Influence of Potassium-Based Activation on Adsorptive Properties of Carbon Spheres Modified with Iron(III) Citrate

Abstract

1. Introduction

2. Experimental Part

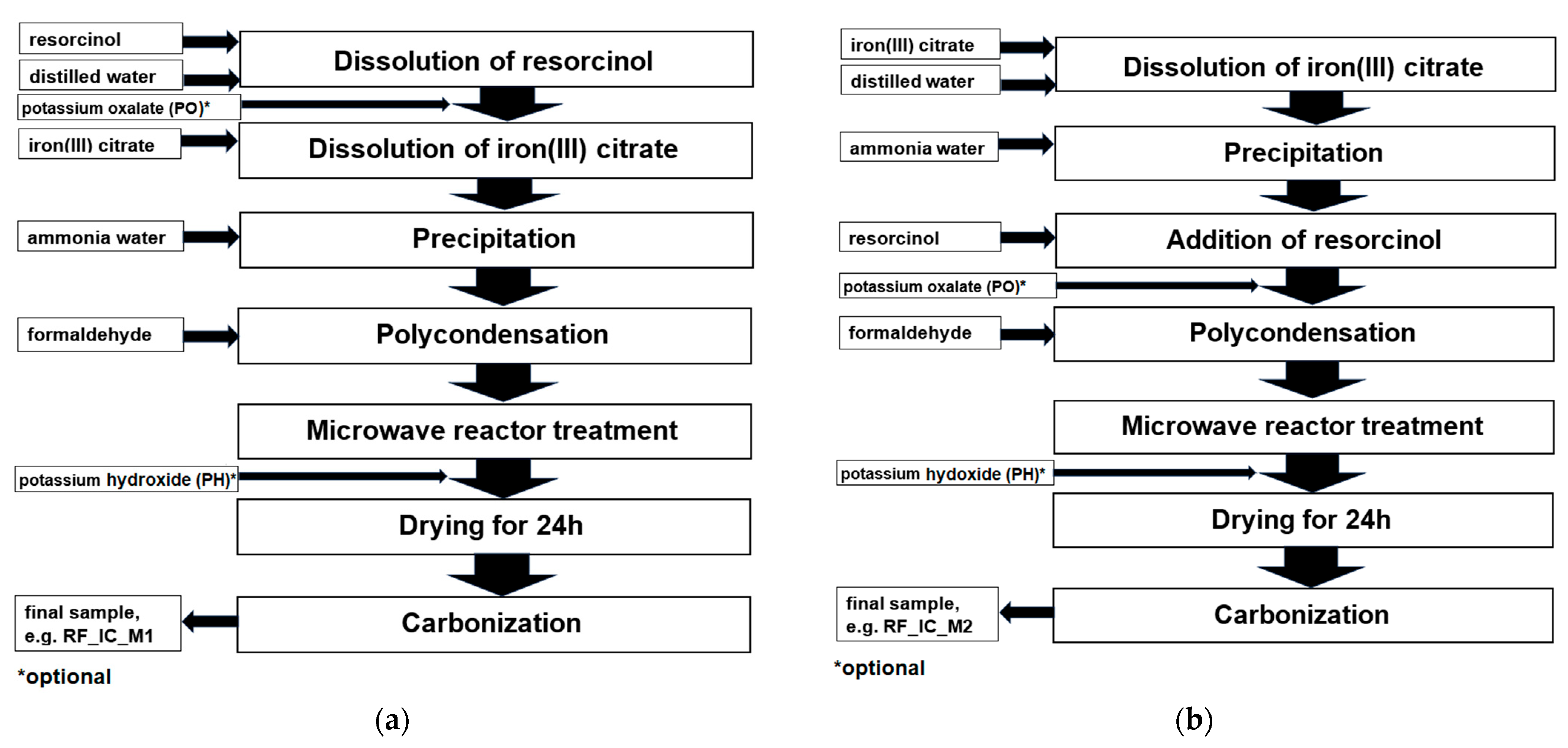

2.1. Materials Preparation

2.2. Material Characterization

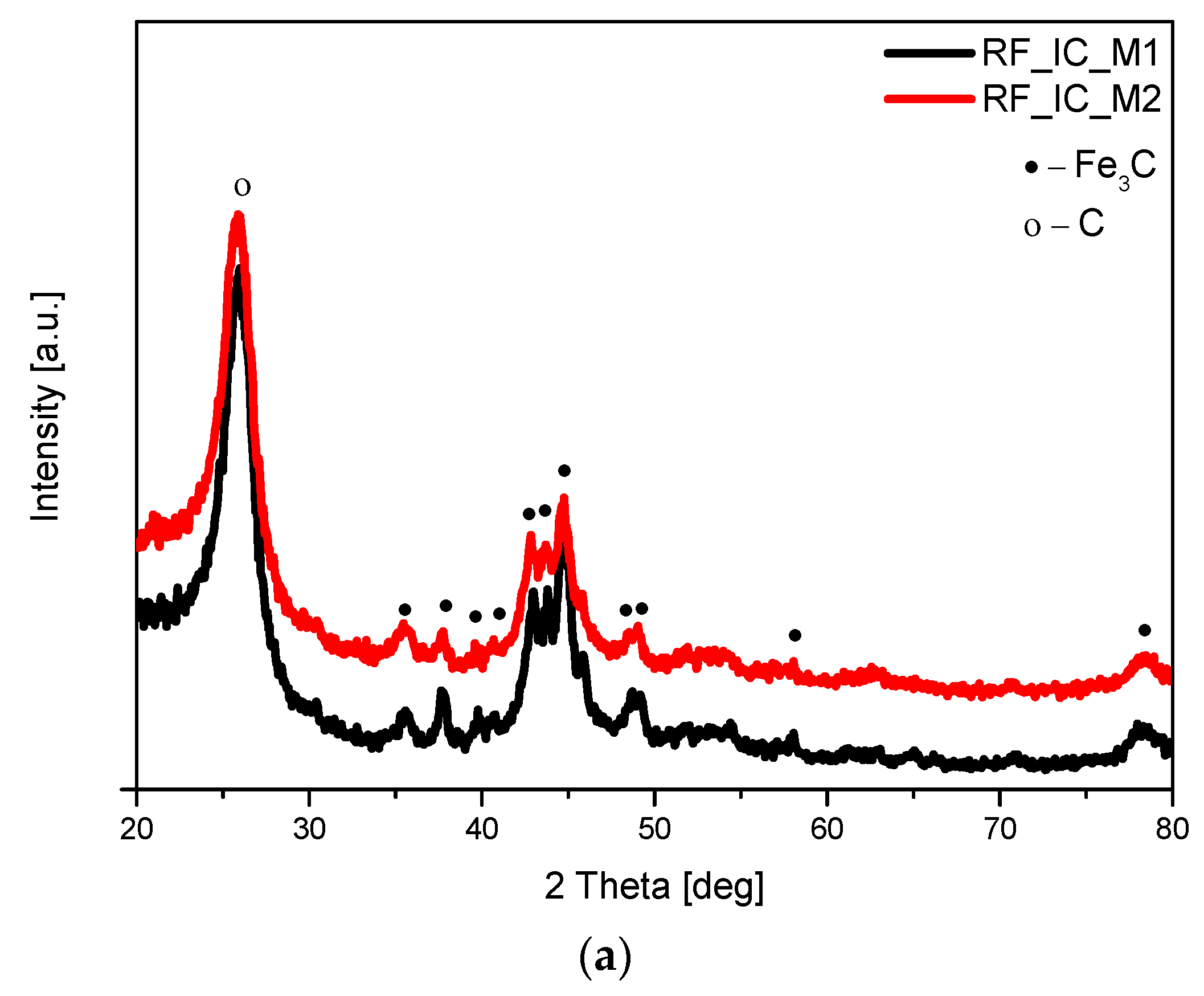

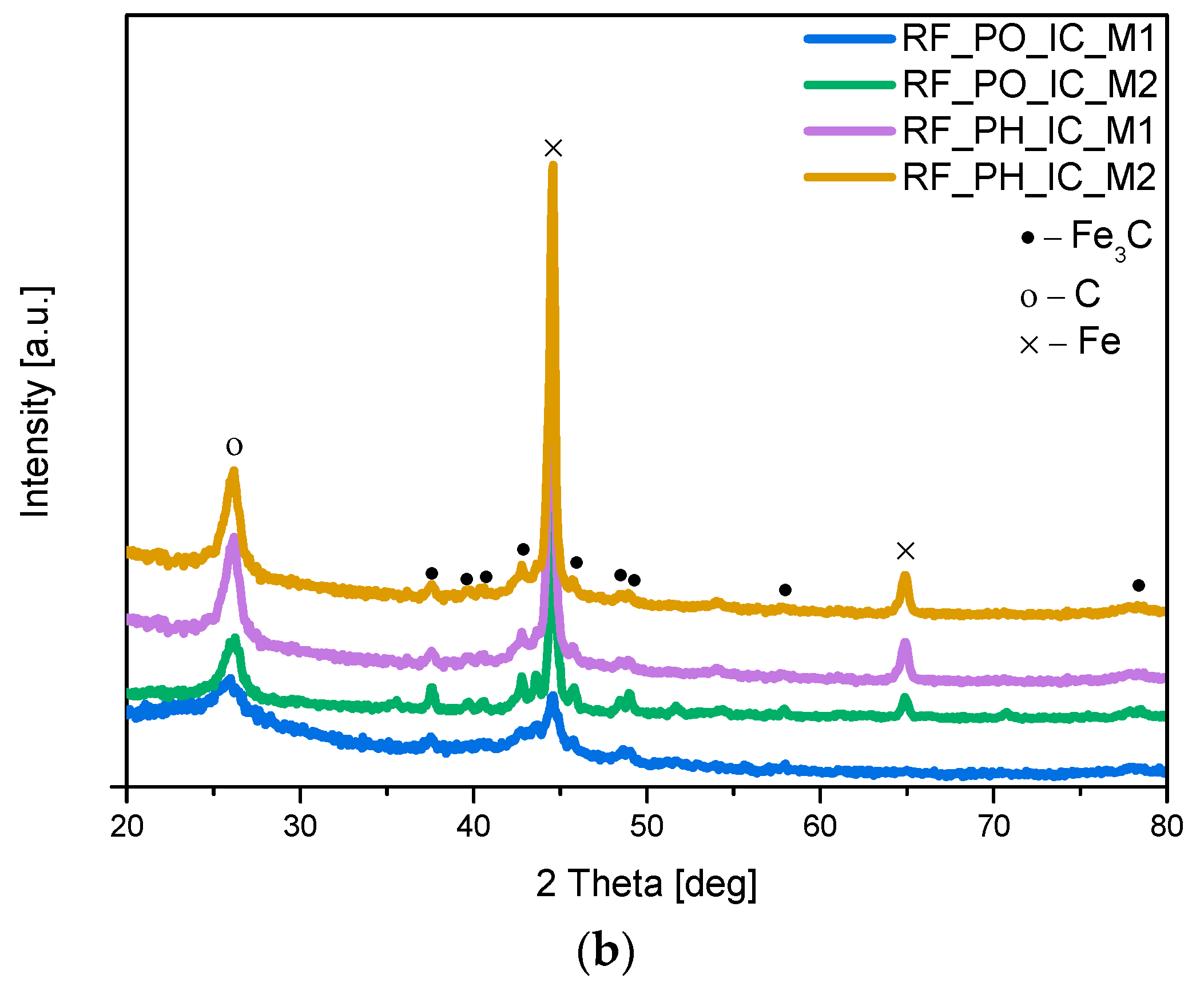

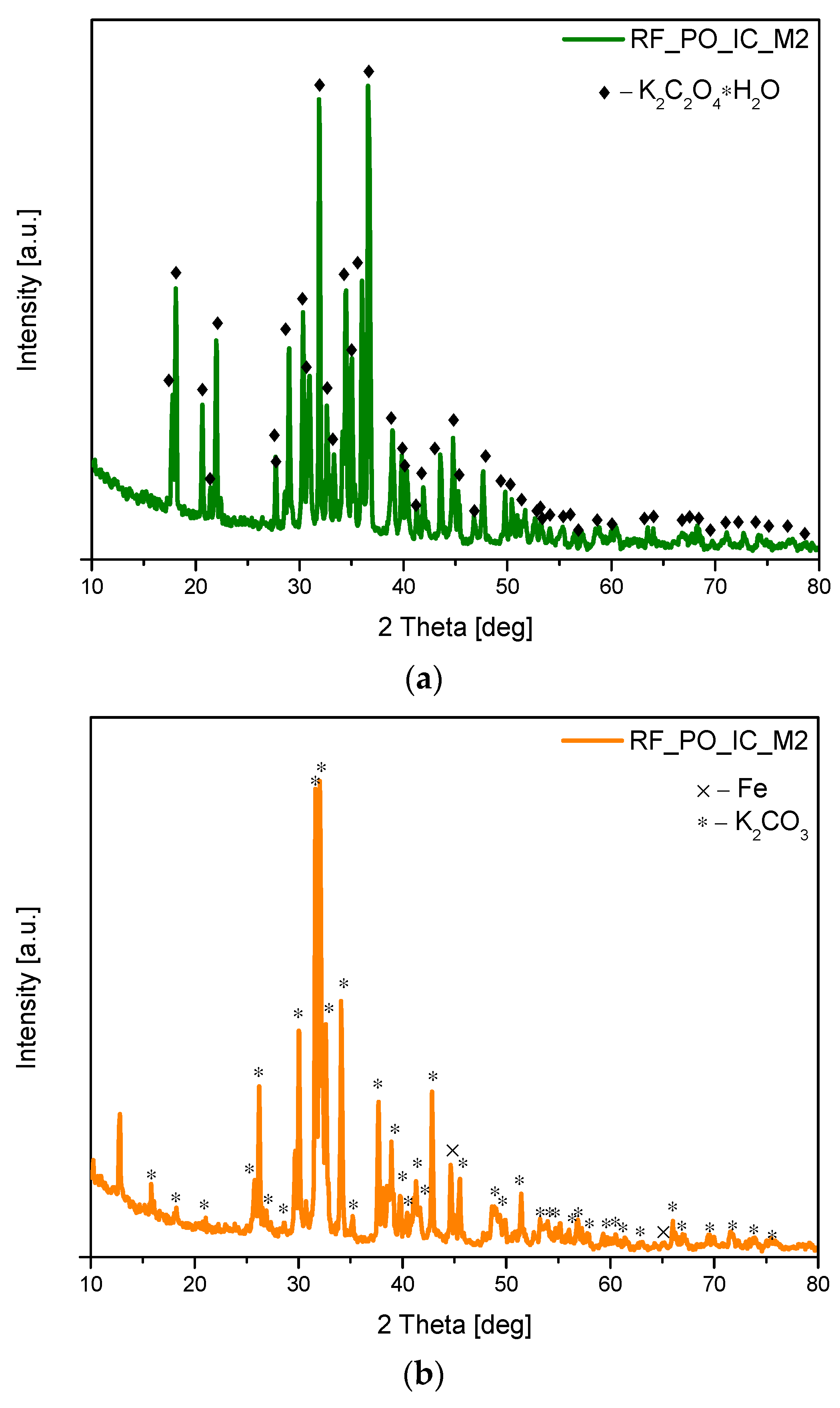

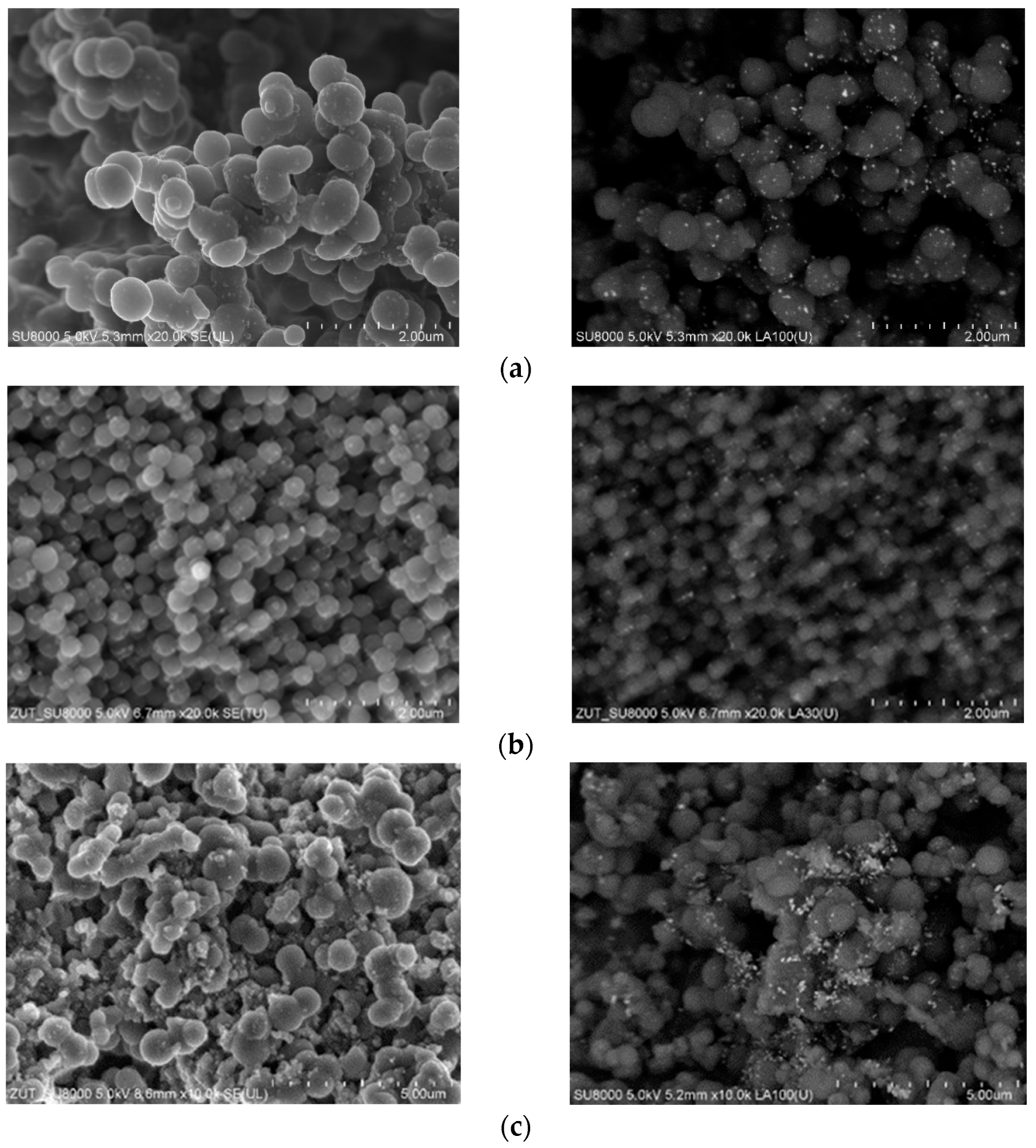

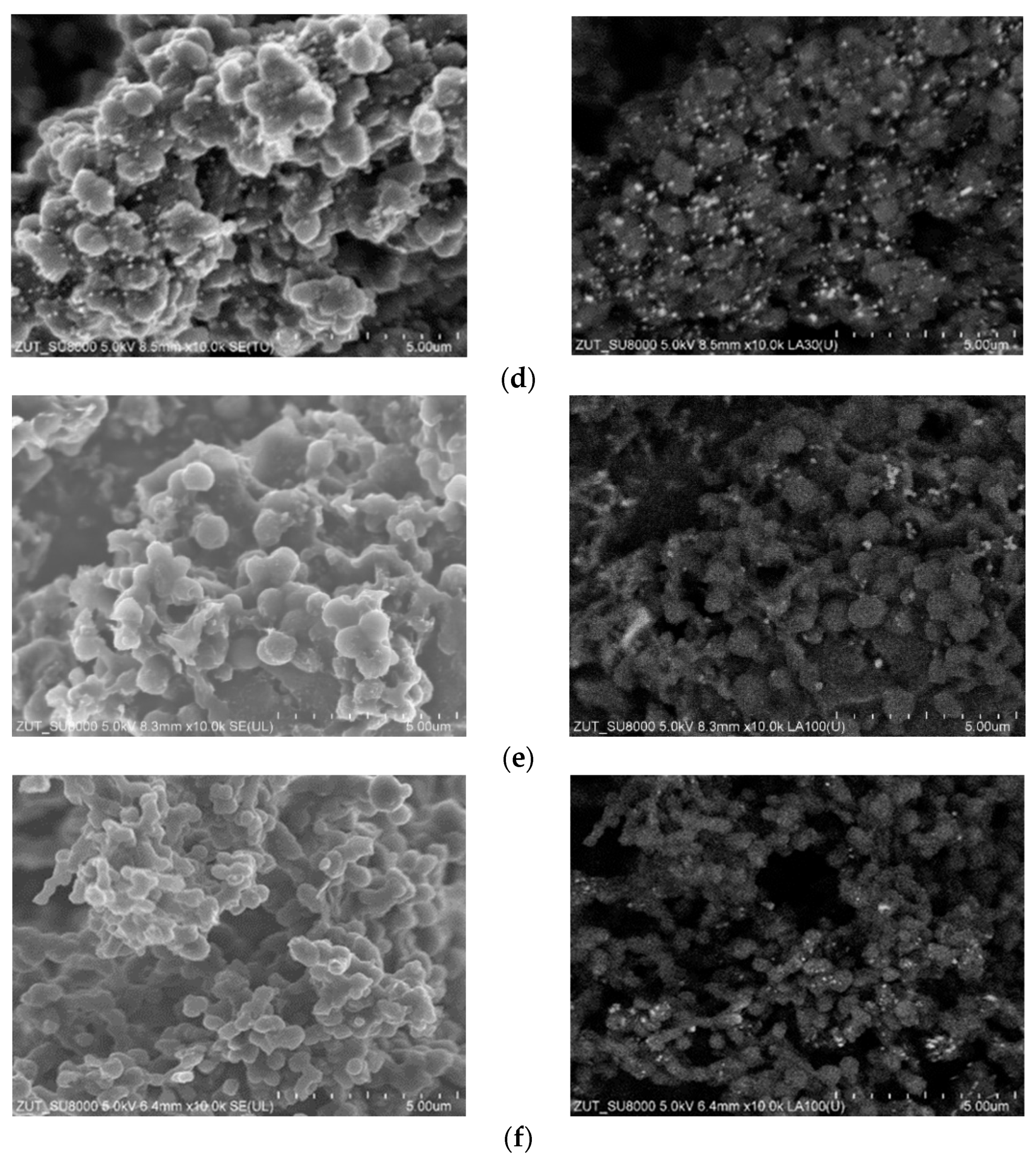

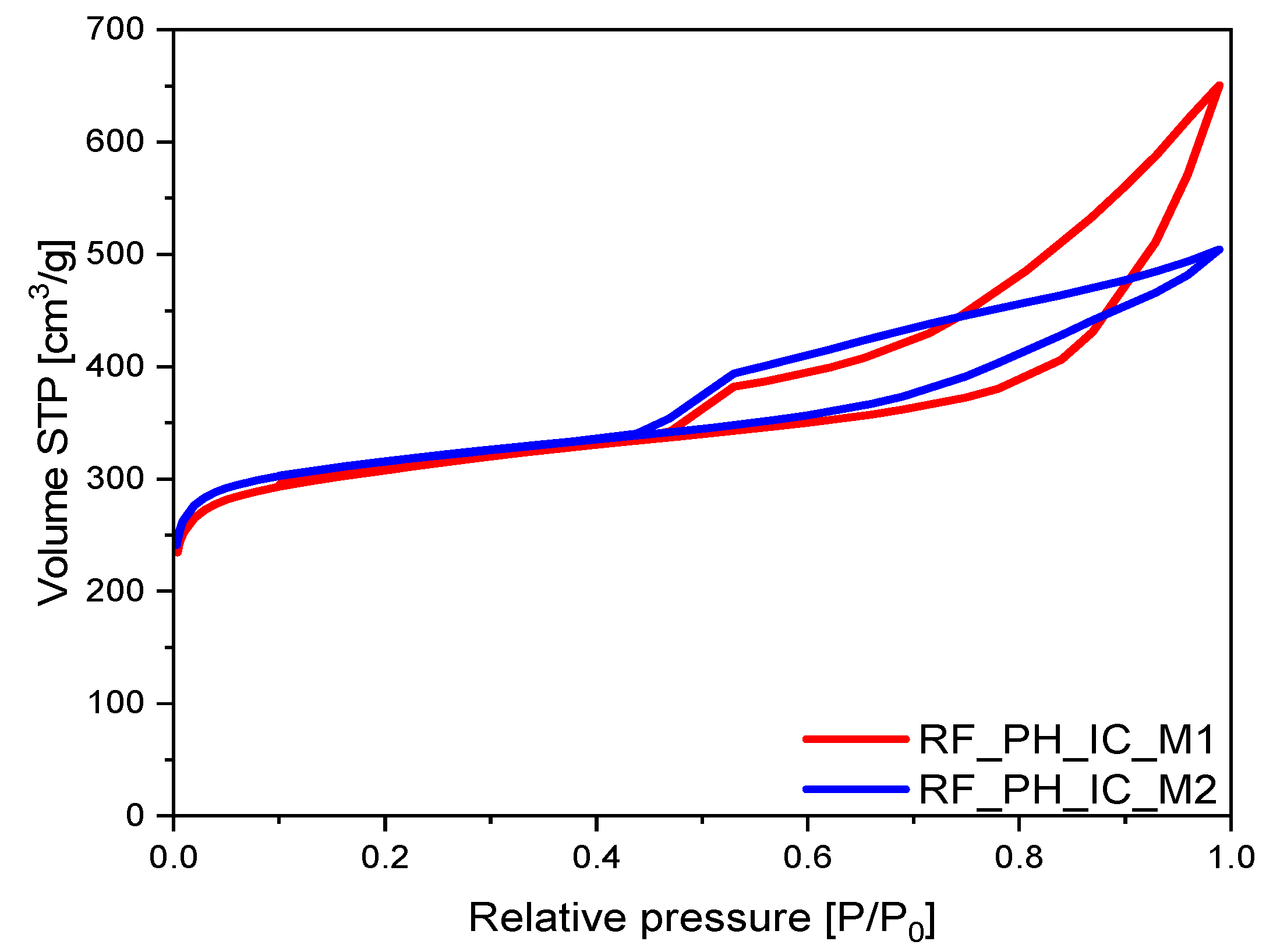

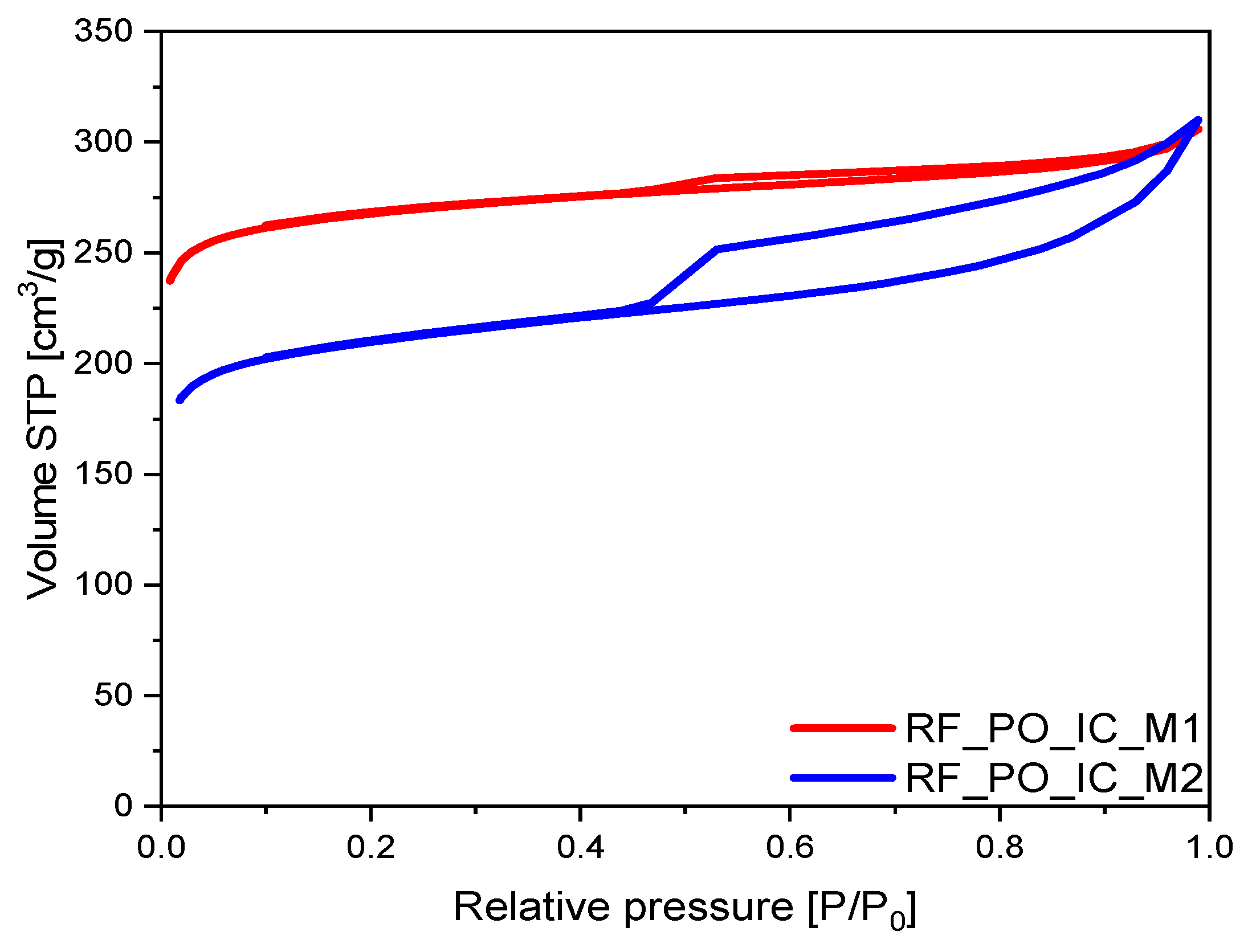

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, J.; Qiao, S.Z.; Liu, H.; Chen, J.; Orpe, A.; Zhao, D.; Lu, D.Q.M. Extension of the Stöber method to the preparation of monodisperse resorcinol-formaldehyde resin polymer and carbon spheres. Angew. Chem. Int. Ed. 2011, 50, 5947–5951. [Google Scholar] [CrossRef] [PubMed]

- Sibera, D.; Narkiewicz, U.; Kapica, J.; Serafin, J.; Michalkiewicz, B.; Wróbel, R.J.; Morawski, A.W. Preparation and characterisation of carbon spheres for carbon dioxide capture. J. Porous Mater. 2019, 26, 19–27. [Google Scholar] [CrossRef]

- Zhao, C.; Song, Y.; Xiang, T.; Qu, W.; Lou, S.; Yin, X.; Xin, F. Uniform cobalt nanoparticles embedded in hexagonal mesoporous nanoplates as a magnetically separable, recyclable adsorbent. Beilstein J. Nanotechnol. 2018, 9, 1770–1781. [Google Scholar] [CrossRef] [PubMed]

- Xiang, H.; Ren, G.; Zhong, Y.; Xu, D.; Zhang, Z.; Wang, X.; Yang, X. Fe3O4@C Nanoparticles Synthesized by In Situ Solid-Phase Method for Removal of Methylene Blue. Nanomaterials 2021, 11, 330. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Sun, H.; Ang, M.H.M.; Tadé, O.; Wang, S. Magnetic Fe3O4/carbon sphere/cobalt composites for catalytic oxidation of phenol solutions with sulfate radicals. Chem. Eng. J. 2014, 245, 1–9. [Google Scholar] [CrossRef]

- Wang, H.; Wang, W.; Xu, Y.Y.; Dong, S.; Xiao, J.; Wang, F.; Liu, H.; Xia, B.Y. Hollow Nitrogen-Doped Carbon Spheres with Fe3O4 Nanoparticles Encapsulated as a Highly Active Oxygen-Reduction Catalyst. ACS Appl. Mater. Interfaces 2017, 9, 10610–10617. [Google Scholar] [CrossRef]

- Zhou, L.; Shao, Y.; Liu, J.; Ye, Z.; Zhang, H.; Ma, J.; Jia, Y.; Gao, W.; Li, Y. Preparation and characterization of magnetic porous carbon microspheres for removal of methylene blue by a heterogeneous Fenton reaction. ACS Appl. Mater. Interfaces 2014, 6, 7275–7285. [Google Scholar] [CrossRef]

- Ma, J.; Zhou, L.; Dan, W.; Zhang, H.; Shao, Y.; Bao, C.; Jing, L. Novel magnetic porous carbon spheres derived from chelating resin as a heterogeneous Fenton catalyst for the removal of methylene blue from aqueous solution. J. Colloid Interface Sci. 2015, 446, 298–306. [Google Scholar] [CrossRef]

- Sun, H.; Zhou, G.; Liu, S.; Ang, H.M.; Tadé, M.O.; Wang, S. Nano-Fe0 encapsulated in microcarbon spheres: Synthesis, characterization, and environmental applications. ACS Appl. Mater. Interfaces 2012, 4, 6235–6241. [Google Scholar] [CrossRef]

- Su, L.; Han, D.; Zhu, G.; Xu, H.; Luo, W.; Wang, L.; Jiang, W.; Dong, A.; Yang, J. Tailoring the Assembly of Iron Nanoparticles in Carbon Microspheres toward High-Performance Electrocatalytic Denitrification. Nano Lett. 2019, 19, 5423–5430. [Google Scholar] [CrossRef]

- Xie, J.; Zheng, Y.; Zhang, Q.; Li, S.; Gu, J.; Zhou, M.; Wang, C.; Li, Y. Constructing a carbon sphere-embedded Fe0 for accelerating electro-peroxone oxidation effectively: The dual catalytic role with O3 and H2O2. Appl. Catal. B Environ. 2023, 320, 121935. [Google Scholar] [CrossRef]

- Zhang, B.T.; Wang, Q.; Zhang, Y.; Teng, Y.; Fan, M. Degradation of ibuprofen in the carbon dots/Fe3O4@carbon sphere pomegranate-like composites activated persulfate system. Sep. Purif. Technol. 2020, 242, 116820. [Google Scholar] [CrossRef]

- Long, Q.; Liu, F.; Yuan, Y.; Dai, Y.; Wang, C.; Li, X.; Zhang, J. Enhanced degradation performance of p-chlorophenol in photo-Fenton reaction activated by nano-Fe0 encapsulated in hydrothermal carbon: Improved Fe(III)/Fe(II) cycle. Colloids Surf. A Physicochem. Eng. Asp. 2020, 594, 124650. [Google Scholar] [CrossRef]

- Kang, S.; Wang, G.; Wang, Z.; Cai, W. Monodispersed Zerovalent Iron Nanoparticles Decorated Carbon Submicrospheres for Enhanced Removal of DDT from Aqueous Solutions. ChemistrySelect 2019, 4, 12134–12142. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, C.; Veder, J.P.; Saunders, M.; Tade, M.; Wang, S.; Shao, Z. Hierarchically porous cobalt-carbon nanosphere-in-microsphere composites with tunable properties for catalytic pollutant degradation and electrochemical energy storage. J. Colloid Interface Sci. 2018, 530, 556–566. [Google Scholar] [CrossRef]

- Jia, L.; Cheng, P.; Yu, Y.; Chen, S.; Wang, C.; He, L.; Nie, H.; Wang, J.; Zhang, J.; Fan, B.; et al. Regeneration mechanism of a novel high-performance biochar mercury adsorbent directionally modified by multimetal multilayer loading. J. Environ. Manag. 2023, 326, 116790. [Google Scholar] [CrossRef]

- Wen, Z.; Wang, Q.; Zhang, Q.; Li, J. Hollow carbon spheres with wide size distribution as anode catalyst support for direct methanol fuel cells. Electrochem. Comm. 2007, 9, 1867–1872. [Google Scholar] [CrossRef]

- Xiong, H.; Motchelaho, M.A.M.; Moyo, M.; Jewell, L.L.; Coville, N.J. Correlating the preparation and performance of cobalt catalysts supported on carbon nanotubes and carbon spheres in the Fischer–Tropsch synthesis. J. Catal. 2011, 278, 26–40. [Google Scholar] [CrossRef]

- Xiong, H.; Moyo, M.; Motchelaho, M.A.M.; Jewell, L.L.; Coville, N.J. Fischer–Tropsch synthesis over model iron catalysts supported on carbon spheres: The effect of iron precursor, support pretreatment, catalyst preparation method, and promoters. Appl. Catal. A Gen. 2010, 388, 168–178. [Google Scholar] [CrossRef]

- Nieto-Márquez, A.; Toledano, D.; Sánchez, P.; Romero, A.; Valverde, J.L. Impact of nitrogen doping of carbon nanospheres on the nickel-catalyzed hydrogenation of butyronitrile. J. Catal. 2010, 269, 242–251. [Google Scholar] [CrossRef]

- Fu, T.; Wang, X.; Zheng, H.; Li, Z. Effect of Cu location and dispersion on carbon sphere supported Cu catalysts for oxidative carbonylation of methanol to dimethyl carbonate. Carbon 2017, 115, 363–374. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, P.; Lv, X.; Niu, X.; Lin, X.; Zhong, S.; Wang, D.; Lin, H.; Chen, J.; Bai, S. Stacking Engineering of Semiconductor Heterojunctions on Hollow Carbon Spheres for Boosting Photocatalytic CO2 Reduction. ACS Catal. 2022, 12, 2569–2580. [Google Scholar] [CrossRef]

- Liu, S.; Ke, J.; Sun, H.; Liu, J.; Tade, M.O.; Wang, S. Size dependence of uniformed carbon spheres in promoting graphitic carbon nitride toward enhanced photocatalysis. Appl. Catal. B Environ. 2017, 204, 358–364. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, T.; Pan, J.; Chen, A.; Chen, Y. Design and fabrication of carbon spheres-supported cerium oxide heterostructured composites for enhanced photocatalytic activity. Ceram. Int. 2022, 48, 17714–17722. [Google Scholar] [CrossRef]

- Boudjemaa, A.; Nongwe, I.; Mutuma, B.K.; Matsoso, B.J.; Bachari, K.; Coville, N.J. TiO2@hollow carbon spheres: A photocatalyst for hydrogen generation under visible irradiation. J. Photochem. Photobiol. A Chem. 2021, 417, 113355. [Google Scholar] [CrossRef]

- Wang, W.; Xu, D.; Cheng, B.; Yu, J.; Jiang, C. Hybrid carbon@TiO2 hollow spheres with enhanced photocatalytic CO2 reduction activity. J. Mater. Chem. A 2017, 5, 5020–5029. [Google Scholar] [CrossRef]

- Staciwa, P.; Sibera, D.; Pelech, I.; Narkiewicz, U.; Lojkowski, W.; Dabrowska, S.; Cormia, R. Effect of microwave assisted solvothermal process parameters on carbon dioxide adsorption properties. Microporous Mesoporous Mater. 2021, 314, 110829. [Google Scholar] [CrossRef]

- Pelech, I.; Staciwa, P.; Sibera, D.; Pelech, R.; Sobczuk, K.S.; Kayalar, G.Y.; Narkiewicz, U.; Cormia, R. CO2 Adsorption Study of Potassium-Based Activation of Carbon Spheres. Molecules 2022, 27, 5379. [Google Scholar] [CrossRef]

- Sobczuk, K.S.; Pelech, I.; Narkiewicz, U.; Staciwa, P.; Sibera, D.; Moszynski, D. The influence of the synthesis pH on the morphology and adsorption properties of carbon spheres. Appl. Surf. Sci. 2023, 608, 155196. [Google Scholar] [CrossRef]

- Myers, A.L.; Prausnitz, J.M. Thermodynamics of mixed-gas adsorption. AIChE 1965, 11, 121–127. [Google Scholar] [CrossRef]

- Gomez-Martin, A.; Schnepp, Z.; Ramirez-Rico, J. Structural Evolution in Iron-Catalyzed Graphitization of Hard Carbons. Chem. Mater. 2021, 33, 3087–3097. [Google Scholar] [CrossRef]

- Dollimore, D. The thermal decomposition of oxalates. A review. Thermochim. Acta 1987, 117, 331–363. [Google Scholar] [CrossRef]

- Randhawa, B.; Kaur, M. The thermolysis of zinc bis(citrato)ferrate(III) dodecahydrate. J. Radioanal. Nucl. Chem. 2003, 256, 509–511. [Google Scholar] [CrossRef]

- Staciwa, P.; Narkiewicz, U.; Sibera, D.; Moszyński, D.; Wróbel, R.J. Carbon Spheres as CO2 Sorbents. Appl. Sci. 2019, 9, 3349. [Google Scholar] [CrossRef]

- Pełech, I.; Staciwa, P.; Sibera, D.; Kusiak-Nejman, E.; Morawski, A.W.; Kapica-Kozar, J.; Narkiewicz, U. The Effect of the Modification of Carbon Spheres with ZnCl2 on the Adsorption Properties towards CO2. Molecules 2022, 27, 1387. [Google Scholar] [CrossRef]

- Pełech, I.; Sibera, D.; Staciwa, P.; Kusiak-Nejman, E.; Kapica-Kozar, J.; Wanag, A.; Narkiewicz, U.; Morawski, A.W. ZnO/carbon spheres with excellent regenerability for post-combustion CO2 capture. Materials 2021, 14, 6478. [Google Scholar] [CrossRef] [PubMed]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Song, Y.; Li, W.; Xu, Z.; Ma, C.; Liu, Y.; Xu, M.; Wu, X.; Liu, S. Hierarchical porous carbon spheres derived from larch sawdust via spray pyrolysis and soft-templating method for supercapacitors. SN Appl. Sci. 2019, 1, 122. [Google Scholar] [CrossRef]

- Salihovic, M.; Zickler, G.A.; Fritz-Popovski, G.; Ulbricht, M.; Paris, O.; Hüsing, N.; Presser, V.; Elsaesser, M.S. Reversibly compressible and freestanding monolithic carbon spherogels. Carbon 2019, 153, 189–195. [Google Scholar] [CrossRef]

- Wang, H.; Wang, T.; Yu, M.; Huang, X.; Zhong, J.; Huang, W.; Chen, R. Elaborate control over the morphology and pore structure of porous silicas for VOCs removal with high efficiency and stability. Adsorption 2017, 23, 37–50. [Google Scholar] [CrossRef]

- Phuriragpitikhon, J.; Ghimire, P.; Jaroniec, M. Tannin-derived micro-mesoporous carbons prepared by one-step activation with potassium oxalate and CO2. J. Colloid Interface Sci. 2020, 558, 55–67. [Google Scholar] [CrossRef]

- Lv, M.; Xie, W.; Sun, S.; Wu, G.; Zheng, L.; Chu, S.; Gao, C.; Bao, J. Activated-carbon-supported K–Co–Mo catalysts for synthesis of higher alcohols from syngas. Catal. Sci. Technol. 2015, 5, 2925–2934. [Google Scholar] [CrossRef]

- Sing, K.S.W. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Provisional). Pure Appl. Chem. 1982, 54, 2201–2218. [Google Scholar] [CrossRef]

- Musa, M.S.; Sanagi, M.M.; Nur, H.; Ibrahim, W.A.W. Understanding pore formation and structural deformation in carbon spheres during KOH activation. Sains Malays. 2015, 44, 613–618. [Google Scholar] [CrossRef]

- Wickramaratne, N.P.; Jaroniec, M. Importance of small micropores in CO2 capture by phenolic resin-based activated carbon spheres. J. Mater. Chem. A 2013, 1, 112. [Google Scholar] [CrossRef]

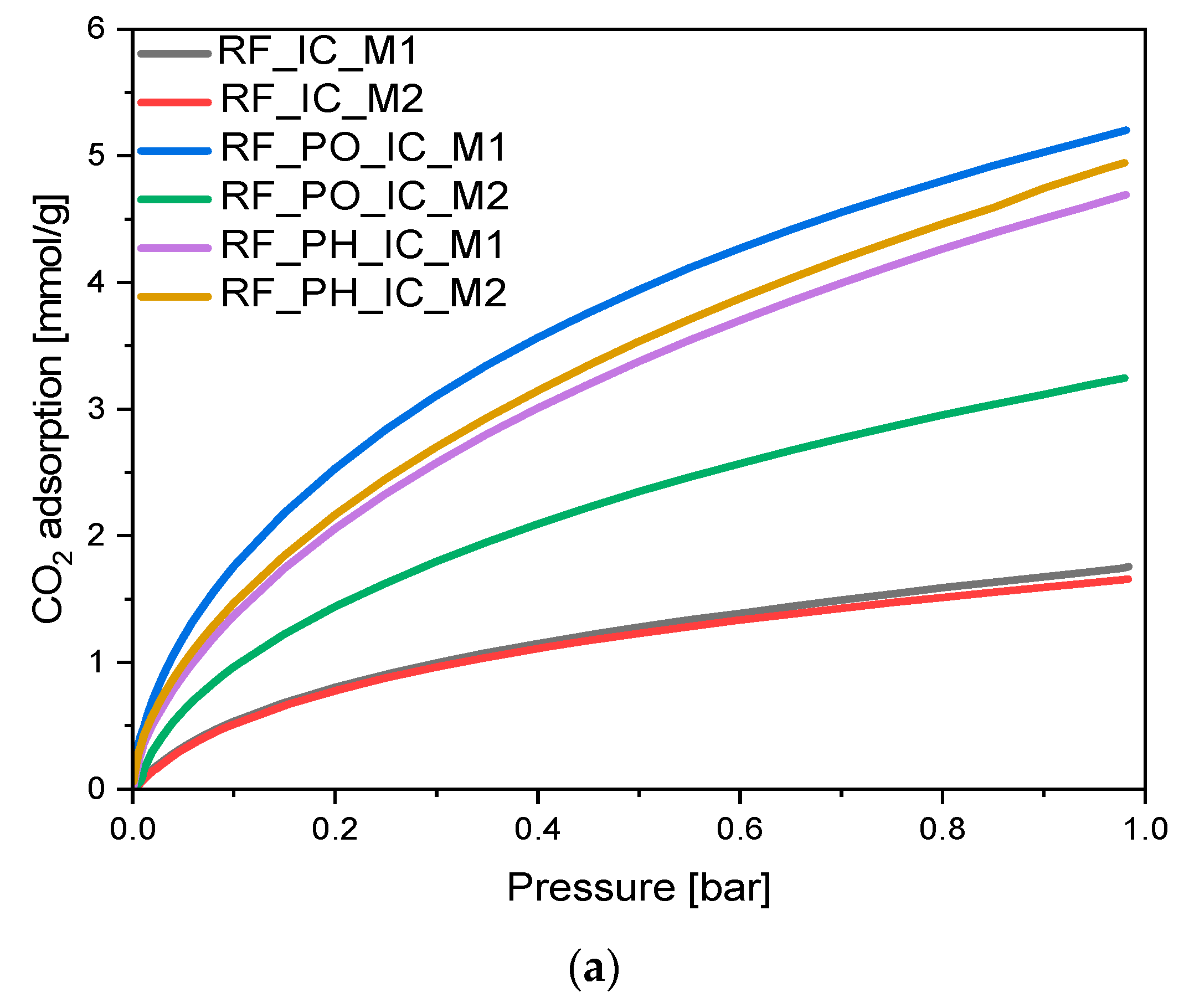

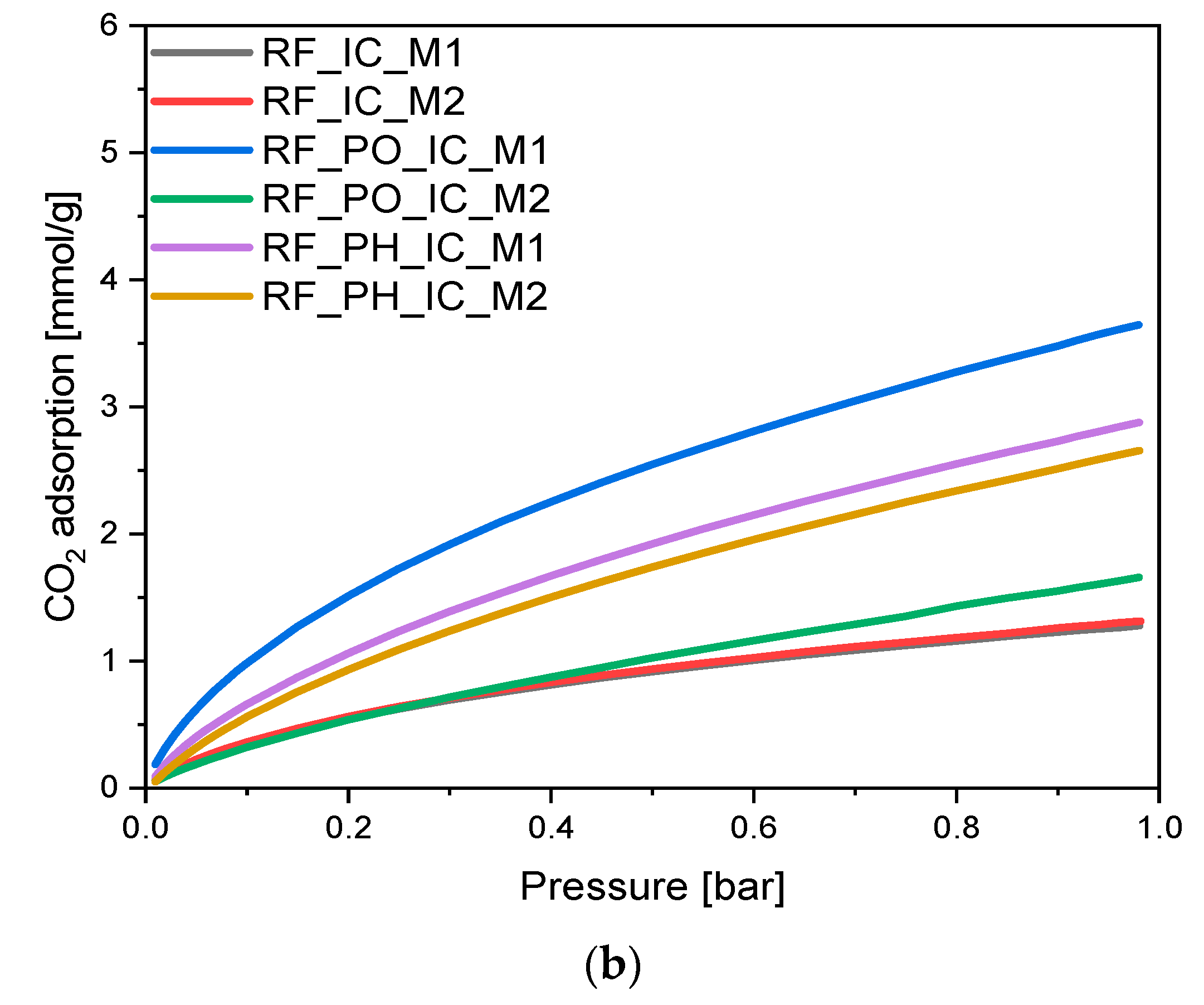

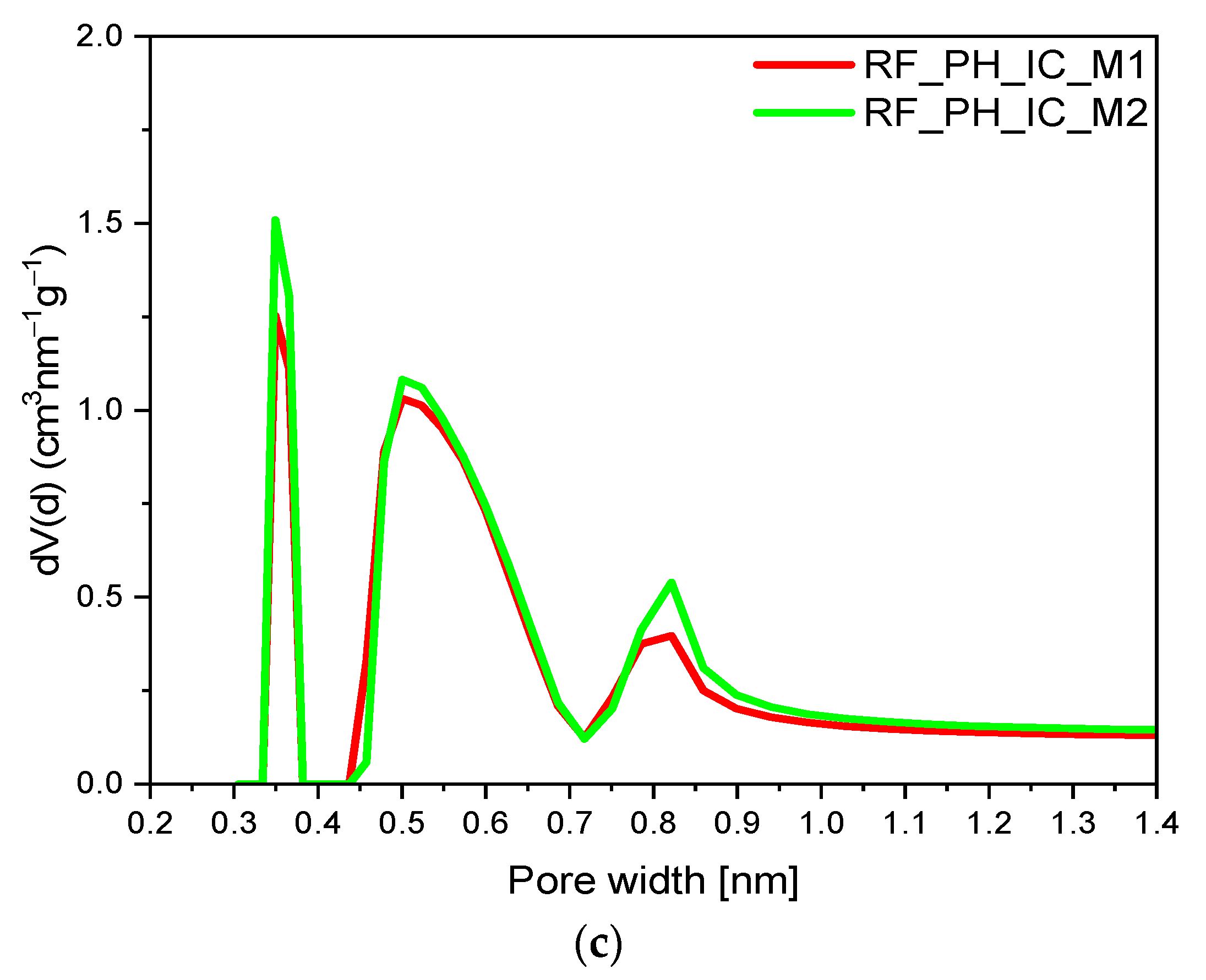

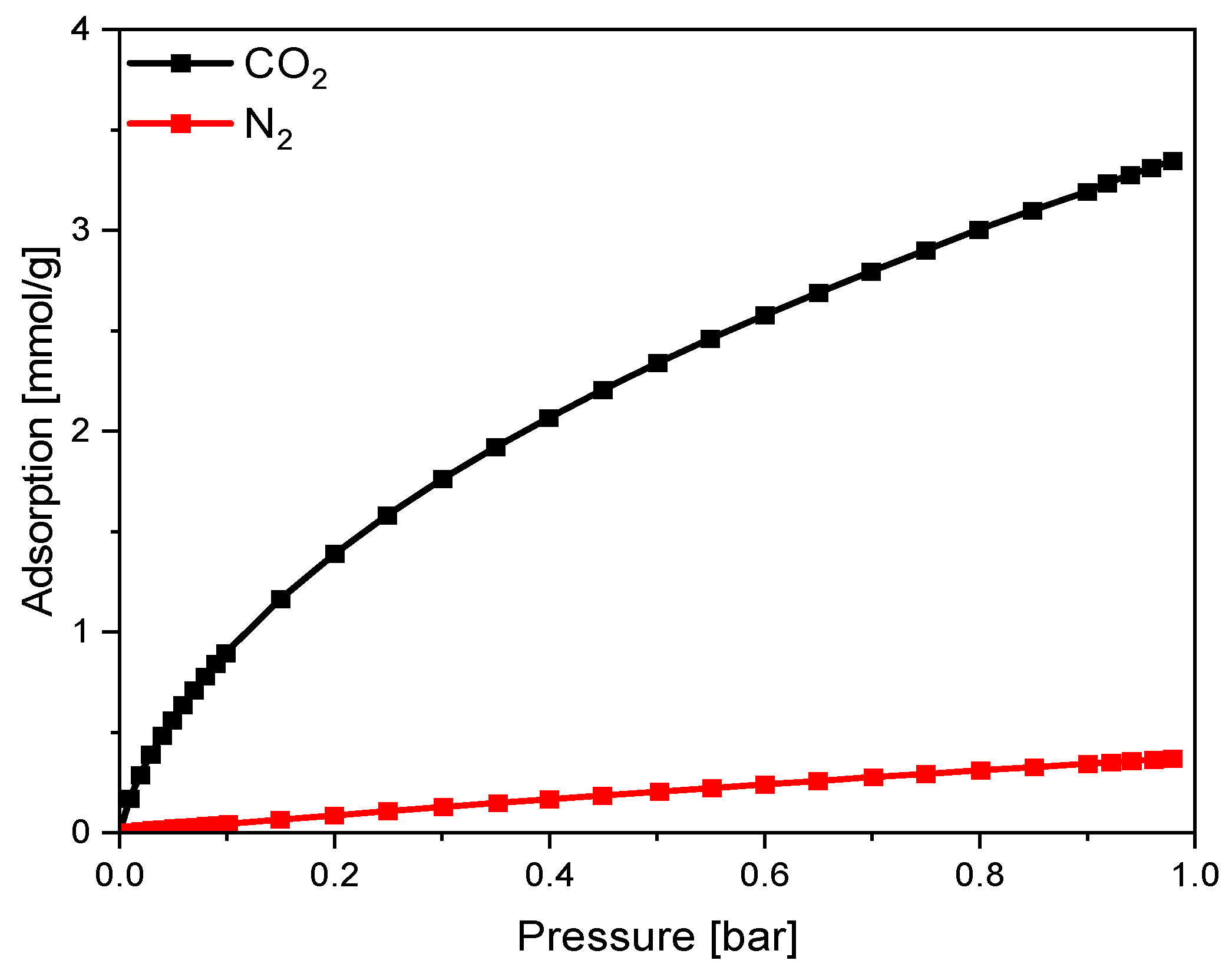

| SBET | TPV | Vs | Vm | Vmeso | CO2, 0 °C | CO2, 25 °C | SIAST (CO2/N2) | ||

|---|---|---|---|---|---|---|---|---|---|

| [m2/g] | [cm3/g] | [cm3/g] | [cm3/g] | [cm3/g] | [mmol/g] | [mmol/g] | - | ||

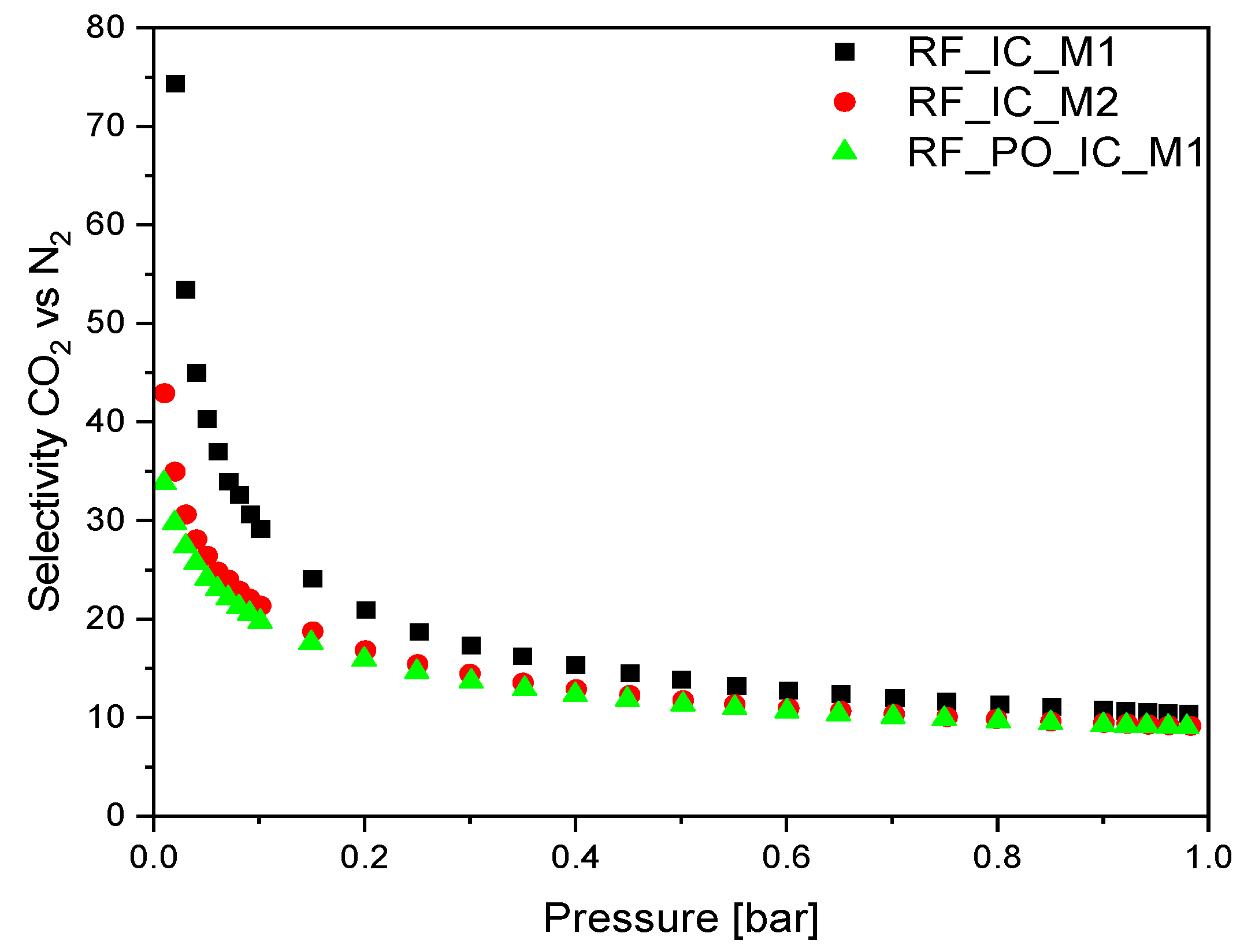

| RF_IC_M1 | 400 | 0.33 | 0.11 | 0.13 | 0.20 | 1.76 | 1.28 | 23.91 | |

| RF_IC_M2 | 439 | 0.39 | 0.10 | 0.14 | 0.25 | 1.66 | 1.31 | 21.06 | |

| RF_PO_IC_M1 | 826 | 0.47 | 0.30 | 0.37 | 0.10 | 5.20 | 3.35 | 20.10 | |

| RF_PO_IC_M2 | 656 | 0.48 | 0.20 | 0.27 | 0.21 | 3.25 | 1.66 | 14.00 | |

| RF_PH_IC_M1 | 991 | 0.78 | 0.30 | 0.39 | 0.39 | 4.94 | 2.88 | 15.62 | |

| RF_PH_IC_M2 | 974 | 1.01 | 0.28 | 0.37 | 0.64 | 4.69 | 2.66 | 13.82 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pełech, I.; Sibera, D.; Staciwa, P.; Sobczuk, K.S.; Narkiewicz, U. Influence of Potassium-Based Activation on Adsorptive Properties of Carbon Spheres Modified with Iron(III) Citrate. Materials 2023, 16, 5227. https://doi.org/10.3390/ma16155227

Pełech I, Sibera D, Staciwa P, Sobczuk KS, Narkiewicz U. Influence of Potassium-Based Activation on Adsorptive Properties of Carbon Spheres Modified with Iron(III) Citrate. Materials. 2023; 16(15):5227. https://doi.org/10.3390/ma16155227

Chicago/Turabian StylePełech, Iwona, Daniel Sibera, Piotr Staciwa, Konrad S. Sobczuk, and Urszula Narkiewicz. 2023. "Influence of Potassium-Based Activation on Adsorptive Properties of Carbon Spheres Modified with Iron(III) Citrate" Materials 16, no. 15: 5227. https://doi.org/10.3390/ma16155227

APA StylePełech, I., Sibera, D., Staciwa, P., Sobczuk, K. S., & Narkiewicz, U. (2023). Influence of Potassium-Based Activation on Adsorptive Properties of Carbon Spheres Modified with Iron(III) Citrate. Materials, 16(15), 5227. https://doi.org/10.3390/ma16155227