Microstructure and Mechanical Properties of Al-Si Alloys Produced by Rapid Solidification and Hot Extrusion

Abstract

:1. Introduction

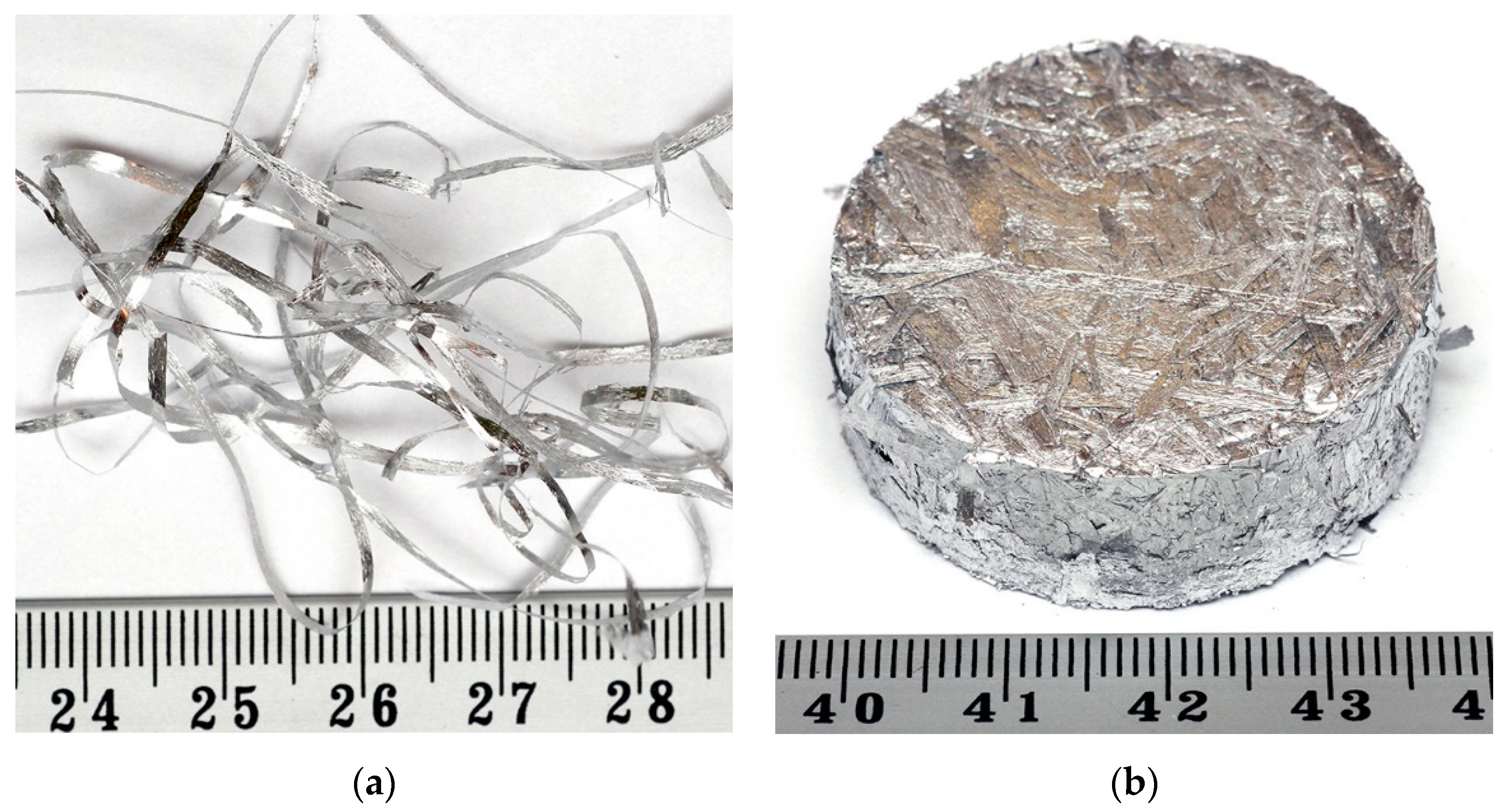

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Meyers, M.A.; Mishra, A.; Benson, D.D. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Edelstein, A.S.; Murday, J.S.; Rath, B.B. Challenges in nanomaterials design. Prog. Mater. Sci. 1997, 42, 5–21. [Google Scholar] [CrossRef]

- Lu, K. Nanocrystalline metals crystallized from amorphous solids: Nanocrystallization, structure, and properties. Mater. Sci. Eng. R Rep. 1996, 16, 161–221. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Froes, F.H. Production of nanostructure titanium-based alloys by mechanical alloying. Nanostruct. Mater. 1992, 1, 191–196. [Google Scholar] [CrossRef]

- Inoue, A. Amorphous, nanoquasicrystalline and nanocrystalline alloys in Al-based systems. Prog. Mater. Sci. 1998, 43, 365–520. [Google Scholar] [CrossRef]

- Boylan, K.; Ostrander, D.; Erb, U.; Palumbo, G.; Aust, K.T. An in-situ tem study of the thermal stability of nanocrystalline Ni-P. Scr. Metall. Mater. 1991, 25, 2711–2716. [Google Scholar] [CrossRef]

- Palumbo, G.; Erb, U.; Aust, K.T. Triple line disclination effects on the mechanical behaviour of materials. Scr. Metall. Mater. 1990, 24, 2347–2350. [Google Scholar] [CrossRef]

- Wloch, G.; Skrzekut, T.; Sobota, J.; Woźnicki, A.; Cisoń, J. The structure and mechanical properties of plastically consolidated Al-Ni alloy. Key Eng. Mater. 2016, 682, 245–251. [Google Scholar] [CrossRef]

- Noga, P.; Piotrowicz, A.; Skrzekut, T.; Zwoliński, A.; Strzępek, P. Effect of various forms of aluminum 6082 on the mechanical properties, microstructure and surface modification of the profile after extrusion process. Materials 2021, 14, 5066. [Google Scholar] [CrossRef]

- Skrzekut, T.; Kula, A.; Blaz, L. Effect of annealing temperature on the structure of mechanically alloyed Al-AgO composite. In Proceedings of the METAL 2015—24th International Conference on Metallurgy and Materials, Conference Proceedings, Brno, Czech Republic, 3–5 June 2015; pp. 1639–1643. [Google Scholar]

- Tong, H.Y.; Wang, J.T.; Ding, B.Z.; Jiang, H.G.; Lu, K. The structure and properties of nanocrystalline Fe78B13Si9 alloy. J. Non-Cryst. Solids 1992, 150, 444–447. [Google Scholar] [CrossRef]

- Sanders, P.G.; Youngdahl, C.J.; Weertman, J.R. The strength of nanocrystalline metals with and without flaws. Mater. Sci. Eng. A 1997, 234–236, 77–82. [Google Scholar] [CrossRef]

- Jaworska, L.; Skrzekut, T.; Stepień, M.; Pałka, P.; Boczkal, G.; Zwoliński, A.; Noga, P.; Podsiadło, M.; Wnuk, R.; Ostachowski, P. The Pressure Compaction of Zr-Nb Powder Mixtures and Selected Properties of Sintered and KOBO-Extruded Zr-xNb Materials. Materials 2021, 14, 3172. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Ni, S.; Liao, X.; Song, M.; Zhu, Y. Structural evolutions of metallic materials processed by severe plastic deformation. Mater. Sci. Eng. R Rep. 2018, 133, 1–59. [Google Scholar] [CrossRef]

- Zhang, Y. Inhomogeneous deformation in metallic glasses. Mater. Sci. Technol. 2008, 24, 379–391. [Google Scholar] [CrossRef]

- Inoue, A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 2000, 48, 279–306. [Google Scholar] [CrossRef]

- Blaz, L.; Sugamata, M.; Wloch, G.; Sobota, J.; Kula, A. Structure and consolidation od rapidly solidified Meso10 alloy flakes. J. Alloys Compd. 2010, 506, 179–187. [Google Scholar] [CrossRef]

- Zygmunt-Kiper, M.; Blaz, L.; Sugamata, M. Effect of magnesium addition and rapid solidification procedure on structure and mechanical properties of Al-Co alloy. Arch. Metall. Mater. 2013, 58, 397–406. [Google Scholar] [CrossRef] [Green Version]

- Salamci, E.; Cochrane, R.F. Microstructure and mechanical properties of spray deposited and extruded 7000 series aluminium alloys. Mater. Sci. Technol. 2003, 19, 1130–1136. [Google Scholar] [CrossRef]

- Trivedi, R.; Jin, F.; Anderson, I.E. Dynamical evolution of microstructure in finely atomized droplets of Al-Si alloys. Acta Mater. 2003, 51, 289–300. [Google Scholar] [CrossRef]

- Paulin, I.; Donik, C.; Cvahte, P.; Godec, M. Bimodal Microstructure Obtained by Rapid Solidification to Improve the Mechanical and Corrosion Properties of Aluminum Alloys at Elevated Temperature. Metals 2021, 11, 230. [Google Scholar] [CrossRef]

- Jung, S.; Park, Y.; Lee, Y. A Novel Approach to Investigate the Superheating Grain Refinement Process of Aluminum-Bearing Magnesium Alloys Using Rapid Solidification Process. Materials 2023, 16, 4799. [Google Scholar] [CrossRef] [PubMed]

- Shen, G.; Xiang, Z.; Ma, X.; Huang, J.; Zhao, Y.; Li, J.; Wang, Z.; Shi, G.; Chen, Z. Investigation of Microstructures and Mechanical Properties of Ultra-High Strength Al-Zn-Mg-Cu Alloy Prepared by Rapid Solidification and Hot Extrusion. Metals 2023, 13, 293. [Google Scholar] [CrossRef]

- Chaieb, O.; Olufayo, O.A.; Songmene, V.; Jahazi, M. Investigation on Surface Quality of a Rapidly Solidified Al–50%Si Alloy Component for Deep-Space Applications. Materials 2022, 13, 3412. [Google Scholar] [CrossRef] [PubMed]

- Okugawa, M.; Furushiro, Y.; Koizumi, Y. Effect of Rapid Heating and Cooling Conditions on Microstructure Formation in Powder Bed Fusion of Al-Si Hypoeutectic Alloy: A Phase-Field Study. Materials 2022, 15, 6092. [Google Scholar] [CrossRef] [PubMed]

- Peng, Q.; Yang, B.; Milkereit, B.; Liu, D.; Spronger, A.; Rettenmayr, M.; Schick, C.; Keßler, O. Nucleation Behavior of a Single Al-20Si Particle Rapidly Solidified in a Fast Scanning Calorimeter. Materials 2021, 14, 2920. [Google Scholar] [CrossRef]

- Haghshenas, M.; Jamali, J. Assessment of circumferential cracks in hypereutectic Al-Si clutch housings. Case Stud. Eng. Fail. Anal. 2017, 8, 11–20. [Google Scholar] [CrossRef]

- Ye, H. An Overview of the Development of Al-Si-Alloy Based Material for Engine Applications. J. Mater. Eng. Perform. 2003, 12, 288–297. [Google Scholar] [CrossRef]

- PN-EN ISO 6892-1:2020-05; Metals—Tensile Test—Room Temperature Test Method. Polish Committee for Standardization: Warsaw, Poland, 2020.

- Rajabi, M.; Vahidi, M.; Simchi, A.; Davami, P. Effect of rapid solidification on the microstructure and mechanical properties of hot-pressed Al–20Si–5Fe alloys. Mater. Charact. 2009, 60, 1370–1381. [Google Scholar] [CrossRef]

- Ernst, F. Metal-oxide interfaces. Mater. Sci. Eng. R Rep. 1995, 14, 97–156. [Google Scholar] [CrossRef]

- Saito, T.; Shoji, E.; Kubo, M.; Tsukada, T.; Kikugawa, G.; Surblys, D. Evaluation of the work of adhesion at the interface between a surface-modified metal oxide and an organic solvent using molecular dynamics simulations. J. Chem. Phys. 2021, 154, 114703. [Google Scholar] [CrossRef]

- Gerland, S.; Raatz, A. Adhesive Bonding of an Aluminum Alloy with and without an Oxide Layer in Atmospheres with Different Oxygen Contents. Appl. Sci. 2022, 13, 547. [Google Scholar] [CrossRef]

- Prudnikov, A.N. Production, Structure, and Properties of Engine Pistons Made from Transeutectic Deformable Silumin. Steel Transl. 2009, 39, 391–393. [Google Scholar] [CrossRef]

- Trepczyńska-Łent, M.; Muller, K. Use of the Precipitation Hardening to Improve the Properties of Combustion Engine Pistons Made of Eutectic Silumins. Arch. Foundry Eng. 2021, 21, 77–81. [Google Scholar] [CrossRef]

- Piątkowski, J.; Wieszała, R. Influence, of modifications on fatigue of AlSi17CuMg(Fe) alloys used for pistons for internal combustion engines. Arch. Metall. Mater. 2018, 63, 135–141. [Google Scholar] [CrossRef]

- Dybiec, H.; Kozak, P. Mechanical Properties of Aluminium Wires Produced by Plastic Consolidation of Fine Grained Powders. Solid State Phenom. 2005, 101–102, 131–134. [Google Scholar] [CrossRef]

- Sugamata, M.; Kanego, J.; Fuji, H.; Kubota, M. Effect of Mg addition on the structures and mechanical properties of rapidly solidified Al-transmision metal alloys. Mater. Sci. Forum 2000, 331–337, 1157–1162. [Google Scholar] [CrossRef]

- Salleh, M.S.; Omar, M.Z.; Syarif, J. The effects of Mg addition on the microstructure and mechanical properties of thixoformed Al–5%Si–Cu alloys. J. Alloys Compd. 2015, 621, 121–130. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Parson, N.C.; Poole, W.J. Precipitation on grain boundaries in Al-Mg-Si alloys: The role of grain boundary misorientation. Scr. Mater. 2022, 211, 114494. [Google Scholar] [CrossRef]

- Koju, R.K.; Mishin, Y. Atomistic study of grain-boundary segregation and grain-boundary diffusion in Al-Mg alloys. Acta Mater. 2020, 201, 596–603. [Google Scholar] [CrossRef]

- Hirsch, J.; Al-Samman, T. Superior light metals by texture engineering: Optimized aluminum and magnesium alloys for automotive applications. Acta Mater. 2013, 61, 818–843. [Google Scholar] [CrossRef]

| Element | Al | Si | Fe | Cu | Mg | Mn | Other |

|---|---|---|---|---|---|---|---|

| AlSi5 | 94.28 | 5.23 | 0.17 | 0.03 | 0.07 | 0.02 | 0.20 |

| AlSi11 | 88.26 | 11.41 | 0.16 | 0.01 | 0.02 | 0.03 | 0.13 |

| AlSi20 | 79.37 | 20.21 | 0.17 | 0.02 | 0.04 | 0.03 | 0.16 |

| AlSi5 | Mg-K | Al-K | Si-K | Mn-K | Fe-K | Cu-K |

|---|---|---|---|---|---|---|

| 1 | 0.00 | 97.00 | 2.99 | 0.00 | 0.10 | 0.00 |

| 2 | 0.00 | 8.96 | 91.04 | 0.00 | 0.00 | 0.00 |

| 3 | 0.00 | 55.32 | 28.60 | 0.16 | 15.92 | 0.00 |

| AlSi11 | Mg-K | Al-K | Si-K | Mn-K | Fe-K | Cu-K |

|---|---|---|---|---|---|---|

| 1 | 0.00 | 97.89 | 2.01 | 0.00 | 0.10 | 0.00 |

| 2 | 0.00 | 7.86 | 92.14 | 0.00 | 0.00 | 0.00 |

| 3 | 0.00 | 54.32 | 29.80 | 1.16 | 14.72 | 0.00 |

| AlSi20 | Mg-K | Al-K | Si-K | Mn-K | Fe-K | Cu-K |

|---|---|---|---|---|---|---|

| 1 | 0.00 | 97.91 | 1.99 | 0.00 | 0.10 | 0.00 |

| 2 | 0.00 | 8.76 | 91.24 | 0.00 | 0.00 | 0.00 |

| 3 | 0.00 | 56.32 | 28.70 | 0.16 | 14.82 | 0.00 |

| Average Grain Diameter | Standard Deviation | |

|---|---|---|

| AlSi5 | 5.90 | 0.73 |

| AlSi5 RS | 1.38 | 0.15 |

| AlSi11 | 6.16 | 0.64 |

| AlSi11 RS | 1.67 | 0.22 |

| AlSi20 | 9.87 | 1.37 |

| AlSi20 RS | 3.78 | 0.16 |

| Element | UTS, MPa | YS, MPa | Elongation, % | Hardness, HV2 | Density, g/cm3 |

|---|---|---|---|---|---|

| AlSi5 | 131 | 81 | 17.1 | 35 | 2.67 |

| AlSi5 RS | 155 | 108 | 15.2 | 48 | 2.67 |

| AlSi11 | 162 | 90 | 11.1 | 45 | 2.64 |

| AlSi11 RS | 203 | 132 | 12.6 | 64 | 2.64 |

| AlSi20 | 148 | 94 | 4.1 | 50 | 2.56 |

| AlSi20 RS | 276 | 168 | 6.2 | 86 | 2.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Noga, P.; Skrzekut, T.; Wędrychowicz, M. Microstructure and Mechanical Properties of Al-Si Alloys Produced by Rapid Solidification and Hot Extrusion. Materials 2023, 16, 5223. https://doi.org/10.3390/ma16155223

Noga P, Skrzekut T, Wędrychowicz M. Microstructure and Mechanical Properties of Al-Si Alloys Produced by Rapid Solidification and Hot Extrusion. Materials. 2023; 16(15):5223. https://doi.org/10.3390/ma16155223

Chicago/Turabian StyleNoga, Piotr, Tomasz Skrzekut, and Maciej Wędrychowicz. 2023. "Microstructure and Mechanical Properties of Al-Si Alloys Produced by Rapid Solidification and Hot Extrusion" Materials 16, no. 15: 5223. https://doi.org/10.3390/ma16155223

APA StyleNoga, P., Skrzekut, T., & Wędrychowicz, M. (2023). Microstructure and Mechanical Properties of Al-Si Alloys Produced by Rapid Solidification and Hot Extrusion. Materials, 16(15), 5223. https://doi.org/10.3390/ma16155223