| 7 | 1686 ± 11 | 1621 ± 9 | 16.24 ± 0.77 | 7.85 ± 0.34 | 470 ± 9 | 761 ± 15 |

| 8 | 1675 ± 12 | 1578 ± 11 | 9.38 ± 1.36 | 9.90 ± 0.51 | 500 ± 16 | 748 ± 13 |

| 9 | 1729 ± 21 | 1619 ± 12 | 12.50 ± 0.28 | 9.60 ± 0.37 | 479 ± 18 | 761 ± 23 |

| 10 | 1443 ± 16 | 1393 ± 13 | 26.88 ± 1.86 | 10.35 ± 1.21 | 417 ± 7 | 724 ± 20 |

| 11 | 1390 ± 7 | 1341 ± 8 | 23.75 ± 1.80 | 10.80 ± 0.59 | 421 ± 6 | 759 ± 25 |

| 12 | 1409 ± 14 | 1363 ± 23 | 23.75 ± 1.75 | 11.00 ± 0.75 | 426 ± 10 | 703 ± 15 |

| 13 | 1339 ± 11 | 1293 ± 15 | 18.75 ± 1.66 | 11.15 ± 0.91 | 437 ± 11 | 776 ± 26 |

| 14 | 1332 ± 19 | 1288 ± 12 | 31.88 ± 2.25 | 11.15 ± 1.12 | 426 ± 14 | 691 ± 6 |

| 15 | 1388 ± 20 | 1335 ± 20 | 22.50 ± 2.39 | 10.35 ± 0.54 | 424 ± 16 | 777 ± 29 |

| 16 | 1576 ± 19 | 1505 ± 17 | 20.00 ± 1.89 | 9.50 ± 0.66 | 461 ± 17 | 712 ± 16 |

| 17 | 1509 ± 15 | 1444 ± 11 | 17.50 ± 0.97 | 10.25 ± 0.48 | 459 ± 15 | 766 ± 20 |

| 18 | 1501 ± 8 | 1454 ± 7 | 21.88 ± 1.32 | 10.00 ± 0.45 | 475 ± 21 | 754 ± 8 |

| Mechanical Properties | Experiment Indexes | Factors | ||||

|---|---|---|---|---|---|---|

| A | B | C | D | E | ||

| Rm (MPa) | k1j | 1586 | 1512 | 1491 | 1510 | 1505 |

| k2j | 1420 | 1479 | 1509 | 1503 | 1497 | |

| k3j | 1697 | 1508 | 1499 | 1486 | 1497 | |

| k4j | 1414 | |||||

| k5j | 1353 | |||||

| k6j | 1529 | |||||

| R | 344 | 34 | 17 | 24 | 7 | |

| Factors order | Primary→Secondary: A→B→D→C→E | |||||

| Rp0.2 (MPa) | k1j | 1511 | 1451 | 1440 | 1442 | 1446 |

| k2j | 1365 | 1417 | 1437 | 1441 | 1433 | |

| k3j | 1606 | 1442 | 1434 | 1426 | 1431 | |

| k4j | 1366 | |||||

| k5j | 1305 | |||||

| k6j | 1467 | |||||

| R | 301 | 34 | 6 | 16 | 15 | |

| Factors order | Primary→Secondary: A→B→D→E→C | |||||

| ak (J/cm2) | k1j | 15.00 | 19.27 | 22.71 | 19.48 | 20.42 |

| k2j | 21.46 | 20.42 | 18.23 | 20.10 | 20.63 | |

| k3j | 12.71 | 19.38 | 18.13 | 19.48 | 18.02 | |

| k4j | 24.79 | |||||

| k5j | 24.38 | |||||

| k6j | 19.79 | |||||

| R | 12.08 | 1.15 | 4.58 | 0.63 | 2.60 | |

| Factors order | Primary→Secondary: A→C→E→D→B | |||||

| EL (%) | k1j | 9.47 | 9.78 | 10.03 | 10.28 | 9.91 |

| k2j | 10.67 | 10.48 | 10.12 | 10.18 | 10.23 | |

| k3j | 9.12 | 10.13 | 10.23 | 9.93 | 10.25 | |

| k4j | 10.72 | |||||

| k5j | 10.88 | |||||

| k6j | 9.92 | |||||

| R | 1.77 | 0.70 | 0.20 | 0.36 | 0.34 | |

| Factors order | Primary→Secondary: A→B→D→E→C | |||||

| Tempered hardness (HV) | k1j | 462 | 448 | 448 | 447 | 442 |

| k2j | 432 | 447 | 448 | 452 | 452 | |

| k3j | 483 | 448 | 446 | 444 | 450 | |

| k4j | 422 | |||||

| k5j | 429 | |||||

| k6j | 465 | |||||

| R | 5.0 | 0.2 | 0.2 | 0.8 | 0.7 | |

| Factors order | Primary→Secondary: A→D→E→B, C | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Wang, J.; Pan, D.; Han, J.; Zhu, L.; Diao, C.; Han, J.; Jiang, Z. Optimising Two-Stage Vacuum Heat Treatment for a High-Strength Micro-Alloyed Steel in Railway Spring Clip Application: Impact on Microstructure and Mechanical Performance. Materials 2023, 16, 4921. https://doi.org/10.3390/ma16144921

Lu Y, Wang J, Pan D, Han J, Zhu L, Diao C, Han J, Jiang Z. Optimising Two-Stage Vacuum Heat Treatment for a High-Strength Micro-Alloyed Steel in Railway Spring Clip Application: Impact on Microstructure and Mechanical Performance. Materials. 2023; 16(14):4921. https://doi.org/10.3390/ma16144921

Chicago/Turabian StyleLu, Yao, Jun Wang, Di Pan, Jian Han, Lisong Zhu, Chenglei Diao, Jingtao Han, and Zhengyi Jiang. 2023. "Optimising Two-Stage Vacuum Heat Treatment for a High-Strength Micro-Alloyed Steel in Railway Spring Clip Application: Impact on Microstructure and Mechanical Performance" Materials 16, no. 14: 4921. https://doi.org/10.3390/ma16144921

APA StyleLu, Y., Wang, J., Pan, D., Han, J., Zhu, L., Diao, C., Han, J., & Jiang, Z. (2023). Optimising Two-Stage Vacuum Heat Treatment for a High-Strength Micro-Alloyed Steel in Railway Spring Clip Application: Impact on Microstructure and Mechanical Performance. Materials, 16(14), 4921. https://doi.org/10.3390/ma16144921