Reduction of Friction and Wear for AISI321 Stainless Steel through Surface Modification Using Nanocrystallization

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

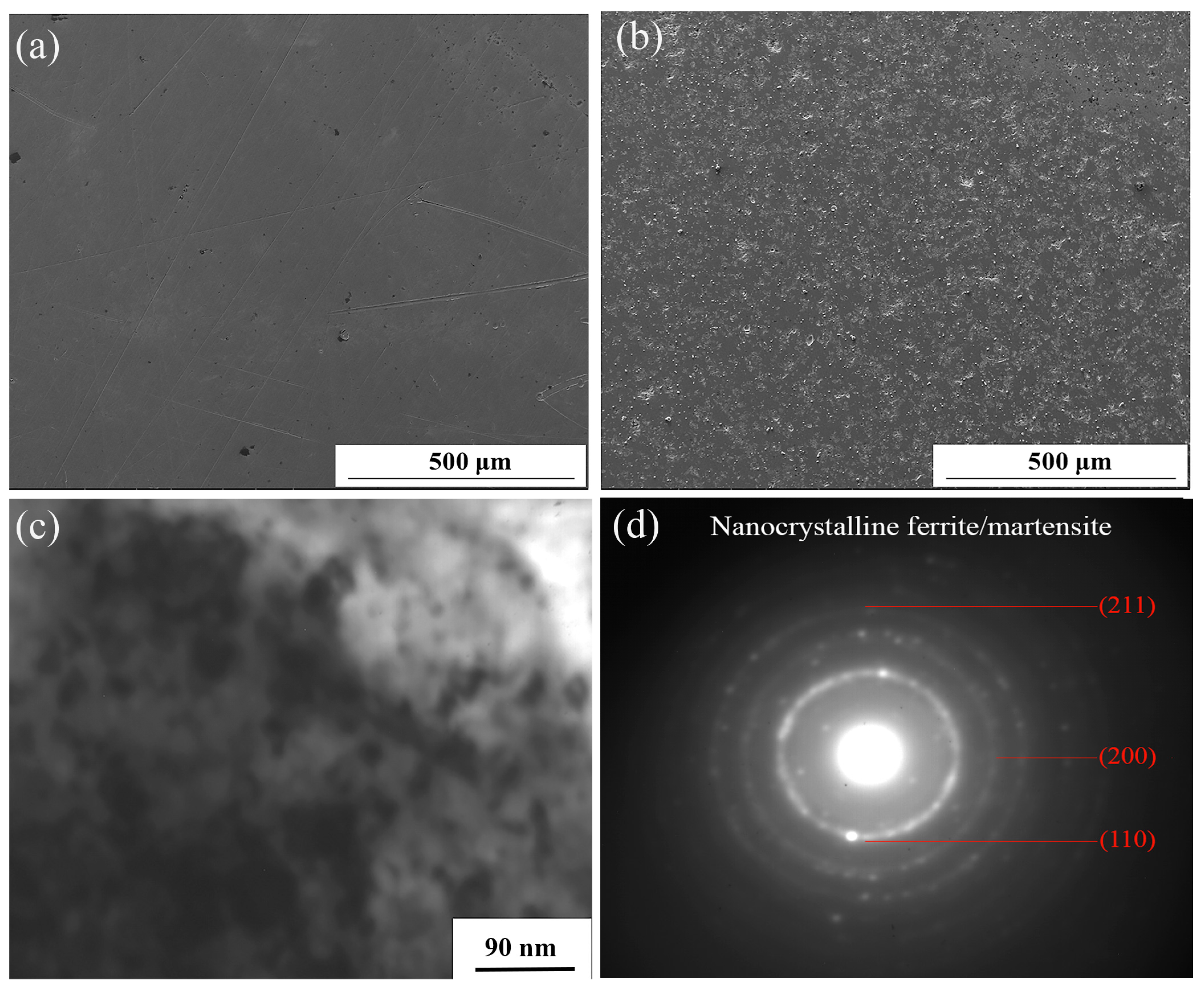

3.1. Characterization of Nanostructured Layer on AISI321 Stainless Steel Treated Using SFPB

3.2. Effect of SFPB on the Microstructure and Properties of Sulfurized Layer

3.2.1. Effect of SFPB on the Microstructure of Sulfurized layer

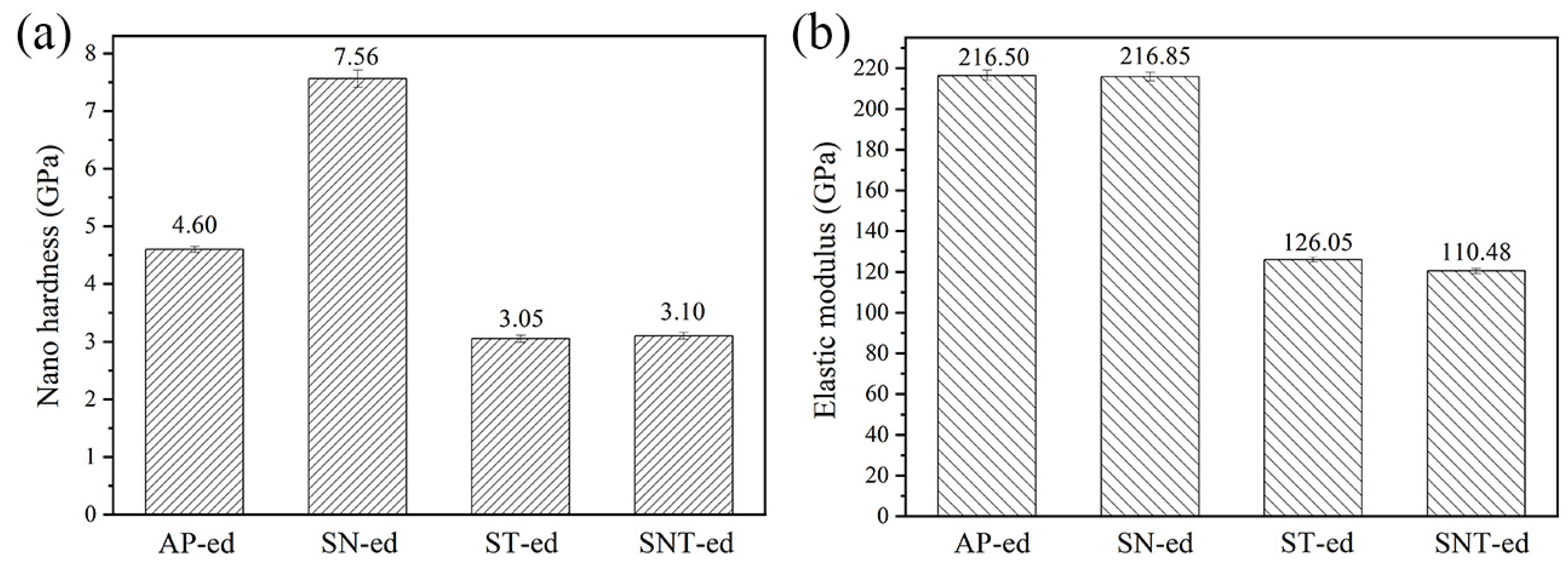

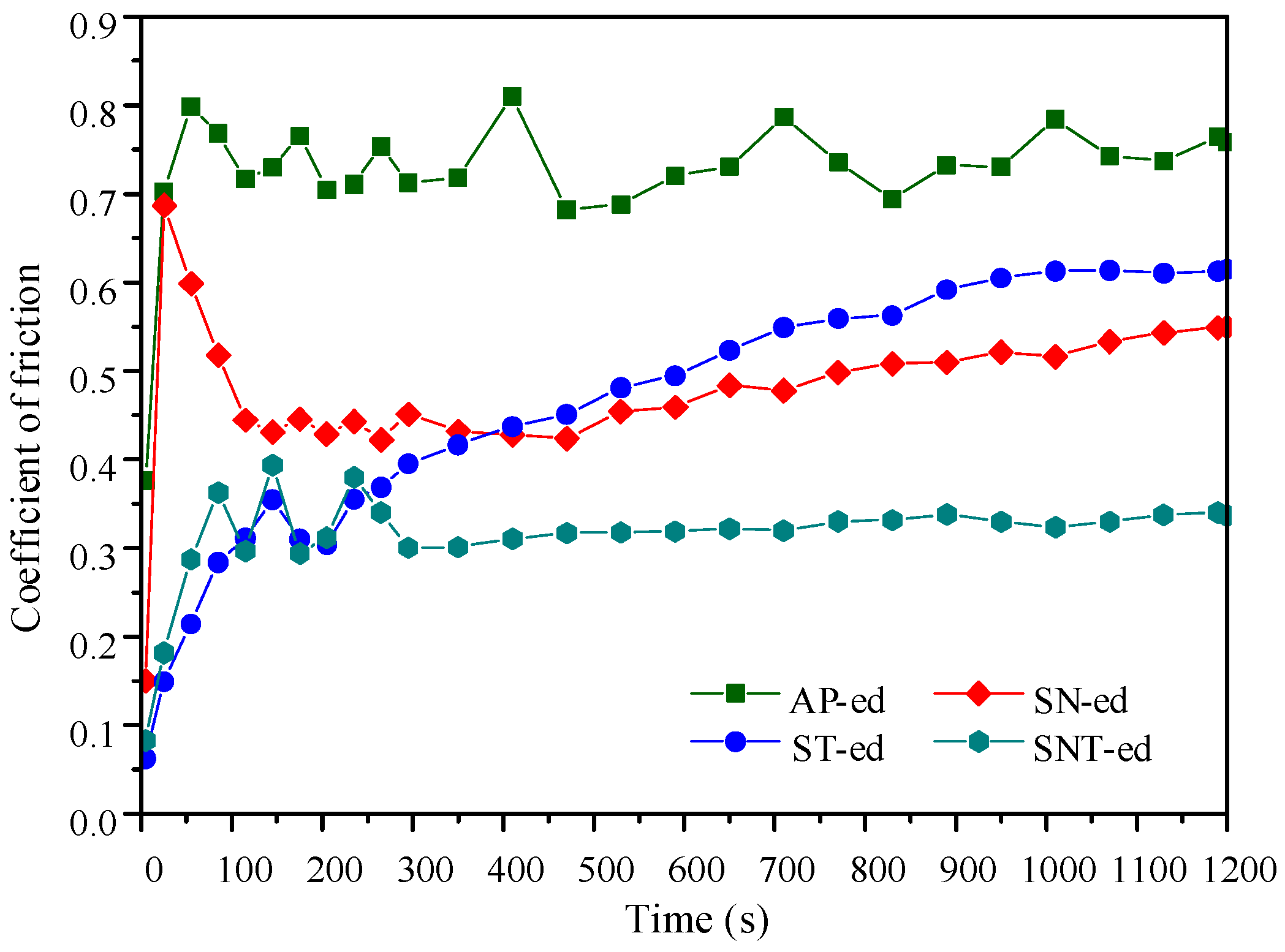

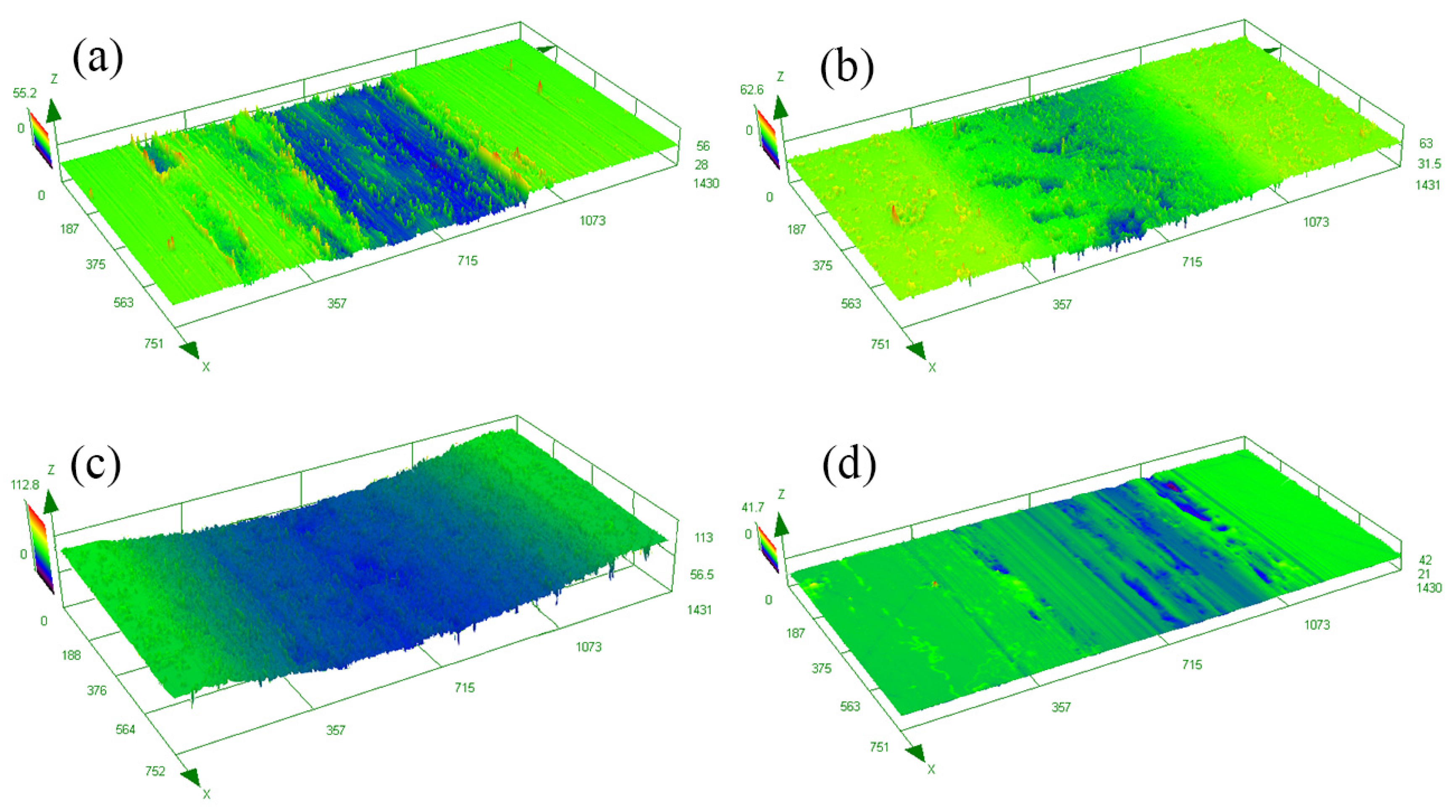

3.2.2. Effect of SFPB on the Mechanical and Tribological Properties of Sulfurized Layer

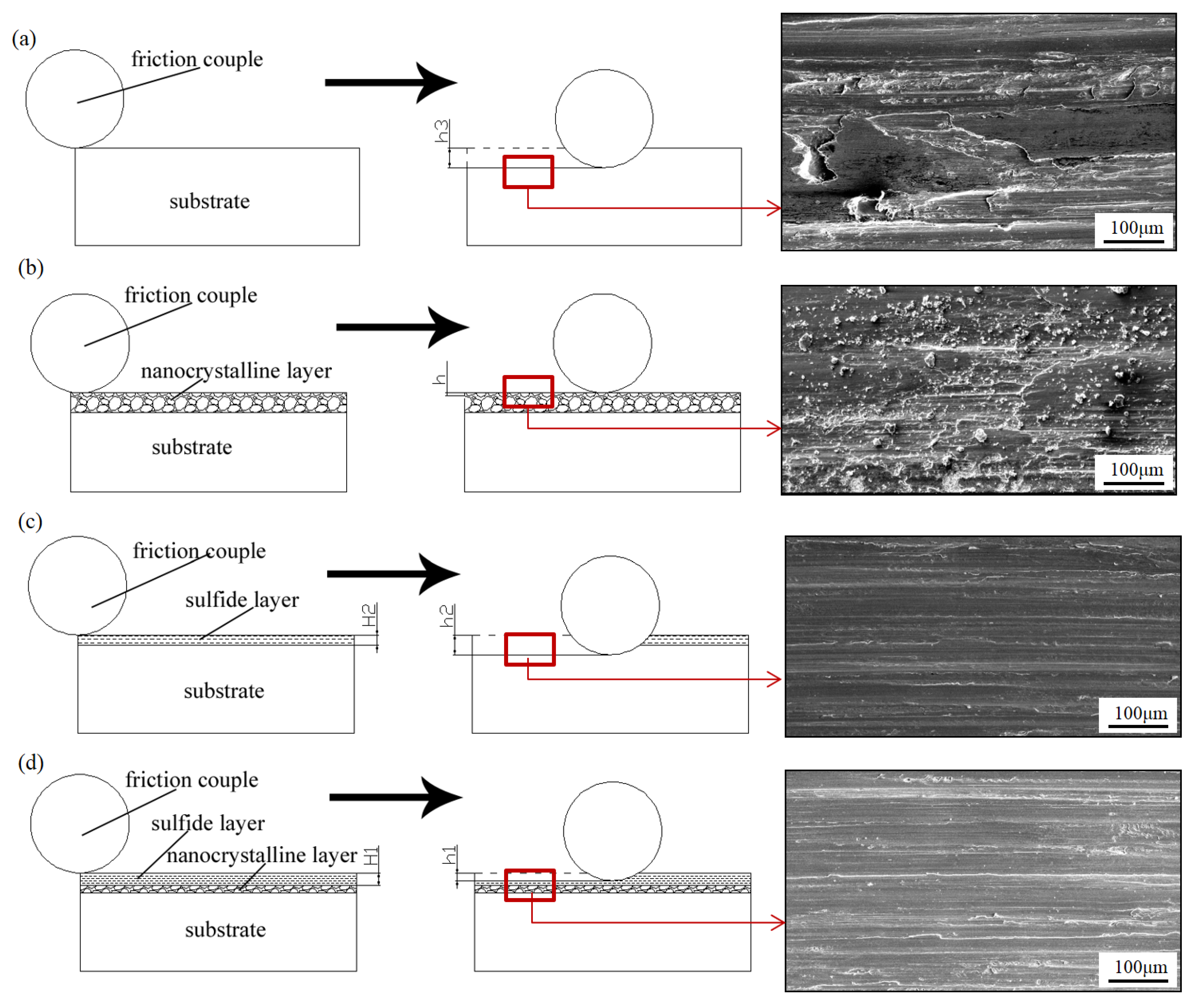

3.2.3. Friction-Reduction Mechanism Model of Compound-Treated Layer

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saraeian, P.; Mehr, H.S.; Moradi, B.; Tavakoli, H.; Alrahmani, O.K. Study of Magnetic Abrasive Finishing for AISI321 Stainless Steel. Mater. Manuf. Process. 2016, 31, 2023–2029. [Google Scholar] [CrossRef]

- Mehran, N.; Kiumars, A.; Tohid, S. Effect of ultrasonic vibrations in TIG welded AISI321 stainless steel: Microstructure and mechanical properties. Mater. Res. Express. 2018, 5, 1–10. [Google Scholar]

- Zhang, N.; Zhuang, D.M.; Wang, Y.H.; Liu, J.J.; Fang, X.D.; Gong, M.X. Structure and friction-reducing property of low temperature ion sulphuration layer. Chin. J. Mater. Res. 2000, 14, 61–65. [Google Scholar]

- Huang, Z.; Liu, M.; Xiong, D.; Li, J. Surface texturing for adaptive Ag/MoS2 solid lubricant plating. Rare Met. 2012, 31, 560–565. [Google Scholar] [CrossRef]

- He, L.; Tan, Y.-F.; Wang, X.-L.; Jing, Q.-F.; Hong, X. Tribological properties of laser cladding TiB2 particles reinforced Ni-base alloy composite coatings on aluminum alloy. Rare Met. 2015, 34, 789–796. [Google Scholar] [CrossRef]

- Lu, L.; Ma, Z.; Wang, F.-C.; Liu, Y.-B. Friction and wear behaviors of Al2O3–13 wt%TiO2 coatings. Rare Met. 2013, 32, 87–92. [Google Scholar] [CrossRef]

- Han, B.; Zhang, M.K.; Qi, C.H.; Cui, N.; Wang, Y. Characterization and friction-reduction performances of composite coating produced by laser cladding and ion sulfurizing. Mater. Lett. 2015, 150, 35–38. [Google Scholar] [CrossRef]

- Zhang, N.; Zhuang, D.M.; Liu, J.J. Tribological behaviors of steel surfaces treated with ion sulphurization duplex processes. Surf. Coat. Technol. 2009, 203, 3173–3177. [Google Scholar] [CrossRef]

- Yue, W.; Gao, X.C.; Liu, Y.D.; Sun, X.J.; Wang, C.B.; Liu, J.J. Tribological properties of sulfurized-nitrided layer prepared by a two-step method. Vacuum 2011, 85, 1011–1016. [Google Scholar] [CrossRef]

- Cui, G.; Han, B.; Zhao, J.B.; Li, M.Y. Comparative study on tribological properties of the sulfurizing layers on Fe, Ni and Co based laser cladding coatings. Tribol. Int. 2019, 134, 36–49. [Google Scholar] [CrossRef]

- Karimi, A.; Amini, S. Steel 7225 surface ultrafine structure and improvement of its mechanical properties using surface nanocrystallization technology by ultrasonic impact. Int. J. Adv. Manuf. Technol. 2016, 83, 1–8. [Google Scholar] [CrossRef]

- Cheng, M.L.; Zhang, D.Y.; Chen, H.W.; Qin, W.; Li, J.S. Surface nanocrystallization and its effect on fatigue performance of high-strength materials treated by ultrasonic rolling process. Int. J. Adv. Manuf. Technol. 2016, 83, 123–131. [Google Scholar]

- Aliofkhazraei, M.; Sabour Rouhaghdam, A.; Hassannejad, H. Effect of electrolyte temperature on the nano-carbonitride layer fabricated by surface nanocrystallization and plasma treatment on a γ-TiAl alloy. Rare Met. 2009, 28, 454–459. [Google Scholar] [CrossRef]

- Kong, L.Y.; Lao, Y.X.; Xiong, T.Y.; Li, T.F. Nanocrystalline surface layer on AISI 52100 steel induced by supersonic fine particles bombarding. J. Therm. Spray Technol. 2013, 22, 1007–1013. [Google Scholar] [CrossRef]

- Gao, H.M.; Chen, W.G.; Zhang, Z.J. Evolution mechanism of surface nano-crystallization of tungsten-copper alloys. Mater. Lett. 2016, 176, 181–184. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Ma, A.B.; Jiang, J.H.; Song, D.; Yang, D.H.; Chen, J.Q. Electrochemical corrosion properties of the surface layer produced by supersonic fine-particles bombarding on low-carbon steel. Surf. Coat. Technol. 2013, 232, 412–418. [Google Scholar] [CrossRef]

- Zhang, B.S.; Dong, Q.S.; Ba, Z.X.; Wang, Z.Z.; Shi, H.C.; Xue, Y.T. Tribological properties of surface-textured and plasma-nitrided pure titanium under oil lubrication condition. J. Mater. Eng. Perform. 2018, 27, 186–193. [Google Scholar] [CrossRef]

- Tao, N.R.; Wang, Z.B.; Tong, W.P.; Sui, M.L.; Lu, J.; Lu, K. An investigation of surface nanocrystallization mechanism in Fe induced by surface mechanical attrition treatment. Acta Mater. 2002, 50, 4603–4616. [Google Scholar] [CrossRef]

- Pandey, V.; Rao, G.S.; Chattopadhyay, K.; Santhi Srinivas, N.C.; Singh, V. Effect of surface Nanostructuring on LCF behavior of aluminum alloy 2014. Mat. Sci. Eng. A 2015, 647, 201–211. [Google Scholar] [CrossRef]

- Bajda, S.; Dymek, S.; Krzyzanowski, M.; Retraint, D.; Majta, J.; Łukasz, L.; Kwiecień, M. Characterization of nanocrystallised multilayered metallic materials produced by the SMAT followed by constrained compression. Mater. Charact. 2018, 145, 250–257. [Google Scholar] [CrossRef]

- Umemura, M.T.; Varela, L.B.; Pinedo, C.E.; Cozza, R.C.; Tschiptschin, A.P. Assessment of tribological properties of plasma nitrided 410S ferriticmartensitic stainless steels. Wear 2019, 426–427, 49–58. [Google Scholar] [CrossRef]

- Konchits, V.V.; Markova, L.V. Estimation of lubricant interlayer shear strength under conditions of imperfect boundary lubrication. Tribotest J. 1998, 44, 367–375. [Google Scholar] [CrossRef]

| C | Si | Mn | S | P | Cr | Ni | Ti | Fe |

|---|---|---|---|---|---|---|---|---|

| 0.1 | 1.0 | 1.0 | 0.003 | 0.035 | 17.5 | 8.5 | 0.4 | Bal. |

| Airflow Pressure | Jetting Medium | Particle Diameter | Bombardment Distance | Bombardment Angle | Processing Time | Airflow Temperature |

|---|---|---|---|---|---|---|

| 1.6 MPa | Al2O3 powder | 20~30 μm | 15 mm | 90° | 360 s | 50 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, L.; Li, Y. Reduction of Friction and Wear for AISI321 Stainless Steel through Surface Modification Using Nanocrystallization. Materials 2023, 16, 5303. https://doi.org/10.3390/ma16155303

Ding L, Li Y. Reduction of Friction and Wear for AISI321 Stainless Steel through Surface Modification Using Nanocrystallization. Materials. 2023; 16(15):5303. https://doi.org/10.3390/ma16155303

Chicago/Turabian StyleDing, Lifen, and You Li. 2023. "Reduction of Friction and Wear for AISI321 Stainless Steel through Surface Modification Using Nanocrystallization" Materials 16, no. 15: 5303. https://doi.org/10.3390/ma16155303

APA StyleDing, L., & Li, Y. (2023). Reduction of Friction and Wear for AISI321 Stainless Steel through Surface Modification Using Nanocrystallization. Materials, 16(15), 5303. https://doi.org/10.3390/ma16155303