On the Degree of Plastic Strain during Laser Shock Peening of Ti-6Al-4V

Abstract

:1. Introduction

2. Materials and Methods

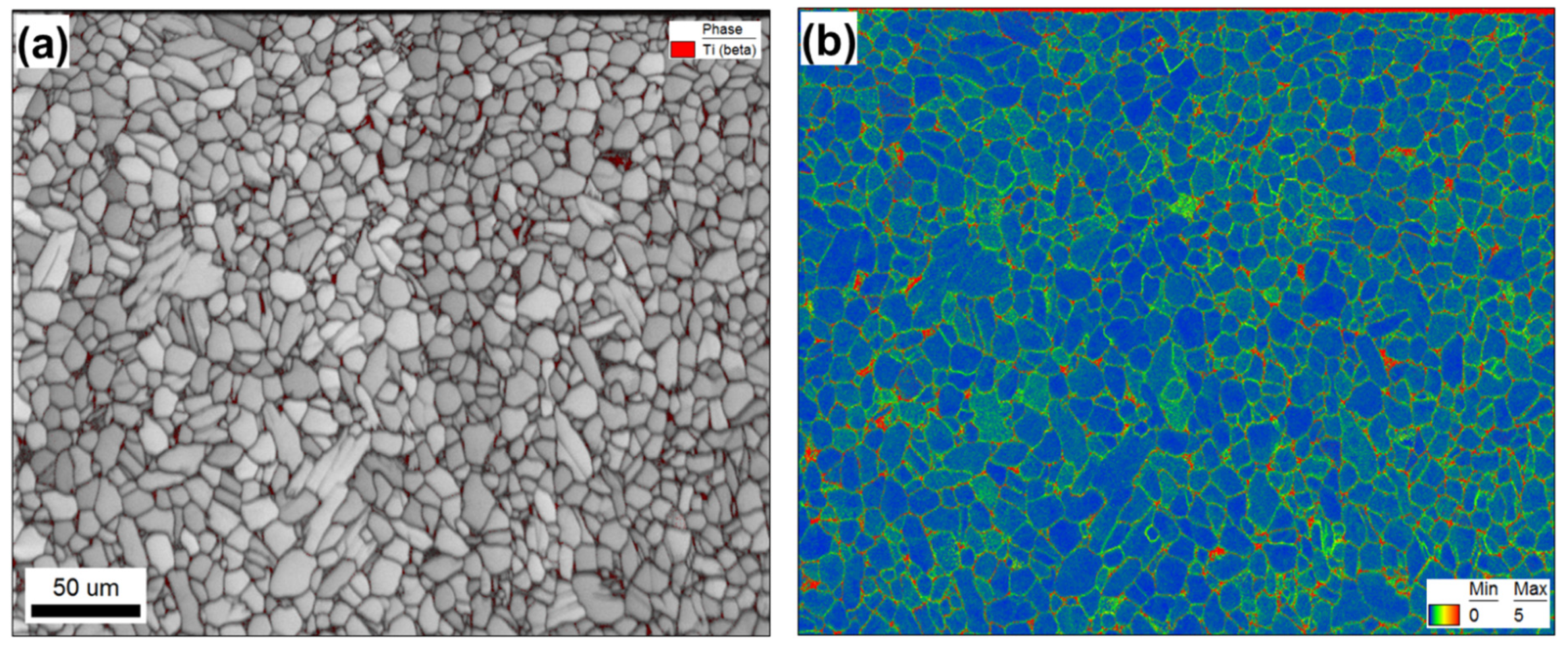

3. Results

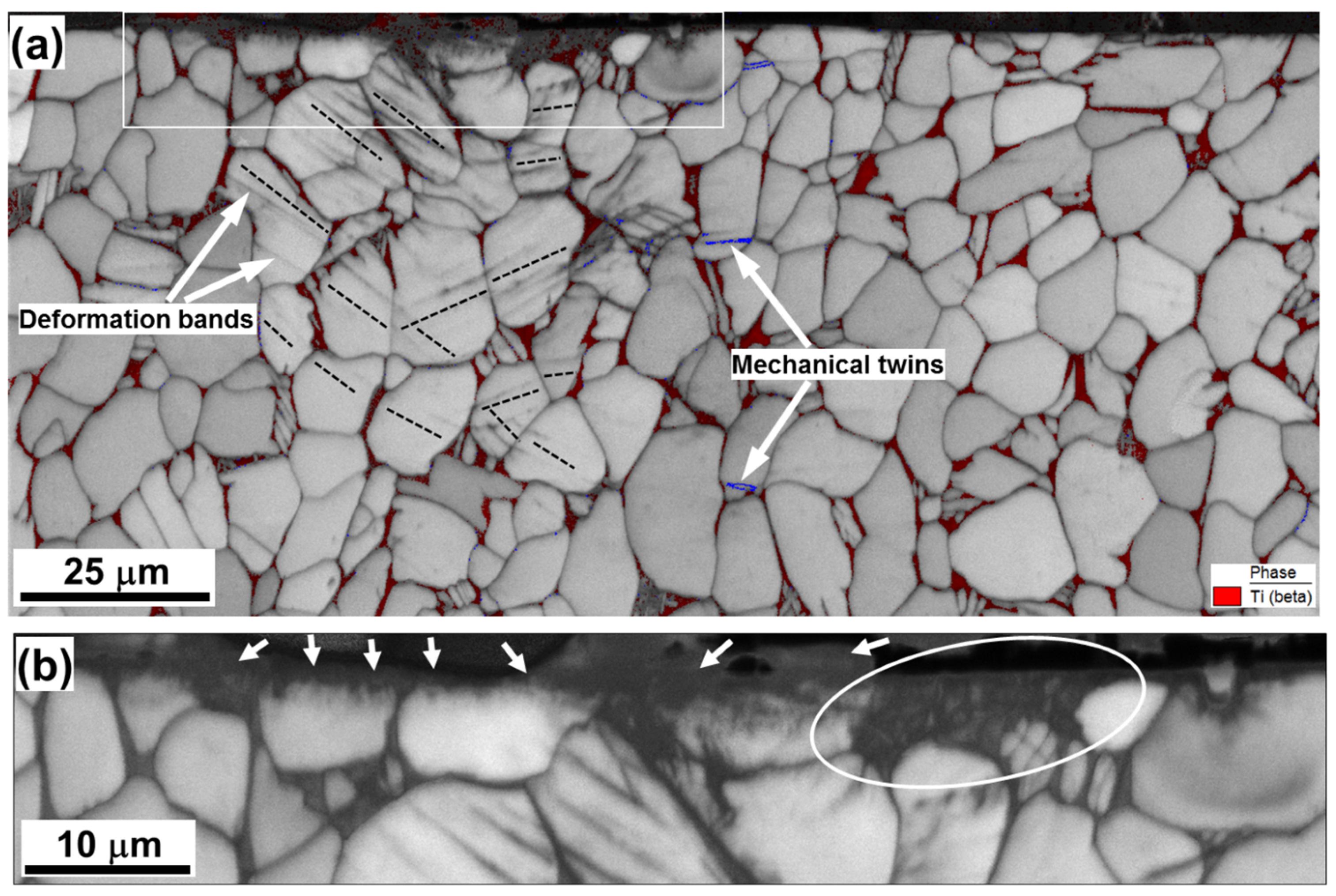

3.1. Three LSP Passes

3.1.1. Surface Phenomena

3.1.2. Subsurface Processes

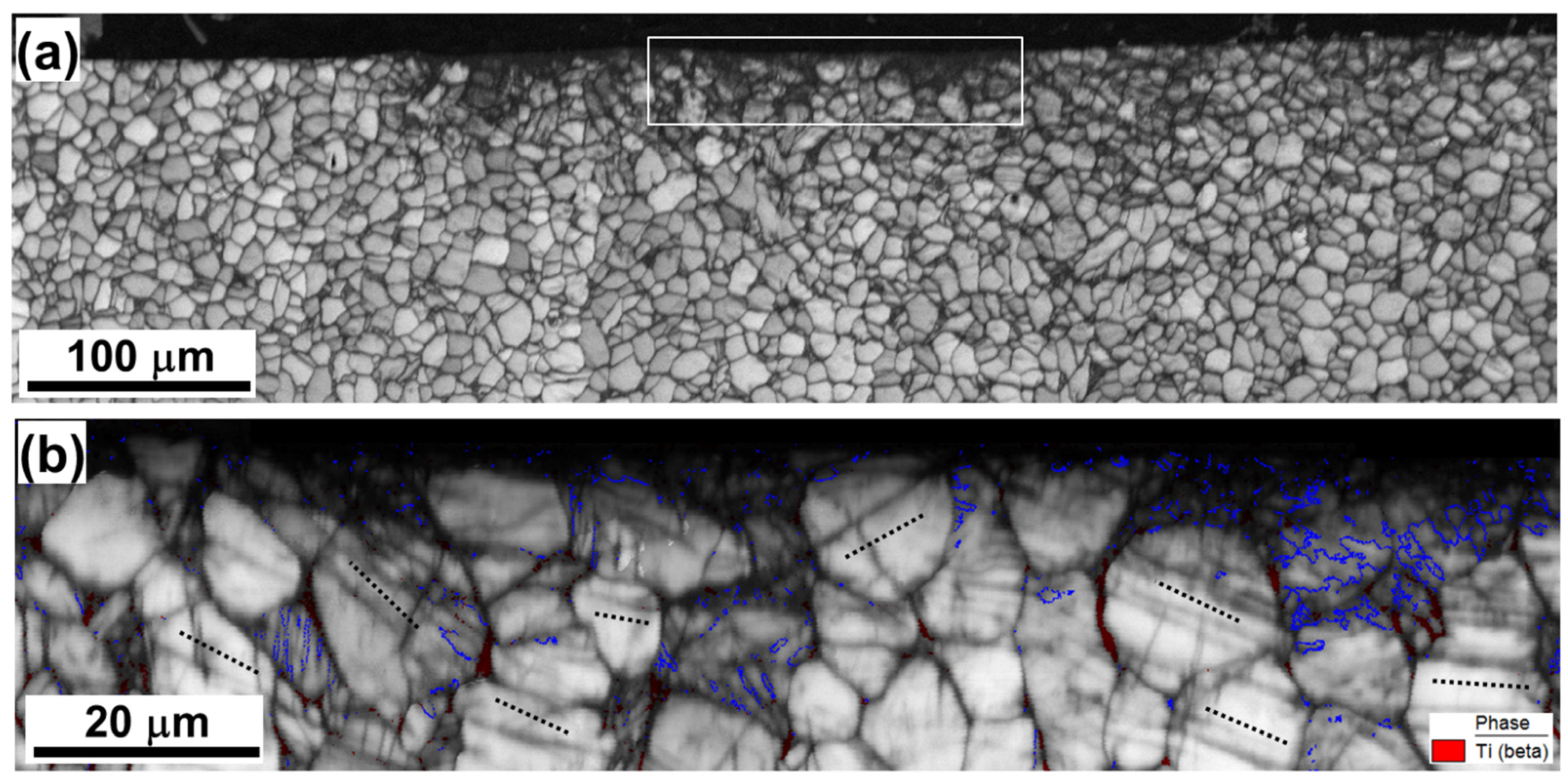

3.2. Five LSP Passes

4. Discussion

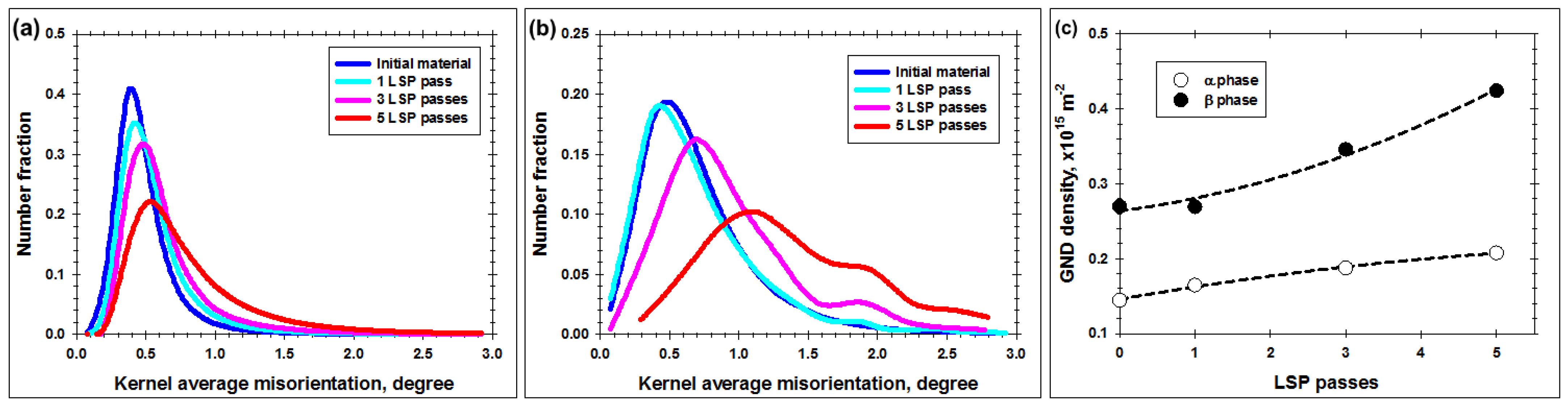

4.1. Evaluation of the Degree of the LSP-Induced Strain

4.2. Magnitude of LSP-Induced Stress

4.3. Strain Hardening Rate of LSP

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- King, A.; Steuwer, A.; Woodward, C.; Withers, P.J. Effects of Fatigue and Fretting on Residual Stresses Introduced by Laser Shock Peening. Mater. Sci. Eng. A 2006, 12–18, 435–436. [Google Scholar] [CrossRef]

- Wang, Z.-M.; Jia, Y.-F.; Zhang, X.-C.; Fu, Y.; Zhang, C.-C.; Tu, S.-T. Effects of Different Mechanical Surface Enhancement Techniques on Surface Integrity and Fatigue Properties of Ti-6Al-4V: A Review. Crit. Rev. Sol. Stat. Mater. Sci. 2019, 44, 445–469. [Google Scholar] [CrossRef]

- Jin, X.; Lan, L.; Gao, S.; He, B.; Rong, Y. Effects of Laser Shock Peening on Microstructure and Fatigue Behavior of Ti-6Al-4V Alloy Fabricated via Electron Beam Melting. Mater. Sci. Eng. A 2020, 780, 139–199. [Google Scholar] [CrossRef]

- Zhang, X.C.; Zhang, Y.K.; Lu, J.Z.; Xuan, F.Z.; Wang, Z.D.; Tu, S.T. Improvement of Fatigue Life of Ti-6Al-4V Alloy by Laser Shock Peening. Mater. Sci. Eng. A 2010, 527, 3411–3415. [Google Scholar] [CrossRef]

- Zhang, H.; Cai, Z.; Guo, W.; Zhang, H.; Yan, J.; He, G.; Zhang, Y.; Sun, R.; Che, Z. Experimental and Numerical Studies of Fatigue Behavior of Ti6Al4V Alloy Treated by Laser Shock Peening. Surf. Coat. Technol. 2022, 441, 128524. [Google Scholar] [CrossRef]

- Praveenkumar, K.; Mylavarapu, P.; Sarkar, A.; Isaac Samuel, E.; Nagesha, A.; Swaroop, S. Residual Stress Distribution and Elevated Temperature Fatigue Behaviour of Laser Peened Ti-6Al-4V with a Curved Surface. Int. J. Fatig. 2022, 156, 106641. [Google Scholar] [CrossRef]

- Ren, X.; Chen, B.; Jiao, J.; Yang, Y.; Zhou, W.; Tong, Z. Fatigue Behavior of Double-Sided Laser Shock Peened Ti-6Al-4V Thin Blade Subjected to Foreign Object Damage. Optic. Laser Technol. 2020, 121, 105784. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, W.; Chen, B.; Tong, Z.; Chen, L.; Ren, X. Fatigue Behaviors of Foreign Object Damaged Ti-6Al-4V Alloys Under Laser Shock Peening. Int. J. Fatig. 2020, 136, 105596. [Google Scholar] [CrossRef]

- Luo, X.; Dang, N.; Wang, X. The Effect of Laser Shock Peening, Shot peening and Their Combination on the Microstructure and Fatigue Properties of Ti-6Al-4V Titanium Alloy. Int. J. Fatig. 2021, 153, 106465. [Google Scholar] [CrossRef]

- Spanrad, S.; Tong, J. Characterisation of Foreign Object Damage (FOD) and Early Fatigue Crack Growth in Laser Shock Peened Ti-6Al-4V Aerofoil Specimens. Mater. Sci. Eng. A 2011, 528, 2128–2136. [Google Scholar] [CrossRef]

- Lin, B.; Lupton, C.; Spanrad, S.; Schofield, J.; Tong, J. Fatigue Crack Growth in Laser-Shock-Peened Ti-6Al-4V Aerofoil Specimens due to Foreign Object Damage. Int. J. Fatig. 2014, 59, 23–33. [Google Scholar] [CrossRef]

- Zabeen, S.; Preuss, M.; Withers, P.J. Evolution of a Laser Shock Peened Residual Stress Field Locally with Foreign Object Damage and Subsequent Fatigue Crack Growth. Acta Mater. 2015, 83, 216–226. [Google Scholar] [CrossRef] [Green Version]

- Cuellar, S.D.; Hill, M.R.; DeWald, A.T.; Rankin, J.E. Residual Stress and Fatigue Life in Laser Shock Peened Open Hole Samples. Int. J. Fatig. 2012, 44, 8–13. [Google Scholar] [CrossRef]

- Shepard, M.J. Laser Shock Processing Induced Residual Compression: Impact on Predicted Crack Growth Threshold Performance. J. Mater. Eng. Perform. 2005, 14, 495–502. [Google Scholar] [CrossRef]

- Lan, L.; Jin, X.; Gao, S.; He, B.; Rong, Y. Microstructural Evolution and Stress State Related to Mechanical Properties of Electron Beam Melted Ti-6Al-4V alloy Modified by Laser Shock Peening. J. Mater. Sci. Technol. 2020, 50, 153–161. [Google Scholar] [CrossRef]

- Zhou, W.; Ren, X.; Liu, F.; Ren, Y.; Li, L. Nanocrystallization in the Duplex Ti-6Al-4V Alloy Processed by Multiple Laser Shock Peening. Metals 2016, 6, 297. [Google Scholar] [CrossRef] [Green Version]

- Lv, J.; Luo, K.; Lu, H.; Wang, Z.; Liu, J.; Lu, J. Achieving High Strength and Ductility in Selective Laser Melting Ti-6Al-4V Alloy by Laser Shock Peening. J. Alloys Compd. 2022, 899, 163335. [Google Scholar] [CrossRef]

- Laine, S.J.; Knowles, K.M.; Doorbar, P.J.; Cutts, R.D.; Rugg, D. Microstructural Characterisation of Metallic Shot Peened and Laser Shock Peened Ti-6Al-4V. Acta Mater. 2017, 123, 350–361. [Google Scholar] [CrossRef] [Green Version]

- Mironov, S.; Ozerov, M.; Kalinenko, A.; Stepanov, N.; Plekhov, O.; Sikhamov, R.; Ventzke, V.; Kashaev, N.; Salishchev, G.; Semiatin, L.; et al. On the Relationship between Microstructure and Residual Stress in Laser-Shock-Peened Ti-6Al-4V. J. Alloys Compd. 2022, 900, 163383. [Google Scholar] [CrossRef]

- Gujba, A.K.; Hackel, L.; Medraj, M. Water Droplet Erosion Performance of Laser Shock Peened Ti-6Al-4V. Metals 2016, 6, 262. [Google Scholar] [CrossRef] [Green Version]

- Lu, J.; Lu, H.; Xu, X.; Yao, J.; Cai, J.; Luo, K. High-Performance Integrated Additive Manufacturing with Laser Shock Peening–Induced Microstructural Evolution and Improvement in Mechanical Properties of Ti6Al4V Alloy Components. Int. J. Mach. Tool. Manuf. 2020, 148, 103475. [Google Scholar] [CrossRef]

- Lu, H.; Wang, Z.; Cai, J.; Xu, X.; Luo, K.; Wu, L.; Lu, J. Effects of Laser Shock Peening on the Hot Corrosion Behaviour of the Selective Laser Melted Ti6Al4V Titanium Alloy. Corr. Sci. 2021, 188, 109558. [Google Scholar] [CrossRef]

- Lan, L.; Xin, R.; Jin, X.; Gao, S.; He, B.; Rong, Y.; Min, N. Effects of Laser Shock Peening on Microstructure and Properties of Ti-6Al-4V Titanium Alloy Fabricated via Selective Laser Melting. Materials 2020, 23, 3261. [Google Scholar] [CrossRef]

- Zhang, H.; Cai, Z.; Chi, J.; Sun, R.; Che, Z.; Lin, L.; Peng, P.; Zhang, H.; Guo, W. Gradient Microstructure Evolution in Laser Shock Peened Ti6Al4V Titanium Alloy. Surf. Coat. Technol. 2022, 437, 128378. [Google Scholar] [CrossRef]

- Ge, M.Z.; Tang, Y.; Zhang, Y.K.; Wang, Y. Enhancement in Fatigue Property of Ti-6Al-4V Alloy Remanufactured by Combined Laser Cladding and Laser Shock Peening Processes. Surf. Coat. Technol. 2022, 444, 128671. [Google Scholar] [CrossRef]

- Altenberger, I.; Nalla, R.K.; Sano, Y.; Wagner, L.; Ritchie, R.O. On the Effect of Deep-Rolling and Laser-Peening on the Stress-Controlled Low- and High-Cycle Fatigue Behavior of Ti-6Al-4V at Elevated Temperatures up to 550 °C. Int. J. Fatigue 2012, 44, 292–302. [Google Scholar] [CrossRef]

- Brockman, R.A.; Braisted, W.R.; Olson, S.E.; Tenaglia, R.D.; Clauer, A.H.; Langer, K.; Shepard, M.J. Prediction and Characterization of Residual Stresses from Laser Shock Peening. Int. J. Fatigue 2012, 36, 96–108. [Google Scholar] [CrossRef]

- Pan, X.; He, W.; Huang, X.; Wang, X.; Shi, X.; Jia, W.; Zhou, L. Plastic Deformation Behavior of Titanium Alloy by Warm Laser Shock Peening: Microstructure Evolution and Mechanical Properties. Surf. Coat. Technol. 2021, 405, 126670. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, L.; Mironov, S.; Xiao, R.; Liang, G.; Ting, H. Effect of Crystallographic Orientation on Structural Response of Silicon to Femtosecond Laser Irradiation. Appl. Phys. A 2021, 127, 196. [Google Scholar] [CrossRef]

- Etesami, S.A.; Fotovvati, B.; Asadi, E. Heat Treatment of Ti-6Al-4V Alloy Manufactured by Laser-Based Powder-Bed Fusion: Process, Microstructures, and Mechanical Properties Correlations. J. Alloys Compd. 2022, 895, 162618. [Google Scholar] [CrossRef]

- Carrozza, A.; Marchese, G.; Saboori, A.; Bassini, E.; Aversa, A.; Bondioli, F.; Ugues, D.; Biamino, S.; Fino, P. Effect of Aging and Cooling Path on the Super β-transus Heat-Treated Ti-6Al-4V Alloy Produced via Electron Beam Melting (EBM). Materials 2022, 15, 4067. [Google Scholar] [CrossRef] [PubMed]

- He, W.; Ma, W.; Pantleon, W. Microstructure of Individual Grains in Cold-Rolled Aluminium from Orientation Inhomogeneities Resolved by Electron Backscattering Diffraction. Mater. Sci. Eng. A 2008, 494, 21–27. [Google Scholar] [CrossRef]

- Jin, P.; Tang, Q.; Li, K.; Feng, Q.; Ren, Z.; Song, J.; Nie, Y.; Ma, S. The Relationship between the Macro- and Microstructure and the Mechanical Properties of Selective-Laser-Melted Ti6Al4V Samples under Low Energy Inputs: Simulation and Experiment. Optic. Laser Technol. 2022, 148, 107713. [Google Scholar] [CrossRef]

- Bovid, S.; Clauer, A.; Kattoura, M.; Vivek, A.; Daehn, G.; Niezgoda, S.S. Measurement and Characterization of Nanosecond Laser Driven Shockwaves Utilizing Photon Doppler Velocimetry. J. Appl. Phys. 2021, 129, 205101. [Google Scholar] [CrossRef]

- Fabbro, R.; Fournier, J.; Ballard, P.; Devaux, D.; Virmont, J. Physical Study of Laser-Produced Plasma in Confined Geometry. J. Appl. Phys. 1990, 68, 775–784. [Google Scholar] [CrossRef]

- Berthe, L.; Fabbro, R.; Peyre, P.; Tollier, L.; Bartnicki, E. Shock Waves from a Water-Confined Laser-Generated Plasma. J. Appl. Phys. 1997, 85, 2826–2832. [Google Scholar] [CrossRef]

- Bovid, S.; Kattoura, M.; Clauer, A.; Vivek, A.; Daehn, G.; Niezgoda, S. Pressure Amplification and Modelization in Laser Shock Peening of Ti-6Al-4V and AA7085 with Adhesive-Backed Opaque Overlays. J. Mater. Proc. Technol. 2022, 299, 117381. [Google Scholar] [CrossRef]

- Bikdeloo, R.; Farrahi, G.H.; Mehmanparast, A.; Mahdavi, S.M. Multiple Laser Shock Peening Effects on Residual Stress Distribution and Fatigue Crack Growth Behaviour of 316L Stainless Steel. Theor. Appl. Fract. Mech. 2020, 105, 102429. [Google Scholar] [CrossRef]

- Wang, H.; Keller, S.; Chang, Y.; Kashaev, N.; Yan, K.; Gurevich, E.L.; Ostendorf, A. Effect of Laser Shock Peening without Protective Coating on the Surface Mechanical Properties of NiTi alloy. J. Alloys Compd. 2022, 896, 163011. [Google Scholar] [CrossRef]

- Ballard, P.; Fournier, J.; Fabbro, R.; Frelat, J. Residual Stresses Induced by Laser-Shocks. J. Phys. 1991, 1, 487–494. [Google Scholar] [CrossRef]

- Wu, X.; Huang, C.; Wang, X.; Song, H. A New Effective Method to Estimate the Effect of Laser Shock Peening. Int. J. Impact Eng. 2011, 38, 322–329. [Google Scholar] [CrossRef] [Green Version]

- Wu, B.; Shin, Y.C. Laser Pulse Transmission through the Water Breakdown Plasma in Laser Shock Peening. Appl. Phys. Letter. 2006, 88, 041116. [Google Scholar] [CrossRef]

- Berthe, L.; Fabbro, R.; Peyre, P.; Bartnick, E. Wavelength Dependent of Laser Shock-Wave Generation in the Water-Confinement Regime. J. Appl. Phys. 1999, 85, 7552–7555. [Google Scholar] [CrossRef]

- Kostina, A.; Zhelnin, M.; Gachegova, E.; Prokhorov, A.; Vshivkov, A.; Plekhov, O.; Swaroop, S. Finite-Element Study of Residual Stress Distribution in Ti-6Al-4V Alloy Treated by Laser Shock Peening with Varying Parameters. Frat. Ed. Integrità Strutt. 2022, 16, 419–436. [Google Scholar] [CrossRef]

| Material Condition | Scan Step Size, µm | Acquired Area, µm2 | Number of Pixels | Average Confidence Index |

|---|---|---|---|---|

| Initial state | 1 | 1300 × 1300 | 1,953,350 | 0.52 |

| 0.2 | 500 × 500 | 7,218,944 | 0.61 | |

| 1 LSP pass | 1 | 3460 × 1000 | 3,998,033 | 0.34 |

| 0.2 | 695 × 320 | 6,436,626 | 0.57 | |

| 348 × 287 | 2,880,695 | 0.51 | ||

| 1384 × 300 | 11,996,693 | 0.49 | ||

| 348 × 211 | 2,115,755 | 0.55 | ||

| 3 LSP passes | 1 | 3458 × 1026 | 4,101,781 | 0.26 |

| 0.2 | 694 × 207 | 4,141,389 | 0.48 | |

| 695 × 250 | 5,020,066 | 0.45 | ||

| 695 × 350 | 7,023,986 | 0.47 | ||

| 0.05 | 174 × 80 | 6,422,724 | 0.56 | |

| 5 passes | 1 | 3461 × 1798 | 7,189,536 | 0.37 |

| 0.2 | 695 × 300 | 6,023,042 | 0.46 | |

| 630 × 300 | 5,459,817 | 0.50 | ||

| 695 × 300 | 6,024,775 | 0.52 | ||

| 695 × 250 | 5,020,066 | 0.58 | ||

| 0.1 | 345 × 100 | 3,985,328 | 0.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mironov, S.; Ozerov, M.; Kalinenko, A.; Zuiko, I.; Stepanov, N.; Plekhov, O.; Salishchev, G.; Semiatin, L.; Zherebtsov, S. On the Degree of Plastic Strain during Laser Shock Peening of Ti-6Al-4V. Materials 2023, 16, 5365. https://doi.org/10.3390/ma16155365

Mironov S, Ozerov M, Kalinenko A, Zuiko I, Stepanov N, Plekhov O, Salishchev G, Semiatin L, Zherebtsov S. On the Degree of Plastic Strain during Laser Shock Peening of Ti-6Al-4V. Materials. 2023; 16(15):5365. https://doi.org/10.3390/ma16155365

Chicago/Turabian StyleMironov, Sergey, Maxim Ozerov, Alexander Kalinenko, Ivan Zuiko, Nikita Stepanov, Oleg Plekhov, Gennady Salishchev, Lee Semiatin, and Sergey Zherebtsov. 2023. "On the Degree of Plastic Strain during Laser Shock Peening of Ti-6Al-4V" Materials 16, no. 15: 5365. https://doi.org/10.3390/ma16155365

APA StyleMironov, S., Ozerov, M., Kalinenko, A., Zuiko, I., Stepanov, N., Plekhov, O., Salishchev, G., Semiatin, L., & Zherebtsov, S. (2023). On the Degree of Plastic Strain during Laser Shock Peening of Ti-6Al-4V. Materials, 16(15), 5365. https://doi.org/10.3390/ma16155365