The Machine Learning Methods in Non-Destructive Testing of Dynamic Properties of Vacuum Insulated Glazing Type Composite Panels

Abstract

:1. Introduction

1.1. Purpose and Scope of Work

1.2. Motivation

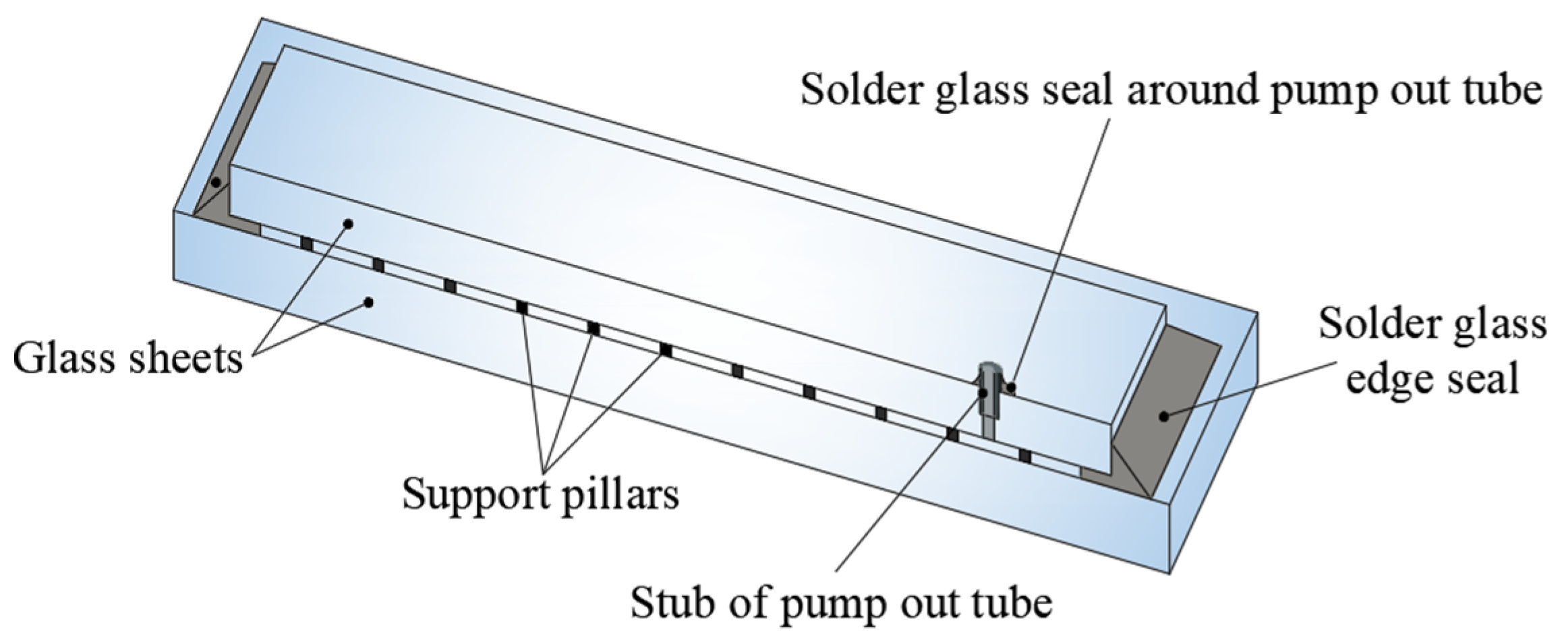

1.3. VIG Panels Description

2. Materials and Methods

2.1. Subject of the Study

2.2. Laboratory Experiments

- cross-spectrum(acc_top,hammer)–Input

- cross-spectrum(acc_bottom,hammer)–Input

- cross-spectrum(acc_top,acc_frame)–Input

- cross-spectrum(acc_bottom,acc_frame)–Input

2.3. Finite Element Method

2.4. Machine Learning Method

2.4.1. Extreme Gradient Boosting

2.4.2. Deep Neural Networks

2.4.3. Input and Output Data

3. Results

3.1. Experimental Analysis

3.2. Numerical Analysis

3.3. Machine Learning

3.3.1. Extreme Gradient Boosting

3.3.2. Neural Networks

4. Machine Learning in Non-Destructive Experiments of VIG Units

5. Conclusions and Future Research

- the experimental tests were properly performed;

- the created numerical model is extremely sensitive with respect to natural frequencies;

- the provided data are immensely corelated and ML models are not able to generalize themselves;

- the final results are not satisfactory.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Simko, T.M. Heat Transfer Processes and Stresses in Vacuum Glazing. Ph.D. Thesis, The University of Sydney, Sydney, Australia, 1996. [Google Scholar]

- Cho, S.; Kim, S.-H. Analysis of the Performance of Vacuum Glazing in Office Buildings in Korea: Simulation and Experimental Studies. Sustainability 2017, 9, 936. [Google Scholar] [CrossRef] [Green Version]

- Arya, F.; Hyde, T. Theoretical Study of Flexible Edge Seals for Vacuum Glazing. Int. J. Struct. Construct. Eng. 2017, 11, 1133–1137. [Google Scholar]

- Ashmore, N.; Cabrera, D.; Kocer, C. Acoustic Properties of Vacuum Insulating Glazing. In Proceedings of the Acoustics Hunter Valley, Sydney, Australia, 15–18 November 2015. [Google Scholar]

- Kowalczyk, I.; Kozanecki, D.; Krasoń, S.; Rabenda, M. Computational Modelling of VIG Plates Using FEM: Static and Dynamic Analysis. Materials 2022, 15, 1467. [Google Scholar] [CrossRef] [PubMed]

- Zoller, A. Hohle Glasscheibe. Deutsches Reich Patents Nr. 387655, 29 October 1913. [Google Scholar]

- Bao, M. Structural and Functional Integrity of Energy-Efficient Glazing Units. Ph.D. Thesis, The University of Birmingham, Birmingham, UK, 2014; p. 39. [Google Scholar]

- Zheng, W.; Li, R.; Liu, J. Study on stress and deformation of support pillar of vacuum flat glazing. In Proceedings of the 2011 Second International Conference on Mechanic Automation and Control Engineering, Inner Mongolia, China, 15–17 July 2011; pp. 2609–2612. [Google Scholar]

- McSporran, N. Properties and Performance of Vacuum Insulated Glazing. J. Green Build. 2014, 9, 60–74. [Google Scholar] [CrossRef]

- Vogel-Martin, M.M.; Wolk, M.B.; Free, M.B.; Benson, O.; Schwartz, E.L.; Kamrath, R.F.; Kolb, B.U.; Humpal, K.M.; Hendrickson, M.J. Vacuum Glazing Pillars for Insulated Glass Units. Application Number 14/025958. U.S. Patent Application 20150079313, 19 March 2015. [Google Scholar]

- Collins, R.; Simko, T. Current status of the science and technology of vacuum glazing. Sol. Energy 1998, 62, 189–213. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, H.; Wang, A.; Zhao, Y.; Li, Y. The Application and Development Trend of Vacuum Insulated Glass. The Glass Performance Days. 28 August 2020. Available online: https://www.glassonweb.com/article/application-and-development-trend-vacuum-insulated-glass (accessed on 13 June 2023).

- Oran, B.E. The Fast Fourier Transform and Its Applications; Prentice-Hall, Inc.: Upper Saddle River, NJ, USA, 1988. [Google Scholar]

- Zhu, W. Effects of Pillar and Sealing Design on thermal and Mechanical Performance of Vacuum Insulated Glazing. Master’s Thesis, University of Tennessee, Knoxville City, CO, USA, August 2021. [Google Scholar]

- Han, Z.M.; Bao, Y.W.; Wu, W.D.; Liu, Z.Q.; Liu, X.G.; Tian, Y. Evaluation of Thermal Performance for Vacuum Glazing by Using Three-Dimensional Finite Element Model. Key Eng. Mater. 2011, 492, 328–332. [Google Scholar] [CrossRef]

- Abaqus Version 6.6. Documentation, 3DS Dessault System. Available online: https://classes.engineering.wustl.edu/2009/spring/mase5513/abaqus/docs/v6.6/index.html (accessed on 1 December 2021).

- Quili Sun, E. Shear Locking and Hourglassing in MSC Nastran, Abaqus, and Ansys. In Proceedings of the Msc Software Users Meeting, January 2006. [Google Scholar]

- Eight-Node Brick Element with Reduced Integration (C3D8R and F3D8R). Available online: https://web.mit.edu/calculix_v2.7/CalculiX/ccx_2.7/doc/ccx/node27.html (accessed on 20 November 2021).

- Chen, T.; Guestrin, C. XGBoost: A Scalable Tree Boosting System. In Proceedings of the KDD ’16: 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; pp. 785–794. [Google Scholar] [CrossRef] [Green Version]

- Miller, B.; Ziemiański, L. Optimization of dynamic behavior of thin-walled laminated cylindrical shells by genetic algorithms and deep neural networks supported by modal shape identification. Adv. Eng. Softw. 2020, 147, 102830. [Google Scholar] [CrossRef]

- Mcculloch, W.S.; Pitts, W.H. A logical calculus of the ideas immanent in nervous activity. Bull. Math. Biophys. 1943, 5, 115–133. [Google Scholar] [CrossRef]

- Rosenblatt, F. The perceptron: A probabilistic model for information storage and organization in the brain. Psychol. Rev. 1958, 65, 386–408. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lefik, M. Zastosowanie Metod Numerycznych W Analizie Wybranych Zagadnień Geotechniki I Geotechniki Środowiskowej; Wydawnictwo Politechniki Łódzkiej: Łódź, Poland, 2021. [Google Scholar]

- Tadeusiewicz, R. Sieci Neuronowe; Akademicka Oficyna Wydawnicza: Warsaw, Poland, 1993; Volume II, p. 14. [Google Scholar]

- Werbos, P.; John, P. Beyond Regression: New Tools for Prediction and Analysis in the Behavioral Sciences. Ph.D. Thesis, Harvard University, Cambridge, MA, USA, January 1974. [Google Scholar]

| No. | Dimensions in Projection | Overall Thickness | Thickness of a Single Glass Pane | Number of Pillars along the Shorter Side | Number of Pillars along the Longer Side |

|---|---|---|---|---|---|

| [mm × mm] | [mm] | [mm] | [-] | [-] | |

| 1 | 400 × 800 | 10.3 | 4 | 8 | 10 |

| 2 | 500 × 600 | 8.3 | 4 | 8 | 10 |

| 3 | 500 × 600 | 10.3 | 5 | 6 | 14 |

| 4 | 1000 × 1000 | 8.3 | 4 | 17 | 17 |

| 5 | 1000 × 1000 | 10.3 | 5 | 17 | 17 |

| 6 | 1000 × 1000 | 12.3 | 6 | 17 | 17 |

| 7 | 1000 × 1500 | 12.3 | 6 | 26 | 17 |

| Plate Element | Material | Thickness | Height | Diameter | Spacing |

|---|---|---|---|---|---|

| [mm] | [mm] | [mm] | [mm] | ||

| Glass sheets | Tempered Glass: Poisson’s ratio: υg = 0.22 Density: ρg = 2500 kg/m3 Young’s modulus: Eg = 72 GPa | according to Table 1 | n.a. | n.a. | n.a. |

| Gas between the sheets of glass | Vacuum (0.1 Pa) | 0.3 | n.a. | n.a. | n.a. |

| Edge sealing | Steel Poisson’s ratio: υu = 0.31 Density: ρu = 7850 kg/m3 Young’s modulus: Eu = 200 GPa | n.a. | n.a. | n.a. | n.a. |

| Supporting pillars | Steel Poisson’s ratio: υs = 0.31 Density: ρs = 7850 kg/m3 Young’s modulus: Es = 200 GPa | n.a. | 0.3 | 0.6 | 55 |

| Combination No. | Accelerometer Location | Place of Application of Force |

|---|---|---|

| 1 | Location No. 1 | Location No. 1 on the opposite corner |

| 2 | Location No. 2 | Location No. 1 |

| 3 | Location No. 1 | Location No. 2 |

| 4 | Location No. 1 | Random |

| 5 | Location No. 2 | Random |

| Parameter | Unit | Dataset Name | Description |

|---|---|---|---|

| INPUT DATA | |||

| m | VIG dimension in X-direction | ||

| m | VIG dimension in Y-direction | ||

| mm | Thickness of a glass pane | ||

| - | Number of pillars in X-direction | ||

| - | Number of pillars in Y-direction | ||

| mm | Pillars’ offset from the VIG edge in X-direction | ||

| mm | Pillars’ offset from the VIG edge in Y-direction | ||

| Hz | First thirty natural frequencies obtained from the numerical analysis | ||

| OUTPUT DATA | |||

| Ep | GPa | Young’s modulus of pillars’ material | |

| Plate No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Mode No. | [Hz] | [Hz] | [Hz] | [Hz] | [Hz] | [Hz] | [Hz] |

| 1 | 16 | 19 | 15 | 11 | 11 | 10 | 5 |

| 2 | 20 | 21 | 17 | 11 | 11 | 10 | 10 |

| 3 | 26 | 26 | 24 | 13 | 15 | 12 | 14 |

| 4 | 40 | 40 | 39 | 14 | 17 | 17 | 18 |

| 5 | 45 | 50 | 49 | 24 | 24 | 25 | 24 |

| 6 | 55 | 54 | 50 | 24 | 24 | 25 | 27 |

| 7 | 95 | 115 | 136 | 39 | 52 | 58 | 47 |

| 8 | 126 | 123 | 140 | 51 | 64 | 63 | 57 |

| 9 | 195 | 163 | 190 | 64 | 74 | 79 | 68 |

| 10 | 230 | 214 | 255 | 81 | 95 | 104 | 73 |

| 11 | 275 | 235 | 279 | 81 | 95 | 104 | 78 |

| 12 | 326 | 262 | 305 | 114 | 120 | 141 | 90 |

| 13 | 340 | 339 | 410 | 114 | 120 | 141 | 110 |

| 14 | 343 | 345 | 420 | 124 | 144 | 165 | 120 |

| 15 | 436 | 354 | 428 | 128 | 149 | 179 | 129 |

| 16 | 475 | 415 | 506 | 150 | 160 | 184 | 146 |

| 17 | 483 | 440 | 533 | 168 | 195 | 244 | 156 |

| 18 | 589 | 504 | 611 | 177 | 204 | 247 | 160 |

| 19 | 594 | 517 | 625 | 177 | 204 | 247 | 174 |

| 20 | 635 | 563 | 685 | 188 | 225 | 260 | 194 |

| 21 | 674 | 586 | 724 | 209 | 254 | 279 | 205 |

| 22 | 680 | 648 | 789 | 209 | 254 | 279 | 225 |

| 23 | 759 | 673 | 815 | 234 | 285 | 336 | 227 |

| 24 | 766 | 689 | 831 | 247 | 291 | 345 | 245 |

| 25 | 858 | 694 | 842 | 250 | 303 | 356 | 247 |

| 26 | 889 | 775 | 849 | 268 | 320 | 364 | 259 |

| 27 | 903 | 803 | 991 | 268 | 320 | 364 | 265 |

| 28 | 956 | 870 | 1070 | 288 | 342 | 402 | 282 |

| 29 | 1051 | 902 | 1100 | 298 | 349 | 412 | 292 |

| 30 | 1090 | 913 | 1111 | 317 | 366 | 435 | 295 |

| Parameter | Unit | Assumed Values | Number of Combinations |

|---|---|---|---|

| m | 0.30; 0.60; 0.90; 1.20; 1.50 | 15 | |

| m | 0.30; 0.60; 0.90; 1.20; 1.50 | ||

| mm | 4.0; 5.0; 6.0 | 3 | |

| mm | 0.30 | 1 | |

| mm | 9.0 | 1 | |

| - | Depended on A and B: 0.30–5; 0.60–10; 0.90–15; 1.20–21; 1.50–21 | - | |

| - | Depended on A and B: 0.30–5; 0.60–10; 0.90–15; 1.20–21; 1.50–21 | ||

| mm | 0.6 | 1 | |

| mm | Depended on A and B: 0.30–40.0; 0.60–52.5; 0.90–65.0; 1.20–50.0; 1.50–62.5 | - | |

| mm | Depended on A and B: 0.30–40.0; 0.60–52.5; 0.90–65.0; 1.20–50.0; 1.50–62.5 | ||

| kg/m3 | 2500.0 | 1 | |

| GPa | 72.0 | 1 | |

| - | 0.22 | 1 | |

| kg/m3 | 7850.0 | 1 | |

| - | 0.31 | 1 | |

| kg/m3 | 7850.0 | 1 | |

| GPa | 210.0 | 1 | |

| - | 0.31 | 1 | |

| Ep | GPa | 160.0; 170.0; 180.0; 190.0; 200.0; 210.0; 220.0 | 7 |

| Total number of combinations | 315 | ||

| Parameter | Range of Values | Final Value |

|---|---|---|

| Number of estimators (decision trees) | 500, 1000, 1500, 2000, 2500 | 2500 |

| Gamma factor | 0.0, 0.1, 0.2 | 0.0 |

| Learning rate | 0.01, 0.1, 0.2, 0.23, 0.26, 0.29, 0.32, 0.35 | 0.2 |

| Maximum depth of a single tree | 3, 5, 10, 20, 30 | 10 |

| Grow policy | Depthwise, Lossguide | Depthwise |

| Colsample by tree | 0.3, 0.6, 1.0 | 0.6 |

| Subsample | 0.3, 0.6, 1.0 | 0.6 |

| Data Set | RMSE [GPa] |

|---|---|

| Train data set | 0.0005 |

| Test data set | 7.6107 |

| Parameter | Range of Values | Final Value |

|---|---|---|

| Number of hidden layers | 5, 10, 20, 30, 50 | 5 |

| Size of a hidden layer | 5, 10, 25, 50, 100 | 100 |

| Learning rate | 0.1, 0.05, 0.01, 0.005, 0.001 | 0.1 |

| Activation function | ReLU, Linear, SELU | SELU |

| Droput Probability | 0.1, 0.2, 0.3 | 0.0 |

| Batchnorm usage | True, False | True |

| Weight decay | 0.1, 0.01, 0.001, 0.0001 | 0.01 |

| Batch size | 32, 64, 128 | 128 |

| Number of epochs | 250, 500, 750, 1000 | 500 |

| Data Set | RMSE [GPa] |

|---|---|

| Train data set | 20.4017 |

| Test data set | 18.6143 |

| No. | XGB Predictive Model [GPa] | DNN Predictive Model [GPa] | Expected Value [GPa] | XGB Relative Error [%] | DNN Relative Error [%] |

|---|---|---|---|---|---|

| 1 | 208.65 | 193.52 | 200.00 | 4.33 | 3.35 |

| 2 | 196.55 | 186.55 | 200.00 | 1.76 | 7.21 |

| 3 | 212.32 | 192.91 | 200.00 | 6.16 | 3.68 |

| 4 | 188.02 | 189.54 | 200.00 | 6.37 | 5.52 |

| 5 | 182.54 | 192.88 | 200.00 | 9.57 | 3.69 |

| 6 | 171.83 | 189.73 | 200.00 | 16.39 | 5.41 |

| 7 | 185.71 | 189.80 | 200.00 | 7.69 | 5.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozanecki, D.; Kowalczyk, I.; Krasoń, S.; Rabenda, M.; Domagalski, Ł.; Wirowski, A. The Machine Learning Methods in Non-Destructive Testing of Dynamic Properties of Vacuum Insulated Glazing Type Composite Panels. Materials 2023, 16, 5055. https://doi.org/10.3390/ma16145055

Kozanecki D, Kowalczyk I, Krasoń S, Rabenda M, Domagalski Ł, Wirowski A. The Machine Learning Methods in Non-Destructive Testing of Dynamic Properties of Vacuum Insulated Glazing Type Composite Panels. Materials. 2023; 16(14):5055. https://doi.org/10.3390/ma16145055

Chicago/Turabian StyleKozanecki, Damian, Izabela Kowalczyk, Sylwia Krasoń, Martyna Rabenda, Łukasz Domagalski, and Artur Wirowski. 2023. "The Machine Learning Methods in Non-Destructive Testing of Dynamic Properties of Vacuum Insulated Glazing Type Composite Panels" Materials 16, no. 14: 5055. https://doi.org/10.3390/ma16145055