Investigation of the Impact of High-Speed Machining in the Milling Process of Titanium Alloy on Tool Wear, Surface Layer Properties, and Fatigue Life of the Machined Object

Abstract

:1. Introduction

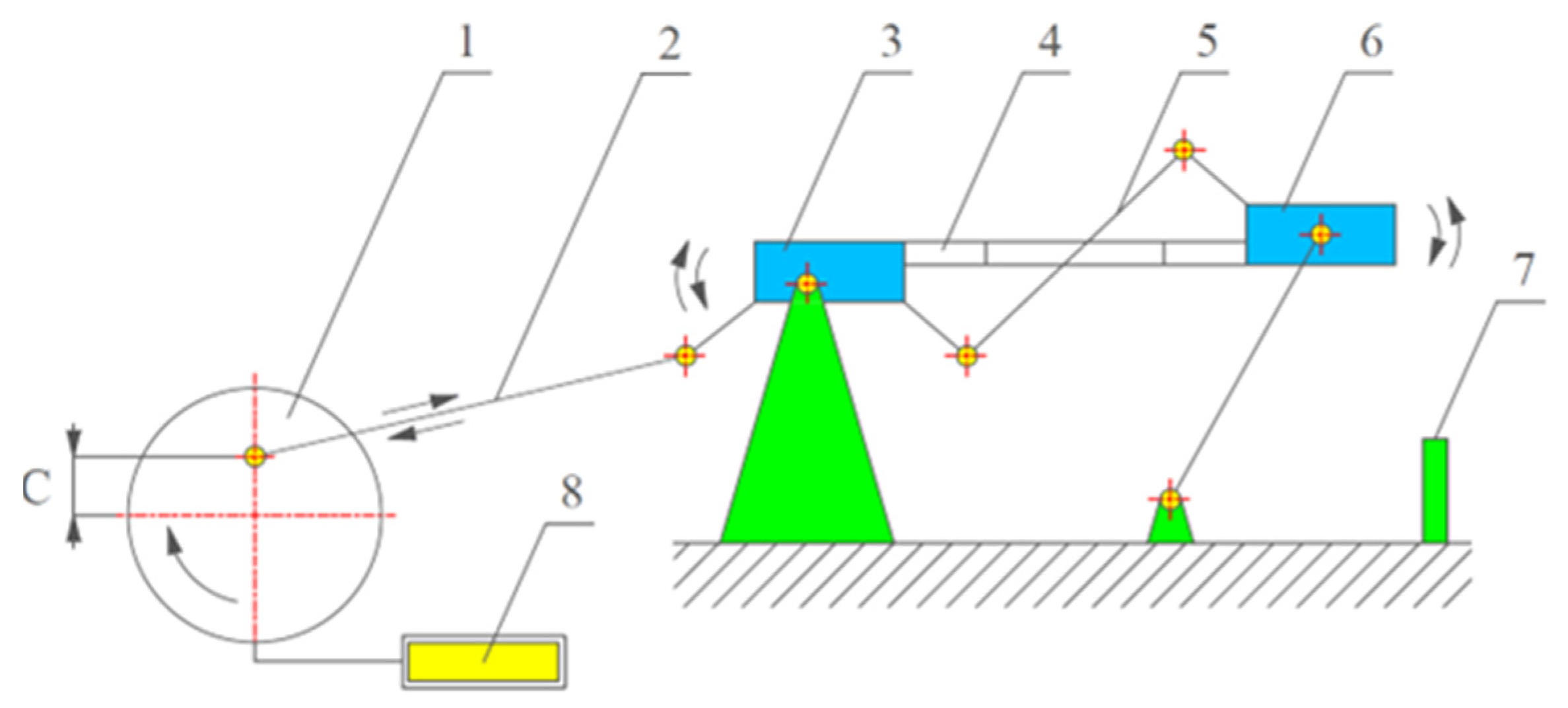

2. Materials and Methods

2.1. Shape of Research Material

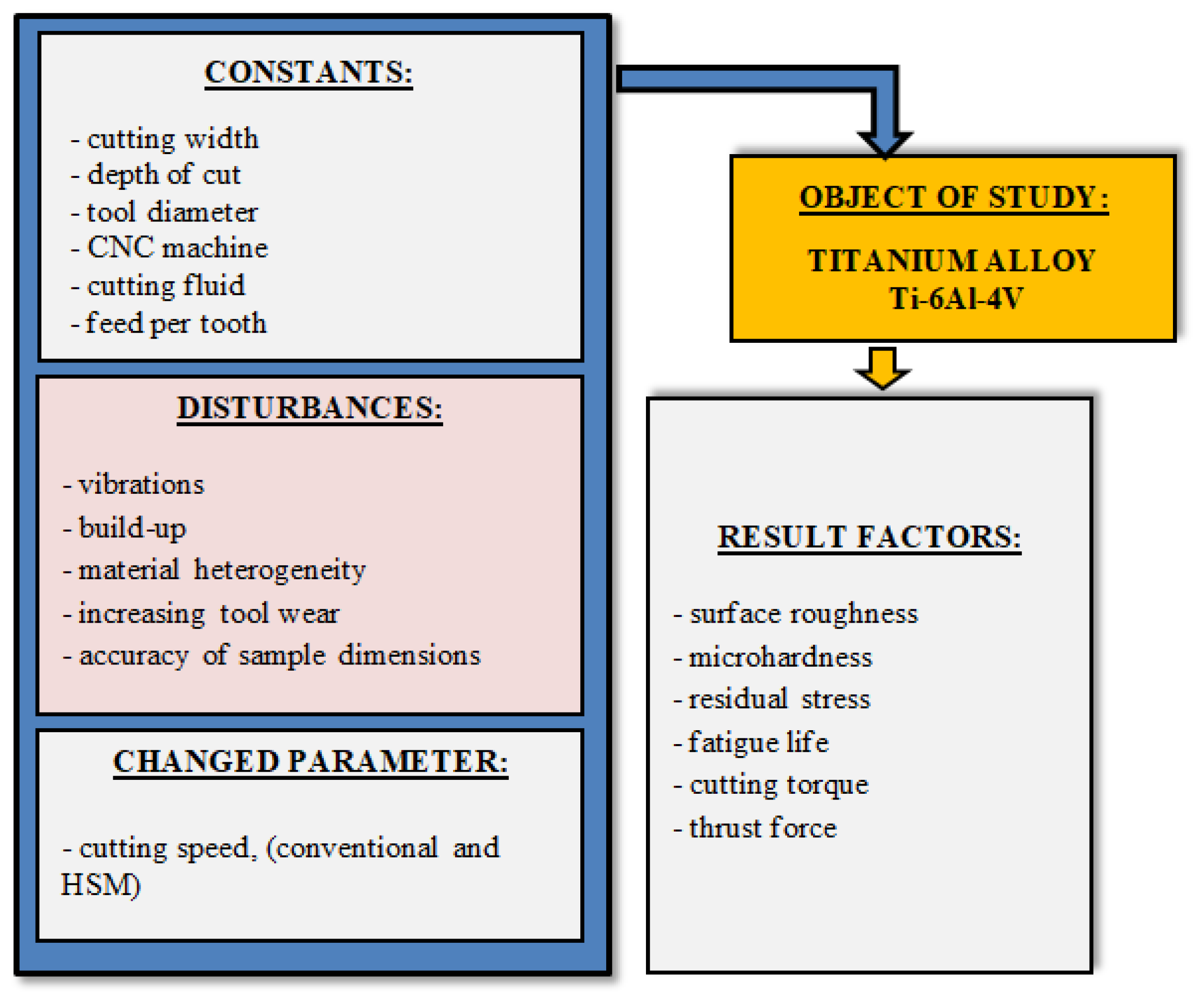

2.2. General Methodology

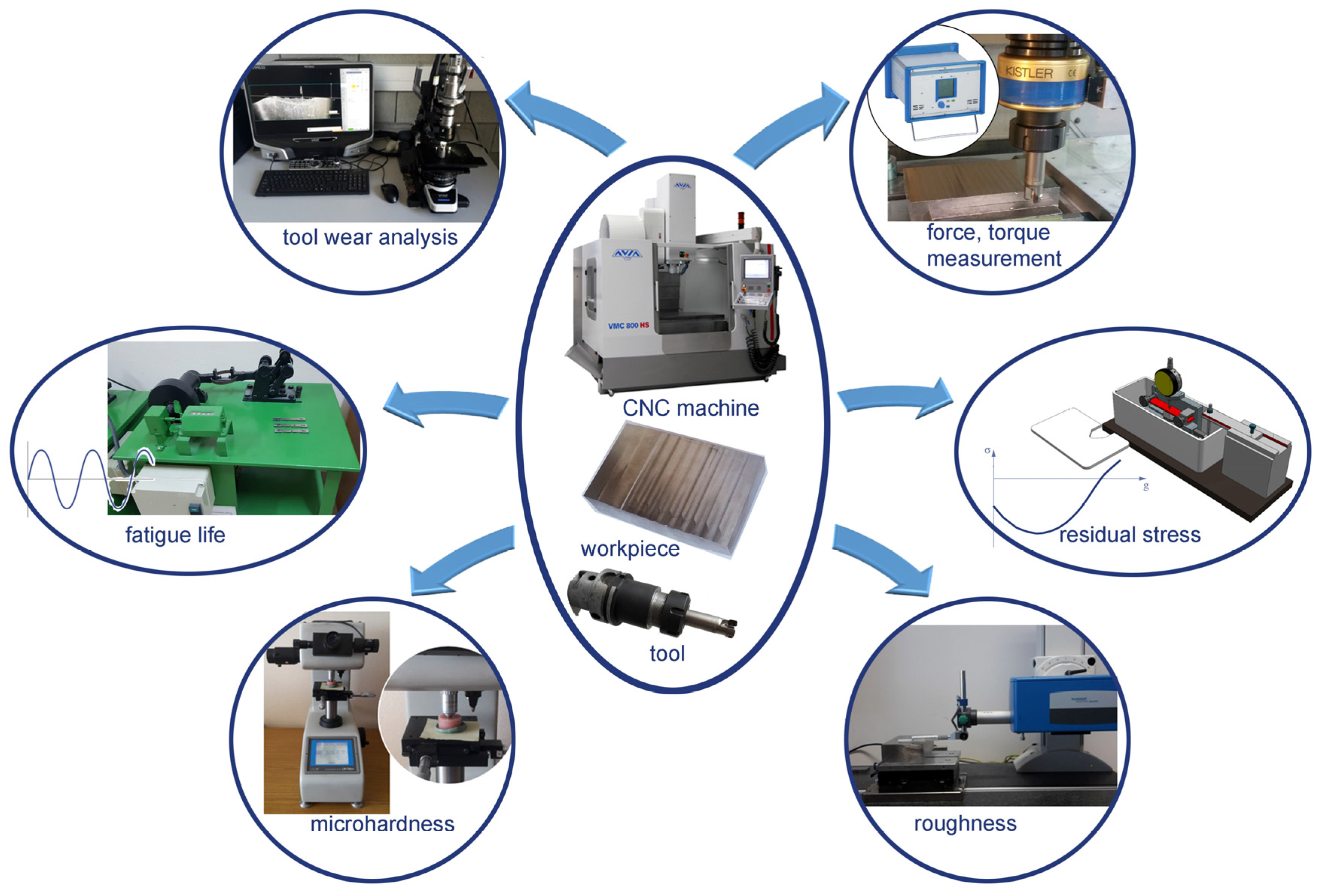

2.3. Measurements Equipment

3. Results

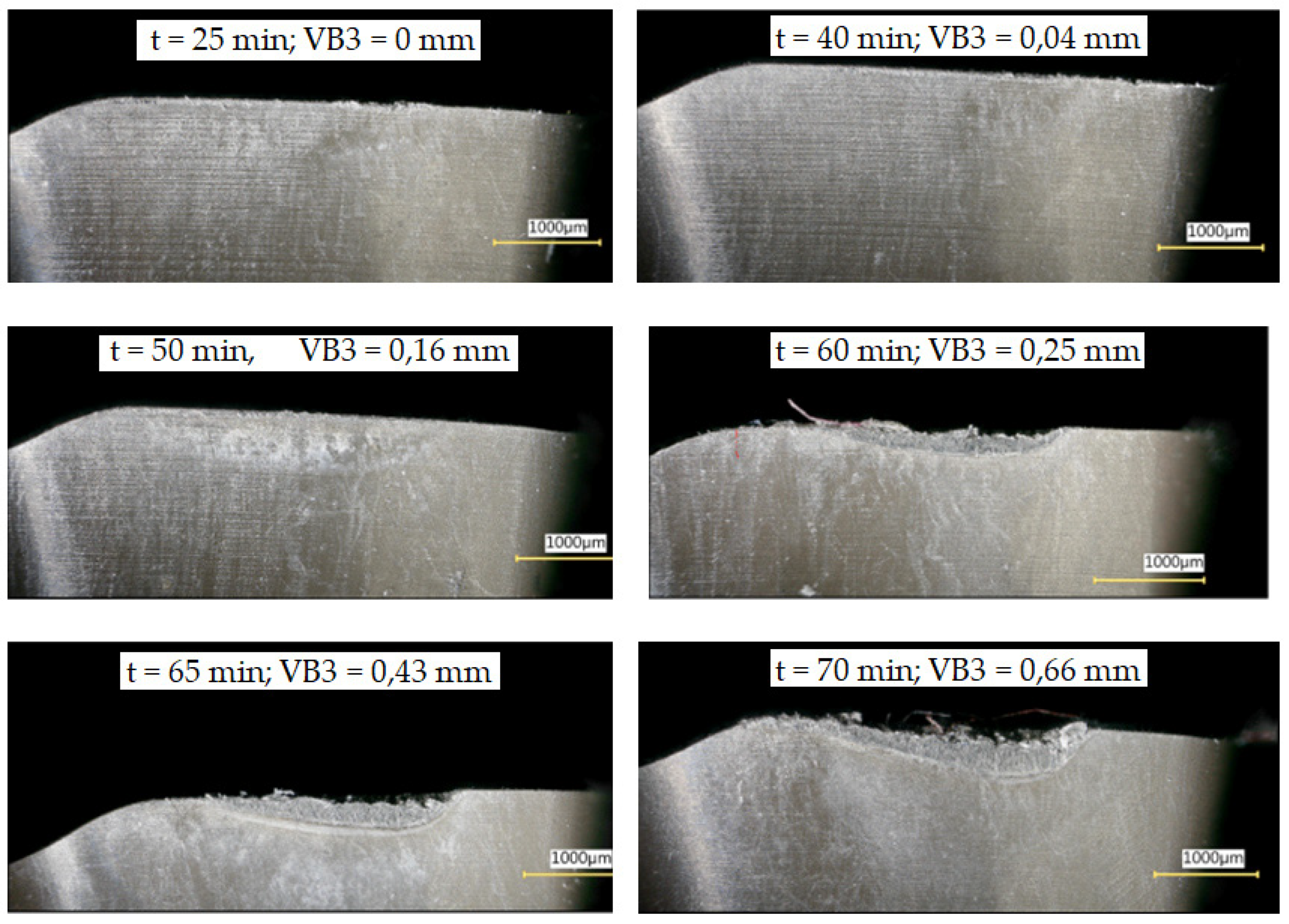

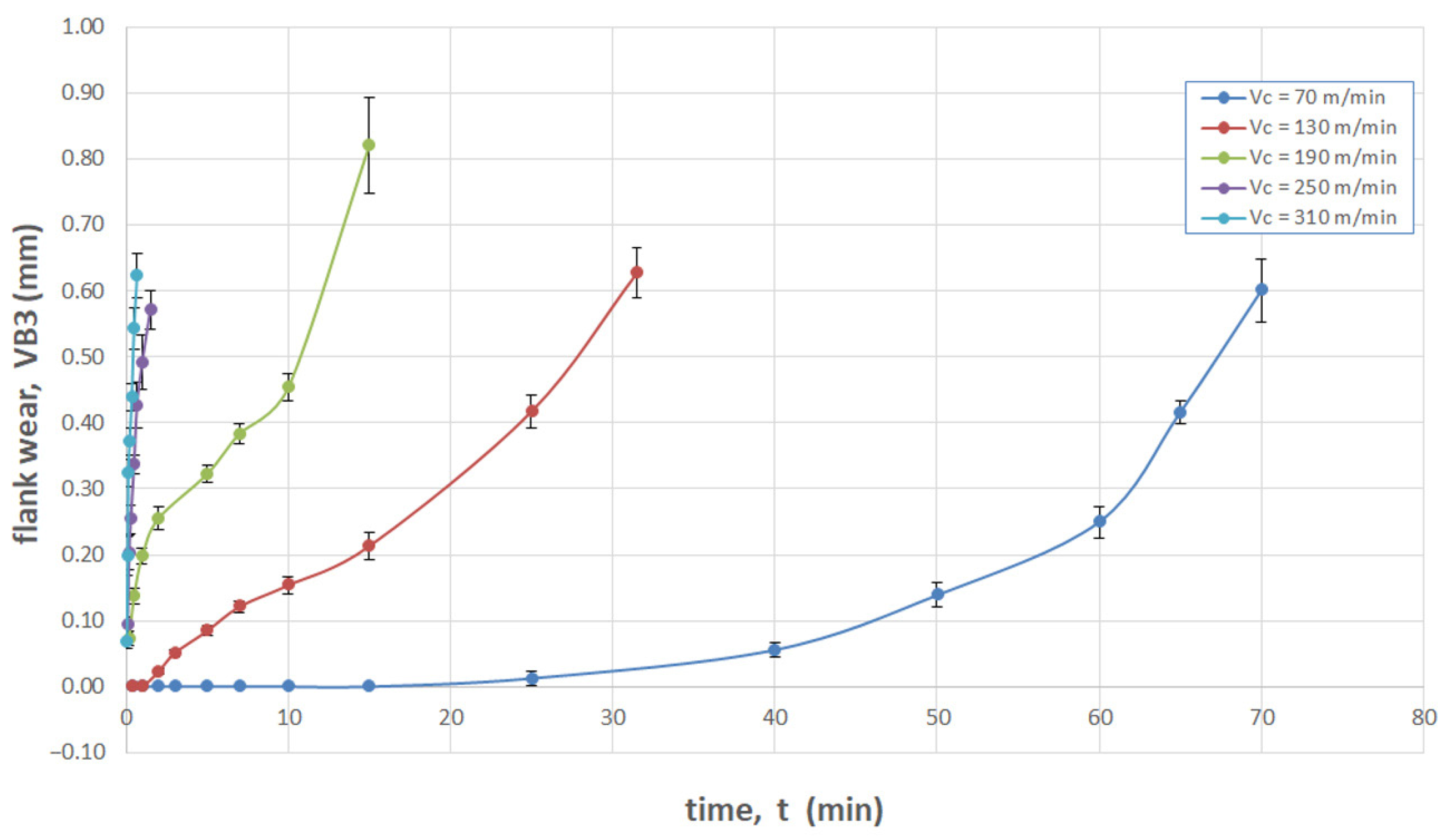

3.1. Tool Wear Tests

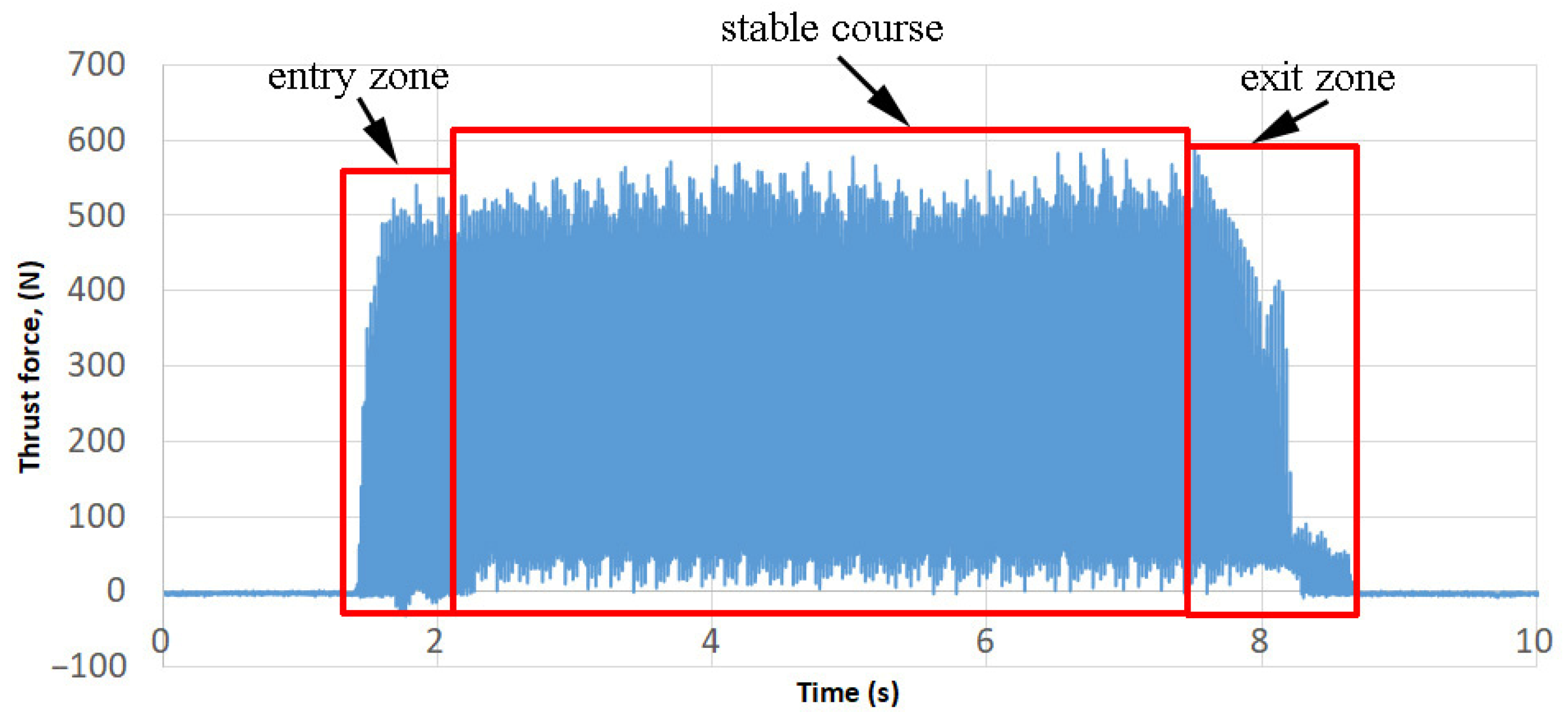

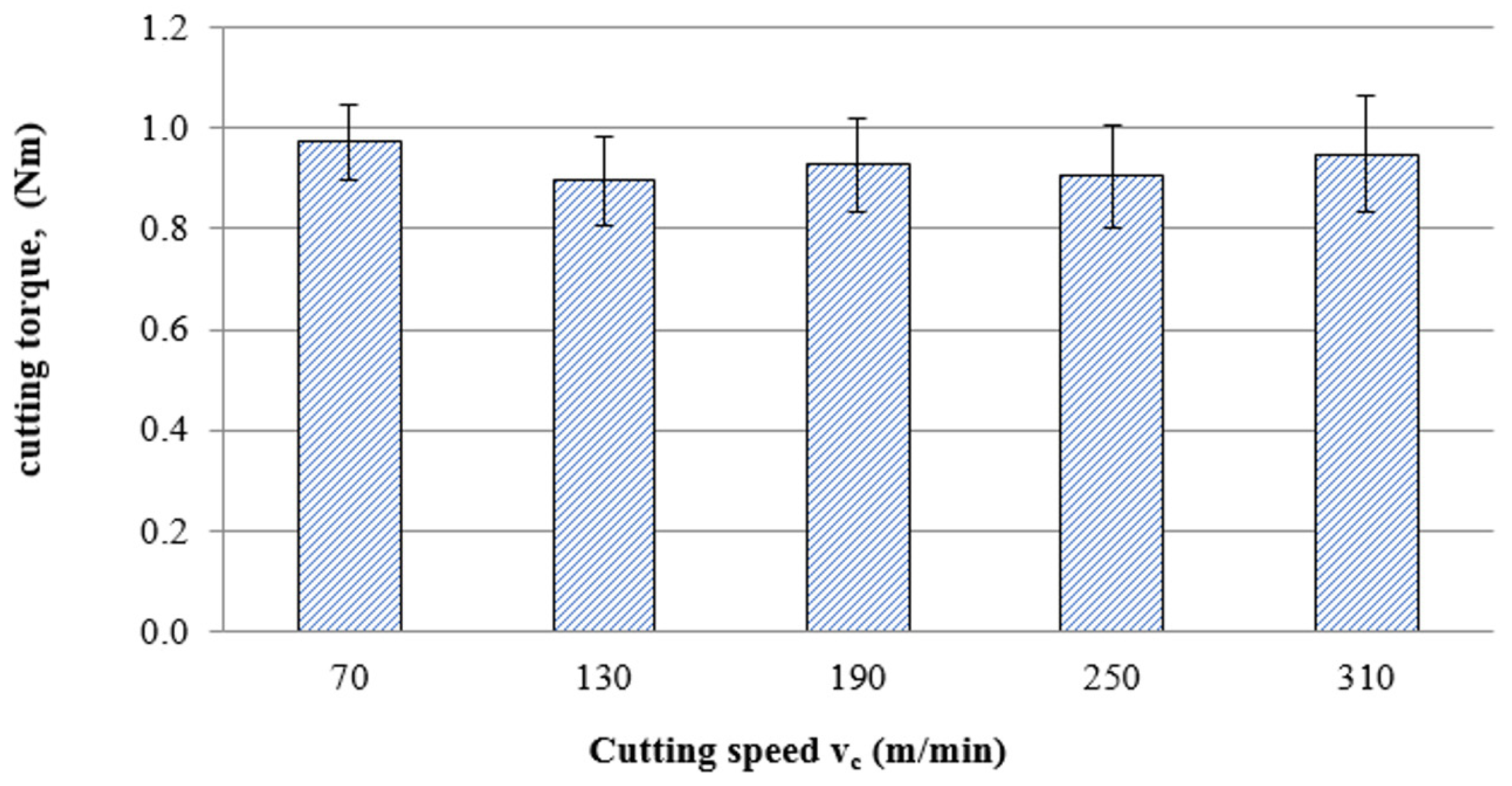

3.2. Tests of Thrust Force and Cutting Torque in the Milling Process

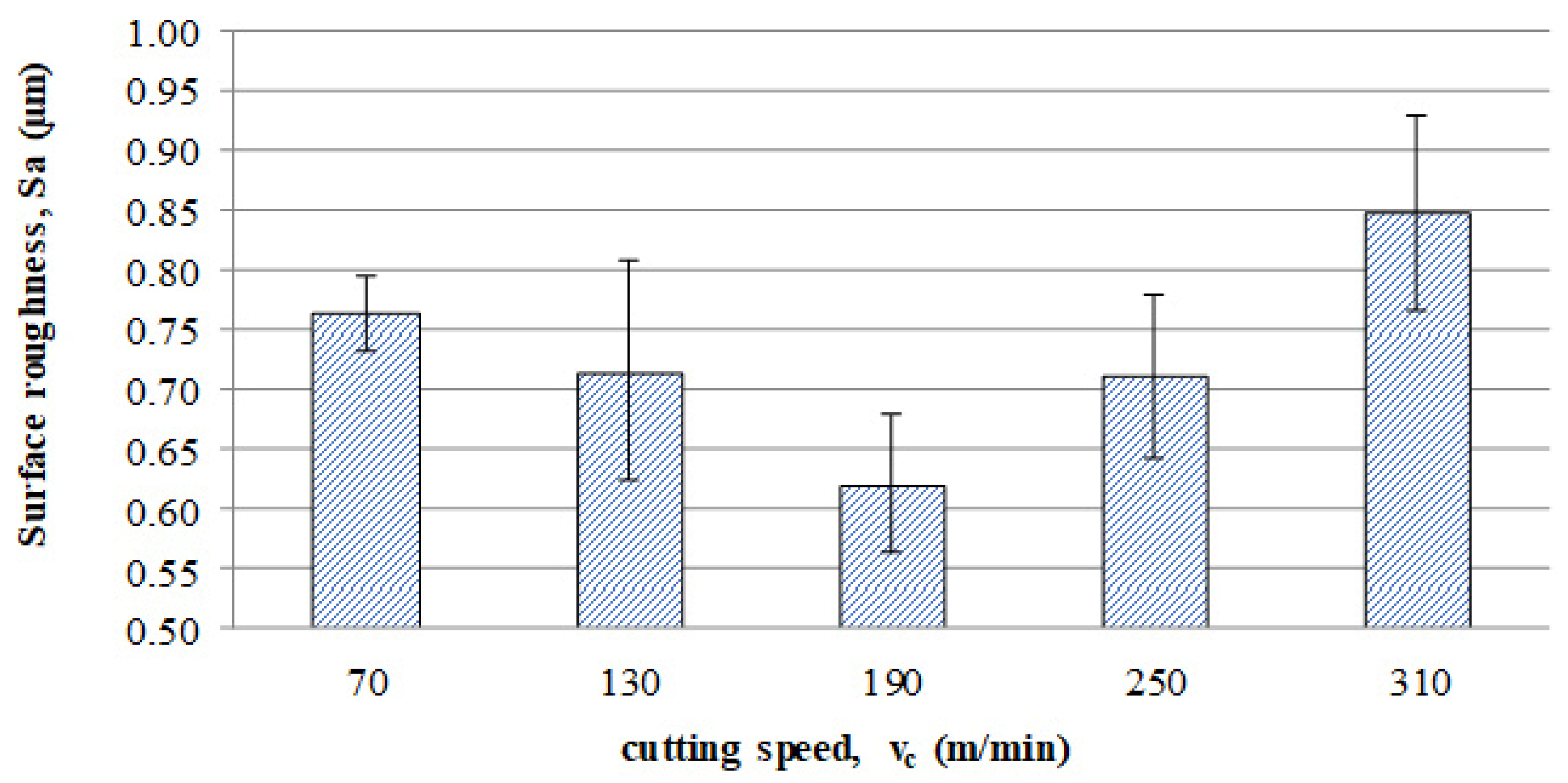

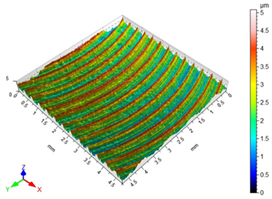

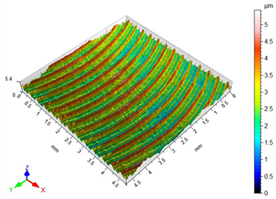

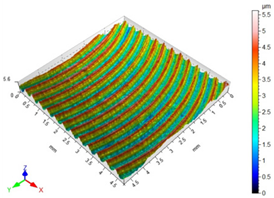

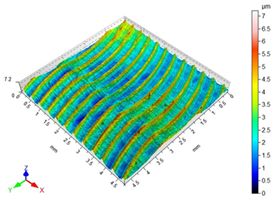

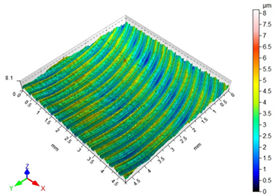

3.3. Surface Roughness

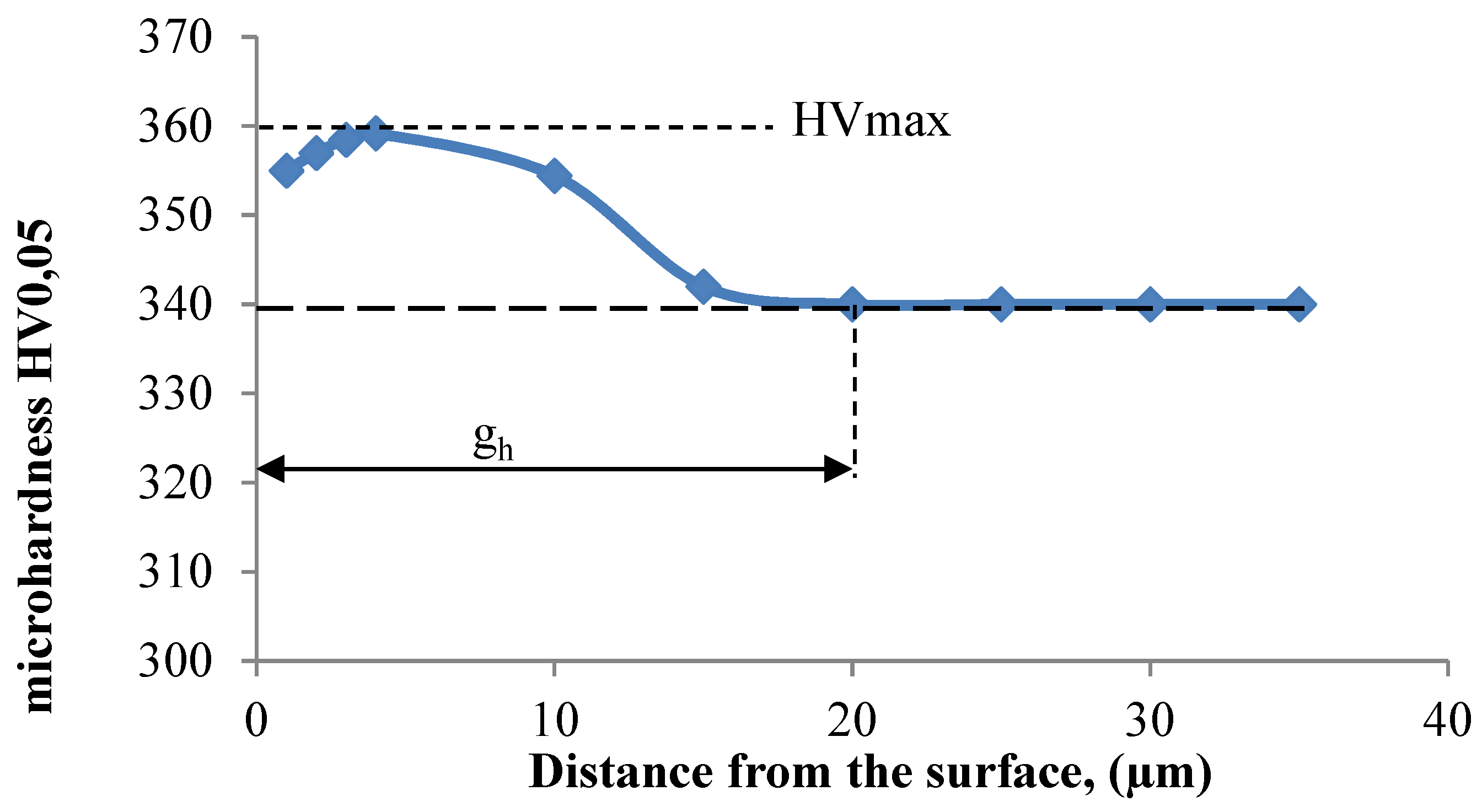

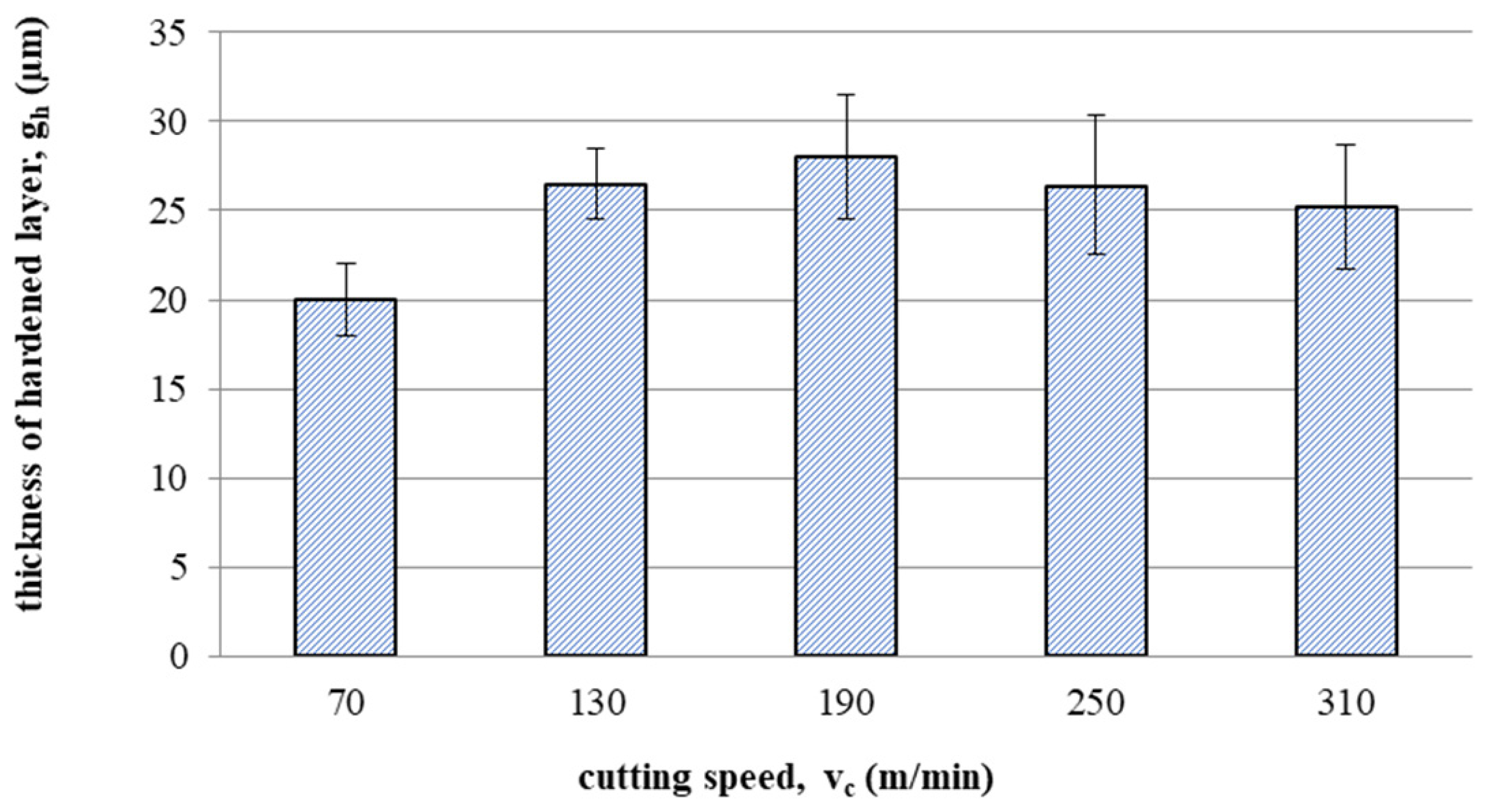

3.4. Surface Layer Microhardness

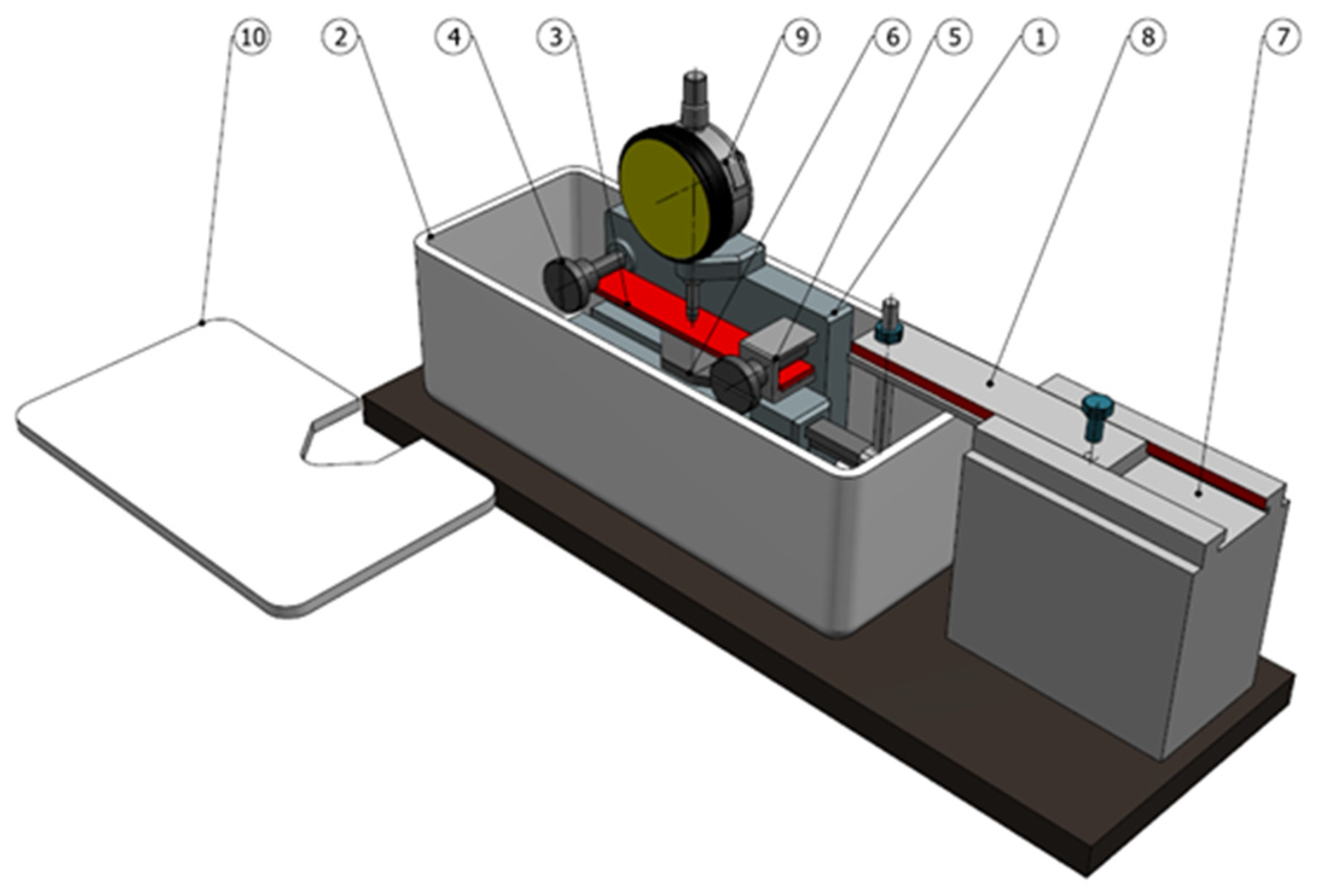

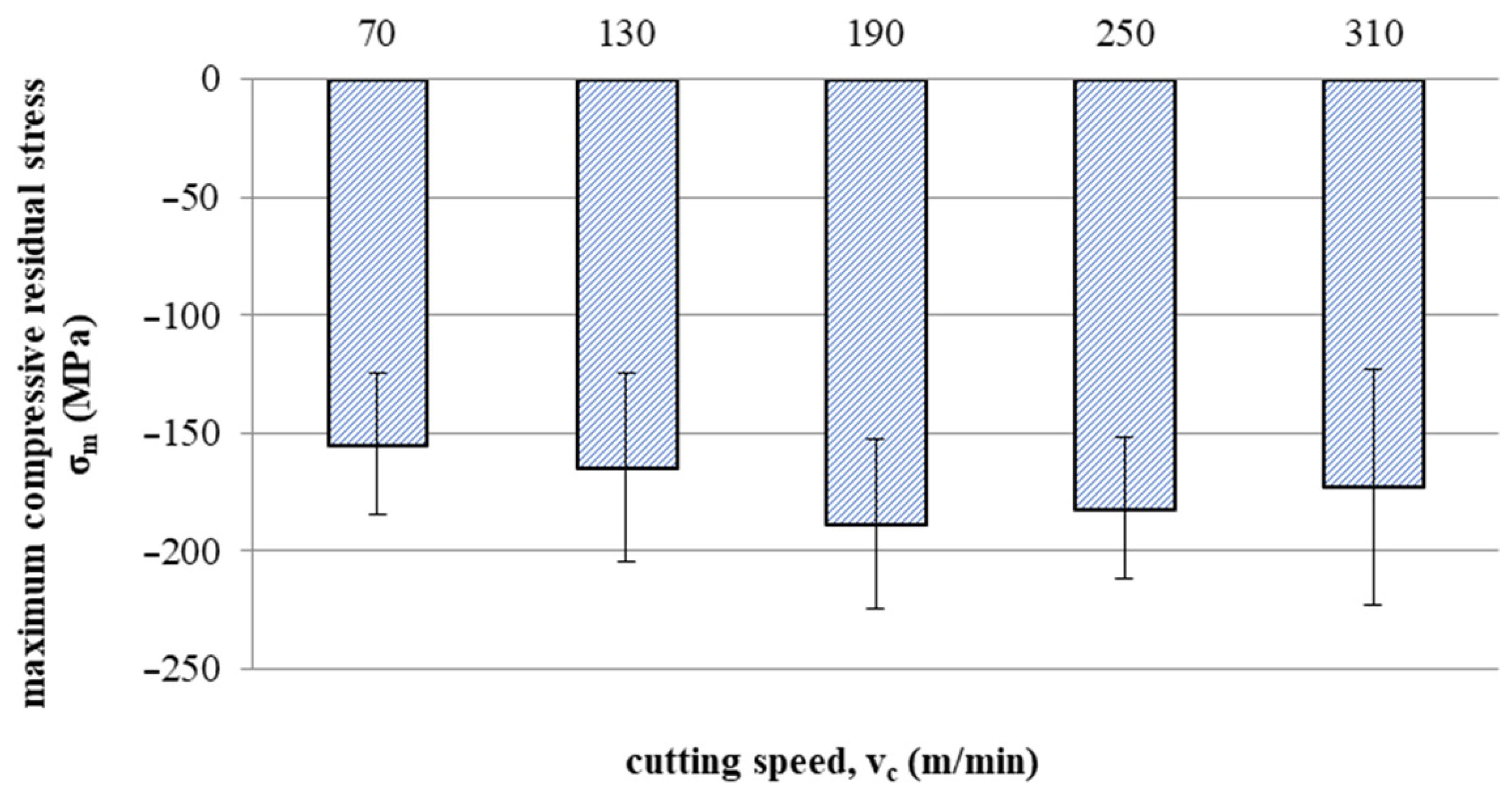

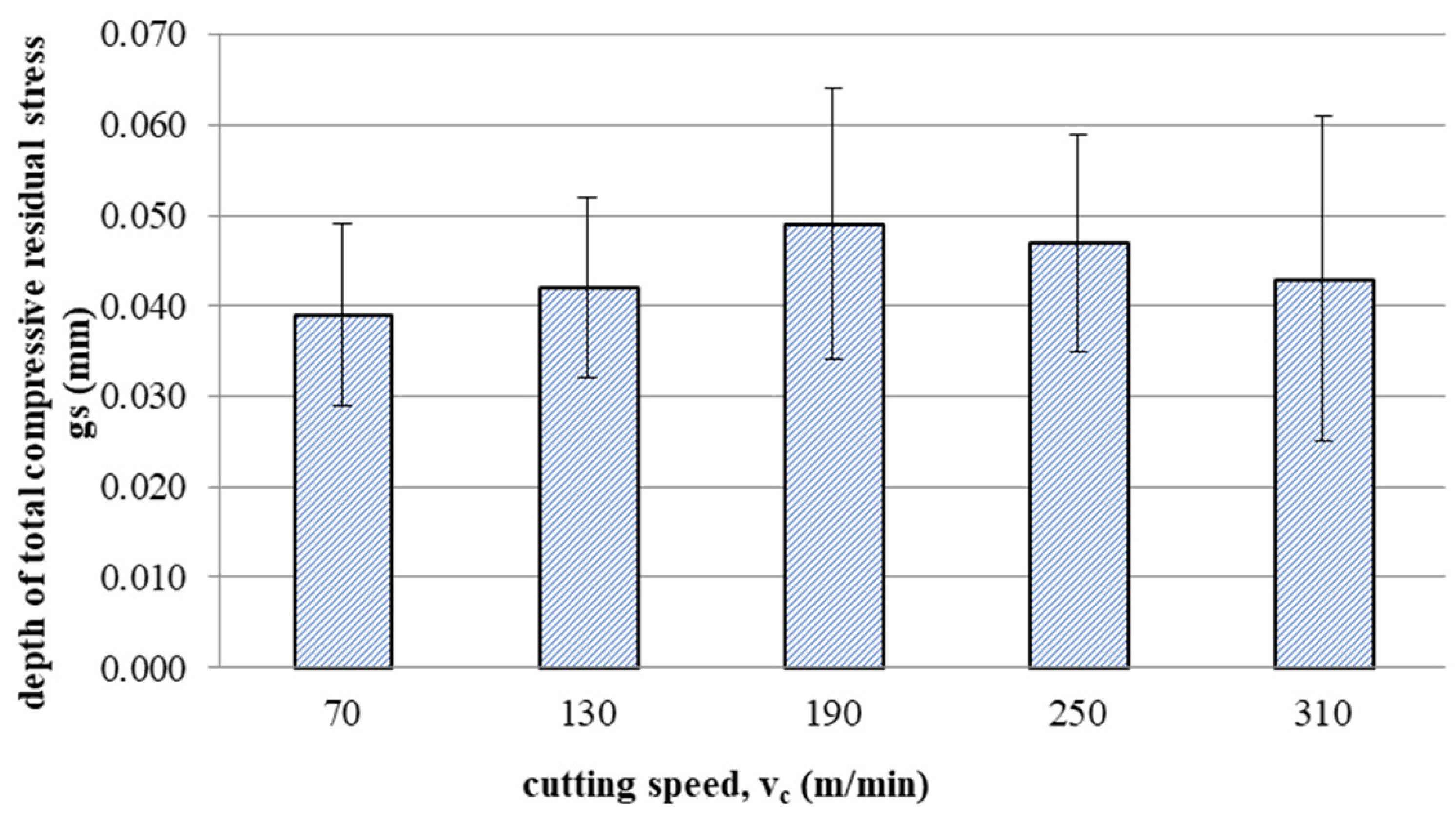

3.5. Residual Stress

- Compressive residual stress on the surface Ϭp;

- Maximum compressive residual stress Ϭm;

- Depth of maximum compressive residual stress gm;

- Depth of total compressive residual stress gs.

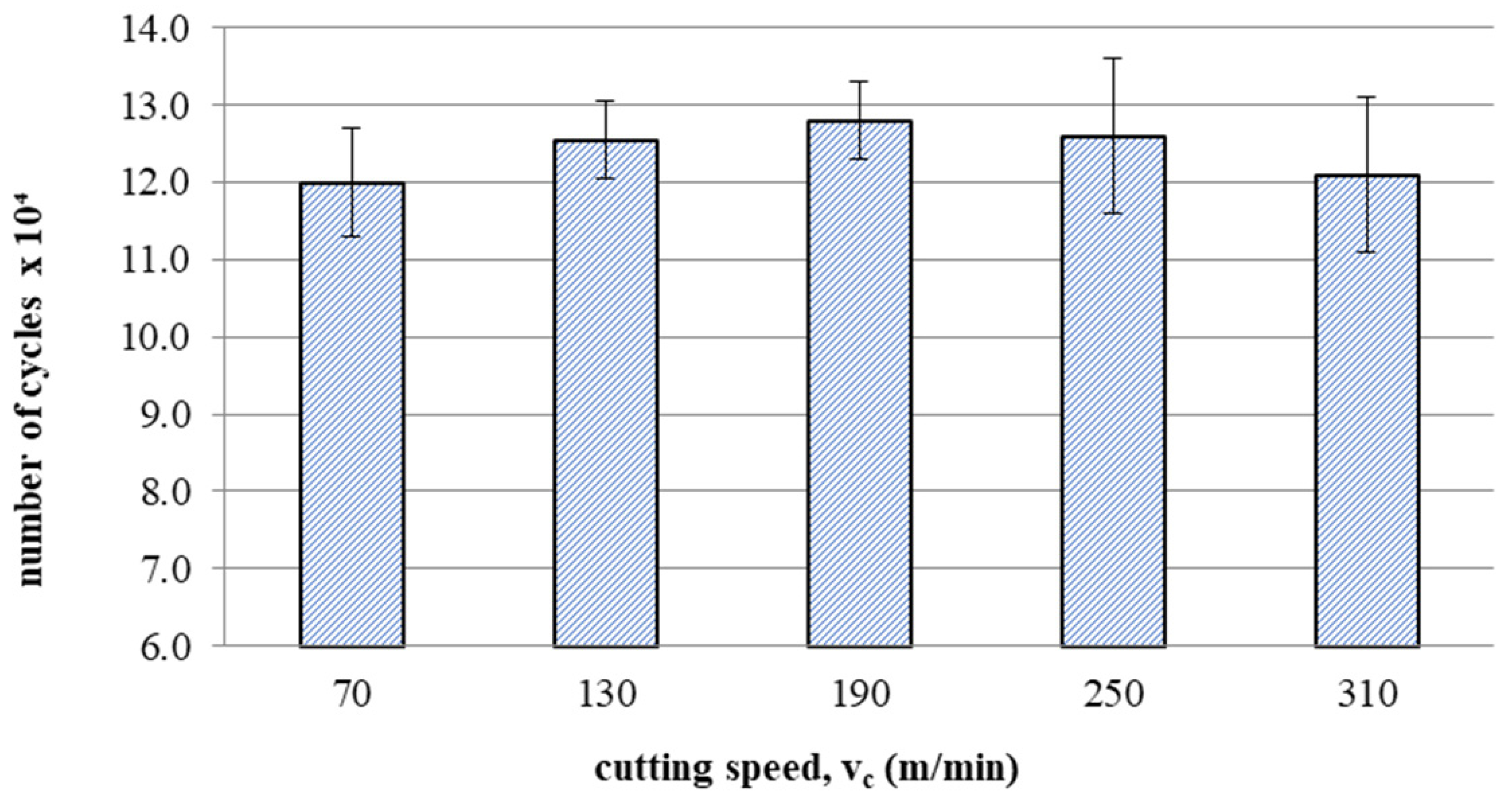

3.6. Fatigue Life Tests after Milling

4. Conclusions

- Machining of titanium alloy at higher cutting speeds reduces blade life;

- The best ratio of tool life to machining time under higher cutting speeds was obtained for the speed of 130 m/min;

- An increase in the cutting speed above vc = 190 m/min results in a several times faster increase in the flank wear (VB3) compared to conventional speeds (vc = 70 m/min);

- Cutting speeds in the range of vc = 250 to 310 m/min are not recommended due to rapid tool wear: Despite favourable changes in the surface layer properties in industrial practice, frequent tool changes preclude the use of vc = 250 and vc = 310 m/min speeds in the production of parts made of Ti6-Al-4V titanium alloy.

- In the range of the adopted cutting speeds, no significant changes in thrust force and cutting torque were observed;

- Up to the cutting speed of vc = 190 m/min, as the cutting speed increases, the surface roughness (Sa) decreases, and a further increase in cutting speed causes an increase in surface roughness: This may be related to the combination of several phenomena occurring in the process that with the increase in cutting speed up to 190 m/min, the temperature increases, which causes heating of the material and a decrease in the friction coefficient, while above this speed, rapid edge wear occurs (Figure 8), which may be the dominant factor;

- The cutting speed affects the hardened surface layer thickness: The thickness of the hardened layer varied from 20 to 28 micrometres;

- The cutting speed affects the residual stresses: The highest values of maximum compressive residual stress σm and the largest thickness of total compressive residual stress gs were obtained for the speed of vc = 190 m/min;

- Changes in the properties of the surface layer caused by milling affect the fatigue life, which is an important factor in terms of variable loads of manufactured elements: The largest number of cycles was obtained for the speed vc = 190 m/min.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Grzesik, W. Effect of the Machine Parts Surface Topography Features on the Machine Service. Mechanik 2015, 88, 587–593. [Google Scholar] [CrossRef] [Green Version]

- Kuczmaszewski, J.; Zaleski, K.; Matuszak, J.; Pałka, T.; Mądry, J. Studies on the Effect of Mill Microstructure upon Tool Life during Slot Milling of Ti6Al4V Alloy Parts. Eksploat. Niezawodn.-Maint. Reliab. 2017, 19, 590–596. [Google Scholar] [CrossRef]

- Li, M.; Yue, C.; Liu, X.; Zang, W.; Jiang, Z. Diffusion between Ti6Al4V and Cemented Carbide with Different Compositions. Metals 2023, 13, 240. [Google Scholar] [CrossRef]

- Wojciechowski, S.; Krajewska-Śpiewak, J.; Maruda, R.W.; Krolczyk, G.M.; Nieslony, P.; Wieczorowski, M.; Gawlik, J. Study on Ploughing Phenomena in Tool Flank Face—Workpiece Interface Including Tool Wear Effect during Ball-End Milling. Tribol. Int. 2023, 181, 108313. [Google Scholar] [CrossRef]

- Samborski, S.; Józwik, J.; Skoczylas, J.; Kłonica, M. Adaptation of Fracture Mechanics Methods for Quality Assessment of Tungsten Carbide Cutting Inserts. Materials 2021, 14, 3441. [Google Scholar] [CrossRef]

- Machado, A.R.; Wallbank, J. Machining of Titanium and Its Alloys—A Review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 1990, 204, 53–60. [Google Scholar] [CrossRef]

- Lebaal, N.; Nouari, M.; Ginting, A. A New Optimization Approach Based on Kriging Interpolation and Sequential Quadratic Programming Algorithm for End Milling Refractory Titanium Alloys. Appl. Soft Comput. 2011, 11, 5110–5119. [Google Scholar] [CrossRef]

- Abdel-Aal, H.A.; Nouari, M.; El Mansori, M. Influence of Thermal Conductivity on Wear When Machining Titanium Alloys. Tribol. Int. 2009, 42, 359–372. [Google Scholar] [CrossRef]

- Maruda, R.; Leksycki, K.; Wojciechowski, S.; Feldshtein, E.; Łukaszewicz, A. Evaluation of the Surface Topography of Ti6Al4V Alloy after the Finish Turning Process under Ecological Conditions. Adv. Sci. Technol. Res. J. 2023, 17, 63–70. [Google Scholar] [CrossRef]

- Kaltenbrunner, T.; Maier, K.; Klünsner, T.; Krückl, H.P.; Krobath, M.; Pötz, M.; Wosik, J.; Binder, O.; Teppernegg, T.; Czettl, C.; et al. Combined Experimental and Numerical Analysis of Critical Loading Conditions for Hard Metal Tool Damage in Titanium Milling. J. Manuf. Process. 2022, 77, 125–137. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Nieslony, P.; Wojciechowski, S.; Michalski, M.; Legutko, S. The Influence of the Cooling Conditions on the Cutting Tool Wear and the Chip Formation Mechanism. J. Manuf. Process. 2016, 24, 107–115. [Google Scholar] [CrossRef]

- Khatri, A.; Jahan, M.P.; Ma, J. Assessment of Tool Wear and Microstructural Alteration of the Cutting Tools in Conventional and Sustainable Slot Milling of Ti-6Al-4V Alloy. Int. J. Adv. Manuf. Technol. 2019, 105, 2799–2814. [Google Scholar] [CrossRef]

- Rahman, M.; Wong, Y.S.; Zareena, A.R. Machinability of Titanium Alloys. JSME Int. J. Ser. C 2003, 46, 107–115. [Google Scholar] [CrossRef] [Green Version]

- Machado, A.R.; Wallbank, J.; Pashby, I.R.; Ezugwu, E.O. Tool Performance and Chip Control When Machining Ti6a14v and Inconel 901 Using High Pressure Coolant Supply. Mach. Sci. Technol. 1998, 2, 1–12. [Google Scholar] [CrossRef]

- Kuljanic, E.; Fioretti, M.; Beltrame, L.; Miani, F. Milling Titanium Compressor Blades with PCD Cutter. CIRP Ann. 1998, 47, 61–64. [Google Scholar] [CrossRef]

- Kitagawa, T.; Kubo, A.; Maekawa, K. Temperature and Wear of Cutting Tools in High-Speed Machining of Inconel 718 and Ti6Al6V2Sn. Wear 1997, 202, 142–148. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Da Silva, R.B.; Bonney, J.; Machado, Á.R. The Effect of Argon-Enriched Environment in High-Speed Machining of Titanium Alloy. Tribol. Trans. 2005, 48, 18–23. [Google Scholar] [CrossRef]

- Hon, K.; Baharudin, B.H.T. The Impact of High Speed Machining on Computing and Automation. Int. J. Autom. Comput. 2006, 3, 63–68. [Google Scholar] [CrossRef]

- Childerhouse, T.; M’Saoubi, R.; Franca, L.F.P.; Crawforth, P.; Jackson, M. Machining Performance and Wear Behaviour of Polycrystalline Diamond and Coated Carbide Tools during Milling of Titanium Alloy Ti-54M. Wear 2023, 523, 204791. [Google Scholar] [CrossRef]

- Erdel, B.P. High-Speed Machining; Society of Manufacturing Engineers: Dearborn, Mich, 2003; ISBN 978-0-87263-649-1. [Google Scholar]

- Wang, Z.G.; Wong, Y.S.; Rahman, M. High-Speed Milling of Titanium Alloys Using Binderless CBN Tools. Int. J. Mach. Tools Manuf. 2005, 45, 105–114. [Google Scholar] [CrossRef]

- Wang, Z.G.; Rahman, M.; Wong, Y.S. Tool Wear Characteristics of Binderless CBN Tools Used in High-Speed Milling of Titanium Alloys. Wear 2005, 258, 752–758. [Google Scholar] [CrossRef]

- Vijay, S.; Krishnaraj, V. Machining Parameters Optimization in End Milling of Ti-6Al-4V. Procedia Eng. 2013, 64, 1079–1088. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Chen, Z.; Zhou, Z. Influence of Cutting Speed and Tool Wear on the Surface Integrity of the Titanium Alloy Ti-1023 during Milling. Int. J. Adv. Manuf. Technol. 2015, 78, 1113–1126. [Google Scholar] [CrossRef] [Green Version]

- Ciecieląg, K.; Skoczylas, A.; Matuszak, J.; Zaleski, K.; Kęcik, K. Defect Detection and Localization in Polymer Composites Based on Drilling Force Signal by Recurrence Analysis. Measurement 2021, 186, 110126. [Google Scholar] [CrossRef]

- Zawada-Michałowska, M.; Kuczmaszewski, J.; Pieśko, P. Effect of the Geometry of Thin-Walled Aluminium Alloy Elements on Their Deformations after Milling. Materials 2022, 15, 9049. [Google Scholar] [CrossRef] [PubMed]

- Ciecieląg, K.; Zaleski, K. Milling of Three Types of Thin-Walled Elements Made of Polymer Composite and Titanium and Aluminum Alloys Used in the Aviation Industry. Materials 2022, 15, 5949. [Google Scholar] [CrossRef] [PubMed]

- Matuszak, J.; Zaleski, K.; Ciecieląg, K.; Skoczylas, A. Analysis of the Effectiveness of Removing Surface Defects by Brushing. Materials 2022, 15, 7833. [Google Scholar] [CrossRef]

- Twardowski, P.; Wieczorowski, M. Monitoring of Cutting Process and Tool Condition of Metal and Metal Composite. Materials 2023, 16, 3660. [Google Scholar] [CrossRef]

- Rusinek, R.; Lajmert, P.; Kęcik, K.; Kruszyński, B.; Warmiński, J. Chatter Identification Methods on the Basis of Time Series Measured during Titanium Superalloy Milling. Int. J. Mech. Sci. 2015, 99, 196–207. [Google Scholar] [CrossRef]

- Rusinek, R.; Zaleski, K. Dynamics of Thin-Walled Element Milling Expressed by Recurrence Analysis. Meccanica 2016, 51, 1275–1286. [Google Scholar] [CrossRef] [Green Version]

- Kurpiel, S.; Zagórski, K.; Cieślik, J.; Skrzypkowski, K. Investigation of Selected Surface Topography Parameters and Deformation during Milling of Vertical Thin-Walled Structures from Titanium Alloy Ti6Al4V. Materials 2023, 16, 3182. [Google Scholar] [CrossRef] [PubMed]

- Aly, H.A.; El-Sayed Seleman, M.M.; Bakkar, A.; Albaijan, I.; Ahmed, M.M.Z.; Ibrahim, K.M. Effect of Si Content on the Thermal Expansion of Ti15Mo(0–2 Si) Biomaterial Alloys during Different Heating Rates. Materials 2023, 16, 4768. [Google Scholar] [CrossRef]

- Ibrahim, S.A.; Seleman, M.M.; Ahmed, H.M.; Hannora, A.E. Phase Stability of Mechanically Alloyed Ti-Fe-Al Alloys. IOP Conf. Ser. Mater. Sci. Eng. 2020, 973, 012025. [Google Scholar] [CrossRef]

- Kluz, R.; Habrat, W.; Bucior, M.; Krupa, K.; Sęp, J. Multi-Criteria Optimization of the Turning Parameters of Ti-6Al-4V Titaniumalloy Using the Response Surface Methodology. Eksploat. Niezawodn.–Maint. Reliab. 2022, 24, 668–676. [Google Scholar] [CrossRef]

- Ulutan, D.; Ozel, T. Machining Induced Surface Integrity in Titanium and Nickel Alloys: A Review. Int. J. Mach. Tools Manuf. 2011, 51, 250–280. [Google Scholar] [CrossRef]

- Kuczmaszewski, J.; Zaleski, K.; Matuszak, J.; Mądry, J. Testing Geometric Precision and Surface Roughness of Titanium Alloy Thin-Walled Elements Processed with Milling. In Advances in Manufacturing II; Lecture Notes in Mechanical, Engineering; Diering, M., Wieczorowski, M., Brown, C.A., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 95–106. ISBN 978-3-030-18681-4. [Google Scholar]

- Ginting, A.; Nouari, M. Surface Integrity of Dry Machined Titanium Alloys. Int. J. Mach. Tools Manuf. 2009, 49, 325–332. [Google Scholar] [CrossRef]

- Su, H.; Liu, P.; Fu, Y.; Xu, J. Tool Life and Surface Integrity in High-Speed Milling of Titanium Alloy TA15 with PCD/PCBN Tools. Chin. J. Aeronaut. 2012, 25, 784–790. [Google Scholar] [CrossRef] [Green Version]

- Sun, J.; Guo, Y.B. A Comprehensive Experimental Study on Surface Integrity by End Milling Ti–6Al–4V. J. Mater. Process. Technol. 2009, 209, 4036–4042. [Google Scholar] [CrossRef]

| Chemical Composition, wt.% | Mechanical Properties | ||

|---|---|---|---|

| Al | 6.25–6.31 | Rm (MPa) E (GPa) | 1014 120 |

| V | 4.09–4.12 | ||

| C | 0.026–0.027 | ||

| Fe | 0.18–0.21 | HRC | 33 |

| Ti | Rest | ||

| vc | Surface Topography | Roughness Parameters, (µm) |

|---|---|---|

| 70 m/min |  | Sp = 3.47 Sv = 3.76 Sz = 5.23 Sa = 0.80 |

| 130 m/min |  | Sp = 2.49 Sv = 2.56 Sz = 4.95 Sa = 0.67 |

| 190 m/min |  | Sp = 3.47 Sv = 2.99 Sz = 5.45 Sa = 0.63 |

| 250 m/min |  | Sp = 3.08 Sv = 3.64 Sz = 7.12 Sa = 0.77 |

| 310 m/min |  | Sp = 3.05 Sv = 4.00 Sz = 8.08 Sa = 0.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matuszak, J.; Zaleski, K.; Zyśko, A. Investigation of the Impact of High-Speed Machining in the Milling Process of Titanium Alloy on Tool Wear, Surface Layer Properties, and Fatigue Life of the Machined Object. Materials 2023, 16, 5361. https://doi.org/10.3390/ma16155361

Matuszak J, Zaleski K, Zyśko A. Investigation of the Impact of High-Speed Machining in the Milling Process of Titanium Alloy on Tool Wear, Surface Layer Properties, and Fatigue Life of the Machined Object. Materials. 2023; 16(15):5361. https://doi.org/10.3390/ma16155361

Chicago/Turabian StyleMatuszak, Jakub, Kazimierz Zaleski, and Andrzej Zyśko. 2023. "Investigation of the Impact of High-Speed Machining in the Milling Process of Titanium Alloy on Tool Wear, Surface Layer Properties, and Fatigue Life of the Machined Object" Materials 16, no. 15: 5361. https://doi.org/10.3390/ma16155361

APA StyleMatuszak, J., Zaleski, K., & Zyśko, A. (2023). Investigation of the Impact of High-Speed Machining in the Milling Process of Titanium Alloy on Tool Wear, Surface Layer Properties, and Fatigue Life of the Machined Object. Materials, 16(15), 5361. https://doi.org/10.3390/ma16155361