Control of Mechanical Properties of FRP (Fiber-Reinforced Plastic) via Arrangement of High-Strength/High-Ductility Fiber in a Blended Fabric

Abstract

:1. Introduction

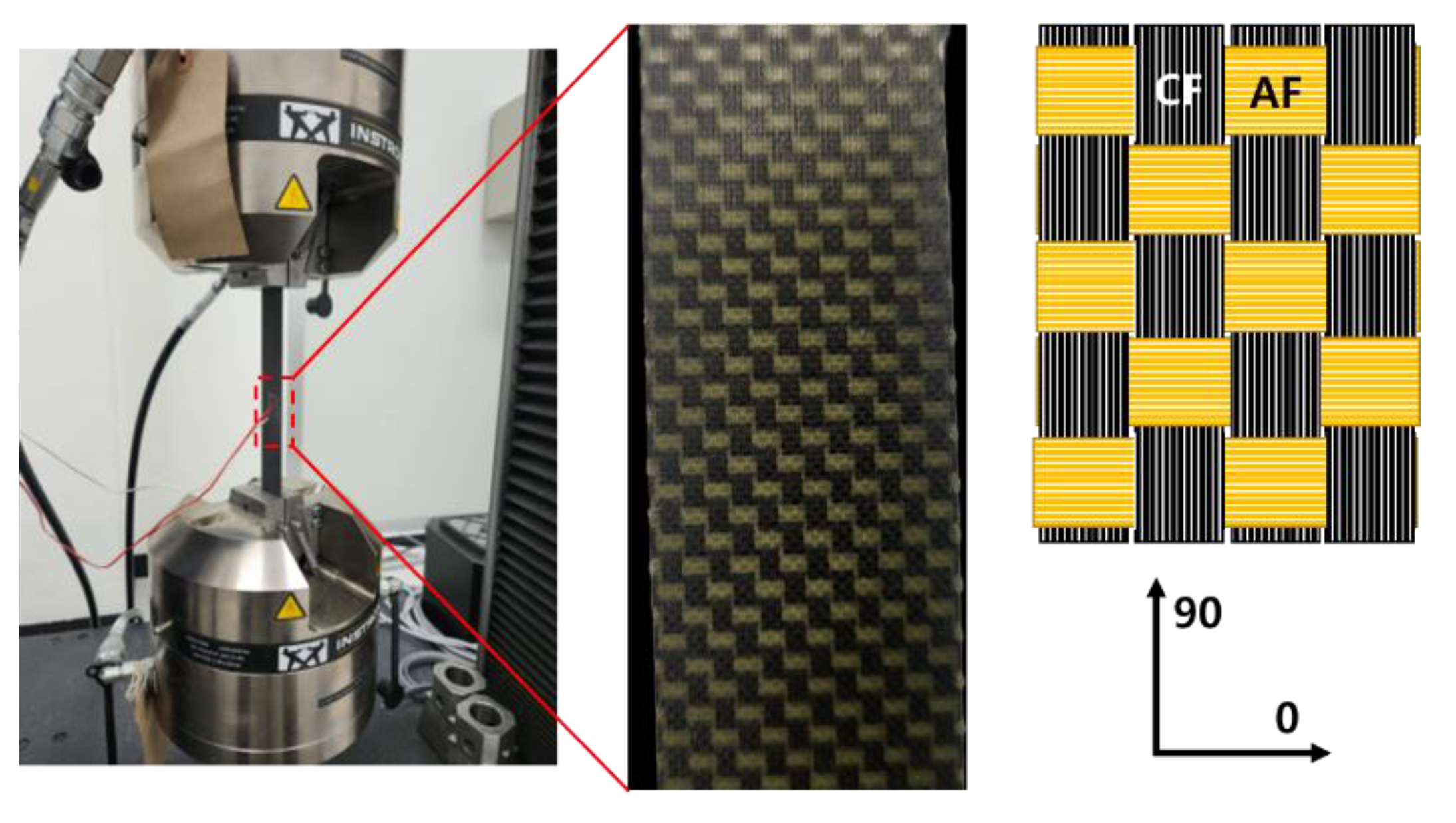

2. Materials and Methods

2.1. Materials

2.2. FRP Manufacturing Method

2.3. Analysis Method

3. Results and Discussion

3.1. FRP Fiber/Resin Content Evaluation

3.2. Tensile/Compressive/Flexural Properties of the Reference Fabrics

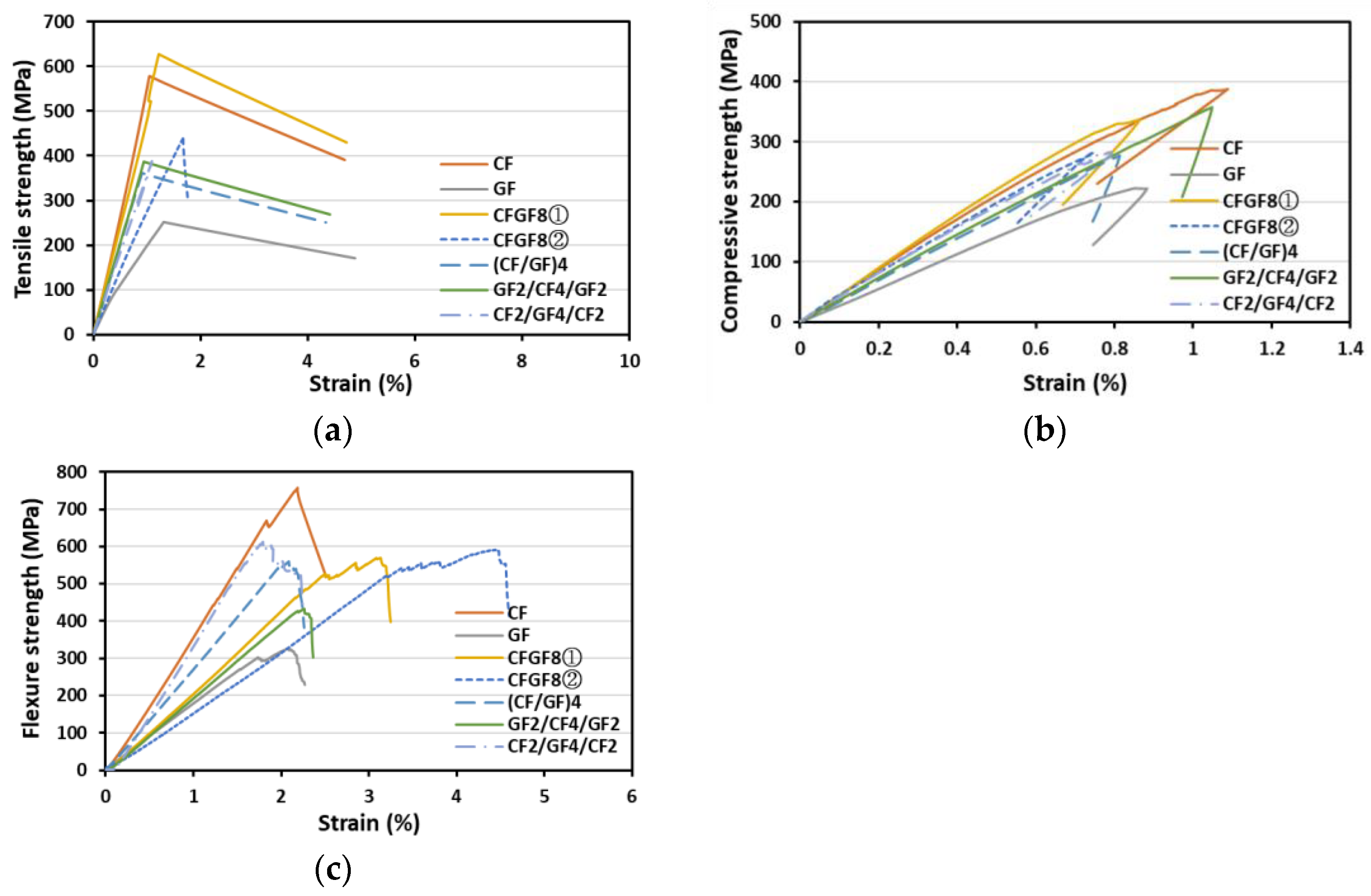

3.3. Tensile/Compressive/Flexural Properties of the CF-GF Hybrid/Blended Fabrics

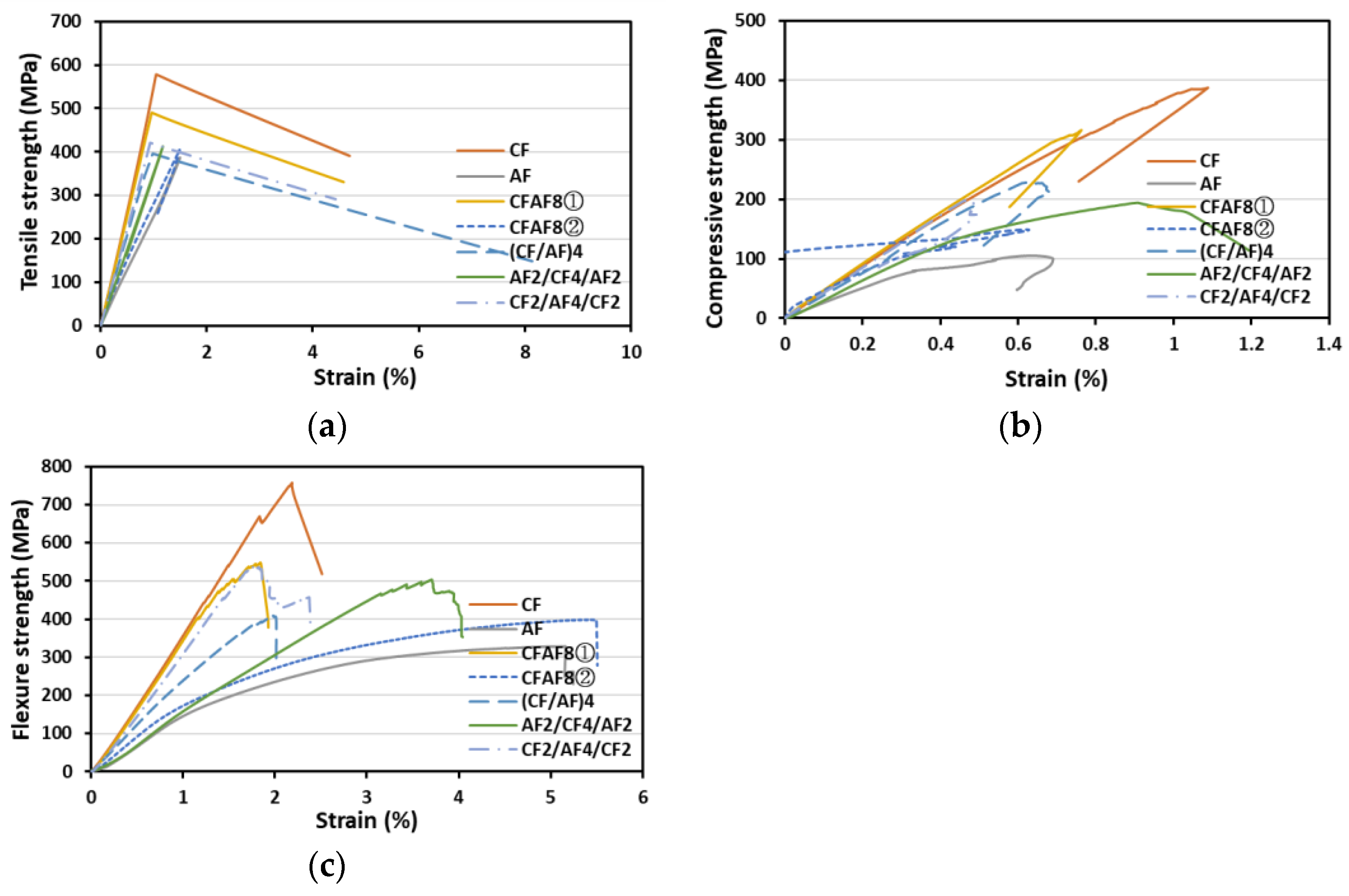

3.4. Tensile/Compressive/Flexural Properties of the CF-AF Hybrid/Blended Fabrics

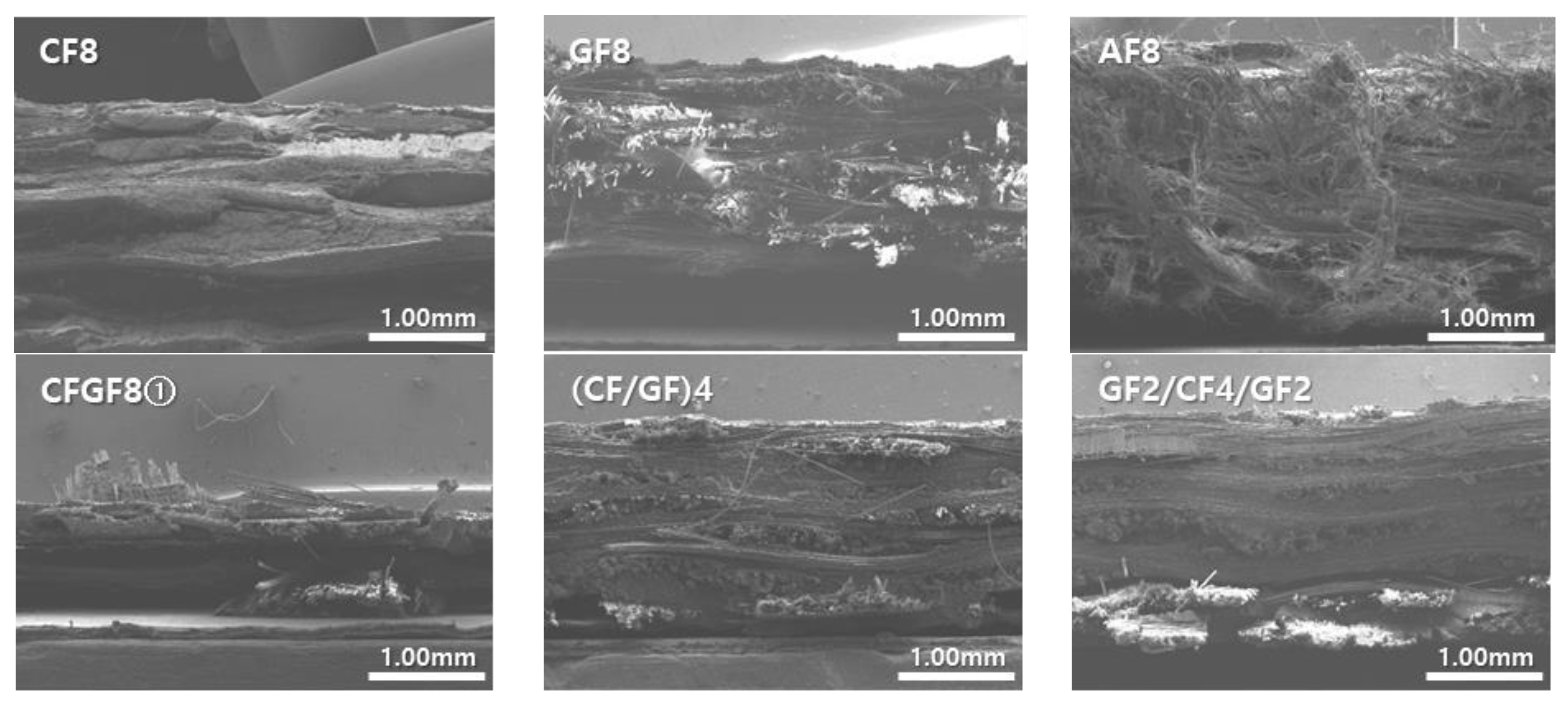

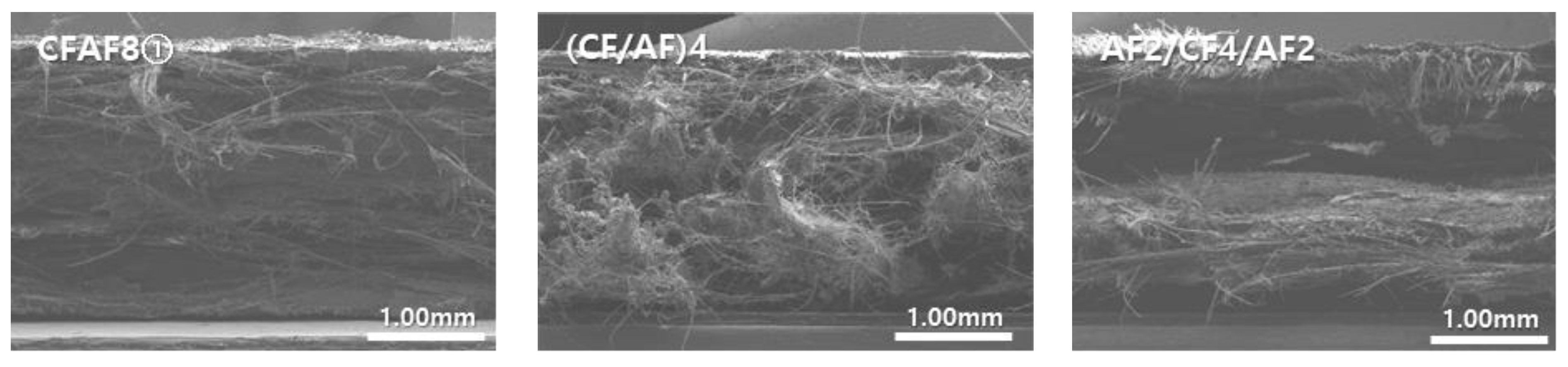

3.5. Evaluation of the FRP Fracture Shapes

3.6. Difference in Tensile Strength Depending on the Fiber Direction

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- James, A.; Bazarchi, E.; Chiniforush, A.A.; Aghdam, P.P.; Hosseini, M.R.; Akbarnezhad, A.; Martek, I.; Ghodoosi, F. Rebar corrosion detection, protection, and rehabilitation of reinforced concrete structures in coastal environments: A review. Constr. Build. Mater. 2019, 126, 1026–1039. [Google Scholar] [CrossRef]

- Aydin, F. Experimental investigation of thermal expansion and concrete strength effects on FRP bars behavior embedded in concrete. Constr. Build. Mater. 2018, 163, 1–8. [Google Scholar] [CrossRef]

- Khan, I.; François, R.; Castel, A. Prediction of reinforcement corrosion using corrosion induced cracks width in corroded reinforced concrete beams. Cem. Concr. Res. 2014, 56, 84–96. [Google Scholar] [CrossRef]

- Oh, B.H.; Kim, K.H.; Jang, B.S. Corrosion Amount to Cause Cracking of Reinforced Concrete Structures. ACI Mater. J. 2009, 106, 333–339. [Google Scholar]

- Jin, L.; Zhang, R.; Du, X.; Li, Y. Investigation on the cracking behavior of concrete cover induced by corner located rebar corrosion. Eng. Fail. Anal. 2015, 52, 129–143. [Google Scholar] [CrossRef]

- Zhang, B.; Masmoudi, R.; Benmokrane, B. Behaviour of one-way concrete slabs reinforced with CFRP grid reinforcements. Constr. Build. Mater. 2004, 18, 625–635. [Google Scholar] [CrossRef]

- Gadve, S.; Mukherjee, A.; Malhotra, S.N. Corrosion of steel reinforcements embedded in FRP wrapped concrete. Constr. Build. Mater. 2009, 23, 153–161. [Google Scholar] [CrossRef]

- Jabbar, S.A.A.; Farid, S.B.H. Replacement of steel rebars by GFRP rebars in the concrete structures. Karbala Int. J. Mod. Sci. 2018, 4, 216–227. [Google Scholar] [CrossRef]

- Wang, B.; Uji, K.; Wu, T.; Dai, H.; Yan, D.; Guo, R. Experimental investigation of stress transfer and failure mechanism between existing concrete and CFRP grid-sprayed PCM. Constr. Build. Mater. 2019, 215, 43–58. [Google Scholar] [CrossRef]

- Huang, Z.; Miao, X.; Shen, J.; Li, H.; Zhang, J. Experimental investigation on shear behavior of concrete beams with CFRP grid shear reinforcements. Structures 2021, 33, 3081–3093. [Google Scholar] [CrossRef]

- Zhang, W.; Deng, M.; Han, Y.; Li, R.; Yang, S. Uniaxial tensile performance of high ductile fiber-reinforced concrete with built-in basalt textile grids. Constr. Build. Mater. 2022, 315, 125716. [Google Scholar] [CrossRef]

- Wang, A.; Liu, X.; Yue, Q.; Xian, G. Tensile properties hybrid effect of unidirectional flax/carbon fiber hybrid reinforced polymer composites. J. Mater. Res. Technol. 2023, 24, 1373–1389. [Google Scholar] [CrossRef]

- Sun, G.; Tong, S.; Chen, D.; Gong, Z.; Li, Q. Mechanical properties of hybrid composites reinforced by carbon and basalt fibers. Int. J. Mech. Sci. 2018, 148, 636–651. [Google Scholar] [CrossRef]

- Hakeem, I.; Hosen, M.A.; Alyami, M.; Qaidi, S. Influence of Heat-Cool Cyclic Exposure on the Performance of Fiber-reinforced High-Strength Concrete. Sustainability 2023, 15, 1433. [Google Scholar] [CrossRef]

- Madenci, E.; Ozkilic, Y.O.; Aksoylu, C.; Asyraf, M.R.M.; Syamsir, A.; Supian, A.B.M.; Mamaev, N. Buckling Analysis of CNT-Reinforced Polymer Composite Beam Using Experimental and Analytical Methods. Materials 2023, 16, 614. [Google Scholar] [CrossRef] [PubMed]

- Madenci, E.; Ozkilic Gemi, L.; Madenci, E.; Aksoylu, C. Effects of stirrup spacing on shear performance of hybrid composite beams produced by pultruded GFRP profile infilled with reinforced concrete. Archiv. Civ. Mech. Eng. 2023, 23, 36. [Google Scholar] [CrossRef]

- Madenci, E.; Ozkilic, Y.O.; Aksoylu, C.; Safonov, A. The Effect of Eccentric Web Openeings on the Compressive Preformance of Pultruded GFRP Boxes Wrapped with GFRP and CFRP Sheets. Polymers 2022, 14, 4567. [Google Scholar] [CrossRef] [PubMed]

- Falkowicz, K. Stability Analysis of Thin-Walled Perforated Composite Columns Using Finite Element Method. Materials 2022, 15, 8919. [Google Scholar] [CrossRef]

- Rozylo, P. Comparison of Failure for Thin-Walled Composite Columns. Materials 2022, 15, 167. [Google Scholar] [CrossRef]

- ASTM D3039; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D6641; Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Jiang, H.; Liu, X.; Jiang, S.; Ren, Y. Hybrid effects and interactive failure mechanisms of hybrid fiber composites under flexural loading: Carbon/Kevlar, carbon/glass, carbon/glass/Kevlar. Aerosp. Sci. Technol. 2023, 133, 108105. [Google Scholar] [CrossRef]

- Margabandu, S.; Subramaniam, S.K. Influence of fiber stacking sequences and matrix materials on mechanical and vibration behavior of jute/carbon hybrid composites. World J. Eng. 2022, 19, 639–651. [Google Scholar] [CrossRef]

- Chen, D.; Xia, S.; Yang, B.; Yang, G.; Zhu, T.; Wang, M.; Zhang, Z. Axial crushing response of carbon/glass hybrid composite tubes: An experimental and multi-scale computational study. Compos. Strut. 2022, 294, 115640. [Google Scholar] [CrossRef]

| Sample | Name | Stacking Pattern | Mixing Ratio (v/v) | |

|---|---|---|---|---|

| Reference fabric | CF8 |  | 100 | - |

| GF8, AF8 |  | - | 100 | |

| Hybrid fabric | CF2/GF4/CF2, CF2/AF4/CF2 |  | 50 | 50 |

| GF2/CF4/GF, CF2/GF4/CF2 |  | 50 | 50 | |

| (CF/GF)4, (CF/AF)4 |  | 50 | 50 | |

| Blended fabric | CFGF8①,②, CFAF8①,② |  | 50 | 50 |

: Blended carbon–glass fiber fabric (CFGF) or blended carbon–aramid fiber fabric (CFAF).

: Blended carbon–glass fiber fabric (CFGF) or blended carbon–aramid fiber fabric (CFAF).| Category | Calculated Value | TGA | Thermal Expansion Coefficient | ||||

|---|---|---|---|---|---|---|---|

| Resin Content vol.% | Fiber Content vol.% | Resin Content wt.% | Fiber Content wt.% | Resin Content wt.% | Fiber Content wt.% | μm/m°C | |

| Matrix resin | 61.20 | ||||||

| CF8 | 39.44 | 60.56 | 39.87 | 60.13 | 47.24 | 52.76 | 64.50 |

| GF8 | 49.56 | 50.44 | 30.23 | 69.77 | 29.48 | 70.52 | 42.30 |

| AF8 | 47.34 | 52.66 | 37.2 | 62.8 | 37.65 | 62.35 | 78.50 |

| CFGF8①,② | 42.84 | 57.16 | 27.99 | 72.01 | 36.81 | 63.19 | 54.80 |

| (CF/GF)4 | 52.49 | 47.51 | 36.42 | 63.58 | 37.53 | 62.47 | 59.90 |

| GF2/CF4/GF2 | 51.2 | 48.8 | 35.23 | 64.77 | 42.15 | 57.85 | 60.50 |

| CF2/GF4/CF2 | 46.78 | 53.22 | 31.31 | 68.69 | - | - | 46.00 |

| CFAF8①,② | 52.99 | 47.01 | 42.05 | 57.95 | - | - | 84.80 |

| (CF/AF)4 | 52.85 | 47.15 | 41.91 | 58.09 | - | - | 69.10 |

| AF2/CF4/AF2 | 51.23 | 48.77 | 40.34 | 59.66 | - | - | 58.70 |

| CF2/AF4/CF2 | 48.65 | 51.35 | 37.88 | 62.12 | - | - | 85.70 |

| Category | Tensile Strength (MPa) | Elasticity (GPa) | Strain (%) | Compressive Strength (MPa) | Elasticity (GPa) | Strain (%) | Flexural Strength (MPa) | Elasticity (GPa) | Strain (%) |

|---|---|---|---|---|---|---|---|---|---|

| CF8 | 568.17 | 53.88 | 0.97 | 381.04 | 48.32 | 0.87 | 658.23 | 33.58 | 1.91 |

| GF8 | 251.56 | 24.06 | 1.31 | 224.52 | 26.6 | 0.9 | 339.7 | 17.63 | 2.27 |

| AF8 | 379.9 | 25.76 | 1.61 | 102.72 | 21.54 | 0.88 | 325.76 | 13.01 | 5 |

| Category | Tensile Strength (MPa) | Tensile Modulus (GPa) | Strain (%) | Compressive Strength (MPa) | Tensile Modulus (GPa) | Strain (%) | Flexural Strength (MPa) | Tensile Modulus (GPa) | Strain (%) |

|---|---|---|---|---|---|---|---|---|---|

| CF8 | 568.17 | 33.58 | 0.97 | 381.04 | 48.32 | 0.87 | 658.23 | 53.88 | 1.91 |

| CFGF8① | 608.34 | 20.01 | 1.3 | 356.6 | 45.07 | 0.75 | 536.25 | 48.32 | 3.06 |

| CFGF8② | 428.31 | 17.3 | 1.71 | 286.88 | 37.62 | 0.81 | 584.2 | 29.06 | 3.99 |

| (CF/GF)4 | 367.31 | 25.62 | 0.93 | 285.02 | 38.42 | 0.67 | 538.11 | 40.55 | 2.1 |

| GF2/CF4/GF2 | 409.06 | 21.2 | 1.05 | 319.75 | 38 | 0.86 | 462.07 | 39.83 | 2.33 |

| CF2/GF4/CF2 | 388.01 | 31.17 | 1.09 | 284.48 | 38.88 | 0.79 | 592.1 | 37.85 | 1.95 |

| Category | Tensile Strength (MPa) | Tensile Modulus (GPa) | Strain (%) | Compressive Strength (MPa) | Tensile Modulus (GPa) | Strain (%) | Flexural Strength (MPa) | Tensile Modulus (GPa) | Strain (%) |

|---|---|---|---|---|---|---|---|---|---|

| CF8 | 568.17 | 53.88 | 0.97 | 381.04 | 48.32 | 0.87 | 658.23 | 33.58 | 1.91 |

| CFAF8① | 516.3 | 54.1 | 0.97 | 300.95 | 42.55 | 0.72 | 542 | 32.21 | 1.82 |

| CFAF8② | 417.34 | 30.95 | 1.61 | 146.35 | 29.28 | 0.63 | 391.57 | 19.23 | 5.24 |

| (CF/AF)4 | 386.36 | 44.35 | 0.94 | 216.27 | 36.11 | 0.67 | 428.65 | 24.8 | 2 |

| AF2/CF4/AF2 | 412.85 | 37.06 | 1.13 | 235.88 | 35.42 | 0.73 | 519.13 | 15.1 | 3.48 |

| CF2/AF4/CF2 | 399.14 | 46.05 | 0.77 | 233.99 | 40.95 | 0.61 | 545.5 | 29.33 | 1.84 |

| Authors | Stacking Method | Mixing | Tensile Strength | Tensile Modulus | Strain |

|---|---|---|---|---|---|

| MPa | GPa | % | |||

| Sun et al. [13] | - | [C]8 | 504.73 | - | - |

| - | [B]8 | 413.50 | - | - | |

| sandwich-stacking | [C2B2]s | 354.39 | - | 1.07 | |

| sandwich-stacking | [B2C2]s | 385.22 | - | 1.19 | |

| cross-stacking | [BCBC]s | 437.15 | - | 1.26 | |

| Margabandu et al. [24] | - | [CC]s | 301.17 | 22.84 | 1.45 |

| - | [JJ]s | 54.98 | 6.47 | 1.24 | |

| sandwich-stacking | [JC]s | 234.68 | 15.35 | 2.74 | |

| sandwich-stacking | [CJ]s | 158.74 | 12.75 | 2.14 | |

| Chen et al. [25] | - | CC | 679.1 | 59.2 | 1.5 |

| blended-stacking | C90G0 | 656.5 | 62.2 | 1.5 | |

| blended-stacking | C0G90 | 483.7 | 22.1 | 2.7 | |

| - | GG | 478 | 22.1 | 2.7 |

| Category | Unit | Gauge Length | CF8 | CFGF8① | CFGF8② |

|---|---|---|---|---|---|

| Horizontal length change | mm | 130 | 131.26 | 131.26 | 131.7 |

| Vertical length change | mm | 25 | 24.88 | 24.81 | 24.84 |

| Vertical difference (εy) | mm | - | 0.12 | 0.19 | 0.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.H.; Song, B.K.; Song, J.H.; Min, K.J. Control of Mechanical Properties of FRP (Fiber-Reinforced Plastic) via Arrangement of High-Strength/High-Ductility Fiber in a Blended Fabric. Materials 2023, 16, 5001. https://doi.org/10.3390/ma16145001

Kim JH, Song BK, Song JH, Min KJ. Control of Mechanical Properties of FRP (Fiber-Reinforced Plastic) via Arrangement of High-Strength/High-Ductility Fiber in a Blended Fabric. Materials. 2023; 16(14):5001. https://doi.org/10.3390/ma16145001

Chicago/Turabian StyleKim, Ji Hyun, Bhum Keun Song, Joon Hyuk Song, and Kyoung Jae Min. 2023. "Control of Mechanical Properties of FRP (Fiber-Reinforced Plastic) via Arrangement of High-Strength/High-Ductility Fiber in a Blended Fabric" Materials 16, no. 14: 5001. https://doi.org/10.3390/ma16145001

APA StyleKim, J. H., Song, B. K., Song, J. H., & Min, K. J. (2023). Control of Mechanical Properties of FRP (Fiber-Reinforced Plastic) via Arrangement of High-Strength/High-Ductility Fiber in a Blended Fabric. Materials, 16(14), 5001. https://doi.org/10.3390/ma16145001