Effect of De-Icing Chemicals on Concrete Scaling: The Role of Storage Water

Abstract

:1. Introduction

- Damage to the surface layer of concrete is significantly worse when the water applied to the concrete surface contains a certain amount of solute [23].

- The effectiveness of the concentration is almost independent of the character of the de-icing chemical in the solution (e.g., salts, urea). All these de-icing chemicals have been found to have similar effects on concrete [24].

- Damage to the surface layer of concrete is initially reflected in the formation of small chips or flakes of material that gradually fall off the surface [25].

- Without a free liquid with de-icing chemicals on the surface of the concrete, actual scaling will not occur, even when the concrete is saturated with water and subjected to alternating freeze–thaw cycles [26].

- The concentration of salts in the liquid applied to the concrete surface is more important than the concentration of the liquid in the pores of the internal structure of the concrete [23].

2. Testing Methods

2.1. Procedure According to SS 13 72 44 [32]

2.2. Procedure According to CEN/TS 12390-9 [31]

2.3. Procedure According to RILEM TC 117-FDC/CDF [33]

2.4. ASTM C672/C672M-12 Procedure [34]

2.5. Procedure According to MTO LS-412 and BNQ NQ 2621-900 [35]

2.6. Procedure According to ČSN 73 1326 [36]

3. Experimental

3.1. Pilot Experiment—Mortar Testing

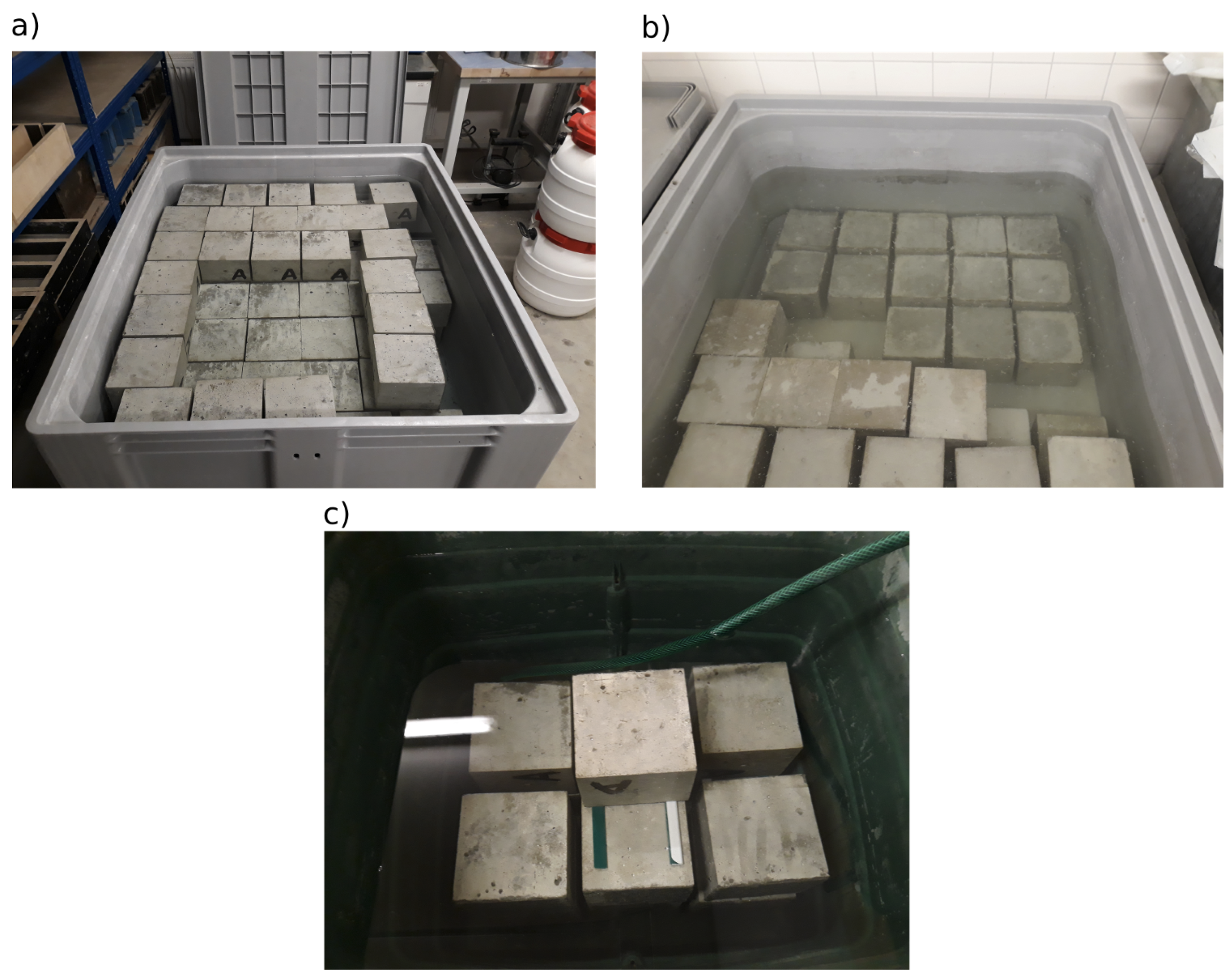

3.2. The Second Experiment—Testing Concrete

4. Results and Discussion

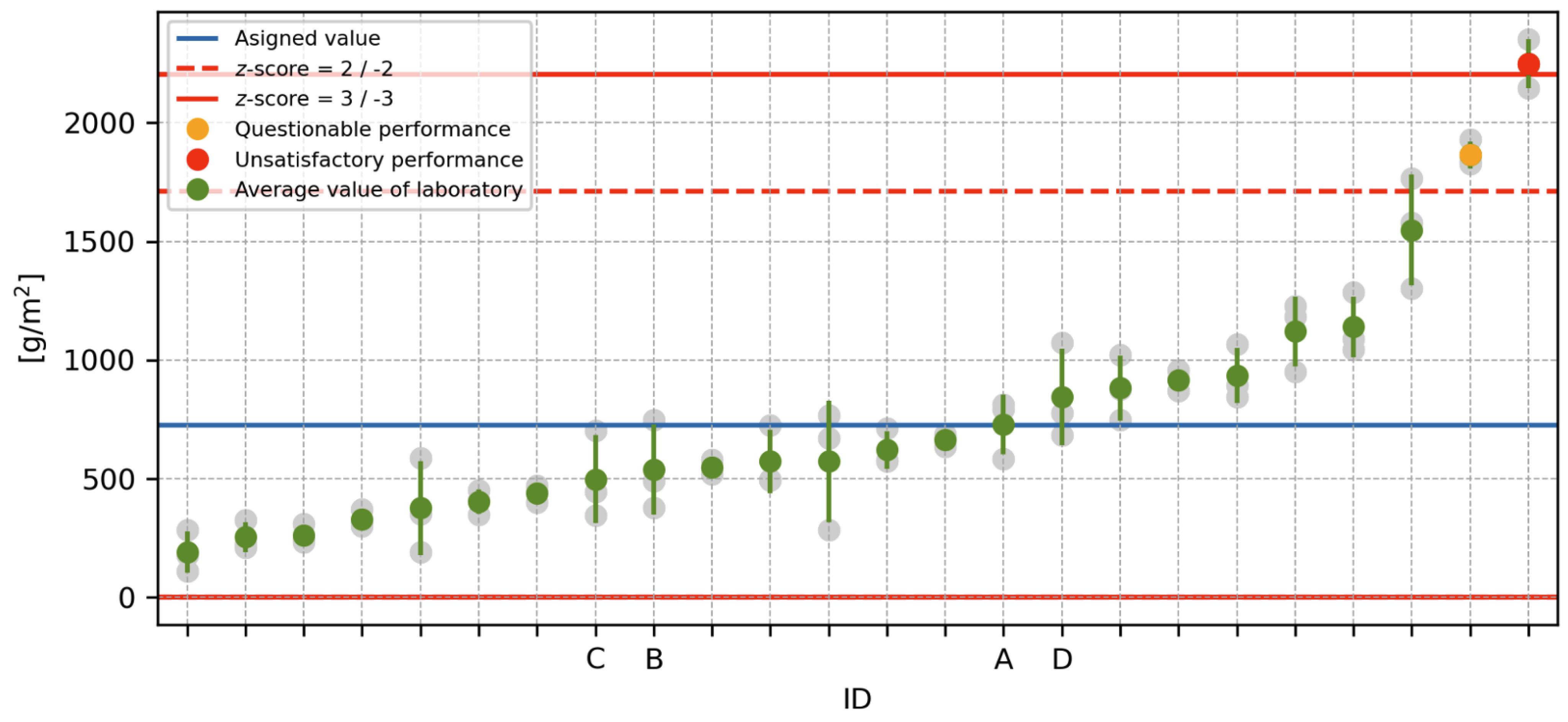

4.1. Validation of Test Results

4.2. Assessment of Homogeneity of Test Results

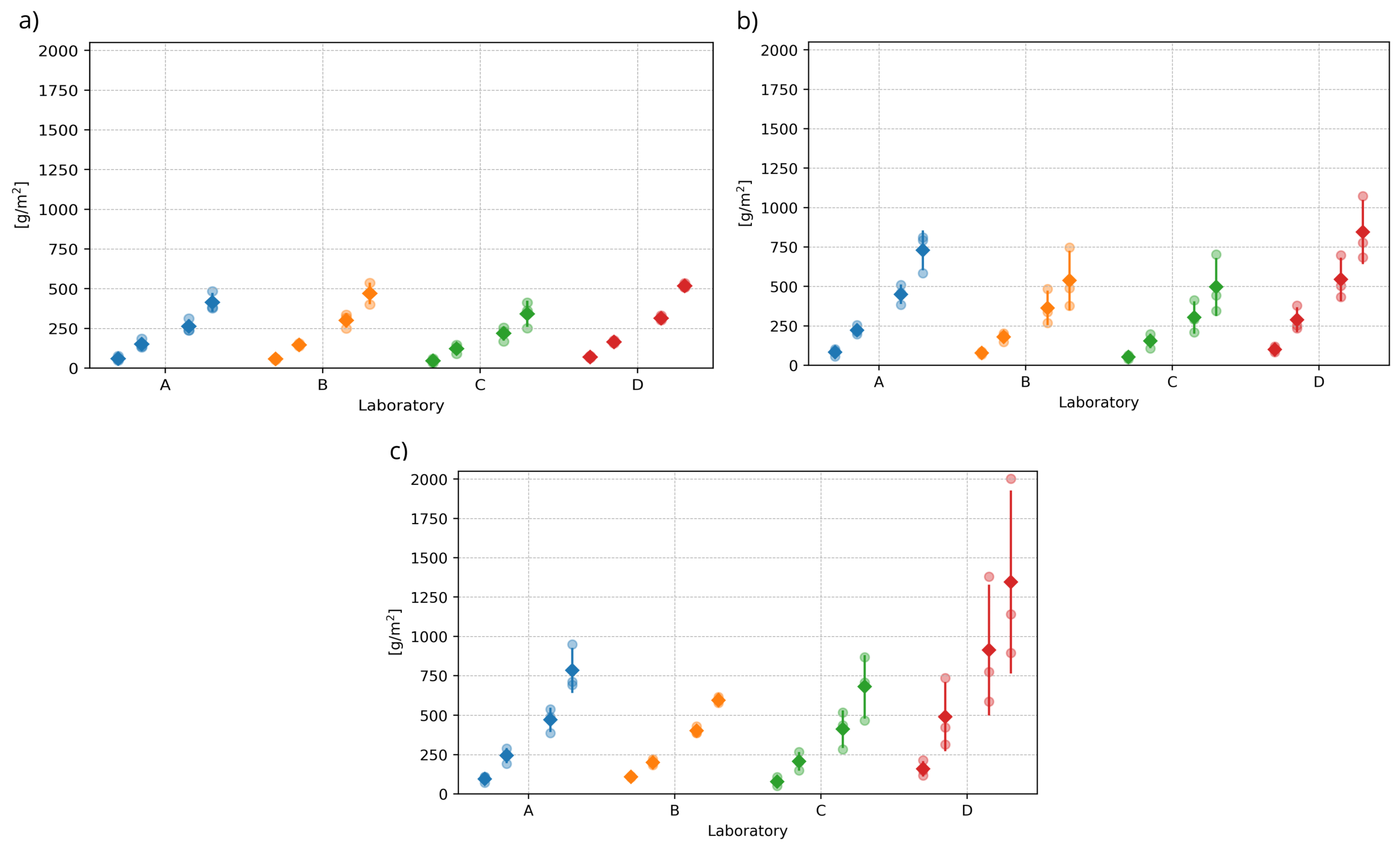

4.3. Assessment of Test Results from the Perspective of Chemical Processes

5. Conclusions

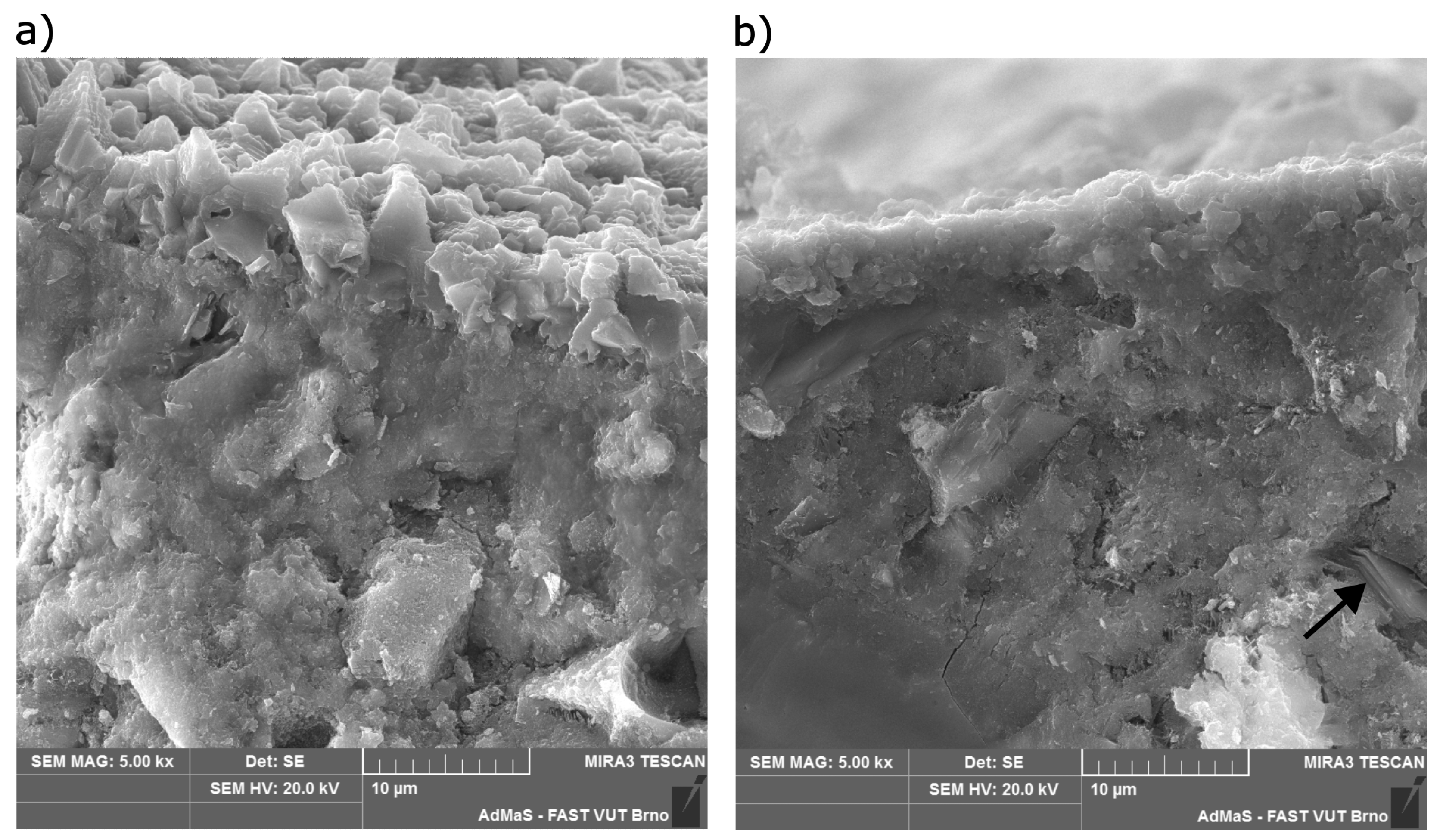

- The aggressive CO2 and bicarbonate content in water storage is an important factor influencing the formation of CaCO3 on the concrete surface.

- The leached Ca(OH)2 from the concrete into the water leads to the production of CaCO3, which forms a thin, firmly adhering layer on the concrete surface that significantly contributes to the peel resistance of the concrete surface layer. This was validated using the ANOVA statistical test at the 0.01 significance level.

- The amount of scaling detected in the de-icing chemicals test depends on the concrete quality and the type of water in which the specimens are stored before testing.

- Further research is needed to better understand the effect of CaCO3 and other factors on the durability and quality of the concrete surface layer, especially concerning concrete durability test results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Prasad Yadav, K.; Samanta, A.K. Characterization and Development of Alccofine Based Sustainable Concrete—A Review. Mater. Today Proc. 2023, S2214785323029632, in press. [Google Scholar] [CrossRef]

- Sharma, D.; Sharma, S.; Goyal, A. Utilization of Waste Foundry Slag and Alccofine for Developing High Strength Concrete. Int. J. Electrochem. Sci. 2016, 11, 3190–3205. [Google Scholar] [CrossRef]

- U.S.: Cement Production 2022. Available online: https://www.statista.com/statistics/219343/cement-production-worldwide/ (accessed on 20 June 2023).

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards Sustainable Concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef] [PubMed]

- Making Concrete Change: Innovation in Low-Carbon Cement and Concrete. 2018. Available online: https://www.chathamhouse.org/2018/06/making-concrete-change-innovation-low-carbon-cement-and-concrete (accessed on 20 June 2023).

- Wada, Y.; Van Beek, L.P.H.; Van Kempen, C.M.; Reckman, J.W.T.M.; Vasak, S.; Bierkens, M.F.P. Global Depletion of Groundwater Resources: GLOBAL GROUNDWATER DEPLETION. Geophys. Res. Lett. 2010, 37, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Nilimaa, J. Smart Materials and Technologies for Sustainable Concrete Construction. Dev. Built Environ. 2023, 15, 100177. [Google Scholar] [CrossRef]

- Grebenkov, D.S. Depletion of Resources by a Population of Diffusing Species. Phys. Rev. E 2022, 105, 054402. [Google Scholar] [CrossRef]

- Müller, H.S.; Haist, M.; Vogel, M. Assessment of the Sustainability Potential of Concrete and Concrete Structures Considering Their Environmental Impact, Performance and Lifetime. Constr. Build. Mater. 2014, 67, 321–337. [Google Scholar] [CrossRef]

- Alexander, M.G.; Bentur, A.; Mindess, S. (Eds.) Durability of Concrete: Design and Construction; Modern Concrete Technology Series; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Kocáb, D.; Terzijski, I.; Strnad, J.; Ševčík, M. Determination of Concrete Resistance to Corrosive Effects of Water with Aggressive CO2 Using Model Mortars. Solid State Phenom. 2020, 309, 31–37. [Google Scholar] [CrossRef]

- Terzijski, I.; Kocáb, D.; Štěpánek, P.; Strnad, J.; Girgle, F.; Šimůnek, P. Development of Variants of High-Performance Self-Compacting Concrete with Improved Resistance to the Attack of Sulfates. Appl. Sci. 2021, 11, 5945. [Google Scholar] [CrossRef]

- Piasta, W.; Góra, J.; Turkiewicz, T. Properties and Durability of Coarse Igneous Rock Aggregates and Concretes. Constr. Build. Mater. 2016, 126, 119–129. [Google Scholar] [CrossRef]

- Collepardi, M. The New Concrete; Tintoretto: Treviso, Italy, 2006. [Google Scholar]

- Yi, Y.; Zhu, D.; Guo, S.; Zhang, Z.; Shi, C. A Review on the Deterioration and Approaches to Enhance the Durability of Concrete in the Marine Environment. Cem. Concr. Compos. 2020, 113, 103695. [Google Scholar] [CrossRef]

- Ma, D.; Zhang, M.; Cui, J. A Review on the Deterioration of Mechanical and Durability Performance of Marine-Concrete under the Scouring Action. J. Build. Eng. 2023, 66, 105924. [Google Scholar] [CrossRef]

- Maus, S.; Bahafid, S.; Hendriks, M.; Jacobsen, S.; Geiker, M.R. X-ray Micro-Tomographic Imaging and Modelling of Saline Ice Properties in Concrete Frost Salt Scaling Experiments. Cold Reg. Sci. Technol. 2023, 208, 103780. [Google Scholar] [CrossRef]

- Nowak-Michta, A. Salt Scaling Resistance of Variable w/c Ratio Air-Entrained Concretes Modified with Polycarboxylates as a Proper Consequence of Air Void System. Materials 2022, 15, 5839. [Google Scholar] [CrossRef]

- Faheem, A.; Hasholt, M.T. The Effect of Temperature Distribution in Mortar on Frost Scaling. Cem. Concr. Res. 2022, 157, 106824. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Li, Y.; Yuan, J.; Wu, Y. Research Progresses on Salt Scaling and Protective Methods for Concrete Pavements. Constr. Build. Mater. 2022, 342, 127993. [Google Scholar] [CrossRef]

- Ding, Z.; Quy, N.X.; Kim, J.; Hama, Y. Evaluations of Frost and Scaling Resistance of Fly Ash Concrete in Terms of Changes in Water Absorption and Pore Structure under the Accelerated Carbonation Conditions. Constr. Build. Mater. 2022, 345, 128273. [Google Scholar] [CrossRef]

- Cappellesso, V.G.; Van Mullem, T.; Gruyaert, E.; Van Tittelboom, K.; De Belie, N. Bacteria-Based Self-Healing Concrete Exposed to Frost Salt Scaling. Cem. Concr. Compos. 2023, 139, 105016. [Google Scholar] [CrossRef]

- Liu, Z.; Hansen, W. Freezing Characteristics of Air-Entrained Concrete in the Presence of Deicing Salt. Cem. Concr. Res. 2015, 74, 10–18. [Google Scholar] [CrossRef]

- Valenza, J.J.; Scherer, G.W. Mechanism for Salt Scaling of a Cementitious Surface. Mater. Struct. 2007, 40, 259–268. [Google Scholar] [CrossRef]

- Valenza, J.J.; Scherer, G.W. A Review of Salt Scaling: I. Phenomenology. Cem. Concr. Res. 2007, 37, 1007–1021. [Google Scholar] [CrossRef]

- Fagerlund, G.; Setzer, M. Freeze-Thaw and de-Icing Resistance of Concrete: Research Seminar Held in Lund, June 17, 1991: RILEM Committee TC-117 FDC. In Report TVBM; Lund Institute of Technology: Lund, Sweden, 1992; Available online: https://lucris.lub.lu.se/ws/portalfiles/portal/4868047/1781975.pdf (accessed on 15 June 2023).

- Shang, H.S.; Cao, W.Q.; Wang, B. Effect of Fast Freeze-Thaw Cycles on Mechanical Properties of Ordinary-Air-Entrained Concrete. Sci. World J. 2014, 2014, e923032. [Google Scholar] [CrossRef] [Green Version]

- Penttala, V. Surface and Internal Deterioration of Concrete Due to Saline and Non-Saline Freeze–Thaw Loads. Cem. Concr. Res. 2006, 36, 921–928. [Google Scholar] [CrossRef]

- Sun, Z.; Scherer, G.W. Effect of Air Voids on Salt Scaling and Internal Freezing. Cem. Concr. Res. 2010, 40, 260–270. [Google Scholar] [CrossRef]

- Kocáb, D.; Misák, P.; Vymazal, T.; Komárková, T.; Halamová, R. Stanovení odolnosti povrchu betonu proti působení vody a chemických rozmrazovacích látek—Metody, praxe a problémy. Beton TKS 2017, 2, 42–47. [Google Scholar]

- CEN/TS 12390-9; Testing Hardened Concrete—Part 9: Freeze-Thaw Resistance with De-Icing Salts—Scaling. CEN: Brussels, Belgium, 2016.

- SS 13 72 44; Betongprovning—Hårdnad Betong—Draghållfasthet Hos Provkroppar. SIS: Stockholm, Sweden, 2005.

- RILEM TC 117-FDC. TC 117-FDC Recommendation—CDF Test—Test Method for the Freez Thaw and Deicing Resistance of Concrete—Tests with Sodium Chloride (CDF). Mater. Struct. 1996, 1996, 29. [Google Scholar]

- ASTM C672; Standard Test Method for Scaling Resistance of Concrete Surfaces Exposed to Deicing Chemicals. ASTM International: West Conshohocken, PA, USA, 2012.

- Vassilev, D.G. Evaluation of Test Methods for De-Icer Scaling Resistance of Concrete. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2012. [Google Scholar]

- ČSN 73 1326: Stanovení Odolnosti Povrchu Cementového Betonu Proti Působení Vody a Chemických Rozmrazovacích Látek, 1985. ČSN 73 1326. Available online: http://seznamcsn.agentura-cas.cz/Detailnormy.aspx?k=31089 (accessed on 20 June 2023).

- Kocáb, D.; Komárková, T.; Králíková, M.; Misák, P.; Moravcová, B. Experimental Determination of the Influence of Fresh Concrete’s Composition on Its Resistance to Water and de-Icing Chemicals by Means of Two Methods. Mater. Tehnol. 2017, 51, 387–395. [Google Scholar] [CrossRef]

- EN 196-1; Methods of Testing Cement—Part 1: Determination of Strength. CEN: Brussels, Belgium, 2016.

- ISO/IEC 17043:2023; Conformity assessment – General requirements for proficiency testing. International Organization for Standardization: Geneva, Switzerland, 2023.

- ISO 5725-2:2019; Accuracy (Trueness and Precision) of Measurement Methods and Results—Part 2: Basic Method for the Determination of Repeatability and Reproducibility of a Standard Measurement Method. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 13528:2022; Statistical Methods for Use in Proficiency Testing by Interlaboratory Comparison. International Organization for Standardization: Geneva, Switzerland, 2022.

- MPZ. Available online: http://www.ptprovider.cz/ (accessed on 20 June 2023).

- BS 1881-208:1996; Testing Concrete. Recommendations for the Determination of the Initial Surface Absorption of Concrete. The British Standards Institution: London, UK, 2020.

- Moczko, A.; Moczko, M. GWT—New Testing System for “in-Situ” Measurements of Concrete Water Permeability. Procedia Eng. 2016, 153, 483–489. [Google Scholar] [CrossRef] [Green Version]

- Zhang, D.; Li, K. Concrete Gas Permeability from Different Methods: Correlation Analysis. Cem. Concr. Compos. 2019, 104, 103379. [Google Scholar] [CrossRef]

- EN 12390-10; Testing Hardened Concrete—Part 10: Determination of the Carbonation Resistance of Concrete at Atmospheric Levels of Carbon Dioxide. CEN: Brussels, Belgium, 2018.

- EN 12390-12; Testing Hardened Concrete—Part 12: Determination of the Carbonation Resistance of Concrete—Accelerated Carbonation Method. CEN: Brussels, Belgium, 2020.

| Component | kg/m3 |

|---|---|

| Cement CEM I 42.5 R (Morká cement plant, CZ) | 400 |

| Fine aggregate 0–4 mm (Bratčice, CZ) | 807 |

| Coarse aggregate 8–16 mm (Olbramovice, CZ) | 915 |

| Air-entraining admixture LPS A 94 (Sika, CZ) | 1 |

| Plasticizing admixture SVC-4035 (Sika, CZ) | 2.2 |

| Water | 182 |

| Water Storage | Number of Cycles | ANOVA p-Value | Shapiro Test p-Value (Normality Test) | Shapiro Test p-Value (Normality Test) after Excluding Outliers |

|---|---|---|---|---|

| Slow flowing water | 25 | 0.141 | 0.810 | - |

| 50 | 0.169 | 0.633 | - | |

| 75 | 0.065 | 0.174 | - | |

| 100 | 0.038 | 0.262 | - | |

| Fresh water | 25 | 0.043 | 0.992 | - |

| 50 | 0.047 | 0.227 | - | |

| 75 | 0.099 | 0.861 | - | |

| 100 | 0.131 | 0.647 | - | |

| Previously used water | 25 | 0.052 | 0.044 | 0.204 |

| 50 | 0.045 | 0.001 | 0.232 | |

| 75 | 0.061 | 0.001 | 0.362 | |

| 100 | 0.072 | 0.003 | 0.654 |

| Number of Cycles | p-Value |

|---|---|

| 25 | 0.000141 |

| 50 | 0.001576 |

| 75 | 0.000399 |

| 100 | 0.000480 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Misák, P.; Kocáb, D.; Bayer, P.; Vymazal, T.; Rovnaníková, P. Effect of De-Icing Chemicals on Concrete Scaling: The Role of Storage Water. Materials 2023, 16, 4928. https://doi.org/10.3390/ma16144928

Misák P, Kocáb D, Bayer P, Vymazal T, Rovnaníková P. Effect of De-Icing Chemicals on Concrete Scaling: The Role of Storage Water. Materials. 2023; 16(14):4928. https://doi.org/10.3390/ma16144928

Chicago/Turabian StyleMisák, Petr, Dalibor Kocáb, Patrik Bayer, Tomáš Vymazal, and Pavla Rovnaníková. 2023. "Effect of De-Icing Chemicals on Concrete Scaling: The Role of Storage Water" Materials 16, no. 14: 4928. https://doi.org/10.3390/ma16144928

APA StyleMisák, P., Kocáb, D., Bayer, P., Vymazal, T., & Rovnaníková, P. (2023). Effect of De-Icing Chemicals on Concrete Scaling: The Role of Storage Water. Materials, 16(14), 4928. https://doi.org/10.3390/ma16144928