Effect of a Multiaxial Load of Reverse Torsion on Open-Cell Aluminum Foams Behavior

Abstract

1. Introduction

2. Materials and Testing Procedure

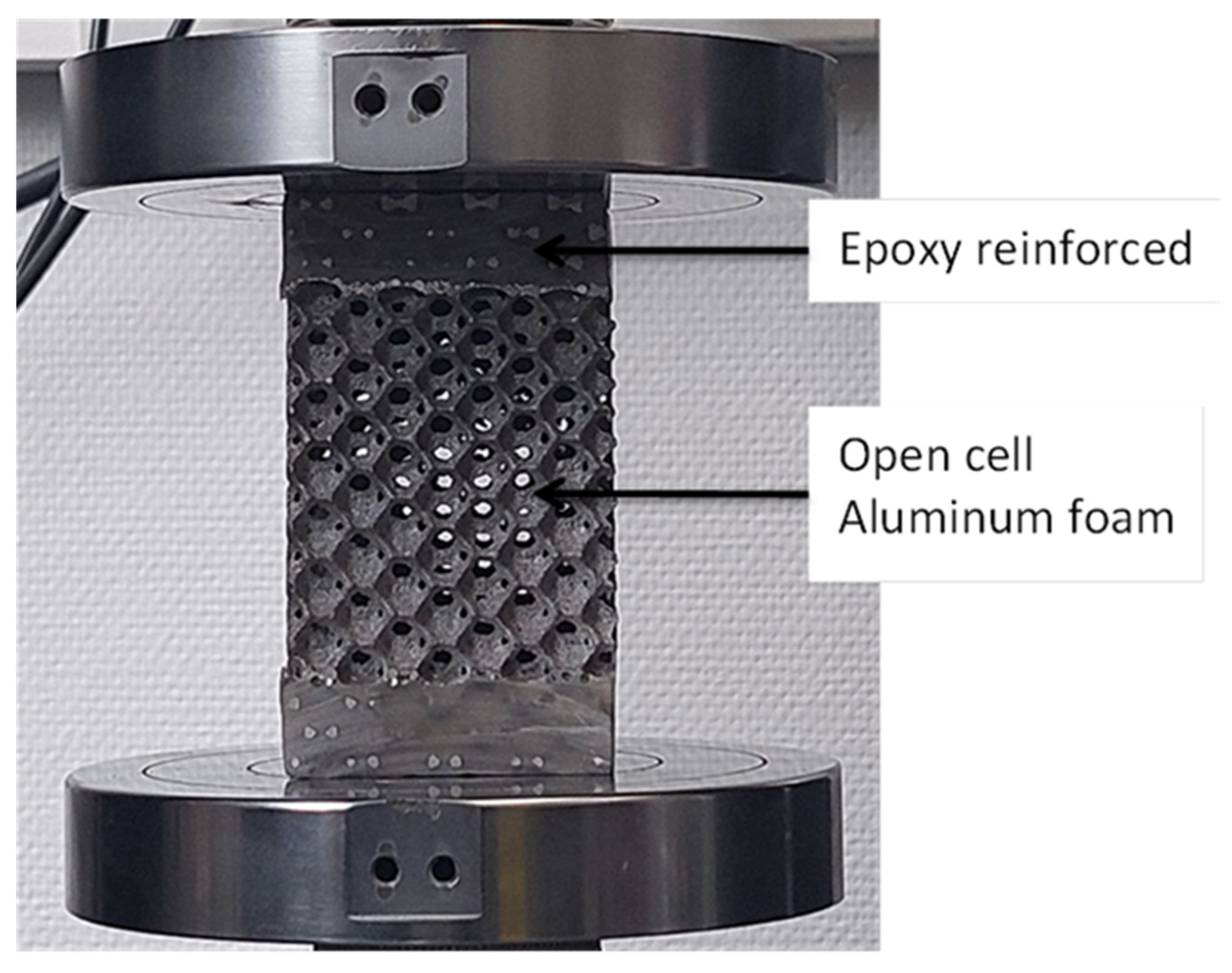

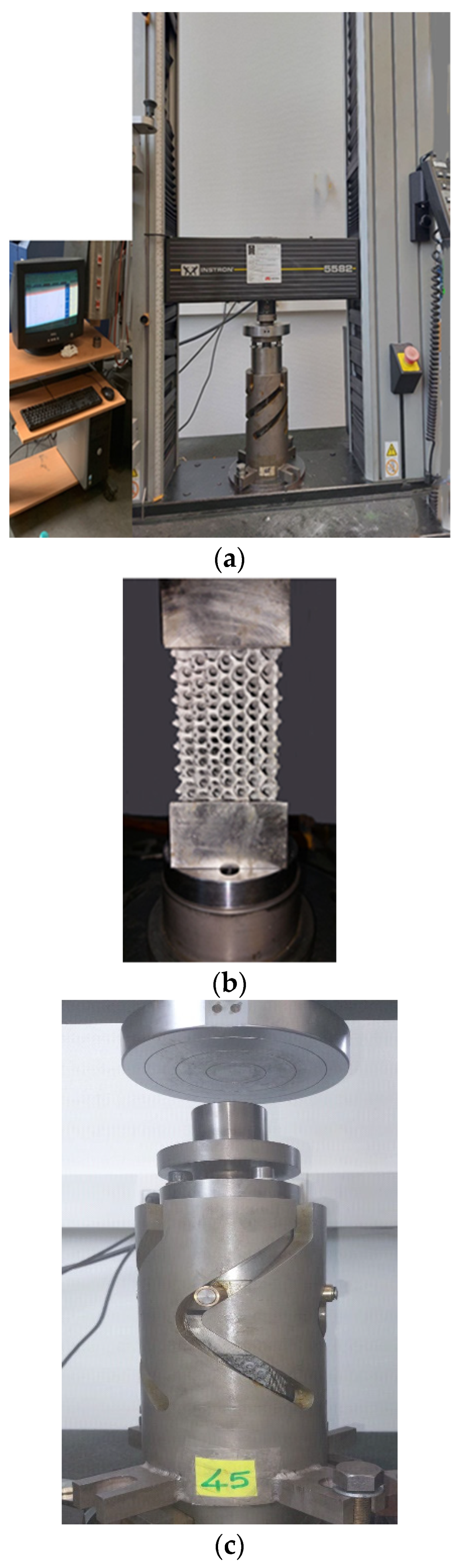

2.1. Uniaxial Tests

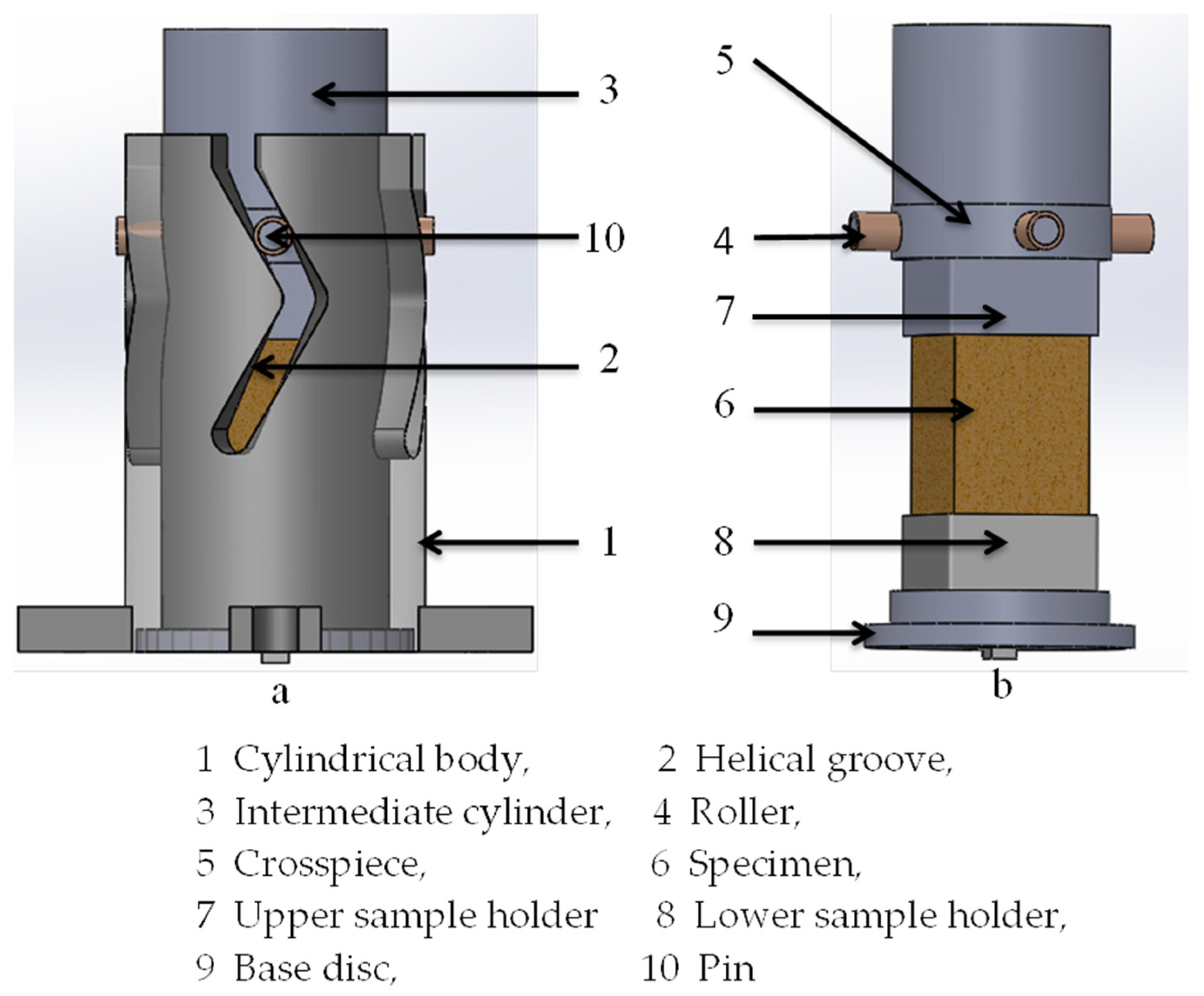

2.2. Combined Compression-Torsion Tests

3. Results: Mechanical Properties

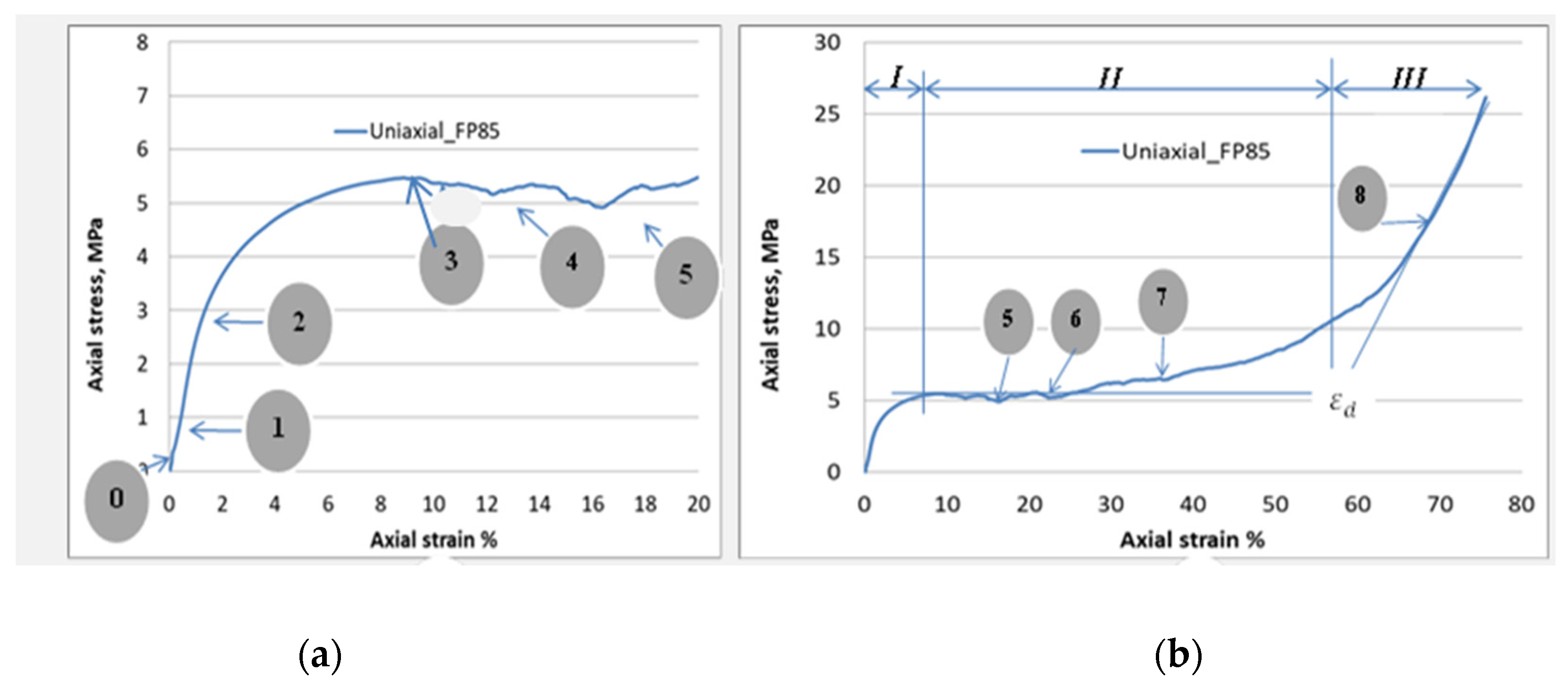

3.1. Uniaxial Plastic Flow

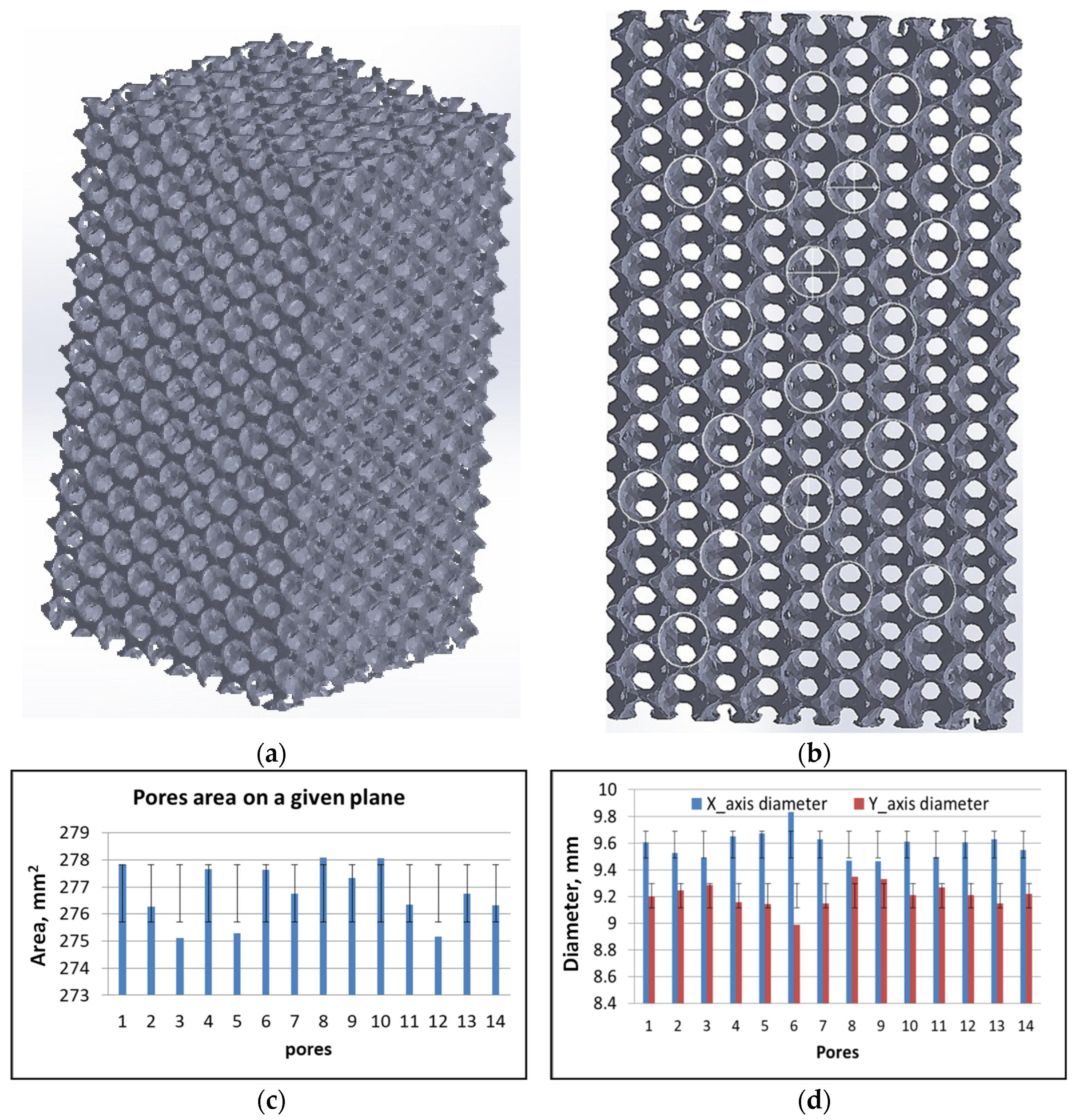

3.2. Cell Morphology and Pore Size Distribution

3.3. Uniaxial Compression

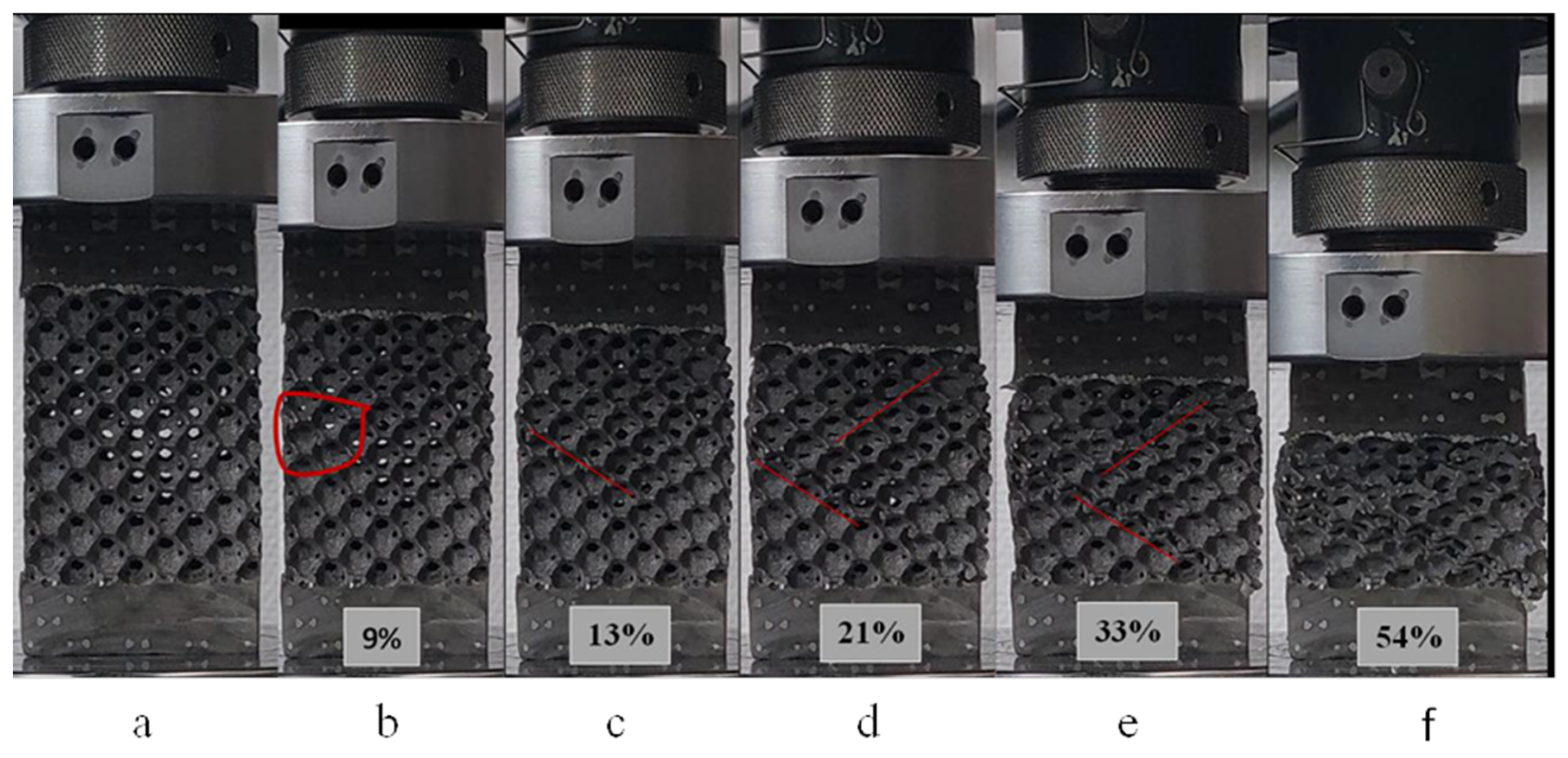

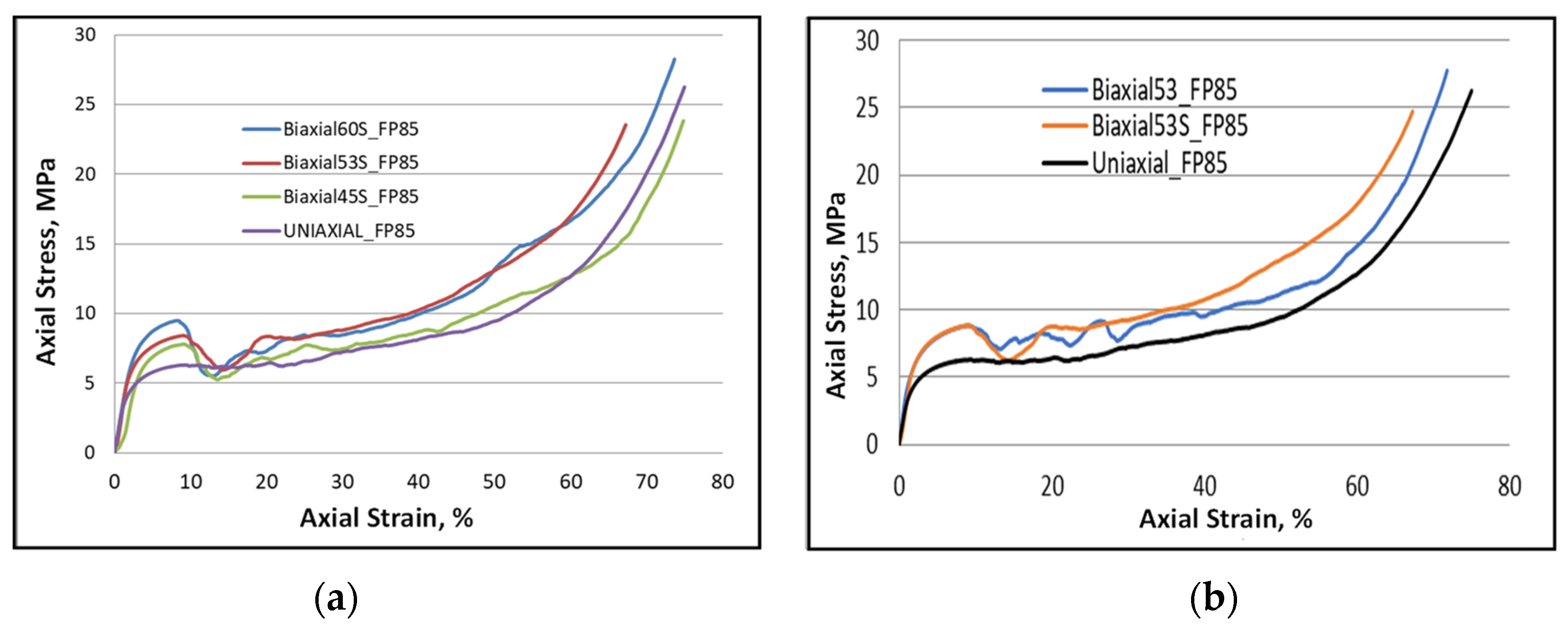

3.4. Biaxial Loading Configurations

- (i)

- The maximum shear stress generated by the ACTP rig corresponds to the maximum torsion rate given by these two loading configurations.

- (ii)

- Additional strain hardening can be developed due to the change in twist direction, i.e., from forward to reverse. Indeed, Figure 8b shows the effect of the shear component (forward and reverse) after a value of strain of 20% where the hardening continues increasing up to the end of the load. This could be due to the dislocation multiplication within the microstructure of the employed metal generated by such a load. Such an interpretation could be based on the additional hardening induced by the biaxial cyclic loading, in particular when one of the cyclic loadings applied is a shear component [33,34]. This requires further investigation.

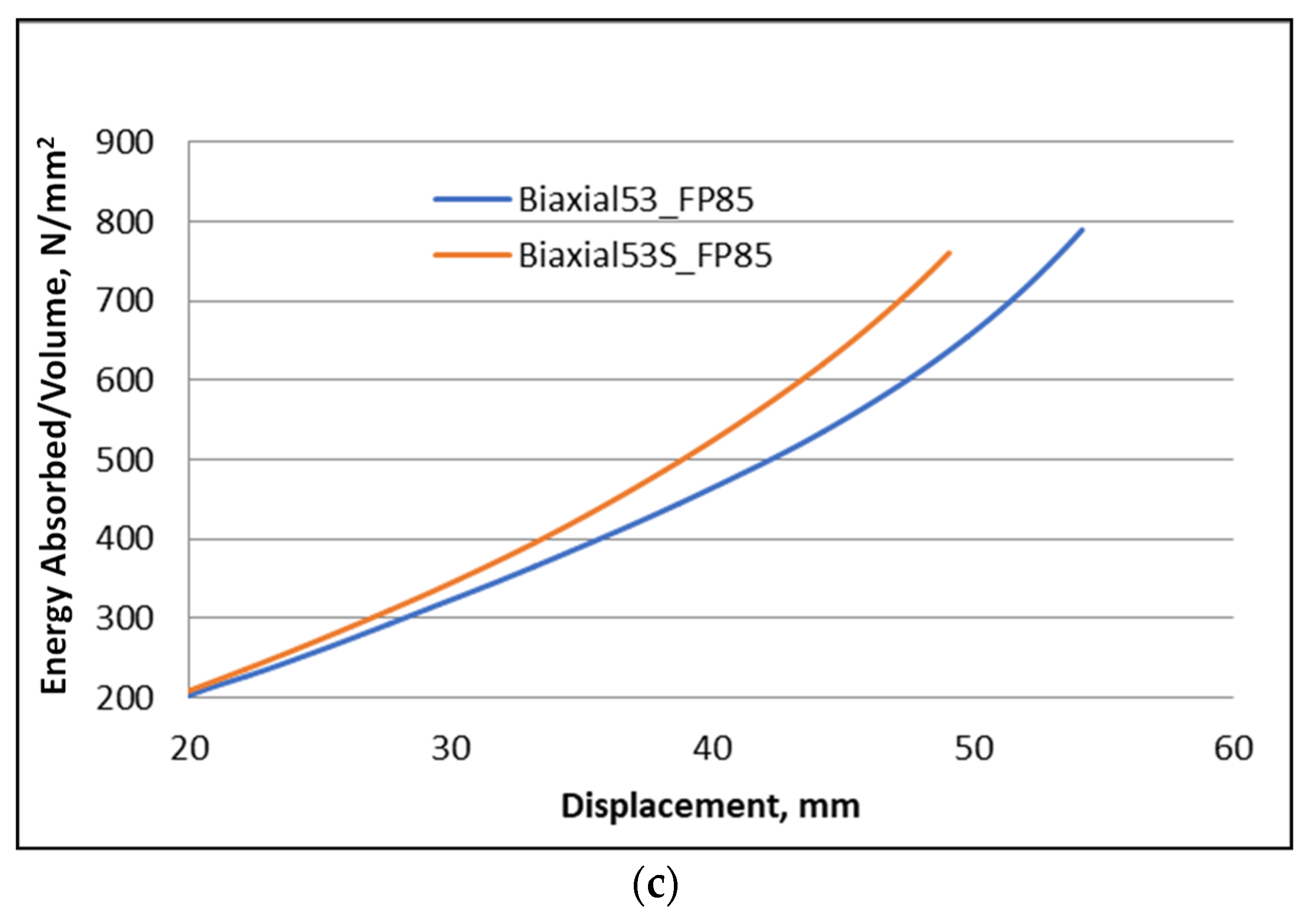

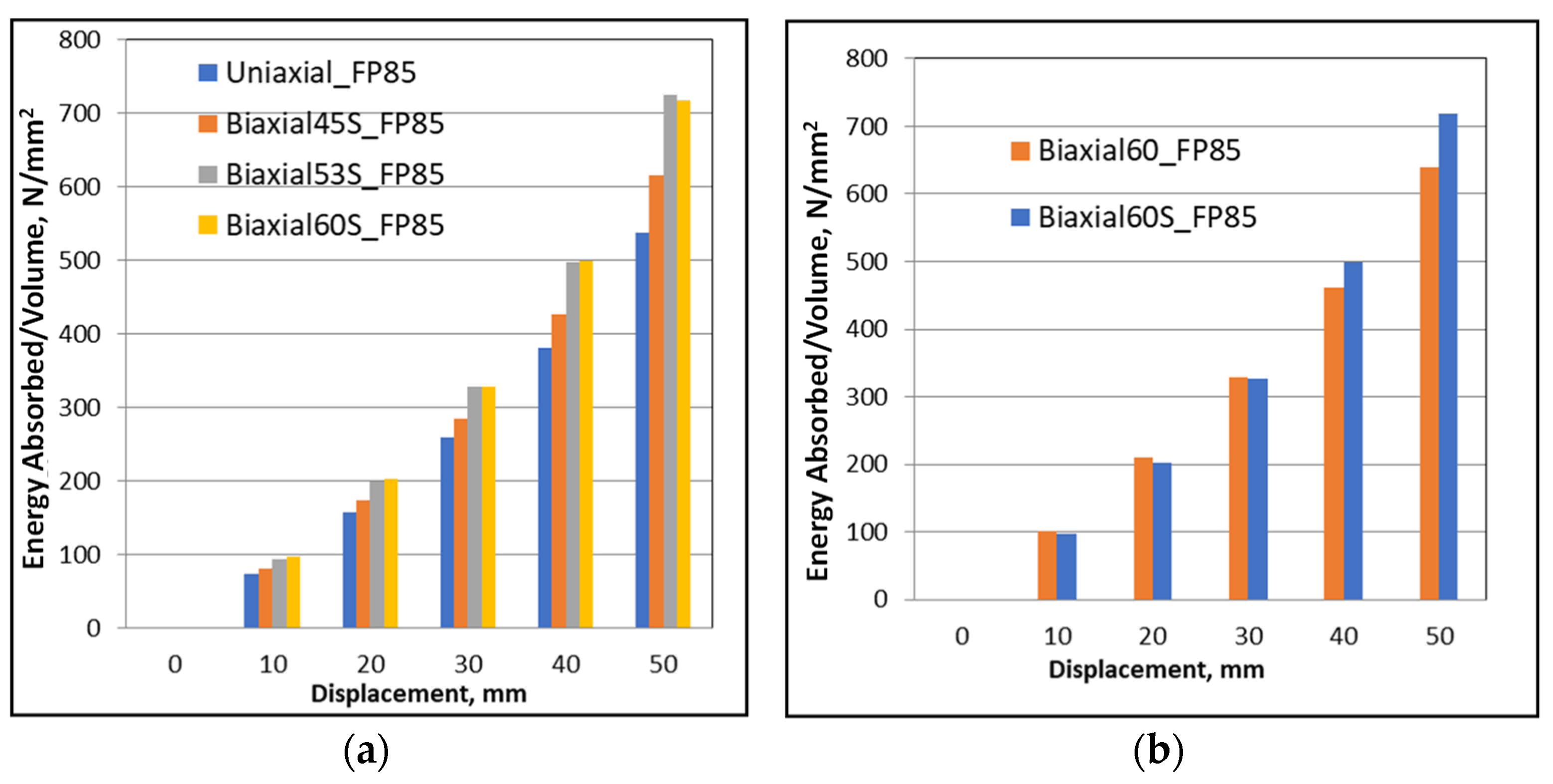

3.5. Energy Disspatation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gibson, L.J. Mechanical behavior of metallic foams. Annu. Rev. Mater. Sci. 2000, 30, 191–227. [Google Scholar] [CrossRef]

- Inoue, A.; Kimura, H. High-strength aluminum alloys containing nanoquasicrystalline particles. Mater. Sci. Eng. 2000, 286, 1–10. [Google Scholar] [CrossRef]

- Luna, E.; Abuserwal, A.F.; Luna, E.M.E.; Goodall, R. Accepted Version Article: The Effective Thermal Conductivity of Open Cell Replicated Aluminium Metal Sponges Department of Mechanical Engineering. Int. J. Heat Mass Transf. 2017, 108, 1439–1448. [Google Scholar]

- Han, F.; Seiffert, G.; Zhao, Y.; Gibbs, B. Acoustic absorption behaviour of an open-celled aluminum foam. J. Phys. D Appl. Phys. 2003, 36, 294–302. [Google Scholar] [CrossRef]

- Badiche, X.; Forest, S.; Guibert, T.; Bienvenu, Y.; Bartout, J.; Ienny, P. Mechanical properties and non-homogeneous deformation of open-cell nickel foams: Application of the mechanics of cellular solids and of porous materials. Mater. Sci. Eng. 2000, A289, 276–288. [Google Scholar] [CrossRef]

- Xu, F.; Zhang, X.; Zhang, H. A review on functionally graded structures and materials for energy absorption. Eng. Struct. 2018, 171, 309–325. [Google Scholar] [CrossRef]

- Gibson, L.G.; Ashby, M. Cellular Solids. Structure and Properties, 2nd ed.; Press Syndicate of the University of Cambridge: Cambridge, UK, 1997. [Google Scholar] [CrossRef]

- San Marchi, C.; Despois, J.F.; Mortensen, A. Uniaxial deformation of open-cell aluminum foam: The role of internal damage. Acta Mater. 2004, 52, 2895–2902. [Google Scholar] [CrossRef]

- Fiedler, T.; Öchsner, A.; Grácio, J. The uniaxial strain test—A simple method for the characterization of porous materials. Struct. Eng. Mech. 2006, 22, 17–32. [Google Scholar] [CrossRef]

- Kriszt, B.; Foroughi, B.; Faure, K.; Degischer, H.P. Behaviour of aluminum foam under uniaxial compression. Mater. Sci. Technol. 2000, 16, 792–796. [Google Scholar] [CrossRef]

- Triantafillou, T.C.; Gibson, L.J. Multiaxial Failure Criteria for Cellular Materials. MRS Online Proc. Libr. 1990, 207, 9–14. [Google Scholar] [CrossRef]

- Sridhar, I.; Fleck, N.A. The multiaxial yield behaviour of an aluminum. J. Mater. Sci. 2005, 40, 4005–4008. [Google Scholar] [CrossRef]

- Gioux, G.; Mccormack, T.M.; Gibson, L.J. Failure of aluminum foams under multiaxial loads. Int. J. Mech. Sci. 2000, 42, 1097–1117. [Google Scholar] [CrossRef]

- Luo, G.; Xue, P.; Sun, S. Investigations on the yield behavior of metal foam under multiaxial loadings by an imaged-based mesoscopic model. Int. J. Mech. Sci. 2018, 142–143, 153–162. [Google Scholar] [CrossRef]

- Doyoyo, M.; Wierzbicki, T. Experimental studies on the yield behavior of ductile and brittle aluminum foams. Int. J. Plasticity 2003, 19, 1195–1214. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, Z.; Zhao, L.; Shu, X. Composites: Part B Uniaxial and biaxial failure behaviors of aluminum alloy foams. Compos. Part B 2014, 61, 340–349. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, Z.; Zhao, L.; Shu, X. Loading rate effect on yield surface of aluminum alloy foams. Mater. Sci. Eng. A 2012, 543, 193–199. [Google Scholar] [CrossRef]

- Zhou, Z.; Su, B.; Wang, Z.; Shu, X.; Zhao, L. Impact Response of Aluminium Alloy Foams Under Complex Stress States. Lat. Am. J. Solids Struct. 2016, 13, 665–689. [Google Scholar] [CrossRef]

- Arcan, M.; Hashin, Z.; Voloshin, A. A method to produce uniform plane-stress states with applications to fiber-reinforced materials—A specially designed specimen yields material properties under pure shear or uniform plane-stress conditions. Exp. Mech. 1978, 18, 141–146. [Google Scholar] [CrossRef]

- Kossa, A. A new biaxial compression fixture for polymeric foams. Polym. Test. 2015, 45, 47–51. [Google Scholar] [CrossRef]

- Mosleh, Y.; Vanden Bosche, K.; Depreitere, B.; Vander Sloten, J.; Verpoest, I.; Ivens, J. Effect of polymer foam anisotropy on energy absorption during combined shear-compression loading. J. Cell. Plast. 2018, 54, 597–613. [Google Scholar] [CrossRef]

- Li, Z.; Li, X.; Zheng, Y. Biaxial mechanical behavior of closed-cell aluminum foam under combined shear-compression loading. Trans. Nonferrous Met. Soc. China 2020, 30, 41–50. [Google Scholar] [CrossRef]

- Zhou, Z.; Su, B.; Wang, Z.; Li, Z.; Shu, X.; Zhao, L. Shear-compression failure behavior of PMMA at different loading rates. Mater. Lett. 2013, 109, 151–153. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Fleck, N.A. Multi-axial yield behaviour of polymer foams. Acta Mater. 2001, 49, 1859–1866. [Google Scholar] [CrossRef]

- Ruan, D.; Lu, G.; Chen, F.L.; Siores, E. Compressive behaviour of aluminum foams at low and medium strain rates. Compos. Struct. 2002, 57, 331–336. [Google Scholar] [CrossRef]

- Combaz, E.; Bacciarini, C.; Charvet, R.; Dufour, W.; Dauphin, F.; Mortensen, A. Yield surface of polyurethane and aluminum replicated foam. Acta Mater. 2010, 58, 5168–5183. [Google Scholar] [CrossRef]

- Wang, E.; Sun, G.; Zheng, G.; Li, Q. Characterization of initial and subsequent yield behaviors of closed-cell aluminum foams under multiaxial loadings. Compos. Part B Eng. 2020, 202, 108247. [Google Scholar] [CrossRef]

- Abdul–Latif, A.; Menouer, A.; Baleh, R.; Deiab, I.M. Plastic response of open cell aluminum foams of highly uniform architecture under different quasi-static combined biaxial compression-torsion loading paths. Mater. Sci. Eng. B 2021, 266, 115051. [Google Scholar] [CrossRef]

- Abdul-Latif, A.; Baleh, R. Shock-Absorbing Device Comprising a Plastically-Deformable Member, Which Is Intended, for Example, for Transport Vehicles. Patent WO2005090822A1, 29 September 2005. [Google Scholar]

- Abdul-Latif, A.; Baleh, R. Dynamic Biaxial Plastic Buckling of circular shells. J. Appl. Mech. Trans. ASME 2008, 75, 0310131. [Google Scholar] [CrossRef]

- Baleh, R.; Abdul-Latif, A. Quasi-static biaxial plastic buckling of tubular structures used as an energy absorber. J. Appl. Mech. Trans. ASME 2007, 74, 628–635. [Google Scholar] [CrossRef]

- Huluka, S.; Abdul-Latif, A.; Baleh, R.; Larbi, A.; Deiab, I.; Khanafer, K. Biaxial characterization of open-cell aluminum foams from macro to micro responses. Mater. Sci. Eng. A 2023, 868, 144588. [Google Scholar] [CrossRef]

- Ferney, V. Etude de l’Ecrouissage Cyclique sous Sollicitations Complexes. Ph.D. Thesis, Université de Technologie de Compiègne, Compiègne, France, 1994. [Google Scholar]

- Abdul-Latif, A.; Clavel, M.; Ferney, V.; Saanouni, K. On the Modeling of Nonproportional Cyclic Plasticity of Waspaloy. J. Eng. Mater. Technol. 1994, 116, 35–44. [Google Scholar] [CrossRef]

| Elements | %Si | %Fe | %Cu | %Mn | %Mg | %Ni | %Zn | %Ti |

|---|---|---|---|---|---|---|---|---|

| AS7G06 | 6.7–7.3 | <0.14 | <0.04 | <0.09 | 0.5–0.6 | <0.04 | <0.09 | 0.08–0.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huluka, S.B.; Baleh, R.; Alsaleh, N.A.; Alfozan, A.; Abdul-Latif, A.; Ataya, S. Effect of a Multiaxial Load of Reverse Torsion on Open-Cell Aluminum Foams Behavior. Materials 2023, 16, 5136. https://doi.org/10.3390/ma16145136

Huluka SB, Baleh R, Alsaleh NA, Alfozan A, Abdul-Latif A, Ataya S. Effect of a Multiaxial Load of Reverse Torsion on Open-Cell Aluminum Foams Behavior. Materials. 2023; 16(14):5136. https://doi.org/10.3390/ma16145136

Chicago/Turabian StyleHuluka, Solomon Bayu, Rachid Baleh, Naser A. Alsaleh, Adel Alfozan, Akrum Abdul-Latif, and Sabbah Ataya. 2023. "Effect of a Multiaxial Load of Reverse Torsion on Open-Cell Aluminum Foams Behavior" Materials 16, no. 14: 5136. https://doi.org/10.3390/ma16145136

APA StyleHuluka, S. B., Baleh, R., Alsaleh, N. A., Alfozan, A., Abdul-Latif, A., & Ataya, S. (2023). Effect of a Multiaxial Load of Reverse Torsion on Open-Cell Aluminum Foams Behavior. Materials, 16(14), 5136. https://doi.org/10.3390/ma16145136