Effect of Nb on the Damping Property and Pseudoelasticity of a Porous Ni-Ti Shape Memory Alloy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of Porous Ni-Ti SMAs

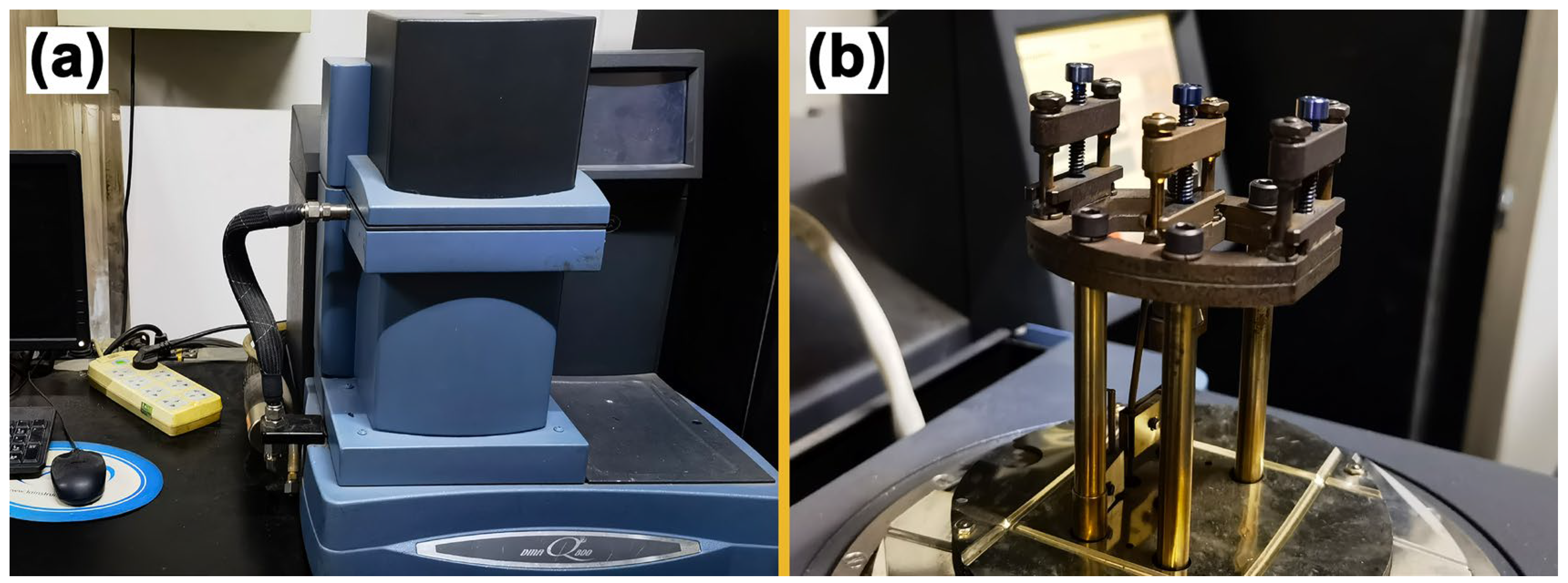

2.2. Characterization of Specimens

2.3. Property Tests

3. Results and Discussion

3.1. Phase Composition and Microstructures of Specimens

3.2. Effect of Nb on the Damping Property

3.3. Effect of Nb on the PE Property

4. Conclusions

- Porous Ni-Ti SMAs with different Nb contents were fabricated. The pores were uniformly distributed in the Ni-Ti matrix and connected with each other, forming a three-dimensional network. The addition of Nb can effectively reduce the numbers of micro pores and precipitates in the Ni-Ti matrix.

- With the increase in Nb content, the IF peak of the porous Ni-Ti SMAs arising from the reverse MT gradually shifts towards the low temperature side. This can be attributed to the hindering effect of Nb on the precipitation of Ni-rich phases as well as the replacement of Nb atoms on Ti atoms.

- With the increase in Nb content, both the damping and the PE of the porous Ni-Ti SMAs increase first and then decrease. The Nb9 specimen has the highest damping and the best PE. The improvement in damping can be ascribed to the formation of mobile interfaces around β-Nb phase, whereas the improvement in PE is related to the formation of twinned martensites and the strengthening of the NiTi matrix. In addition, the decrease in the content of low damping Ni-rich phases without PE is also conductive to the improvements in damping and PE. The decrease in damping and PE is caused by the decrease in the NiTi content.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Stanley, J.; Kumar, S.A.; Ariraman, M.; Mandhakini, M. Role of amines in microstructure tuning for synergistic damping and mechanical properties in epoxy resins. Prog. Org. Coat. 2021, 150, 105896. [Google Scholar] [CrossRef]

- Poddaeva, O.; Fedosova, A. Damping capacity of materials and its effect on the dynamic behavior of structures. Review. Energy Rep. 2021, 7, 299–307. [Google Scholar] [CrossRef]

- Yi, X.Y.; Huang, B.W.; Gao, W.H.; Sun, B.; Feng, X.X.; Cao, X.J.; Guo, Y.L.; Meng, X.L.; Gao, Z.Y.; Wang, H.Z. Damping behaviors and strain recovery characteristics of Hf-modified TiNb-based shape memory alloys. Mater. Res. Bull. 2023, 158, 112084. [Google Scholar] [CrossRef]

- He, Y.J.; Yin, H.; Zhou, R.H.; Sun, Q.P. Ambient effect on damping peak of NiTi shape memory alloy. Mater. Lett. 2010, 64, 1483–1486. [Google Scholar] [CrossRef]

- Nair, V.S.; Nachimuthu, R. The role of NiTi shape memory alloys in quality of life improvement through medical advancements: A comprehensive review. J. Eng. Med. 2022, 236, 923–950. [Google Scholar] [CrossRef]

- Safavi, M.S.; Bordbar-Khiabani, A.; Walsh, F.C.; Mozafari, M.; Khalil-Allafi, J. Surface modified NiTi smart biomaterials: Surface engineering and biological compatibility. Curr. Opin. Biomed. Eng. 2023, 25, 100429. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti-Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Kohl, M.; Bram, M.; Moser, A.; Buchkremer, H.P.; Beck, T.; Stover, D. Characterization of porous, net-shaped NiTi alloy regarding its damping and energy absorbing capacity. Mater. Sci. Eng. A 2011, 528, 2454–2462. [Google Scholar] [CrossRef]

- Zhang, X.X.; Hou, H.W.; Wei, L.S.; Chen, Z.X.; Wei, W.T.; Geng, L. High damping capacity in porous NiTi alloy with bimodal pore architecture. J. Alloys Compd. 2013, 550, 297–301. [Google Scholar] [CrossRef]

- Villa, F.; Nespoli, A.; Passaretti, F.; Villa, E. Microstructural and Thermo-Mechanical Characterization of Cast NiTiCu20 Shape Memory Alloy. Materials 2021, 14, 3770. [Google Scholar] [CrossRef]

- Shuitcev, A.; Li, L.; Markova, G.V.; Golovin, I.S.; Tong, Y.X. Internal friction in Ti29.7Ni50.3Hf20 alloy with high temperature shape memory effect. Mater. Lett. 2020, 262, 127025. [Google Scholar] [CrossRef]

- Cai, W.; Lu, X.L.; Zhao, L.C. Damping behavior of TiNi-based shape memory alloys. Mater. Sci. Eng. A 2005, 394, 78–82. [Google Scholar] [CrossRef]

- Bao, Z.Z.; Guo, S.; Xiao, F.; Zhao, X.Q. Development of NiTiNb in-situ composite with high damping capacity and high yield strength. Prog. Nat. Sci. 2011, 21, 293–300. [Google Scholar] [CrossRef] [Green Version]

- Pant, D.C.; Pal, S. Phase transformation and energy dissipation of porous shape memory alloy structure under blast loading. Mech. Mater. 2019, 132, 31–46. [Google Scholar] [CrossRef]

- Guo, X.; Dong, X.J.; Yu, Z.L.; Zhang, Z.H.; Xie, X.Y.; Wang, X.B.; Xin, R.L.; Yan, W. Study on the mechanical properties of bionic protection and self-recovery structures. Materials 2020, 13, 389. [Google Scholar] [CrossRef] [Green Version]

- Zheng, H.X.; Mentz, J.; Brarn, M.; Buchkremer, H.P.; Stover, D. Powder metallurgical production of TiNiNb and TiNiCu shape memory alloys by combination of pre-alloyed and elemental powders. J. Alloys Compd. 2008, 463, 250–256. [Google Scholar] [CrossRef]

- Li, B.; Zhang, F.; Zheng, L.; Zhang, H. The role of Sc on the microstructures and mechanical properties of the Ni-rich NiTi alloy. Mater. Today Commun. 2022, 31, 103556. [Google Scholar] [CrossRef]

- Oezerim, G.; Anlas, G.; Moumni, Z. The effect of heat treatment on pseudoelastic behavior of spark plasma sintered NiTi. Mater. Today Commun. 2022, 31, 11. [Google Scholar] [CrossRef]

- Sun, B.; Fu, M.W.; Lin, J.P.; Ning, Y.Q. Effect of low temperature aging treatment on thermally and stress induced phase transformations of nanocrystalline and coarse grained NiTi wires. Mater. Des. 2017, 131, 49–59. [Google Scholar] [CrossRef]

- Cao, L.T.; Fu, Q.X.; Si, Y.; Ding, B.; Yu, J.Y. Porous materials for sound absorption. Compos. Commun. 2018, 10, 25–35. [Google Scholar] [CrossRef]

- Guo, W.; Kato, H. Submicron-porous NiTi and NiTiNb shape memory alloys with high damping capacity fabricated by a new top-down process. Mater. Des. 2015, 78, 74–79. [Google Scholar] [CrossRef]

- Fan, Q.C.; Sun, M.Y.; Zhang, Y.H.; Wang, Y.Y.; Zhang, Y.; Peng, H.B.; Sun, K.H.; Fan, X.H.; Huang, S.K.; Wen, Y.H. Influence of precipitation on phase transformation and mechanical properties of Ni-rich NiTiNb alloys. Mater. Charact. 2019, 154, 148–160. [Google Scholar] [CrossRef]

- Fan, G.; Zhou, Y.; Chen, W.; Yang, S.; Ren, X.; Otsuka, K. Precipitation kinetics of Ti3Ni4 in polycrystalline Ni-rich TiNi alloys and its relation to abnormal multi-stage transformation behavior. Mater. Sci. Eng. A 2006, 438, 622–626. [Google Scholar] [CrossRef]

- Fan, Q.C.; Zhang, Y.H.; Wang, Y.Y.; Sun, M.Y.; Meng, Y.T.; Huang, S.K.; Wen, Y.H. Influences of transformation behavior and precipitates on the deformation behavior of Ni-rich NiTi alloys. Mater. Sci. Eng. A 2017, 700, 269–280. [Google Scholar] [CrossRef]

- Chen, Y.; Jiang, H.C.; Rong, L.J.; Xiao, L.; Zhao, X.Q. Mechanical behavior in NiTiNb shape memory alloys with low Nb content. Intermetallics 2011, 19, 217–220. [Google Scholar] [CrossRef]

- Wang, L.Q.; Wang, C.; Dunand, D.C. Microstructure and strength of NiTi-Nb eutectic braze joining NiTi wires. Met. Mater. Trans. A 2015, 46A, 1433–1436. [Google Scholar] [CrossRef]

- Wang, X.B.; Verlinden, B.; Van Humbeeck, J. R-phase transformation in NiTi alloys. Mater. Sci. Technol. 2014, 30, 1517–1529. [Google Scholar] [CrossRef]

- Zeng, J.M.; Jiang, H.C.; Liu, S.W.; Rong, L.J. Damping behavior of Ti50.1Ni49.9 alloy in reverse martensitic transformation region. Sci. China Technol. Sci. 2012, 55, 470–474. [Google Scholar] [CrossRef]

- Shi, H.; Frenzel, J.; Martinez, G.T.; Van Rompaey, S.; Bakulin, A.; Kulkova, S.; Van Aert, S.; Schryvers, D. Site occupation of Nb atoms in ternary Ni-Ti-Nb shape memory alloys. Acta Mater. 2014, 74, 85–95. [Google Scholar] [CrossRef]

- Uchida, K.; Shigenaka, N.; Sakuma, T.; Sutou, Y.; Yamauchi, K. Effect of Nb content on martensitic transformation temperatures and mechanical properties of Ti-Ni-Nb shape memory alloys for pipe joint applications. Mater. Trans. 2007, 48, 445–450. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.Q.; Xie, L.C.; Zhang, L.C.; Chen, L.Y.; Ding, Z.H.; Lv, Y.T.; Zhang, W.; Lu, W.J.; Zhang, D. Microstructure evolution and superelasticity of layer-like NiTiNb porous metal prepared by eutectic reaction. Acta Mater. 2018, 143, 214–226. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, P.; Wang, Q.; Feng, J.; Ji, P.; Zhang, J.; Yin, F. Effect of Nb on the Damping Property and Pseudoelasticity of a Porous Ni-Ti Shape Memory Alloy. Materials 2023, 16, 5057. https://doi.org/10.3390/ma16145057

Sun P, Wang Q, Feng J, Ji P, Zhang J, Yin F. Effect of Nb on the Damping Property and Pseudoelasticity of a Porous Ni-Ti Shape Memory Alloy. Materials. 2023; 16(14):5057. https://doi.org/10.3390/ma16145057

Chicago/Turabian StyleSun, Peng, Qingzhou Wang, Jianhang Feng, Puguang Ji, Jianjun Zhang, and Fuxing Yin. 2023. "Effect of Nb on the Damping Property and Pseudoelasticity of a Porous Ni-Ti Shape Memory Alloy" Materials 16, no. 14: 5057. https://doi.org/10.3390/ma16145057

APA StyleSun, P., Wang, Q., Feng, J., Ji, P., Zhang, J., & Yin, F. (2023). Effect of Nb on the Damping Property and Pseudoelasticity of a Porous Ni-Ti Shape Memory Alloy. Materials, 16(14), 5057. https://doi.org/10.3390/ma16145057